Page 1

48/50HG014---028, 48/50PG20---28

Single---Package Rooftop Units

with COMFORTLinkt and Electro ---Mechanical Controls

Return and Supply Smoke Detector s Acces s ory

Installation Instructions

PART NO. CRSM KDET001D00, CRSMKSUP001B00, CRSMKSEN001A00

TABLE OF CONTENTS

GENERAL 1........................................

SAFETY CONSIDERATIONS 1........................

INSTALLATION 2...................................

Check Package Contents 2...........................

Return Air Smoke Detector Installation 2...............

Supply Air Smoke Detector Installation 5...............

Sensor Installation 7...............................

Configuring the ComfortLinkt Controller 8............

OPERATION 8......................................

MAINTENANCE 9...................................

Cleaning Procedure 9..............................

Recommended Service Schedule 9....................

Sensor Tests 9....................................

Controller T ests 9..................................

TROUBLESHOOTING 10.............................

Dirty LED 10....................................

Power LED 10....................................

Trouble LED 10..................................

IMPORTANT: There are two different design revision 48/50HG

units that have been produced. Because of these differences, there

are two different versions of this accessory. This accessory

literature covers accessories manufactured for units with design

revision 1. This revision designator is found in the 13th digit of

the unit model number located on the units’ rating plate. Design

revision 0 units are not covered in this accessory book.

To determine the design revision, refer to the full unit model

number. See Fig. 1 for an example of an HG model number. The

design revision number in the model number nomenclature is

located in position 13.

DESIGN REVISION NUMBER

Position No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Example: 4 8 H G D 0 1 6 A A C 6 1 1 A A

C07172

Fig. 1 --- Model Number Chart

GENERAL

An HVAC (heating, ventilation and air-conditioning) system

supplies conditioned air to virtually every area of a building.

Smoke introduced into this air duct system will be distributed

throughout the entire building. Smoke detectors designed for use

inside the unit are used to sense the presence of smoke passing

through the unit.

The smoke detector utilizes photoelectric technology for the

detection of smoke. This detection method, when combined with

an efficient ducting design, samples air passing through the unit.

If sufficient smoke is sensed, an alarm signal is initiated and the

ComfortLink controls will shut down the unit. With the unit shut

down, the unit will not blow toxic smoke and fire gases

throughout the areas served by the duct system.

The return air smoke detector is part number

CRSMKDET001D00, which includes a Smoke Sensor and a

Smoke Control Module combined with sampling tube, harnesses

and hardware. The supply air smoke detector is part number

CRSMKSUP001B00, which includes a Smoke Sensor and a

Smoke Control Module combined with sampling tube, harnesses

and hardware. Part number CRSMKSEN001A00 is a Smoke

Sensor only for use as a second (Supply with existing Return, or

Return with existing Supply) Air Smoke Detector with sampling

tube, harnesses and hardware.

The Control Module can be attached to a Smoke Sensor and

installed as an assembled unit, or it can be installed separate from

a sensor. One Controller can be used to control up to two

detectors (Smoke Sensors).

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install, repair,

or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance functions

of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

care when handling and installing the accessory.

Recognize safety information. This is the safety--alert symbol

. When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

1

Page 2

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. W ARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

!

FIRE HAZARD

Failure to follow this warning could cause personal

injury and/or equipment damage.

This device will not sense smoke unless the ventilation

system is operating and the cover is installed.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

Disconnect all power to the unit before performing

maintenance or service. Install Lock Out tags on

disconnects or breakers.

CRSMK

!

FIRE HAZARD

Failure to follow this warning could cause personal

injury and/or death.

The National Fire Protection Association has

established that DUCT DETECTORS MUST NOT BE

USED AS A SUBSTITUTE FOR OPEN AREA

DETECTOR PROTECTION as a means of providing

life safety. Nor are they a substitute for early warning in

a building’s regular fire detection system. Carrier

supports this position and strongly recommends that the

user read NFPA Standards 90A, 72, and 101. This

smoke detector is listed per UL 268A.

!

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could cause personal

injury.

This device will not operate without electrical power.

Fire situations may cause an interruption of power. The

system safeguards should be discussed with your local

fire protection specialist.

WARNING

WARNING

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury and/or equipment damage.

For this detector to function properly, it MUST be

installed according to the instructions in this manual.

The detector MUST be operated within ALL electrical

and environmental specifications listed in this manual.

Failure to comply with these requirements may prevent

the detector from activating when smoke is present in

the air duct.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

When installing the smoke detector in the unit, follow all

local codes.

Check Package Contents

Remove accessory packaging and inspect shipment for damage.

If any damage is found, file a claim with the shipping agent

immediately. If any item is missing or any part does not assemble

properly, notify the Carrier distributor.

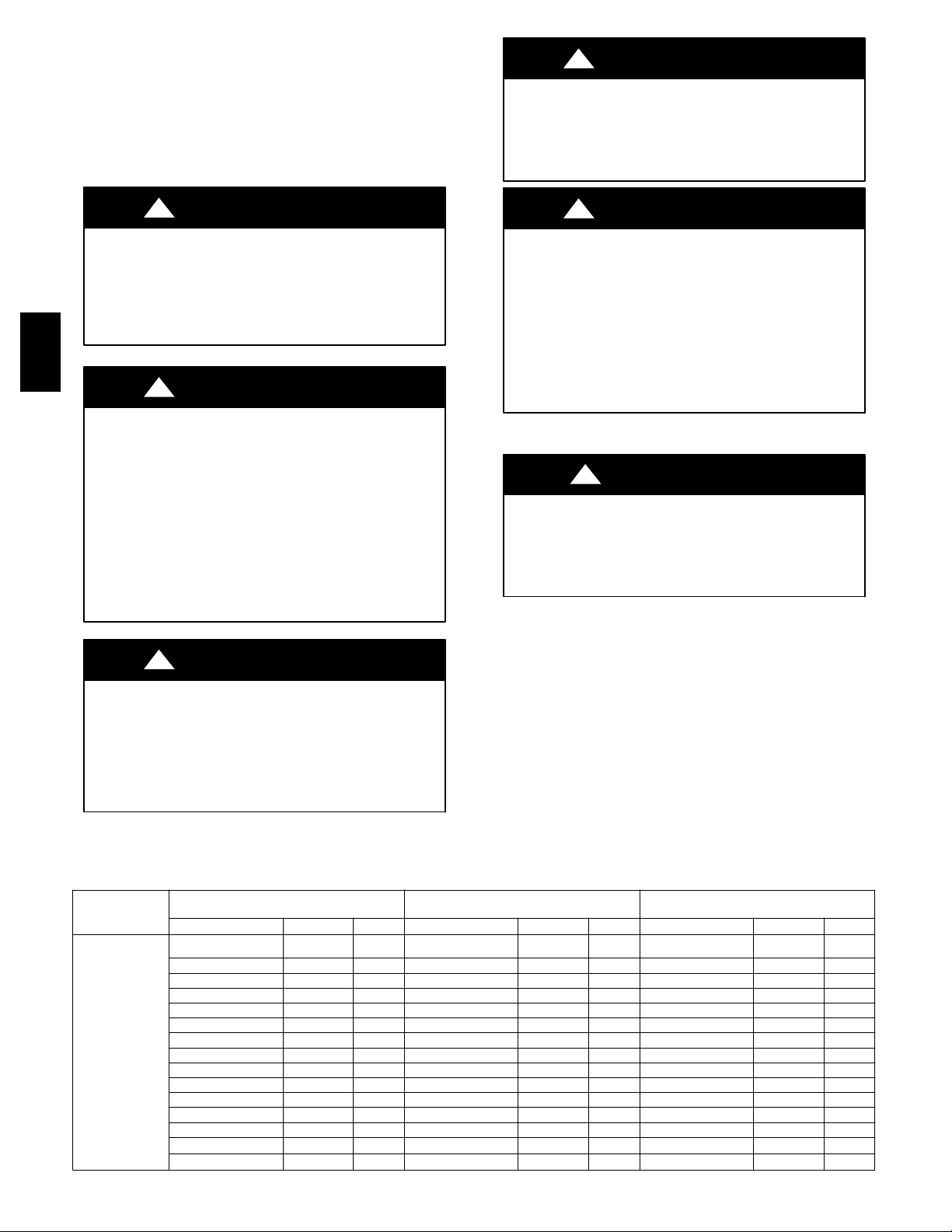

Table 1 lists the accessory package contents. Fig. 2 shows the

smoke detector.

Return Air Smoke Detector Installation

(CRSMKDET001D00)

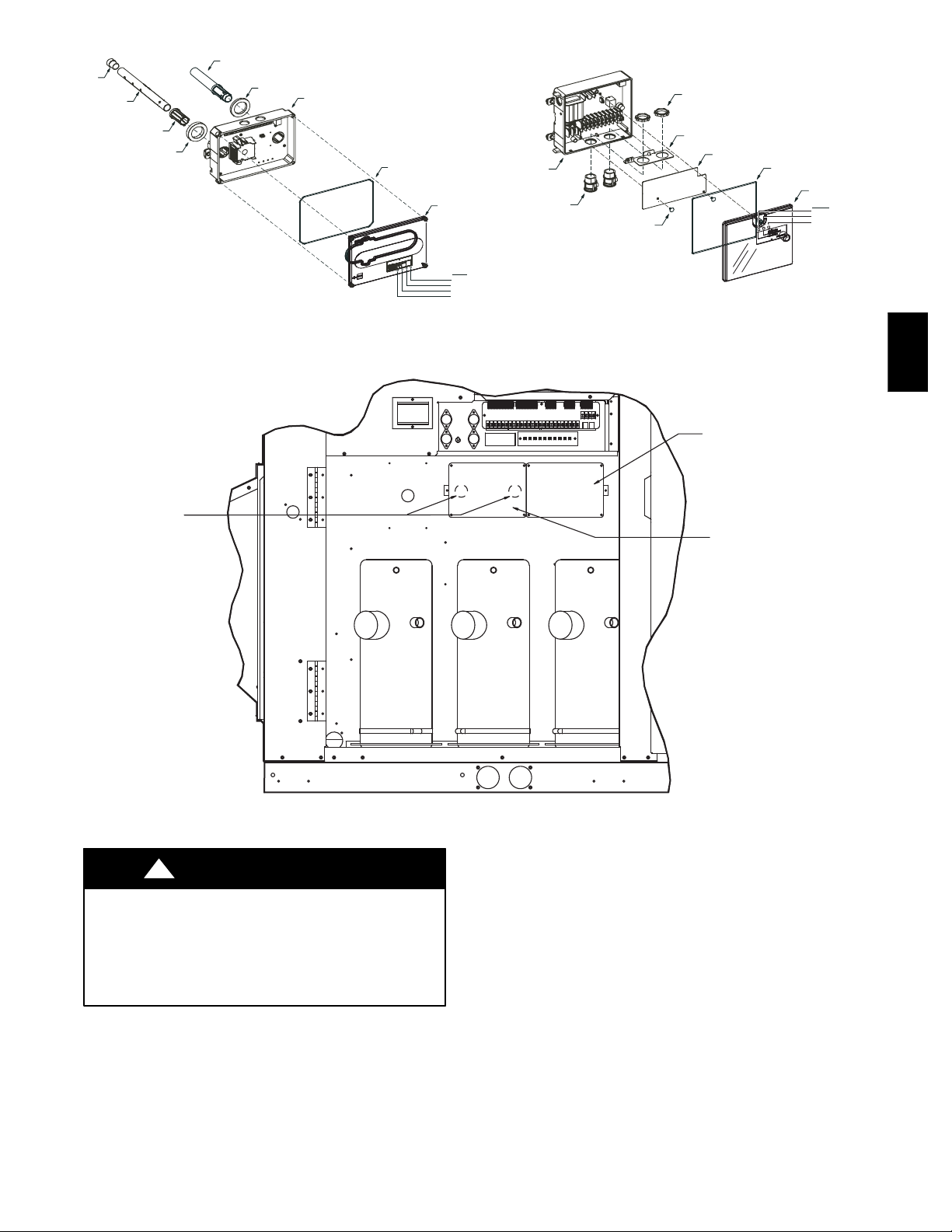

The return air smoke detector is to be installed in the predrilled

holes located above compressor B1/A2 in the

electrical/compressor section. (See Fig. 3.)

!

WARNING

INSTALLATION

!

CAUTION

UNIT

48/50HG014-028,

48/50PG20-28

Table 1—Accessory Package Contents — Return Air Smoke Detector (CRSMKDET001D00),

Supply Air Smoke Detector (CRSMKSUP001B00), Sensor (CRSMKSEN001A00)

RETURN SMOKE DETECTOR

CRSMKDET001D00

Description Part Number Quantity Description Part N umb er Quantity Description Part Numbe r Quantity

Sensor/Controller/

Harness/Tube

Screw AL56AU168 2 Screw AL56AU168 5 Screw AL56AU168 1

Screw AL48AM397 2 Sensor Module HK50ZT001 1 Screw AL48AM397 2

Bracket 50TG501113 1 Tube RN20ZT008 1 Bracket 50TG501113 1

Large Bushing HY93NH085 1 Cable Assy RM91ZT015 1 Large Bushing HY93NH085 1

Sampling Tube RN20ZT060 1 Plug — 1 Sampling Tube RN20ZT060 1

Plug — 1 Rubber Gasket — 2 Plug — 1

Rubber Gasket — 2 Sampling Tube Collar — 1 Rubber Gasket — 2

Sampling Tube Collar — 1 Snap-in Wire T ie HY76TB110 2 Sampling Tube Collar — 1

Wire Tie HY76TB125 1 Wi re Tie HY76TB125 2 Tub e RN20ZT008 1

Bushing HY93NH069 1 Bushing HY93NH069 1 Cable Assy RM91ZT015 1

Harness Assy 50TG403507 1 Harness Assy 50TG403507 1 Snap-in Wire T ie HY76TB110 5

Exhaust Tube — 1 Exhaust Tube — 1 Wire Tie HY76TB125 1

HK61ZT001 1

SUPPLY SMOKE DETECTOR

CRSMKSUP001B00

Controller/

RJ-45 Harness

HK28ZT001 1 Sensor Module HK50ZT001 1

2

ADDITIONAL SENSOR

CRSMKSEN001A00

Cable Assy RM91ZT001 1

Exhaust Tube — 1

Page 3

Plug

Sampling tube

Exhaust tube

Rubber gasket

Sensor housing

and electronics

Conduit nuts

( field supplied )

Collar

Rubber

gasket

Smoke Sensor

PLUG LOCATION

Cover gasket

(ordering option)

Sensor cover

LEDs

Power

Dirty

Trouble

Alarm

Controller housing

and electro nics

Conduit cou plings

( field supplied )

Fig. 2 --- Smoke Detector

Fastener

(2X)

Smoke Control Module

Conduit sup port plate

Terminal block cover

Cover gasket

(ordering option)

SMOKE CONTROL MODULE

RETURN SMOKE SENSOR

Controll er cover

LEDs

Alarm

Trouble

Power

C07173

CRSMK

Fig. 3 --- Return Air Smoke Detector Location

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury and/or death.

Prior to installation of this accessory, make sure all

power is disconnected to the unit and locked out and

tagged.

NOTE: For horizontal applications it is easiest to install the

smoke detector prior to making duct connections.

1. Open the hinged electrical/compressor access door and

secure.

2. Find the 2 plugs located above compressor B1/A2,

remove and discard. Cut holes in the insulation located behind the partition.

A1B1/A2C1/B1

C07174

3. Remove cover from smoke detector. The screws will

remain captured in the cover.

4. Slide exhaust tube into the sensor. The exhaust tube

should be inserted from the back of the sensor, into the

hole with four slots, and locked into place. (See Fig. 2.)

5. Slide smoke detector into holes in partition with the terminal block to the right. Do not secure at this time.

6. Slide the sampling tube collar over the sampling tube until the tabs lock into the tube. (See Fig. 2.)

7. Slide long sampling tube (P/N RN20ZT060) into left-hand hole of smoke detector. It might be necessary to tilt

the smoke detector upwards in order to properly align the

sampling tube, making sure that the sampling holes

point DOWN. (See Fig. 4.)

8. Install plug into far end of sampling tube.

9. Remove the unit side panel at the return end of the unit.

Save screws for use later.

3

Page 4

10. Mount the sampling tube support bracket to the

cross member with two 1/4AB-14 5/8-in. screws

(P/N AL48AM307) as shown in Fig. 5. Insert large snap

bushing (P/N HY93NH085) into hole in bracket.

11. Slide sampling tube into bracket. (See Fig. 4.) Pull the

sampling tube so that the locking collar snaps into the

smoke detector.

12. Attach smoke detector to partition using two, 8-18 3/4-in.

pan head screws (P/N AL56AU168).

NOTE: This step is not needed with 48/50PG Humidi--MiZert

units because they have plug 19 harness already installed in the

control box. The harness assembly part number 50TG403507

that came with the accessory is not used. Factory installed PL--19

can be located outside the contol box by its appropriate label. For

Humidi--MiZer smoke detector wiring refer to Fig. 8.

16. Connect PL-19 from the smoke detector control module to

the PL-19 on the control box harness installed in Step 15.

NOTE: On 48PG Humidi--MiZer units the control box harness

has a jumper plug attached. This needs to be disconnected so

!

CAUTION

PL--19 from the smoke detector can be snaped in.

17. Restore power to the unit.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Do not overtighten the screws.

13. Replace the unit side panel.

14. Install the snap bushing (P/N HY93NH069) in the center

CRSMK

knockout underneath the control terminal strips located in

the bottom right-hand corner of the control box.

18. Configure ComfortLink controller as specified in Con-

figuring the ComfortLink Controller.

19. Perform Sensor and Controller tests. At a minimum, the

Magnet test should be performed to verify smoke detector

wiring.

20. Replace smoke detector cover.

21. Check for alarms. Correct any problems.

15. Feed wires through snap bushing and connect to appropriate terminals as shown in Fig. 6 for ComfortLinkt units

or Fig. 7 for Electro--Mechanical units.

INSTALL SUPPLY SENSOR TUBE

WITH HOLES POINTING

UP

INSTALL RETURN SENSOR TUBE

WITH HOLES POINTING

DOWN

BRACKET

BUSHING

Fig. 4 --- Supply and Return Sensor Tube

INSTALL RETURN EXHAUST

TUBE HERE

C07175

4

Page 5

SAMPLING TUBE

SUPPORT BRACKET

CRSMK

C07176

Fig. 5 --- Sampling Tube Support Bracket

PL19

Fig. 6 --- Return and Supply Air Smoke Detector Wiring on ComfortLink Units

Supply Air Smoke Detector Installation

(CRSMKSUP001D00)

The supply air smoke detector is to be installed in the predrilled

holes located on the front of the first indoor blower. (See Fig. 9.)

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury and/or death.

Prior to installation of this accessory, make sure all

power is disconnected to the unit and locked out and

tagged.

WARNING

CUT OFF CONNECTOR, LABELED TB3-5, ON ORN WIRE

C07177

1. Open the indoor fan access door and secure.

2. Open and secure hinged electrical/compressor access door.

3. Disconnect wires located on the right-hand side of the fan

deck. On gas heat units, the indoor fan plug and the limit

switch quick connects must be disconnected. On units

without gas heat, only the indoor fan plug must be

disconnected.

4. Find the 2 plugs located in the blower side plate. Remove

the plugs and discard. It will be necessary to remove some

of the tape holding the plugs in place.

5. Remove cover from smoke detector. The screws will

remain captured in the cover.

5

Page 6

CRSMK

C07178

Fig. 7 --- Smoke Detector Wiring on Electro--Mechanical Control Units

Fig. 8 --- 48/50PG Humidi--MiZert Smoke Detector Wiring

6

C07179

Page 7

6. Slide the sampling tube collar over the sampling tube

until the tabs lock into the tube.

7. Slide sampling tube into smoke detector with eight slots.

Make sure sampling tube holes are aligned facing UP.

8. Insert plug into far end of the sampling tube.

9. Place rubber gaskets over each sampling tube on smoke

detector. (See Fig. 2.)

10. Remove one knockout from top of smoke detector.

11. Insert one end of RJ-45 wire harness through knockout

and wire to smoke detector as shown in Fig. 10.

12. Slide smoke detector into holes in fan side plate with

the terminal block at the top and secure using two,

3

/4-in. pan head screws (P/N AL56AU168). Replace

8-18

cover.

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Do not overtighten the screws.

13. Attach cable to fan side plate using snap-in wire ties.

See Fig. 9 for clarification. Secure to center post.

14. Secure cable to back side of cable tray using three snap-in

wire ties.

15. In the Electrical/Compressor section, install snap bushing

in the center knockout underneath the terminal strips located in the bottom right-hand corner of control box.

16. Connect wires to terminal strips as shown in Fig. 6 for

ComfortLinkt units or Fig. 7 for Electro--Mechanical

Units.

NOTE: This step is not needed with 48/50PG Humidi--MiZert

units because they have plug 19 harness already installed in the

control box. The harness assembly part number 50TG403507

that came with the accessory is not used. Factory installed PL--19

can be located outside the contol box by its appropriate label. For

Humidi--MiZer smoke detector wiring refer to Fig. 8.

17. Remove cover from control module and remove knockout

from side of module nearest the RJ-45 connector.

18. Using three 8-18

(P/N AL56AU168) screws, secure control module to compressor partition above compressor B1/A2 location.

19. Connect PL-19 from control module to PL-19 from wiring harness installed in Step 16.

NOTE: On 48PG Humidi--MiZer units, the control box harness

has a jumper plug attached. This needs to be disconnected so

PL--19 from the smoke detector can be snapped in.

3

/4-in. pan head screws

20. Route cable from supply smoke sensor, along the outside

of the control box, through the control module knockout

and connect to the J1 RJ-45 connector.

21. Using wire ties, secure the wiring so it does not interfere

with unit operation.

22. Replace control module cover.

23. Restore power to the unit.

24. Configure ComfortLink controller as specified in Config-

uring the ComfortLink Controller below.

25. Perform Sensor and Controller tests. At a minimum, the

Magnet test should be performed to verify smoke detector

wiring.

26. Turn off power to the unit.

27. Reconnect the indoor fan plug and the limit switch wires if

applicable.

28. Close the indoor fan section door.

29. Restore power to the unit and check for alarms. Correct

any problems encountered.

30. Close Electrical/Compressor section door.

Sensor Installation (CRSMKSEN001A00)

When adding return smoke sensor to previously installed supply

smoke detector:

1. Open electrical/compressor section access door/panel.

2. Disconnect PL-19 from control module to terminal strip

by separating plug connectors.

3. Remove control module cover. Disconnect supply sensor

RJ-45 wire from control module.

4. Remove three screws attaching control module to compressor partition and save screws for later use.

5. Remove control module from unit.

6. Slide feet of control module into receptacle on the return

sensor housing and secure from the backside using one

screw removed in Step 4. The J1 RJ-45 connector on sensor should be nearest the control module. Knockout holes

should align. (See Fig. 11.)

7. Route short RJ-45 wire from J1 connector of sensor,

through knockout holes, and connect to J1 connector of

control module.

8. Follow steps 2-20 of instructions for installing return

smoke detector.

IMPORTANT: Step 15 requires connecting the supply smoke

sensor RJ--45 wire to connector J2 in the control module.

When adding supply smoke sensor to previously installed return

smoke detector:

Follow steps 1-14 and 19-29 from supply smoke detector

installation instructions.

CRSMK

7

Page 8

SMOKE DETECTOR

WIRE TIES

CRSMK

C07180

Fig. 9 --- Supply Smoke Detector Location and Wire Routing (Top View)

RJ-45 HARNESS

INSTALL CONTROL

MODULE HERE

USING THREE SCREWS

CUT TAPE BEFORE

INSERTING SMOKE DETECTOR.

ROUTE RJ-45 HARNESS ALONG

SMOKE POWER HARNESS

THRU BOX, AND OUT

AS SHOWN TO

SUPPLY SMOKE DETECTOR

PUNCH OUT KNOCK OUT

PLUG

Fig. 10 --- Supply Control Module Installation (Side View)

Configuring the ComfortLinkt Controller

Configuration settings for the ComfortLink controller are

changed by using the Scrolling Marquee display. A password

may be required to edit the configurations, depending on the

previous settings configured in the unit. Default password is

“1111.” Use the arrow keys to scroll the red LED on the display

ENTER

again. Press

.Scroll

.After

to the “Configuration” position and press

ENTER

through the menu until UNIT is found and press

reaching the UNIT sub-menu, scroll to FS.SW (Fire Shutdown

Input) and press

ENTER

Open) with the arrow keys, press

ESCAPE

three times to return to the top level of the menu.

twice, change the value to 1 (Normal

ENTER

Additional information about changing configurations can be

found in the Control and Troubleshooting Guide for 48/50HG

and 48/50PG units.

OPERATION

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the

unit.

The smoke detector must be tested and maintained regularly

following NFPA 72 requirements. The smoke detector

should be cleaned at least once a year.

8

C07181

Page 9

The smoke detector contains a photoelectric detector approved

for an extended air speed range of 100 to 4000 feet per minute

and an operational temperature range of -4_ to 158_F. Do not

operate the smoke detector out of these ranges.

The smoke detector operates on 24 vac, 120 vac, or

220/240 vac. The thermostat power terminals on the unit are used

to power the smoke detector.

The cover of the controller contains the Alarm, Trouble, Dirty

and Power LEDs. The cover of the sensor contains the Alarm,

Trouble and Power LEDs. (See Fig 2.)

The smoke detector can be reset by a momentary power

interruption, by the reset button on the front cover, by the control

panel, or by the remote reset accessory.

E

CONTROL MODULE

J2

CONTROL MODULE

J2

SECURE FROM BEHIND

WITH SCREW

J1

J1

TERMINAL STRIP

C07182

RETURN SENSOR

S

RETURN SENSOR

S

J1

E

J1

Fig. 11 --- Sensor Installation

HVAC duct

Sensor

housing

Optic

plate

Retainer

clip

Optic

housing

C07183

Airflow

Sampling

tube

Fig. 12 --- Sensor Cleaning Diagram

3. Squeeze the retainer clips on both sides of the optic housing then lift the housing away from the printed circuit

board.

4. Gently remove dirt and debris from around the optic plate

and inside the optic housing.

5. Replace the optic housing and sensor cover.

6. Connect power to the duct detector then perform a sensor

alarm test.

Recommended Service Schedule

Visually inspect each sensor connected to the controller

S

upon installation and once every 6 months thereafter.

S Perform a sensor alarm test on each sensor connected

to the controller upon installation and once every

12 months thereafter.

S Perform a sensor dirty test upon installation and once

every 6 months thereafter or more frequently, as

conditions warrant.

Sensor Tests

Sensor Alarm Test

The sensor alarm test checks a sensor’s ability to signal an alarm

state. This test requires the use of a SD-MAG test magnet.

IMPORTANT: This test places the duct detector into the alarm

state. Unless part of the test, disconnect all auxiliary equipment

from the controller before performing the test. If duct detector is

connected to a fire alarm system, notify the proper authorities

before performing the test.

To perform a sensor alarm test:

1. Hold the test magnet where indicated on the side of the

sensor housing for seven seconds. Verify that the sensor’s

Alarm LED turns on.

2. Reset the sensor by holding the test magnet against the

sensor housing for two seconds. Verify that the sensor’s

Alarm LED turns off.

Sensor Dirty T

The sensor dirty test provides an indication of the sensor’s ability

to compensate for gradual environmental changes. A sensor that

can no longer compensate for environmental changes is

considered 100% dirty and requires cleaning or replacing. This

test requires the use of a SD-MAG test magnet.

To perform a sensor dirty test, hold the test magnet where

indicated on the side of the sensor housing for seven seconds.

Verify that the sensor’s Dirty LED flashes.

IMPORTANT: Holding the test magnet against the sensor

housing for longer than 7 seconds will put the duct detector into

the alarm state and activate all automatic alarm responses.

The sensor’s Dirty LED indicates the results of the dirty test as

shown below.

est

CRSMK

MAINTENANCE

IMPORTANT: Notify the proper authorities that the smoke

detector system is undergoing maintenance, and that the system

will temporarily be out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

Cleaning Procedure

1. Disconnect power from the duct detector then remove the

sensor’s cover.

2. Using a vacuum cleaner, clean compressed air, or a soft

bristle brush, remove loose dirt and debris from inside the

sensor housing and cover. (See Fig 12.)

Use isopropyl alcohol and a lint-free cloth to remove dirt

and other contaminants from the gasket on the sensor’s

cover.

FLASHES DESCRIPTION

1

2 26 to 50% dirty

3 51 to 75% dirty

4 76 to 99% dirty

0 to 25% dirty. This is typical on a newly installed duct

detector.

Controller Tests

Controller Alarm Test

The controller alarm test checks the controller’s ability to initiate

and indicate an alarm state

IMPORTANT: This test places the duct detector into the alarm

state. Unless part of the test, disconnect all auxiliary equipment

from the controller before performing the test. If duct detector is

connected to a fire alarm system, notify the proper authorities

before performing the test.

9

.

Page 10

To perform a controller alarm test:

1. Press the controller’s test/reset switch for seven seconds.

Verify that the controller’s Alarm LED turns on.

2. After performing a controller alarm test, reset the sensor

by pressing the test/reset switch for two seconds. Verify

that the controller’s Alarm LED turns off.

Controller Dirty T

est

The controller dirty test checks the controller’s ability to initiate a

sensor dirty test and indicate its results.

To perform a sensor dirty test, press the controller’s test/reset

switch for two seconds. Verify that the controller’s Trouble LED

flashes.

TROUBLESHOOTING

Dirty LED

Sensor’s Dirty LED is Flashing

Clean the sensor assembly as described in Cleaning Procedure.

Power LED

Sensor’s Power LED is OFF

CRSMK

1. Check the controller’s Power LED. If it is off, determine

why the controller does not have power and make the

necessary repairs.

2. Check the wiring between the sensor and the controller. If

wiring is loose or missing, repair or replace as required.

Controller’s Power LED is

1. Make sure the circuit supplying power to the controller is

operational. If not, make sure JP2 and JP3 are set correctly

on the controller before applying power.

OFF

2. Verify that power is applied to the controller’s supply input terminals. If power is not present, replace or repair wiring as required.

Trouble LED

Controller’s Trouble LED is On

1. Check the Trouble LED on each sensor connected to the

controller. If a sensor’s Trouble LED is on, determine the

cause and make the necessary repairs.

2. Check the wiring between the sensor and the controller. If

wiring is loose or missing, repair or replace as required.

Controller’s Trouble LED is

1. One or both of the sensors is 100% dirty. Determine which

sensor’s Dirty LED is flashing.

2. Clean the sensor assembly as described in Cleaning

Procedure.

Sensor’s Trouble LED is

1. Check the sensor’s Dirty LED. If it is flashing, the sensor

is dirty and must be cleaned.

2. Check the sensor’s cover. If it is loose or missing, secure

the cover to the sensor housing.

3. Replace sensor assembly.

Sensor’s Trouble LED is On But Controller’s Trouble LED

Off

Remove JP1 on the controller.

Flashing

On

is

Copyright 2007 Carrier Corp. S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the r ight to change, at any time, specifications and designs without notice and without obligations.

Printed in U.S.A. Edition Date:7/07

10

Catalog No:48/50H,P--- 24SI

Replaces:48/50H,P--- 10SI

Loading...

Loading...