Carrier 48GH User Manual

Carrier Parkway • Syracuse NY 13221

Combination Heating/Cooling Units

MOTE TO INSTALLER: THESE INSTRUCTIONS SHOULD BE

LEFT WITH THE EQUIPMENT OWNER.

INDEX

Page

SAFETY CONSIDERATIONS

INTRODUCTION

GENERAL

INSTALLATION

..................................................

............................................................

................................................

Step 1 — Rig and Place Unit .............................. 2

..............................

2-8

2

2

2

• ROOFTOP INSTALLATION

• GROUND LEVEL INSTALLATION

• CLEARANCES

• CONDENSATE DISPOSAL

• VENTING

Step 2—Make Gas Piping Connections... 5

PLUGGED ACCESS HOLE

FOR REFRIGERANT . raSS-K

PRESSURE GAGE HOSES

Page

Step 3 — Make Duct Connections ..................... 5

Step 4 — Make Wiring Connections ... 6-8

• HIGH-VOLTAGE CONNECTIONS

• SPECIAL PROCEDURES FOR

208-V OPERATION

• LOW-VOLTAGE CONNECTIONS

• HEAT ANTICIPATOR SETTING

START-UP .........................................................8-16

OPERATING SEQUENCE

SERVICE .........................................................17-20

TROUBLESHOOTING CHARTS

CONTROLS ACCESS

DOOR

BLOWER ACCESS

DOOR

I

LOW VOLTAGE-

INLET

K HIGH VOLTAGE

INLET

..............................

......................

•VENT CAP

COMBUSTION AIR INLET BOX

16,17

21,22

# MPT

DRAIN CONN

© Carrier Corporation 1982

EVAPORATOR AIRFLOW

o

*NOT ON MODELS 48GL0I8 THRU

036; GH024 THRU 030

48GH.GL REQUIRED CLEARANCES (ft-in )

Above flue vent 3-0

Duct side of unit 0-6

Side opposite ducts 2-6

Blower access panel side 2-6

Side opposite blower access panel 2-6

Bottom of unit 0

NOTE Provision must be made for fresh ambient air to reach the

outdoor coil without recirculation of the air from the outdoor fan

discharge

CONDENSER AIRFLOW

Fig. 1 — Dimensions

NOT ON MODELS

48GL0I8 THRU 036;

GH024 THRU 030

Form 48GH.GL-5SI

ge

16

17

20

22

lOX

a

)36;

O

SAFETY CONSIDERATIONS

Installation, start-up and servicing of this equip

ment can be hazardous due to system pressures,

electrical components and equipment location

(roofs, elevated structures, etc.).

Only trained, qualified installers and service

mechanics should install, start-up and service this

equipment.

Consult the Owner’s Manual for routine main

tenance. All other operations should be performed

by trained service personnel.

When working on the equipment, observe pre

cautions in the literature, tags, stickers and labels

attached to the equipment and any other safety

precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky

equipment.

WARNING; Do Hot discosaect electric power

to this appliance wiiliout Htst mrnirfg oft the gas

supply. Be sure power to ©quipmeot is shut off

before perforuiiug maintenance (»r service.

INTRODUCTION

Models 48GH/GL Packaged Gas/Electric Units

are fully self-contained, combination gas-heating/

electric-cooling units designed for outdoor installa

tion either on a rooftop or ground-level slab. See

Fig. 1.

These units are equipped with an energy-saving

automatic intermittent electric spark ignition system

that does not have a continuously-burning pilot.

Also included is the Time Guard II circuit for added

compressor protection. All units are manufactured

with natural gas controls.

Models 48GH/GL are AG A design-certified with

2 input ratings. See Table 1. All units are manu

factured for operation at the minimum rating. For

operation at the maximum ratings, optional burner

orifices must be field installed. See Table 3.

These units are factory charged with R-22 refrig

erant. To install: connect gas supply, air ducts, high-

and low-voltage wiring, condensate drain, and

install a field-supplied air filter in the return-air

ductwork.

All units can be connected into existing duct

systems that are properly sized and designed to

handle an airflow of 350 to 450 cfm per each 12,000

Btuh of rated cooling capacity. See Tables 1 and 4

for cooling and heating airflow requirements.

NOTE: When installing any accessory item, see

Installation Instructions packaged with the

accessory.

IMPORTANT —

READ BEFORE INSTALLING

L This insiaUation must conform with all

applicable local and national codes.

2. Power .supply (volts, hertz and phase) must

correspond to that specified on unit rating

plate.

3- Elecíríeal supply provided by utility mast be

sufikient to handle load imposed by this unit.

4. Refer to the 4SGH / GL dimensionai drawing

for locations of gas inlet, elearical inlets,

condensate drain, duct connections, and

required clearances before setting unit in

place.

5. Locate the nnit where the vent cap will be a

minimum of 4 ft from openable windows or

doors.

6. This installation must conform with local

building codes and with the National Fuel

Gas code ANSÍ Z223.1-1980.

GENERAL

Models 48GH/GL Packaged Gas/Electric Units

have been designed and tested in accordance with

ANSI Z21.47-1978, ARI Standard 210-79 and ARI

Standard 270-75. The appliance design is certified

by the American Gas Association (AGA) for use

with natural or LP (propane) gases with appropriate

components and orifices.

INSTALLATION

Step 1 — Rig and Place Unit

CAUTION: W'hen rigging unit to be lifted, use

spreader bars to protect top and sides. Models

4^GH/GL must he rigged for lifting as shown

in Fig, 2. Use extreme caution to prevent

damage when moving unit.

SPREADER BARS:

(2)2x4xUNIT LENGTH PLUS IO"WITH

if DEEP 90° NOTCHES EACH END

(2) 2x4xUNIT WIDTH WITH 1^’

DEEP 90° NOTCHES

EACH END

PACKAGED UNIT-

LOCATE CHAINS THRU

HOLES IN BASE

CHANNELS

Fig. 2 — 48GH/GL Suggested Rigging

USE SPREADER BARS

TO PROTECT UNIT

CHAIN

TWO OR THREE BASE

CHANNELS ATTACHED TO

BOTTOM OF UNIT

5SI

Unit must remain in an upright position during all

rigging and moving operations. Unit must be level

for proper condensate drainage; therefore, groundlevel pad or field-supplied mounting curb must be

level before setting unit in place.

ROOFTOP INSTALLATION

CAUllONt When ìnstaHjjig «mt <m a rooftop,

be sure rooi wiU soppori. ibe additional weight.

Refer to Produot Data Digest to obtain total

weight and comer weight infonrnation.

When installing a Model 48GH/GL enddischarge unit with a field-supplied downflow

plenum, a field-supplied roof-mounting curb must

be installed on and flashed into roof before unit

installation.

When installing a Model 48GH/GL end-

discharge unit without a downflow plenum, place

unit on a level base that provides proper support. On

flat roofs be sure that unit is located at least 4 in.

above highest expected water level on roof to pre

vent flooding. Consult local codes for additional

installation requirements.

GROUND-LEVEL INSTALLATION - Place

unit on a solid, level concrete pad that is a minimum

of 4 in. thick and that extends approximately 2 in.

beyond casing on all 4 sides of unit. Do not secure

unit to pad except when required by local codes.

CLEARANCES — The required minimum oper

ating and service clearances are shown in Fig. 1.

CAUTION: Douot resïîicî ccsdenser air^ow:.

An air restriction at either outdoor-air inlet (the

entire surface of the outdoor coil) or fan dis

charge can he detfinaeniai to compressor hfe.

Condenser Ian discharges thru top of unit. En

sure that fan discharge does not recirculate to

condenser coil. Do not locate unit in either a corner

or under a complete overhead obstruction. Mini

mum clearance under a partial overhang (such as a

normal house roof overhang) is 3 ft above vent cap.

Do not locate unit where water, falling ice or snow

from an overhang or roof will damage or flood the

unit. Do not locate unit where grass, shrubs, or

other plants will interfere with airflow either into

or out of unit.

CONDENSATE DISPOSAE

NOTE. Ensure that condensate-water disposal

methods comply with local codes, restrictions and

practices.

Models 48GH/GL dispose of condensate water

thru a 3/4-in. MPT drain fitting. See Fig. 1 for

location.

Install a 3-in. trap at drain fitting to ensure

proper drainage. See Fig. 3. Make sure trap outlet

is at least 2 in. lower than unit drain pan connection

to prevent pan from overflowing. Prime trap with

water.

If the installation requires draining condensate

water away from the unit, connect a drain tube

using a minimum of 7/8-in. OD copper tubing.

3/

no

at

ru

ro

on

W

aw

FRC

VI

du

CO

lo(

St£

tO|

bl(

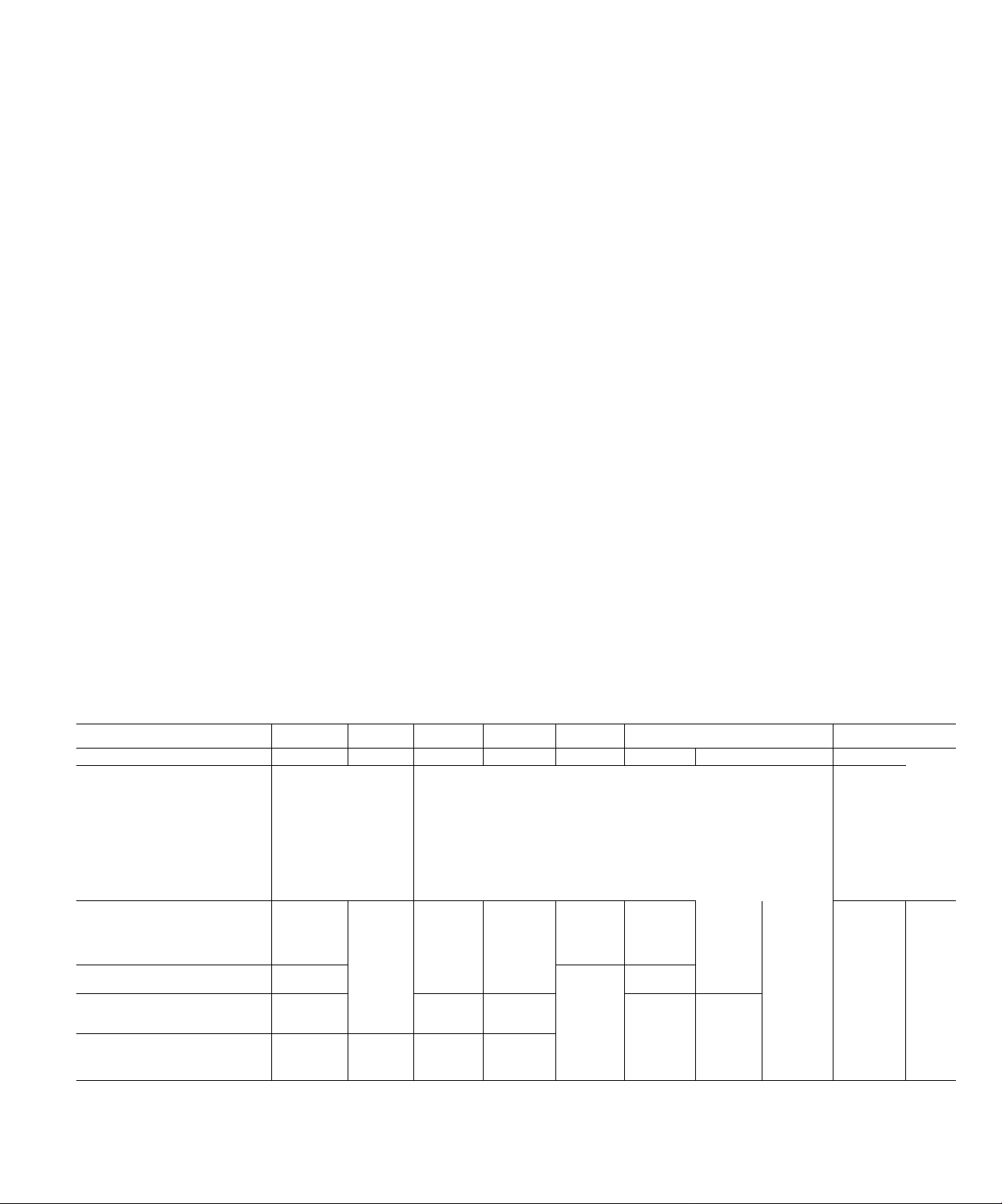

MODEL 48

SERIES 320 320

DIMENSIONS |ft-in.)

FIELD-SUPPLIED FILTER

SIZE (sq. in.)*

Standard Disposable Type

Cleanable- or

High-Capacity Type

OPERATING WT (lb)

SHIPPING WT (lb)

HEATING INPUTS (Btuh)

COOLING AIRFLOW (Cfm) 600

EXTERNAL STATIC

PRESSURE (in. wg)

A 4-5-578

B

C 3-2D 1 -4

E 1 -4

F

G 0- 11

H

K 0-1-

Min

Max

GL018 GL024

2-6-3/8

1/8

0-7-

1/4

1-0-5/8

3/32

289 396

188 257

320

330 335

40,000

50,000

0 10

^Recommended, field-supplied air filter areas shown are based on either cooling airflow at a velocity of 300 ft per

minute or heating airflow at a temperature of 60 F. depending on whichever value is larger Air filter pressure drop

should not exceed 0 08 in wg for unit to produce rated cooling performance

fWhen Models 48GH024 or GH036 are installed for operation at minimum rated heating input, recommended

minimum air filter area Is the smaller sq in figure shown for each type of filter Larger figures shown are mini-

325

40,000

50,000

825

0 10

GH024 GL030

320

396/433t

257/281t

375 375

385

60,000 40,000

75,000 50,000

825

0 10

320/330

*

1088

0 15

522

339

385

GH030

320/330 320/330

4-5-5/8

3-4-3/8

3-5-1/8

1 -7

1-1 1/4

0-8-7/8

0-10

1-5-5/8

3/8

0-1

522 576

339 374 374 374

375 380

385 390

60,000 60,000

75,000 75,000

1088 ^ 1200

0 15 0 15

GL036

520/530 1 620/630

576 576

380

390

60,000 60,000

75,000

1200 1200

0 15 0 15

Table 1 — Installation

GH036

320/330 520/5

380 475

390 485

100,000

75,000

1 25,000

583/722f

379/469t

1215

0 15

583/72

379/461

100,00

125,00

475

485

1215

0 15

h(

tAI

or

3/4-in. galvanized pipe,“ or 7/€-in. plastic pipe. Do

not undersize the tube. Pitch drain tube downward

at a slope of at least 1 in. in every 10 ft of horizontal

run. Be sure to check drain tube for leaks.

Condensate water can be drained directly onto

roof in rooftop installations (where permitted) or

onto a gravel apron in ground-level installations.

When using a gravel apron, make sure it slopes

away from unit.

TO DRAIN

Fig. 3 — Condensate Trap

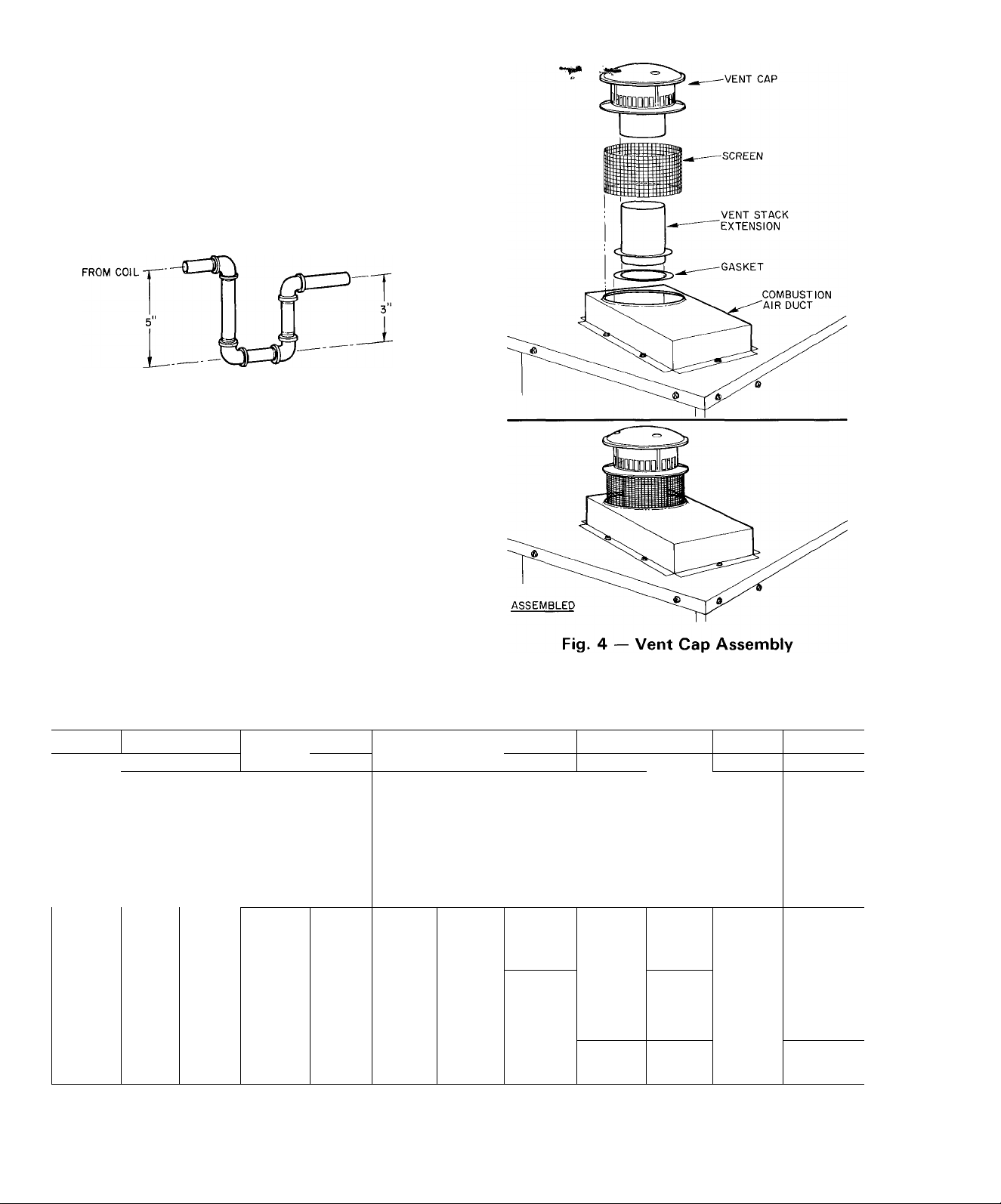

VENTING — The vent cap and combustion-air

duct assemblies are shipped in either the blower or

control compartment. Remove access doors to

locate assemblies. See Fig. 1 for door locations. Vent

stack extension is shipped either in air hole in unit

top or fastened to back of the control box or in

blower compartment.

CAUTION: Venting system is designed to en

sure proper venting. Vent cap assembly must be

installed as indicated in this section of installa

tion Instructions.

allation Data

036

520/530

583/722t

379/469t

475 420 420

485 430 430

100,000

125,000

1215

0 15 0 15 0 15

672 672 672

437 437

60,000

75,000

1400

GL042

5- 5-5/8

3- 8-5/8

3-10-1/8

2-

0

1- 1 -1/4

0- 8-7/8

0-10

1- 6-1/4

1-10-5/8

0- 1

-3/8

520

60,000

75,000

1400

GH042

... “0^

672 768

437 437

440

450

80,000 80,000

100,000 100,000

1400 1400

0 15

440

450

0 15

GL048

320 520

499 499

535

545

80,000

100,000

1600 1600

0 20

80,000

100,000

768

535

545

0 20

620

768

499

535

545

80,000

100,000

1600

0 20

6- 0-3/8

3- 8-5/8

4- 6-1/8

2- 8

-1/4

1- 1

0- 8-7/8

0-10-1/2

1- 3-1/4

2-0-11/16

-3/8

0- 1

GH048

320

768 768

499 499

555 555

565 565

100,000

125,000

1600 1600

0 20 0 20 0 20 0 20

520

100,000

1 25,000

GL060

320/330 320/330

6- 0-3/8

3- 8-5/8

4- 6-1/8

1- 1-1/4

0- 8-7/8

0-10-1/2

1- 6-1/4

2-0-11/16

0- 1-3/8

951

618

575

585 615

100,000 120,000

1 25,000

1981 1981

150,000

GH060

2- 8

951

618

605

mum recommended filter areas when these units have been field converted for operation at maximum rated

heating input

JAH units have a minimum and maximum AGA-certified rated heating input and are manufactured with burner

orifices for heating operation at minimum rating Units may not be derated below this minimum rating

IP

NOTE: Screw holes in vent stack extension and

unit top are positioned to ensure proper orientation

when installed.

Refer to Fig. 4 and install vent cap as follows:

1. Place combustion-air duct over combustion-air

opening in unit top, and line up screw holes in

duct with holes in top. Secure duct to top using

screws with rubber washers (provided).

2. Place gasket and vent stack extension thru hole

in combustion-air duct, orient screw holes in

base of vent stack extension with holes in unit

top, and secure gasket and vent stack extension

to unit top using screws provided.

3. Form flat wire screen (provided) into circular

shape around protruding lip of combustion-air

duct, and bend wire ends thru holes of screen

mesh to secure screen in place. Make sure that

no sharp edges are left exposed.

4. Place vent cap sleeve inside vent stack extension.

Orient spring clip of vent cap with slot in

extension. Be sure that clip snaps into slot to

secure clip onto extension.

Step 2 — Make Gas Piping Connections — The

gas supply pipe enters unit thru access hole pro

vided. See Fig. 1 for location. The gas connection

to unit is made to the 1/2-in. FPT gas inlet on

gas valve.

Install a separate gas supply line that runs

directly from meter to heating section. Do not use

cast-iron or galvanized pipe. Check local utility for

recommendations concerning existing lines. Choose

a supply pipe that is large enough to keep pressure

loss as low as practical. Never use pipe .smaller than

the 112-in. FPT gas inlet on gas valve.

When installing gas supply line, observe local

codes pertaining to gas pipe installations. Refer to

National Fuel Gas Code ANSI Z223.1-1980 in

absence of local building codes. Adhere to pertinent

recommendations.

1. Avoid low spots in long runs of pipe. Grade all

pipe 1 / 4-in. in every 15 ft to prevent traps. Grade

all horizontal runs downward to risers. Use risers;

to connect to heating section and to meter.

2. Support all piping with appropriate hangers, etc.

Use a minimum of one hanger in every 6 feet. For

pipe sizes larger than 1/2 in., follow recom

mendations of national codes.

3. Apply joint compounds (pipe dope) sparingly

and only to male threads of joint when making

pipe connections. Use only pipe dope that is

resistant to action of liquefied petroleum gases

as specified by local and/ or national codes.

Never use Teflon tape.

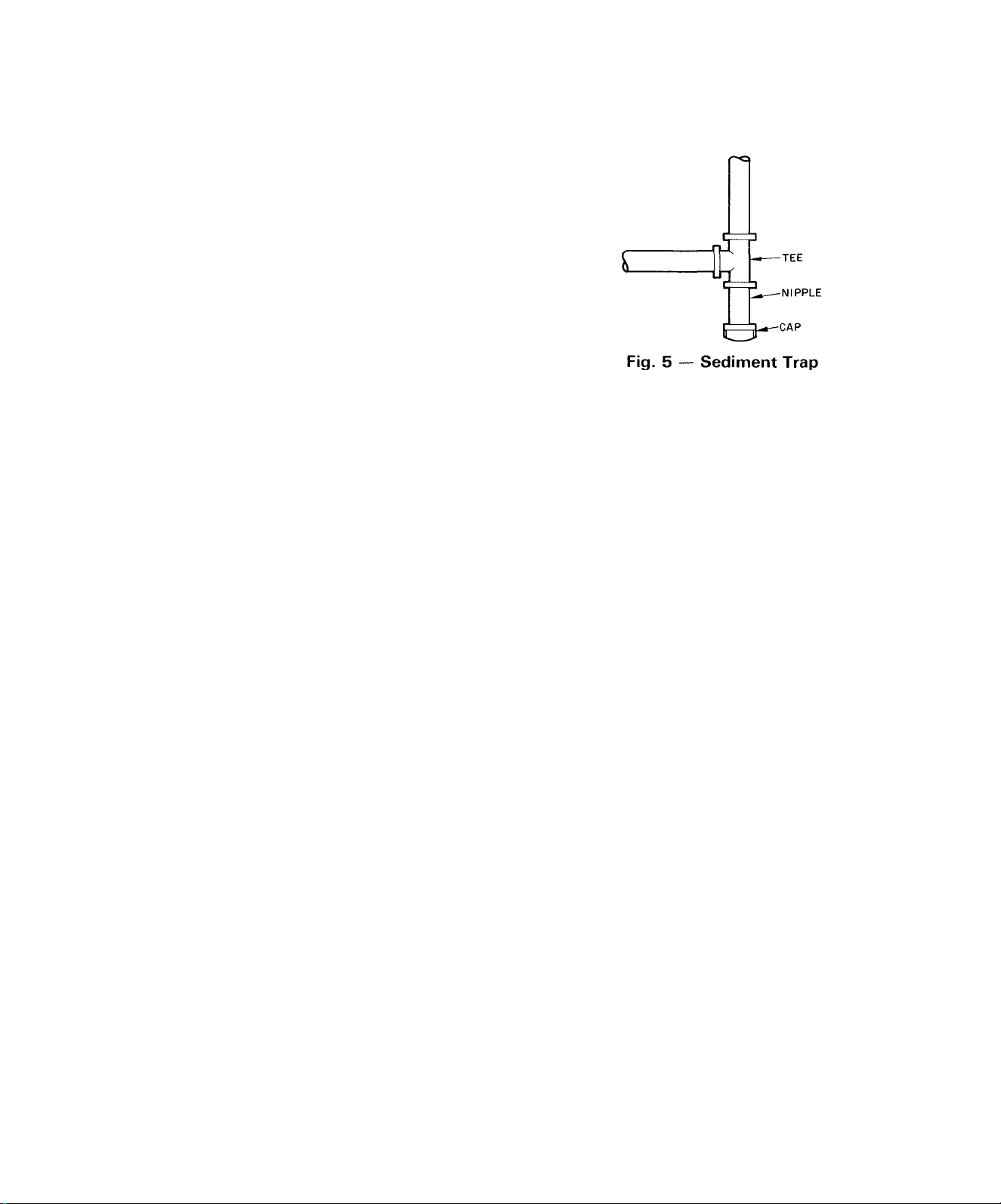

4. Install a sediment trap in riser leading to the

heating section. This drip leg functions as a trap

for dirt and condensate. Install trap where con

densate cannot freeze. Install this sediment trap

by connecting a piping tee to riser leading to

heating section so that straight-thru section of

tee is vertical. See Fig. 5. Then, connect capped

nipple into lower end of tee. Extend capped

nipple below level of gas controls.

5. Install an accessible, external, manual shutoff

valve in gas supply pipe within 6 ft of heating

section. Install a 1/8-in. NET plugged tapping

that is accessible for test-gage connection

immediately upstream of gas supply connection

to heating section.

6. Install ground-joint union close to heating

section between gas valve and external manual

shutoff valve.

CAUTION: Unstable operaiion may occur,

particuiarly under htgh-wind conditions^ when

gas valve and manifold assembly are forced out

of piKiltion while connecting improperly routed

rigid gas piping to gas vaive. Use a backup

wrench when making connection to avoid strain

on, or distortion of, gas control piping.

7. Use flexible gas pipe to make connection between

rigid gas piping and gas valve where permitted

by local codes. Flexible pipe ensures proper

alignment between manifold orifices and burner.

WARNING; Never use a match or other open

flame when checking for gas ieaks„

8. Check for gas leaks at all field-insialled and

factory-installed gas lines after all piping connec

tions have been completed. Use soap-and-water

solution (or method specified by local codes

and/or regulations).

Step 3 — Make Duct Connections — Model

48GH/GL has duct flanges on the supply- and

return-air openings on side of unit. See Fig. 1 for

connection sizes and locations.

W'ARNÌNG: The dc-sign and instailation of duct

system must be in accordance with staodardsof

National Fire PTotectson Associatkm for

Instailatiou of nonresidence-type mr condìtioning and ventiiatmg sysieras, NFPA No. 90;

or residence-type, NFP.ÀNo, 90S; and/or local

codes and ordinances.

Table 2 — Electrical Data

OPER

MODEL

48

GL018

GL024

GH024

GL030

GH030

GL036

GH036

GL042

GH042

GL048

GH048

GL060

GH060

AWG —American Wire Gage

MCA —Minimum Circuit Ampacity

*Maximum Dual Element Size.

tUse only copper wire for field connections to unit. Wire size is

based on 60 C or 75 C copper conductor at 86 F (30 C) ambient

temperature and ampacity shown in table If other than 60 C or

SERIES

320

320

320

320/330 208-230-1

320/330

320/330

520/530

620/630

320/330

520/530

320

520

320

520

320

520

620

320

520

320/330

320/330 230-1

V-PH

208-230-1

208-230-1

208-230-1

208-230-1

208-230-1

208/230-3

460-3

208-230-1

208/230-3

208-230-1

208/230-3 187 253 21 9

208-230-1 197 253

208/230-3 187 253 21.3

230-1 207 253

208/230-3 187 253

460-3 414 506

230-1

208/230-3 187 253

230-1

VOLTAGE

RANGE

Min Max

197

197

197

197

197

197

187

414 506 9 1

197

187

197 253 26.4

207 253

207 253 43.4

207 253

253

253 160

253 17 3

253 19 3

253

253 25 0

253 18 6

253 24.8

253 19 5

TOTAL

AMPS

11 4

19.1

26 2

30 3

26 6

11.7

29 5

24 6

43 7

MAX BRANCH

CIRCUIT FUSE

SIZE (Amps)*

20 13.8

30

30 20 7 10 112

35 23 4 10 100

35

45 30.0 r 10 77

35 21 9 10 121

15 108

45 29 8

35 22.8 10 116

50 31 8 8

40 25.8

50 31 6 8 117

40 25.2 10

60 36 3 8 107

45 30 8 8 135

20

60 35.5 8 110

45 28 8 10

60 52 3 6

60

75 C copper conductor is used, if ambient temperature is above

86F, or if voltage drop of the wire exceeds 2% of total rated

voltage of the unit, determine wire size from ampacity shown

and National Electrical Code (NEC). Wire lengths shown are

measured one way along wire path between unit and service

panel for minimum voltage drop.

MCA

194 12

23 2

135 14 169

52 6 j 6

MIN

WIRE SIZE

(AWG)t

14

10

14

10 78

10 103

MAX WIRE

LENGTH

(ft)t

67

76

101

218

117

106

92

116

116

Adhere to the following criteria when selecting,

sizing, and installing duct system:

1. Select and size ductwork, supply-air registers

and return-air grilles according to Carrier Sys

tem Design Manual, Part 2. System airflow must

he within range of temperature rise and external

static pressure shown on unit AGA rating plate.

CAUTION; When duci-sj'stem fastening boks

are being drilled into side of Model 4M}HfCL

instead of the unit ductnanges, use extreme care

to avoid puncturing coil or coil tubes.

2. Use a flexible transition between rigid ductwork

and unit to prevent transmission of vibration.

The transition may be screwed or bolted to duct

flanges. Use suitable gaskets to ensure a weather

and airtight seal.

3. Install an external, field-supplied air filter(s)

in return-air ductwork where it is easily accessible

for service. Recommended filter sizes are shown

in Table 1.

4. Size all ductwork for maximum required airflow

(either heating or cooling) for unit being in

stalled. Avoid abrupt duct size increases or

decreases.

5. Adequately insulate and weatherproof all duct

work located outdoors. Insulate ducts passing

thru an unconditioned space, and use a vapor

barrier in accordance with latest issue of

SMACNA and NESCA minimum installation

standards for heating and air conditioning

systems. Secure all ducts to building structure.

6. Flash, weatherproof and vibration-isolate all

openings in building structure in accordance

with local codes and good building practices.

Step 4 — Make Wiring Connections

WARNING: Umt cabinet must have an un~

intemipted. unbroken electrical ground to

minimize the possibility of personal injury'

if an electrical fault should occur. Ibis ground

may consist of electrical wire connected to unit

ground lug in control compartment, or conduit

approved for electrical ground when installed in

accordance with National Electrical Code and

local electrical codes. Do not use gas piping

as an electrical ground. A failure to follow this

warning could result in the installer being liable

for the personal injury' of others.

CAUI ION: A failure lo follow' these precau

tions could result in damage to unit being

installed:

1. Make all electrical connections in accordance

with National Electrical Code and local elec

trical codes governing such wiring.

2. Use only copper conductor for connections

between field-supplied electrical disconnect

switch and the unit. Do not use aluminum or

copper-clad aluminum wire.

3. Ensure that high-voltage power to unit is within

operating voltage range indicated on unit rating

plate. On 3-phase units, ensure that phases are

balanced within 2%. Consult the local power

company for correction of improper voltage

and/or phase imbalance.

4. Insulate low-voltage wires for highest voltage

contained within conduit when low-voltage

control wires are run in same conduit as highvoltage wires.

5. Do not damage internal components when

drilling thru any panel to mount electrical

hardware, conduit, etc.

6. Make sure that service conductors used between

the electrical service panel and field-supplied

electrical disconnect switch do not have a current

capacity less than the copper wire specified, and

do not create a total voltage drop in excess of 2%

of rated voltage of the unit.

NOTE: When using aluminum conductor from

electrical service to disconnect switch (where local

codes permit use of aluminum wire), make the

connections in accordance with National Electrical

Code. Prepare all aluminum wire immediately be

fore installation by “brush-scratching” the wire,

then coating the wire with a corrosion inhibitor

(such as Pentrox A). Be sure that entire connection

is completely covered to prevent an electrochemical

reaction that will cause the connection to fail very

quickly. Do not reduce effective size of wire by

cutting off strands to fit wire into a connector.

Always use properly sized connectors.

HIGH-VOLTAGE CONNECTIONS ^ Unit must

have a separate electrical service with a fieldsupplied, waterproof, fused disconnect switch per

NEC mounted at, or within sight from, the unit.

Refer to unit rating plate for maximum fuse size and

minimum circuit amps (ampacity) for wire sizing.

Table 2 shows recommended wire sizes and lengths

based on rating plate data.

The field-supplied disconnect switch box may be

mounted on unit over the high-voltage inlet hole

in control corner panel. See Fig. 1.

WARNING: Label part no, A-74I9ÍB, whickis

shipped loose in bag of parts, must be affixed to

the disconnect switch, box. This iabei states;

“DO NOT DISCONNECT THE ELEC

TRICAL POW'ER TO THIS APPLIANCE

WITHOUT FIRST TURNING OFF THE

GAS SUPPLY ”

1 — Control Transformer

2 — Compressor Contactor

3 — Ground Lug

4 — Dual Run Capacitor

(for compressor and

condenser fan motor)

5 — Low-Voltage Pigtail

Leads

6 — Compressor/Control

Compartment Divider

Panel

7 — Igniter Module

8 — Manual On/Off Knob

9 — Gas Valve Inlet

10 — Pipe Plug —

LP (Propane) unit

pressure switch

mounts here

Fig. 6 — Model 48GL036 — Side View

(Partial) with Access Doors Removed

11 — Pilot Tube

12 - Model 646A-X

Gas Valve

13 — Pressure Tap Pipe Plug

14 — Gas Valve Outlet

15 — Gas Manifold

16 — Gas Burner

17 — Burner Air Shutter

18 — Secondary-Air Shield

19 — Blower Housing

20 — Evaporator Motor

Run Capacitor

21 — Blower/Control

Compartment Divider

Panel

22 — Heating Relay

23 — Cooling Relay

Proceed as follows to complete the high-voltage

connections to unit:

1. Connect ground lead to chassis ground connec

tion when using a separate ground wire.

2. Run high-voltage leads with field-supplied

conduit into unit control box and connect to

contactor. See unit wiring label, and Fig. 6

and 7.

NOTE: On 3-phase units, connect third high-voltage

lead to brown high-voltage pigtail lead. See unit

wiring label and Fig. 7.

SPECIAL PROCEDURES FOR 208-V

OPERATION

WARNING; Make stire that power supply to

«iut k switched OFF before ruakipg any wiring

changes.

Loading...

Loading...