Page 1

COBRA™ Energy Recovery Units

48/50HJ004-014 with 62AQ060-300

Single-Package Rooftop Units

with Energy Recovery Capability

Installation, Start-Up,

and Service Supplement

IMPORTANT: This is a supplemental instruction for the

48/50HJ and the 62AQ Installation, Start-Up and Service

Instructions. It is not intended to take the place of either

instruction o r to be a com plete piec e in itse lf.

CONTENTS

SAFETY CONSIDERATIONS

GENERAL

INSTALLATION

Step 1 — Inspect Shipment

Step 2 — Provide Unit Support

•ROOF CURB

Step 3 — Field Fabricate Ductwork

Step 4 — Rig and Place Unit

• POSITIONING

Step 5 — Install Flue Hood (48HJ Only)

Step 6 — Install Gas Piping (48HJ Only)

Step 7 — Install External Trap for Condensate

Drain

Step 8 — Make Electrical Connections

• FIELD POWER SUPPLY

• FACTORY-SUPPLIED NON-FUSED

DISCONNECT

• FIELD CONTROL WIRING

• HEAT ANTICIPA T OR SETTINGS

Step 9 — Assemble and Mount

Supply-Air Hood

Step 10 — Mount the Barometric Relief Damper

Step 11 — Set the Outdoor Cooling and

Heating Thermostats

LIGHT COMMERCIAL THERMIDISTAT

ACCESSORY

General

Power

Dehumidification Equipment and Connections

Step 1 — Select Light Commercial

Thermidistat Location

Step 2 — Set DIP Switches

Step 3 — Install Light Commercial Thermidistat

Step 4 — Set Light Commercial Thermidistat

Configuration

Step 5 — Conduct Light Commercial

Thermidistat Start-Up and Checkout

Step 6 — Make Final Settings

OPERATIONAL INFORMATION

PRE-START-UP

START-UP

SERVICE

TROUBLESHOOTING

ROOFTOP UNIT AND ENERGY$RECYCLER2

START-UP CHECKLIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-37

. . . . . . . . . . . . . . . . . . . . . . . . . 38-41

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . 11

. . . . . . . . . 11

. . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . CL-1, CL-2

Page

. . 28

. . . 30

. . 31

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe precautions in the li terature, t ags and labe ls attached to the uni t, and

other safety precautions that apply.

Verify that the power source supplied to the unit matches

the voltages and amperages listed on the unit rating plate.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations. Have

fire extinguishers available for all brazing operations.

Disconnect gas piping from unit when leak

testing at pressure greater than 1/2 psig. Pressures greater than 1/2 psig will cause gas

valve damage resulting in hazardous condition. If gas valve is subjected to pressure

greater than

before use. When pressure testing fieldsupplied gas piping at pressures of

less, a unit connected to such piping must be

isolated by manually closing the gas valve.

Before performing service or maintenance operations on

unit, turn off main power switch to unit and install a lockout tag. Electrical shock could cause personal injury.

1

/2 psig, it must be replaced

1

/2 psig or

GENERAL

Carrier’s factory-installed optional COBRA Energy Recovery units precondition ventilation air for the rooftop unit during

winter and summer operation and recover energy from the

building exhaust air. These units are designed to satisfy the

higher ventilation requirements and other building codes while

minimizing energy costs.

Factory installation of the energy recovery section provides

the benefit of reduced field-installation time, single point power connections, and the assurance of a factory test for the complete COBRA Energy Recovery unit. The energy recovery section requires less maintenance than other energy recovery

systems and can be serviced by any qualified refrigeration

technici an .

NOTE: Because of the location of the energy recovery section,

the unit nameplate has been moved to the opposite end of the

rooftop section, on the upper, right-hand part of the panel.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1144

Tab 1a1b6a6b

PC 111 Catalog No. 534-80122 Printed in U.S.A. Form 48/50HJ,62AQ-2SIS Pg 1 9-02 Replaces: 48/50HJ,62AQ-1SIS

Page 2

INSTALLATION

Step 1 — Inspect Shipment —

shipping company if shipment is inco mplete or damaged. See

Fig. 1 for a typical shipping packa ging for a COBRA™ energy

recovery unit.

File a claim with the

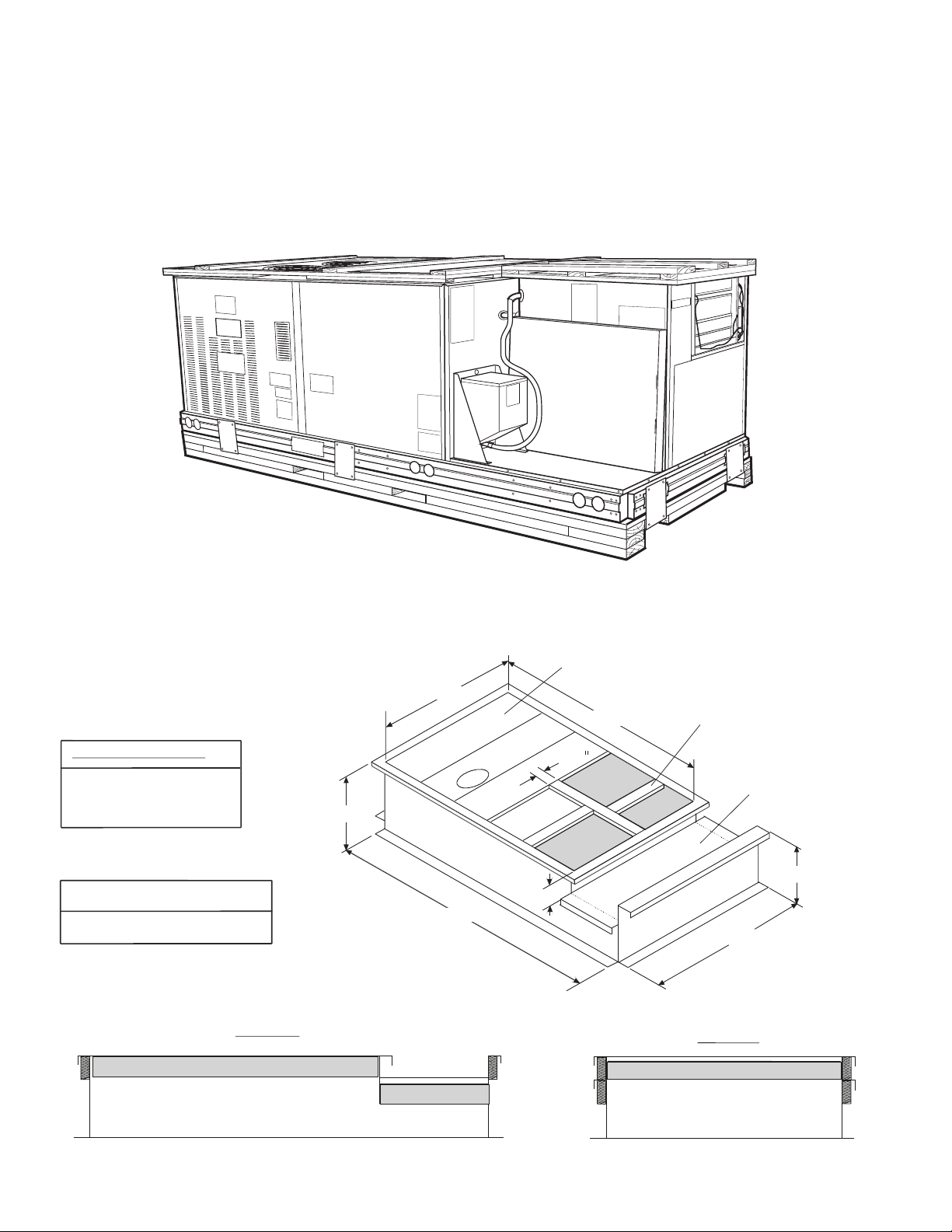

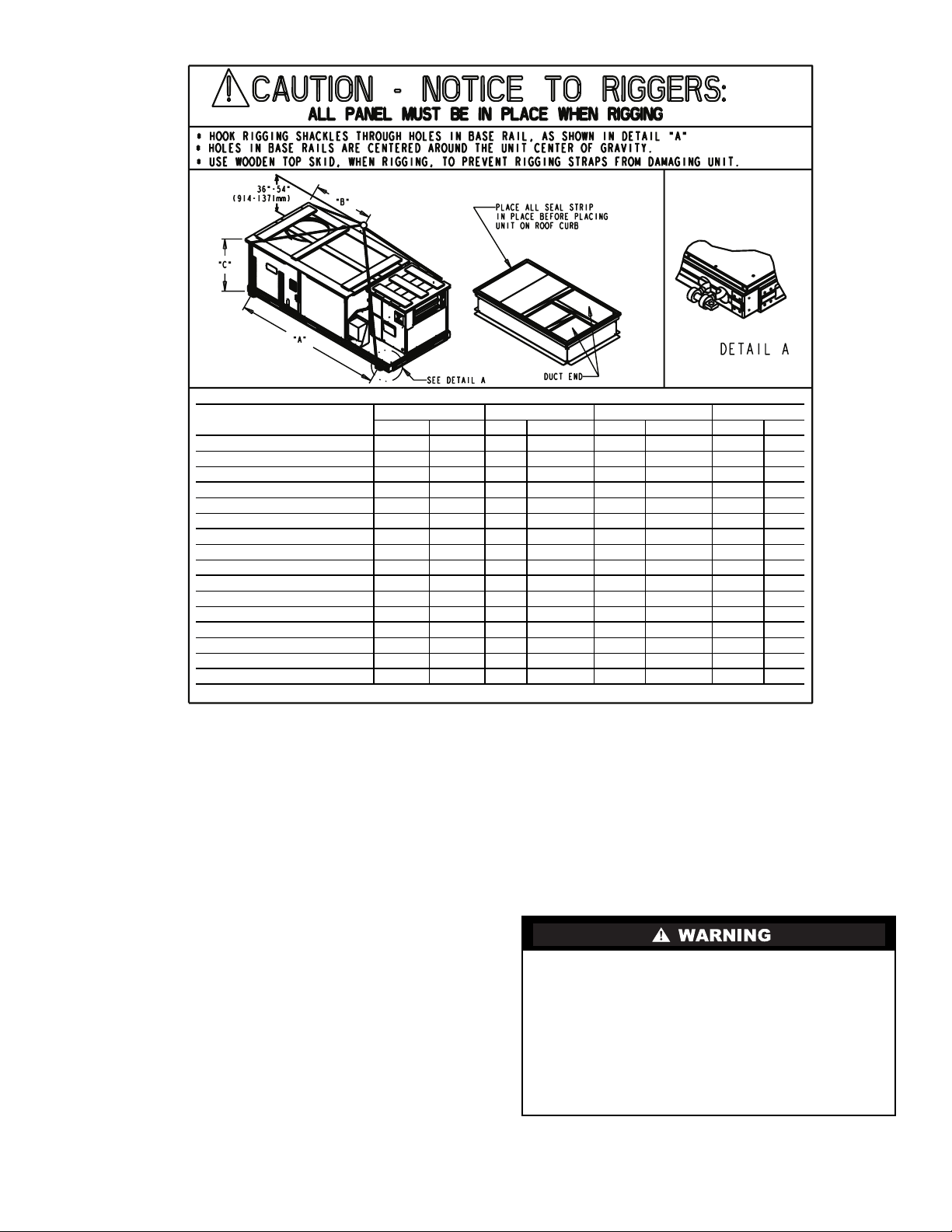

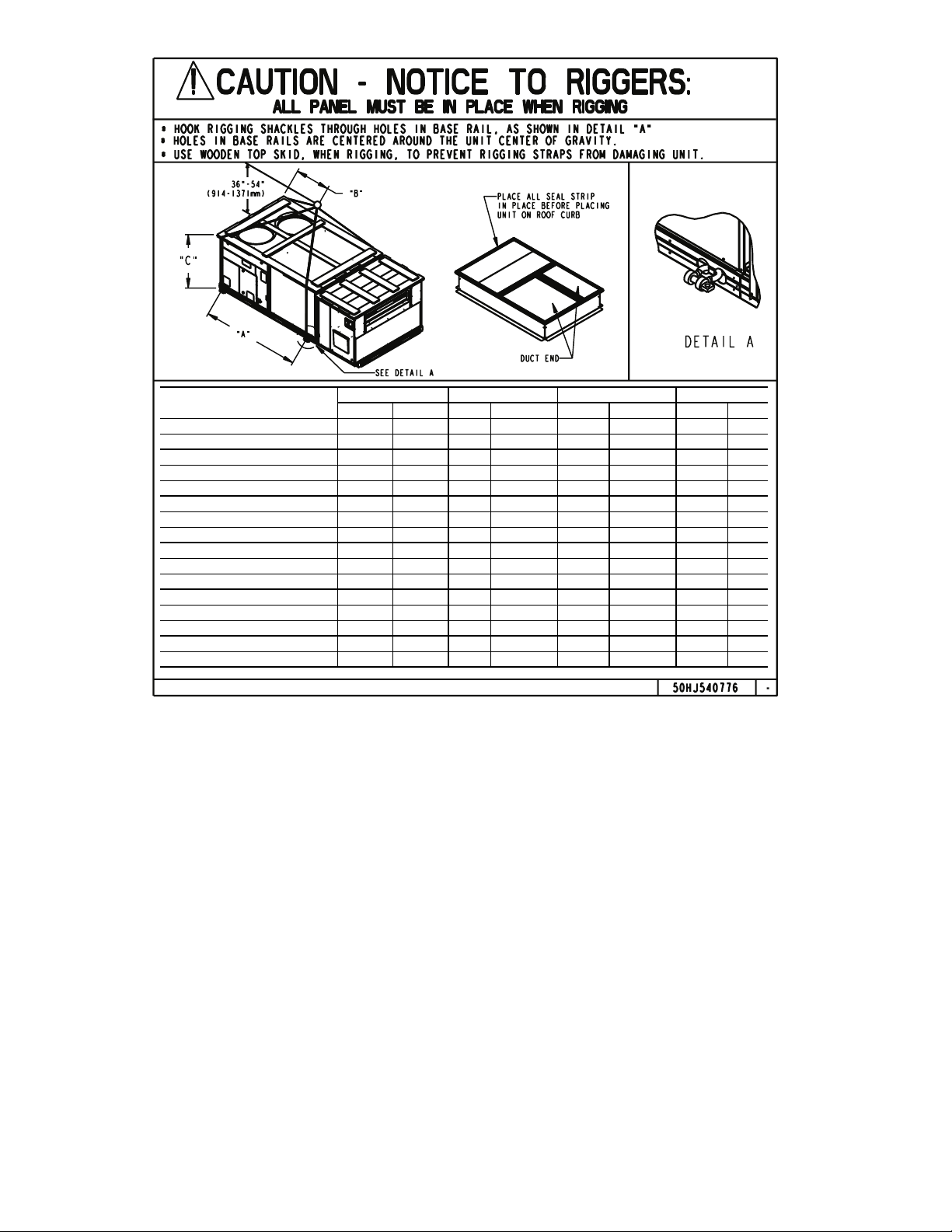

Step 2 — Provide Unit Support

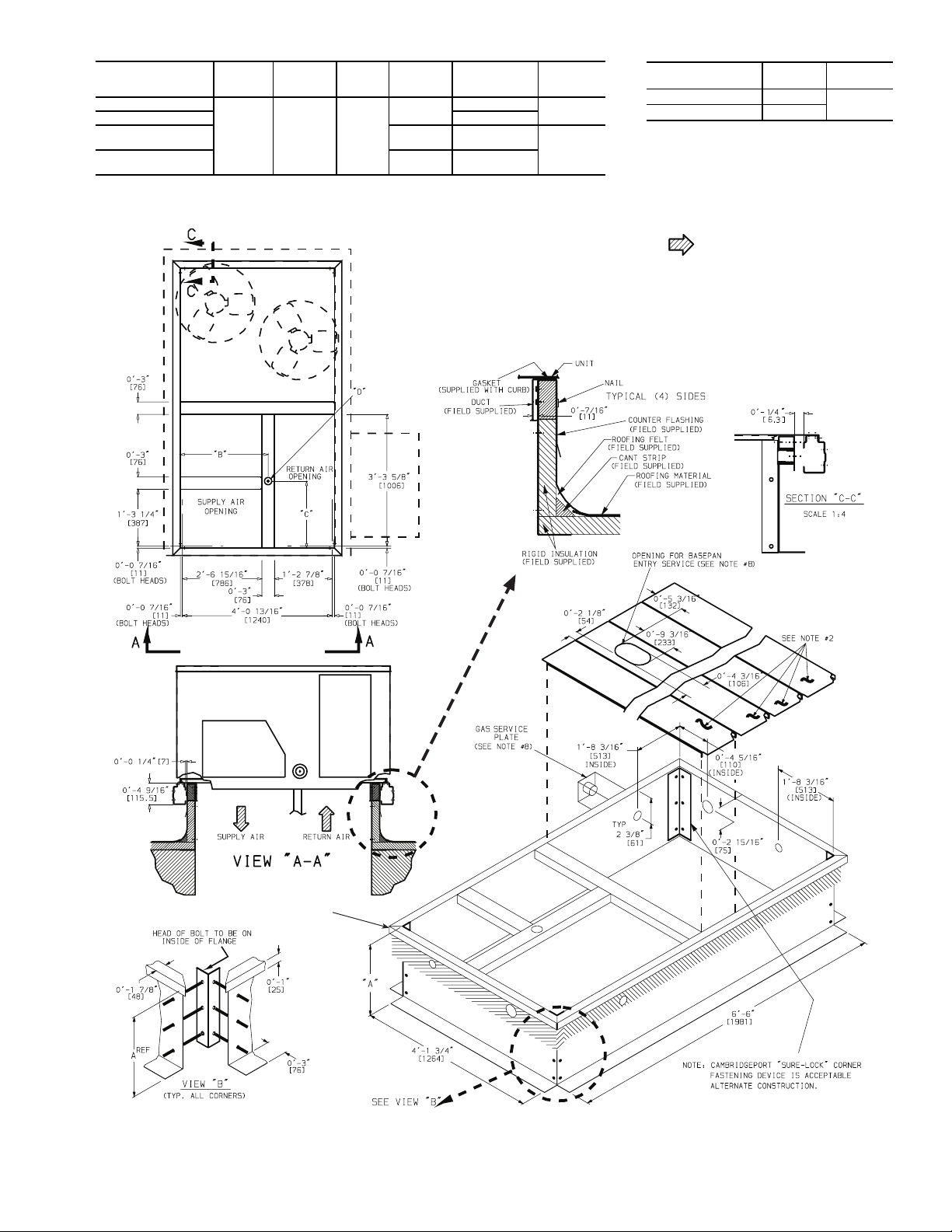

ROOF CU RB — The COBRA energy recove ry unit can use a

full-perimeter roof c urb or a standard ro of curb for the roof top

section of the unit with a supplemental equipment support for the

energy recovery section. The supplemental equipment support is

not required. The stan dard rooftop unit roof curb is capable of

supporting both the rooftop unit section and the energy recovery

section. Assemble and install accessory roof curb in accordance

with instructions shipped with curb. See Fig. 2A-4. Install insulation, cant strips, roofing felt, and counter flashing as shown .

Ductwork must be attached to curb, not to th e unit. The accessory thru-the-bottom power and gas conne ction package mu st be

installed befor e the unit is set on the r o of curb.

DUCT OPENING SIZES

Supply = 13 7/8" x 20 1/4"

R1 = 13 5/8" x 17 3/4"

R2 = 13 5/8" x 12 5/16"

R1 = Return from building to HVAC

R2 = Return from building to 62AQ

Fig. 1 — Shipping Packaging (48/50HJ004-006 Shown)

Deck pans

37 3/16"

67 3/8"

3 1/4

R1

14”

Supply

2"

92 1/2"

2" Return support.

Only used on some

applications.

Deck pans

R2

14"

37 3/16"

SIDE VIEW

END VIEW

Fig. 2A — COBRA Energy Recovery Unit Full-Perimeter Roof Curb — 48/50HJ004-007 with 62AQ060,100

2

Page 3

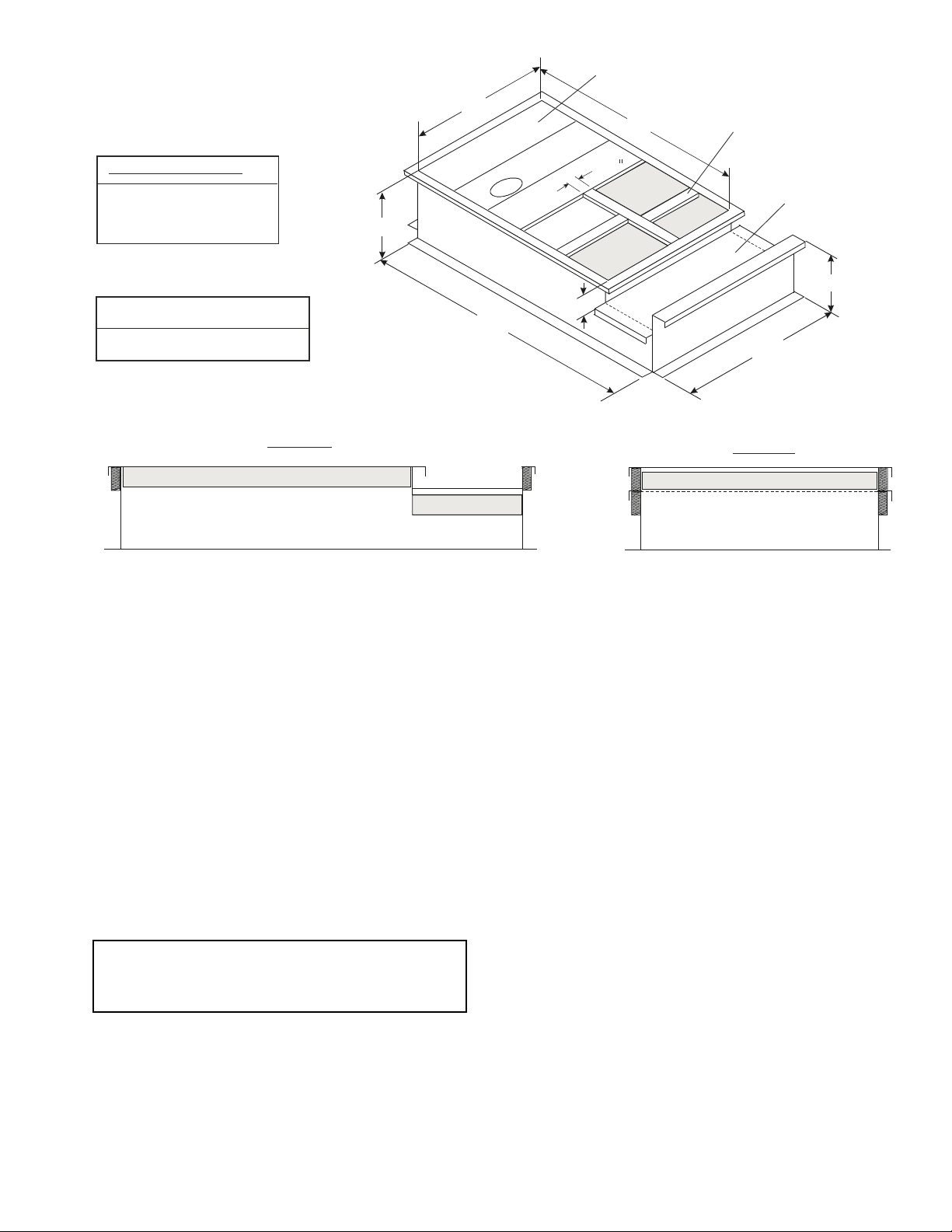

49 15/16"

Deck pans

78 1/4"

2" Return support.

Only used on some

applications.

DUCT OPENING SIZES

Supply = 15 11/16" x 31 3/8"

R1 = 15 5/16" x 29 1/16"

R2 = 15 5/16" x 9"

R1 = Return from building to HVAC

R2 = Return from building to 62AQ

SIDE VIEW

14"

110 11/16"

3 1/4

R1

Deck pans

R2

Supply

14"

2"

49 15/16"

END VIEW

Fig. 2B — COBRA™ Energy Recovery Unit Full-Perimeter Roof Curb — 48/50HJ008-014 with 62AQ200,300

If electric control power or gas service is to be routed

through the basepan, a field-installed accessory thru-thebottom connection must be used. Attach the accessory to the

basepan per the information in the accessory installation

instructions. Thru-the-bottom connections must be installed

before unit is set on roof.

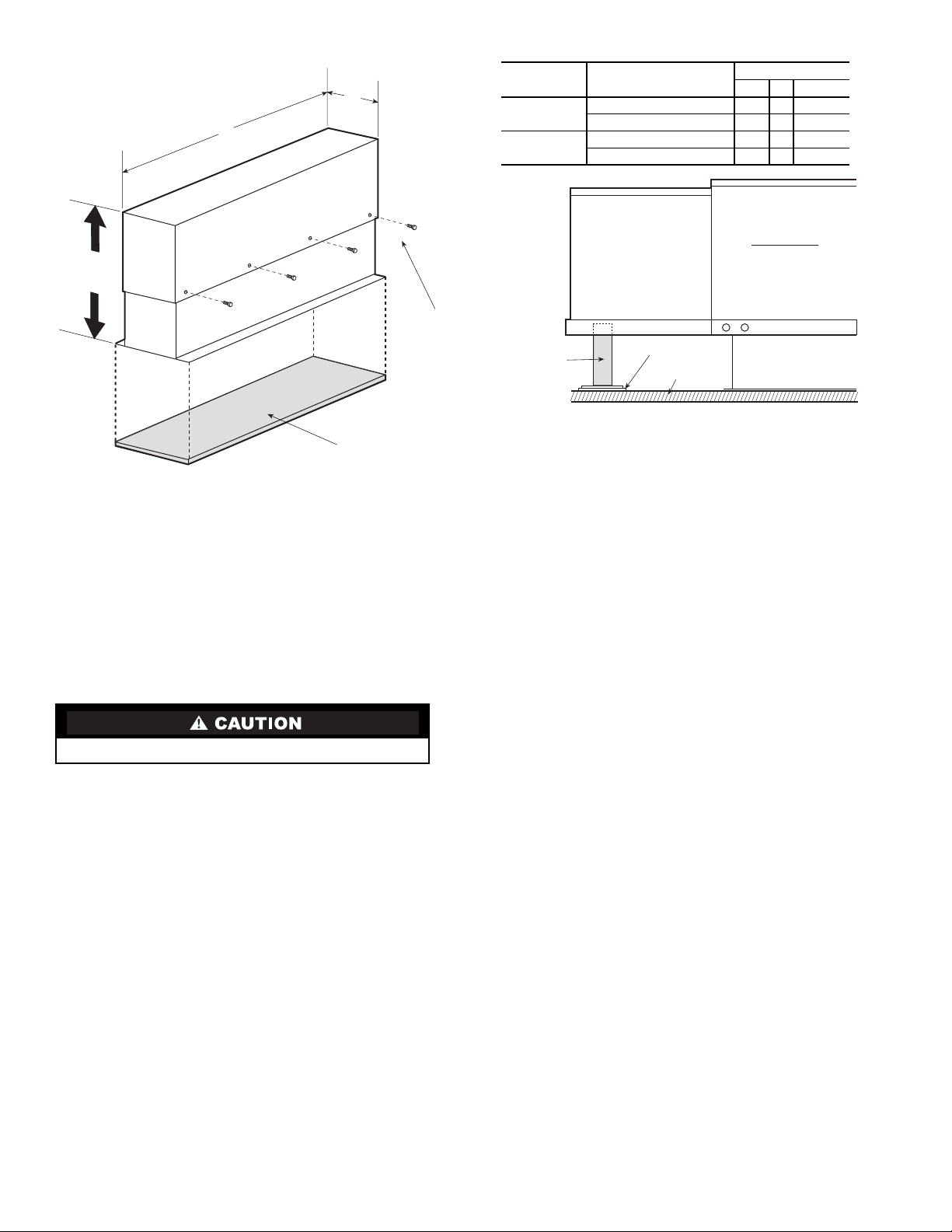

If the combined unit roof curb is not being used, additional

support may be desired under the energy recovery section of

the unit. An accessory support and pad for the energy recovery

section can be used. See Fig. 4. Place the protective rubber pad

on the roof so that the edge near the unit is located about 6-in.

from the end of the energy recovery section. Measure the

distance from the bottom of energy recovery rails to t he pad.

Adjust the energy recovery equipment support to match the

measured distance and screw into plac e with the 4 screws provided. See Fig. 4. Place the support underneath the energy recovery unit and on the protective rubber pa d. This is done by

lifting the end of the energy recovery section slightly above

level and then sliding the support underneath the rails.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasket supplied with the

roof curb as shown in Fig. 3A and 3B. Improperly applied

gasket can result in air leaks and poor unit performance.

Curb should be level. This is necessary for unit condensate

drain to function properly. Refer to Accessory Roof Curb

Installation Instructions for additional information as required.

Step 3 — Field Fabricate Ductwork —

Secure all

ducts to roof curb and building structure. Do not connect duct-

work to unit. Insulate and weatherproof all external ductwork,

joints, and roof openings with counter flashing and mastic in

accordance with applicable codes. See Fig. 5A and 5B for duct

dimensions.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier. If a plenum return is

used, the return should be ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork.

These units are designed for a minimum continuous heating

return-air temperature of 50 F (dry bulb), or an intermittent

operation down to 45 F (dry bulb), such as when used with a

night set-back thermostat. To operate at lower return-air

temperatures, a field-supplied outdoor-air temperature control

must be used to initiate both stages of heat when t he temperature is below 45 F. Indoor comfort may be compromised when

these lower air temperature s are us ed with in sufficient heati ng

temperature rise.

3

Page 4

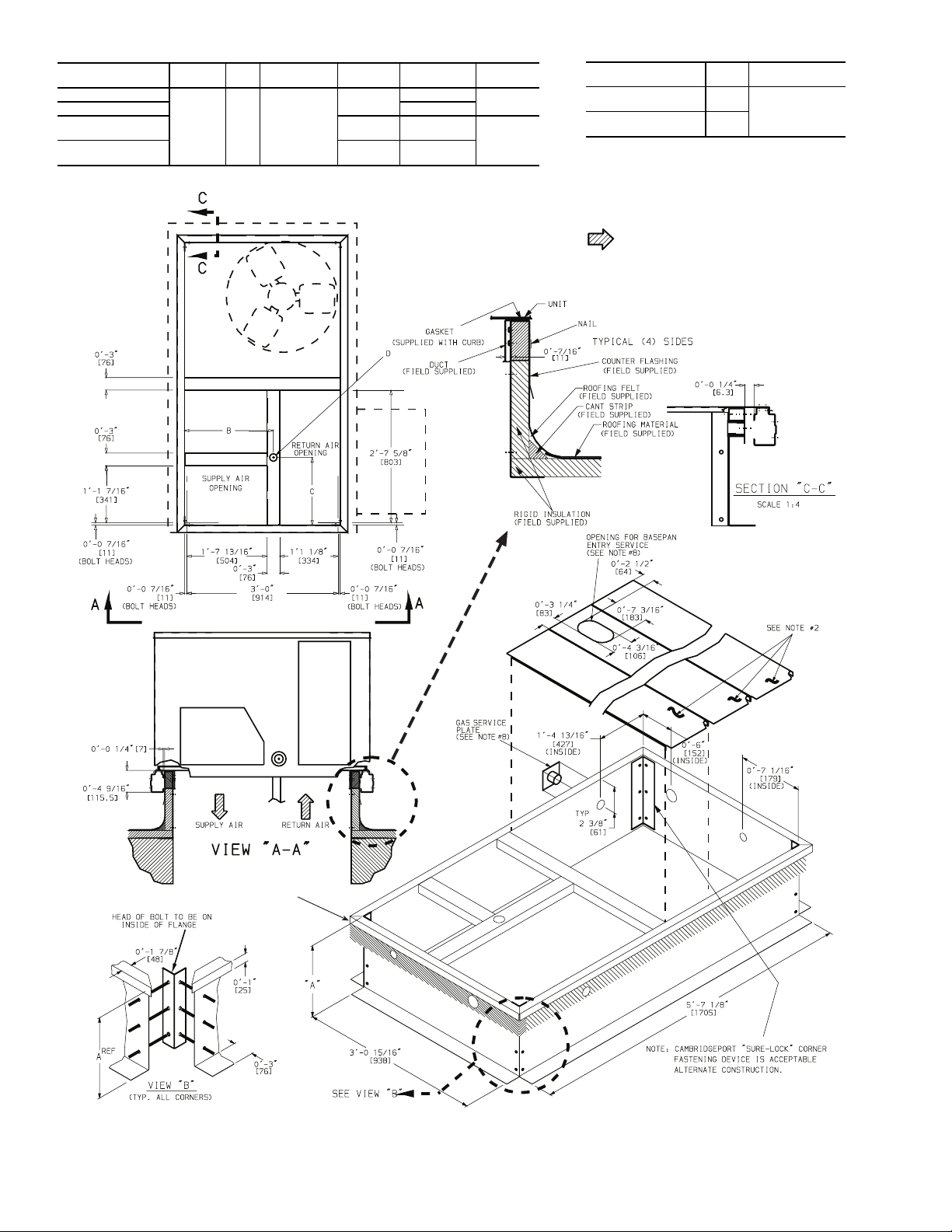

CONNECTOR

PKG. ACCY.

BC

CRBTMPWR001A00

CRBTMPWR002A00 1

CRBTMPWR003A00

1′-9

11

[551]

″

/

1′-4″

16

[406]

CRBTMPWR004A00

D ALT

DRAIN HOLE

3

″

/

1

4

[44.5]

GAS POWER CONTROL

3

/4″

[19] NPT

1

″

/

2

[12.7] NPT

3

/4″

[19] NPT

3

″ [19] NPT

/

4

1

″ [31.7]

/

4

3

/4″ [19] NPT

1

1

″ [31.7]

/

4

1

/2″

[12.7]

1

/

2

[12.7]

ROOF CURB

ACCESSORY

CRRFCURB001A00

″

CRRFCURB002A00

NOTES:

1. Roof curb accessory is shipped disassembled.

2. Insulated panels.

3. Dimensions in [ ] are in millimeters.

4. Roof curb: galvanized steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance: 4 ft on each side.

A UNIT SIZE

1′-2″

[356]

2′-0″

[610]

48/50HJ

004-007

7. Direction of airflow.

8. Connector packages CRBTMPWR001A00 and

002A00 are for thru-the-curb type gas. Packages

CRBTMPWR003A00 and 004A00 are for thru-thebottom type gas connections.

TO ENSURE AIRTIGHT CONNECTION.

PLACE UNIT AS CLOSE TO THIS

END AS POSSIBLE

TO ENSURE AIRTIGHT CONNECTION.

PLACE UNIT AS CLOSE TO THIS

END AS POSSIBLE

Fig. 3A — Roof Curb Details (48/50HJ004-007 Section Only)

4

Page 5

CONNECTOR

PKG. ACCY.

BC

CRBTMPWR001A00

CRBTMPWR002A00 1

CRBTMPWR003A00

2′-8

7

[827]

″

1′-10

/

16

[583]

CRBTMPWR004A00

D ALT

DRAIN

HOLE

15

3

″

1

/

/

16

[44.5]

GAS POWER CONTROL

3

/4″

[19] NPT

1

″

4

″

/

2

[12.7] NPT

3

″

/

4

[19] NPT

3

″ [19] NPT

/

4

1

″ [31.7]

/

4

3

/4″ [19] NPT

11/4″ [31.7]

1

/2″

[12.7] NPT

1

″

/

2

[12.7] NPT

ROOF CURB

ACCESSORY

“A”

CRRFCURB003A00 1′-2″ [356]

CRRFCURB004A00 2′-0″ [610]

NOTES:

1. Roof curb accessory is shipped disassembled.

2. Insulated panels: 1-in. thick polyurethane foam,

3

/4 lb density.

1

3. Dimensions in [ ] are in millimeters.

4. Roof curb: 16-gage steel.

5. Attach ductwork to curb (flanges of duct rest on

curb).

6. Service clearance 4 ft on each side.

UNIT SIZE

48/50HJ

008-014

7. Direction of airflow.

8. Connector packages CRBTMPWR001A00 and

2A00 are for thru-the-curb gas type. Packages

CRBTMPWR003A00 and 4A00 are for thruthe-bottom type gas connections.

TO ENSURE AN AIRTIGHT CONNECTION,

PLACE UNIT ON CURB AS CLOSE TO

DUCT END AS POSSIBLE.

TO ENSURE AN AIRTIGHT CONNECTION,

PLACE UNIT ON CURB AS CLOSE TO

DUCT END AS POSSIBLE.

Fig. 3B — Roof Curb Details (48/50HJ008-014 Section Only)

5

Page 6

UNIT SIZE

4”

3-6 Ton

A

1

7

/2-121/2 Ton

EQUIPMENT SUPPORT

PART N U M BER

CRAQSUPT001A00 36.9 40 8 to 14

CRAQSUPT002A00 36.9 40 14 to 24

CRAQSUPT003A00 49.7 54 8 to 14

CRAQSUPT004A00 49.7 54 14 to 24

DIMENSIONS (in.)

AB C

C”

10” x B (SEE CHART)

PROTECTIVE

RUBBER PAD

(EPDM)

Fig. 4 — Supplemental Energy Recovery Section Equipment Support

Step 4 — Rig and Place Unit —

Keep unit upright

and do not drop. Spreader bars are not required if top crating is

left on unit. Rollers may be used to move unit across a roof.

Remove the bottom wooden skids that are under the unit by

removing the wooden plates that hold the bottom wooden

frame to the unit. Level by using unit frame as a reference. Lifting holes are provided in base rails as shown in Fig. 6A and 6B.

Refer to rigging instructions on unit.

All panels must be in place when rigging.

POS ITION ING — Maintain cleara nce around and above unit

to provide minimum distance from combustible materials,

proper airflow, and service access. A properly positioned unit

will have the following clearances between unit and roof curb:

1

/4-in. clearance between roof curb and base rails on each side

and duct end of unit; 1/4-in. clearance between roof curb and

condenser coil end of unit.

Do not install unit in an indoor location. Do not locate unit

air inlets near exhaust vents or other sources of cont aminated

air.

Be sure that unit is installed such that snow will not block

the combustion intake or flue outlet.

SCREW

SUPPORT

IN PLACE

HVAC UNIT

CURB

ADJUSTABLE

EQUIPMENT

SUPPORT

ENERGY

RECOVERY

SECTION

PAD

ROOF

Unit may be installed directly on wood flooring or on

Class A, B, or C roof-covering material when roof curb is used.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Flue vent discharge must have a minimum horizontal clearance of 4 ft from electric and gas meters, gas regulators, and

gas relief equipment.

Minimum distance between unit and other electrically live

parts is 48 inches.

Flue gas can deteriorate building materials. Orient unit

such that flue gas will not affect building materials. Locate

mechanical draft system fl ue assembly at leas t 48 in. from an

adjacent building or combustible material.

Adequate combustion- and ventilation-air space must be

provided for proper operation of this equipment. Be sure that

installation complies with all local codes and Section 5.3, Air

for Combustion and Ventilation, NFGC (National Fuel Gas

Code), and ANSI (American National Standards Institute)

Z223.1, and NFPA (National Fire Protection Association)

54 TIA-54-84-1. In Canada, installation must be in accordance

with the CAN1-B149 installation codes for gas burning

appliances.

After unit is in position, remove rigging skids and shipping

materials.

6

Page 7

REAR

SIDE

RIGHT

RIGHT SIDE

FRONT

FRONT

LEFT

SIDE

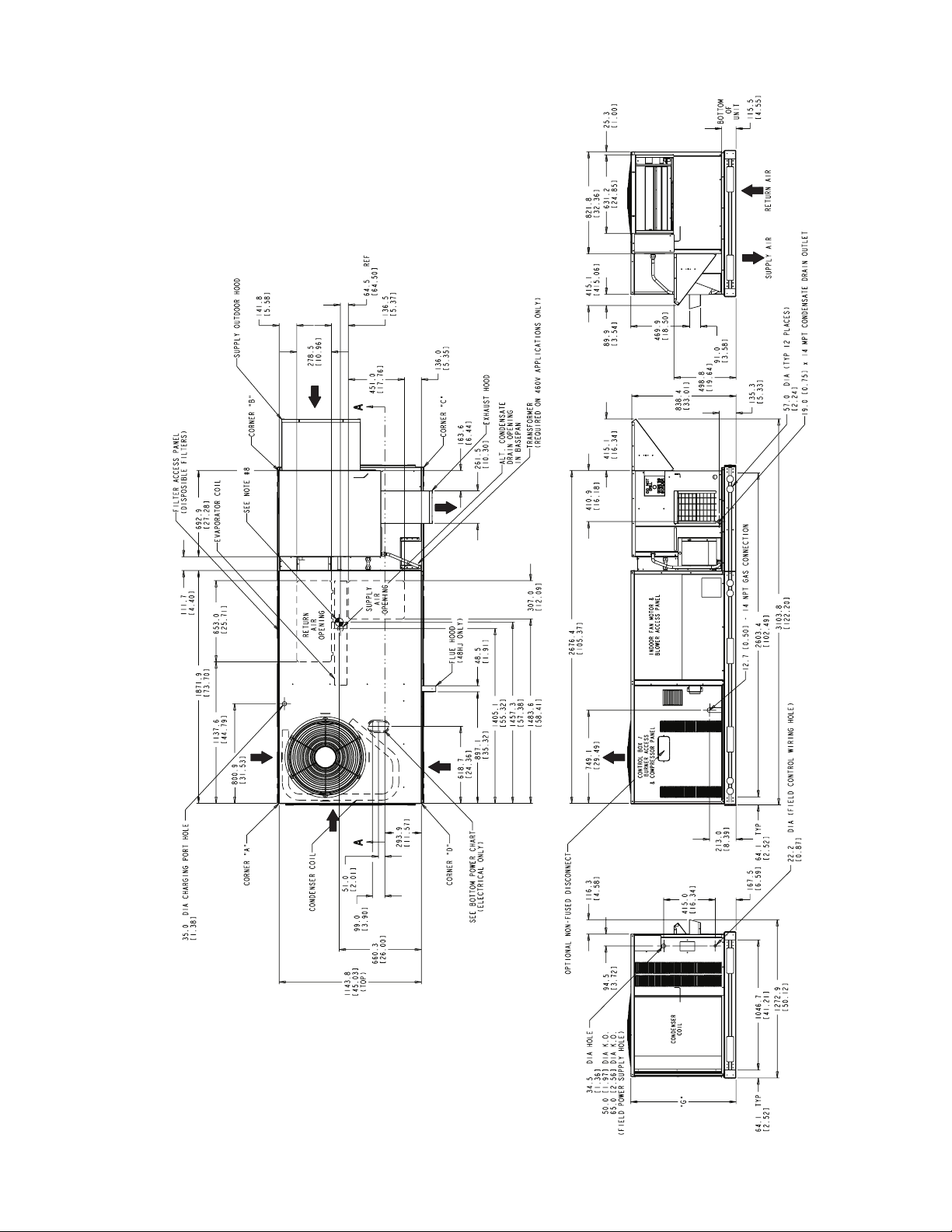

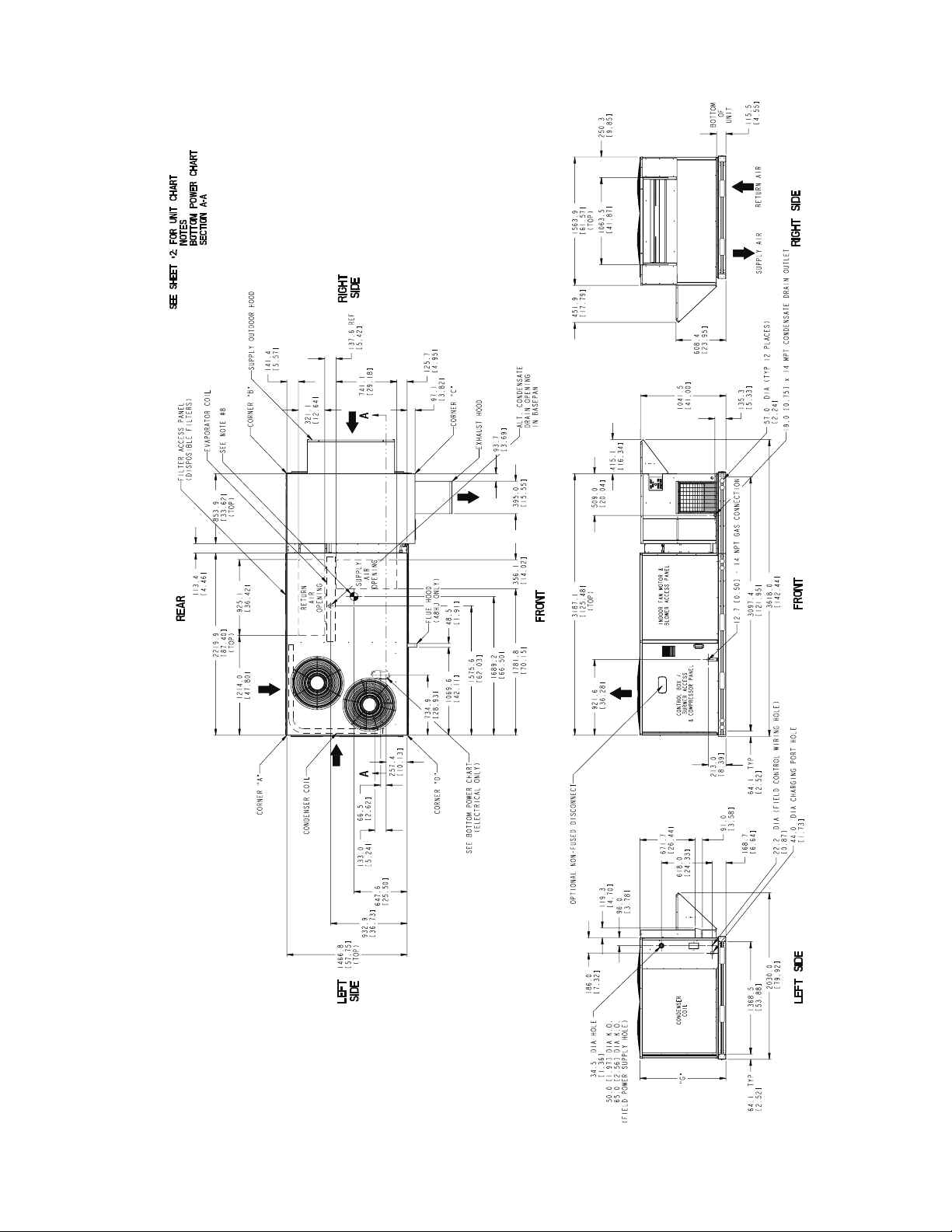

Fig. 5A — Base Unit Dimensions — COBRA™ Energy Recovery Unit — 48/50HJ004-007 with 62AQ060,100

LEFT SIDE

7

Page 8

Fig. 5A — Base Unit Dimensions — COBRA™ Energy Recovery Unit — 48/50HJ004-007 with 62AQ060,100 (cont)

8

Page 9

Fig. 5B — Base Unit Dimensions — COBRA™ Energy Recovery Unit — 48/50HJ008-014 with 62AQ200,300

9

Page 10

10

Fig. 5B — Base Unit Dimensions — COBRA™ Energy Recovery Unit — 48/50HJ008-014 with 62AQ200,300 (cont)

Page 11

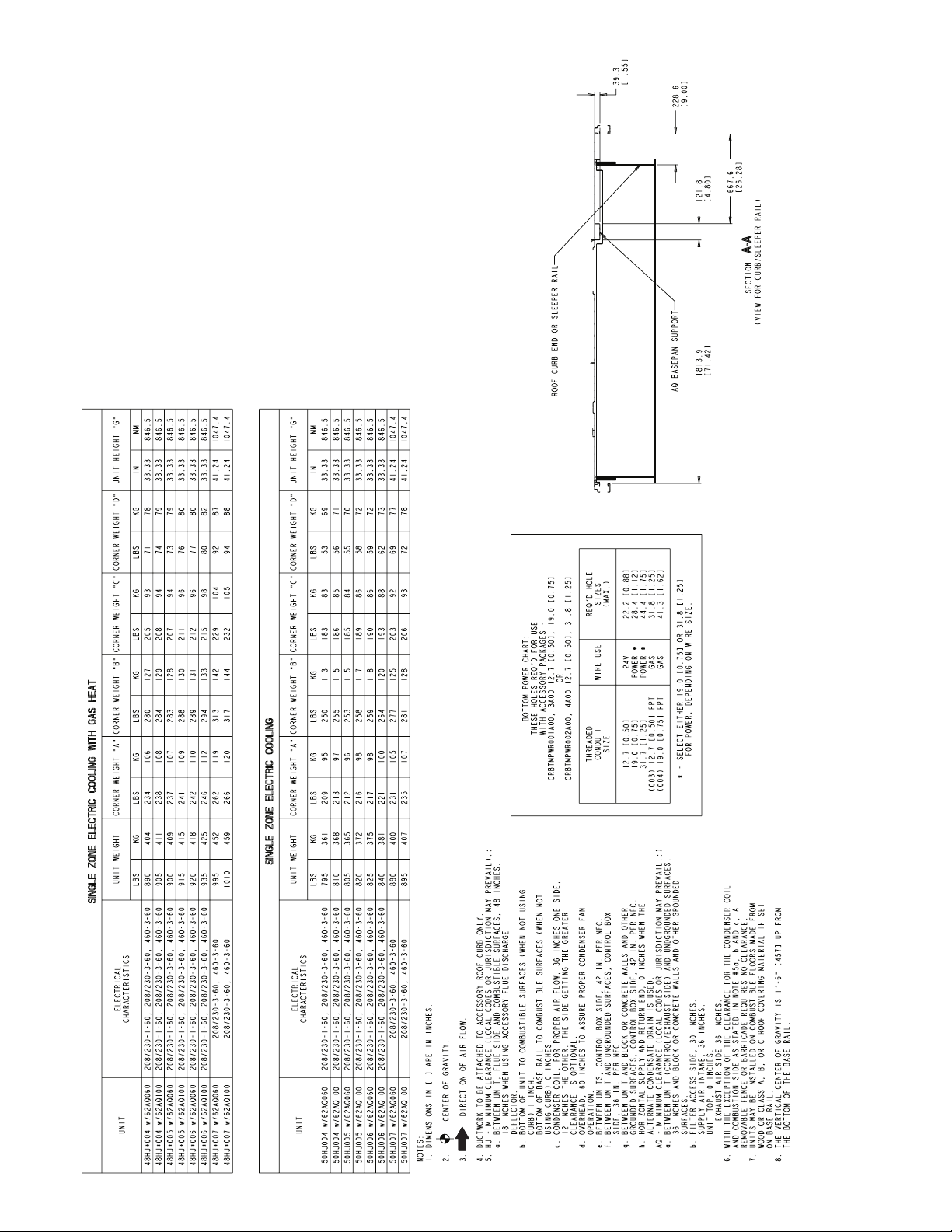

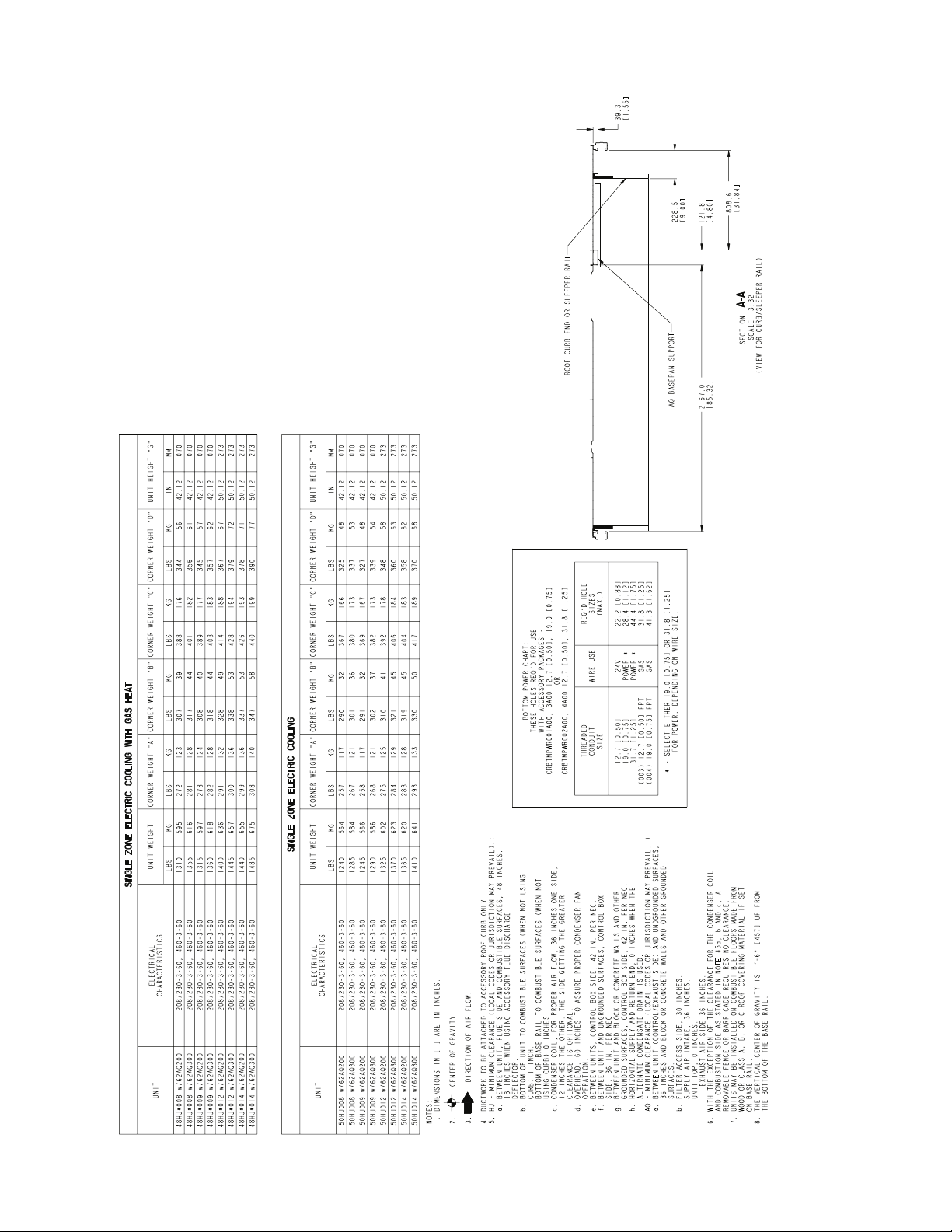

MAX WEIGHT A B C

48HJ004 w/62AQ060 890 404 95.6 2428.20 57.38 1457.30 33.35 847

48HJ004 w/62AQ100 905 411 95.6 2428.20 57.38 1457.30 33.35 847

48HJ005 w/62AQ060 900 409 95.6 2428.20 57.38 1457.30 33.35 847

48HJ005 w/62AQ100 915 415 95.6 2428.20 57.38 1457.30 33.35 847

48HJ006 w/62AQ060 920 418 95.6 2428.20 57.38 1457.30 33.35 847

48HJ006 w/62AQ100 935 425 95.6 2428.20 57.38 1457.30 33.35 847

48HJ007 w/62AQ060 995 452 95.6 2428.20 57.38 1457.30 42.12 1070

48HJ007 w/62AQ100 1010 459 95.6 2428.20 57.38 1457.30 42.12 1070

50HJ004 w/62AQ060 795 361 95.6 2428.20 57.38 1457.30 33.35 847

50HJ004 w/62AQ100 810 368 95.6 2428.20 57.38 1457.30 33.35 847

50HJ005 w/62AQ060 805 365 95.6 2428.20 57.38 1457.30 33.35 847

50HJ005 w/62AQ100 820 372 95.6 2428.20 57.38 1457.30 33.35 847

50HJ006 w/62AQ060 825 375 95.6 2428.20 57.38 1457.30 33.35 847

50HJ006 w/62AQ100 840 381 95.6 2428.20 57.38 1457.30 33.35 847

50HJ007 w/62AQ060 880 400 95.6 2428.20 57.38 1457.30 42.12 1070

50HJ007 w/62AQ100 895 407 95.6 2428.20 57.38 1457.30 42.12 1070

lb kg in. mm in mm in. mm

Fig. 6A — Rigging Label — COBRA™ Energy Recovery Unit — Sizes 48/50HJ004-007

Step 5 — Install Flue Hood (48HJ Rooftop Sections Only) —

information on installing the flue hood.

Refer to the 48HJ installation instructions for

Step 6 — Install Gas Piping (48HJ Rooftop Sections Only) —

information on installing the gas piping.

Refer to the 48HJ installation instructions for

Step 7 — Install External Trap For Condensate

Drain —

condensate from the upper coil of the energy recovery section

is internally piped to the condensate pan in the lower section of

the energy recovery section. For this reason, the bottom drain

on the rooftop unit CANNOT be used for a condensate drain.

The

located near the bottom left of the exhaust air section. See

Fig. 5A and 5B. The energy recovery section must have a

field-fabricated, external, P-trap installed for condensate drainage. Trap must be at least 4-in. deep to protect against freezeup. If the drain line is installed downstream from the external

The condensate from the rooftop unit along with

3

/4-in. drain connection on the energy recovery section is

trap, pitch the line away from the unit a t 1-in. per 10-ft of run.

Do not use a pipe smaller than the connection (

3

/4-in.).

Step 8 — Make Electrical Connections

Unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of personal injury if

an electrical fault should occur. This ground may consist of

electrical wire connected to unit ground lug in control compartment, or conduit approved for electrical ground when

installed in accordance with NEC (National Electrical

Code), ANSI/NFPA, latest edition, and local electrical

codes. Do not use gas piping as an electrical ground. Failure to follow this warning could result in the installer being

liable for personal injury of others.

FIELD POWER SUPPLY — All units except 208/230-v

units are factory wired for the voltage shown on the nameplate.

11

Page 12

MAX WEIGHT A B C

lb kg in. mm in. mm in. mm

48HJ008 w/62AQ200 1310 595 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ008 w/62AQ300 1355 616 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ009 w/62AQ200 1315 597 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ009 w/62AQ300 1360 618 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ012 w/62AQ200 1400 636 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ012 w/62AQ300 1445 657 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ014 w/62AQ200 1440 655 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ014 w/62AQ300 1485 675 77.42 1966.5 66.50 1689.10 50.12 1273

50HJ008 w/62AQ200 1240 564 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ008 w/62AQ300 1285 584 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ009 w/62AQ200 1245 566 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ009 w/62AQ300 1290 586 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ012 w/62AQ200 1325 602 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ012 w/62AQ300 1370 623 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ014 w/62AQ200 1345 620 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ014 w/62AQ300 1410 641 77.42 1966.5 66.50 1689.10 42.12 1070

Fig. 6B — Rigging Label — COBRA™ Energy Recovery Unit — Sizes 48/50HJ008-014

If the 208/230-v unit is to be connected to a 208-v power supply, the t ransformer must be rewired by moving the black wire

with the

nection and moving to the 200-volt

1

/4-in. female space connector from the 230-volt con-

1

/4-in. male terminal on the

primary side of the transformer.

Refer to unit label diagram for additional information. Pigtails are provided for field wire connections. Use factorysupplied splices or UL (Underwriters’ Laboratories) approved

copper/aluminum connector.

When installing units, provide a disconnect per the NEC.

All field wiring must comply with NEC and local

requir e ments.

Install field wiring as follows:

1. Install conduit through side panel openings. Install conduit between disconnect and control box.

2. Install power lines to terminal connections as shown in

Fig. 7.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (see

T ables 1A-1H). On 3-phase units, voltages between phases must

be balanced within 2% and the current within 10%. Use the formula shown in the legend for Tables 1A-1H, Note 2 to determine the percent of voltage imbalance. Operation on improper

line voltage or excessive phase imbalance constitutes abuse and

may cause damage to electrical components. Such operation

would invalidate any applicable Carrier warranty.

F ACT ORY-SUPPLIED NON-FUSED DISCONNECT — The

factory-supplied disconnect is capable of handling disconnect

amps up to 80 A for a COBRA Energy Recovery unit. For disconnect amps greater than 80 A, a field-supplied disconnect is

required.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermidistat assembly according to installation

instructions included with the accessory. Locate thermidistat as-

sembly on a solid wall in the con diti one d spac e to sens e avera ge

temperature in accordanc e with th ermidistat installation i nstructions on page 30. Connect thermidistat wires to terminal board.

Route thermidistat cable or equivalent single leads of colored wire from subbase terminals through connector on unit to

low-voltage connections (shown in Fig. 8). Thermidistat control wiring is routed to both the rooftop unit control box and the

energy recovery section control box.

If a PremierLink™ control is used, a thermidistat does not

need to be used. A humidistat and a separate room air sensor

are used. Two extra terminal blocks (TB2 and TB3) are provided in the control box for all units with PremierLink controls.

No wiring should be directly connected to the PremierLink

control. Wire sensors to TB2 or TB3. Humidistat is wired to

TB1 and energy recovery section control box.

12

Page 13

NOTE: For wire runs up 50 ft, use no. 18 A WG (American Wire

Gage) insulated wire (35 C minimum). For 50 to 75 ft, use no.

16 AWG insulated wire (35 C minimum). For over 75 ft, use no.

14 AWG insulated wire (35 C minimum). All wire larger than

no. 18 AWG cannot be directly connected to the thermostat and

will require a junction box and splice at the thermostat.

Pass the control wires through the hole provided in the corner post; then feed wires through the raceway built into the

corner post to the 24-v barrier located on the left side of the

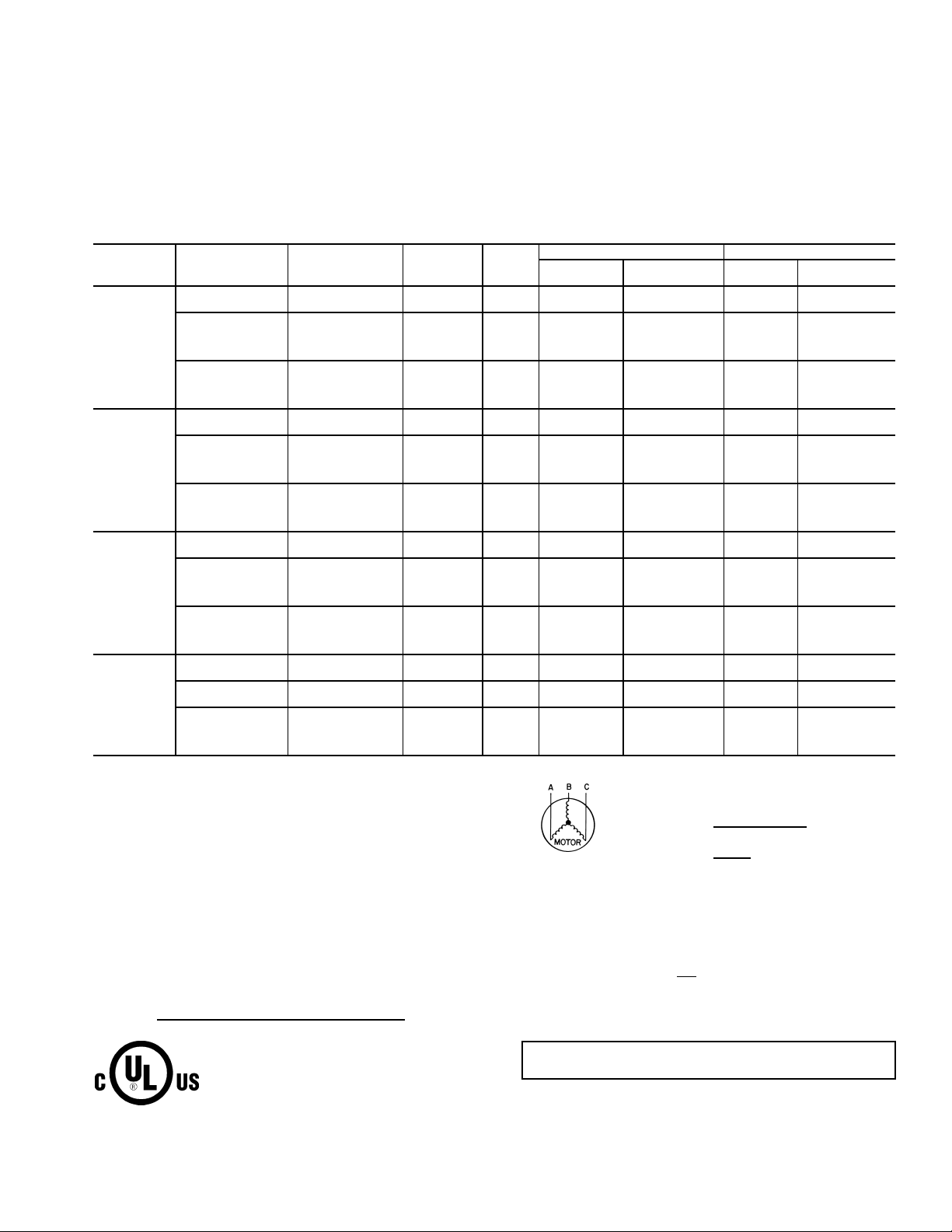

Table 1A — Electrical Data (COBRA™ Energy Recovery 48HJ004-007 Units with 62AQ060)

control box. See Fig. 10. The raceway provides the UL

required clearance between high- and low-voltage wiring.

NOTE: A humidistat and a temperature sensor can be used in

place of a thermidistat for PremierLink™ units.

HEAT ANTICIPATOR SETTINGS — Set heat anticipator

settings at .14 amp for the first stage and .14 amp for secondstage heating, when available.

UNIT

48HJ004

48HJ005

48HJ006

48HJ007

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

UL — Underwriters’ Laboratories

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective

device for the unit shall be fuse or HACR breaker. UL, Canada units may be

fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%. Use the following formula to determine the percent of volt-

age imbalance.

= 100 x

NOMINAL

V-P H -H z

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-3-60

208/230-3-60

460-3-60

LEGEND

max voltage deviation from average voltage

average voltage

IFM

TYPE

STD NO 9.2 34.8/34.8 40/40 35/35 135/135

STD YES 9.2 40.8/40.8 45/45 41/41 140/140

STD NO 9.2 27.7/27.7 35/35 29/29 124/124

STD YES 9.2 33.7/33.7 40/35 34/34 129/129

HIGH STATIC NO 9.2 28.6/28.6 35/35 30/30 154/154

HIGH STATIC YES 9.2 34.6/34.6 40/40 35/35 158/158

STD NO 9.2 13.6 20 14 63

STD YES 9.2 16.3 20 20 67

HIGH STATIC NO 9.2 14.0 20 15 77

HIGH STATIC YES 9.2 16.7 20 20 82

STD NO 9.2 44.4/44.4 60/60 44/44 173/173

STD YES 9.2 50.4/50.4 60/60 50/50 178/178

STD NO 9.2 31.7/31.7 40/40 33/33 140/140

STD YES 9.2 37.7/37.7 40/40 38/38 145/145

HIGH STATIC NO 9.2 32.6/32.6 40/40 34/34 170/170

HIGH STATIC YES 9.2 38.6/38.6 45/45 39/39 174/174

STD NO 9.2 15.2 20 16 70

STD YES 9.2 17.9 20 21 75

HIGH STATIC NO 9.2 15.6 20 16 84

HIGH STATIC YES 9.2 18.3 20 22 89

STD NO 9.2 55.5/55.5 70/70 56/56 250/250

STD YES 9.2 61.5/61.5 70/70 61/61 255/255

STD NO 9.2 38.1/38.1 45/45 39/39 202/202

STD YES 9.2 44.1/44.1 50/50 44/44 207/207

HIGH STATIC NO 9.2 39.8/39.8 45/45 41/41 221/221

HIGH STATIC YES 9.2 45.8/45.8 50/50 46/46 226/226

STD NO 9.2 19.3 25 20 101

STD YES 9.2 22.0 25 25 106

HIGH STATIC NO 9.2 20.1 25 20 110

HIGH STATIC YES 9.2 22.8 25 26 115

STD NO 9.2 42.0/42.0 50/50 42/42 234/234

STD YES 9.2 48.0/48.0 60/60 48/48 239/239

HIGH STATIC NO 9.2 43.7/43.7 50/50 44/44 253/253

HIGH STATIC YES 9.2 49.7/49.7 60/60 50/50 258/258

STD NO 9.2 19.8 25 20 114

STD YES 9.2 22.5 25 26 118

HIGH STATIC NO 9.2 20.6 25 21 123

HIGH STATIC YES 9.2 23.3 30 26 128

CONV

OUTLET

62AQ

FLA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum

allowable 2%.

POWER SUPPLY DISCONNECT SIZE*

MCA

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

452 + 464 + 455

1371

=

3

= 457

FLA LRA

3

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately.

13

Page 14

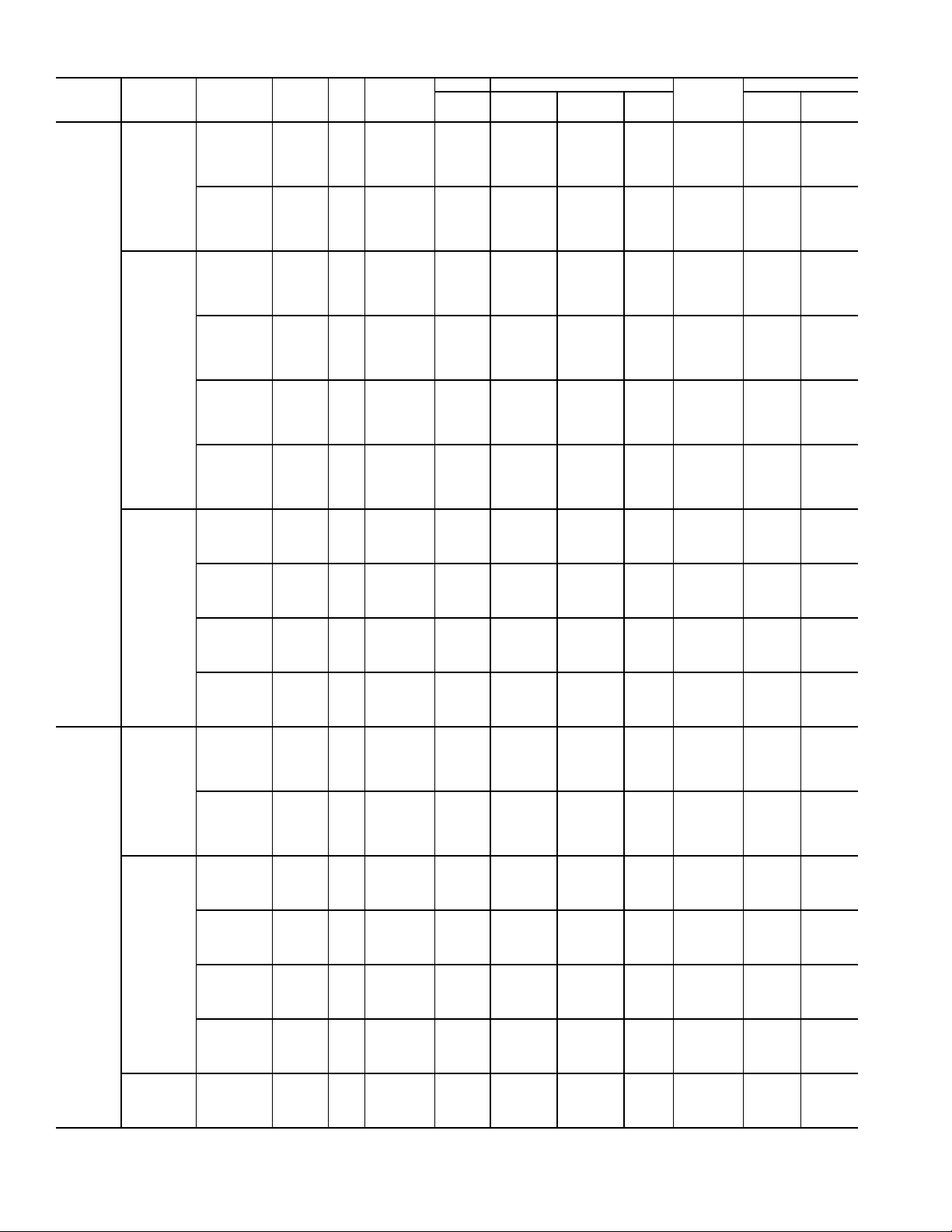

UNIT

50HJ004

50HJ005

Table 1B — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ060)

NOMINAL

V-P H- Hz

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60 STD NO 9.2

IFM

TYPE

STD NO 9.2

STD YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

CONV

OUTLET

HEATER

62AQ

CRHEATER

FLA

---A00

NONE —/— 34.8/ 34.8 40/40 ——35/ 35 135/135

001 15.9/18.3 35.7/ 38.8 40/45 ——35/ 37 135/135

002 23.5/27.1 45.2/ 49.7 50/50 ——43/ 47 135/135

003 31.4/36.3 55.1/ 61.2 — 60/ 70 004 52/ 58 135/135

004 37.9/43.8 63.2/ 70.5 — 70/ 80 004 60/ 67 135/135

002+002 46.9/54.2 74.5/ 83.6 — 80/ 90 005 70/ 79 135/135

NONE —/— 40.8/ 40.8 45/45 ——41/ 41 140/140

001 15.9/18.3 40.8/ 43.0 45/50 ——41/ 42 140/140

002 23.5/27.1 50.0/ 53.9 60/60 ——49/ 52 140/140

003 31.4/36.3 59.9/ 65.4 — 60/ 70 004 58/ 63 140/140

004 37.9/43.8 68.0/ 74.7 — 70/ 80 005 65/ 71 140/140

002+002 46.9/54.2 79.3/ 87.8 — 80/ 90 005 76/ 83 140/140

NONE —/— 27.7/ 27.7 35/35 ——29/ 29 124/124

001 9.2/10.6 27.7/ 29.1 35/35 ——29/ 29 124/124

002 13.6/15.6 32.8/ 35.4 40/40 ——32/ 34 124/124

003 18.1/20.9 38.5/ 42.0 45/45 ——37/ 40 124/124

004 21.9/25.3 43.2/ 47.4 45/50 ——41/ 45 124/124

005 33.4/38.5 57.5/ 64.0 — 60/ 70 002 55/ 60 124/124

NONE —/— 33.7/ 33.7 40/35 ——34/ 34 129/129

001 9.2/10.6 33.7/ 33.7 40/40 ——34/ 34 129/129

002 13.6/15.6 37.6/ 39.6 45/45 ——37/ 39 129/129

003 18.1/20.9 43.3/ 46.2 50/50 ——43/ 45 129/129

004 21.9/25.3 48.0/ 51.6 50/60 ——47/ 50 129/129

005 33.4/38.5 62.3/ 68.2 — 70/ 70 002 60/ 65 129/129

NONE —/— 28.6/ 28.6 35/35 ——30/ 30 154/154

001 9.2/10.6 28.6/ 30.0 35/35 ——30/ 30 154/154

002 13.6/15.6 33.7/ 36.3 40/40 ——33/ 35 154/154

003 18.1/20.9 39.4/ 42.9 45/45 ——38/ 41 154/154

004 21.9/25.3 44.1/ 48.3 50/50 ——42/ 46 154/154

005 33.4/38.5 58.4/ 64.9 — 60/ 70 002 56/ 62 154/154

NONE —/— 34.6/ 34.6 40/40 ——35/ 35 158/158

001 9.2/10.6 34.6/ 34.6 40/40 ——35/ 35 158/158

002 13.6/15.6 38.5/ 40.5 45/45 ——38/ 40 158/158

003 18.1/20.9 44.2/ 47.1 50/50 ——44/ 46 158/158

004 21.9/25.3 48.9/ 52.5 60/60 ——48/ 51 158/158

005 33.4/38.5 63.2/ 69.1 — 70/ 70 003 61/ 66 158/158

NONE — 13.6 20 —— 14 63

006 7.2 16.7 20 —— 14 63

007 10.6 20.9 25 —— 15 63

008 13.8 25.0 25 —— 24 63

009 16.8 28.7 30 —— 27 63

NONE — 16.3 20 —— 20 67

006 7.2 18.8 25 —— 20 68

007 10.6 23.0 25 —— 20 68

008 13.8 27.1 30 —— 29 68

009 16.8 30.8 35 —— 32 68

NONE — 14.0 20 —— 15 77

006 7.2 17.1 20 —— 15 77

007 10.6 21.3 25 —— 15 77

008 13.8 25.4 30 —— 24 77

009 16.8 29.1 30 —— 28 77

NONE — 16.7 20 —— 20 82

006 7.2 19.2 25 —— 20 82

007 10.6 23.4 25 —— 20 82

008 13.8 27.5 30 —— 29 82

009 16.8 31.2 35 —— 32 82

NONE —/— 44.4/ 44.4 60/60 ——44/ 44 173/173

001 15.9/18.3 44.4/ 44.4 60/60 ——44/ 44 173/173

003 31.4/36.3 55.1/ 61.2 — 60/ 70 004 52/ 58 173/173

002+002 46.9/54.2 74.5/ 83.6 — 80/ 90 005 70/ 79 173/173

003+003 62.8/72.5 94.4/106.5 — 100/110 005 88/100 173/173

004+004 75.8/87.5 110.6/125.2 — 125/150 005 103/117 173/173

NONE —/— 50.4/ 50.4 60/60 ——50/ 50 178/178

001 15.9/18.3 50.4/ 50.4 60/60 ——50/ 50 178/178

003 31.4/36.3 59.9/ 65.4 — 60/ 70 004 58/ 63 178/178

002+002 46.9/54.2 79.3/ 87.8 — 80/ 90 005 76/ 83 178/178

003+003 62.8/72.5 99.2/110.7 — 100/125 005 94/104 178/178

004+004 75.8/87.5 115.4/129.4 — 125/150 005 109/122 178/178

NONE —/— 31.7/ 31.7 40/40 ——33/ 33 140/140

002 13.6/15.6 32.8/ 35.4 40/40 ——33/ 34 140/140

003 18.1/20.9 38.5/ 42.0 45/45 ——37/ 40 140/140

005 33.4/38.5 57.5/ 64.0 — 60/ 70 002 55/ 60 140/140

004+004 43.8/50.5 70.6/ 79.0 — 80/ 80 003 67/ 74 140/140

NONE —/— 37.7/ 37.7 40/40 ——38/ 38 145/145

002 13.6/15.6 37.7/ 39.6 45/45 ——38/ 39 145/145

003 18.1/20.9 43.3/ 46.2 50/50 ——43/ 45 145/145

005 33.4/38.5 62.3/ 68.2 — 70/ 70 002 60/ 65 145/145

004+004 43.8/50.5 75.4/ 83.2 — 80/ 90 003 72/ 79 145/145

NONE —/— 32.6/ 32.6 40/40 ——34/ 34 170/170

002 13.6/15.6 33.7/ 36.3 40/40 ——34/ 35 170/170

003 18.1/20.9 39.4/ 42.9 45/45 ——38/ 41 170/170

005 33.4/38.5 58.4/ 64.9 — 60/ 70 002 56/ 62 170/170

004+004 43.8/50.5 71.5/ 79.9 — 80/ 80 003 68/ 75 170/170

NONE —/— 38.6/ 38.6 45/45 ——39/ 39 174/174

002 13.6/15.6 38.6/ 40.5 45/45 ——39/ 40 174/174

003 18.1/20.9 44.2/ 47.1 50/50 ——44/ 46 174/174

005 33.4/38.5 63.2/ 69.1 — 70/ 70 003 61/ 66 174/174

004+004 43.8/50.5 76.3/ 84.1 — 80/ 90 003 73/ 80 174/174

NONE — 15.2 20 —— 16 70

006 7.2 16.7 20 —— 16 71

008 13.8 25.0 25 —— 18 71

009 16.8 28.7 30 —— 27 71

008+008 27.7 42.3 45 — 025 40 71

HEAT POWER SUPPLY SINGLE

FLA MCA

FUSE OR

HACR BKR

POINT BOX

MOCP FLA LRA

CRSINGLE

---A00

DISCONNECT SIZE*

14

Page 15

Table 1B — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ060) (cont)

UNIT

50HJ005

(cont)

50HJ006

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective device

for the unit shall be fuse or HACR breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

2.

Never operate a motor where a phase imbalance in supply voltage is greater

than 2%. Use the following formula to determine the percent of voltage

imbalance.

= 100 x

NOMINAL

V- PH - Hz

460-3-60

208/230-1-60

208/230-3-60

460-3-60

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

LEGEND

max voltage deviation from average voltage

IFM

TYPE

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

average voltage

CONV

OUTLET

62AQ

HEATER

CRHEATER

FLA

---A00

NONE — 17.9 20 —— 21 75

006 7.2 18.8 25 —— 21 75

008 13.8 27.1 30 —— 21 75

009 16.8 30.8 35 — 025 32 75

008+008 27.7 44.4 45 — 025 44 75

NONE — 15.6 20 —— 16 84

006 7.2 17.1 20 —— 16 85

008 13.8 25.4 30 —— 19 85

009 16.8 29.1 30 —— 28 85

008+008 27.7 42.7 45 — 025 40 85

NONE — 18.3 20 —— 22 89

006 7.2 19.2 25 —— 22 90

008 13.8 27.5 30 —— 22 90

009 16.8 31.2 35 — 025 32 90

008+008 27.7 44.8 45 — 025 45 90

NONE —/— 55.5/ 55.5 70/70 ——56/ 56 250/250

002 23.5/27.1 55.5/ 55.5 — 70/ 70 004 56/ 56 250/250

003 31.4/36.3 59.5/ 65.5 — 70/ 70 004 57/ 62 250/250

002+002 46.9/54.2 78.9/ 87.9 — 80/ 90 005 75/ 83 250/250

003+003 62.8/72.5 98.7/110.8 — 100/125 005 93/104 250/250

004+004 75.8/87.5 115.0/129.6 — 125/150 005 108/121 250/250

NONE —/— 61.5/ 61.5 70/70 ——61/ 61 255/255

002 23.5/27.1 61.5/ 61.5 — 70/ 70 004 61/ 61 255/255

003 31.4/36.3 64.3/ 69.7 — 70/ 70 005 62/ 67 255/255

002+002 46.9/54.2 83.7/ 92.1 — 90/100 005 80/ 88 255/255

003+003 62.8/72.5 103.5/115.0 — 110/125 005 98/109 255/255

004+004 75.8/87.5 119.8/133.8 — 125/150 005 113/126 255/255

NONE —/— 38.1/ 38.1 45/45 ——39/ 39 202/202

002 13.6/15.6 38.1/ 38.1 45/45 ——39/ 39 202/202

004 21.9/25.3 44.1/ 48.3 50/50 ——42/ 46 202/202

005 33.4/38.5 58.4/ 64.9 — 60/ 70 002 56/ 62 202/202

004+004 43.8/50.5 71.5/ 79.9 — 80/ 80 003 68/ 75 202/202

004+005 55.2/63.8 85.8/ 96.4 — 90/100 003 81/ 91 202/202

NONE —/— 44.1/ 44.1 50/50 ——44/ 44 207/207

002 13.6/15.6 44.1/ 44.1 50/50 ——44/ 44 207/207

004 21.9/25.3 48.9/ 52.5 60/60 ——48/ 51 207/207

005 33.4/38.5 63.2/ 69.1 — 70/ 70 003 61/ 66 207/207

004+004 43.8/50.5 76.3/ 84.1 — 80/ 90 003 73/ 80 207/207

004+005 55.2/63.8 90.6/100.6 — 100/110 003 86/ 95 207/207

NONE —/— 39.8/ 39.8 45/45 ——41/ 41 221/221

002 13.6/15.6 39.8/ 39.8 45/45 ——41/ 41 221/221

004 21.9/25.3 45.9/ 50.1 50/60 ——44/ 48 221/221

005 33.4/38.5 60.3/ 66.7 — 70/ 70 003 58/ 63 221/221

004+004 43.8/50.5 73.3/ 81.7 — 80/ 90 003 70/ 77 221/221

004+005 55.2/63.8 87.6/ 98.3 — 90/100 003 83/ 93 221/221

NONE —/— 45.8/ 45.8 50/50 ——46/ 46 226/226

002 13.6/15.6 45.8/ 45.8 50/50 ——46/ 46 226/226

004 21.9/25.3 50.7/ 54.3 60/60 ——50/ 53 226/226

005 33.4/38.5 65.1/ 70.9 — 70/ 80 003 63/ 68 226/226

004+004 43.8/50.5 78.1/ 85.9 — 80/ 90 003 75/ 82 226/226

004+005 55.2/63.8 92.4/102.5 — 100/110 003 88/ 97 226/226

NONE — 19.3 25 —— 20 101

006 7.2 19.3 25 —— 20 101

008 13.8 25.4 30 —— 20 101

009 16.8 29.1 30 —— 28 101

008+008 27.7 42.7 45 — 025 40 101

008+009 30.7 46.4 50 — 025 44 101

NONE — 22.0 25 —— 25 106

006 7.2 22.0 25 —— 25 106

008 13.8 27.5 30 —— 25 106

009 16.8 31.2 35 — 025 32 106

008+008 27.7 44.8 45 — 025 45 106

008+009 30.7 48.5 50 — 025 48 106

HEAT POWER SUPPLY SINGLE

FLA MCA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately.

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

MOCP FLA LRA

7

457

POINT BOX

CRSINGLE

---A00

452 + 464 + 455

1371

=

3

= 457

DISCONNECT SIZE*

3

15

Page 16

Table 1B — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ060) (cont)

UNIT

50HJ006

(cont)

50HJ007

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective device

for the unit shall be fuse or HACR breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

2.

Never operate a motor where a phase imbalance in supply voltage is greater

than 2%. Use the following formula to determine the percent of voltage

imbalance.

= 100 x

NOMINAL

V- PH - Hz

460-3-60

208/230-3-60

460-3-60

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

LEGEND

max voltage deviation from average voltage

IFM

TYPE

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

STD NO 9.2

STD YES 9.2

HIGH STATIC NO 9.2

HIGH STATIC YES 9.2

average voltage

CONV

OUTLET

62AQ

HEATER

CRHEATER

FLA

---A00

NONE — 20.1 25 —— 20 110

006 7.2 20.1 25 —— 20 111

008 13.8 26.2 30 —— 20 111

009 16.8 29.9 30 —— 29 111

008+008 27.7 43.5 45 — 025 41 111

008+009 30.7 47.2 50 — 025 44 111

NONE — 22.8 25 —— 26 115

006 7.2 22.8 25 —— 26 116

008 13.8 28.3 30 —— 26 116

009 16.8 32.0 35 — 025 33 116

008+008 27.7 45.6 50 — 025 46 116

008+009 30.7 49.3 50 — 025 49 116

NONE —/— 42.0/ 42.0 50/50 ——42/42 234/234

002 13.6/15.6 42.0/ 42.0 50/50 ——42/42 234/234

004 21.9/25.3 44.1/ 48.3 50/50 ——42/46 234/234

005 33.4/38.5 58.4/ 64.9 — 60/ 70 002 56/62 234/234

004+004 43.8/50.5 71.5/ 79.9 — 80/ 80 003 68/75 234/234

004+005 55.2/63.8 85.8/ 96.4 — 90/100 003 81/91 234/234

NONE —/— 48.0/ 48.0 60/60 ——48/48 239/239

002 13.6/15.6 48.0/ 48.0 60/60 ——48/48 239/239

004 21.9/25.3 48.9/ 52.5 60/60 ——48/51 239/239

005 33.4/38.5 63.2/ 69.1 — 70/ 70 003 61/66 239/239

004+004 43.8/50.5 76.3/ 84.1 — 80/ 90 003 73/80 239/239

004+005 55.2/63.8 90.6/100.6 — 100/110 003 86/95 239/239

NONE —/— 43.7/ 43.7 50/50 ——44/44 253/253

002 13.6/15.6 43.7/ 43.7 50/50 ——44/44 253/253

004 21.9/25.3 45.9/ 50.1 50/60 ——44/48 253/253

005 33.4/38.5 60.3/ 66.7 — 70/ 70 003 58/63 253/253

004+004 43.8/50.5 73.3/ 81.7 — 80/ 90 003 70/77 253/253

004+005 55.2/63.8 87.6/ 98.3 — 90/100 003 83/93 253/253

NONE —/— 49.7/ 49.7 60/60 ——50/50 258/258

002 13.6/15.6 49.7/ 49.7 60/60 ——50/50 258/258

004 21.9/25.3 50.7/ 54.3 60/60 ——50/53 258/258

005 33.4/38.5 65.1/ 70.9 — 70/ 80 003 63/68 258/258

004+004 43.8/50.5 78.1/ 85.9 — 80/ 90 003 75/82 258/258

004+005 55.2/63.8 92.4/102.5 — 100/110 003 88/97 258/258

NONE — 19.8 25 —— 20 114

006 7.2 19.8 25 —— 20 114

008 13.8 25.4 30 —— 20 114

009 16.8 29.1 30 —— 28 114

008+008 27.7 42.7 45 — 025 40 114

008+009 30.7 46.4 50 — 025 44 114

NONE — 22.5 25 —— 26 118

006 7.2 22.5 25 —— 26 119

008 13.8 27.5 30 —— 26 119

009 16.8 31.2 35 — 025 32 119

008+008 27.7 44.8 45 — 025 45 119

008+009 30.7 48.5 50 — 025 48 119

NONE — 20.6 25 —— 21 123

006 7.2 20.6 25 —— 21 124

008 13.8 26.2 30 —— 21 124

009 16.8 29.9 30 —— 29 124

008+008 27.7 43.5 45 — 025 41 124

008+009 30.7 47.2 50 — 025 44 124

NONE — 23.3 30 —— 26 128

006 7.2 23.3 30 —— 26 128

008 13.8 28.3 30 —— 26 128

009 16.8 32.0 35 — 025 33 128

008+008 27.7 45.6 50 — 025 46 128

008+009 30.7 49.3 50 — 025 49 128

HEAT POWER SUPPLY SINGLE

FLA MCA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately.

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

MOCP FLA LRA

7

457

POINT BOX

CRSINGLE

---A00

452 + 464 + 455

1371

=

3

= 457

DISCONNECT SIZE*

3

16

Page 17

Table 1C — Electrical Data (COBRA™ Energy Recovery 48HJ004-007 Units with 62AQ100)

UNIT

48HJ004

48HJ005

48HJ006

48HJ007

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combi-

2.

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

nation load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR

breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%. Use the following formula to determine

the percent of voltage imbalance.

= 100 x

NOMINAL

V- PH -H z

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60

208/230-3-60

460-3-60

LEGEND

max voltage deviation from average voltage

average voltage

IFM

TYPE

STD NO 15.1 40.7/40.7 45/45 42/42 161/161

STD YES 15.1 46.7/46.7 50/50 48/48 166/166

STD NO 15.1 33.6/33.6 40/40 36/36 150/150

STD YES 15.1 39.6/39.6 45/45 41/41 155/155

HIGH STATIC NO 15.1 34.5/34.5 40/40 37/37 180/180

HIGH STATIC YES 15.1 40.5/40.5 45/45 42/42 184/184

STD NO 15.1 16.5 20 18 76

STD YES 15.1 19.2 20 23 80

HIGH STATIC NO 15.1 16.9 20 18 90

HIGH STATIC YES 15.1 19.6 25 24 95

STD NO 15.1 50.3/50.3 60/60 51/51 199/199

STD YES 15.1 56.3/56.3 70/70 57/57 204/204

STD NO 15.1 37.6/37.6 45/45 39/39 166/166

STD YES 15.1 43.6/43.6 50/50 45/45 171/171

HIGH STATIC NO 15.1 38.5/38.5 45/45 40/40 196/196

HIGH STATIC YES 15.1 44.5/44.5 50/50 46/46 200/200

STD NO 15.1 18.2 20 19 83

STD YES 15.1 20.9 25 25 88

HIGH STATIC NO 15.1 18.6 25 19 97

HIGH STATIC YES 15.1 21.3 25 25 102

STD NO 15.1 61.4/61.4 70/70 62/62 276/276

STD YES 15.1 67.4/67.4 80/80 68/68 281/281

STD NO 15.1 44.0/44.0 50/50 46/46 228/228

STD YES 15.1 50.0/50.0 60/60 51/51 233/233

HIGH STATIC NO 15.1 45.7/45.7 60/60 48/48 247/247

HIGH STATIC YES 15.1 51.7/51.7 60/60 53/53 252/252

STD NO 15.1 22.2 25 23 114

STD YES 15.1 24.9 30 28 119

HIGH STATIC NO 15.1 23.0 30 24 123

HIGH STATIC YES 15.1 25.7 30 29 128

STD NO 15.1 47.9/47.9 60/60 49/49 260/260

STD YES 15.1 53.9/53.9 60/60 55/55 265/265

HIGH STATIC NO 15.1 49.6/49.6 60/60 51/51 279/279

HIGH STATIC YES 15.1 55.6/55.6 60/60 57/57 284/284

STD NO 15.1 22.8 30 23 127

STD YES 15.1 25.5 30 29 131

HIGH STATIC NO 15.1 23.6 30 24 136

HIGH STATIC YES 15.1 26.3 30 30 141

CONV

OUTLET

62AQ

FLA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER SUPPLY DISCONNECT SIZE*

MCA

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

FLA LRA

452 + 464 + 455

3

1371

=

3

= 457

17

Page 18

UNIT

50HJ004

50HJ005

Table 1D — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ100)

NOMINAL

V-P H- Hz

208/230-1-60

208/230-3-60

460-3-60

208/230-1-60

208/230-3-60

460-3-60 STD NO 15.1

IFM

TYPE

STD NO 15.1

STD YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

STD YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

CONV

OUTLET

62AQ

FLA

HEATER

CRHEATER

---A00

NONE —/— 40.7/ 40.7 45/45 ——42/ 42 161/161

001 15.9/18.3 42.5/ 45.5 50/60 ——42/ 44 161/161

002 23.5/27.1 52.0/ 56.5 — 60/ 70 004 50/ 54 161/161

003 31.4/36.3 61.9/ 67.9 — 70/ 70 004 59/ 65 161/161

004 37.9/43.8 70.0/ 77.3 — 80/ 80 004 67/ 73 161/161

002+002 46.9/54.2 81.3/ 90.3 — 90/100 005 77/ 85 161/161

NONE —/— 46.7/ 46.7 50/50 ——48/ 48 166/166

001 15.9/18.3 47.3/ 49.7 60/60 ——48/ 49 166/166

002 23.5/27.1 56.8/ 60.7 — 70/ 70 004 56/ 59 166/166

003 31.4/36.3 66.7/ 72.1 — 70/ 80 004 65/ 70 166/166

004 37.9/43.8 74.8/ 81.5 — 80/ 90 005 72/ 78 166/166

002+002 46.9/54.2 86.1/ 94.5 — 90/100 005 82/ 90 166/166

NONE —/— 33.6/ 33.6 40/40 ——36/ 36 150/150

001 9.2/10.6 34.1/ 35.9 45/45 ——36/ 36 150/150

002 13.6/15.6 39.6/ 42.2 50/50 ——39/ 41 150/150

003 18.1/20.9 45.3/ 48.8 60/60 ——44/ 47 150/150

004 21.9/25.3 50.0/ 54.2 60/60 ——48/ 52 150/150

005 33.4/38.5 64.3/ 70.7 — 70/ 80 002 61/ 67 150/150

NONE —/— 39.6/ 39.6 45/45 ——41/ 41 155/155

001 9.2/10.6 39.6/ 40.1 50/50 ——41/ 41 155/155

002 13.6/15.6 44.4/ 46.4 60/60 ——44/ 46 155/155

003 18.1/20.9 50.1/ 53.0 60/60 ——49/ 52 155/155

004 21.9/25.3 54.8/ 58.4 — 60/ 70 002 54/ 57 155/155

005 33.4/38.5 69.1/ 74.9 — 80/ 80 002 67/ 72 155/155

NONE —/— 34.5/ 34.5 40/40 ——37/ 37 180/180

001 9.2/10.6 35.0/ 36.8 45/45 ——37/ 37 180/180

002 13.6/15.6 40.5/ 43.1 50/50 ——40/ 42 180/180

003 18.1/20.9 46.2/ 49.7 60/60 ——45/ 48 180/180

004 21.9/25.3 50.9/ 55.1 60/60 ——49/ 53 180/180

005 33.4/38.5 65.2/ 71.6 — 70/ 80 002 62/ 68 180/180

NONE —/— 40.5/ 40.5 45/45 ——42/ 42 184/184

001 9.2/10.6 40.5/ 41.0 50/50 ——42/ 42 184/184

002 13.6/15.6 45.3/ 47.3 60/60 ——45/ 47 184/184

003 18.1/20.9 51.0/ 53.9 60/60 ——50/ 53 184/184

004 21.9/25.3 55.7/ 59.3 — 70/ 70 002 55/ 58 184/184

005 33.4/38.5 70.0/ 75.8 — 80/ 80 003 68/ 73 184/184

NONE — 16.5 20.0 —— 18 76

006 7.2 20.1 25.0 —— 18 76

007 10.6 24.3 30.0 —— 18 77

008 13.8 28.4 35.0 — 025 27 80

009 16.8 32.1 35.0 — 025 31 83

NONE — 19.2 20.0 —— 23 80

006 7.2 22.2 30.0 —— 23 81

007 10.6 26.4 30.0 —— 23 81

008 13.8 30.5 35.0 — 025 32 82

009 16.8 34.2 40.0 — 025 35 85

NONE — 16.9 20.0 —— 18 90

006 7.2 20.5 25.0 —— 18 90

007 10.6 24.7 30.0 —— 18 91

008 13.8 28.8 35.0 — 025 28 94

009 16.8 32.5 35.0 — 025 31 97

NONE — 19.6 25.0 —— 24 95

006 7.2 22.6 30.0 —— 24 95

007 10.6 26.8 30.0 —— 24 95

008 13.8 30.9 35.0 — 025 32 96

009 16.8 34.6 40.0 — 025 36 99

NONE —/— 50.3/ 50.3 60/60 ——51/ 51 199/199

001 15.9/18.3 50.3/ 50.3 60/60 ——51/ 51 199/199

003 31.4/36.3 61.9/ 67.9 — 70 70 004 59/ 65 199/199

002+002 46.9/54.2 81.3/ 90.3 — 90/100 005 77/ 85 199/199

003+003 62.8/72.5 101.2/113.3 — 110/125 005 95/106 199/199

004+004 75.8/87.5 117.4/132.0 — 125/150 005 110/124 199/199

NONE —/— 56.3/ 56.3 70/70 ——57/ 57 204/204

001 15.9/18.3 56.3/ 56.3 — 70/ 70 004 57/ 57 204/204

003 31.4/36.3 66.7/ 72.1 — 70/ 80 004 65/ 70 204/204

002+002 46.9/54.2 86.1/ 94.5 — 90/100 005 82/ 90 204/204

003+003 62.8/72.5 106.0/117.5 — 110/125 005 101/111 204/204

004+004 75.8/87.5 122.2/136.2 — 125/150 005 116/128 204/204

NONE —/— 37.6/ 37.6 45/45 ——39/ 39 166/166

002 13.6/15.6 39.6/ 42.2 50/50 ——39/ 41 166/166

003 18.1/20.9 45.3/ 48.8 60/60 ——44/ 47 166/166

005 33.4/38.5 64.3/ 70.7 — 70/ 80 002 61/ 67 166/166

004+004 43.8/50.5 77.3/ 85.8 — 80/ 90 003 73/ 81 166/166

NONE —/— 43.6/ 43.6 50/50 ——45/ 45 171/171

002 13.6/15.6 44.4/ 46.4 60/60 ——45/ 46 171/171

003 18.1/20.9 50.1/ 53.0 60/60 ——49/ 52 171/171

005 33.4/38.5 69.1/ 74.9 — 80/ 80 002 67/ 72 171/171

004+004 43.8/50.5 82.1/ 90.0 — 90/ 90 003 79/ 86 171/171

NONE —/— 38.5/ 38.5 45/45 ——40/ 40 196/196

002 13.6/15.6 40.5/ 43.1 50/50 ——40/ 42 196/196

003 18.1/20.9 46.2/ 49.7 60/60 ——45/ 48 196/196

005 33.4/38.5 65.2/ 71.6 — 70/ 80 002 62/ 68 196/196

004+004 43.8/50.5 78.2/ 86.7 — 80/ 90 003 74/ 82 196/196

NONE —/— 44.5/ 44.5 50/50 ——46/ 46 200/200

002 13.6/15.6 45.3/ 47.3 60/60 ——46/ 47 200/200

003 18.1/20.9 51.0/ 53.9 60/60 ——50/ 53 200/200

005 33.4/38.5 70.0/ 75.8 — 80/ 80 003 68/ 73 200/200

004+004 43.8/50.5 83.0/ 90.9 — 90/100 003 80/ 87 200/200

NONE — 18.2 20 —— 19 83

006 7.2 20.1 25 —— 19 84

008 13.8 28.4 35 — 025 19 84

009 16.8 32.1 30 — 025 31 84

008+008 27.7 45.6 50 — 025 43 94

HEAT POWER SUPPLY SINGLE

FLA MCA

FUSE OR

HACR BKR

POINT BOX

MOCP FLA LRA

CRSINGLE

---A00

DISCONNECT SIZE*

18

Page 19

Table 1D — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ100) (cont)

UNIT

50HJ005

(cont)

50HJ006

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective device

for the unit shall be fuse or HACR breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

2.

Never operate a motor where a phase imbalance in supply voltage is greater

than 2%. Use the following formula to determine the percent of voltage

imbalance.

= 100 x

NOMINAL

V-P H- Hz

460-3-60

208/230-1-60

208/230-3-60

460-3-60

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

LEGEND

max voltage deviation from average voltage

IFM

TYPE

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

STD YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

average voltage

CONV

OUTLET

HEATER

62AQ

CRHEATER

FLA

---A00

NONE — 20.9 25 —— 25 88

006 7.2 22.2 30 —— 25 88

008 13.8 30.5 35 — 025 25 88

009 16.8 34.2 40 — 025 35 88

008+008 27.7 47.7 50 — 025 48 96

NONE — 18.6 25 —— 19 97

006 7.2 20.5 25 —— 19 98

008 13.8 28.8 35 — 025 19 98

009 16.8 32.5 35 — 025 31 98

008+008 27.7 46.0 50 — 025 43 108

NONE — 21.3 25 —— 25 102

006 7.2 22.6 30 —— 25 103

008 13.8 30.9 35 — 025 25 103

009 16.8 34.6 40 — 025 36 103

008+008 27.7 48.1 50 — 025 48 110

NONE —/— 61.4/ 61.4 70/70 ——62/ 62 276/276

002 23.5/27.1 61.4/ 61.4 — 70/ 70 004 62/ 62 276/276

003 31.4/36.3 65.8/ 71.8 — 70/ 80 004 64/ 69 276/276

002+002 46.9/54.2 85.2/ 94.2 — 90/100 005 81/ 90 276/276

003+003 62.8/72.5 105.1/117.2 — 110/125 005 100/111 276/276

004+004 75.8/87.5 121.3/135.9 — 125/150 005 115/128 276/276

NONE —/— 67.4/ 67.4 80/80 ——68/ 68 281/281

002 23.5/27.1 67.4/ 67.4 — 80/ 80 004 68/ 68 281/281

003 31.4/36.3 70.6/ 76.0 — 80/ 80 005 69/ 74 281/281

002+002 46.9/54.2 90.0/ 98.4 — 90/100 005 87/ 95 281/281

003+003 62.8/72.5 109.9/121.4 — 110/125 005 105/116 281/281

004+004 75.8/87.5 126.1/140.1 — 150/150 005 120/133 281/281

NONE —/— 44.0/ 44.0 50/50 ——46/ 46 228/228

002 13.6/15.6 44.0/ 44.0 50/50 ——46/ 46 228/228

004 21.9/25.3 50.9/ 55.1 60/60 ——49/ 53 228/228

005 33.4/38.5 65.2/ 71.6 — 70/ 80 002 62/ 68 228/228

004+004 43.8/50.5 78.2/ 86.7 — 80/ 90 003 74/ 82 228/228

004+005 55.2/63.8 92.6/103.2 — 100/110 003 88/ 97 228/228

NONE —/— 50.0/ 50.0 60/60 ——51/ 51 233/233

002 13.6/15.6 50.0/ 50.0 60/60 ——51/ 51 233/233

004 21.9/25.3 55.7/ 59.3 — 70/ 70 002 55/ 58 233/233

005 33.4/38.5 70.0/ 75.8 — 80/ 80 003 68/ 73 233/233

004+004 43.8/50.5 83.0/ 90.9 — 90/100 003 80/ 87 233/233

004+005 55.2/63.8 97.4/107.4 — 100/110 003 93/102 233/233

NONE —/— 45.7/ 45.7 60/60 ——48/ 48 247/247

002 13.6/15.6 45.7/ 45.7 60/60 ——48/ 48 247/247

004 21.9/25.3 52.6/ 56.8 — 60/ 70 002 51/ 55 247/247

005 33.4/38.5 66.9/ 73.3 — 70/ 80 002 64/ 70 247/247

004+004 43.8/50.5 79.9/ 88.4 — 80/ 90 003 76/ 84 247/247

004+005 55.2/63.8 94.3/104.9 — 100/110 003 90/ 99 247/247

NONE —/— 51.7/ 51.7 60/60 ——53/ 53 252/252

002 13.6/15.6 51.7/ 51.7 60/60 ——53/ 53 252/252

004 21.9/25.3 57.4/ 61.0 — 70/ 70 002 57/ 60 252/252

005 33.4/38.5 71.7/ 77.5 — 80/ 80 003 70/ 75 252/252

004+004 43.8/50.5 84.7/ 92.6 — 90/100 003 82/ 89 252/252

004+005 55.2/63.8 99.1/109.1 — 100/110 003 95/104 252/252

NONE — 22.2 25 —— 23 114

006 7.2 22.2 25 —— 23 114

008 13.8 28.8 35 — 025 23 114

009 16.8 32.5 35 — 025 31 114

008+008 27.7 46.0 50 — 025 43 114

008+009 30.7 49.8 50 — 025 47 114

HEAT POWER SUPPLY SINGLE

FLA MCA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately.

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

MOCP FLA LRA

7

457

POINT BOX

CRSINGLE

---A00

452 + 464 + 455

1371

=

3

= 457

DISCONNECT SIZE*

3

19

Page 20

Table 1D — Electrical Data (COBRA™ Energy Recovery 50HJ004-007 Units with 62AQ100) (cont)

UNIT

50HJ006

(cont)

50HJ007

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective device

for the unit shall be fuse or HACR breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

2.

Never operate a motor where a phase imbalance in supply voltage is greater

than 2%. Use the following formula to determine the percent of voltage

imbalance.

= 100 x

NOMINAL

V-P H- Hz

460-3-60

208/230-3-60

460-3-60

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

LEGEND

max voltage deviation from average voltage

IFM

TYPE

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

STD NO 15.1

STD YES 15.1

HIGH STATIC NO 15.1

HIGH STATIC YES 15.1

average voltage

CONV

OUTLET

62AQ

HEATER

CRHEATER

FLA

---A00

NONE — 24.9 30 ——28 119

006 7.2 24.9 30 ——28 119

008 13.8 30.9 35 — 025 28 119

009 16.8 34.6 40 — 025 36 119

008+008 27.7 48.1 50 — 025 48 119

008+009 30.7 51.9 60 — 025 52 119

NONE — 23.0 30 ——24 123

006 7.2 23.0 30 ——24 124

008 13.8 29.6 35 — 025 24 124

009 16.8 33.3 35 — 025 32 124

008+008 27.7 46.8 50 — 025 44 124

008+009 30.7 50.6 60 — 025 48 124

NONE — 25.7 30 ——29 128

006 7.2 25.7 30 ——29 129

008 13.8 31.7 35 — 025 29 129

009 16.8 35.4 40 — 025 37 129

008+008 27.7 48.9 50 — 025 49 129

008+009 30.7 52.7 60 — 025 53 129

NONE —/— 47.9/ 47.9 60/60 ——49/ 49 260/260

002 13.6/15.6 47.9/ 47.9 60/60 ——49/ 49 260/260

004 21.9/25.3 50.9/ 55.1 60/60 ——49/ 53 260/260

005 33.4/38.5 65.2/ 71.6 — 70/ 80 002 62/ 68 260/260

004+004 43.8/50.5 78.2/ 86.7 — 80/ 90 003 74/ 82 260/260

004+005 55.2/63.8 92.6/103.2 — 100/110 003 88/ 97 260/260

NONE —/— 53.9/ 53.9 60/60 ——55/ 55 265/265

002 13.6/15.6 53.9/ 53.9 60/60 ——55/ 55 265/265

004 21.9/25.3 55.7/ 59.3 — 70/ 70 002 55/ 58 265/265

005 33.4/38.5 70.0/ 75.8 — 80/ 80 003 68/ 73 265/265

004+004 43.8/50.5 83.0/ 90.9 — 90/100 003 80/ 87 265/265

004+005 55.2/63.8 97.4/107.4 — 100/110 003 93/102 265/265

NONE —/— 49.6/ 49.6 60/60 ——51/ 51 279/279

002 13.6/15.6 49.6/ 49.6 60/60 ——51/ 51 279/279

004 21.9/25.3 52.6/ 56.8 — 60/ 70 002 51/ 55 279/279

005 33.4/38.5 66.9/ 73.3 — 70/ 80 002 64/ 70 279/279

004+004 43.8/50.5 79.9/ 88.4 — 80/ 90 003 76/ 84 279/279

004+005 55.2/63.8 94.3/104.9 — 100/110 003 90/ 99 279/279

NONE —/— 55.6/ 55.6 60/60 ——57/ 57 284/284

002 13.6/15.6 55.6/ 55.6 60/60 ——57/ 57 284/284

004 21.9/25.3 57.4/ 61.0 — 70/ 70 002 57/ 60 284/284

005 33.4/38.5 71.7/ 77.5 — 80/ 80 003 70/ 75 284/284

004+004 43.8/50.5 84.7/ 92.6 — 90/100 003 82/ 89 284/284

004+005 55.2/63.8 99.1/109.1 — 100/110 003 95/104 284/284

NONE — 22.8 30 ——23 127

006 7.2 22.8 30 ——23 127

008 13.8 28.8 35 — 025 23 127

009 16.8 32.5 35 — 025 31 127

008+008 27.7 46.0 50 — 025 43 127

008+009 30.7 49.8 50 — 025 47 127

NONE — 25.5 30 ——29 131

006 7.2 25.5 30 ——29 132

008 13.8 30.9 35 — 025 29 132

009 16.8 34.6 40 — 025 36 132

008+008 27.7 48.1 50 — 025 48 132

008+009 30.7 51.9 60 — 025 52 132

NONE — 23.6 30 ——24 136

006 7.2 23.6 30 ——24 137

008 13.8 29.6 35 — 025 24 137

009 16.8 33.3 35 — 025 32 137

008+008 27.7 46.8 50 — 025 44 137

008+009 30.7 50.6 60 — 025 48 137

NONE — 26.3 30 ——30 141

006 7.2 26.3 30 ——30 141

008 13.8 31.7 35 — 025 30 141

009 16.8 35.4 40 — 025 37 141

008+008 27.7 48.9 50 — 025 49 141

008+009 30.7 52.7 60 — 025 53 141

HEAT POWER SUPPLY SINGLE

FLA MCA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately.

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

MOCP FLA LRA

7

457

POINT BOX

CRSINGLE

---A00

452 + 464 + 455

1371

=

3

= 457

DISCONNECT SIZE*

3

20

Page 21

Table 1E — Electrical Data (COBRA™ Energy Recovery 48HJ008-014 Units with 62AQ200)

UNIT

48HJ008

48HJ009

48HJ012

48HJ014

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combi-

2.

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

nation load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR

breaker. UL, Canada units may be fuse or circuit breaker.

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%. Use the following formula to determine

the percent of voltage imbalance.

= 100 x

NOMINAL

V-PH -H Z

208/230-3-60

460-3-60

208/230-3-60

460-3-60

208/230-3-60

460-3-60

208/230-3-60

460-3-60

LEGEND

max voltage deviation from average voltage

average voltage

IFM

TYPE

STD NO 21.9 60.1 70 66 366

STD YES 21.9 66.1 70 71 371

HIGH STATIC NO 21.9 63.2 70 69 391

HIGH STATIC YES 21.9 69.2 80 75 395

STD NO 10.2 29.4 35 32 184

STD YES 10.2 32.1 35 34 186

HIGH STATIC NO 10.2 30.8 35 34 197

HIGH STATIC YES 10.2 33.5 35 36 199

STD NO 21.9 62.1 70 68 400

STD YES 21.9 68.1 70 73 405

HIGH STATIC NO 21.9 65.2 70 71 425

HIGH STATIC YES 21.9 65.2 70 71 425

STD NO 10.2 31.7 35 34 206

STD YES 10.2 34.4 40 37 208

HIGH STATIC NO 10.2 33.1 35 36 219

HIGH STATIC YES 10.2 35.8 40 38 221

STD NO 21.9 74.9 80 81 465

STD YES 21.9 80.9 90 87 469

HIGH STATIC NO 21.9 79.3 90 86 488

HIGH STATIC YES 21.9 85.3 90 92 493

STD NO 10.2 35.1 40 38 234

STD YES 10.2 37.8 40 40 236

HIGH STATIC NO 10.2 37.7 40 41 245

HIGH STATIC YES 10.2 40.4 45 43 247

STD NO 21.9 82.5 90 89 550

STD YES 21.9 88.5 100 95 555

STD NO 10.2 39.3 45 43 270

STD YES 10.2 42.0 45 45 272

CONV

OUTLET

62AQ

FLA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER SUPPLY DISCONNECT SIZE*

MCA

FUSE OR

HACR BKR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

= 1.53%

457

FLA LRA

452 + 464 + 455

3

1371

=

3

= 457

21

Page 22

UNIT

50HJ008

50HJ009

Table 1F — Electrical Data (COBRA™ Energy Recovery 50HJ008-014 Units with 62AQ200)

NOMINAL

V-P H- Hz

208/230-3-60

460-3-60

208/230-3-60

460-3-60

IFM

TYPE

STD NO 21.9

STD YES 21.9

HIGH STATIC NO 21.9

HIGH STATIC YES 21.9

STD NO 10.2

STD YES 10.2

HIGH STATIC NO 10.2

HIGH STATIC YES 10.2

STD NO 21.9

STD YES 21.9

HIGH STATIC NO 21.9

HIGH STATIC YES 21.9

STD NO 10.2

STD YES 10.2

HIGH STATIC NO 10.2

HIGH STATIC YES 10.2

CONV

OUTLET

62AQ

FLA

HEATER

CRHEATER

---A00

NONE —/— 60.1/ 60.1 70/70 —/—— 66/ 66 366/366

017 21.7/ 25.0 60.1/ 64.0 — 70/ 80 007 66/ 66 366/366

010 33.4/ 38.5 74.5/ 80.9 — 80/ 90 007 72/ 78 366/366

011 51.7/ 59.7 97.4/107.4 — 100/110 009 93/102 366/366

012 66.7/ 77.0 116.2/129.0 — 125/150 009 111/122 366/366

012+017 88.4/102.0 143.3/160.3 — 150/175 009 135/151 366/366

NONE —/— 66.1/ 66.1 70/70 —/—— 71/ 71 371/371

017 21.7/ 25.0 66.1/ 68.2 — 80/ 80 007 71/ 71 371/371

010 33.4/ 38.5 79.3/ 85.1 — 90/ 90 009 78/ 83 371/371

011 51.7/ 59.7 102.2/111.6 — 110/125 009 99/107 371/371

012 66.7/ 77.0 121.0/133.2 — 125/150 009 116/127 371/371

012+017 88.4/102.0 148.1/164.5 — 150/175 009 141/156 371/371

NONE —/— 63.2/ 63.2 70/70 —/—— 69/ 69 391/391

017 21.7/ 25.0 63.2/ 67.1 — 80/ 80 007 69/ 69 391/391

010 33.4/ 38.5 77.6/ 84.0 — 90/ 90 009 76/ 82 391/391

011 51.7/ 59.7 100.5/110.5 — 110/125 009 97/106 391/391

012 66.7/ 77.0 119.3/132.1 — 125/150 009 114/126 391/391

012+017 88.4/102.0 146.4/163.4 — 150/175 009 139/155 391/391

NONE —/— 69.2/ 69.2 80/80 —/—— 75/ 75 395/395

017 21.7/ 25.0 69.2/ 71.3 — 80/ 80 007 75/ 75 395/395

010 33.4/ 38.5 82.4/ 88.2 — 90/100 009 81/ 86 395/395

011 51.7/ 59.7 105.3/114.7 — 110/125 009 102/111 395/395

012 66.7/ 77.0 124.1/136.3 — 125/150 009 120/131 395/395

012+017 88.4/102.0 151.2/167.6 — 175/175 009 145/160 395/395

NONE — 29.4 35.0 ——32.0 184.0

016 16.7 36.1 40.0 — 006 35.0 184.0

013 19.8 40.0 45.0 — 006 38.0 184.0

014 33.4 57.0 60.0 — 006 54.0 184.0

015 39.7 64.8 — 70.0 008 61.0 184.0

014+016 50.2 77.9 — 80.0 010 73.0 184.0

NONE — 32.1 35.0 ——34.0 186.0

016 16.7 38.2 45.0 — 006 37.0 186.0

013 19.8 42.1 45.0 — 006 41.0 186.0

014 33.4 59.1 60.0 — 006 57.0 186.0

015 39.7 66.9 — 70.0 008 64.0 186.0

014+016 50.2 80.0 — 80.0 010 76.0 186.0

NONE — 30.8 35.0 ——34.0 196.0

016 16.7 37.5 40.0 — 006 36.0 197.0

013 19.8 41.4 45.0 — 006 40.0 197.0

014 33.4 58.4 60.0 — 006 56.0 197.0

015 39.7 66.2 — 70.0 008 63.0 197.0

014+016 50.2 79.3 — 80.0 010 75.0 197.0

NONE — 33.5 35.0 ——36.0 198.0

016 16.7 39.6 45.0 — 006 39.0 199.0

013 19.8 43.5 45.0 — 006 42.0 199.0

014 33.4 60.5 — 70.0 008 58.0 199.0

015 39.7 68.3 — 70.0 008 65.0 199.0

014+016 50.2 81.4 — 90.0 010 77.0 199.0

NONE —/— 62.1/ 62.1 70/70 ——68/ 68 400/400

017 21.7/ 25.0 62.1/ 64.0 — 70/ 80 012 68/ 68 400/400

010 33.4/ 38.5 74.5/ 80.9 — 80/ 90 012 72/ 78 400/400

011 51.7/ 59.7 97.4/107.4 — 100/110 015 93/102 400/400

012 66.7/ 77.0 116.2/129.0 — 125/150 015 111/122 400/400

012+017 88.4/102.0 143.3/160.3 — 150/175 015 135/151 400/400

NONE —/— 68.1/ 68.1 70/70 ——73/ 73 405/405

017 21.7/ 25.0 68.1/ 68.2 — 80/ 80 012 73/ 73 405/405

010 33.4/ 38.5 79.3/ 85.1 — 90/ 90 015 78/ 83 405/405

011 51.7/ 59.7 102.2/111.6 — 110/125 015 99/107 405/405

012 66.7/ 77.0 121.0/133.2 — 125/150 015 116/127 405/405

012+017 88.4/102.0 148.1/164.5 — 150/175 015 141/156 405/405

NONE —/— 65.2/ 65.2 70/70 —/—— 71/ 71 425/425

017 21.7/ 25.0 65.2/ 67.1 — 80/ 80 012 71/ 71 425/425

010 33.4/ 38.5 77.6/ 84.0 — 90/ 90 015 76/ 82 425/425

011 51.7/ 59.7 100.5/110.5 — 110/125 015 97/106 425/425

012 66.7/ 77.0 119.3/132.1 — 125/150 015 114/126 425/425

012+017 88.4/102.0 146.4/163.4 — 150/175 015 139/155 425/425

NONE —/— 71.2/ 71.2 80/80 —/—— 77/ 77 429/429

017 21.7/ 25.0 71.2/ 71.3 — 80/ 80 012 77/ 77 429/429

010 33.4/ 38.5 82.4 /88.2 — 90/100 015 81/ 86 429/429

011 51.7/ 59.7 105.3/114.7 — 110/125 015 102/111 429/429

012 66.7/ 77.0 124.1/136.3 — 125/150 015 120/131 429/429

012+017 88.4/102.0 151.2/167.6 — 175/175 015 145/160 429/429

NONE — 31.7 35.0 ——34.0 206.0

016 16.7 36.1 40.0 — 011 35.0 206.0

013 19.8 40.0 45.0 — 011 38.0 206.0

014 33.4 57.0 60.0 — 011 54.0 206.0

015 39.7 64.8 — 70.0 014 61.0 206.0

014+016 50.2 77.9 — 80.0 016 73.0 206.0

NONE — 34.4 40.0 ——37.0 208.0

016 16.7 38.2 45.0 — 011 37.0 208.0

013 19.8 42.1 45.0 — 011 41.0 208.0

014 33.4 59.1 60.0 — 011 57.0 208.0

015 39.7 66.9 — 70.0 014 64.0 208.0

014+016 50.2 80.0 — 80.0 016 76.0 208.0

NONE — 33.1 35.0 ——36.0 218.0

016 16.7 37.5 40.0 — 011 36.0 219.0

013 19.8 41.4 45.0 — 011 40.0 219.0

014 33.4 58.4 60.0 — 011 56.0 219.0

015 39.7 66.2 — 70.0 014 63.0 219.0

014+016 50.2 79.3 — 80.0 016 75.0 219.0

NONE — 35.8 40.0 ——38.0 220.0

016 16.7 39.6 45.0 — 011 39.0 221.0

013 19.8 43.5 45.0 — 011 42.0 221.0

014 33.4 60.5 — 70.0 014 58.0 221.0

015 39.7 68.3 — 70.0 014 65.0 221.0

014+016 50.2 81.4 — 90.0 016 77.0 221.0

HEAT POWER SUPPLY SINGLE

FLA MCA

FUSE OR

HACR BKR

MOCP FLA LRA

POINT BOX

CRSINGLE

---A00

DISCONNECT SIZE*

22

Page 23

Table 1F — Electrical Data (COBRA™ Energy Recovery 50HJ008-014 Units with 62AQ200) (cont)

UNIT

50HJ012

50HJ014

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

UL —

*Used to determine minimum disconnect per NEC.

†Single point box CRSINGLE017A00 is part of base unit.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment

(refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall

be fuse or HACR breaker. UL, Canada units may be fuse or circuit breaker.

2.

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

Use the following formula to determine the percent of voltage imbalance.

= 100 x

NOMINAL

V- PH -H z

208/230-3-60

460-3-60

208/230-3-60

460-3-60

Full Load Amps

Heating, Air Conditioning and Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Underwriters’ Laboratories

LEGEND

max voltage deviation from average voltage

IFM

TYPE

STD NO 21.9

STD YES 21.9

HIGH STATIC NO 21.9

HIGH STATIC YES 21.9

STD NO 10.2

STD YES 10.2

HIGH STATIC NO 10.2

HIGH STATIC YES 10.2

STD NO 21.9

STD YES 21.9

STD NO 10.2

STD YES 10.2

average voltage

CONV

OUTLET

62AQ

HEATER

CRHEATER

FLA

---A00

NONE —/— 74.9/ 74.9 — 80/ 80 † 81/ 81 465/465

017 21.7/ 25.0 74.9/ 74.9 — 80/ 80 † 81/ 81 465/465

010 33.4/ 38.5 77.6/ 84.0 — 90/ 90 † 81/ 82 465/465

012 66.7/ 77.0 119.3/132.1 — 125/150 † 114/126 465/465