Page 1

48LJE/LJF004

48L J D/L J E/L J F005-007

HEATING & COOLING

Single-Package Rooftop Heating/Cooling Units

Installation, Start-Up, and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS ...

INSTALLATION .......................................................1

Step 1 — Provide Unit Support

• ROOF CURB

• SLAB MOUNT

Step 2 — Field Fabricate Ductwork .........................

Step 3 — Install External Trap for

Condensate Drain ..................................................

Step 4 — Rig and Place Unit ....................................

• POSITIONING

Step 5 — Install Flue Hood........................................

Step 6 — Install Gas Piping

Step 7 — Make Electrical Connections

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

• HEAT ANTICIPATOR SETTINGS

Step 8 - Make Outdoor-Air Adjustments and

Install Outdoor-Air Hood

• MANUAL OUTDOOR-AIR DAMPER

• TWO-POSITION DAMPER

• OPTIONAL ECONOMIZER

Step 9 — Adjust Evaporator-Fan Speed..................13

• DIRECT DRIVE MOTORS

• BELT DRIVE MOTORS

START-UP

................

................................

.....................................

...................

.......................................

SERVICE ..................

TROUBLESHOOTING

19

1

10

20,21

21-25

26-31

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical com

ponents. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance func

tions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service per

sonnel. When working on air-conditioning equipment, ob

serve precautions in the literature, tags and labels attached

to the unit, and other safety precautions that apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

A WARNING

Disconnect gas piping from unit when leak

testing at pressure greater than V2 psig. Pres

sures greater than ’/2 psig will cause gas valve

damage resulting in hazardous condition. If

gas valve is subjected to pressure greater than

■ /2 psig, it must be replaced before use. When

pressure testing field-supplied gas piping at

i

pressures of V2 psig or less, a unit connected

to such piping must be isolated by manually

closing the gas valve(s).

Before performing service or maintenance operations

on unit, turn off main power switch to unit. Electrical

shock could cause personal injury.

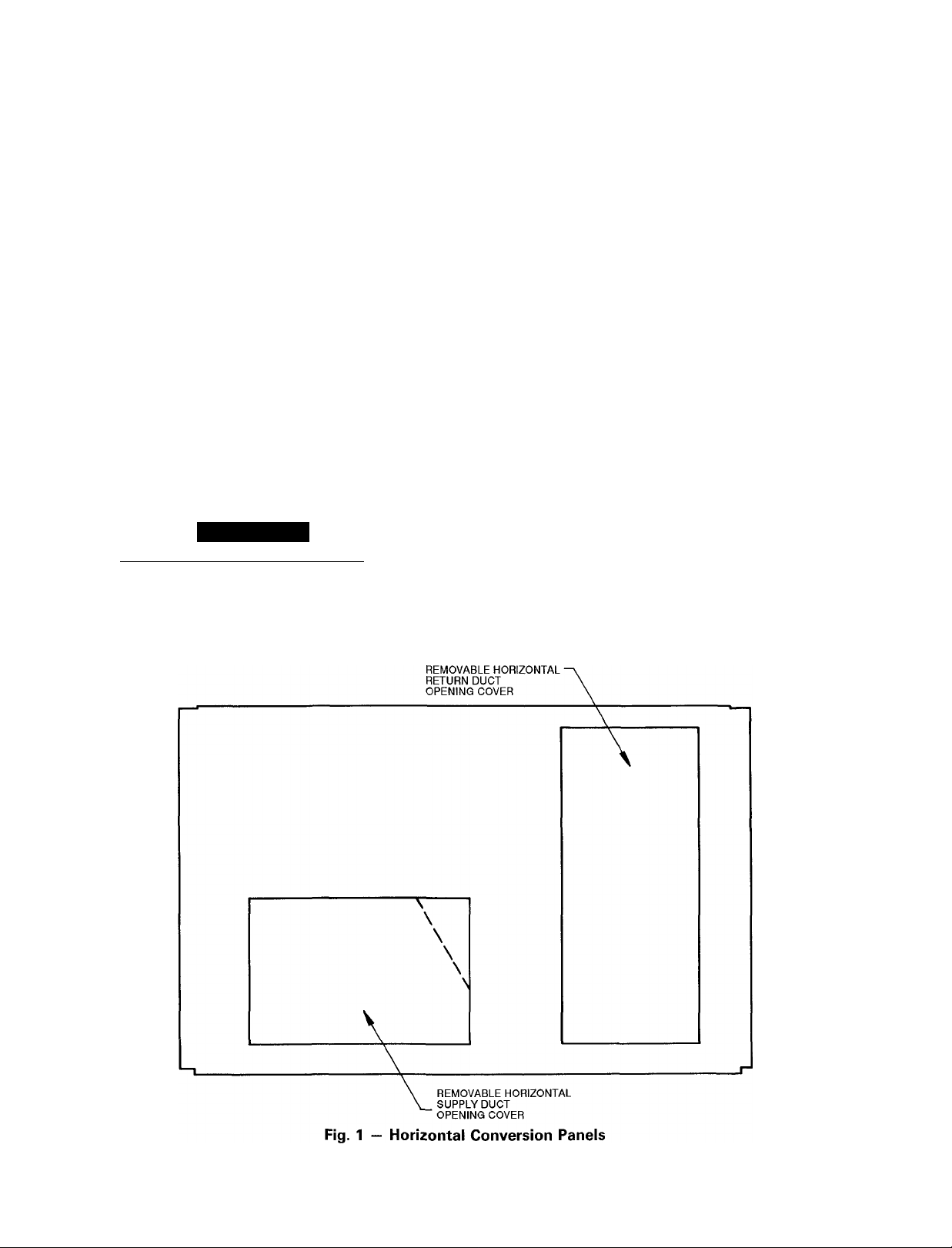

Unit is shipped in the vertical discharge configuration.

To convert to horizontal configuration, remove screws from

side duct opening covers and remove covers. Using the same

screws, install covers on vertical duct openings with the

insulation-side down. Seals around duct openings must be

tight. See Fig. 1.

IMPORTANT: An external filter kit MUST be used

or the filters MUST be field-installed outside the unit

on horizontal discharge applications with optional econ

omizer. Otherwise, the economizer must be partially

removed to access the filters. The area of the fieldinstalled filters should be equal to the area of the factoryinstalled filters.

Step 1 — Provide Unit Support

ROOF CURB — Assemble and install accessory roof curb

in accordance with instructions shipped with curb. See

Fig. 2. Install insulation, cant strips, roofing felt, and counter

flashing as shown. Ductwork must be attached to curb, not

to the unit. If gas, electric power, or control power is to be

routed through the curb, attach the accessory thm-the-curb

service connection plates to the roof curb in accordance with

the accessory installation instmctions. Connection plates must

be installed before unit can be set on roof curb.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for a watertight seal. Install gasket sup

plied with the roof curb as shown in Fig. 2. Improp

erly applied gasket can result in air leaks and poor

unit performance.

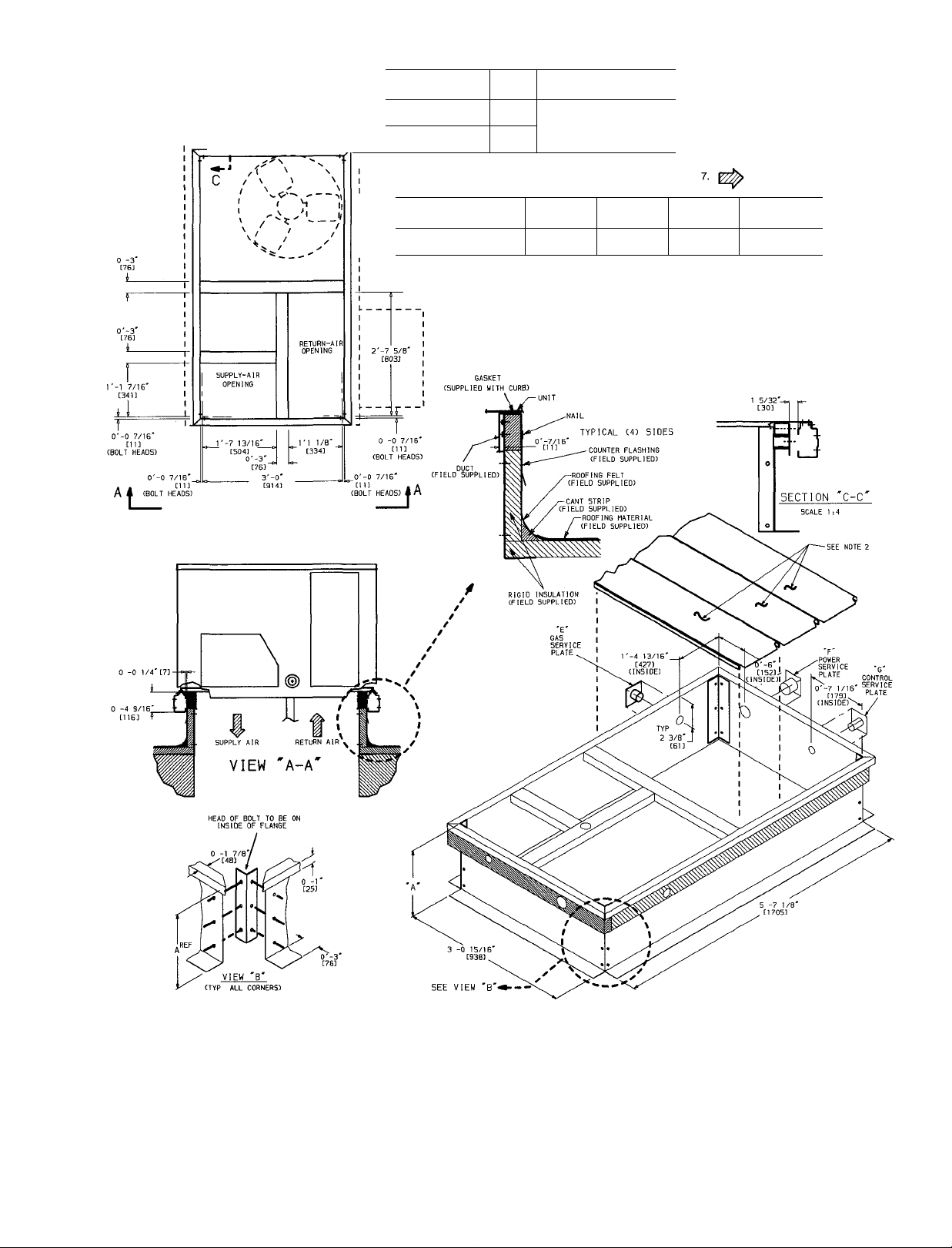

Curb should be level. Unit leveling tolerances are shown

in Fig. 3. This is necessary for unit drain to function prop

erly. Refer to Accessory Roof Curb Installation Instruc

tions for additional information as required.

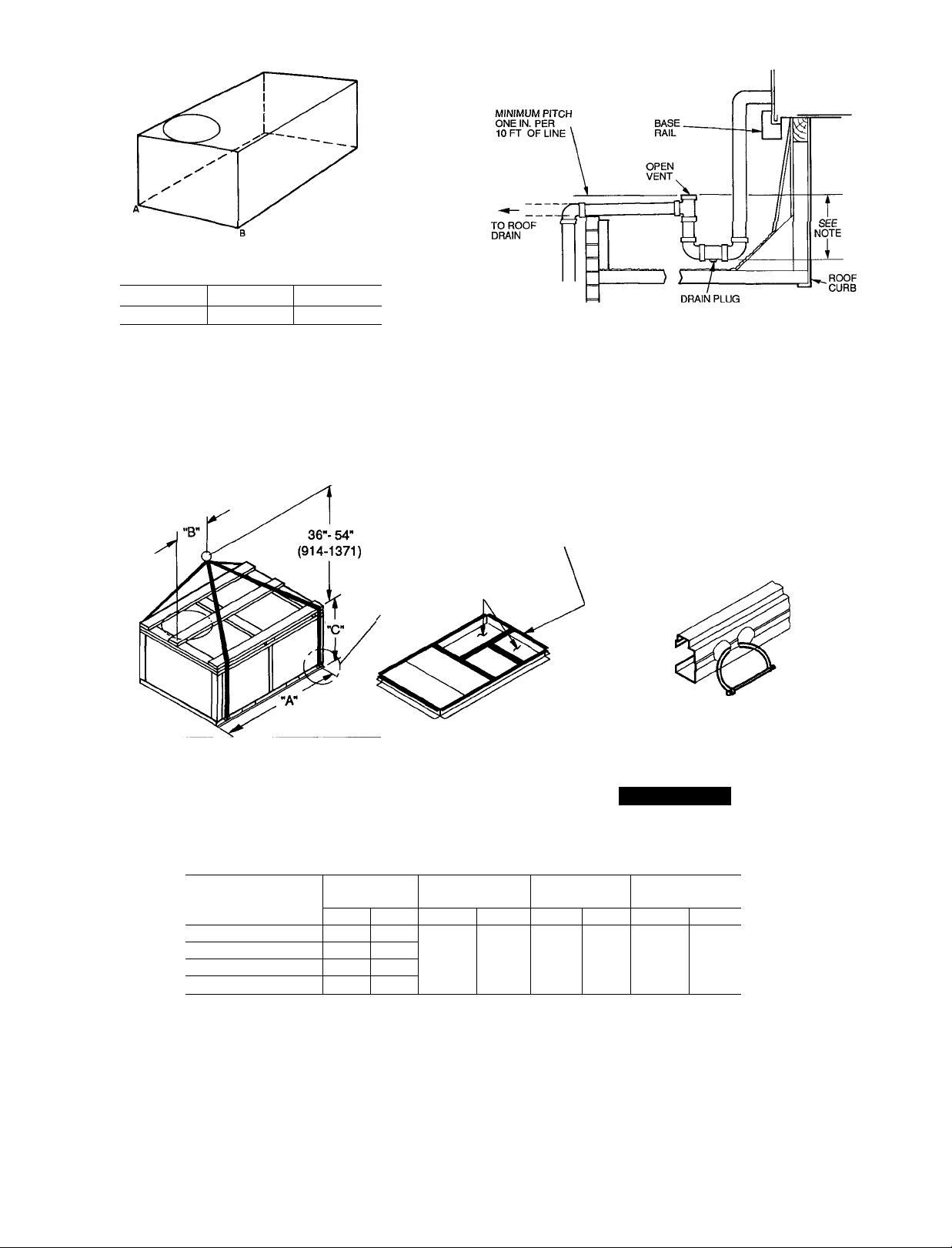

SLAB MOUNT (Horizontal Units Only) — Provide a level

concrete slab that extends a minimum of 6 in. beyond unit

cabinet. Install a gravel apron in front of condenser coil air

inlet to prevent grass and foliage from obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

Step 2 — Field Fabricate Ductwork — Secure all

ducts to roof curb and building structure on vertical units.

Do not connect ductwork to unit. For horizontal applica

tions, field-supplied flanges should be attached to horizon

tal discharge openings and all ductwork should be secured

to the flanges. Insulate and weatherproof all external duct

work, joints, and roof openings with counter flashing andmastic in accordance with applicable codes.

A WARNING

INSTALLATION

Book|1 |4 PC 111 Catalog No. 564-987 Printed in U S A Form 48LJ-7SI Pg 1 4-93 Replaces: 48LJ-5SI

Tab la 6a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Page 2

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with ap

plicable fire codes.

A minimum clearance is not required around ductwork.

Cabinet return air static shall not exceed —.35 in. wg with

economizer or — .45 in. wg without economizer.

Step 3 — Install External Trap for Condensate

Drain — All units must have an external trap added for

condensate drainage. A y4-in. NPT connection is located

on the side of the unit. Use a trap at least 4-in. deep and

protect against freeze-up.

If drain line is run to a drain, pitch line away from unit at

1 in. per 10 ft of run. Do not use a pipe size smaller than

the unit connection. See Fig. 4 for more details.

Step 4 — Rig and Place Unit — Inspect unit for

transportation damage. File any claim with transportation

agency. Keep unit upright and do not drop. Spreader bars

are not required if top crating is left on unit. Rollers may be

used to move unit across a roof. Level by using unit frame

as a reference. See Table 1 and Fig. 5 for additional infor

mation. Operating weight is shown in Table 1 and Fig. 5.

Lifting holes are provided in base rails as shown in

Fig. 6. Refer to rigging instructions on unit.

A CAUTION

I

______

POSITIONING — Maintain clearance around and above

unit to provide minimum distance from combustible mate

rials, proper airflow, and service access. See Fig. 6. A prop

All panels must be in place when rigging.

_________

erly positioned unit will have the following clearances

between unit and roof curb: 'A-in. clearance between roof

curb and base rails on each side and front of unit; U/32-in.

clearance between roof curb and rear of unit. (See Fig. 2,

section C-C.)

Do not install unit in an indoor location. Do not locate

unit air inlets near exhaust vents or other sources of con

taminated air.

Be sure that unit is installed such that snow will not block

the combustion intake or flue outlet.

Unit may be installed directly on wood flooring or on

Class A, B, or C roof-covering material when roof curb is

used.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least

48 in. from any opening through which combustion prod

ucts could enter the building, and at least 48 in. from an

adjacent building. When unit is located adjacent to public

walkways, flue assembly must be at least 7 ft above grade.

Flue vent discharge must have a minimum horizontal clear

ance of 4 ft from electric and gas meters, gas regulators,

and gas relief equipment.

Flue gas can deteriorate building materials. Orient unit

such that flue gas will not affect building materials.

Adequate combustion-air space must be provided for proper

operation of this equipment. Be sure that installation

complies with all local codes and Section 5.3, Air for Com

bustion and Ventilation, NFGC (National Fuel Gas Code),

|

ANSI (American National Standards Institute) Z223.1-

1984 and addendum Z223.la-1987. In Canada, instal

lation must be in accordance with the CAN LB 149.1 and

CAN1.B149.2 installation codes for gas burning

appliances.

Page 3

c

—!J------------------

—1

-------------------

ROOF CURB

ACCESSORY

50DJ900771

- 1

50DJ900781

A

1 '-2”

[356]

2"-0'

[610]

UNIT SIZE

48LJE/LJF004

48UD/LJE/UF005-007

NOTES:

1. Roof curb accessory is shipped

unassembled

2. Insulated panels.

3 Dimensions in [ ] are in millimeters

4. Roof Curb: galvanized steel

5 Attach ductwork to curb (Flanges of

duct rest on curb.)

6 Service clearance is 4 ft on each side.

Direction of airflow

UNIT SIZE

48LJE/LJF004

48LJD/LJE/LJF005-007

“E”

GAS

%" [19] NPT

“F”

POWER

%" [19] NPT 3/4" [19] NPT

“G”

CONTROL

CONNECTOR

PKG ACY

50DJ900791

Fig. 2 — Roof Curb Dimensions

Page 4

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

/■

A-B

0.5 1.0 1.0

B-C

A-C

Fig. 3 — Unit Leveling Tolerances

NOTE: Trap should be deep enough to offset maximum unit static

difference, A 4-in. trap is recommended.

PLACE ALL SEAL STRIPS

IN PLACE BEFORE PLACING

UNIT ON ROOF CURB.

SEE DETAIL DUCT END

"A"

Fig. 4 — External Trap Condensate Drain

DETAIL "A"

NOTES:

1. Dimensions in ( ) are in miilimeters

2 Hook rigging shackles through holes in base rail, as shown in de

tail “A.” Holes in base rails are centered around the unit center of

gravity Use wooden top skid when rigging to prevent rigging straps

from damaging unit

MAX

UNIT

48LJE/LJF004 530 240

48LJD/LJE/LJF005 540 245

48LJD/LJE/LJF006

48LJD/LJE/LJF007 615 279

WEIGHT

Lb

560 254

Kg

Fig. 5 — Rigging Details

3 Unit weights do not include economizer. See Table 1 for

A B

in.

73.69

mm

1872

economizer weights.

All panels must be in place when rigging.

in.

35.5

mm in.

902

A CAUTION

C

mm

32.52 826

Page 5

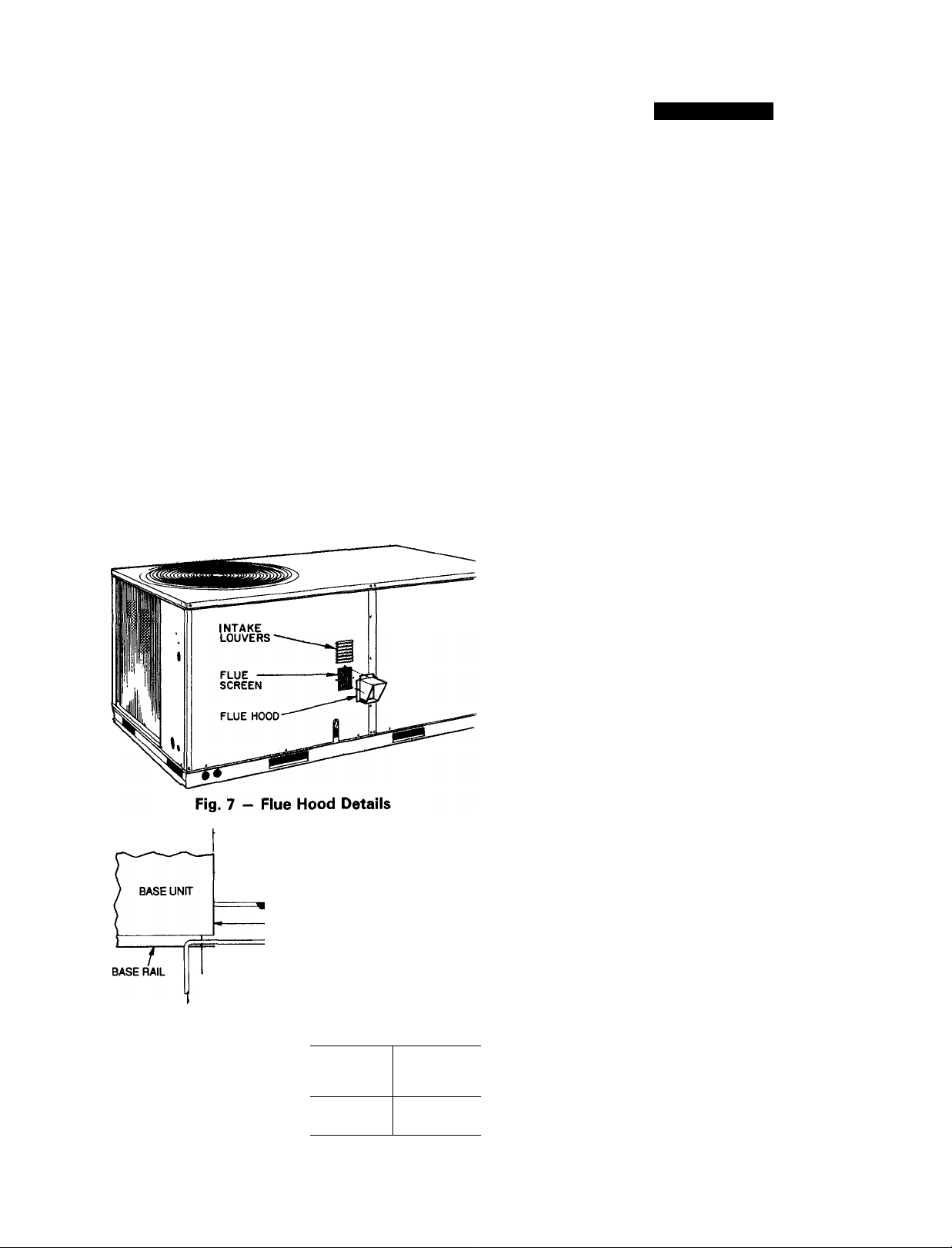

Table 1 — Physical Data

BASE UNIT 48

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit

Economizer

Roof Curb

COMPRESSOR

Quantity

Oil (oz)

REFRIGERANT TYPE

Operating Charge (Ib-oz) 6-0

CONDENSER FAN Propeiier Type

Quantity...Diameter (in.) 1 ..26.0

Nominal Cfm

Motor Hp...Rpm

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Size (in.)

Type Drive

Nominal Cfm

Maximum Continuous Bhp

Motor Frame

Nominal Rpm High/Low

Fan Rpm Range

Motor Bearing Type

Maximum Fan Rpm

Motor Pulley Pitch Diameter A/B (in.)

Fan Pulley Pitch Diameter (in.)

Belt — Type...Length (in.)

Pulley Center Line Distance (in.)

Speed Change Per Full Turn of

Moveable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns

From Closed Position

Factory Setting — Full Turns Open

Factory Speed Setting (rpm)

Fan Shaft Diameter at Pulley (in.) —

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

FURNACE SECTION

Burner Orifice Diameter (in. ...drill size)*

Natural Gas — Std

Liquid Propane — Alt

Thermostat Heat Anticipator Setting (amps)

208/230/460 V

First Stage

Second Stage

Gas Input

First Stage

Second Stage

Efficiency (Steady State) (%)

Temperature Rise Range

Manifold Pressure (in. wg)

Natural Gas — Std

Liquid Propane — Alt

Field Gas Connection Size (in.)

HIGH-PRESSURE SWITCH (psig)t

Standard Compressor Internal Relief

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCHf

(liquid Line) (psig)

Cutout

Reset (Auto.)

FREEZE PROTECTION THERMOSTATf

Opens (F)

Closes (F)

OUTDOOR-AIR INLET SCREENS

Qty...Size (in.)

RETURN-AIR FILTERS

Qty...Size (in.)

Std

Alt Direct

Std

Alt 81

Std

Alt 48

Std

Ait 1080/970

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std — —

Alt

std — —

Alt

LJE/LJF004

3

530

34

115

Reciprocating

1

55

4600

Уз 850

1.. 17

12 25

10 X 10

Direct

1200

34

48

860/845

—

—

Baii

2100

—

—

— —

—

—

—

—

—

— —

—

—

—

—

—

2. 15 2.. 15

4 17 55 55

113 33

089 43

.14

-/14

74,000/82,000

-/115,000

80

25-55/55-85

35

3.5

.5

LEGEND

Bhp — Brake Horsepower

*The 48LJD005-007 and 48LJE004 (74,000 Btuh) units have 2 burners The 48LJE005-007 and 48LJF004 (115,000 Btuh) units and

the 48LJF005-007 (150,000 Btuh) units have 3 burners

flndioates a FlOP (Factory-instalied Option) that requires a control kit.

LJD/LJE/LJF005

4

540

34

115 115

LJD/LJE/LJF006

560 615

Scroil

1 1

55

7-6 8-3 9-12

1 ..26.0 1...26.0

4600

Уз...850

Enhanced Copper Tubes, Aiuminum Lanced Fins

2.. 17

12.25

10 X 10

Direct

Beit

1600

.81

1 20

48

56

1080/970

—

_

970-1310

Bali

2100

—

1 9/2 9

3.5

— A 39

A 31

—

14 7-15 5

68

—

5

3

1110

5/8 У2

Enhanced Copper Tubes, Aluminum Doubie Wavy Fins, Acutroi'“ Feed Device

113. 33/113 33/129 30 113. 33/113 33/129. 30

.089.. 43/089 .43/.102 .38 089 43/089 43/102 38

.14 14

-/-/14

74,000/115,000/120,000 74,000/115,000/120,000

-/-/150,000

80 80

25-55/35-65/50-80

35

3.5

.5

R-22

Centrifugai Type

-/-/150,000

25-55/35-65/50-80

625

428

320

7 ± 3

22 ± 7

30 ± 5

45 ± 5

Cieanabie

1

..20 X 24 X 1

Throwaway

2.. 16 X 25 X 2

4100

У3...850 Уз . 850

2.. 17 2.. 17

12.25

10 X 10

Beit

2000

1 80

900-1300

Baii Bail

2100

2 4/3 4

14 7-15.5

1060 1230

3.. 15 4...15

-/-/14

5 6

34 34

115

Reciprocating

LJD/LJE/LJF007

70 65

1 . 26.0

4i00

12.25

10 X 10

— —

—

56

—

—

—

—

—

4.5 45

— —

— —

— —

80

—

5

_

3 3

— —

Beit

2400

2 40

1070-1460

2100

2.8/3.8

A 39

14 7-15 5

—

113 33/113 33/.129.30

089 43/089 43/102 38

-/-/14

74,000/115,000/120,000

-/-/150,000

25-55/35-65/50-80

35

3.5 3.5

.5 .5

—

56

—

—

—

—

79

—

—

Ув

5.5

3.5

1

—

5

14

80

Page 6

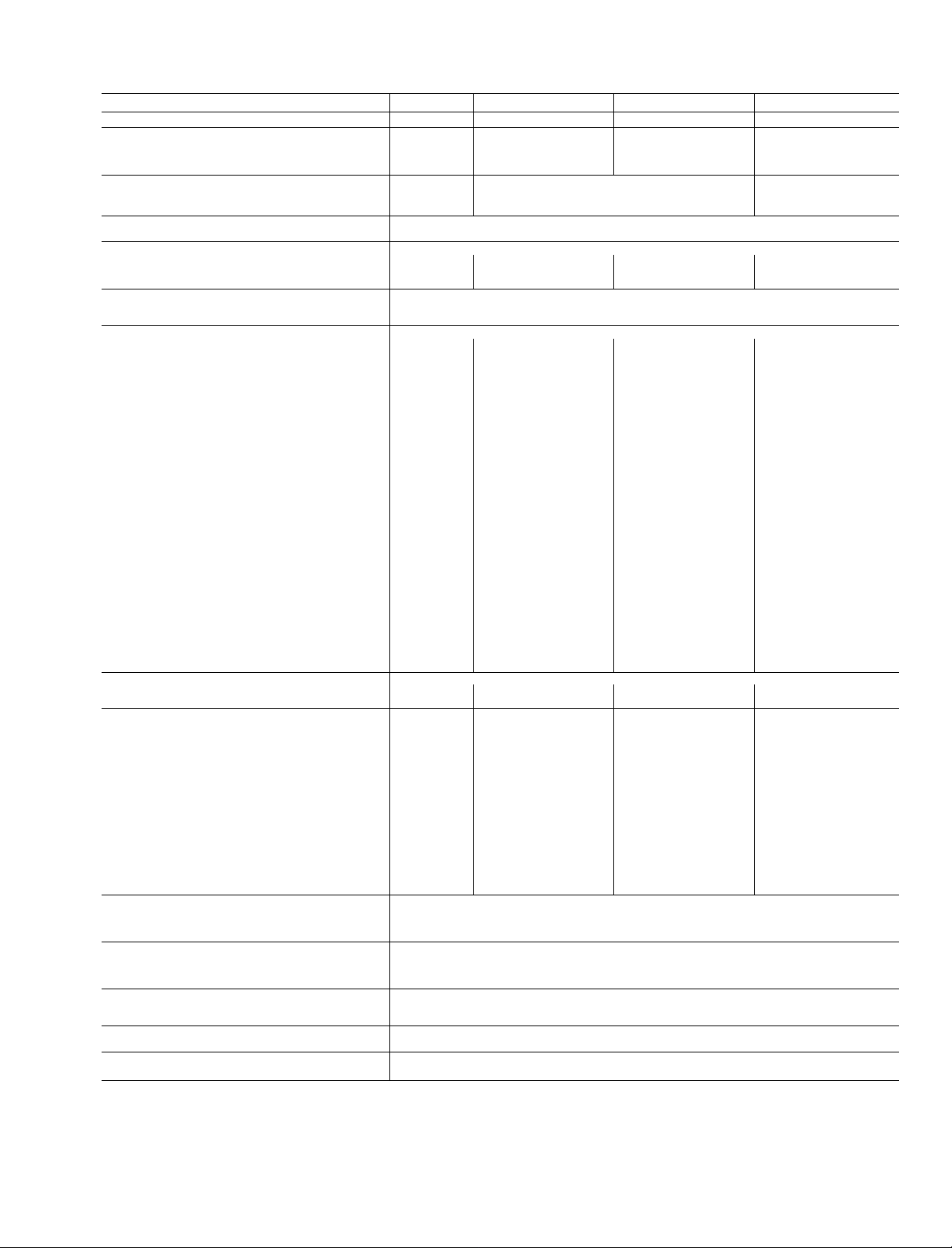

STD UNIT

UNIT

48LJE/LJF004 530

48LJD/LJE/UF005 540

48UD/UE/UF006

48UD/UE/UF007 615 279

WEIGHT

Lb

560

Kg

240

245

254

ECONOMIZER

WEIGHT

Lb

Kg

34

15.4

34 15.4

34 154 110

34 154 120

CORNER

WEIGHT (A)

Lb

Kg

104

47.2 97

106 48 1

49.9

54.4

CORNER

WEIGHT (B)

Lb

Kg

44.0

98 44.5

102 46 3

112 50.8

RIGHT SIDE

'Indicates horizontal center of gravity

flndicates vertical center of gravity

NOTES:

1. Dimensions in [ ] are in millimeters.

Center of Gravity.

3 Direction of airflow

4. On vertical discharge units, ductwork is to be

attached to accessoiy roof curb only. For hor

izontal discharge units, field-supplied flanges

should be attached to horizontal discharge

openings and all ductwork should be at

tached to the flanges.

5 Minimum clearances are as follows (local codes

or jurisdiction may prevail):

NOTE: When installing these units, use the

maximum clearance stated for your application

a Between unit, flue side, and combustible

surfaces, 36 inches. (Minimum clearance

to combustibles, flue side, is 18 in for units

with accessory flue discharge deflector.)

b. Bottom to combustible surfaces (when not

using curb), 0 in. for LJD,LJE units and

1 in. for LJF units.

c. Condenser coil for proper airflow, 36-in one

side, 12 in the other The side getting the

greater clearance is optional

d. Overhead, 60 in to assure proper con

denser fan operation

e. Horizontal supply and return end, 0 inches

f Between units, control box side, 42 in per

NEC (National Electrical Code),

g Between unit and ungrounded surfaces, con

trol box side, 36 in. per NEC.

h. Between unit and block or concrete walls

and other grounded surfaces, control box

side, 42 in. per NEC.

6. With the exception of the clearance for the

condenser coil and combustion side, as stated

in Notes 5a, b, and c, a removable fence or

barricade requires no clearance

7 Units may be instailed on combustible floors

made from wood or class A, B, or C roof cov

ering material

UNIT

48LJE/LJF004

48LJD/LJE/LJF005 162

48LJD/LJE/LJF006 168

48LJD/LJE/LJF007

WEIGHT (C)

Lb

159

185

FRONT

CORNER

Kg

72.1 171

73.5 174 78.9

76.2

83.9 198

CORNER

WEIGHT (D)

Lb

77.6

81.6

180

89.8

Kg

Connection Sizes

1%" Dia [351 Field Power Supply Hole

A

2" Dia [50.51 Power Supply Knockout

B

2¥i6" Dia [551 Charging-Port Hole

c

%" [221 Field Control Wiring Hole

D

%" Condensate Drain

E

V2"-14 NPT Gas Connection

F

LEFT SIDE

Fig. 6 — Base Unit Dimensions

FRONT

O'-O 3/B

r’OJ

L

Page 7

i'

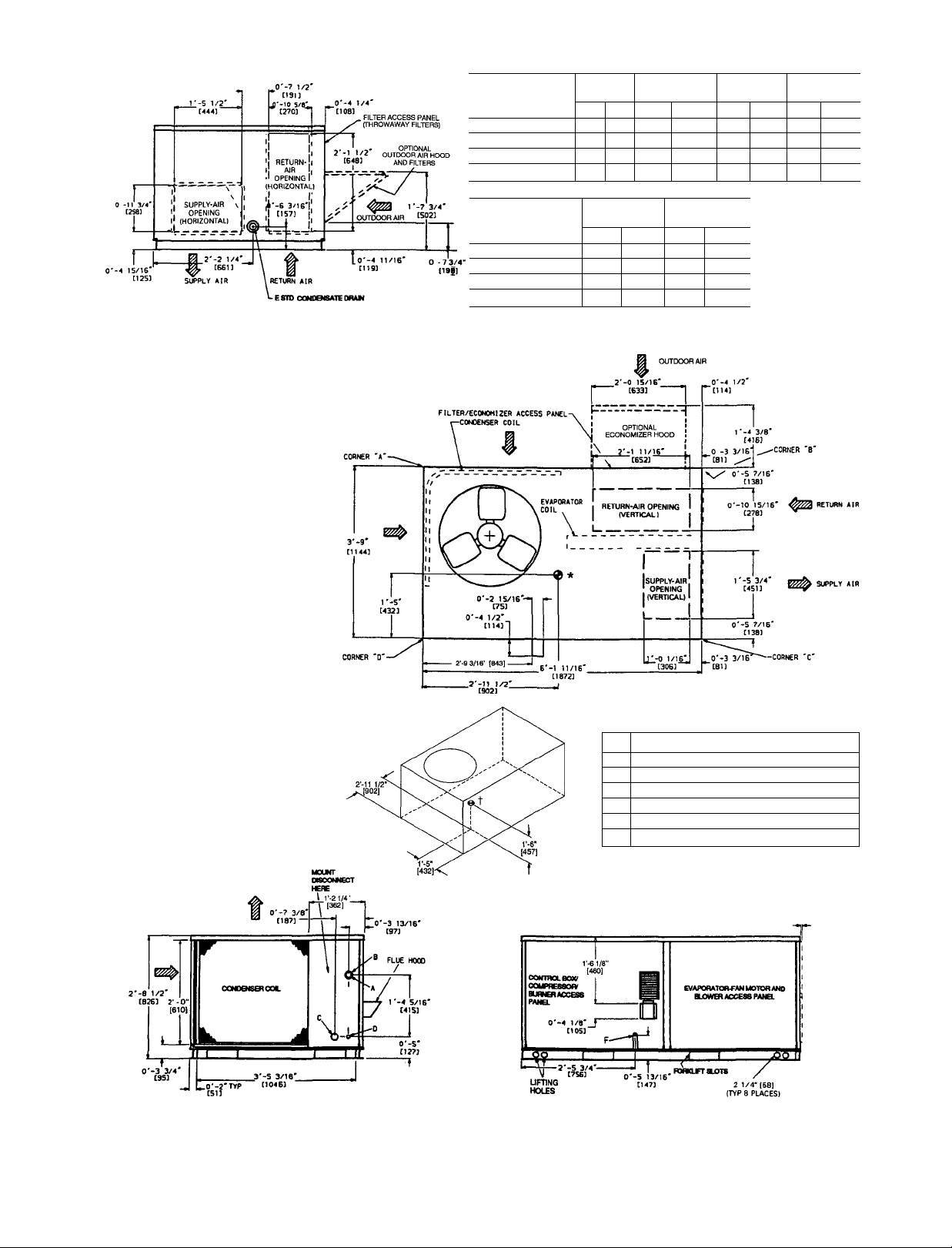

Step 5 — Install Flue Hood — Flue hood and screen

are shipped screwed to the burner compartment access panel.

Remove from shipping location and using screws provided,

install flue hood and screen in location shown in Fig. 7.

Step 6 — Install Gas Piping — Unit is equipped for

use with type of gas shown on nameplate. Refer to local

building codes, or in the absence of local codes, to ANSI

Z223.1-1984 and addendum Z223-1A-1987 entitled Na

tional Fuel Gas Code. In Canada, installation must be in

accordance with the CANl.B 149.1 and CAN1.B149.2 in

stallation codes for gas burning appliances.

For natural gas applications, gas pressure at unit gas con

nection must not be less than 4 in. wg or greater than

13.0 in. wg while unit is operating. On 48LJ005,006,007

high heat units, the gas pressure at unit gas connection must

not be less than 5 in. wg or greater than 13 in. wg while the

unit is operating. For propane applications, the gas pressure

must not be less than 5 in. wg or greater than 13 in. wg at

the unit connection.

Size gas supply piping for 0.5 in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas connec

tion. Support gas piping as shown in the table in Fig. 8. For

example, a %-in. gas pipe must have one field-fabricated

support beam every 8 ft. Therefore, an 18-ft long gas pipe

would have a minimum of 2 support beams, a 48-ft long

pipe would have a minimum of 6 support beams.

See Fig. 8 for typical pipe guide and locations of exter

nal manual main shutoff valve.

9” MINIMUM CLEARANCE

FOR PANEL REMOVAL

MANUAL GAS GAS

I SHUTOFF VALVE* REGUUTOR*

48" MINIMUM -

DRIP LEG PER NFGC

ROOF CURB

FROM GAS METER

LEGEND

NFGC — National Fuel Gas Code

"Field supplied.

NOTE: Follow all local codes

FIELD-FABRICATED*

SUPPORT

SPACING OF SUPPORTS

STEEL PIPE

NOMINAL

DIAMETER

(In.)

%

*/4 or 1 8

1’/4 or larger 10

Fig. 8 — Gas Piping Guide (With Accessory

Thru-the-Curb Service Connections)

7

X

DIMENSIONS

(feet)

6

Step 7 — Make Electrical Connections

A WARNING

Unit cabinet must have an uninterrupted, unbroken elec

trical ground to minimize the possibility of personal in

jury if an electrical fault should occur. This ground may

consist of electrical wire connected to unit ground lug

in control compartment, or conduit approved for elec

trical ground when installed in accordance with NEC

(National Electrical Code), ANSI/NFPA (National Fire

Protection Association), latest edition, and local elec

trical codes. Do not use gas piping as an electrical ground.

Failure to follow this warning could result in the in

staller being liable for personal injury of others.

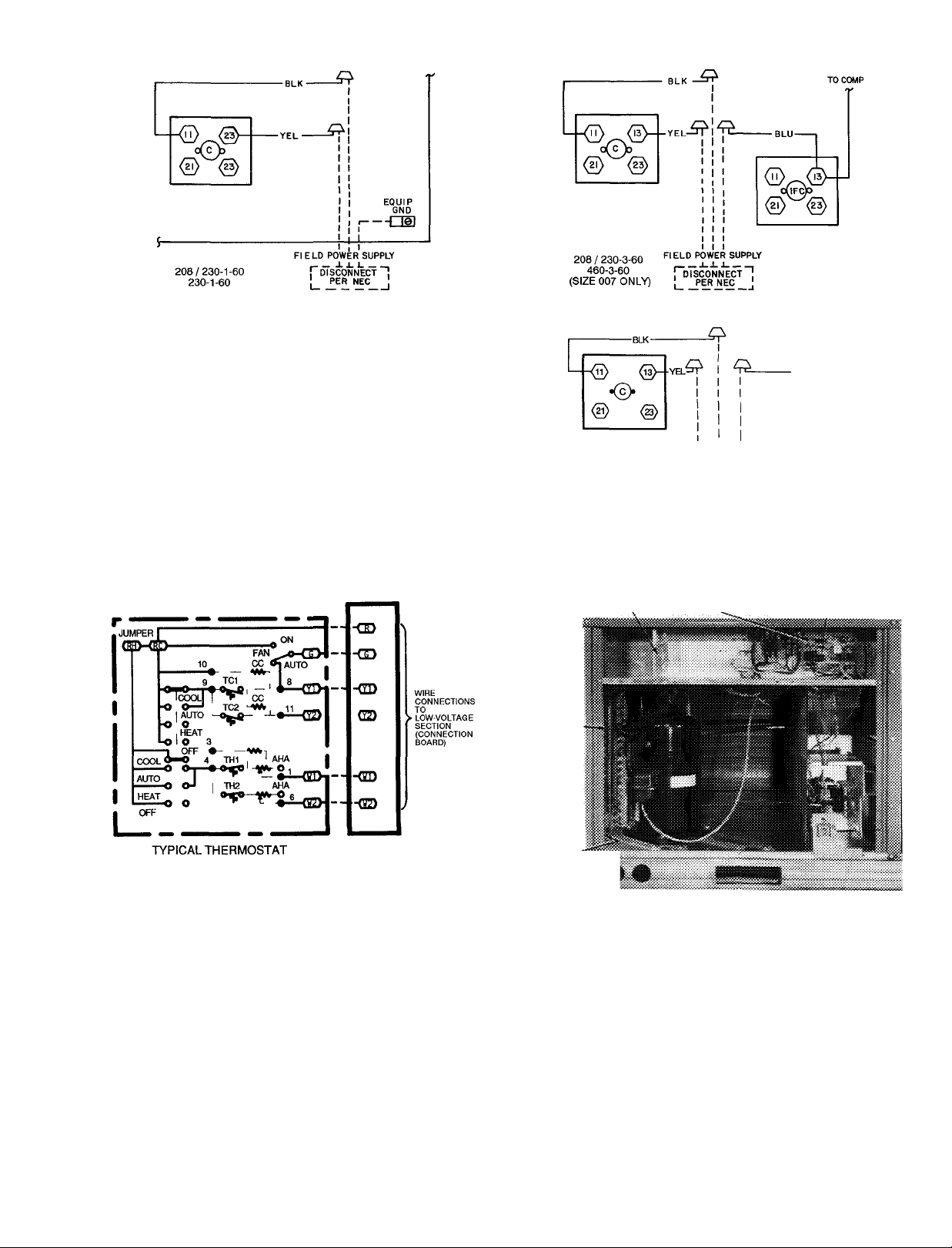

FIELD POWER SUPPLY - All units except 208/230-v

units are factory wired for the voltage shown on the name

plate. If the 208/230-v unit is to be connected to a 208-v

power supply, the transformer must be rewired by moving

the black wire from the 230-v orange wire on the trans

former and connecting it to the 200-v red wire from

the transformer. The end of the orange wire must then be

insulated.

Refer to unit label diagram for additional information.

Wiring leads are provided for field service. Use copper con

ductors only when splice connectors are used.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local require

ments. In Canada, electrical connections must be in accor

dance with CSA (Canadian Standards Association) C22.1

Canadian Electrical Code Part 1.

Install conduit through side panel openings indicated in

Fig. 6. Route power lines through connector to terminal

connections as shown in Fig. 9.

Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Table 2). On 3-phase units, voltages between phases

must be balanced within 2% and the current within 10%.

Use the formula shown in the legend for Table 2, Note 2 to

determine the percent voltage imbalance. Operation on im

proper line voltage or excessive phase imbalance consti

tutes abuse and may cause damage to electrical components.

Such operation would invalidate any applicable Carrier

warranty.

FIELD CONTROL WIRING - Install a Carrier-approved

accessory thermostat assembly according to installation in

structions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense

average temperature in accordance with thermostat instal

lation instmctions. Connect thermostat wires to terminal board.

Route thermostat cable or equivalent single leads of col

ored wire from subbase terminals through connector on unit

to low-voltage connections (shown in Fig. 10).

Connect thermostat wires to matching screw terminals of

low-voltage connection board. See Fig. 10.

NOTE; For wire runs up 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to

75 ft, use no. 16 AWG insulated wire (35 C minimum).

For over 75 ft, use no. 14 AWG insulated wire (35 C min

imum). All wire larger than no. 18 AWG cannot be directly

connected to the thermostat and will require a junction box

and splice at the thermostat.

Pass the control wires through the hole provided in the

end panel; then feed wires through the raceway built into

the comer post to the 24-v barrier located on the left side of

the control box. See Fig. 11. The barrier provides the UL

(Underwriters’ Laboratories) required clearance between highand low-voltage wiring.

Page 8

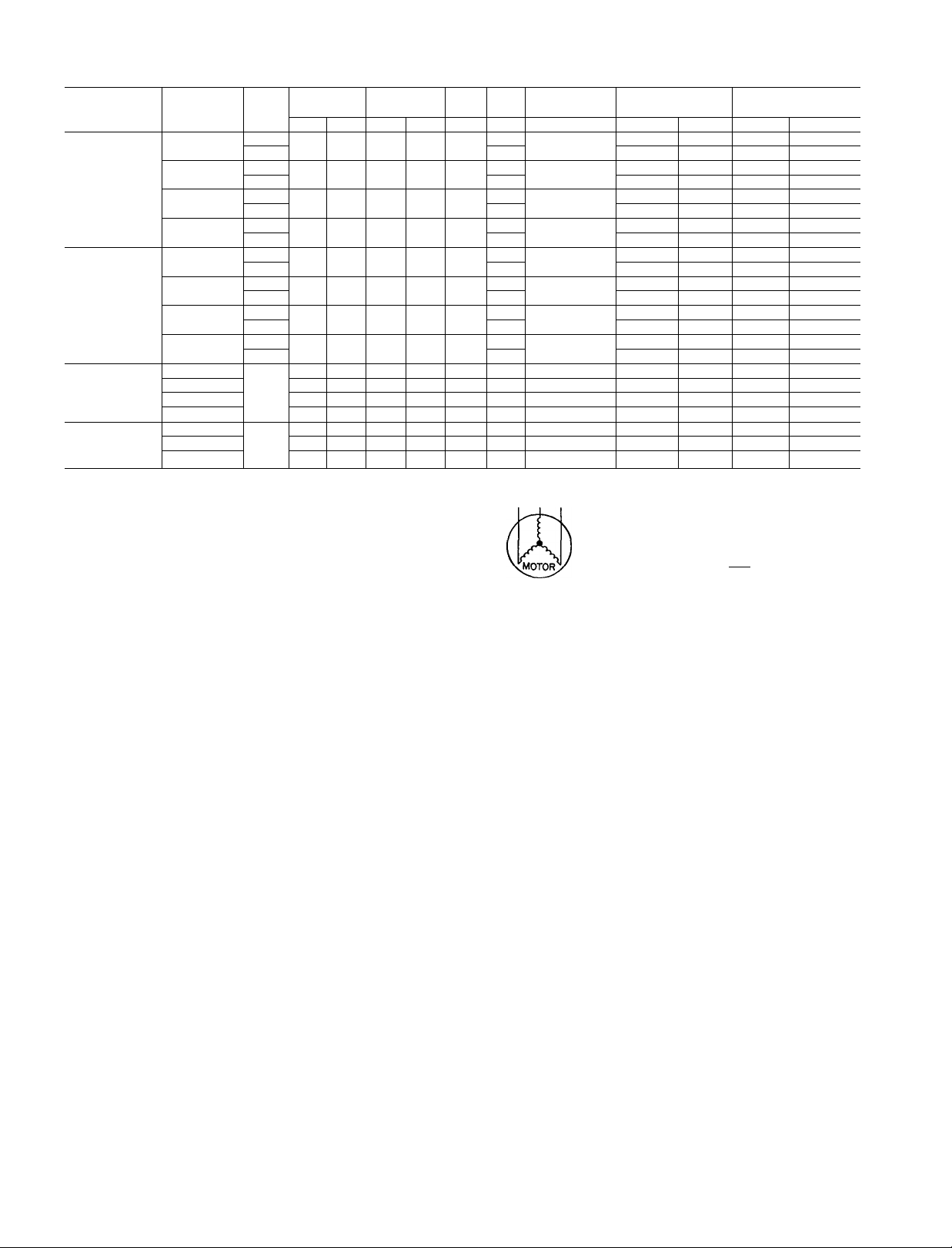

Table 2 — Electrical Data

VOLTAGE

UNIT

48LJE/LJF004

(3 Tons)

48LJD/LJE/LJF

005

(4 Tons)

48LJD/LJE/LJF

006

(5 Tons)

48LJD/LJE/LJF

007

(6 Tons)

IMPORTANT: Optional, alternate evaporator-fan motor and drive are not

available for 48LJ006,007 units. Contact your local Carrier representative

for more information about field-installed motors

COMPR

FLA

HACR

IFM

LRA

MCA

MOCP

OFM

RLA

*Fuse or HACR circuit breaker

NOTES:

1. In compliance with NEC (National Electrical Code) requirements for multi

motor and combination load equipment (refer to NEC Articles 430 and 440),

the overcurrent protective device for the unit shali be fuse or HACR breaker

Canadian Standards Association (CSA) units may be fuse or circuit breaker

2 Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalanoe in supply voltage is greater

than 2% Use the following formula to determine the percent voltage im

balance.

% Voltage Imbalance

100 X

NOMINAL

V-PH-HZ

208/230-1-60

208/230-3-60

460-3-60

575-3-60

208/230-1-60

208/230-3-60

460-3-60

575-3-60

230-1-60

208/230-3-60

460-3-60

575-3-60

208/230-3-60

460-3-60

575-3-60

LEGEND

Compressor

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

Outdoor (Condenser) Fan Motor

Rated Load Amps

max voltage deviation from average voltage

average voltage

IFM

TYPE

Std

Alt 3.8 28.1/28 1

Std

Alt 38

Std

Alt 1.9 105

Std

Alt

Std

Alt 57 38.6/38 6

Std

Alt

Std

Alt 2.8 13.5

Std

Alt

Std

Std

RANGE

Min Max RLA

187 254 179

187 254 11 2

414

508

632 45

518

187 254 24 8

187 254 157

414

508 78

632 55

518

187 254 27.8

187

254

414 508 96

518 632 83

187 254 21 9

414 508

518 632 96

COMPR

(each)

6 1

19.2

104

OFM

LRA FLA FLA FLA

93 1 9

80 1 9

40 1 0

29 1 9

127 1 9

99 1.9

50 1 0

40 1.9

135 1 9 85 .57

105 1 9

55 1 0

45 1 9

142 1 9 5.8 57 35.1/35.1

72

1 0

58 5 1 9

11 0

FAN MOTOR

2.8

28

1 5

2.8

38 7.9

38

3.8

5.7 27 2/27.2

1 9

38

5.7 9.9

8.5 .57

4.5

85

2.6

Example: Supply voltage is 460-3-60.

ABC BC = 464v

NOTE: The 575-v units are CSA only

Determine maximum deviation from average voltage

(AB) 457 - 452 = 5 V

(BC) 464 - 457 = 7 V

(AC) 457 - 455 = 2 V

Maximum deviation is 7 v.

Determine % voltage imbalance

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum

allowable 2%

IMPORTANT: If the supply voltage phase imbalance is more than 2%,

contact your local electric utility company immediately

57

.57

30

57

57

57

.30

57

30

.57

30

57

COMBUSTION

IFM

POWER SUPPLY

MCA

27 1/27 1

18 7/18.7 25/25 18/18

19 7/19.7

101

7.5

36 7/36.7

25 3/25.3

126

9.2

45 2 60

34.4/34.4 40/40 34/34

17.5

14.5

16.6

172

AB = 452V

AC = 455V

Average Voltage

-----------

= 1 53%

DISCONNECT SIZE

MOCP* FLA

35/35

35/35 27/27

25/25 19/19

15

15 10

15 7

15

45/45

45/45 37/37

30/30 25/25 113/113

35/35 27/27 116/116

15

26/26

10

8

35/35

12

20 13

15

15

9

10

44 164

20 17 81

20 14

40/40 34/34 188/188

20 16

20 17 81

452 4- 464 4- 455

_ 1371

3

= 457

7

457

LRA

105/105

107/107

92/92

94/94

46

46

34

34

141/141

144/144

56

58

45

47

134/134

57

95

Page 9

c

COMP

EQUIP

GND

IFC

NEC

LEGEND

Contactor

Compressor

Equipment

Ground

Indoor (Evaporator) Fan Contactor

National Electrical Code

TO

c

Fig. 9 — Power Wiring Connections

LEGEND

AHA

CC

TC

NOTE: Connect Y2 when unit is equipped with an economizer.

Adjustable Heat

Anticipator

Cooling Compensator

Thermostat-Cooling

TH — Thermostat-Heating

---------

Field Wiring

----------

Factory Wiring

Fig. 10 - Low-Voitage Connections

208 / 230-3-60

460-3-60

(SIZES 004-006)

575-3-60

(SIZES 004-007)

CONNECTION BOARD LED

RACEWAY

HOLE

IN

END

PANEL--(HIDDENV

LED — Light-Emitting Diode

FIELD POWER SUPPLY

Fig. 11 — Fieid Control Wiring Raceway

DISCONNECT

PER NEC

INTEGRATED GAS UNIT

CONTROLLER (IGC)

Page 10

HEAT ANTICIPATOR SETTINGS - Set heat anticipator

settings at. 14 amp for the first stage and . 14 amp for secondstage heating, when available.

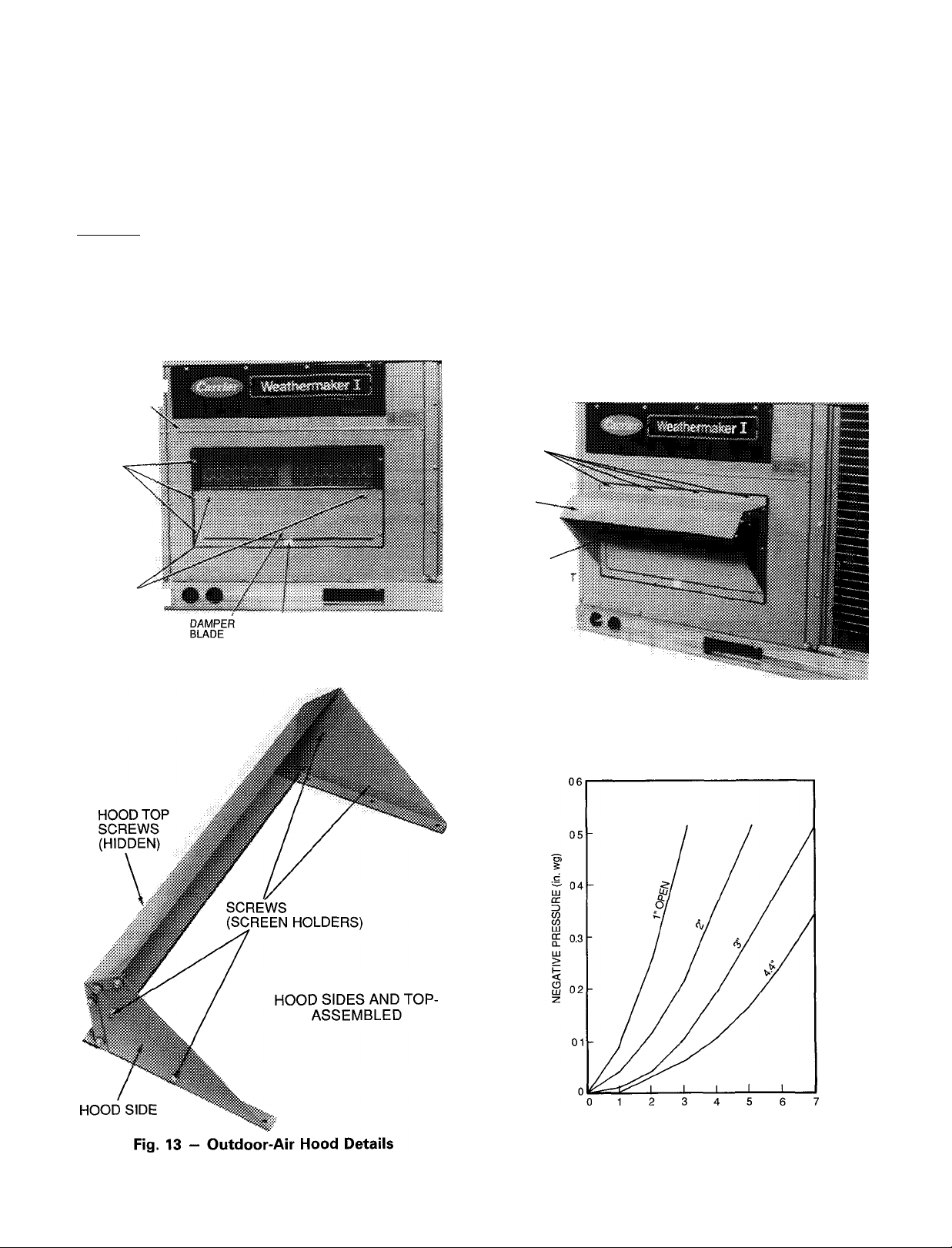

Step 8 - Make Outdoor-Air Adjustments and Install Outdoor-Air Hood

MANUAL OUTDOOR-AIR DAMPER - The outdoor-air

hood and screen are attached to the basepan at the bottom

of the unit for shipping.

Assembly:

1. Determine quantity of ventilation required for building.

Record amount for use in Step 8.

2. Remove and save evaporator coil access panel and screws.

See Fig. 12.

3. Separate hood and screen from basepan by removing the

4 screws securing them. Save all screws.

EVAPORATOR

COIL ACCESS ?

PANEL \

SCREWS

(SIDE) “

4. Replace evaporator coil access panel.

5. Place hood on front of evaporator coil access panel. See

Fig. 13 for hood details. Secure top of hood with the 4

screws removed in Step 3. See Fig. 14.

6. Remove and save 6 screws (3 on each side) from sides

of the manual outdoor-air damper.

7. Align screw holes on hood with screw holes on side of

manual outdoor-air damper. See Fig. 13 and 14. Secure

hood with 6 screws from Step 6.

8. Adjust minimum position setting of the damper blade by

adjusting the manual outdoor air adjustment screws on

the front of the damper blade. See Fig. 12. Slide blade

vertically until it is in the appropriate position deter

mined by Fig. 15. Tighten screws.

9. Remove and save screws currently on sides of hood. In

sert screen. Secure screen to hood using the screws. See

Fig. 14.

SCREW

HOLES

(TOP)

HOOD

MANUAL

OUTDOOR-AIR »

ADJUSTMENT

SCREWS

POSITION

SETTING SCALE

Fig. 12 — Damper Panel with Manual Outdoor-Air

Damper Installed

HOOD

SCREEN

LOCATION

(SCREEN NO

SHOWN)

Fig. 14

Outdoor-Air Damper with Hood

Attached

OUTDOOR AIRFLOW (cfm x 100)

Fig. 15 - Position Setting

10

Page 11

TWO-POSITION DAMPER - The outdoor-air hood and

screen are attached to the basepan at the bottom of the unit.

Assembly:

1. Determine quantity of ventilation air required for build

ing. Record amount of air for use in Step 9.

2. Remove and save evaporator coil access panel and screws.

See Fig. 16.

3. Separate hood from basepan by removing the 4 screws

securing the hood. Save screws.

4. Insert two-position damper plug from wiring harness

(supplied with the unit) into the wiring harness (sup

plied with the two-position damper).

5. Replace evaporator coil access panel.

6. Place hood on front of evaporator coil access panel.

See Fig. 13 for hood details. Secure top of hood with

the 4 screws removed in Step 3. See Fig. 14.

EVAPORATOR

COIL ACCESS

PANEL

SCREW

HOLES

(SIDE)

EVAPORATOR

COIL ACCESS

PANEL

BLOCK-OFF

PANEL

------

'

mm

Fig. 17 — Access Panel Location

i

OUTDOOR-AIR

ADJUSTMENT

SCREWS

POSITION

SETTING SCALE

Fig. 16 — Damper Panel with Two-Position

Damper Installed

7. Remove and save 6 screws (3 on each side) from sides

of the two-position damper.

8. Align screw holes on hood with screw holes on side of

two-position damper. See Fig. 13 and 14. Secure hood

with 6 screws from Step 7.

9. Determine two-position damper setting by using

Fig. 15. Set the damper panel position using the air ad

justment screws. See Fig. 16. Tighten screws.

10. Remove and save 4 screws currently on sides of hood.

Insert screen. Secure screen to hood using the 4 screws.

See Fig. 14.

OPTIONAL ECONOMIZER — The economizer hood as

sembly is packaged and shipped in the filter section. Damper

blades are installed at the factory and the economizer is shipped

in the vertical position.

Assembly:

1. Determine quantity of ventilation air required for build

ing. Record amount of air for use in Step 8.

2. Remove evaporator coil access panel (see Fig. 17). Save

panel and screws.

3. Assemble outdoor-air hood top and side plates as shown

in Fig. 18. Install seal strips on hood top and sides. Put

aside screen retainer and screws for later assembly. Do

not attach hood to unit at this time.

4. The block-off panel should be removed from the evap

orator coil access panel and discarded. Save screws.

See Fig. 17.

HOOD SIDES AND TOP ASSEMBLED

Fig. 18 — Outdoor-Air Hood Details

5. Remove screws securing barometric relief damper, if

desired. See Fig. 19.

6. To convert to horizontal discharge application:

a. Remove filters from filter track.

IMPORTANT: Filters must be installed outside the

unit on horizontal discharge applications with econo

mizer. Otherwise, economizer must be partially re

moved to access the filters. The area of the fieldinstalled filters should be equal to the area of the factoryinstalled filters.

Rotate economizer 90 degrees until economizer mo

b.

tor faces condenser section (see Fig. 20). If neces

sary, disassemble economizer to replace filter.

Rotate barometric relief damper 90 degrees so that it

c.

opens and closes vertically.

11

Page 12

d. Install horizontal discharge block-off plate over

opening on the access panel. Block-off plate

MUST be installed before installing hood assembly

(see Fig. 21).

NOTE: Install spacers at the same time as the hori

zontal block-off plate using same screws. The spac

ers are used to cover gaps between the economizer

assembly and the unit.

ECONOMIZER

WIRE

HARNESS

PLUGS

BAROMETRI!

RELIEF

DAMPER^

Fig. 19 — Economizer Installed in Unit

BLOCK-OFF PLATE

Fig. 21 — Horizontal Discharge Block-Off Plate

7. Insert economizer plug from the wiring harness (sup

plied with the unit) into the wiring harness plug (sup

plied with the economizer). See Fig. 19.

8. Determine economizer damper position setting (see

Fig. 22). Adjust damper setting by adjusting screws on

the position setting bracket (see Fig. 23). Slide posi

tion setting bracket until top screw (see Fig. 23) is in

the position determined by Fig. 22. Tighten screws.

9. Install evaporator coil access panel with screws saved

from Step 2.

10. Fasten hood top and side plate assembly to unit with

screws saved from the block-off panel removal (see

Fig. 18).

11. Remove tape from outdoor-air thermostat (OAT). Fas

ten OAT to inside of hood using screws and speed clips

provided (see Fig. 24). Make sure OAT terminals are

up.

12. Place knob, supplied with economizer, on OAT. Set it

for 3 F below indoor room thermostat setting. If ac

cessory solid-state enthalpy control (EC) is used in

stead of the OAT, see instructions shipped with EC for

installation and adjustment (see Fig. 24).

13. Connect OAT per Fig. 25.

14. Slide outdoor-air inlet screens into screen track on hood

side plates. While holding screens in place, fasten screen

retainer to hood using screws provided.

15. Turn on base unit power.

BAROMETRIC

RELIEF DAMPER

Fig. 20 — Horizontal Economizer Installation

(90 Degree Rotation)

12

Page 13

Example:

Given —

Return-Air Negative Static Pressure .........................0 2 in wg

Outdoor Air

Determine —

Setting = 5

Fig. 22 — Economizer Damper Minimum Position Setting

Fig. 23 - Minimum Position Damper Setting

OUTDOOR AIRFLOW (cfm x 100)

......................................................

Step 9 — Adjust Evaporator-Fan Speed — Ad

just evaporator-fan speed to meet jobsite conditions.

Table 3 shows fan rpm at motor pulley settings. Refer to

Tables 4-15 to determine fan speed settings.

DIRECT DRIVE MOTORS — The evaporator-fan motor

factory speed setting is shown on label diagram affixed to

base unit. If other than factory setting is desired, refer to

label diagram for motor reconnection.

BELT DRIVE MOTORS — Ean motor pulleys are factory

set for speed shown in Table 1.

NOTE: Before adjusting fan speed, make sure the new fan

speed will provide an air temperature rise range as shown

in Table 1.

To change fan speed:

1. Shut off unit power supply.

2. Loosen belt by loosening fan motor mounting nuts. See

Fig. 26.

3. Loosen movable pulley flange setscrew (see Fig. 27).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed. In

creasing fan speed increases load on motor. Do not ex

ceed maximum speed specified in Table 1.

5. Set movable flange at nearest key way of pulley hub and

tighten setscrew. (See Table 1 for speed change for each

full turn of pulley flange.)

900 cfm

13

Page 14

OR ACCESSORY

ENTHALPY

CONTROL

GRAY

---------------

OAT

---------------------------------------

Fig. 25 — Wiring Connections for

Outdoor-Air Thermostat

■i\fcTOR MOUNTffviS

ieiATe NUTSJ

ASSvAvA'A'Mv.

ORANGE-

HOOD.

"ERMWALS

bUTOObR-AiRTHERMOStATl

(TERMiNAl-S ARE UP) ,; |

iii

Fig. 24 — Outdoor-Air Thermostat/

Enthalpy Control Installation

\

HOOD

Fig. 26 - Belt Drive Motor Mounting

Fig. 27 — Evaporator-Fan Pulley Adjustment

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting.

To adjust belt tension:

1. Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for proper

belt tension ('/2-in. deflection with one finger).

3. Tighten motor mounting nuts.

4. Adjust bolt and tighten nut to secure motor in fixed

position.

14

Page 15

Table 3 — Fan Rpm at Motor Pulley Settings

UNIT

48LJD/LJE

005* 1310

006

007 1460

0

1300

'Indicates alternate motor.

Table 4 — Fan Performance, 48LJE/LJF004 Vertical

AIRFLOW

(Cfm)

900

1000

1100

1200

1300

1400

1500

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE: Values Include losses for filters, unit casing, and wet coils.

MOTOR PULLEY TURNS OPEN

Va 1

1285 1245

1260 1220

1420 1380

IVa

1210

1180

1340

2

2Va

1175 1140

1140

1100

1300

1265

3

1110

1060

1230

3Va

1075

1020

1190

Discharge Units; Standard Motor (Direct)

LOW SPEED HIGH SPEED

208

ESP

0 46 0.17

0.44

0.40

0 32

0.28 0.24

0.22

0 16 0 27 0 18

230, 460, 575 208

Bhp

0.20 0.45

0.21

0.23

ESP Bhp

0 48 0.19 0.49 0.21 0.51

0.42 0.24

0 37 0.25

0 32 0.26

0.26 0 25

ESP

0.22

0.47 0.23 0.48

0.44 0.25 0.45

0.38 0.27 0.40

0.32 0.29 0.34

0.28

0.26 0.30 0.28

0.33

0.20 0.31 0.21

Bhp

4

1005 970

1040

980 940 900

1110

1150

230, 460, 575

ESP

Bhp

0.25

0.27

0.29

0.31

0.32

0.33

0.34

4Va

5

1070

Table 5 — Fan Performance, 48LJE/LJF004 — Vertical

Discharge Units; Alternate Motor (Direct)

AIRFLOW

(Cfm)

900

1000

1100

1200

1300

1400

1500

ESP Bhp ESP

0.77

0.70 0 38

0.25 0.53 0 33

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE: Values include losses for filters, unit casing, and wet coils.

LOW SPEED HIGH SPEED

208 230, 460, 575 208 230, 460, 575

0.83 0 38 0.97 0.48 1.09 0.60

0.36

0.62

0 53 0.44 0.58

0 44

0.35 0.50

0 75

0 66 0.45 0.80 0 53 0.92

0.41

0 48 0.50

0 42

Bhp

0 41

0 48 0.72 0.56 0 84 0 65

0.50 0.64 0.60 0.75 0.68

0.54

0.58 0.47 0.65

Bhp

ESP

0.89 0 51 1.01

0.63 0 67 0 69

0.56

ESP

0.58

Bhp

0.62

0 64

0 72

15

Page 16

Table 6 — Fan Performance, 48LJD/LJE/LJF005 Vertical Discharge

Units; Standard Motor (Direct)

AIRFLOW

(Cfm)

1200

1300

1400

1500

1600

1700

1800

1900

2000

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE: Values include losses for filters, unit casing, and wet coils.

0.53

LEGEND

LOW SPEED

208

ESP Bhp

0.44

0 44

0,48

0.35

0.50

0.25

0 53 0 33

0.16 0 57

0.09

0 58

0 00

0.61

_

—

—

—

230, 460, 575

ESP

0 58

0.50

0 42

0 24

0 15

0 06

Bhp ESP Bhp ESP

0 48

0.50

0.54 0 56 0 63

0.58

0 60

0 63

0 65

— —

— —

HIGH SPEED

0.56

0.60

0 65

0 69

0 73

230, 460, 575

Bhp

0.84

0.75 0.68

0.67 0.69

0.58 0 72

0 50 0.74

0 40

0.32

0.24

0 65

0.76

0.78

0.79

208

0 72

0 64

0.47

0 38 0 68

0 30

0.22 0 71

0.12

0.03 0.74 0.15 0.81

Table 7 — Fan Performance, 48LJD/LJE/LJF005 Vertical Discharge Units; Alternate Motor (Belt)

AIRFLOW

(Cfm)

1200 701 0.22 758

1300

1400

1500 836

1600

1700 925 0.55 981

1800

1900 1011

2000 1058 0 81 1100

Bhp — Brake Horsepower

NOTES:

1. Boldface indicates field-supplied drive required. (See Note 5.)

2 indicates field-supplied motor and drive required

3 Maximum usable bhp is 1.2. Extensive motor and electrical test

ing on these units ensures that the full horsepower range of the

0.1

Rpm Bhp Rpm Bhp

747

0.27 800 0.34

792

0.33

0.39

0.47

881

964

0.63

0.73

LEGEND

02

0.28

847

0.40

897

0.46

0.54

945

0.61

1024

0.72

1068 0.79

0.85

1 0.3 1

Rpm Bhp

834

865

901 0.47

947 0.55

983

1020 0.68

1084 0 75

1120

1160

EXTERNAL STATIC PRESSURE (in. wg)

1 0.4

Rpm Bhp

0.35 914 0.42

0.41

945 0.52

960 0.56

1000 0.61 1132

0 62

1065 0.67 1172

1103 0 72 1202 0 88

1140 0.82

0.82

1172

0 90

1237

1 0.6 1

Rpm

1012

1050

1091

1230

0 91 1256

1 20

Bhp

0 56

0 62

0.67

0 72

0.77

0 97

1,18

motor can be utilized with confidence Using your fan motors up

to the horsepower ratings shown will not result in nuisance

tripping or premature motor failure. Unit warranty will not be affected.

Values include losses for filters, unit casing, and wet coils

Alternate motor drive range: 970 to 1310 rpm. All other rpms re

quire field-supplied drive

Use of field-supplied motor may affect wire sizing Contact Car

rier representative to verify.

1 0.7 1 08

Bhp Rpm

Rpm

1056 0.59 1098

0 63 1132 0 68

1090

1130 0.70

1170

1207 0.86 1238

1243

1268

,.1,13:3

1310

1165

0.75 1205

0 98 1270 1 1.05 1350 1.16

1 07

1300!

Bhp Rpm Bhp

0.62 1180 0 68 1255 0.76

0.72 1242 0.82

0 82 1275 0 91 1330 0.98

0 92 1310 1.05 1350 1.08

1.15

L 1.0

____

1212 0.72

1 1-2

1

Rpm Bhp

1280 0 78

1310 0.89

1372 1.19

16

Page 17

Table 8 — Fan Performance, 48LJD/LJE/LJF006 Vertical Discharge Units; Standard Motor (Belt)

AIRFLOW

(Cfm)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

LEGEND

Bhp — Brake Horsepower

NOTES:

1 Boldface indicates fieid-suppiied drive required. (See Note 6)

2. indicates field-supplied motor and drive required.

3 Maximum usable bhp is 1.8 Extensive motor and electrical test

ing on these units ensures that the full horsepower range of the

0.1

Bhp Rpm

Rpm

0.37

750

0.44

794

0.52 884 0.58

839

885 0.61

0.72

932

979 0 83 1008

1026 0.96 1051 1 01

1074 1.10 1095

1 25

1122

1 42

1170

1.61 1231

1218

808

846

924

965

1140

1185

0.2

Bhp

0.43

0.50

0.67

0.77

0 88

1.15

1.30

1.46

1 64

EXTERNAL STATIC PRESSURE (in. wg)

Table 9 — Fan Performance, 48LJD/LJE/LJF007 Vertical Discharge Units; Standard Motor (Belt)

motor can be utilized with confidence Using your fan motors up

to the horsepower ratings shown will not result in nuisance trip

ping or premature motor failure. Unit warranty will not be af

fected.

4. Values include losses for filters, unit casing, and wet coils

5 Use of a field-supplied motor may affect wire sizing. Contact Car

rier representative to verify.

6 Standard motor drive range is 900 to 1300 rpm. All other rpms

require field-supplied drive.

LEGEND

Bhp — Brake Horsepower

NOTES:

1 Boldface indicates field-supplied drive required (See Note 6)

indicates field-supplied motor and drive required.

Maximum usable bhp is 2 4 Extensive motor and electrical test

ing on these units ensures that the full horsepower range of the

motor can be utilized with confidence Using your fan motors up

to the horsepower ratings shown will not result in nuisance trip

ping or premature motor failure. Unit warranty will not be

affected.

4 Values include losses for filters, unit casing, and wet coils.

5 Use of a field-supplied motor may affect wire sizing Contact Car

rier representative to verify.

6. Standard motor drive range is 1070 to 1460 rpm. All other rpms

require field-supplied drive.

17

Page 18

Table 10 — Fan Performance, 48LJE/LJF004 Horizontal

Discharge Units; Standard Motor (Direct)

AIRFLOW

(Cfm)

900

1000

1100

1200

1300

1400

1500

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE: Values include losses for filters, unit casing, and wet coils

LOW SPEED

208

ESP

0 53

0.48 0.20

0.43 0.21

0 36

0 28 0.24

0.20 0.26 0.24

0 11

230, 460, 575

Bhp

ESP Bhp ESP Bhp ESP

0.17

0 55

0.51 0.22

0.45 0.24 0.52 0.25

0.23 0.40 0 25

0.32 0 26 0 38 0.29

0 27

0.14

0.19

0 28 0.31 0.30

0 33

HIGH SPEED

208

0.63 0 21

0.57

0.23

0 47

0.27

0.21

0.31

230, 460, 575

0.64 0.25

0.60

0.54 0 29

0 47 0.31

0 41

0 32 0.33

0.22 0.34

Table 11 — Fan Performance, 48LJE/LJF004 Horizontal

Discharge Units; Alternate Motor (Direct)

AIRFLOW

(Cfm)

900

1000

1100

1200

1300

1400

1500

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE; Vaiues include losses for filters, unit casing, and wet coils.

0 96 0.38 1 04 0.42

0.88 0.41 0.94 0 44

0.62 0.50

LEGEND

LOW SPEED HIGH SPEED

208

ESP

1.05 0.36 1 12

0 78 0.44

0 70 0.48

0 52 0.53

230, 460, 575 208

Bhp

ESP Bhp ESP Bhp ESP

0 39 1.17

1.09 0 49

0.54

1 00

0.78 0.63

0.69

0 85 0.48 0.92 0.56 1.01

0 76 0.50 0.84 0 60

0.68

0.59 0.58

230, 460, 575

0.47 1.26

0.52 1 08

0 65

1.17 0 60

0.94

0.87

0 78

Bhp

0.27

0.32

Bhp

0 58

0.63

0 65

0 68

0 69

0 72

Table 12 — Fan Performance, 48LJD/LJE/LJF005 — Horizontal

Discharge Units; Standard Motor (Direct)

AIRFLOW

(Cfm)

1200 0 78

1300

1400

1500

1600

1700

1800

1900

2000

LEGEND

Bhp — Brake Horsepower

ESP — External Static Pressure

NOTE; Values include losses for filters, unit casing, and wet coils.

LOW SPEED HIGH SPEED

208

ESP

0.70 0.48 0.76 0.50 0 84 0.60

0 62

0 52

0.44 0.57

0.34

0.22

0.10 0.63

—

230, 460, 575 208 230, 460, 575

Bhp

ESP

0 44

0.85 0.48 0.92 0 56 1.01

0 50 0.68 0.54 0.78 0 63

0 53 0.59 0.58 0.69 0 65 0 78

0.50 0.60 0 61 0.68 0.70

0 58 0.40 0.63 0 53 0.69

0.61

0 30

0 20 0 68

— 0.09

Bhp ESP Bhp

0 65 0.45

0.69

0.71 0.54 0 78

0 37 0 73 0.48

0 74

0 29

ESP

0.94 0.68

0.87 0.69

0.62 0.76

0.39

Bhp

0.65

0.72

0.74

0 79

0 81

18

Page 19

Table 13 — Fan Performance, 48LJD/LJE/LJF005 Horizontal Discharge Units; Alternate Motor (Belt)

AlHhLUW

(Cfm)

1300

1400

1500

1600 836 0.39

1700

1800

1900

2000 1011 0.73

2100

Bhp — Brake Horsepower

NOTES;

1. Boldface indicates field-supplied drive required (See Note 5 )

2- indicates field-supplied motor and drive required

3 Maximum usable bhp is 1.2. Extensive motor and drive testing

on these units ensures that the full horsepower range of the

0.1

Rpm Bhp Rpm

701 0.22 758 0.28 834

747 0.27 800 0.34 865 0.41

792

0.33

881 0.47 945

925

0.55

964

0.63

1058

0.81

LEGEND

0.2

Bhp Rpm Bhp

847

0.40

897

0.46

0.54

981 0 61 1020 0.68

1024 0 72

1068

0 79

1100 0.85

0.3

901 0.47

947

983

1084

1120

1160 0 90 1237

EXTERNAL STATIC PRESSURE (in. wg)

0.4 0.6

Rpm Bhp Rpm Bhp

0.35

0.55

0 62

0 75

0.82

914 0.42

0.52

945

960

0.56 1091 0.67

1000

0 61 1132 0 72

1065 0 67

1103 0.72

1140 0 82

1172

0.91

1.20

0.56

1012

0.62 1090

1050

1172 0.77

1202 0.88 1243 0.98

1230 0 97 1268

1256.

1.18 1310 . 1.13is

motor can be utilized with confidence. Using your fan motors up

to the horsepower ratings shown will not result in nuisance trip

ping or premature motor failure Unit warranty will not be

affected

Values include losses for filters, unit casing, and wet coils.

Alternate motor drive range: 970 to 1310 rpm. All other rpms re

quire field-supplied drive.

Use of field-supplied motor may affect wire sizing. Contact Car

rier representative to verify

0.7

Rpm Bhp

1056 0 59

0 63

1130 0 70

1170 0 75

1207 0.86

1.07 :::1300:;

0.8

Bhp

Rpm

0 62

1098

1132 0.68 1212

0.72 1242 0.82

1165

0 82

1205

0.92 1310 1.05 1350 1.08

1238

1270 1.05 1350

icis;:

1.0 1.2

Rpm Bhp Rpm Bhp

1180 0 68 1255 0.76

0.72

1275 0.91 1330 0.98

1.16 1372 1,19

1280

0 78

1310 0 89

Table 14 — Fan Performance, 48LJD/LJE/LJF006 Horizontal Discharge Units; Standard Motor (Belt)

AIRFLOW

(Cfm)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

(

2500

Bhp — Brake Horsepower

NOTES:

1. Boldface indicates field-supplied drive required (See Note 6.)

2. indicates field-supplied motor and drive required

3. Maximum usable bhp is 1.8 Extensive motor and electrical test

ing on these units ensures that the full horsepower range of

0.1

Bhp Rpm Bhp

Rpm

720 0.34 776 0.39

760 0.40

801 0.47 853 0.54

842 0.55

883 0.64 931 0 72

0 74 970 0.82

924

965

0.85

1007

0.97

1049 1.10 1090 1.19

1090 1 24 1131

1132 1.39

LEGEND

0.2

814

0.46

891 0.62

1010 0.93

1050 1 06 1128

1.34

1172

1.49

0.4

Rpm

886 0.53

915

950

985

1019

1054

1090 1.09

1166 1 36

1204 1.51

1243

EXTERNAL STATIC PRESSURE (in. wg)

0.6 0.8

Bhp

Rpm Bhp Rpm Bhp

0 59

0 68

0.77

0.87

0 97

1 22

1.68

the motor can be utilized with confidence. Using your fan motors

up to the horsepower ratings shown will not result in nuisance

tripping or premature motor failure. Unit warranty will not be

affected.

Values include losses for filters, unit casing, and wet coils.

Use of a field-supplied motor may affect wire sizing. Contact Car

rier representative to verify

Motor drive range is 900 to 1300 rpm All other rpms require fieldsupplied drive.

1.0 1.2

Rpm

1142

1165 1 04 1240 1.22

1190 1.14

1221

1252

1283 1.51 1346

1315

Rpm Bhp

Bhp

0.96 1207 1.11

1266 1.33

1287 1.42

1.26

1.38 1315

1.65

1.55

1 69

1.4

Rpm Bhp

1245 1 20

1.37

1296

1331 1.50

1358 1.63

1388 , 1,74

1.6

Rpm Bhp

Table 15 — Fan Performance, 48LJD/LJE/LJF007 Horizontal Discharge Units; Standard Motor (Belt)

AIRFLOW

(Cfm)

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

Bhp — Brake Horsepower

NOTES:

1. Bpldfacd indicates field-supplied drive required. (See Note 6.)

2. indicates field-supplied motor and drive required.

3 Maximum usable bhp is 2.4. Extensive motor and electrical test

ing on these units ensures that the full horsepower range of

Rpm

852

894

936

978

1021

1064

1107

1150

1193

1237

1280

1324

1368

LEGEND

0.1

Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

0.55

0.64

0.74

0.85

0.97

1.10

1 24

1.39

1.56

1 74

1.94

2 15

2.37

0.2

0.4

EXTERNAL STATIC PRESSURE (in. wg)

0.6 0.8

1.0 1.2

the motor can be utilized with confidence Using your fan motors

up to the horsepower ratings shown will not result in nuisance

tripping or premature motor failure. Unit warranty will not be

affected.

4. Values include losses for filters, unit casing, and wet coils

5. Use of a field-supplied motor may affect wire sizing. Contact Car

rier representative to verify.

6 Motor drive range is 1070 to 1460 rpm All other rpms require

field-supplied drive.

19

1.4

Rpm Bhp

1371 1.69

1396 1 81

1422 1.94

1452

2.08

ZS4

1483

1.6

Rpm Bhp

1433 1 90

1450 2.03

1485 2.16

1510 2.31

Page 20

START-UP

IMPORTANT: Energize crankcase heater 24 hours prior

to base unit start-up to remove absorbed refrigerant

from oil to prevent damage to compressor. Heater is

energized as long as there is power to the unit.

Unit Preparation — Make sure that unit has been in

stalled in accordance with these installation instructions and

applicable codes.

Return-Air Filters — Make sure correct filters are in

stalled in filter tracks. See Table 1. Do not operate unit

without return-air filters.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring — Check all electrical connections in

unit control boxes. Tighten as required.

Refrigerant Service Ports — Each unit system has

3 Schrader-type service gage ports: one on the suction line,

one on the liquid line, and one on the compressor discharge

line. Be sure that caps on the ports are tight. One Schradertype valve is located under both the high-pressure switch

and the low-pressure switch.

Cooling — Set space thermostat to OFF position. To start

unit, turn on main power supply. Set system selector switch

at COOL position and fan switch at AUTO, position. Ad

just thermostat to a setting below room temperature. Com

pressor starts on closure of contactor.

Check unit charge. Refer to Service, Refrigerant Charge

section, page 22.

Reset thermostat at a position above room temperature.

Compressor will shut off. Evaporator fan will shut off after

30 second delay.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting thermostat at a position above room tem

perature shuts unit off temporarily until space temperature

exceeds thermostat setting.

Main Burners — Main burners are factory set and should

require no adjustment.

TO CHECK ignition of main burners and heating controls,

move thermostat set point above room temperature and ver

ify that the burners light and evaporator fan is energized.

After ensuring that the unit continues to heat the building,

lower the thermostat setting below room temperature and

verify that the burners and evaporator fan turn off. (Fan

will turn off only if fan selector switch is in the AUTO,

position.)

Refer to Table 16 for the correct orifice to use at high

altitudes.

Heating

1. Purge gas supply line of air by opening union ahead of

gas valve. If gas odor is detected, tighten union and wait

5 minutes before proceeding.

2. Turn on electrical supply and manual gas valve.

3. Set system switch selector at HEAT position and fan

switch at AUTO, or ON position. Set heating tempera

ture lever above room temperature.

4. The induced draft motor will start.

5. After a call for heating, the main burners should light

within 5 seconds. If the burner does not light, then there

is a 22 second delay before another 5-second try. If the

burner still does not light, the time delay is repeated. If

the burner does not light within 15 minutes, there is a

lockout. To reset the control, break the 24 v power to

Wl.

6. The evaporator-fan motor will turn on 45 seconds after

the burners are ignited.

7. The evaporator-fan motor will turn off 45 seconds after

thermostat temperature is satisfied.

8. Adjust airflow to obtain a temperature rise within the

range specified on the unit nameplate.

NOTE: The default value for the evaporator-fan motor ON

and OFF delay is 45 seconds. The Integrated Gas Unit Con

troller (IGC) modifies this value when abnormal limit switch

cycles occur. Based upon unit operating conditions, the ON

delay can be reduced to 0 seconds and the OFF delay can

be extended to 180 seconds.

Table 16 — Altitude Compensation*

74,000 AND 115,000

BTUH NOMINAL

ELEVATION

(ft)

0-2,000 33

2,000

3,000 35

4,000

5,000 36

6,000

7,000

8,000 38

9,000

10,000

11,000

12,000

13,000

14,000

*As the height above sea level increases, there is less oxygen per

cubic foot of air Therefore, heat input rate should be reduced at

higher altitudes.

fOrifices available through your Carrier distributor

INPUT

Natural

Gas

Orifice

Sizet

34 43 30

36

37 45 34 43

37

39

41 48 38 45

43 48 39

44 49

44 49

45 50 42 47

Liquid

Propane

Orifice

Sizet

43 30 38

44 31 40

44 32 41

44

45

46 36

47 37 44

150,000 BTUH

NOMINAL INPUT

Natural

Gas

Orifice

Sizet

33

35

40

41 47

Liquid

Propane

Orifice

Sizet

39

42

43

44

45

46

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting heating selector lever below room tem

perature will temporarily shut unit off until space tempera

ture falls below thermostat setting.

Safety Relief — A soft solder joint at the suction ser

vice Schrader port provides pressure relief under abnormal

temperature and pressure conditions (i.e., fire in building).

Ventilation (Continuous Fan) — Set fan and sys

tem selector switches at ON and OFF positions, respec

tively. Evaporator fan operates continuously to provide constant

air circulation. When the evaporator-fan selector switch is

turned to the OFF position, there is a 30 second delay be

fore the fan turns off.

Operating Sequence

COOLING, UNITS WITHOUT ECONOMIZER - When

thermostat calls for cooling, terminals G and Y1 are ener

gized, and the indoor (evaporator) fan motor (IFM), com

pressor, and outdoor (condenser) fan motor (OFM) start.

The OFM runs continuously while the unit is in cooling.

When the thermostat is satisfied, C is deenergized and the

compressor and OFM shut off. After a 30 second delay, the

IFM shuts off. If the thermostat fan selector switch is in the

ON position, the evaporator motor will run continuously.

20

Page 21

HEATING, UNITS WITHOUT ECONOMIZER - When

the thermostat calls for heating, terminal W1 is energized.

To prevent thermostat short-cycling, the unit is locked into

the Heating mode for at least 1 minute when W1 is ener

gized. The induced-draft motor is energized and the burner

ignition sequence begins. The indoor (evaporator) fan mo

tor (IFM) is energized 45 seconds after a flame is ignited.

On units equipped for two stages of heat, when additional

heat is needed, W2 is energized and the high-fire solenoid

on the main gas valve (MGV) is energized. When the ther

mostat is satisfied and W1 is deenergized, the IFM stops

after a 45 second time-off delay.

COOLING, UNITS WITH ECONOMIZER - When the

outdoor-air temperature is above the outdoor-air thermostat

(OAT) setting and the room thermostat calls for cooling,

compressor contactor is energized to start compressor and

the outdoor (condenser) fan motor (OFM). The indoor (evap

orator) fan motor (IFM) is energized and the economizer

damper moves to the minimum position. After the thermo

stat is satisfied, there is a 30 second delay before the evap

orator fan turns off. The damper then moves to the fully

closed position. When using continuous fan, the damper

moves to the minimum position.

When the outdoor-air temperature is below the OAT set

ting and the thermostat calls for cooling, the economizer

damper moves to the minimum position. If the supply-air

temperature is above 57 F, the damper continuous to open

until it reaches the fully open position or until the supplyair temperature drops below 52 F.

When the supply-air temperature falls between 57 F and

52 F, the damper will remain at an intermediate open po

sition. If the supply-air temperature falls below 52 F, the

damper will modulate closed until it reaches the minimum

position or until the supply-air temperature is above 52 F.

When the thermostat is satisfied, the damper moves to the

fully closed position when using AUTO, fan or to the min

imum position when using continuous fan.

If the outdoor air alone cannot satisfy the cooling require

ments of the conditioned space, economizer cooling is in

tegrated with mechanical cooling, providing two stages of

cooling. Compressor and the condenser fan will be ener

gized and the position of the economizer damper will be

determined by the supply-air temperature. When the sec

ond stage of cooling is satisfied, the compressor and OFM

will be deenergized. The damper position will be deter

mined by the supply-air temperature. When the first stage

of cooling is satisfied, there is a 30 second delay before the

evaporator fan shuts off. The damper then moves to the

fully closed position. When using a continuous fan, the damper

moves to the minimum position.

HEATING, UNITS WITH ECONOMIZER - When the

thermostat calls for heating, terminal W1 is energized. To

prevent thermostat short-cycling, the unit is locked into the

Heating mode for at least 1 minute when W1 is energized.

The induced-draft motor is energized and the burner igni

tion sequence begins. The indoor (evaporator) fan motor

(IFM) is energized 45 seconds after a flame is ignited and

the damper moves to the minimum position. On units equipped

for two stages of heat, when additional heat is needed, W2

energized and the high-fire solenoid on the main gas valve

(MGV) is energized. When the thermostat is satisfied and

W1 is deenergized, the IFM stops after a 45 second time-

off delay. The economizer damper then moves to the fully

closed position. When using continuous fan, the damper

will remain in the minimum position.

SERVICE

CAUTION

When servicing unit, shut off all electrical power to

unit to avoid shock hazard or injury from rotating parts.

Cleaning — Inspect unit interior at the beginning of heat

ing and cooling season and as operating conditions require.

EVAPORATOR COIL

1. Turn unit power off. Remove evaporator coil access panel.

2. If economizer is installed, remove economizer by dis

connecting Molex plug and removing economizer mount

ing screws. Refer to accessory economizer installation

instructions or Optional Economizer section on page 11

for more details.

3. Slide filters out of unit.

4. Clean coil using a commercial coil cleaner or dish

washer detergent in a pressurized spray canister. Wash

both sides of coil and flush with clean water. For

best results, backflush toward return-air section to

remove foreign material. Flush condensate pan after

completion.

5. Reinstall economizer and filters.

6. Reconnect wiring.

7. Replace access panels.

CONDENSER COIL — Inspect coil monthly. Clean con

denser coil annually, and as required by location and out

door air conditions.

One-Row Coils — Wash coil with commercial coil cleaner.

It is not necessary to remove top panel.

2-Row Coils

Clean coil as follows:

1. Turn off unit power.

2. Remove top panel screws on condenser end of unit.

3. Remove condenser coil comer post. See Fig. 28. To hold

top panel open, place coil comer post between top panel

and center post. See Fig. 29.

4. Remove screws securing coil to center post.

5. Remove fastener holding coil sections together at return

end of condenser coil. Carefully separate the outer

coil section 3 to 4 in. from the inner coil section. See

Fig. 30.

6. Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and de

bris. Clean the outer surfaces with a stiff brush in the

normal manner.

7. Secure inner and outer coil rows together with a fieldsupplied fastener.

8. Reposition the outer coil section and remove the coil

comer post from between the top panel and center post.

Reinstall the coil comer post and replace all screws.

CONDENSATE DRAIN — Check and clean each year at

start of cooling season. In winter, keep drain dry or protect

against freeze-up.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions re

quire it. Replacement filters must be same dimensions as

original filters.

OUTDOOR-AIR INLET SCREENS - Clean screens with

steam or hot water and a mild detergent. Do not use dis

posable filters in place of screens.

21

Page 22

Lubrication

COMPRESSORS — Each compressor is charged with the

correct amount of oil at the factory.

FAN MOTOR BEARINGS — Fan motor bearings are of

the permanently lubricated type. No further lubrication is

required. No lubrication of condenser or evaporator fan mo

tors is required.

Manual Outdoor-Air Damper — if outdoor-air damper

blade adjustment is required, see Manual Outdoor-Air Damper

section on page 10.

COIL CORNER

CENTER BAFFLE

TOP PANEL

Two-Position Damper —

Refer to Two-Position

Damper section on page 11.

Economizer Adjustment — Refer to Optional Econ

omizer section on page 11.

Condenser-Fan Adjustment (Fig. 31) — Shut off

unit power supply. Remove condenser-fan assembly (grille,

motor, motor cover, and fan) and loosen fan hub setscrews.

Adjust fan height as shown in Fig. 31. Tighten setscrews

and replace condenser-fan assembly.

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate (also refer to Table 1). Refer to

Carrier GTAC2-5 Charging, Recovery, Recycling, and Rec

lamation training manual and the following procedures.

Unit panels must be in place when unit is operating dur

ing charging procedure.

NO CHARGE — Use standard evacuating techniques. Af

ter evacuating system, weigh in the specified amount of re

frigerant. (Refer to Table 1.)

TOP VIEW

TOP PANEL

Fig. 31 — Condenser-Fan Adjustment

22

Page 23

LOW CHARGE COOLING — Using Cooling Charging

Charts, Fig. 32-35, vary refrigerant until the conditions of

the appropriate chart are met. Note the charging charts are

different from type normally used. Charts are based on charg

ing the units to the correct superheat for the various oper

ating conditions. Accurate pressure gage and temperature

sensing device are required. Connect the pressure gage to

the service port on the suction line. Mount the temperature

sensing device on the suction line and insulate it so that

outdoor ambient temperature does not affect the reading.

Indoor-air cfm must be within the normal operating range

of the unit.

TO USE COOLING CHARGING CHART - Take the out

door ambient temperature and read the suction pressure gage.

Refer to chart to determine what suction temperature should

be. If suction temperature is high, add refrigerant. If suc

tion temperature is low, carefully reclaim some of the charge.

Recheck the suction pressure as charge is adjusted.

Example; (Fig. 33)

Outdoor Temperature........................................................85F

Suction Pressure

Suction Temperature should be

...........................................................

.......................................

70 psig

46 F

(Suction Temperature may vary 5 F.)

If Chargemaster® charging device is used, temperature

and pressure readings must be accomplished using the charg

ing chart.

6B9

1 111

M 1 M M

ourooofl TEM P

F C

621

115 46

105 41

J552

S

o

=¡483

«

^345

2

O

§276

n

207

<s>

№

ft

upO

s

pi

§50

<n

' -1 4 I'o ife 2'l 2'?

--

£

?

?

0 B

0

S

JCTiON L

0 ^

NE TEMPE

0 7

F)

RATURE (

SUCTION LINE TEMPERATURE CC)

95 35

85 29

75 24

65 18

55 13

45 7

0 £

Fig. 32 — Cooling Charging Chart, 48LJE/LJF004

0

Fig. 34 — Cooling Charging Chart, 48LJD/LJE/LJF006

SUCTION LINE TEMPERATURE CF)

SUCTION LINE TEMPERATURE CC)

30 40 SO BO

' -I ¡1 I'o I's

SO

73

h

2'l

Fig. 33 — Cooling Charging Chart, 48LJD/LJE/LJF005

Fig. 35 — Cooling Charging Chart, 48LJD/LJE/LJF007

23

Page 24

Flue Gas Passageways — To inspect the flue col

lector box and upper areas of the heat exchanger: