Page 1

48NLT, NMT, NET, NHT AND NVT 018-060

HEATING & COOLING

Packaged Heating/Cooling Units

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS

General

Job Data ..................................

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

• IDENTIFY MACHINE

• INSPECT SHIPMENT

Step 2 — Provide Unit Support

• ROOF CURB

• SLAB MOUNT

Step 3 — Provide Ciearances .................................4

Step 4 — Rig and Place Unit....................................4

Step 5 — Connect Condensate Drain

Step 6 - instali Venting

Step 7 - Instail Gas Piping

Step 8 — Instail Duct Connections

Step 9 - Instail Electrical Connections

• HIGH VOLTAGE CONNECTIONS

• SPECIAL PROCEDURES FOR 208-V

• CONTROL VOLTAGE CONNECTIONS

• HEAT ANTICIPATOR SETTING

• TRANSFORMER CIRCUIT PROTECTION

PRE-START-UP

START-UP

MAINTENANCE

NOTE TO INSTALLER — Before the installation, READ

THESE INSTRUCTIONS CAREFULLY AND COM

PLETELY. Also, make sure the User’s Manual and Re

placement Guide are left with the unit after installation.

...................................

....................

............................

...............................

.....................

......................................

.................................

.....................

.............

OPERATION

..........

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning equipment

can be hazardous due to system pressure and electrical com

ponents. Only trained and qualified personnel should in

stall, repair or service air conditioning equipment.

Untrained personnel can perform basic maintenance func

tions of cleaning coils and filters. All other operations should

be performed by trained service personnel. When working

on air conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit and other safety

precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguisher available for all brazing operations.

A WARNING

Improper installation, adjustment, alteration, service, main

tenance or use can cause carbon monoxide poisoning, fire

or an explosion which can result in personal injury or

unit damage. Consult a qualified installer, service agency

or gas supplier for information or assistance. The quali

fied installer or agency must use only factory-authorized

kits or accessories when modifying this product.

. 1

. 1

. 1

1-10

. 1

4

5

6

6

7

8

10,11

11-20

20-26

________

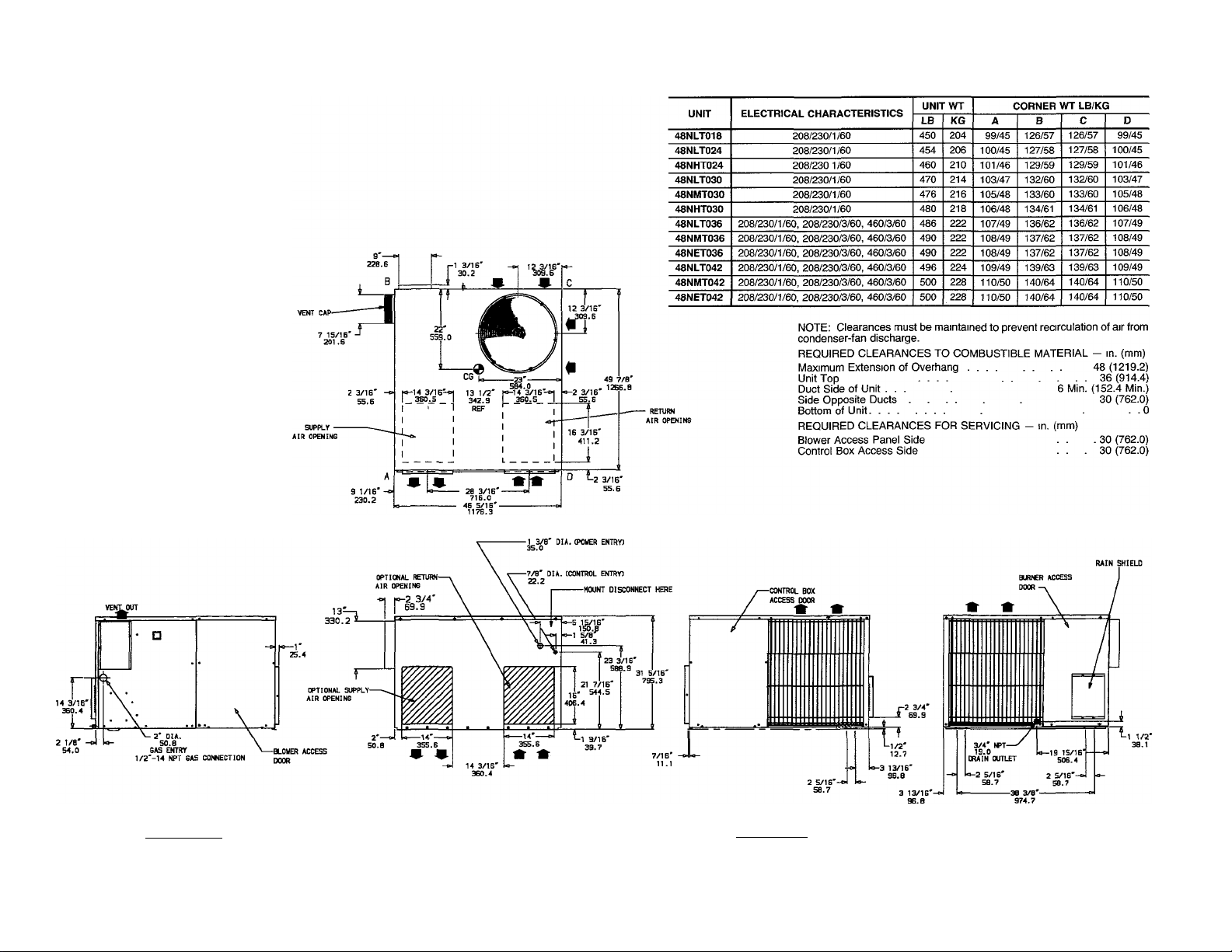

Fig. 1 - Model 48NLT, NMT, NET, NHT and NVT

A WARNING

Before performing service or maintenance operations

on unit, turn off unit main power switch. Electrical shock

could cause personal injury.

General - The 48NLT, NMT, NET, NHT and NVT

units are fully self-contained, combination gas heating/

cooling units designed for outdoor installation. See Fig. 1.

The units are shipped in a vertical configuration and may

be installed either on a rooftop or converted to horizontal

configuration when placed on a ground-level cement slab.

Job Data — Necessary information consists of:

machine location drawings, piping drawings, field wiring

diagrams and rigging guide.

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFY MACHINE — The machine model number and

serial number are stamped on machine identification plate.

Check this information against shipping papers and job data.

INSPECT SHIPMENT — Inspect for shipping damage while

machine is still on shipping pallet. If machine appears to be

damaged or is torn loose from its anchorage, have it exam

ined by transportation inspectors before removal. Forward

claim papers directly to transportation company. Manufac

turer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original pack

ages until installation.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |4 PC 111 Catalog No 564-920 Printed in U.S,A. Form 48NT-20SI Pg 1 11-91 Replaces: 48NT-19SI

Tab la la

Page 2

RIGHT SIDE VIEW

LEFT SIDE VIEW

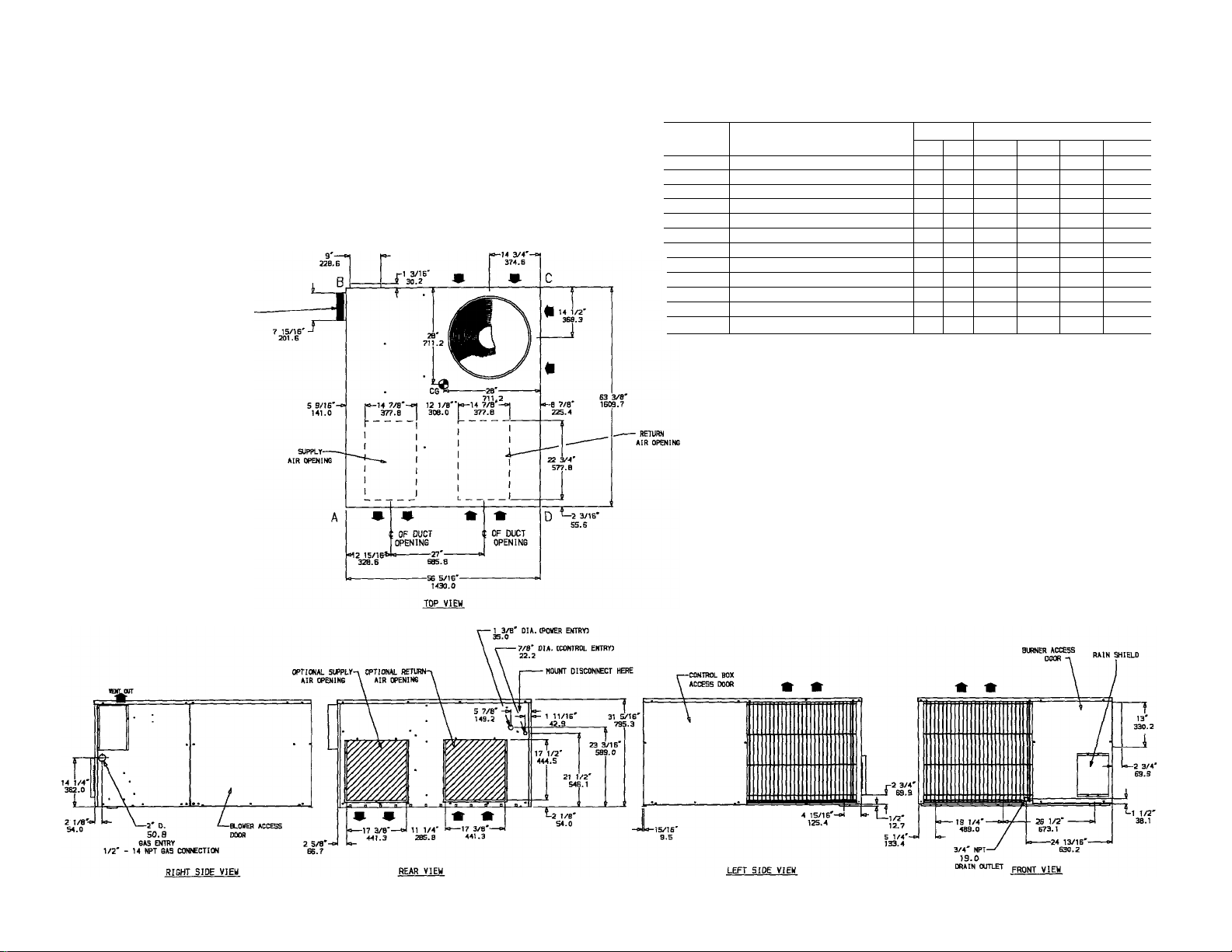

Fig. 2 — 48 Dimensional Drawing, Sizes NLT018 — NET042

Page 3

UNIT

48NHT036

48NVT036

48NHT042

48NVT042

48NLT048

48NMT048

48NHT048

48NVT048

48NLT060

48NMT060

48NHT060

48NVT060

ELECTRICAL CHARACTERISTICS

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60 550

208/230/1/60, 208/230/3/60. 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60,

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60

208/230/1/60, 208/230/3/60, 460/3/60 616 280 139/63

208/230/1/60, 208/230/3/60, 460/3/60 616

NOTE. Clearances must be maintained to prevent recirculation of air from

condenser-fan discharge.

REQUIRED CLEARANCES TO COMBUSTIBLE MATERIAL - in. (mm)

Maximum Extension of Overhang 48(1219.2)

Unit Top ........................... ■ .36(914.4)

Duct Side of Unit . .... 6 Min. (152.4 Min.)

Side Opposite Ducts .30 (762.0)

Bottom of Unit. .... .0

REQUIRED CLEARANCES FOR SERVICING - in. (mm)

Blower Access Panel Side ... . 30 (762.0)

Control Box Access Side . . 30 (762.0)

UNIT WT

LB

530

536 243 119/54 148/67

556

574

580 263 130/59

586 265 131/59 161/73

586

604

610

A B

KG

241 117/53 147/67

249 122/55 152/69

252

124/56 153/69

261 128/58

265

131/59

274

136/62 165/75

277

138/63 166/75

280

139/63

CORNER WT LB/KG

158/72

159/72

161/73

168/76

168/76

C

148/67 118/54

149/68 120/54

153/69

154/70 125/57

159/72

160/73

162/73

162/73

166/75

167/76

169/77

169/77

D

123/56

129/59

131/59

132/60

132/60

137/62

139/63

140/64

140/64

Fig. 3 — 48 Dimensional Drawing, Sizes NHT036 — NVT060

Page 4

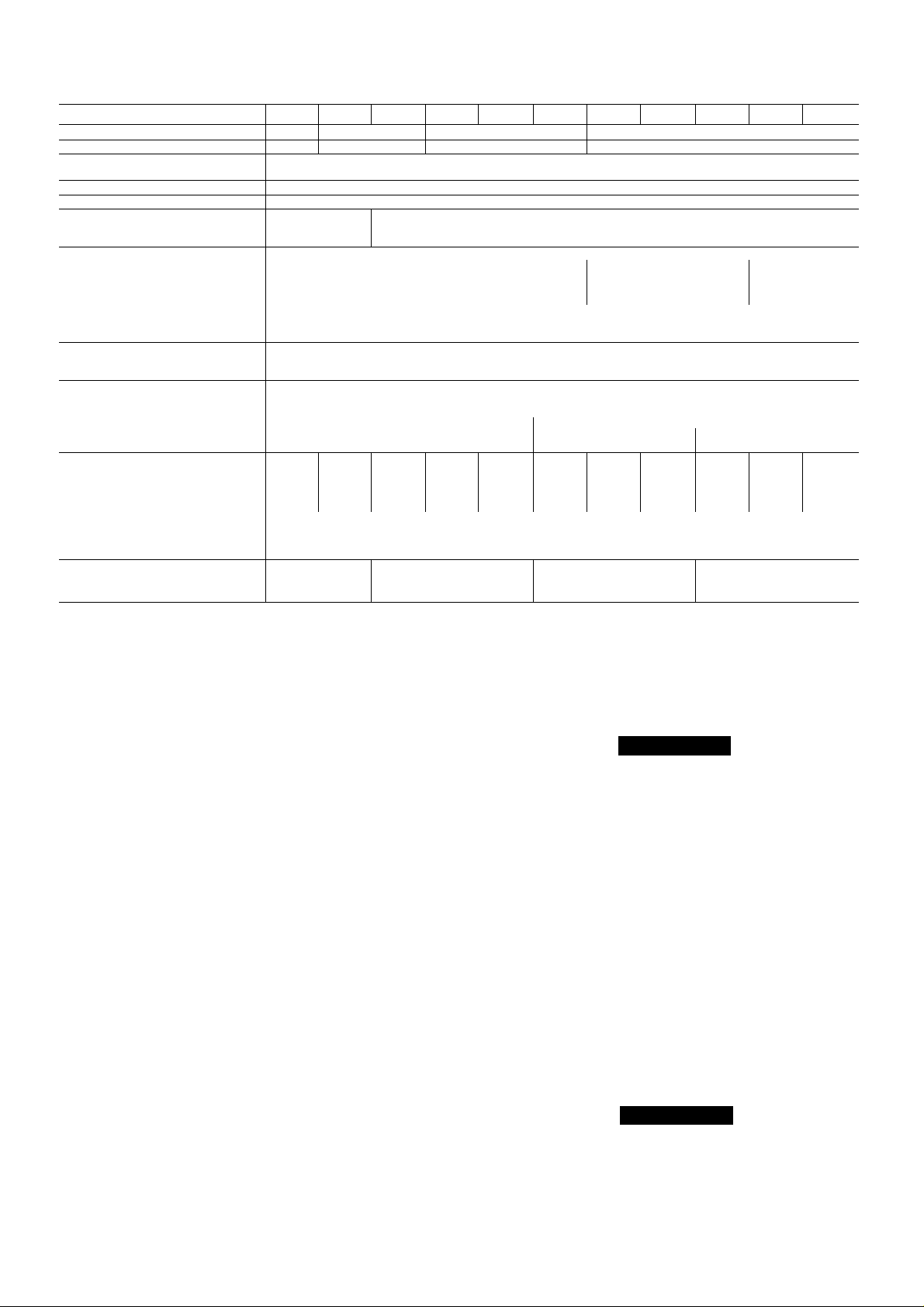

Table 1 — Physical Data

UNIT SIZE 48

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb)

COMPRESSORS

Quantity

REFRIGERANT*

REFRIGERANT METERING DEVICE

CONDENSER COIL

Rows

FIns/in.

CONDENSER FAN

Nominal Airflow (Cfm)

Nominal Speed (Rpm)

Quantlty...Dlameter (in.)

Motor Hp (single-phase)

EVAPORATOR COIL

Rows

Fins/ln.

EVAPORATOR FAN

Nominal Cfm

Nominal Speed (Rpm)

Diameter x Width (in.)

Motor Hp (single-phase)

FURNACE SECTION

Burner Orifice No. (Qty...drlll size)

Burner Orifice No. (Qty...drlll size)

Pilot Orifice Diameter (in. ...drill size)

Pilot Orifice Diameter (In.)

RETURN-AIR FILTERS (sq ln.)t

Disposable

Cleanable

•Operating charge is iisted on unit namepiate

tRequired fieid-suppiied fliter areas are based on the iarger of the ARi-rated (Air Conditioning & Refrigeration institute) cooling airflow or the heating

airflow at a velocity of 300 ft/min for disposable type or 450 ft/min for high-capacity type Air filter pressure drop must not exceed 0.08 in wg

••Single-phase units

ttThree-phase units

(three-phase)

(three-phase)

Natural Gas

Propane Gas

Natural Gas

Propane Gas

NLT018 NLT024

IV2

450

1

20 20

600 800

2 44

2. 55 2 55

288

192

NHT024

2

454

10 X 8

2 44 3 44 2. 44 3 44

NLT030

460 470 476

2000

825

V10

'/3

-

3 55 2 55 3 55

NMT030 NHT030

2V2

Reciprocating Hermetic. 3500 Rpm

1000

528

352 416

AcouRater® Piston

niR 77

NLT036

480

R-22

1 20

3

14

1100

4 44

4 55 3 .55 4 55

NMT036

486

2

2500

1100

V4

1/4

1200

V2

V2

3 44 4 44 4 42 5.44

624 720

NET036 NHT036

490

10 X 10

3

490

4 54 5 55 6 55

530

Vio

Va

3/4

480

%

2500**

3000tt

825**

lioott

1200

NVT036

536

6 .44

i

Step 2 - Provide Unit Support

ROOF CURB — Install accessory roof curb in accordance

with instructions shipped with curb. Install insulation, cant

strips, roofing and flashing. Ductwork must be attached to

curb.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for water integrity. Install gasketing

material supplied with the roof curb. Improperly ap

plied gasketing also can result in air leaks and poor

unit performance.

Curb should be level to within */4 inch. This is necessary

for unit drain to function properly. Refer to Accessory Roof

Curb Installation Instructions for additional information as

required.

SLAB MOUNT — Place the unit on a solid, level concrete

pad that is a minimum of 4-in. thick with 2-in. above grade.

The slab should extend approximately 2-in. beyond the cas

ing on all 4 sides of the unit. Install a gravel apron in front

of condenser-air inlets to prevent obstruction of airflow by

grass or shrubs. Do not secure the unit to the slab except

when required by local codes.

Step 3 — Provide Clearances — The required min

imum operating and service clearances are shown in Fig. 2

and 3. Adequate combustion, ventilation and condenser air

must be provided.

The condenser fan discharges through the top of the unit.

Be sure that the fan discharge does not recirculate to the

condenser coil. Do not locate the unit in either a corner or

under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang)

is 48-in. above the unit top. The maximum horizontal ex

tension of a partial overhang must not exceed 48 inches.

A CAUTION

Do not restrict condenser airflow. An air restriction at

either the outdoor-air inlet (the entire surface of the out

door coil) or the fan discharge can be detrimental to

compressor life.

Do not place the unit where water, ice or snow from an

overhang or roof will damage or flood the unit. Do not in

stall the unit on carpeting, tile or other combustible mate

rials. The unit may be installed on wood flooring or on Class

A, B or C roof covering materials.

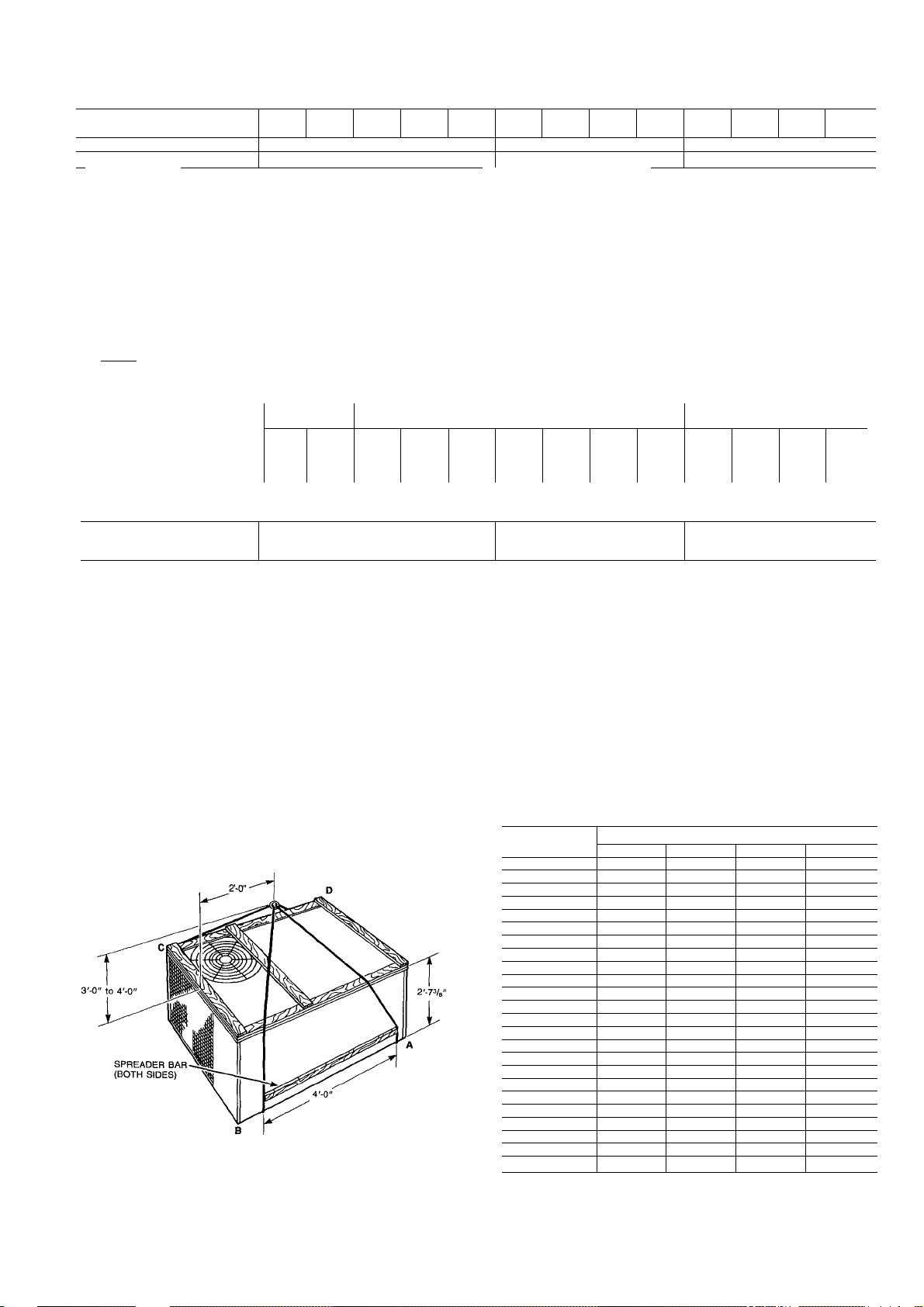

Step 4 — Rig and Place Unit — Use spreader bars

and crate top when rigging the unit. The units must be rigged

for lifting as shown in Fig. 4. Refer to Fig. 4 for rigging

weight and Table 1 for operating weight. Use extreme cau

tion to prevent damage when moving the unit. Unit must

remain in an upright position during all rigging and mov

ing operations. The unit must be level for proper conden

sate drainage; therefore, the ground-level pad or accessory

roof-mounting curb must be level before setting the unit in

place. When a field-fabricated support is used, be sure that

the support is level and properly supports the unit.

A CAUTION

When installing the unit on a rooftop, be sure the roof

will support the additional weight. Refer to Fig. 4 for

corner weight information.

Page 5

Table 1 — Physical Data (cent)

NLT

UNIT SIZE 48

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb) 496 500 500

COMPRESSORS

Quantity______

REFRIGERANT*

REFRIGERANT METERING

DEVICE

CONDENSER COIL

Rows

FIns/ln.

CONDENSER FAN

Nominal Airflow (Cfm)

Nominal Speed (Rpm)

Quantlty...Dlameter (In.)

Motor Hp (single-phase)

EVAPORATOR COIL

Rows

Fins/ln.

EVAPORATOR FAN

Nominal Cfm

Nominal Speed (Rpm)

Diameter x Width (In.)

Motor Hp (single-phase)

FURNACE SECTION

Burner Orifice No.

Burner Orifice No.

Pilot Orifice Diameter

Pilot Orifice Diameter (In.)

RETURN-AIR FILTERS (sq ln.)t

Disposable 720

Cleanable 480

•Operating charge is iisted on unit namepiate

tRequired fieid-suppiied fiiter areas are based on the iarger of the ARi-rated (Air Conditioning & Refrigeration institute) cooling airflow or the heating airflow at a velocity of 300 ft/min

for disposable type or 450 ft/min for high-capacity type. Air filter pressure drop must not exceed 0 08 in wg

(three-phase)

_________

(three-phase)

(Qty...drlll size) Natural Gas

(Qty...drill size) Propane Gas

(In. ...drill size) Natural Gas

Propane Gas

3 44

3 55

NMT

042

2500 3000 3500

V2 3/4

’/2 3/4

4. 44

4 55 4 54 5 55

042

NET

042

3Vz

4 42 5 44

NHT

NVT

042

550

6 44

6. 55 3 .55 4 55 5 55 6 54 3 55

NLT

042

556 574 580

Reciprocating Hermetic, 3500 Rpm

3 44 4 44 5 44 6 42 3 44

NMT

048

R-22

AocuRater® Piston

018 77

NHT

048

048

4

586 586

1

2

20

009

816

544 640

NVT

048

NLT

060

604

NMT

4 44 5 44

4 55 5 55

060

610

5

2000

960

NHT

060

616

NVT

060

616

I 3450

6 42

6 54

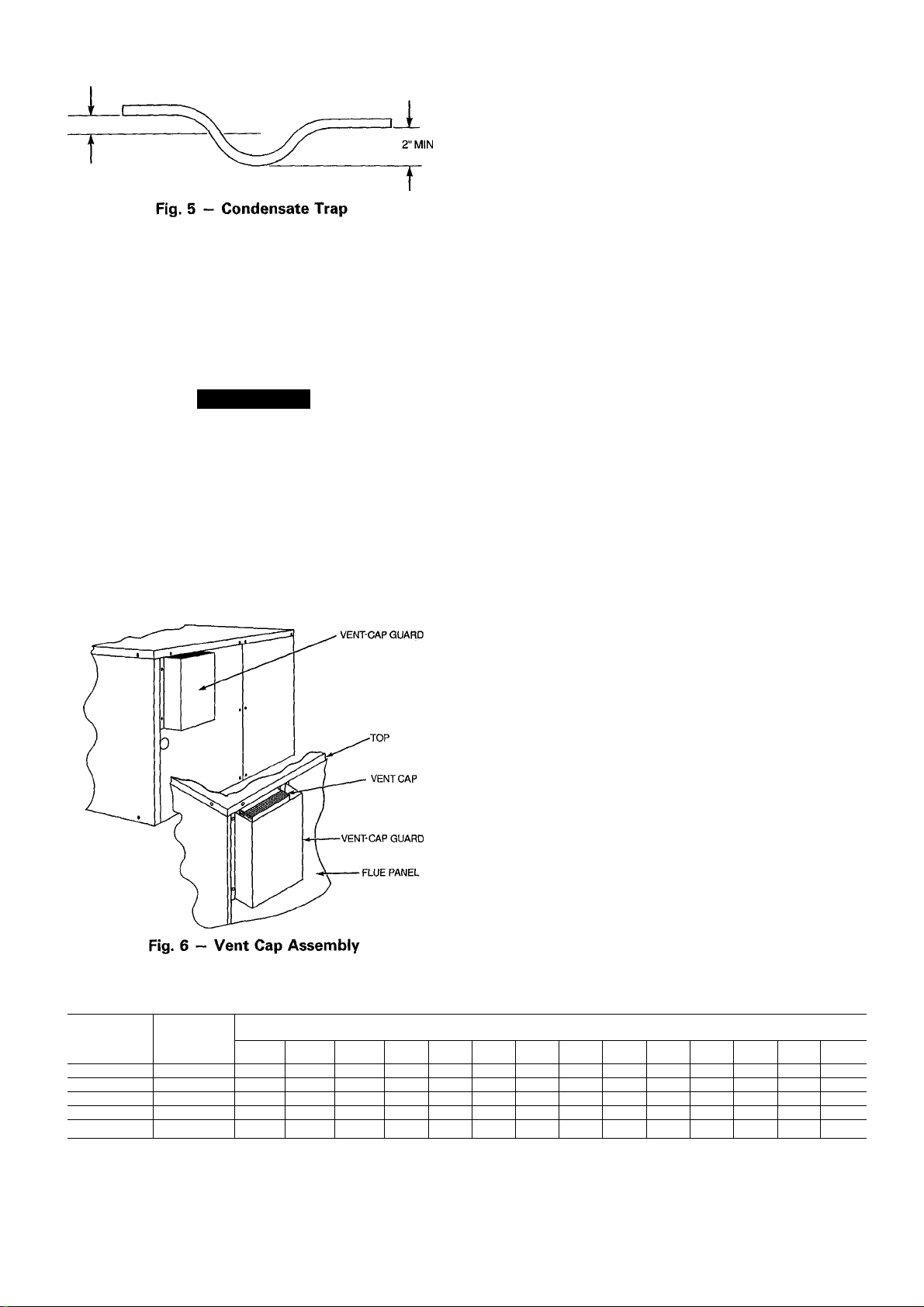

Step 5 — Connect Condensate Drain

NOTE: When installing condensate drain connection be sure

to comply with local codes and restrictions.

The unit disposes of condensate water through a %-in.

NPT drain fitting. See Fig. 2 and 3 for location.

Install a 2-in. trap at the drain fitting to ensure proper

drainage. See Fig. 5. Make sure the outlet of the trap is at

least one-in. lower than the unit drain pan connection to

Fig. 4 - Suggested Rigging

prevent the pan from overflowing. Prime the trap with

water.

If the installation requires draining the condensate water

away from the unit, connect a drain tube using a minimum

of %-in. OD copper tubing, y4-in. galvanized pipe or %-in.

plastic pipe. Do not undersize the tube. Pitch the drain tube

downward at a slope of at least one inch in every 10 ft of

horizontal run. Be sure to check the drain tube for leaks.

UNIT 48

NLT018

NLT024 100

NHT024

NLT030 103 132 132 103

NMT030 105 133 133 105

NHT030 106 134 134 106

NLT036

NMT036 108

NET036 108 137 137 108

NHT036 117 147 148 118

NVT036 119 148 149 120

NLT042 109 139 139 109

NMT042

NET042 110 140 140 110

NHT042 117

NVT042

NLT048 128

NMT048

NHT048

NVT048

NLT060

NMT060

NHT060

NVT060

A

99

101

107

110 140

124

130 159 160 131

131

131

136 165 166 137

138 166 167

139 168 169

139 168 169 140

CORNER WT (LB)

B C D

126 126 99

127

129 129 101

136 136

137 137

147 147 117

153

158 159 129

161

161

127

140

154

162

162

100

107

108

110

125

132

132

139

140

Page 6

r MIN

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel apron

in ground-level installations. When using a gravel apron,

make sure it slopes away from the unit.

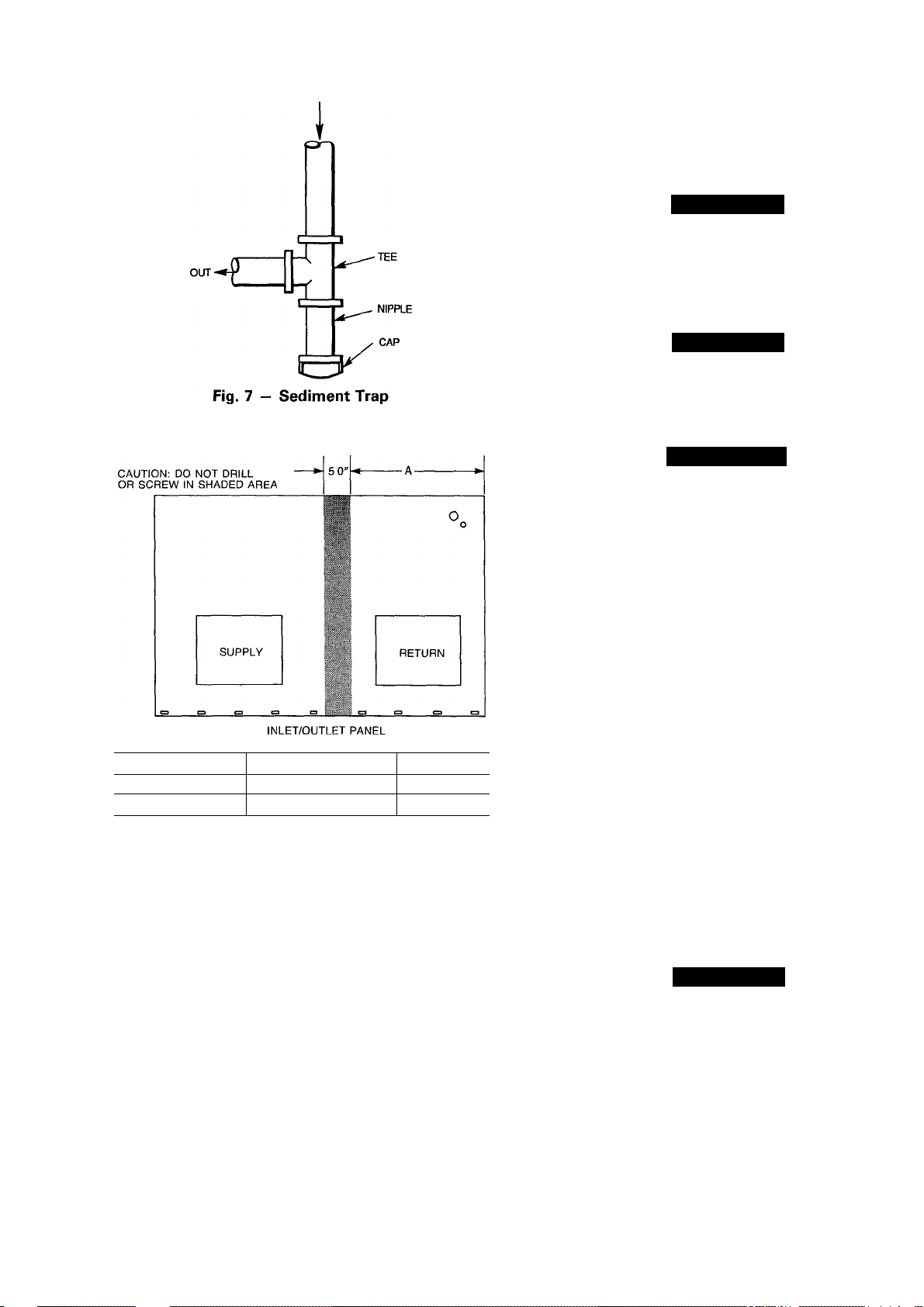

Step 6 — Install Venting — The vent cap assembly

is shipped in the burner compartment. Remove the access

door to locate the assembly.

A CAUTION

The venting system is designed to ensure proper vent

ing. The vent cap assembly must be installed as indi

cated in this section of the unit Installation Instructions.

NOTE; Screw holes in the flue assembly and the unit flue

panel are not symmetrically located. Make sure they are

oriented properly when installing these components.

Refer to Fig. 6 and install the vent cap as follows:

1. Place vent cap assembly over flue panel. Orient screw

holes in vent cap with holes in flue panel.

2. Secure vent cap in place by inserting the single screw on

the right side of vent cap.

3. Place the vent cap guard over the vent cap. Orient holes

in vent cap guard with holes in vent cap and flue panel.

4. Secure the entire assembly with the remaining 2 screws

on the left side of vent cap and vent-cap guard

assembly.

Step 7 — Install Gas Piping — The gas supply pipe

enters the unit through the access hole provided. The gas

connection to the unit is made to the Vi-in. FPT gas inlet on

the manual shutoff or gas valve.

Install a separate gas supply line that runs directly from

the meter to the heating section. Refer to Table 2 and the

National Fuel Gas Code (NFGC) for gas pipe sizing. Do

not use cast-iron pipe. It is recommended that black iron

pipe is used. Check the local utility for recommendations

concerning existing lines. Choose a supply pipe that is large

enough to keep the pressure loss as low as practical. Never

use pipe smaller than the ‘A-in. FPT gas inlet on the unit

gas valve.

For natural gas applications, the gas pressure at unit gas

connection must not be less than 5 in. wg or greater than

13 in. wg while the unit is operating. For propane applica

tions, the gas pressure must not be less than 11 in. wg or

greater than 13 in. wg at the unit connection.

When installing the gas supply line, observe local codes

pertaining to gas pipe installations. Refer to the NFGC ANSI

(American National Standards Institute) Z223.1-1988 NFPA

(National Fire Protection Association) 54-1988 (in Canada,

CAN/CGA [Canadian Gas Association] B 149.1, (2)-M86).

In the absence of local building codes, adhere to the fol

lowing pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe

V4 inch in every 15 ft to prevent traps. Grade all hori

zontal runs downward to risers. Use risers to connect to

heating section and to meter.

2. Protect all segments of piping system against physical

and thermal damage. Support all piping with appropri

ate straps, hangers, etc. Use a minimum of one hanger

every 6 ft. For pipe sizes larger than Уг in., follow rec

ommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape.

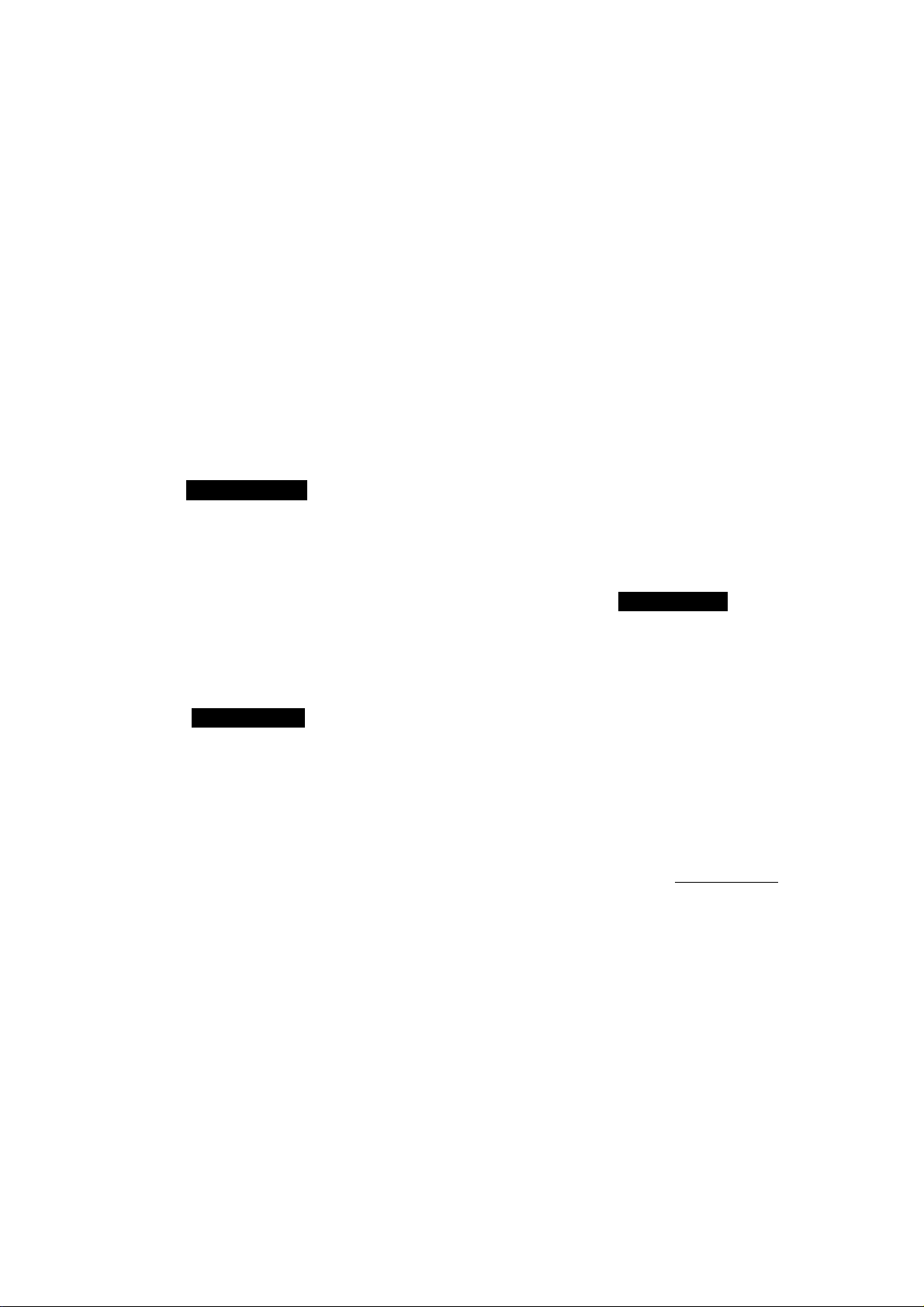

4. Install sediment trap in riser leading to heating section.

This drip leg functions as a trap for dirt and condensate.

Install trap where condensate cannot freeze. Install this

sediment trap by connecting a piping tee to riser leading

to heating section, so that straight-through section of tee

is vertical. See Fig. 7. Then, connect capped nipple into

lower end of tee. Extend capped nipple below level of

gas controls.

Table 2 — Maximum Gas Glow Capacity*

NOMINAL

IRON PIPE,

SIZE

(in.)

V2

%

1 1.049

VA 1.380

VA

‘Capacity of pipe in cu ft of gas per hr for gas pressure of 0 5 psig or less. Pressure drop of 0.5 in. wg

(based on a 0.60 specific gravity gas) Refer to Table C-4, NFPA 54-1984

fThls length includes an ordinary number of fittings

INTERNAL

DIAMETER

(In.)

.622 175 120

.824 360 250

1.610

10 20 30 40 50

680

1400 950

2100

97

465 375 320 285 260 240

1460

200

770 600 580

1180 990

82 73

170

151

900 810

LENGTH OF PIPE, FTf

60 70 80

61 57 53 50

66

125 118

138

530 490 460 430

220

750 690 650 620

90 100 125 150

110 103 93

205 195 175

400 360 325

44

160 145

550 500

175

—

40

84 77

300

460

200

—

72

135

280

430

Page 7

IN

testing of the piping systems when test pressure in excess

of 0.5 psig. Pressure test the gas supply piping system at

pressures equal to or less than 0.5 psig. The unit heating

section must be isolated from the gas piping system by clos

ing the external main manual shutoff valve and slightly open

ing the ground-joint union.

A CAUTION

Unstable operation may occur when the gas valve and

manifold assembly are forced out of position while con

necting improperly-routed rigid gas piping to the gas

valve. Use a backup wrench when making connection

to avoid strain on, or distortion of, the gas control

piping.

A CAUTION

If a flexible conductor is required or allowed by the au

thority having jurisdiction, black iron pipe shall be in

stalled at the gas valve and shall extend a minimum of

2 in. outside the unit casing.

A WARNING

Never use a match or other open flame when checking

for gas leaks. Never purge gas line into combustion

chamber. Failure to follow this warning could result in

an explosion causing personal injury or death.

Size

Small Cabinet

Large Cabinet NHT036-NVT060 25V2 in.

NLT018-NET042 20V2 in.

"A"

Fig. 8 — Location of Coii Area Not to be Drilled

5. Install an accessible, external, manual main shutoff valve

in gas supply pipe within 6 ft of heating section.

6. Install ground-joint union close to heating section be

tween unit manual shutoff and external manual main shut

off valve.

7. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connecting pip

ing to unit.

NOTE; Pressure test the gas supply system after the gas

supply piping is connected to the gas valve. The supply

piping must be disconnected from the gas valve during the

8. Check for gas leaks at the field-installed and factoryinstalled gas lines after all piping connections have been

completed. Use soap-and-water solution (or method spec

ified by local codes and/or regulations).

Step 8 — Install Duct Connections — The unit

has duct flanges on the supply- and return-air openings on

the side and bottom of the unit. See Fig. 2 and 3 for con

nection sizes and locations.

NOTE: The design and installation of the duct system must

be in accordance with the standards of the NFPA for instal

lation of nonresidence-type air conditioning and ventilating

systems, NFPA No. 90A orresidence-type, NFPA No. 90B;

and/or local codes and residence-type, NFPA No. 90B; and/

or local codes and ordinances.

Adhere to the following criteria when selecting, sizing

and installing the duct system;

1. The unit is shipped in vertical configuration. To convert

unit to horizontal application, remove side duct covers,

save screws and install the covers on bottom duct

openings.

2. Select and size ductwork, supply-air registers and returnair grilles according to ASHRAE (American Society of

Heating, Refrigeration and Air Conditioning Engineers)

recommendations.

A CAUTION

When drilling the duct-system fastening holes into the

side of the unit instead of the unit duct flanges, use ex

treme care to avoid puncturing the coil or coil tubes.

See Fig. 8.

Page 8

3. Use flexible transition between rigid ductwork and unit

to prevent transmission of vibration. The transition may

be screwed or bolted to duct flanges. Use suitable gas

kets to ensure weather- and airtight seal.

4. Install external, field-supplied air filter(s) in return-air

ductwork where it is easily accessible for service. Rec

ommended filter sizes are shown in Table 1,

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases.

6. Adequately insulate and weatherproof all ductwork lo

cated outdoors. Insulate ducts passing through uncondi

tioned space, and use vapor barrier in accordance with

latest issue of SMACNA (Sheet Metal and Air Condi

tioning Contractors National Association) and ACCA (Air

Conditioning Contractors of America) minimum instal

lation standards for heating and air conditioning sys

tems. Secure all ducts to building structure,

7. Flash, weatherproof and vibration-isolate all openings

in building structure in accordance with local codes and

good building practices.

Step 9 — Install Electrical Connections

A WARNING

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of per

sonal injury if an electrical fault should occur. This ground

may consist of an electrical wire connected to the unit

ground lug in the control compartment, or conduit ap

proved for electrical ground when installed in accor

dance with NEC (National Electrical Code) ANSI/

NFPA (latest edition) (in Canada, Canadian Electrical

Code CSA C22.1) and local electrical codes. Do not

use gas piping as an electrical ground. Failure to ad

here to this warning could result in personal injury or

death.

A CAUTION

Failure to follow these precautions could result in dam

age to the unit being installed:

1. Make all electrical connections in accordance with NEC

ANSI/NFPA (latest edition) and local electrical codes

governing such wiring. In Canada, all electrical connec

tions must be in accordance with CSA Standard C22.1

Canadian Electrical Code Part 1 and applicable local codes.

Refer to unit wiring diagram.

2. Use only copper conductor for connections between field-

supplied electrical disconnect switch and unit. DO NOT

USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within oper

ating voltage range indicated on unit rating plate. On 3phase units, ensure that phases are balanced within 2%.

Consult local power company for correction of im

proper voltage and/or phase balance.

4. Insulate low-voltage wires for highest voltage contained

within conduit when low-voltage control wires are run

in same conduit as high-voltage wires.

5. Do not damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

HIGH-VOLTAGE CONNECTIONS - The unit must have

a separate electrical service with a field-supplied, water

proof, fused disconnect switch mounted at, or within sight

from, the unit. Refer to the unit rating plate for maximum

fuse/circuit breaker size and minimum circuit amps (ampac

ity) for wire sizing. See Table 3 for electrical data.

The field-supplied disconnect switch box may be mounted

on the unit over the high-voltage inlet hole in the control

corner panel. See Fig. 2 and 3.

Proceed as follows to complete the high-voltage connec

tions to the unit;

1. Connect ground lead to chassis ground connection when

using separate ground wire.

2. Run high-voltage leads into unit control box and con

nect to contactor. See unit wiring label, and Fig. 9.

A CAUTION

TRANSFORMER CONTAINS AUTO

RESET OVERCURRENT PROTECTOR.

IT MAY RESET WITHOUT WARNING

STARTING HEATING OR COOLING

SECTION OF THIS PRODUCT.

DISCONNECT POWER PRIOR TO

SERVICING.

THIS COMPARTMENT MUST BE

CLOSED EXCEPT WHEN SERVICING.

316056-201 REV A

Fig. 9 — Transformer Label

Page 9

Table 3 — Electrical Data

UNIT

SIZE

01B

024

030

036

042

048

060

AWG

FLA

LRA

MCA

MOCP

NEC

RLA

NOTES:

1

In compliance with NEC requirements for multimotor and combination load

and equipment (refer to NEC Articles 430 and 440), the overcurrent pro

tective device for the unit shall be fuse or HACR breaker

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater

than 2% Use the following formula to determine the % voltage imbalance.

% Voltage Imbalance

_ y max voltage deviation from average voltage

NOMINAL

V-PH-HZ

208/230-1-60

208/230-1-60

208/230-1-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

American Wire Gage

Full Load Amps

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Rated Load Amps

Example: Supply voltage is 460-3-60

MODEL NO.

48

NLT018 187 253 82 49 0

NLT024

NHT024

NLT030

NMT030

NHT030

NLT036

NMT036

NET036

NHT036

NVT036

NLT036

NMT036

NET036

NHT036

NVT036

NLT036

NMT036

NET036

NHT036

NVT036

NLT042

NMT042

NET042

NHT042

NVT042

NLT042

NMT042

NET042

NHT042

NVT042

NLT042

NMT042

NET042

NHT042

NVT042

NLT048

NMT048

NHT048

NVT048

NLT048

NMT048

NHT048

NVT048

NLT048

NMT048

NHT048

NVT048

NLT060

NMT060

NHT060

NVT060

NLT060

NMT060

NHT060

NVT060

NLT060

NMT060

NHT060

NVT060

average voltage

AB = 452 volts

BC = 464 volts

AC = 455 volts

Average Voltage

VOLTAGE

RANGE

Min Max RLA

187 253

187 253 14.3

187

187

414

187

187

414 506 77 41 0 1 2

187 253 26 5

187 253 16.8

187

187 253 30 7

187

414 506 104 55 0 1 2

452 + 464 -r 455

3

1371

—JT— =457

11.6

11.6

253 21 1

14.7

253

506 7 1

23.9 95.4 1 5

253

15.3

253

253

253

82

21 4

COMPR

LRA

61 0

61.0

86.0 08

100 0 1 5

67.0

34 0

82 0

1140

84 0

42 0 1 2

135 0

130 0 22

CONDENSER-

FAN MOTOR

FLA

08

08

1 9

1.9

1.9

22

22

1.2

1.9

1 9

1 9

2.2

2.2

2.1

22

2 1

Determine maximum deviation from average voltage.

(AB) 457 - 452 =5 volts

(BC) 464 - 457 =7 volts

(AC) 457 - 455 =2 volts

Maximum deviation is 7 volts.

Determine % voltage imbalance

% Voltage Imbalance =100 x

This amount of phase imbalance is satisfactory as it is below the maximum

allowable 2%

IMPORTANT: If the supply voltage phase imbalance is more than 2%,

contact your local electric utility company immediately

EVAPORATOR-

FAN MOTOR

FLA

2.5

2.5 12 17 1 25

25

25

3.0

30

3.0

45

45

45

30

30

45

45

45

1 5

1 5

23

23

23

3.0

3.0

45

45

4.5

30

3.0

45

4.5

4.5

1 5

1 5

23

23

2.3

4.5

45

4.5

62

45

45

4.5

62

23

23

2.3

32

62 6 46 7

6.2

32 12 17.4 25

AWG MIN

WIRE SIZE

7

"457

14

10

8

10

14

8

10

14

8

6

10

14

8

= 1.53%

POWER SUPPLY

MCA

13 6 20

21 2

21.2

21 7

30.9

30 9

32.4

32 4

32.4

23.3

23 3

24 8

25 1

25 1

11 6

11 6

124

124

12.4

34 3

34 3

35 9

35.9

35 9

24 0

24.0

25 5

25.8

25 8

123

12.3

13 1

13.1

13 1

39 7

39 7

39.7

41 4

27.7

27 7

27 7

29 4

13.8

138

138

147

35 5 50

MOCP

30

40

30

15

50

35

35

40

40

40

20

60

40

20

60

Page 10

SPECIAL PROCEDURES FOR 208-V OPERATION

Á WARNING

Make sure that the power supply to the unit is switched

OFF before making any wiring changes. Electrical shock

can cause personal injury or death.

1. Disconnect the orange transformer-primary lead from the

contactor. See unit wiring label.

2. Remove the tape and cover from the terminal on the end

of the red transformer-primary lead.

3. Save the cover.

4. Connect the red lead to the contactor terminal from which

the orange lead was disconnected.

5. Using the cover removed from the red lead, insulate the

loose terminal on the orange lead.

6. Wrap the cover with electrical tape so that the metal ter

minal cannot be seen.

Indoor blower motor speeds should be changed for 208-v

operation. In the unit control box, change motor leads on

the printed circuit board so that high speed is used for cool

ing and medium speed is used for heating. Do not change

blower speed setting for 460-v rated units. Refer to StartUp, Indoor Airflow and Airflow Adjustments section.

CONTROL VOLTAGE CONNECTIONS - Locate the room

thermostat on an inside wall in the space to be conditioned,

where it will not be subjected to either a cooling or heating

source or direct exposure to sunlight. Mount the thermostat

4 to 5 ft above the floor.

Use no. 18 American Wire Gage (AWG) color-coded,

insulated (35 C minimum) wires to make the control volt

age connections between the thermostat and the unit. If the

thermostat is located more than 100 ft from the unit (as

measured along the control voltage wires), use no. 16 AWG

color-coded, insulated (35 C minimum) wires.

A grommeted, control voltage inlet hole is located in the

panel adjacent to the control access panel. Run the lowvoltage leads from the thermostat, through the inlet hole,

and to the control voltage terminals through a hole in the

bottom of the unit control box. Pass control voltage leads

through wire ties located under unit control box. Connect

the thermostat leads to the terminals as shown in Fig. 10.

HEAT ANTICIPATOR SETTING - The room thermostat

heat anticipator must be adjusted properly to ensure proper

heating performance. Set the heat anticipator, using an

THERMOSTAT (TYPICAL)

-TERMINAL BOARD

I I I

¿)(y)¿(¿

(U);j~

(L2)i^

(Q)- —

CONTROL BOX

FIELD CONTROL-VOLTAGE WIRING

FIELD HIGH-VOLTAGE WIRING

rh

GND

3-PHASE

UNITS ONLY

Fig. 10 — High- and Control-Voltage Connections

-CONTACTOR TERMINALS

(SEE UNIT WIRING LABEL)

V-*cnKr-—

FIELD SUPPLIED

FUSED DISCONNECT

POWER

SUPPLY

ammeter between the W and R terminals to determine the

exact required setting.

NOTE: For thermostat selection purposes, use 0.6 amp for

the approximate required setting.

Failure to make a proper heat anticipator adjustment will

result in improper operation, discomfort to the occupants

of the conditioned space and inefficient energy utilization;

however, the required setting may be changed slightly

to provide a greater degree of comfort for a particular

installation.

TRANSFORMER CIRCUIT PROTECTION - The unit

transformer contains an auto, reset overcurrent protector for

control circuit protection. If this device trips, it may reset

without warning, starting the heating or cooling section of

this product. Use caution when servicing; if overcurrent

protector continues to trip, there is a problem in the lowvoltage electrical circuit, such as an electrical short, ground

or transformer overload. Disconnect power, correct the con

dition, and check for normal unit operation.

PRE-START-UP

A WARNING

Failure to observe the following warnings could result

in serious personal injury:

1. Follow recognized safety practices and wear protec

tive goggles when checking or servicing refrigerant

system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is

in place and secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected.

4. Relieve all pressure from system before touching or

disturbing anything inside terminal box if refriger

ant leak is suspected around compressor terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To re

move a component, wear protective goggles and pro

ceed as follows:

a. Shut off gas supply and then electrical power to

unit.

b. Relieve all pressure from system using both high-

and low-pressure ports.

c. Cut component connecting tubing with tubing cut

ter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Proceed as follows to inspect and prepare the unit for ini

tial start-up:

1. Remove alt access panels.

2. Read and follow instructions on all WARNING, CAU

TION and INFORMATION labels attached to, or shipped

with, unit.

Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. Detecting oil generally indicates

10

Page 11

ф

a refrigerant leak. Leak-test all refrigerant tubing con

nections using electronic leak detector, or liquidsoap solution. If a refrigerant leak is detected, see

Start-Up, Check for Refrigerant Leaks section.

c. Inspect all field- and factory-wiring connections. Be

sure that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and han

dling, carefully straighten fins with a fin comb.

3. Verify the following conditions:

A WARNING

Do not purge gas supply into the combustion cham

ber. Do not use a match or other open flame to

check for gas leaks. Failure to follow this warning

could result in an explosion causing personal injury

or death.

a. Make sure that gas supply has been purged, and that

all gas piping has been checked for leaks.

b. Make sure that outdoor-fan blade is correctly posi

tioned in fan orifice. Blades should clear fan motor

by no more than V4 inch.

c. Make sure that air filter(s) is in place.

d. Make sure that condensate drain pan and trap are filled

with water to ensure proper drainage.

e. Make sure that all tools and miscellaneous loose parts

have been removed.

START-UP

Check for Refrigerant Leaks — Proceed as follows

to locate and repair a refrigerant leak and to charge the unit;

1. Locate leak and make sure that refrigerant system pres

sure has been relieved.

2. Repair leak following accepted practices.

NOTE; Install a filter drier whenever the system has been

opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system

and leak-test unit.

4. Evacuate refrigerant system if additional leaks are not

found.

5. Charge unit with R-22 refrigerant, using a volumetric-

charging cylinder or accurate scale. Refer to unit rating

plate for required charge. Be sure to add extra refrig

erant to compensate for internal volume of filter drier.

Start-Up Heating Section and Make

Adjustments

A CAUTION

Complete the required procedures given in Start-Up sec

tion before starting the unit.

Do not jumper any safety devices when operating the unit.

Make sure that burner orifices are aligned properly. Un

stable operation may occur when the burner orifices in the

manifold are misaligned.

NOTE: When installing a unit in extremely cold climate

areas, a run-in period for the inducer motor is recom

mended. After the unit is installed, disconnect the red wire

from terminal 2 at the ignition control (IGN) and jumper

terminals R-W at the control voltage terminal board. The

inducer motor should run but the burner will not ignite. Al

low inducer motor to run for 4 to 5 hours. Reconnect red

wire to terminal 2 at IGN and remove R-W jumper at the-

control voltage terminal board. Proceed as follows to com

plete heating section start-up.

Follow the lighting instructions on the heating section op

eration label (located inside the burner access door) to start

the heating section.

When lighting the unit for the first time, perform the

following:

If the gas supply pipe was not purged before connecting

the unit, it will be full of air. It is recommended that the

ground joint union be loosened, and the supply line be al

lowed to purge until the odor of gas is detected. Never purge

gas lines into a combustion chamber. Immediately upon de

tection of gas odor, retighten the union. Allow 5 minutes to

elapse, then light unit using the following steps.

CHECK HEATING CONTROL - Start and check the unit

for proper heating control operation as follows: (See fur

nace lighting instructions located inside burner access panel.)

1. Place the room thermostat SYSTEM switch in the HEAT

position and the fan switch in the AUTO, position.

2. Set the heating temperature control of the thermostat above

room temperature.

3. Observe that after built-in time delays, the pilot auto

matically lights, the burners light and the blower motor

starts.

4. Observe that the burners and pilot go out, and that after

a built-in delay the blower motor stops when the heating

control setting of the thermostat is satisfied.

NOTE: The 060-size 460-v models are equipped with a 3phase blower motor. Check blower wheel for correct rota

tion as indicated by arrow on blower housing. If blower

wheel rotates in opposite direction, reverse any 2 blower

motor leads or any 2 line voltage leads. Recheck blower

wheel rotation if necessary to reverse leads.

CHECK GAS INPUT — Check gas input and manifold pres

sure after unit start-up. (See Table 4.) If adjustment is re

quired, proceed as follows.

The rated gas inputs shown in Table 4 are for altitudes

from sea level up to 2000 ft above sea level. These inputs

are based on natural gas with a heating value of 1050 Btu/

ft^ at 0.65 specific gravity, or propane gas with a heating

value of 2500 Btu/fr at 1.5 specific gravity. For elevations

above 2000 ft, reduce input 4% for each 1000 ft above sea

level. When the gas supply being used has a different heat

ing value or specific gravity, refer to national and local codes,

or contact your Distributor or Branch to determine the re

quired orifice size.

A CAUTION

These units are designed to consume the rated gas in

puts using the fixed orifices at specified manifold pres

sures as shown in Table 4. DO NOT REDRILL THE

ORIFICES UNDER ANY CIRCUMSTANCES.

ADJUST GAS INPUT — The gas input to the unit is de

termined by measuring the gas flow at the meter or by mea

suring the manifold pressure. Measuring the gas flow at the

meter is recommended for natural gas units. The manifold

pressure must be measured to determine the input of pro

pane gas units.

Measure Gas Flow (Natural Gas Units') — Minor adjust

ment to the gas flow can be made by changing the manifold

pressure. The manifold pressure must be maintained be

tween 3.2 and 3.8 in. wg. If larger adjustments are

required, change main burner orifices following the recom

mendations of national and local codes.

11

Page 12

Table 4 — Rated Gas Inputs

UNIT 48

NLT018,024,030

NLT036,042; NHT024; NMT030 3 50

NLT048,060; NMT036,042; NHT030

NET036,042

NMT048,060; NHT036.042

NHT048,060; NVT036,042

NVT048,060

‘When a 48N unit is converted to propane, the unit must be modified. See kit instructions.

tBased on altitudes from sea level up to 2000 ft above sea level. For altitudes above 2000 ft, reduce

Input rating 4% for each 1000 ft above sea level In Canada, from 2000 ft above sea level to 4500 ft

above sea level, derate the unit 10%.

NUMBER

OF

ORIFICES

GAS SUPPLY PRESSURE

Min Max Min Max

2 5.0

4

4 5.0 136 11 0 13.6

5 5.0 13.6

6 5.0 13.6 11.0 13.6

6 50 13.6 11.0

5.0 13.6

NOTE; All other appliances that use the same meter must

be turned off when gas flow is measured at the meter.

Proceed as follows:

1. Turn off gas supply to unit.

2. Remove pipe plug on outlet of gas valve, then connect

manometer at this point. Turn on gas to unit.

3. Record number of seconds for gas meter test dial to make

(in. wg)

Natural Propane

13.6

13.6 11.0 13.6 3.5

13 6 35

11 0

11.0 13.6 3.5

11.0 13.6 3.5 10.5

136 3.5 10.5

Measure Manifold Pressure (Propane Units') — The main

burner orifices on a propane gas unit are sized for the unit

rated input when the manifold pressure is 10.5 in. wg.

unit:

1. Turn off gas to unit.

2. Remove pipe plug on outlet of gas valve, then connect

one revolution.

4. Divide number of seconds in Step 3 into 3600 (number

of seconds in one hour).

3. Turn on gas to unit.

4. Remove cover screw over regulator adjustment screw

5. Multiply result of Step 4 by the number of cu ft shown

for one revolution of test dial to obtain cu ft of gas flow

5. Adjust regulator adjustment screw for a manifold pres

per hour.

6. Multiply result of Step 5 by Btu heating value of gas to

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 4. (Consult the local

gas supplier if the heating value of gas is not known.)

6. Replace cover screw.

7. Turn off gas to unit. Remove manometer from pressure

Example: Assume that the size of test dial is one cu ft, one

revolution takes 30 seconds, and the heating value of the

gas is 1050 Btu/ft^. Proceed as follows:

1. 30 seconds to complete one revolution.

2. 3600 30 = 120.

3. 120 X 1 = 120 ft^ of gas flow/hr.

4. 120 X 1050 = 126,000 Btuh input.

If the desired gas input is 125,000 Btuh, only a minor

change in the manifold pressure is required.

Observe manifold pressure and proceed as follows to

adjust gas input;

1. Remove cover screw over regulator adjustment screw

on gas valve.

2. Turn regulator adjustment screw clockwise to increase

gas input, or turn regulator adjustment screw counter

clockwise to decrease input. Manifold pressure must be

between 3.2 and 3.8 in. wg.

CHECK BURNER FLAME — Observe the unit heating

operation, and watch the burner flames through the obser

vation port to see if they are light blue and soft in appear

ance, and that the flames are approximately the same for

each burner. See Fig. 11.

BLOWER HEAT-RELAY OPERATION - Blower relay

PCI (see the unit wiring diagram) is located in the control

box and adjusts to permit either longer or shorter “off” cy

cles. The “on” cycle is factory set for one minute on tim

ing. The adjusting dial on the relay (see Fig. 12) is factory

set at the minimum position to provide optimum perfor

mance for most installations. On unusual installations, the

length of time the blower remains on may need to be

increased. To increase blower operation time, rotate the ad

justing dial counterclockwise. To decrease blower opera

tion time, rotate dial clockwise.

AIRFLOW AND TEMPERATURE RISE - The heating

MANIFOLD

PRESSURE

(in. wg)

Natural

3.5 10.5

35 10.5

Proceed as follows to adjust gas input on a propane gas

manometer at this point.

on gas valve.

sure reading of 10.5 in. wg. Turn adjusting screw clock

wise to increase manifold pressure, or turn adjusting screw

counterclockwise to decrease manifold pressure.

tap. Replace pipe plug on gas valve, then turn on gas to

unit. Check for leaks.

section for each size unit is designed and approved for heat

A WARNING

Unsafe operation of the unit may result if manifold

pressure is outside this range. Personal injury or unit

damage may result.

ing operation within the temperature-rise range stamped on

the unit rating plate.

Table 5 shows the approved temperature-rise range for

each unit, and the air delivery cfm at various temperature

rises. The heating operation airflow must produce a tem

3. Replace cover screw cap on gas valve.

4. Turn off gas supply to unit. Remove manometer from

pressure tap. Replace pipe plug on gas valve. Turn on

perature rise that falls within the approved range.

Refer to Indoor Airflow and Airflow Adjustments sec

tion to adjust heating airflow when required.

gas to unit. Check for leaks.

NATURAL GAS

Orifice

Propane

10.5 44 40,000

10.5 44 60,000

105 44

Heating

Orili

Size

(Btuh)t

42 96,000

44 100,000

44 120,000

42 144,000

PROPANE*

Input

80,000 55

Orifice

Drill

Size

55

55

55

54

54

55

Heating

Input

(Btuh)t

40,000

60,000

80,000

96,000

100,000

120,000

144,000

12

Page 13

PILOT FLAME BURNER FLAME

fl

will close the IFR2 relay 60 seconds after the burners are

ignited and the blower motor (IFM) will start. When the

thermostat is satisfied, the R and W circuit is opened and

power is removed from the PC2 inducer control and the ig

nition module (IGN), which causes the MV to close in

stantly and the IM is deenergized. The electronic timer PCI

will keep the IFM running an additional 60 to 90 seconds.

Then the blower stops and the unit is on standby until an

other call for heat.

NOTE; If the main limit switch opens due to the unit over

heating, the IFM is turned on through the electronic board.

NOTE: When the unit is initially powered, IER2 will close

and run the IFM for the duration of the off-delay cycle (60

to 90 seconds).

If the pilot fails to light within a 120-second trial for ig

nition period from the initial call for heat, the IGN will go

into a Retry mode after a period of approximately 5 min

utes (following the 2-minute trial for ignition period). If the

pilot again fails to light, IGN will go into Retry mode; this

cycle will be repeated until the pilot light ignites. If the pi

lot flame has been established but then extinguishes, the

IGN will immediately reset as if it were the initial call for

heat. If this occurs more than 3 times, the IGN will lock

out the system, and the diagnostic LED (located on the IGN)

will flash. To reset, open the R-W thermostat circuit for 30

seconds and reclose. If the diagnostic LED glows con

stantly, replace control.

LIMIT SWITCHES — Normally closed limit switch LS com

pletes the control circuit through the thermostat R circuit.

See Fig. 13 and 14. Should the leaving-air temperature rise

above the maximum allowable temperature, the limit switch

opens and the R control circuit “breaks.” Any interruption

in the R control circuit instantly closes the gas valve and

stops gas flow to the burners and pilot. The IFM continues

to run until the LS resets.

SAFETY CHECK OF LIMIT CONTROL - The control

shuts off the gas supply and energizes the circulating-air

blower motor if the furnace overheats.

The recommended method of checking this limit control

is to gradually block off the return air after the furnace has

been operating for a period of at least 5 minutes. As soon

as the limit control functions, the return-air opening should

be unblocked to permit normal air circulation. By using this

method to check the limit control, it can be established that

the limit is functioning properly and the furnace will “fail

safe” if there is a restricted circulating air supply or motor

failure. If the limit control does not function during this

test, the cause must be determined and corrected.

HEATING SEQUENCE OF OPERATION - See Fig. 13

for single-phase operation and Fig. 14 for 3-phase opera

tion. Room thermostat calls for heat, closing circuit be

tween R and W 24-V control circuit terminals. (Power to

the R terminal is supplied through LS and ALS safety

switches.) The PC2 inducer control board is energized through

the normally closed set of contacts of pressure switches (CPS),

which starts the inducer motor (IM). The IM comes up to

speed, and the vacuum in the collector box increases, open

ing the normally closed and closing the normally open

contacts of the pressure switch (PS), energizing the circuit

to the ignition control (IGN) and the pilot valve (PV). If

theflame sensor proves the presence of the pilot flame, the

t

internal switching of the ignition control deenergizes the

spark generator and energizes the main gas valve (MV) and

the IFR2 electronic timer. Gas flows to the main burners

and is ignited by the pilot flame. The PCI electronic timer

When the air temperature at the limit switch drops to the

low-temperature setting of the limit switch, the switch closes

and completes the R control circuit. The electric-spark ig

nition system cycles and the unit returns to normal heating

operation.

BLOWER AUXILIARY LIMIT SWITCH - Blower aux

iliary limit switch ALSl is a temperature-actuated auto, re

set switch and is connected in series with the limit switch

LS. The function of the switch is to prevent abnormal blower

compartment temperatures. The switch is mounted on the

blower housing. When the temperature at the auxiliary switch

reaches the maximum allowable temperature, the R control

circuit “breaks”, closing the gas valve and stopping gas

flow to the burners and pilot. The switch will automatically

reset when the blower compartment temperature returns to

normal. The IFM continues to run until ALSl resets.

ROLLOUT AUXILIARY LIMIT SWITCH - Rollout aux

iliary limit switch ALS2 is a temperature-actuated manual

reset switch connected in series with limit switch LS and

blower auxiliary limit switch ALSl. The function of the

switch is to close the main gas valve in the event of flame

rollout. The switch is located above the main burners. When

the temperature at the auxiliary switch reaches the maxi

mum allowable temperature, the R control circuit trips, clos

ing the gas valve and stopping gas flow to the burners and

pilot. To reset the switch, push in the red button. If the

switch cycles again, shut down the unit and call for service.

The IFM continues to run until ALS2 is reset.

13

Page 14

r

SIN6LE STA6E HEAT K SIN6LE STAGE COOL

THERMOSTAT CTYPJ

■@-RED-

BUC

KED -

ORN -

TRAN

BRN —

^ ®©<£>

® PCI ®

® I—I I—3 ®

<!> 0 <»> 0 0

♦-0

r^Pi'

IGN o

PS

ALS1 ALS2 C -

CAP. -

1,2

COMP

EG

GV

IFM

IFR1

IFR2

IM

IR

IGN

LS

NOTES:

1. 230-v operation as shown. For 208-v operation, reverse red and orn leads of transformer.

2. Symbols are an electrical representation only.

3. If any of the original wire, as supplied, must be replaced, use minimum 105° C wiring

4. Use copper wire only for field power supply leads.

5. Compressor and fan motors provided with inherent thermal protection.

Auxiliary Limit Switch (SPST)

NC (Blower)

Auxiliary Limit Switch (SPST)

NC (Rollout)

Contactor

Capacitors (Run)

Compressor

Equipment Ground

Gas Valve

Indoor Fan Motor

Indoor Fan Relay

(SPOT) NO (Cooling)

Indoor Fan Relay

(SPST) NO (Heating)

Inducer Motor

Inducer Relay (DPST) NO

Ignitor

Limit Switch (SPST) NC

material.

LEGEND

MV

OFM

P

PCI

PC2

PI

PS

PV

ST

TRANS

Mam Valve

Outdoor Fan Motor

Pilot (Flame Sensing)

Printed Circuit Board (Blower)

Printed Circuit Board (Inducer)

Pilot Ignitor

Pressure Switch (SPOT) NC

Pilot Valve

Start Thermistor (024-042 only)

Transformer

Field High-Voltage Wiring

Factory High-Voltage Wiring

Factory Low-Voltage Wiring

Field Low-Voltage Wiring

Marked Connection

e

Unmarked Connection

o

internally Connected or

^ Wirenut

SO

o

Fig. 13 — Typical Single-Phase Wiring Diagram

Page 15

FIELD L3

POWER L2

SUPPLY

BLK-

^5—

{j^ I—@

©

ilHl—®

■ RSI ORN -

BRN

TRAN

SIN6LE 5TA6E HEAT S SIN6LE STA6E COOL

TfCRMOSTAT CTYPJ

EG

CAPI

1 Co o)

^ CAP2

ICOMPOWB^T arrangement“

ALS1

ALS2

C

CAP. 1,2

CCH

COMP

EG

GV

IPM

IFR1

IFR2

IM

IR

IQN

LS

NOTES:

1. 230-v operation as shown. For 208-v operation, reverse red and orn leads of transformer.

2. Symbols are an electnca) representation only.

3. If any of the original wire, as supplied, must be replaced, use minimum 105'^C wiring

material.

4. Use copper wire only for field power supply leads.

5. Compressor and fan motors provided with inherent thermal protection.

6. Three-phase motors protected under primary single-phase conditions.

Auxiliary Limit Switch (SPST)

NC (Blower)

Auxiliary Limit Switch (SPST)

NC (Rollout)

Contactor

Capacitors (Run)

Crankcase Heater

Compressor

Equipment Ground

Gas Valve

Indoor Fan Motor

Indoor Fan Relay

(SPOT) NO (Cooling)

Indoor Fan Relay

(SPST) NO (Heating)

Inducer Motor

Inducer Relay (DPST) NO

Ignitor

Limit Switch (SPST) NC

LEGEND

MV

OFM

p

PC1

PC2

PI

PS

PV

TRANS

Mam Valve

Outdoor Fan Motor

Pilot (Flame Sensing)

Printed Circuit Board (Blower)

Printed Circuit Board (Inducer)

Pilot Ignitor

Pressure Switch (SPOT) NC

Pilot Valve

Transformer

Field High-Voltage Wiring

Factory High-Voltage Wiring

Factory Low-Voltage Wiring

Field Low-Voltage Wiring

Marked Connection

©

Unmarked Connection

O

Internally Connected or

Wirenut

Fig. 14 — Typical 3-Phase Wiring Diagram

Page 16

Start-Up Cooling Section and Make

Adjustments

A CAUTION

Complete the required procedures given in the Pre-StartUp section before starting the unit.

Do not jumper any safety devices when operating

the unit.

Do not operate the compressor when the outdoor tem

perature is below 55 F (unless accessory low-temperature

kit is installed).

Do not rapid-cycle the compressor. Allow 5 minutes

between “on” cycles to prevent compressor damage.

CHECKING COOLING CONTROL OPERATION - Start

and check the unit for proper cooling control operation as

follows:

1. Place room thermostat SYSTEM switch in OFF posi

tion. Observe that blower motor starts when FAN switch

is placed in ON position and shuts down when FAN switch

is placed in AUTO, position.

2. Place SYSTEM switch in COOL position and FAN switch

in AUTO, position. Set cooling control below room tem

perature. Observe that compressor, condenser fan and

evaporator blower motors start. Observe that cooling

cycle shuts down when control setting is satisfied. The

blower motor has an off delay of approximately one minute

on shutdown.

3. When using an auto.-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO, positions.

Observe that unit operates in heating mode when tem

perature control is set to “call for heating” (above room

temperature) and operates in cooling mode when tem

perature control is set to “call for cooling” (below room

temperature).

CHECKING AND ADJUSTING REFRIGERANT CHARGE

— The refrigerant system is fully charged with R-22 refrig

erant, tested and factory-sealed.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-22

charge. Eor all applications, the correct R-22 charge for the

best performance is the charge that results in a suction gas

superheat of 5 F at the compressor inlet when the unit is

operating at the ARI rating conditions of 95 F dry-bulb (db)

outdoor and 80 F db/67 F wet-bulb (wb) indoor.

A superheat charging label is attached to the outside of

the compressor access door. The label includes a “Super

heat Charging Table” and a “Required Suction-Tube Tem

perature (F)” chart.

An accurate superheat thermocouple- or thermistor-type

thermometer, a sling psychrometer and a gage manifold are

required when using the superheat charging method for eval

uating the unit charge. Do not use mercury or small dial-

type thermometers because they are not adequate for this

type of measurement.

A CAUTION

When evaluating the refrigerant charge, an indicated

adjustment to the specified factory charge must always

be very minimal. If a substantial adjustment is indi

cated, an abnormal condition exists somewhere in the

cooling system, such as insufficient airflow across

either coil or both coils.

Proceed as follows:

1. Remove caps from lowfittings.

and high-pressure service

2. Using hoses with valve core depressors, attach low- and

high-pressure gage hoses to low- and high-pressure ser

vice fittings, respectively.

3. Start unit in cooling mode and let unit run until system

pressures stabilize.

4. Measure and record the following.

a. Outdoor ambient-air temperature (F db).

b. Evaporator inlet-air temperature (F wb).

c. Suction-tube temperature (F) at low-side service

fitting.

d. Suction (low-side) pressure (psig).

5. Using “Superheat Charging Table,” compare outdoorair temperature (F db) with evaporator inlet-air temper

ature (F wb) to determine desired system operating su

perheat temperature. See Table 6.

6. Using “Required Suction-Tube (F)” table, compare de

sired superheat temperature with suction (low-side)

operating pressure (psig) to determine proper suctiontube temperature. See Table 7.

7. Compare actual suction-tube temperature with proper

suction-tube temperature. Using a tolerance of ± 3 F,

add refrigerant if actual temperature is more than 3 F

higher than proper suction-tube temperature, or remove

refrigerant if actual temperature is more than 3 F lower

than required suction-tube temperature.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to Start-Up, Check for Refrigerant

Leaks section.

INDOOR AIRFLOW AND AIRFLOW ADJUSTMENTS

A CAUTION

For cooling operation, the recommended airflow is 350

to 450 cfm per each 12,000 Btuh of rated cooling ca

pacity. For heating operation, the airflow must pro

duce a temperature rise that falls within the range stamped

on the unit rating plate.

Direct-drive blower motors are factory connected to de

liver the proper heating and cooling airflows at normal ex

ternal static pressures (medium speed cooling, low speed

heating for 230-v units) and high speed cooling (units with

460-V have medium speed cooling and high speed heating).

For 208-v operation on 208/230-v rated direct drive units,

interchange motor leads to high speed for cooling and

medium speed for heating operation.

Table 5 shows the temperature rise at various airflow rates.

Tables 8 and 9 show both heating and cooling airflows at

various external static pressures. Refer to these tables to

determine the airflow for the system being installed.

NOTE: Be sure that all supply- and return-air grilles are

open, free from obstructions and adjusted properly.

A WARNING

Disconnect electrical power to the unit before changing

blower speed. (Be sure to turn off gas supply before

disconnecting electrical power.) Electrical shock can cause

personal injury or death.

A CAUTION

Do not change the blower-motor lead connections on

460-V units from the factory setting. Damage to unit

may result.

i

16

Page 17

Table 5 — Air Delivery (Cfm) at Indicated Temperature Rise and Rated Heating input

NOMINAL SIZE

NLT018,024,030

NHT024; NMT030

f

NLT036,042

NHT030; NMT036,042

NLT048

NLT060

NET036,042

NHT036,042; NMT048

NMT060

NVT036,042; NHT048 120,000

NHT060

NVT048,060

NOTE: Dashed areas of the table do not fall In the approved temperature rise range of the unit

HEATING

INPUT (Btuh)

40,000

60,000

60,000 - 80,000 - - - - - 1316

80,000 80,000

96,000 - - - 100,000

100,000

120,000 - - - 2539

144,000

20

- -

- - - - - 987 888

2370

2962 2370

- - - 2116

- -

- - - - - -

- - - -

30

25

987

1481 1269

1975 1693 1481

1975 1693 1481

2469

2116

UNIT TEMPERATURE RISE (T)

40 45

35

740 658

846

1111

1777

1851 1646

1851 1646 1481

2222 1975 1777

-

1316 1185

1316 1185

1580

2370 2133 1939 1777 1641

50 55

592 538

987

888

1185 1077

1422 1292 1185 1096

1481 1346 1234 1139

1777

60 65

493

808 740 683 634

740

808

987

1077

1346 1234

1616

1616

- - - - -

- - - - - -

1367

1481

1367

1481

70 75

-

- - 592 -

- - - -

911

846 790 -

1015 - -

- - -

- - - 1269

1185 1111

- - -

1523 1422

80

-

Table 6 — Superheat Charging Table*

TEMP (F)

55 9

60

65

70

75

80

85

90

95

100

105

110

115

50

—

— - —

— — - — -

52

12 14 17

7 10 12

- - 7

- - - - 5

- - - - - - 8 11 15 19

- - - - - - - 6

- - - - - - - - 8 12 15

- - - - - - - -

- - - - - - - - - 6

- - - - -

54 56 58

15

10 13 16 19

6

10 13 16

6 9 12

20

18

60 62

23 26

21 24

21 24 27

19 21

15

12 15

8

- - -

64

29 32 35

27 30 33 35

18

5

66

24

21 24 28

18 21 25

9 13 16 21

10 14

5 9 13

- -

68 70

37

30

27

33 36

30

22

18 22

11

72

40

38

33 36 39

31 34 37

28

26 30

24 27

20

17

15 20

8

14

74 76

42 45

40 43

38 41

31

25 29

23

22 26

18 23

35

33

31

27

25

•Superheat at suction service valve.

NOTE: Do not attempt to charge system under these conditions; refrigerant slugging may occur

Table 7 — Required Suction-Tube Temperature (F)*

TEMP (F)

61.5 64.2 67.1 70.0

0 35

2 37

4 39

6

8

10

12

41 43 45

43 45 47 49

45 47

47

14 49 51 53 55

16

51 53 55

16 53

20 55

22

57

24 59 61

26 61 63 65

28

30

32

34

63 65 67

65 67 69

67 69 71

69

36 71 73

38 73 75

40

•Temperature at suction service valve

75 77 79 81

37 39

39 41 43 45 47 49

41

49 51 53

55 57 59 61

57

59 61 63

71 73 75

43 45

49

59 61

63

75

77

41 43

47

51 53

57 59 61

65

67

69 71

71 73 75

73 75

77

79

73.0 76.0 79.2

47

49

51 53 55

55

57 59

63 65 67

65

67 69 71

69 71 73

77 79 81 83 85

79

81

83

45

49 51

51 53

55 57

57

63

67

73

77

81 83 85

83

85

47

59

61

63 65 67

65 67

69 71

75 77

77

79 81 83

85

87

49 51

51 53

53 55

55 57

57

59

61

63 65

69 71

73

75 77

79

87 89

89 91

82.4

85.7

59

61

63

69

73

75

79

81

87

17

Page 18

Table 8 — Dry Coil Air Delivery (Cfm)*

at Indicated External Static Pressure and Voltage

— Horizontal Discharge (Without Filter)

48

V-PH-HZ

NLT018, NLT024,

NHT024

208/230-1-60

NLT030, NMT030

208/230-1-60

NHT030, NLT036

NMT036, NLT042

NMT042

208/230-1-60

208/230-3-60,

460-3-60tt

NET036, 042

208/230-1-60

208/230-3-60

460-3-60tt

NHT036, NVT036

NHT042, NVT042

208/230-1-60

208/230-3-60

460-3-60tt

NLT048, NMT048

NHT048

208/230-1-60

208/230-3-60

460-3-60tt

NVT048

208/230-1-60

208/230-3-60

460-3-60tt

NLT060, NMT060

NHT060, NVT060

208/230-1-60

208/230-3-60

460-3-60tt

*Air delivery values are without air filter and are for dry coil. See Table 10 for wet coil pressure drop.

Deduct field-supplied air filter pressure drop and wet coil pressure drop to obtain external static

pressure available for ducting.

tFactory blower-motor speed setting for heating operation.

‘'Factory blower-motor speed setting for cooling operation.

ttDo not change blower speed settings for units with 460-v (high speed only).

NOTE: Do not operate the unit at a cooling airflow that is less than 350 cfm per each 12,000 Btuh of

rated cooling capacity. Evaporator coil icing may occur at airflows below this point. Water blow-off may

occur at airflows above 450 cfm per 12,000 Btuh of rated cooling capacity

MOTOR

SPEED

Lowf,

Med“

HI

Lowf,

Med“

Hi

Lowf,

Med“

Hi

Lowf,

Med“

Hi

Lowf,

Med“

Hi

Lowf,

Med“

Hi

Lowf,

Med“

Hi

Lowf,

Med“

Hi

in. wg

Watts

Cfm

Watts 511 483 464 440

Cfm

Watts 519

Cfm 1184 1163

Watts 620

Cfm 1443

Watts

Cfm

Watts 670

Cfm 1765 1705 1621 1521 1383

Watts

Cfm

Watts

Cfm

Watts 740 700

Cfm 1913 1820

Watts 790 760 720 690

Cfm 2032

Watts 770 730 690 650

Cfm 1945 1880

Watts 850

Cfm 2138

Watts

Cfm 1931 1901 1862 1813

Watts 1220 1165

Cfm 2376 2311 2244

Watts 1125

Cfm 2184 2125

Watts

Cfm 2380

0.0 0.1

451

1185 1129

1370

560 544 527 505

1515 1452

873 847 814 785 758

1717

1075 1030

2119

985 950

1220 1175

427

1291 1221 1142 1063

507

602

1414

650

1690 1645 1597 1550

2062

1942

810

2045

1055

2307

208 V

0.2 0.3

407 383

1088

1150

1376 1329 1279

1389 1308

2063

1026 979

492

1134 1105

581 559

631

995 960

1995 1913

660

1645 1544

1736

1844 1759 1636

1708 1611

1796

770 730

1943 1846

915

1080

1130

2170

1015 980

2000 1938

1125 1080

2262 2165

0.4 0.5

365 348

420

477 455 431 569

532 493 670

482 461

1227

602 573

930

1863 1793 2135 2066 1998

615 580

650 610

610 575 810 765 730

690

1738

890 860

1768 1703 2183 2125

1035 995

2083

940

1040

2095

0.0

501 477

922

1256 1195

402

1003 1442 1359

1064

1197

1105

542

1254 1857 1795 1708

734 987

1496 1979 1922 1859

900 1121 1087 1046

540 755 725 680

1428

1514

1508 2061 1970 1892 1813

655

1624

2003 2511

1880 2285 2225 2163 2106

1005

2024

561 533 514

1248

1519

610

1597 1530

720 701

1976 1909

850

2086

890 855

2178

820

1095

1300

905

1205 1125

1300 1250

2487

230 V or 460 V

0.1

0.2

0.3

457

1148

1081

1285 1202

557 542

1226 1211 1194 1164

652 631 609 582

1489 1449 1399

593 575 500

1464 1378 1293

680 653 625

1603 1457

911

945

1802

1017 981

1931 1858

1714 1603

1806

820 780

1983 1883

2081

1055 1010

1265 1220

2431

2412 2335 2260 2179

1782 1665

820 780 750

1941 1869 1769

2071 2005 1931 1854

1180 1120

2271 2168

2359

1095 1060 1030

1210 1165 1130 1085

0.4

433

415

1031

490

470

1119

527

505