Page 1

Single-Package Rooftop

Heating/Cooling Units

User’s Information Manual

48HJ004-014

NOTE TO INSTALLER:

This manual should be left with the equipment owner.

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

serious injury or death. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, or the gas

supplier.

Before performing recommended maintenance, be sure

main power switch to unit is turned off. Electrical shock

could cause serious injury or death.

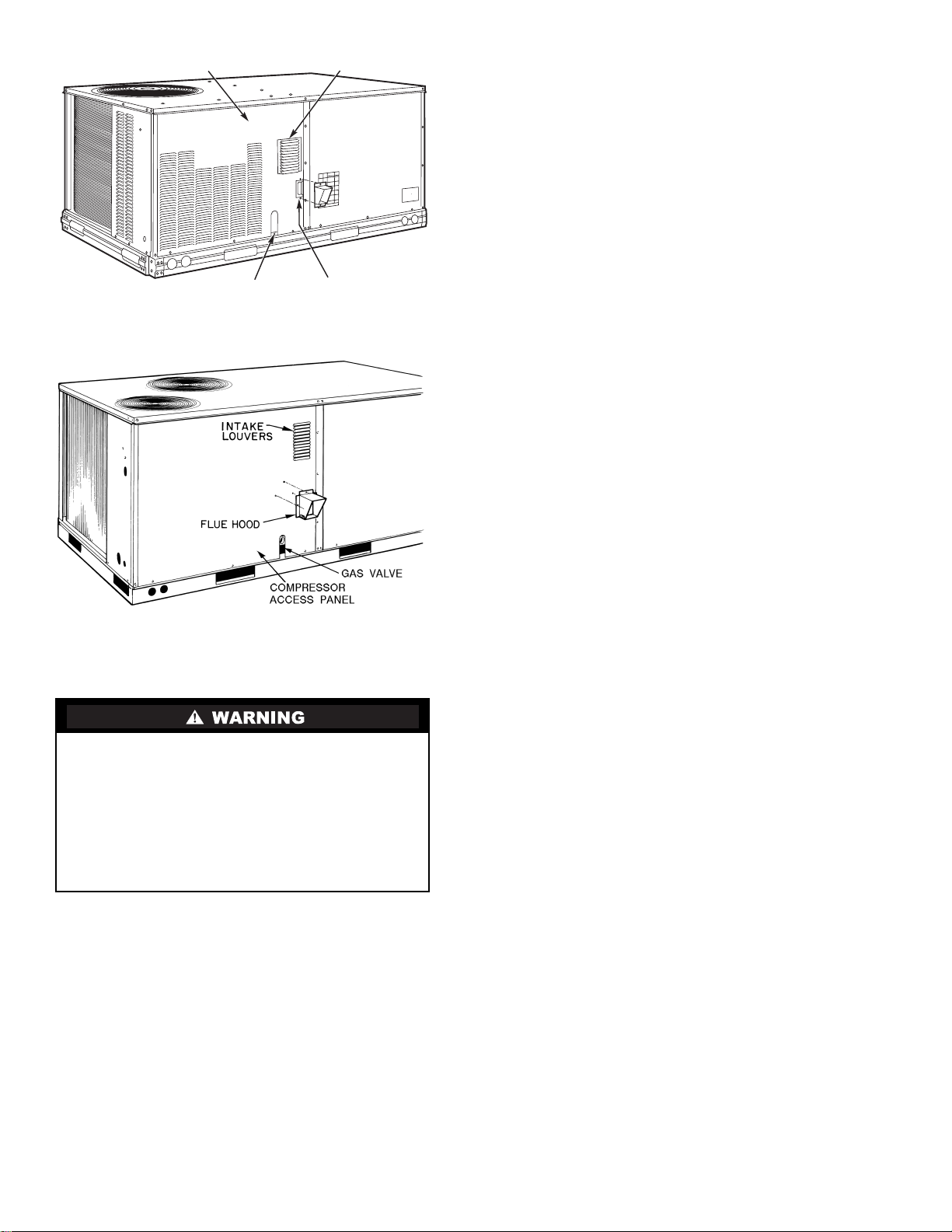

TO LIGHT UNIT

1. D o not turn off the electrical power to unit without

first turning off the gas supply .

2. Before attempting to start the gas heating section,

familiarize yourself with all the procedures that must

be followed.

If you do not follow these instructions exactly, a fire or

explosion may result. Property damage, injury, or loss of

life could occur.

See Fig. 1A and 1B for location of gas valve. Refer to Fig. 2

while proceeding with the following steps.

Step 1 —

setting and set SYSTEM switch to HEA T or AUT O. position.

Step 2 —

Step 3 —

disconnect.

Step 4 —

Step 5 —

and wait 5 minutes.

Step 6 —

Step 7 —

Step 8 —

Step 9 —

Step 10 —

room temperature to start unit. The induced-draft combustion

air fan will start. Main gas valve will open and main burners

should ignite within 5 seconds. If the burners do not light, there

is a 22-second delay before another 5-second try. If the burner

still does not light, the time delay is repeated. If the burner does

not light within 15 minutes, there is a lockout. To reset the control, break the 24-v power to W1. Repeat Steps 1-10. If burners

still do not light, call for service.

Step 11 —

to desired setting.

Set room thermostat to the lowest temperature

Close the manual gas valve.

Turn off the electrical supply to the unit, tag

Remove the compressor access panel.

Move the gas valve switch to the OFF position

Move the gas valve switch to the ON position.

Replace the compressor access panel.

Turn on the electrical supply to unit.

Open the manual gas valve.

Set room thermostat selector slightly above

Set the temperature selector on room thermostat

Your rooftop com bination heating/cooling unit is equipped

with an automatic direct spark ignition and induced-draft combustion blower.

Do not attempt to light by hand; serious injury or death

may result.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 1 a 6 a

PC 111 Catalog No. 534-80017 Printed in U.S.A. Form 48HJ-2SO Pg 1 11-00 Replaces: 48GJ,HJ-1SO

If the main burners fail to light, or the blower fails to come

on, shut down gas heating section and call your dealer for

service. Failure to follow these requirements could result in

serious injury or death.

Page 2

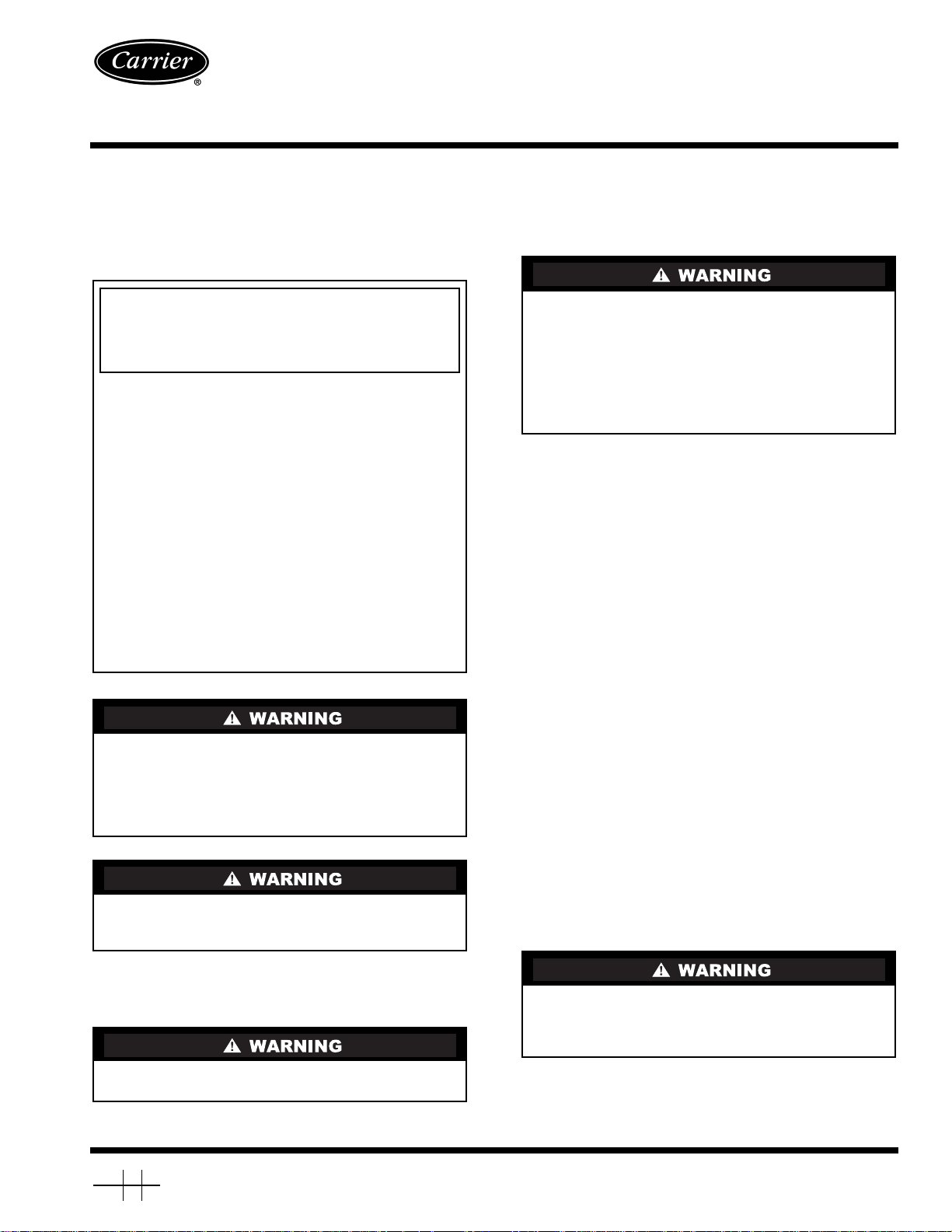

COMPRESSOR ACCESS PANEL

Fig. 1A — Gas Valve Location

(48HJ004-007)

Fig. 1B — Gas Valve Location

(48HJ008-014)

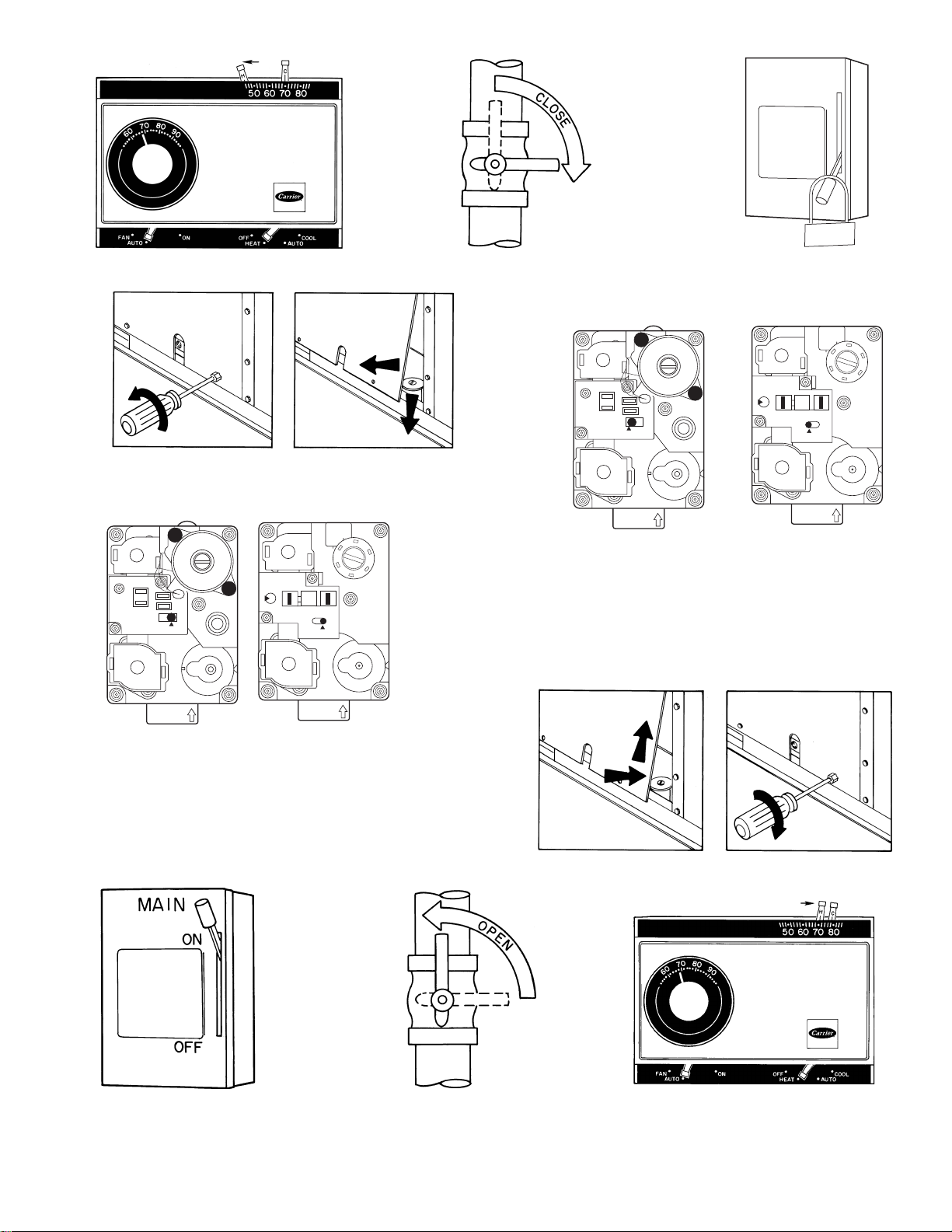

TO SHUT UNIT OFF

GAS VALVE

INTAKE LOUVERS

FLUE OPENING

Refer to Fig. 3 while proceeding with the following steps.

Step 1 —

Set room ther m ostat to lowest te m pe ra t u r e set ting

and set SYSTEM switc h to O FF.

Step 2 —

Step 3 —

Close the external manual gas valve.

Turn off the electrical power supply to unit;

install lockout tag.

Step 4 —

Step 5 —

Step 6 —

Step 7 —

Remove the compressor access panel.

Move the gas valve switch to the OFF position.

Replace compressor access panel.

If unit is being shut down because of a malfunc-

tion, call your dealer as soon as possible.

If unit is being shut down because the heating season has

ended, restore electrical power to the unit and set thermostat to

the COOL position to ensure operation of the cooling system

during the cooling season.

Should overheating occur, or the gas supply fail to shut off,

shut off the manual gas valve to the unit before shutting off the

electrical supply.

Do not use this unit if any part has been under water. Immediately call a qualified service technician to inspect the unit and

to replace any part of the control system and gas control that

has been under water.

MAINTAINING YOUR UNIT

All maintenance should be handled by skilled, experienced

personnel. Your Carri er service technician ca n help you set up

a maintenance schedule.

For your safety, keep the area around the unit clear and free

of combustible materials, gasoline, and other flammable liquids and vapors.

To ensure proper functioning of the unit, flow of combustion and ventilating air must not be obstructed f rom reaching

the unit. Clearance of at least 3 ft on flue and condenser sides

and 6 in. on all other sides is required.

1. D o not turn off the electrical power to unit without

first turning off the gas supply .

2. N ever attempt to manually light the main burners on

unit with a match, lighter, or any other flame. If the

electric sparking device fails to light the main burners,

refer to the following shutdown procedures. Call your

dealer as soon as possible.

Failure to follow these procedures can result in fire, seri-

ous injury or death.

2

Page 3

O

F

F

ON

C

HI

M

R

E

P

L

A

C

E

S

C

R

E

W

L

O

STEP 1

MAIN

ON

OFF

LOCK-OUT

TAG

STEP 3STEP 2

2-STAGE GAS VALVE

W

E

O

R

C

L

S

E

C

A

R

L

P

M

C

HI

48HJD005,006*

48HJE004-006*

48HJF004-006*

48HJD007-014

48HJE007-014

48HJF007-014

E

ON

F

F

O

STEP 4

SINGLE-STAGE GAS

VALVE

WR

P3

C2

M1

ON

F

F

O

48HJD005,006†

48HJE004-006†

48HJF004-006†

48HJG005,006

48HJH004-006

48HJK004-006

48HJL005,006

48HJM004-006

48HJN004-006

STEP 6

2-STAGE GAS VALVE

48HJD005,006*

48HJE004-006*

48HJF004-006*

48HJD007-014

48HJE007-014

48HJF007-014

STEP 7

STEP 5

SINGLE-STAGE GAS

VALVE

WR

P3

C2

M1

ON

F

F

O

48HJD005,006†

48HJE004-006†

48HJF004-006†

48HJG005,006

48HJH004-006

48HJK004-006

48HJL005,006

48HJM004-006

48HJN004-006

*3-phase units only.

†Single-phase units only.

STEP 8

STEP 9

STEP 10

Fig. 2 — To Light Unit

3

Page 4

STEP 1

STEP 4

STEP 2

MAIN

OFF

STEP 3

ON

LOCK-OUT

TAG

2-STAGE GAS VALVE

W

E

O

R

C

L

S

E

C

A

R

L

P

M

C

HI

48HJD005,006*

48HJE004-006*

48HJF004-006*

48HJD007-014

48HJE007-014

48HJF007-014

*3-phase units only.

†Single-phase units only.

E

ON

F

F

O

STEP 5

SINGLE-STAGE GAS

VALVE

WR

P3

C2

M1

ON

F

F

O

48HJD005,006†

48HJE004-006†

48HJF004-006†

48HJG005,006

48HJH004-006

48HJK004-006

48HJL005,006

48HJM004-006

48HJN004-006

STEP 6

STEP 7

Fig. 3 — To Shut Unit Off

4

Page 5

ROUTINE MAINTENANCE AND CARE

FILTER ACCESS PANEL

Fig. 4 — Typical Filter Access Panel Location

(48HJ008-014 Shown)

FOR THE EQUIPMENT OWNER

Consider the following information before maintaining or

servicing equipment:

Units with outdoor air capability have a cleanable filter for

the outdoor air. This filter should be checked semi-annually

and cleaned as necessary with steam or hot water and a mild

detergent. Do not use throwaway filters in place of cleanable

filters.

.

1. TU RN OFF GAS S UPPLY AND THEN ELECTRICAL POWER TO YOUR UNIT AND INSTALL

LOCKOUT TAG BEFORE SERVICING OR PERFORMING MAINTENANCE.

2. D o not turn off electrical power to this unit without

first turning off the gas supply .

3. When re moving access panels or performing main tenance functions inside your unit, be aware of sharp

sheet metal parts and screws. Although special care

has been taken to reduce sharp edges inside the unit,

be extremely careful when handling parts or reaching

into the unit.

4. Failure to follow these instructions could result in

serious injury or death.

Air Filter(s) —

Air filter(s) should be checked at least

every 3 or 4 weeks and changed or cleaned when necessary.

Table 1 indicates the correct filter size for your unit. See Fig. 4

for filter access panel location.

1. Lift up and remove filter access panel.

2. While holding filter, tilt upper filter rack.

3. Remove filters by pulling up and out toward you from the

track.

4. Inspect or replace filters.

5. Retur n filters t filter tracks. Note direction of airflow arrows on filter frame.

6. Reinstall filter access panel.

If you have difficulty in locating your air filter or if you

have questions concerning proper filter maintenance, contact

your dealer for instructions. When replacing your unit filters,

always use the same size and type of filter that was originally

supplied by the installer.

Never operate your unit without filters in place. Failure t o

heed this warning may result in damage to the blower

motor, compressor and/or evaporator coil. An accumulation of dust and lint on internal parts of your unit can cause

loss of efficiency and, in some cases, fire that could result

in serious injury or death.

Table 1 — Indoor-Air Filter Data for 48HJ

UNIT SIZE

48HJ

004-007

008,009

012,014

NOTE: Replacement filters should be UL (Underwriters’ Laborato-

ries) certified or equivalent.

INDOOR-AIR FILTERS

(Throwaway Fiberglass)

Quantity Size (in.)

2 16 x 25 x 2

4 16 x 25 x 2

4 20 x 20 x 2

5

Page 6

Heat Exchanger

NOTE: To ensure dependable and efficient heating operation,

the heat exchanger should be checked by a qualified maintenance person before each heating season, and cleaned when

necessary.

Combustion Area and Vent System —

bustion area and vent system should be visually inspected before each heating season. The normal accumulation of dirt,

soot, rust, and scale can result in loss of efficiency and improper performance if allowed to build up.

The com-

This checkout should not be attempted by anyone not having the required expertise and equipment to do the job

properly.

Checking and/or cleaning the heat exchanger involves

removing the gas controls assembly and the flue collector box

cover. When finished, the gas controls must be reinstalled for

proper operation. Also, the flue collector box cover must be

replaced correctly so that a proper seal is main tained. Contact

your dealer for the required periodic maintenance. At the

beginning of each cooling/heating season and as conditions

require.

Fans and Belts, and Fan Motor —

the condition of fan wheels and housings, belt tension and fan

motor shaft bearings. No lubrication of condenser or evaporator fan bearings or motors is required or recommended.

Evaporator and Condenser Coils —

the coils should be done by qualified service personnel. Contact you dealer for the required annual maintenance.

Condensate Drain —

drain line should be checked and cleaned at the same time the

cooling coils are checked by your dealer.

Compressor —

a normal charge of the correct type refrigeration-grade oil in

them and should not require additional oil.

The drain pan and condensate

All compressors are factory supplied with

Periodically check

Cleaning of

Condenser Fan

If your unit makes any unusual or especially loud noises

during heating, shut down the heating section and call your

qualified Carrier service technician.

See Fig. 1A, 1B, and 5 and proceed as follows to inspect the

combustion area and power-venting system of your unit.

1. Turn off gas supply to your unit.

2. Turn off electrical power to your unit; install lockout tag.

3. Remove compressor access panel.

4. Usi ng a flashlight, carefully inspect the burner areas for

dirt, soot, or scale.

If dirt, soot, rust or scale accumulations are found, call your

dealer and do not operate your heating section.

5. When you have completed your inspection, follow the

start-up procedures in this manual to restore your unit to

operation.

6. Observe unit heating operation.

Components in heat section may be hot after unit has been

started up. When observing flame, be careful not to get

close to or touch heating components. Serious injury could

result.

Do not poke sticks, screwdrivers, or any other object into

revolving fan blades. Severe bodily injury could result.

The fan must be kept free of all obstructions to ensure prop-

er cooling. Contact your dealer for any required service.

Electrical Controls and Wiring —

not contact refrigerant tubing or sharp edges. Electrical controls are difficult to check without proper instrumentation. If inadequate cooling is suspected, contact your qualified local

dealer for service.

Ensure wires do

Watch the burner flame to see if it is bright blue. If you

observe a suspected malfunction or that the burner flame

is not bright blue, call your dealer.

7. Replace compressor access panel.

Unit Panels —

service on the unit, be sure all panels are securely faste ned in

place to prevent rain from entering unit cabinet a nd to prevent

disruption of the correct unit airflow pattern.

After performing any maintenance or

6

Page 7

Fig. 5 — Typical Heat Section Detail

REGULAR DEALER MAINTENANCE

In addition to the type of routine maintenance you might be

willing to perform, your unit should be inspected regularly by a

properly trained and qualified Carrier service technician. An

inspection (preferably each heating/cooling season, but at least

every year) should include the following:

1. Inspection of all flue product passages — including the

burners, heat exchanger, and flue collector box.

2. Inspection of all combustion- and ventilation-air passages

and openings.

3. Close inspection of all gas pipes leading to and inside

your unit.

4. Inspect ion and if re quired, cleani ng of the condenser and

evaporator coils.

5. Inspection, and if required, cleaning of the condensate

drain pan.

6. Inspection and cleaning of blower wheel housing and

motor.

7. Inspection of all supply- and return-air ducts for leaks,

obstructions, and insulation integrity. Any problems

found should be resolved at the time of inspection.

8. Inspect ion of the unit base for cracks, gaps, etc., which

may cause a hazardous condition.

9. Inspection of the unit casing for signs of deterioration.

10. Inspection of all electrical wiring and components to

ensure proper connection.

11. Inspection for leaks in the refrigerant circuit. Pressurecheck to determine appropriate refrigerant charge

12. Inspection of fan w heels and housings, belt tension, and

fan motor shaft bearings.

13. Ope rational check of the unit to determine working conditions. Repair or adjustment should be made at the time

of inspection.

Your servicing dealer may offer an economical service

contract that covers seasonal inspections. Ask f or further

details.

Complete service instructions can be found in the unit

Installation, Start-Up and Service Instructions.

7

Page 8

BEFORE YOU CALL FOR SERVICE,

CHECK FOR PROBLEMS

THAT CAN BE EASILY SOLVED

If insufficient heating or cooling is suspected:

( ) Check for sufficient airflow. Check the air filter for dirt.

Check for blocked return- or supply-air grilles. Be sure they

are open and unobstructed. If these checks do not reveal the

cause, call your servicing dealer.

If your unit is not operating at all, check the following list

for easy solutions:

( ) Check to be sure that your thermostat temperature selec-

tor is set above the indoor temperature during the heating season, or below the indoor temperature during the cooling

season. Be sure the SYSTEM switch in the proper HEAT or

COOL position and not in the OFF position.

( ) Is the electrical supply switch ON? Are any fuses blown,

or has the circuit breaker tripped?

( ) During the heating season, check the external manual

shutoff valve. Is this lever parallel with the pipe, indicating that

the valve is open? Or is the lever at the right angle, indicating

that the valve is closed? If closed, has the gas been shut off for

safety reasons? Otherwise, you may open the valve and follow

the start-up procedures listed in this manual.

NOTE: Before proceeding with the next check, turn OFF the

electrical power supply to the unit. Rem ove the control a ccess

door.

( ) During the heating season, check the control switch on

the gas valve. Is it in the ON position? If it is not, be sure it has

not been turned off for the purpose of safety. If no safety hazards are present, follow the start-up procedures in this manual.

( ) If your unit still fails to operate, call your servicing dealer

for troubleshooting and repairs. Specify the model and serial

numbers of your unit. (Record them in this manual in the space

provided.) If the dealer knows exactly which unit you have, he

may be able to offer suggestions over the phone, or save valuable time through knowledgeable preparation for the service

call.

IN CASE OF TROUBLE

If, after performing the above checks, unit performance is

unsatisfactory, shut off t he unit and call your dealer .

Dealer’s Name _____________________________________

T elephone No.______________________________________

Unit Model ________________________________________

Unit Serial Number _________________________________

Copyright 2000 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Ta b 1 a 6 a

PC 111 Catalog No. 534-80017 Printed in U.S.A. Form 48HJ-2SO Pg 8 11-00 Replaces: 48GJ,HJ-1SO

Loading...

Loading...