Page 1

48/50FC 04--- 07, 48/50GC 04--- 06

Single Package Rooftop Units

with SystemVu™ Controls Version 1.X

and Puronr (R---410A) R efrig er ant

Controls, Start-- Up, Operation

and Troubleshooti ng

IMPORTANT: This literature covers 48/50FC 04--07 and 48/50GC 04 --06 models with SystemVu controls version 1.X (factory--installed

option).

C150173

TABLE OF CONTENTS

Page

SAFETY CONSIDERATIONS 2.........................

GENERAL 3.........................................

Conventions Used in This Manual 3......................

BASIC CONTROL USAGE 3...........................

SystemVu Control (factory--installed option) 3..............

SystemVu Interface 3.................................

Accessory Navigatort Display 4........................

System Pilott andTouchPilott Devices 5................

CCN Tables and Display 5.............................

START--UP 6.........................................

Unit Preparation 6....................................

Refrigerant Service Ports 6.............................

Crankcase Heater 6...................................

Compressor Rotation 6................................

Power Supply 6.....................................

Internal Wiring 6.....................................

Evaporator Fan 6....................................

Condenser Fans and Motors 6...........................

Return--Air Filters 8..................................

Outdoor--Air Inlet Screens 8............................

Accessory Installation 8...............................

Gas Heat (48FC and 48GC) 8...........................

CONTROLS QUICK SET--UP 8.........................

Control Set Point and Confirmation Log 8.................

Initial Startup 8......................................

Thermostat Control 9.................................

Space Temperature Sensor Control -- Direct Wired

(T--55 or T--56 or T --59) 9.............................

Space Humidistat Control 9............................

Space Relative Humidity Sensor Control 9.................

CCN Communication 9...............................

CCN Linkage Control 9...............................

1

Page 2

System Pilott -- Communication Space Sensor 9...........

Accessories 9.......................................

Programming Operating Schedules 10....................

SERVICE TEST 10....................................

Independent Outputs 10...............................

Fan Test 10.........................................

Cooling Test 11.....................................

Heating Test 11......................................

Automatic Test 11....................................

THIRD PARTY CONTROL 12..........................

Cooling/Heating Control 12............................

Dehumidification Control 12...........................

Remote Occupancy 12................................

Remote Shutdown 12.................................

Alarm Output 12.....................................

Economizer Damper Control 12.........................

CONTROLS OPERATION 12...........................

Display Configuration 12..............................

Unit Configuration 12.................................

General Operation 13.................................

Demand Determination 13.............................

Occupancy Determination 15...........................

Indoor Fan Operation 16...............................

Cooling Operation 16.................................

Optional Humidi--MiZer

Indoor Fan Based Dehumidification 21...................

Heating Operation 21.................................

Supply Air Tempering 22..............................

Two Position Damper Operation 22......................

Economizer Operation 22..............................

Power Exhaust 24....................................

Indoor Air Quality (IAQ) 25............................

Pre--occupancy Purge 26...............................

Temperature Compensated Start 26.......................

Linkage 26.........................................

Carrier Comfort Network

BACnet Network Operation 26.........................

Alarm Handling 27...................................

TROUBLESHOOTING 27..............................

Complete Unit Stoppage 27............................

Restart Procedure 27..................................

Faults and Alerts 27..................................

Control Module Communication 34......................

Communication Failures 34............................

Cooling Troubleshooting 35............................

Humidi--MiZer System Troubleshooting 36................

Economizer Troubleshooting 37.........................

Heating Troubleshooting 38............................

Phase Protection 41..................................

Thermistor Troubleshooting 41.........................

Sensor Trim 41......................................

Transducer Troubleshooting 41.........................

R

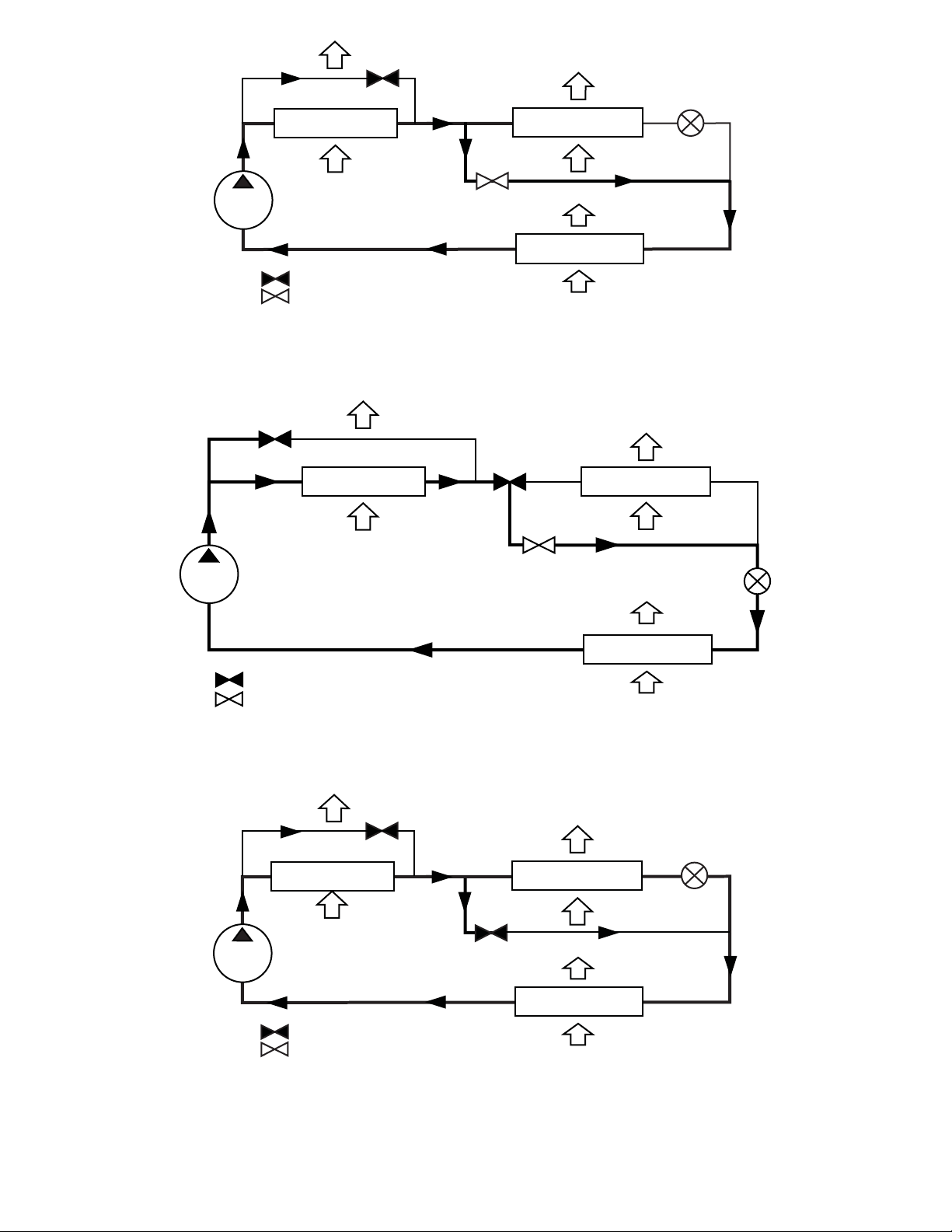

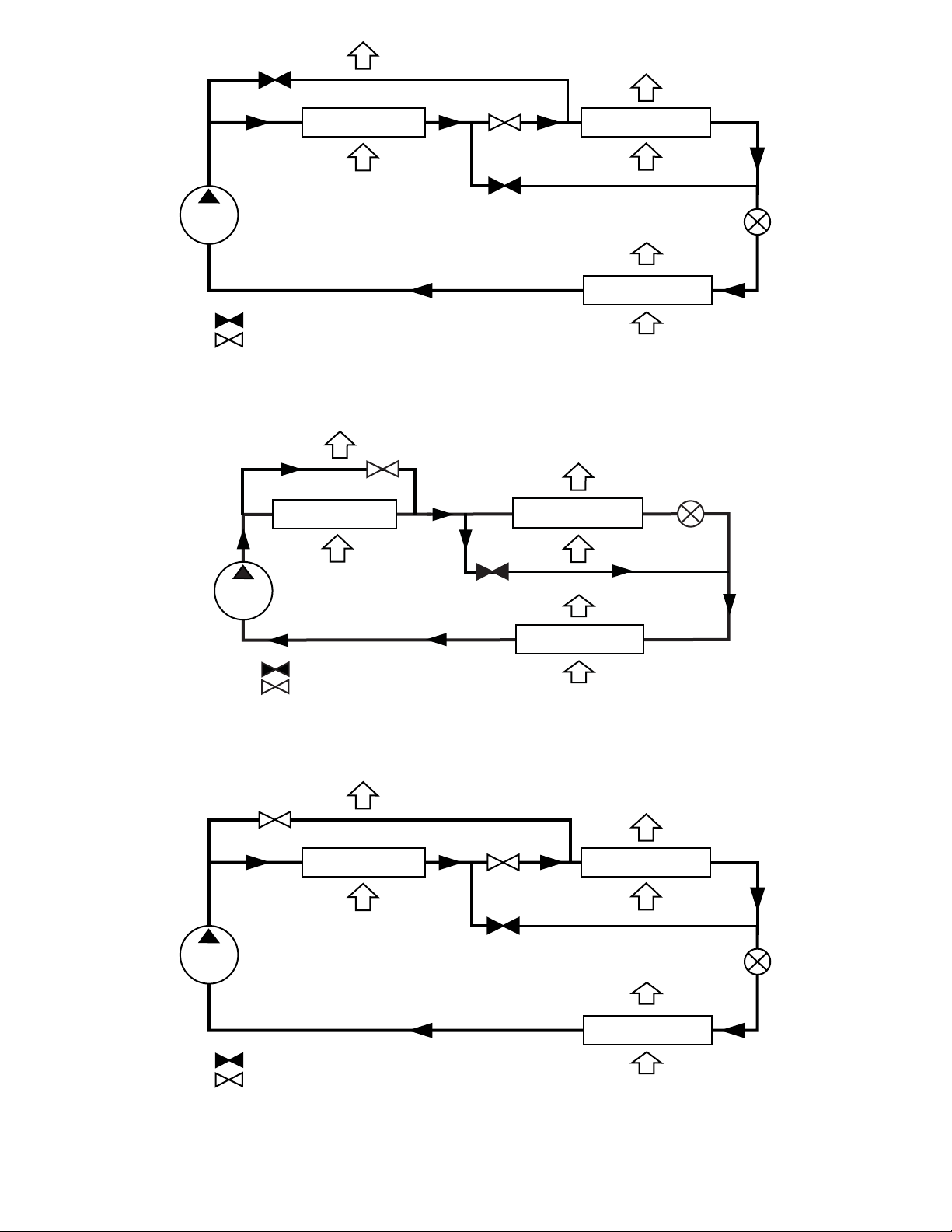

Dehumidification System 17......

R

(CCN) Operation 26............

MAJOR SYSTEM COMPONENTS 46....................

General 46.........................................

Main Base Board (MBB) 54............................

Integrated Gas Control (IGC) Board 56...................

Protective Devices 57.................................

Space Mounted Sensors 57.............................

Carrier Comfort Network

APPENDIX A: SystemVut Controller Display 61...........

APPENDIX B: SystemVu Controller Text Point Reference 83...

APPENDIX C: Navigatort Display 84....................

APPENDIX D: SystemVu Controller CCN Tables 95..........

APPENDIX E: BACnet Points List 119....................

CONTROL SET POINT AND CONFIGURATION L OG 132...

UNIT S TART--UP CHECKLIST 143......................

R

(CCN) Interface 59.............

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should install, repair, or

service air-conditioning equipment. Untrained personnel can

perform the basic maintenance functions of replacing filters.

Trained service personnel should perform all other operations.

When working on air-conditioning equipment, observe precautions in

the literature, tags and labels attached to the unit, and other safety

precautions that may apply. Follow all safety codes. W ear safety

glasses and work gloves. Use quenchi ng cloth for unbrazing

operations. Have fire exti ngui shers availa ble for all brazing operations.

Follow all safety codes. Wear safety glasses and work gloves. Have

fire extinguisher available. Read these instructions thoroughly and

follow all warnings or cautions attached to the unit. Consult local

building codes and National Electrical Code (NEC) for special

requirements.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understa nd the signal words DANGER, WARNING, and CAUTION.

These words are used with the safet y--alert symbol. DANGER

identifies the most serious hazards which will result in severe personal

injury or death. WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may resul t in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

or death.

Before performing service or maintenance operations on

unit, turn off main power switch to unit and install lockout

tag. Ensure electrical service to rooftop unit agrees with

voltage and amperage listed on the unit rating plate.

.

2

Page 3

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may cause equipment

damage.

This unit uses a microprocessor--based electronic control

system. Do not use jumpers or other tools to short out

components or to bypass or otherwise depart from

recommended procedures. Any short--to --ground of the

control board or accompanying wiring may destroy the

electronic modules or electrical components.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, personal injury, or

loss of life. Refer to the User’s Information Manual

provided with this unit for more details.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. What

to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any phone in

your building.

3. IMMEDIATELY call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire

department.

GENERAL

This publication contains Start--Up, Controls, Operation, Service,

and Troubleshooting information for the 48/50FC and 48/50GC

rooftop units equipped with the factory--installed optional

SystemVut controls (version 1.X or higher) and use Puronr

(R--410A) refrigerant. The specific base unit installation

instructions, service manual and/or wiring label diagram may also

be required in conjunction with this book as a guide to a specific

unit on the roof. All units in Table 1 are Staged Air Volume

(SAVt) units that allow for stand--alone or network operation.

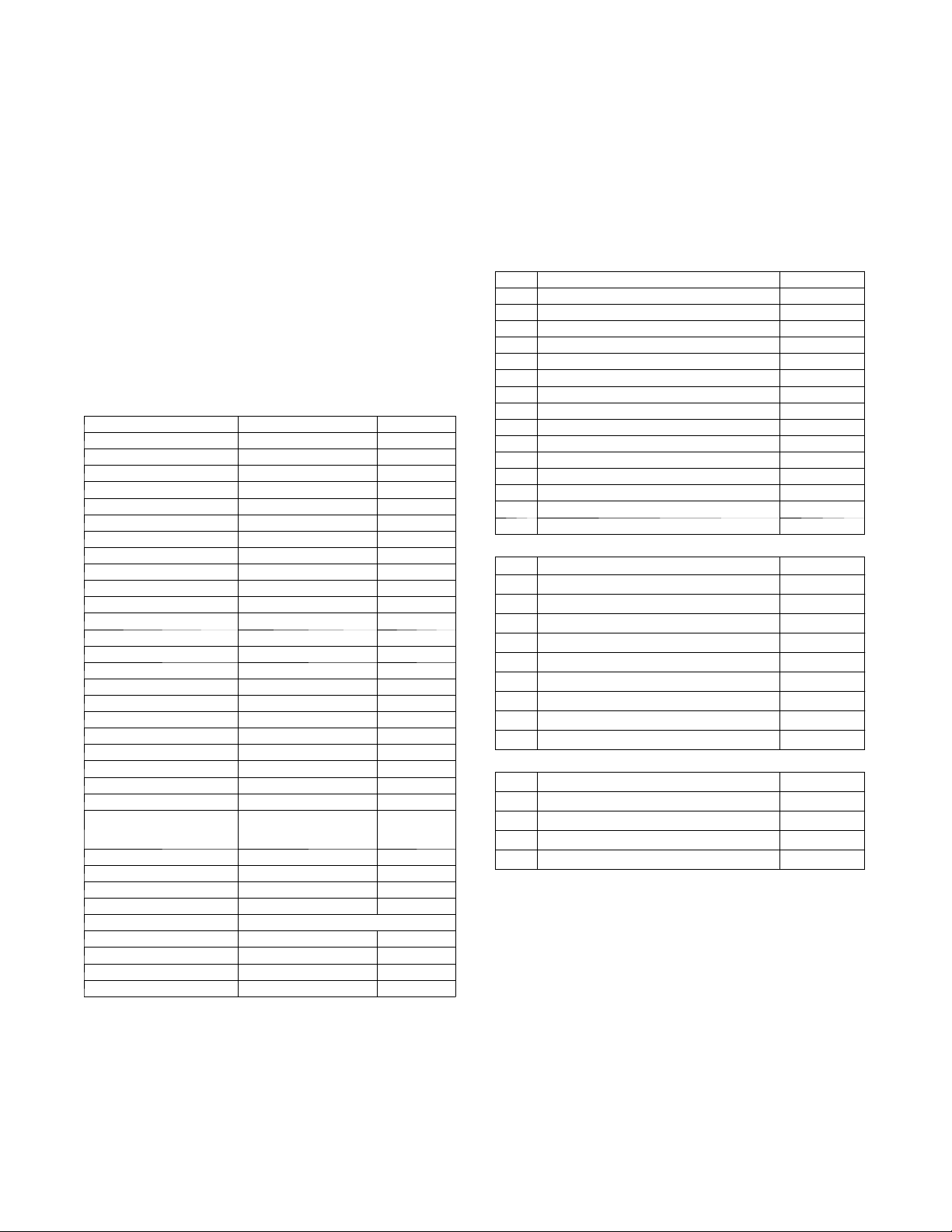

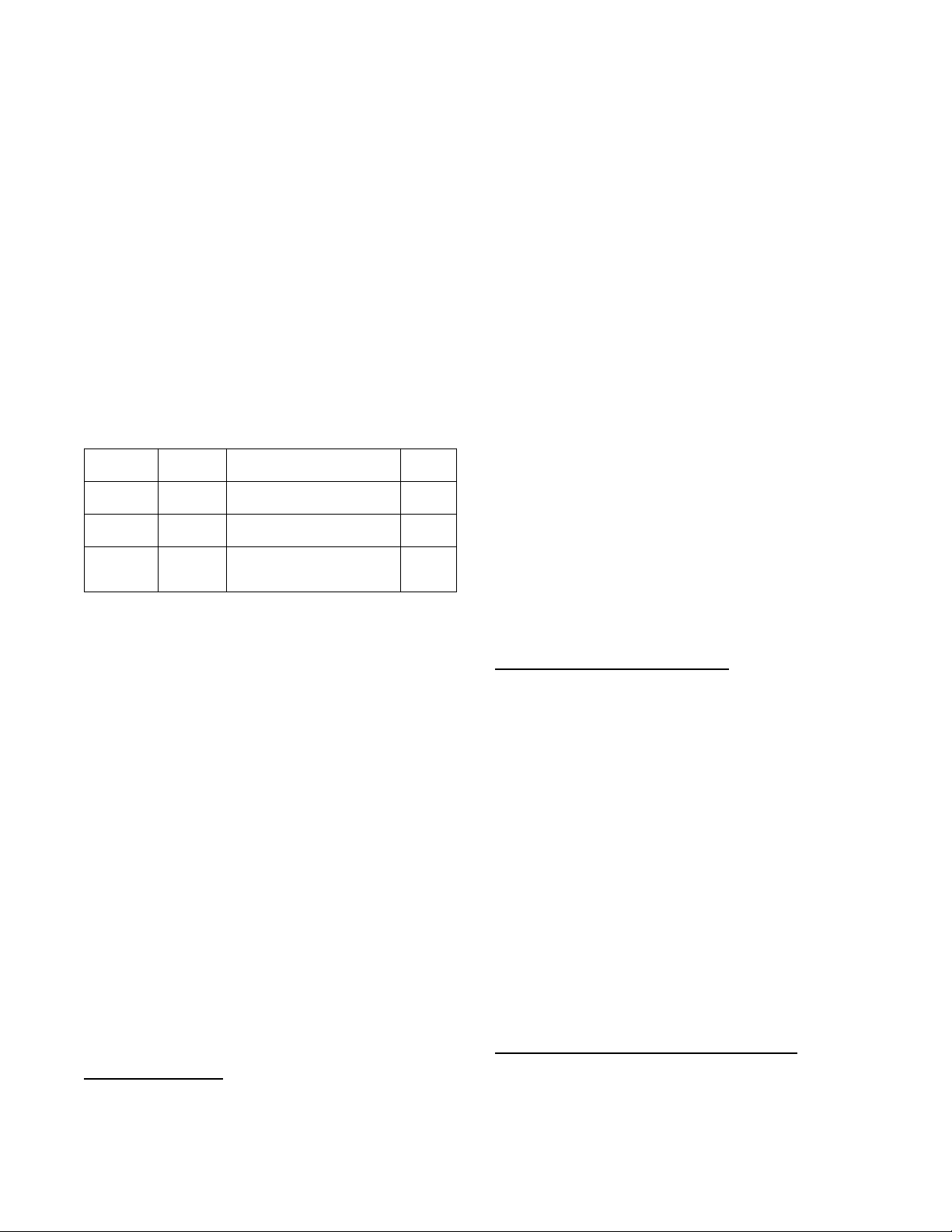

Table 1 – Rooftop Units

MODEL SIZE NOMINAL TONS

04 3

48/50FC

48/50GC

Conventions Used in This Manual

The following conventions for discussing configuration points for

the local display (SystemVu controller or Navigatort accessory)

will be used in this manual.

Menu paths will be written with the main menu name first, then

any menus or sub menus, each separated by an arrow symbol ()

and will also be shown in bold and italics. As an example, the

General sub menu which is located in the Setting main menu under

Unit Configuration menu would be written as SETTINGS

UNIT CONFIGURATIONSGENERAL.

05 4

06 5

07 6

04 3

05 4

06 5

This path name will show the user how to navigate through the

local display to reach the desired menu. The user scrolls through

the Menus using the up and down keys. The arrow symbol in the

path name represents pressing ENTER to move into the next level

of the menu structure.

Point names are referenced in in parentheses and bold and italics as

would be shown on the local display.

CCN point names are also referenced for users configuring the

unit with C C N software instead of the lo cal display. S ee

Appendix A at the end of this manual.

BASIC CONTROL USAGE

SystemVu Control (factory-- installed option)

The SystemVu control is a comprehensive unit-management

system. The control system is easy to access, configure, diagnose

and troubleshoot.

The SystemVu control system is fully communicating and

cable-ready for connection to the Carrier Comfort Network

(CCN), Carrier i--Vu, and Third Party BACnet* building

management systems. The control provides high-speed

communications for remote monitoring via the Internet. Multiple

units can be linked together (and to other Direct Digital Control

(DDC) equipped units) using a 3-wire communication bus.

The SystemVu control system is easy to access through the use of a

integrated display module. A computer is not required for start-up.

Access to control menus is simplified by the ability to quickly

select from 7 main menu items. An expanded readout provides

detailed explanations of control information. Only six buttons are

required to maneuver through the entire controls menu. The

display readout is designed to be visible even in bright sunlight.

System u

RUN

ALERT

FAULT

TESTTEST

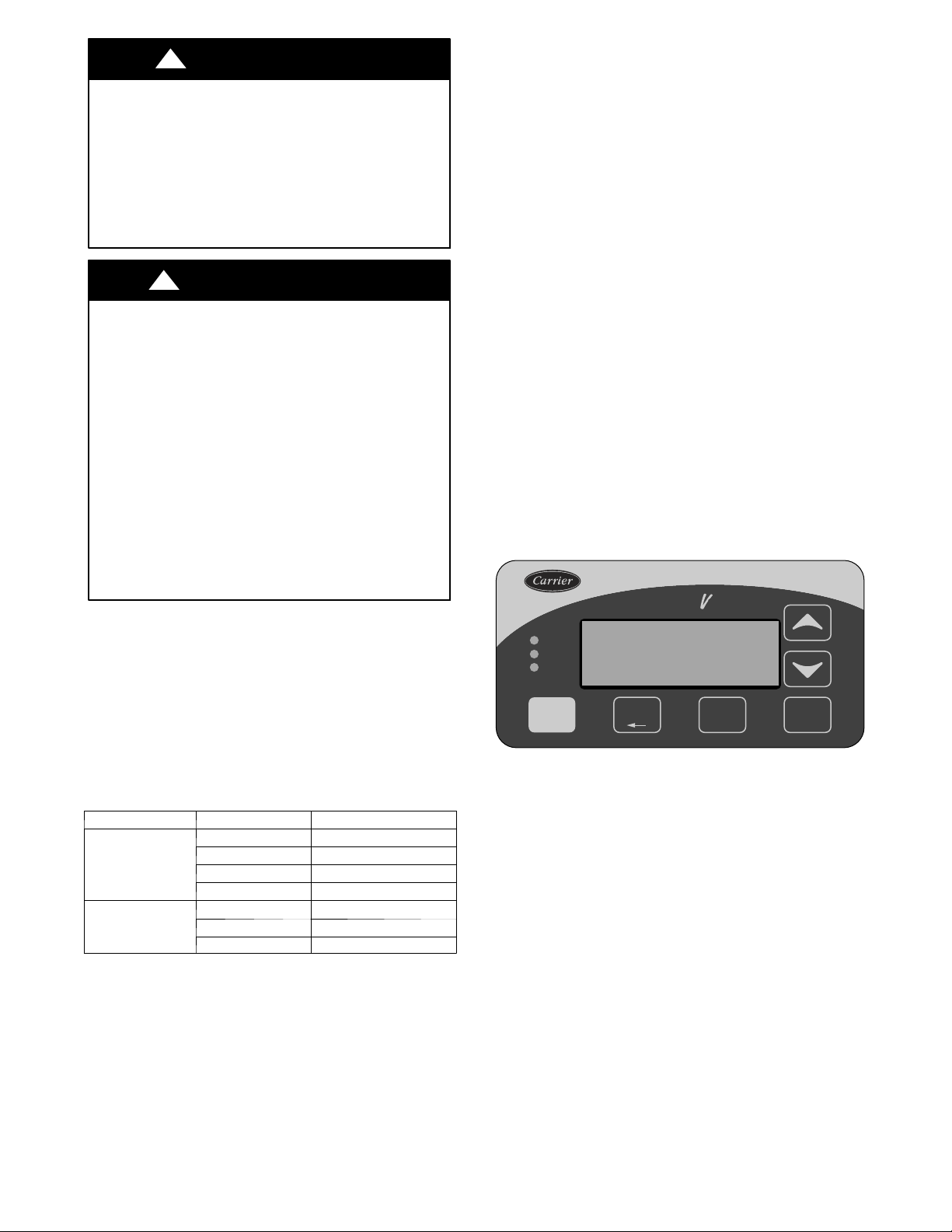

SystemVu Interface

This integrated device is the keypad interface used to access the

control information, read sensor values, and test the unit. The

interface is located in the main control box and is standard on all

units. The interface is a 6 --key, 4x30 character, LCD (liquid--crystal

display) display module. The interface also contains Status LEDs.

(See Fig. 1.) The interface is easy to operate using 6 buttons and

themainmenustructuresshowninFig.2.

Through the SystemVu interface, the user can access all of the

inputs and outputs to check on their values and status, configure

operating parameters, and evaluate the current decision status for

operating modes. The control also includes an alarm history which

can be accessed from the display. The user can access a built--in test

routine that can be used at start--up commissioning and

troubleshooting.

* BACnet is a registered trademark of ASHRAE (American Society of

Heating, Refrigerating and Air --- Conditioning Engineers).

BACK ENTER MENU

C14319

Fig. 1 -- SystemVu Interface

3

Page 4

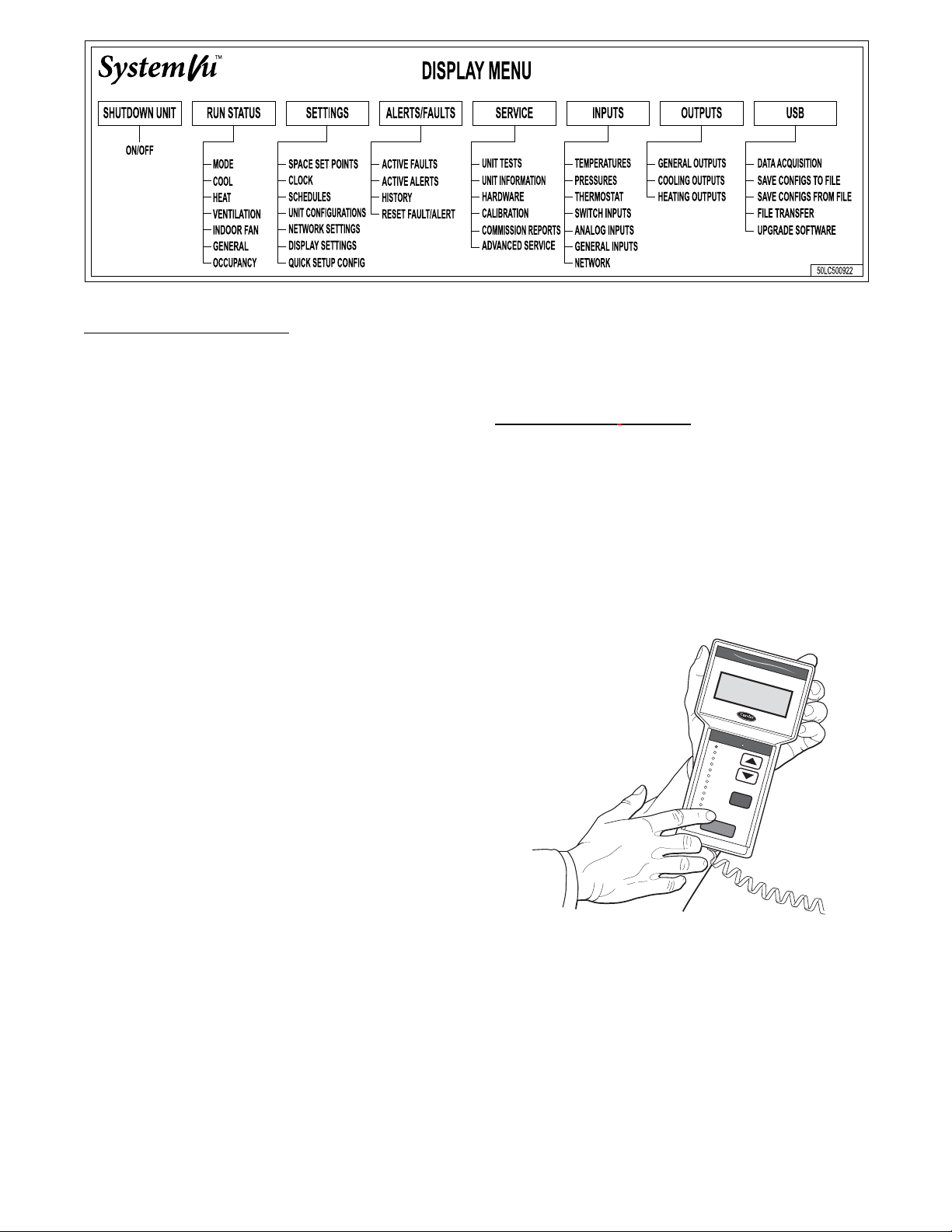

Fig. 2 -- SystemVut -- Main Menu Structures

SystemVu Interface Operation

Units are shipped from the factory with the SystemVu interface

FIOP, located in the main control box. (See Fig. 1.) In addition, the

interface has up and down arrow keys, BACK, ENTER, MENU,

and TEST keys. These keys are used to navigate through the

different levels of the menu structure. All discussions and examples

in this document will be based on the SystemVu display except in

the Navigatort display section. See the Accessory Navigator

Display section for further details and Table 2 for the Navigator

menu structure and usage.

The six keys are used to navigate through the display structure,

which is organized in a tiered menu structure. If the buttons have

not been used for a period, the display will default to a standby

screen intended to provide a quick overall look at the system. To

show the top--level display, press any key first to turn the display

backlight on, and then press the MENU key. Then use the up and

down arrow keys to scroll through the top --level menus. These are

showninFig.2andlistedinAppendixA.

When a specific menu or sub--menu is located, push the ENTER

key to enter the menu. Depending on the menu, there may be

additional tiers. Continue to use the up and down keys and the

ENTER key until the desired display item is found. At any time,

the user can move back a menu level by pressing the BACK key.

Once an item has been selected the display will flash showing the

item, followed by the item value and then followed by the item

units (if any). Pressing the TEST button at any time will jump the

display to the test menu. Pressing the MENU button any time will

jump the display to the main menu.

Items in the Configuration and Service Test menus are password

protected. The display will prompt the enter password screen when

required. Use the ENTER, BACK, and arrow keys to enter the four

digits of the password. The default user password is 1111.

Pressing the BACK and ENTER keys simultaneously will show an

expanded text description screen on the display indicating the full

meaning of each display point. To put the screen in standby, hold

down the BACK key for 5 seconds.

Some points can be force d from the System Vut interface. To force a

variable, follow the same process as editing a configuration

parameter. A forced variable, regardless where the force has come

from will be displayed with a lower case “f” following its value.

For example, if ECON CMD POSITION is forced, the display

shows “80%f”, where the “f” is to signify a force on the point.

Remove the force by selecting the point that is forced with the key

ENTER and then pressing the up and down arrow keys

simultaneously. Pressing ENTER and BACK on a forced item will

display the expanded description for that item including the force

level that is currently applied. Depending on the type of unit

(48FC,GC or 50FC,GC), factory--installed options and

field--installed accessories, some of the items in the various menus

may not apply.

a48--- 10366

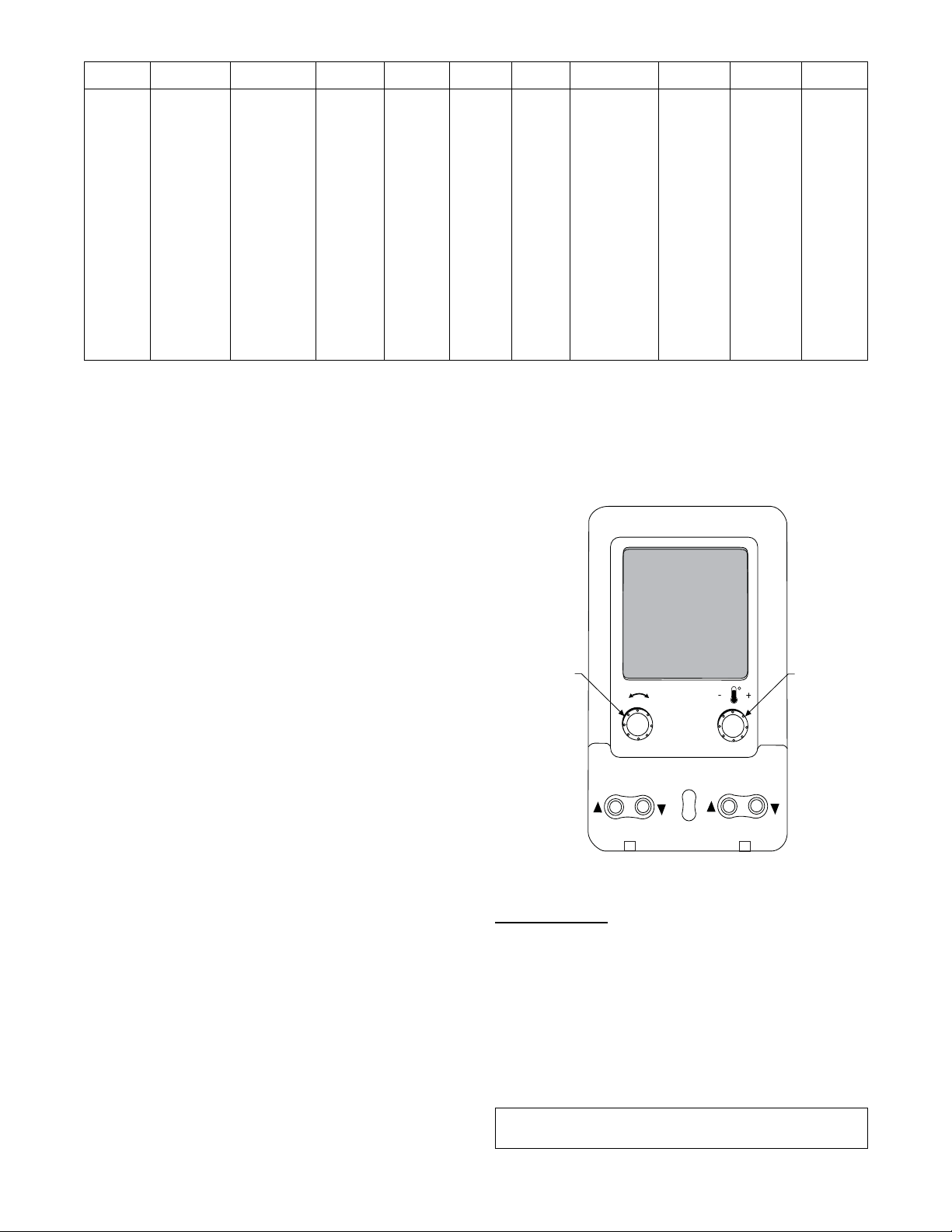

Accessory Navigatort Display

The accessory hand-held Navigator display can be used with the

48/50FG, GC units. (See Fig. 3.) The Navigator display is plugged

into the LEN (local equipment network) port on either the

SystemVu display or the Main Base Board (MBB).

Navigator Display Operation

The Navigator display has up and down arrow keys, an ESCAPE

key and an ENTER key. These keys are used to navigate through

the different levels of the display structure.

The four keys are used to navigate through the display structure,

which is organized in a tiered mode structure. If the buttons have

not been used for a period, the display will default to the AUTO

VIEW display category as shown under the RUN STATUS

category. To show the top-level display, press the ESCAPE key

until a blank display is shown. Then use the up and down arrow

keys to scroll through the top-level categories. These are listed in

Appendix C and will be indicated on the Navigator display by the

LED next to each mode listed on the face of the display.

C

o

m

f

o

r

t

L

N

in

A

V

I

k

G

A

T

O

T

IM

E

W

L

W

S

E

T

M

O

Ru

n Sta

S

e

rv

ice

T

em

p

era

P

res

s

ure

S

e

tpo

in

ts

In

pu

ts

O

utp

uts

C

on

fig

u

ra

tion

T

im

e C

lo

ck

O

p

er

ating

Mod

es

A

la

rm

s

E

N

T

E

R

Fig. 3 -- Accessory Navigator Display

When a specif i c mode or sub-mode is located, push the ENTER key

to enter the mode. Dependi ng on the mode, there may be additional

tier s. Continue to use the up and down keys and the ENTER keys

until the desire d display item is found. At any time, the user can move

back a mode level by pressing the ESCAPE key. Once an item has

been selected the display will flash showing the item, followed by the

item value and then followed by the item units (if any).

Items in the Configuration and Service Test modes are password

protected. The display will flash PASS and WORD when required.

Use the ENTER and arrow keys to enter the four digits of the

password. The default password is 1111.

R

E

1

2

T

.

5

8

5

4

T

.

6

°

F

4

4

P

.1

°

F

4

4

.

0

°

F

D

E

Ala

rm

Sta

tus

tu

s

Te

s

t

ture

s

s

E

S

C

C06321

4

Page 5

RUN

/

STAT US

Auto View of

Run Status

(VIEW)

Cooling

Status

(COOL)

Heating

Status

(HEAT)

Vent ilat ion

Status

(VENT)

Assigned I/O

Channels

(A.IO)

Vers io ns

(VERS)

SERVICE

TEST

Service T est

Mode

(TEST)

T es t Independent

Outputs

(INDP)

Te s t F a n s

(FANS)

Test Cooling

(COOL)

Te s t H e at i n g

(HEAT)

Table 2 – Navigator Mode and Menu Display Structure

TEMPERATURES PRESSURES

SET-

POINTS

INPUTS OUTPUTS CONFIGURATION TIMECLOCK

Thermostat

Inputs

(STAT)

Switch

Inputs

(SW)

Analog

Inputs

(AIS)

General

Inputs

(GEN)

General

Outputs

(GEN)

Cooling

Outputs

(COOL)

Heating

Outputs

(HEAT)

General Unit

Config

(GEN)

Indoor Fan

Config

(I.FAN)

Economizer

Config

(ECON)

Building Net

Config

(NET)

User Display

Config

(DISP)

Time o f Da y

(TIME)

Month, Date

Day and Year

(DATE)

Daylight

Savings

Config

(DST)

Schedules

Adjust

(SCHD)

Holiday

Adjustment

(HLDY)

OPERATING

MODES

ALARMS

Curr Active

Alarm

(CURR)

History

(HIST)

Reset All

Current

Alarms

(R.CUR )

Alarm Reset

History

(R.HIS)

Pressing the ESC and ENTER keys simultaneously will display an

expanded text description across the display indicating the full

meaning of each display point. Pressing the ESCAPE and ENTER

keys when the display is blank (MODE LED level) will return the

display to its default menu of rotating AUTO VIEW display items.

In addition, the password will need to be entered again before

changes can be made.

Changing item values or testing outputs is accomplished in the

same manner. Locate and display the desired item. If the display is

in rotating auto-view, press the ENTER key to stop the display at

the desired item. Press the ENTER key again so that the item value

flashes. Use the arrow keys to change the value of state of an item

and press the ENTER key to accept it. Press the ESCAPE key and

the item, value or units display will resume. Repeat the process as

required for other items.

There are some points that can be forced from the Navigator

display. If the user needs to force a variable, follow the same

process as when editing a configuration parameter. A forced

variable, regardless where the force has come from will be

displayed with a blinking “f” on a Navigator display following its

value. For example, if economizer commanded position (EC.CP) is

forced, the Navigatort display shows “80f”, where the “f” is

blinking to signify a force on the point. Remove the force by

selecting the point that is forced with the key ENTER and then

pressing the up and down arrow keys simultaneously.

Depending on the type of unit (48FC,GC or 50FC,GC),

factory-installed options and field-installed accessories, some of the

items in the various Mode categories may not apply.

See Table 2 and Appendix C for full Navigator display menu

layout.

System Pilott and Touch Pilott Devices

The System Pilot device (33PILOT-01) and Touch Pilot device

(33CNTPILOT) can be used as CCN communication

user--interfaces. These devices can be put on the CCN bus and

addressed to communicate with any other device on the network.

Unlike the SystemVut display and Navigator display, these pilots

read the unit’s CCN tables and its CCN points can be monitored,

forced, or configured. The Pilot devices can be used to install and

commission a 3Vt zoning system, linkage compatible air source,

universal controller, and all other devices operating o n the Carrier

communicating network.

Additionally, the System Pilot device can serve as a wall-mounted

temperature sensor for space temperature measurement. Occupants

can use the System Pilot device to change set points. See Fig. 4 for

System Pilot device details.

CCN Tables and Display

In addition to the unit--mounted SystemVut display, the user can

also access the same information through the CCN tables by using

the service tool or other CCN programs/devices. The variable

names used for the CCN tables and the SystemVu display menus

may be different and more items may be displayed in the CCN

tables. Details on the CCN tables are included in Appendix D.

NAVIGATE/

EXIT

SCROLL

+

PAGE

-

Fig. 4 -- System Pilott User Interface

Force Hierarchy

There is a hierarchy in SystemVu controls with regards to forcing a

point. Programs and devices write a force at different priority

levels. A higher level (smaller number, 1 being the highest) will

override a lower level force. The SystemVu controller uses a

Control Force at level 7. The Navigatort device writes a Service

Force which is level 3. System Pilott and Touch Pilott devices

write Supervisor Forces at level 4. Network programs can be set to

write different level priority forces.

NOTE: In the case of a control power reset, any force in effect at

the time of power reset will be cleared.

IMPORTANT: All further discussions and examples in this

document will be based on the SystemVut controller.

MODIFY

SELECT

C06322

5

Page 6

START-UP

IMPORTANT: Do not attempt to start unit, even momentarily,

until all items on the Start--Up Checklist (see page 143) and the

following steps have been read/completed.

Unit Preparation

Check that unit has been installed in accordance with these

installation instructions and all applicable codes.

Refrigerant Service Ports

The refrigerant system has a total of 3 Schrader-type service gauge

ports per circuit. One port is located on the suction line, one on the

compressor discharge line, and one on the liquid line. Be sure that

caps on the ports are tight.

Crankca se Heater

The compressor is equipped with a crankcase heater. There is a control

function used to turn the crankcas e heaters on and off whe n the

compre ssor is not running. This is a configurable value for which the

factory default value is set to 65_F . If the ambie nt is above the select ed

value the control will preve nt the crankca se heater from turning on.

IMPORTANT: Unit power must be on for 24 hours prior to

start--up to allow the crankcase heater to run. Otherwise, damage to

the compressor may result.

Compressor Rotation

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

Improper wiring will cause compressor stoppage and alarm.

Correct wiring by switching leads as indicated below.

On 3-phase units, it is importa nt to be cert ain the compre ssors are

rotating in the proper dire ction. To deter mine whether or not

compre ssors are rotati ng in the proper direct ion, use a phase-rot ation

mete r on the unit input power to check for L1-L2-L3 or clockwise

rotation or use the Service Test mode to energize a compressor. If the

compre ssor is rotati ng in the wrong direction, the controls will stop the

compressor and display alarm for “Circ ui t A Reverse Rotati on”.

NOTE: Indoor or outdoor fan rotation direction may not indicate

proper input power phase sequence, as some 3-phase units use

single-phase fan motors.

To correct the wrong compressor rotation direction, perform the

following procedure:

1. Turn off power to the unit and lock out the power.

2. Switch any two of the incoming unit power leads.

3. Turn on power to the unit.

4. Verify corrected compressor rotation.

Power Supply

All 208/230-v units are factory wired for 230-v power supply. If

the 208/230-v unit is to be connected to a 208-v power supply, the

transformers must be rewired by moving the wire from the

230-volt connection and moving to the 200-volt terminal on the

primary side of the transformer. Refer to unit label diagram for

additional information.

Internal Wiring

Check all electrical connections in unit control boxes; tighten as

required.

Evaporator Fan

The Evaporator fan does not need to be checked for rotation as it

only operates in one direction. Refer to the unit product data for

full Fan Performance tables and physical data. The specific unit’s

fan performance table is printed and adhered to the control box

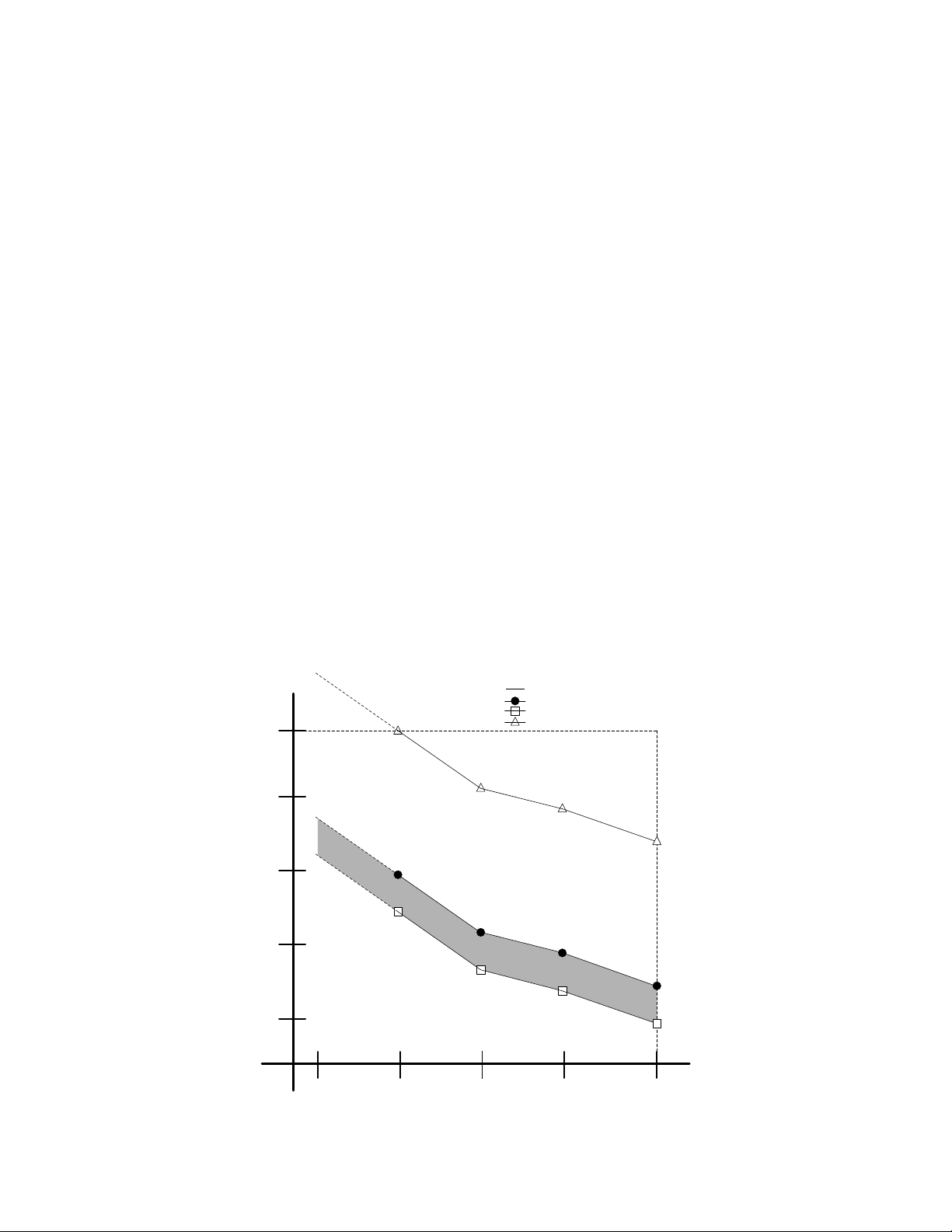

high voltage cover. See Fig. 5 for an example fan performance

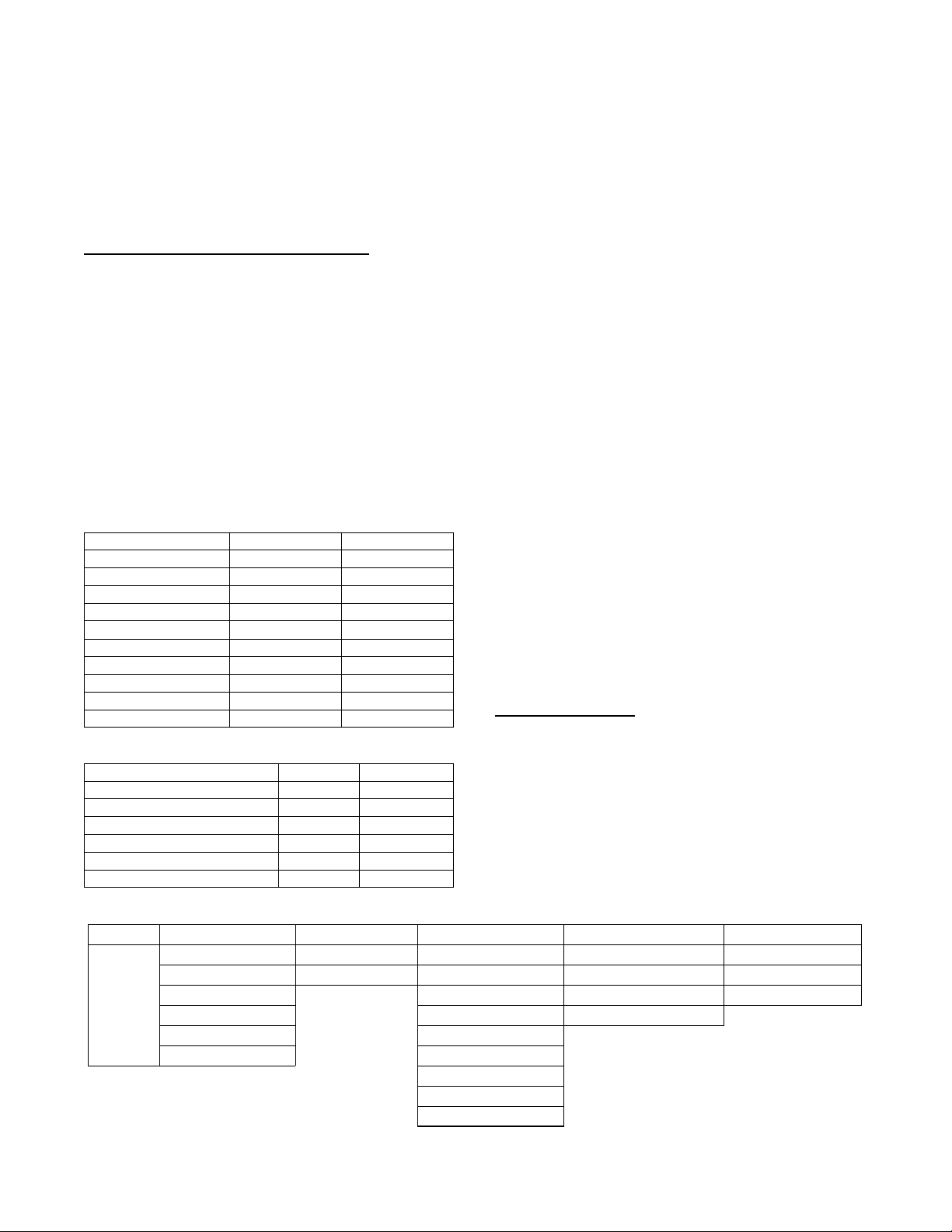

table.

Use the job specifications and unit fan performance table to determine

the operating mode specific fan speeds. The following instructions are

included in the unit i nstallation instructions. When adjusting the

Heating Fan Speed and High Cooling Fan Speed, ensure that the

CFM is not lower than the minimum CFM allowed in the product

data.

1. Check the job specifications for the CFM (cubic feet per

minute) and ESP (external static pressure) required.

2. Using the chart on the Fan Speed Set Up labels (see Fig. 5),

calculate the RPM from the CFM and ESP for the base unit

plus any field accessories (as listed on the label).

NOTE: The Fan Speed Set Up labels are located on the High

Voltage cover in the Control Box.

3. Press any key on the SystemVu interface to activate the

display backlight and then press the MENU key.

4. Using the UP and DOWN arrow keys highlight SETTINGS

and then press ENTER.

5. Use the DOWN arrow key highlight the UNIT

CONFIGURATIONS menu then press ENTER.

6. Highlight UNIT CONFIGURATIONS then press ENTER.

7. Highlight INDOOR FAN and then press ENTER.

8. Refer to the job specifications to set the following,

determining the values per the RPM Calculator label

(Figure 5). Use the UP and DOWN arrow keys and the

BACK key to set the values. Press ENTER after setting

each value to continue to the next selection.

S IDF VENT SPD

S IDF HEAT SPD

S IDF LOW COOL SPD

S IDF HIGH SPD

S IDF FREE COOL SPD

Service test mode can also be used to temporarily operate the

Evaporator Fan with a percentage (0-- 100%) command. The fan

test menu will show the converted RPM from the percentage being

commanded. Refer to the Service test section for more details.

Adjust the IDF Maximum Fan Speed (IDF MAX SPEED) to

restrict higher fan speeds as needed for sensitive applications.

IMPORTANT: The IDF Maximum Fan Speed (IDF MAX

SPEED) RPM must not produce a supply CFM that is lower than

the minimum CFM allowed in the product data for heating and

cooling. The IDF Maximum Fan Speed (IDF MAX SPEED) must

also be grea ter than or equal to the highest operating mode speed

setting.

Condenser Fans and Motors

Condenser fans and motors are factory set.

6

Page 7

RPM

Calculator

1500

1625

1750

1875

2000

CFM

2125

2250

UNIT MODEL NUMBER

Field Accessories:

1 Stage E Heat

2 Stage E Heat

2375

2500

Economizer

0.2

1301

1381

1463

1548

1633

1720

1808

1897

1987

66

80

107

ESP in. wg

0.4

1477

1544

1615

1688

1764

1842

1921

2003

2068

66

80 80 80 80 80 80 80

107 107 107 107 107 107 107

Fig. 5 -- Example of Fan Speed Set Up Labels

0.6

1639

1699

1763

1828

1897

1967

2040

2115

2191

66

0.8

1788

1843

1902

1962

2025

2090

2157

2227

2298

66

1.0

1925

1976

2031

2087

2146

2208

2271

2336

66

1.2

2054

2101

2152

2206

2262

2320

2380

66

1.4

2174

2220

2268

2318

2372

66 66

1.6 1.8 2.0

2289

2332

2378

a50--- 10219

7

Page 8

INDOOR

Y

BLOWER

ACCESS

PAN EL

CONTROL BOX

AND GAS SECTION

ACCESS PANEL

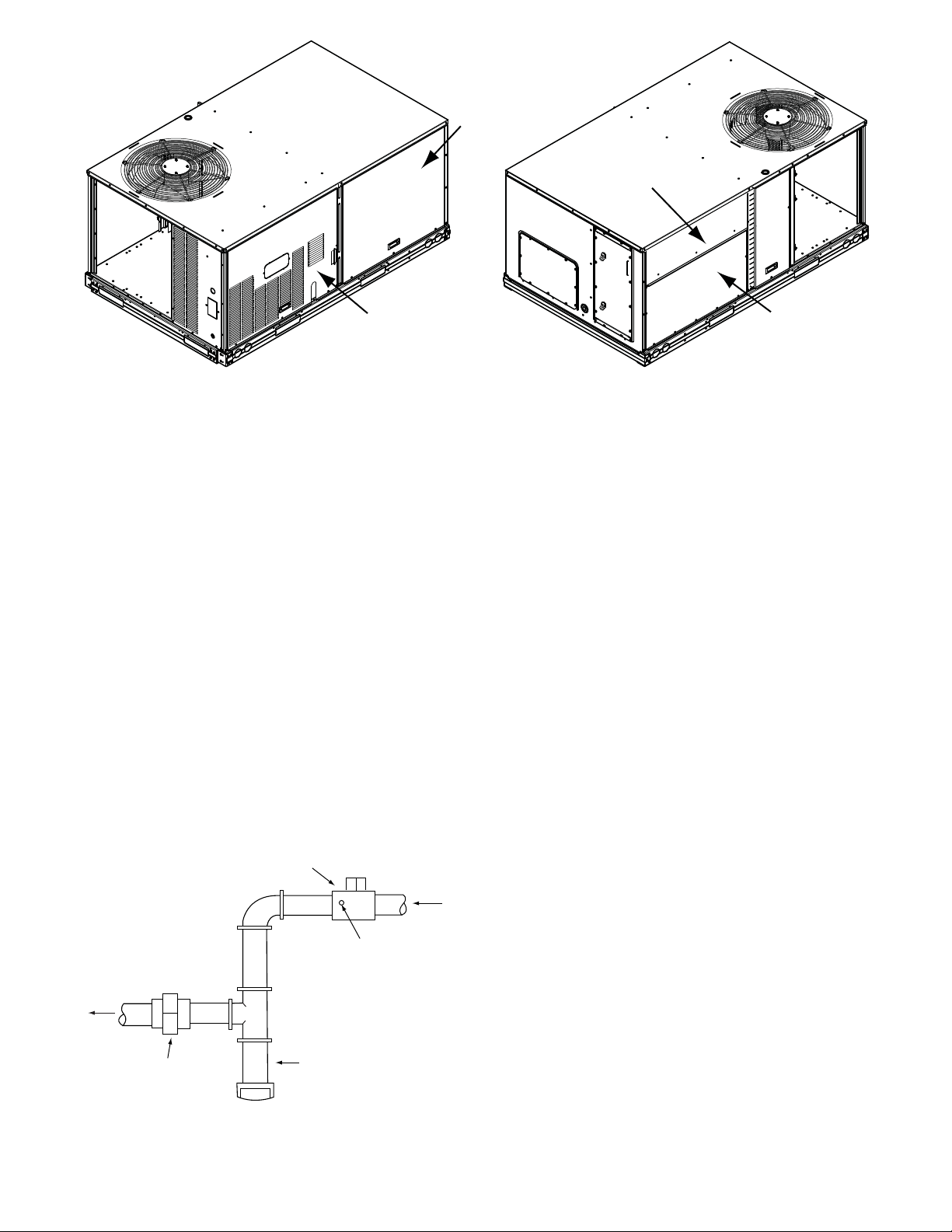

Fig. 6 -- Panel and Filter Locations

FILTER

ACCESS PANEL

INDOOR COIL

ACCESS PANEL

UNIT BACKUNIT FRONT

a48--- 9937

Return--Air Filters

Check that correct filters are installed in filter tracks (see Physical

Data table in unit Product Data). Do not operate unit without

return-air filters. Determine the filter change run time (DIRTY

FILTER TIME) to be set in the quick setup configurations menu.

Outdoor--Air Inlet Screens

Outdoor-air inlet screens must be in place before operating unit.

Accessory Installation

Check to make sure that all accessories including space thermostats

and sensors have been installed and wired as required by the

instructions and unit wiring diagrams.

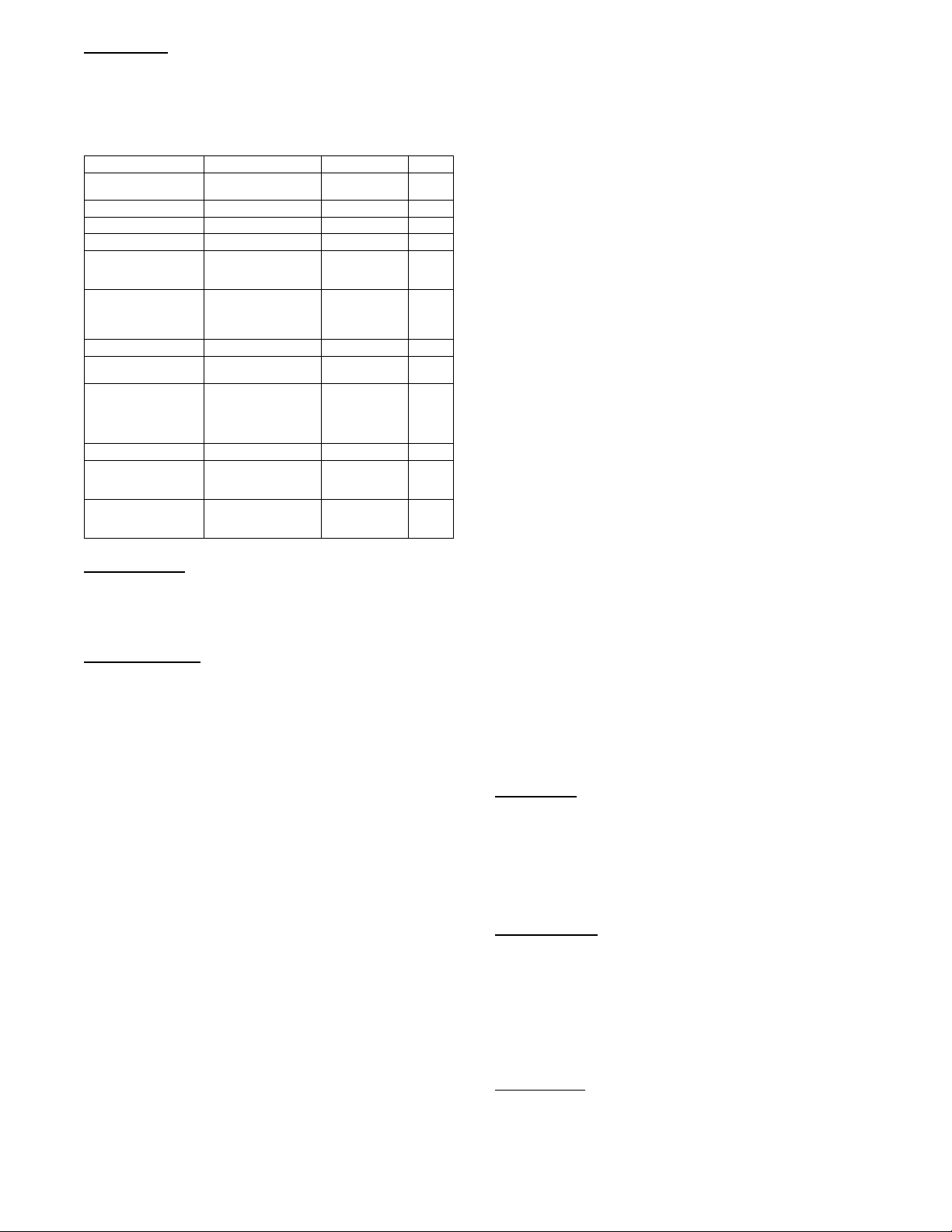

Gas Heat (48FC a nd 48GC)

Inspect the gas heat section of the unit. Verify the number of

burners match the number of heat exchanger openings and the

burner assembly is properly aligned. If the orifices were changed

out for elevation or Liquid Propane purposes, verify proper

installation. Visually inspect other components in heat section.

Verify gas pressures before turning on heat as follows:

1. Close the field-supplied manual gas shut off valve, located

external to the unit.

2. Connect a pr essure gauge to the supply gas pressure tap,

located on the fie ld-supplied manual gas shut off valve (see

Fig. 7).

MANUAL GAS SHUT OFF VALVE

(FIELD SUPPLIED)

GAS

SUPPL

SUPPLY GAS

PRESSURE TAP

(1/8˝ NPT PLUG)

TO

UNIT

UNION

Fig. 7 -- Field Gas Piping

SEDIMENT TRAP

a48--- 9382

3. Connect a pressure gauge to the manifold pressure tap on

the burner assembly located inside the unit.

4. Open the field-supplied manual gas shut off valve. Enter

Service Test mode by setting TEST MODE to “ON” using the

SystemVut controller interface. Use the Service Test feature

to set HEAT 1 TEST to ON (first stage of heat) using the

SystemVu controller interface.

5. After the unit has run for several minutes, verify the supply

gas pressure is adequate per the base unit installation instructions. If not, adjust accordingly.

NOTE: Supply gas pressure must not exceed 13.0--in. wg.

6. Set HEAT 1 TEST to OFF using the SystemVu controller

interface.

7. Exit Service Test mode by setting TEST MODE to “OFF”

using the SystemVu controller interface.

CONTROLS QUICK SET--UP

The following information will provide a quick guide to setting up

and configuring the 48/50FC and 48/50GC series units with

System Vu controls. Unit controls are pre-configured at the fac t ory for

factory-installed options. Field-installed accessories will require

configuration at start-up. Initial System Startup is recommended for

initial start--up. Additionally, specific job requirements may require

changes to default configuration values. See Appendix A and other

sections of the se instructions for more details. Refer t o the Major

System Components or accessory installation instructions for specific

wiring detail.

Control Set Point and Configuration Log

During start up, accessory installation, and equipment service set

points and/or configuration changes might have to be made. When

setting set points or configuration settings, documentation is

recommend. The Control Set Point and Configuration Log starting

on page 132 should be filled out and left with the unit at all times,

a copy should also be provided to the equipment owner. A USB

jump drive can be used to back up the unit’s configurations. Refer

to the USB Operation section for details.

Initial Startup

Initial Startup refers to the first time this particular unit has a startup

performed. The SystemVu controller will continually display the

Initial Startup prompt until it is completed. To complete the initial

startup you must complete the Quick Setup, Network Setup, and

the System Auto Test.

8

Page 9

Quick Setup

This a list of common adjusted configurations set during startup.

These are common accessories, and control means. Set the list in

Table 3. After setting these per the specific unit set the QUICK

SET CHKLIST point to done.

Table 3 – Quick Setup Menu Items

SystemVu™ Display Expanded Name Range Default

QUICK SETUP CONFIG QUICK SETUP

TIME Clock Hour and Minute HH:MM

DATE Current Date MM/DD/YYYY

STARTUP DELAY Unit Startup Delay 10 to 600 30

UNIT CONTR OL TYPE Unit Control Type 0=TSTAT,

THERMOSTAT TYPE Thermostat Hardware

DIRTY FILTER TIME Change Filter Timer 0to9999 600

HEATINGSTAGQTY Number of Heating

VENT METHOD V entilation Method 0=NONE

FREECOOL MAX OAT Free Cooling Max OAT 0to90 65

FIRE SHUTDOWN SW Fire Shutdown S wi tch 0=No Switch,

QUICK SET CHKLIST QUICK SETUP

* These defaults change based on the Unit model number.

CONFIG MENU

Type

Stages

CHECKLIST

1=SPACE SEN,

2=RAT SEN

0=CONV 2C2H,

1=DIGI 2C2H,

2=CONV 3C2H,

3=DIGI 3C2H

1to2 2*

1=ECON

2=2POS DMPR

3=ERV

4=ECON ERV

1=N/Open

2=N/Close

0=Undone,

1=View,

2=Done

0

2

0*

0*

0

Network Setup

This is a shortcut to the Network Settings submenu. In this sub

menu are the specific network settings required to get the network

piece up and running. After setting these per the specific unit set

the NETWORK CHKLIST point to done.

System Auto Test

Turning this to Start will run enable test mode and execute the System

Auto Test. After the auto test has completed, set this to done.

Thermostat Control

Wire accessory thermostat to the corresponding R, Y1, Y2, W1,

W2, and G terminals on the Main Base board.

The Unit Control Type configuration, (UNIT CONTROL TYPE)

default value is for thermostat (0) so there is no need to configure

this item.

The Thermostat Hardware Type, (THERMOSTAT TYPE) selects

the unit response to the thermostat inputs above.

NOTE: May not be compatible with heat anticipator thermostats.

Space Temperature Sensor Control -- Direct Wired

(T--55 or T--56 or T--59)

Wire accessory space temperature sensor(s) to the T-55 terminals

on the field connection terminal board located at the unit control

box. Refer to Space Mounted Sensors section (page 57) for

additional information.

The Unit Control Type configuration, (UNIT CONTROL TYPE)

must be set to Space Sensor (1).

Space Humidistat Control

For units with factory installed Humidi--MiZerRsystem option, the

humidistat input is defaulted for use on the Y3 thermostat input

screw terminal as a normally open switch. This can be changed

with the Humidistat Switch Channel configuration (HUMSTAT

CHANNEL) and the Humidistat switch type configuration

(HUMSTAT SW TYPE).

Space Relative Humidity Sensor Control

For units with factory installed Humidi--MiZer system option, a

Relative Humidity (RH) sensor input can be used in addition to or

in place of the Humidistat switch. This can be done by wiring into

one of the configurable analog inputs and setting the Space

Relative Humidity sensor channel (SPRH SENSOR CHAN) to the

input channel selected. The most field accessible input channel is

AI06 located at TB5--5 on the MBB (Main Base board).

CCN Communication

First configure the building protocol SETTINGS NETWORK

SETTINGS BAS PROTOCOL to CCN (default is 0 = NONE).

Configure the following under the CCN menu (SETTINGS

NETWORK SETTINGS CCN).

CCN ELEMENT # -- D e f a u l t i s 1

BUS NUMBER -- D e f a u l t i s 0

CCN BAUDRATE -- Default is 2 = 38400

CCN Linkage Control

The CCN communication must be properly configured for the

units and all other devices. Linkage configuration is automatically

done by the supervisory CCN Linkage device.

The unit control type configuration, (UNIT CONTROL TYPE)

must be set to space sensor (1).

The factory location of the SAT sensor will read accurately for

heating and cooling for proper operation with linkage applications,

therefore the SAT heating mode sensing configuration (SAT

DURING HEAT?) is enabled from the factory. If a more accurate

SAT reading is need, the sensor can be re--located into the duct and

no configuration adjustment needed.

System Pilott -- Communication Space Sensor

Install the System Pilot device and connect the CCN communication

bus from it to the unit’s CCN connect ion on TB4 -- BAS connect or of

the Main Ba s e Boa rd (MBB). Configure the unit’s CCN

communic ation element number, bus number, and baud rate. Refer to

the System Pilot’s installation instructions for configuring it to be used

as a space temperature and attaching it to a unit.

Accessories

Below are quick configuration settings for field--installed

accessories. When factory--installed as options the points will

already be configured. See the Space Mounted Sensors section

(page 57), third party control, control connection tables, and CCN

or Display parameter tables for any accessories not mentioned

below and refer to installation manual of the accessory.

Economizer

When an economizer is field-- installed, the unit must be configured

for it by setting SETTINGSUNIT CONFIGURATIONS

ECONOMIZER VENT METHOD to ECON. The default

settings for the other economizer configurations should be

satisfactory. If they need to be changed, additional information

about these configuration settings can be found in the Economizer

section.

Power Exhaust

When power exhaust is field-- installed, the unit must be

configu red for it by setting SETTINGSUNIT

CONFIGURATIONSECONOMIZER POWER EXHAUST

CONFIGS PE1 RELAY CHANNEL to the channel the

accessory was wired into. The default settings for the other power

exhaust configurations should be satisfactory. If they need to be

changed, additional information about these configurations can be

found in the Power Exhaust section.

Electric Heat

When electric heat is field--installed, the number of electric heat stages

must be configured by setting SETTINGS UNIT

CONFIGURATI ONS HEATING HEATING STAGE QTY

per the installed heater.

9

Page 10

Fire Shutdown

When Fire Shutdown or Smoke Detector sensors are

field--installed, the unit must be configured for it by setting

SETTINGS UNIT CONFIGURATIONS SWITCH INPUTS

CONFIGS FIRE SHUTDOWN SW to normally open (0) or

normally closed (1).

Outdoor Enthalpy

When an Outdoor Enthalpy sensor is field--installed, the unit must

be configured for it by setting SETTINGS UNIT

CONFIGURATI ONS ANALOG INPUTS CONFIGS OARH

SENSOR CHAN to the channel number the sensor was wired into.

IAQ Sensor

When a CO2sensor is field--installed, the unit must be

configu red for it by setting SETTINGS UNIT

CONFIGURATIONS ANALOG INPUT CONFIGS IAQ

SENSOR CHAN selects the unit response to this input. Default

conversion to 0 to 2000 ppm.

OAQ Sensor

When an Outdoor Air Quality sensor is field--installed, the unit

must be configured for it by setting SETTINGS UNIT

CONFIGURATIONS ANALOG INPUT CONFIGS OAQ

SENSOR CHAN. Default conversion to 0 to 2000 ppm.

Filter Status

When a Filter Status Switch is field--installed, the unit must be

configured by setting the input channel it is wired to and normal state.

SETTINGSUNIT CONFIGURATIONSSWITCH INPUT

CONFIGS FILTER SW CHANNEL and FILTER SW TYPE.

Phase Monitor

When a phase monitor is field--installed, the unit must be

configured by setting the input channel it is wired to and normal

state SETTINGUNIT CONFIGURATIONSSWITCH INPUTS

CONFIGSPHASE MON CHANNEL and PHASE MON SW

TYPE.

Two Position Damper

When a Two Position damper is field--installed, the unit must be

configured by setting the output channel it is wired to.

SETTINGS UNIT CONFIGURATI ON GENERAL 2POS/

ERV CHANNEL.

Programming Operating Schedules

When the building automation system you have the SystemVut

controller configured for (BAS Protocol Select) is None (0) or

CCN (1) the SystemVu controller can follow a standard CCN

occupancy table. The occupancy can be modified from any CCN

tool or from the local display.

OCCUPANCY SCHEDULE — For flexibility of scheduling, the

occupancy programming is broken into eight separate periods. For

each period the schedule contains the following fields: Day of

Week, Occupied From, and Occupied To.

DAY OF WEEK — The day of week configuration consists of

eight fields corresponding to the seven days of the week and a

holiday field in the following order: Monday, Tuesday,

Wednesday, Thursday, Friday, Saturday, Sunday, and Holiday. If a

1 is configured in the corresponding place for a certain day of the

week, the related “Occupied from” and “Occupied to” times for

that period will take effect on that day of the week. If a 1 is placed

in the holiday field, the related times will take effect on a day

configured as a holiday. A zero means the schedule period will not

apply to that day.

Day of week: Range 0 or 1

Default Values 0 for all of the periods.

OCCUPIED FROM — This field is used to configure the hour and

minute, in 24 hour clock, that the mode for the controller will

switchtooccupied.

Occupied From: Units Hours:Minutes

Range 00:00 to 24:00

(Minutes 00 to 59)

Default Value 00:00

OCCUPIED TO — This field is used to configure the hour and

minute, in 24 hour clock, that the mode for the controller switches

from occupied to unoccupied.

Occupied To: Units Hours:Minutes

Range 00:00 to 24:00

(Minutes 00 to 59)

Default Value 00:00

When the building automation system configured to (BAS

PROTOCOL) is BACnet, the occupancy and holiday information

will be reset to defaults in preparation for receiving a BACnet

occupancy object. While participating on a BACnet network these

configurations cannot be changed at the local interface or with

CCN tools. All scheduling is done from the BACnet interface

designated to provide schedules.

SERVICE TEST

The Service Tes t function can be used to verify proper operation of

compre ssors, heating sta ges, indoor f an, outdoor fa ns ,

Humidi--MiZer

crankcase heaters, and the alarm relay. Use of Service Test is

recommended at initial system start up and during troubleshooting.

(See Table 4 for point deta i ls)

Service T est mode has the following changes from normal opera t ion:

S Outdoor air temperature limits for cooling circuits, economizer,

and heating are ignored.

S Normal compressor time guards and other staging delays are

reduced to one minute or less.

S Circuit stri ke out time is reduced to 1 minute instead of 15 minutes .

S It may take up to 30 seconds to actually enter test mode after

activating the command.

Press the TEST button on the SystemVut interface anytime to

access the Test menu. Service Test mode can only be turned

ON/OFF at the unit display. Once turned ON, other entries may be

made with the display or through CCN. To turn Service Test mode

on, change the value of TEST MODE to ON. To turn service test

mode off, change the value of TEST MODE to OFF. Service Test

mode will be automatically turned off based on keypad inactivity

and the Service Mode Test Time out (TEST MODE TIMEOUT).

NOTE: Service Test mode may be password protected. Refer to

Basic Control Usage section for more information. Depending on

the unit model, factory--installed options, and field-- installed

accessories, some of the Service Test functions may not apply.

Independent Outputs

The INDEPENDENTS submenu is used to change output status

for the economizer, Humidi-- MiZer system valves, power exhaust

stages, crankcase heaters, the alarm relay, as well as perform a

compressor bump test. These independent outputs can operate

simultaneously with other Service Test modes. All outputs return to

normal operation when Service Test is turned off. The compressor

bump tests cannot be run while running cooling tests and will

automatically turn off after one minute.

Fan Test

The FA N T E S T S submenu is used to setup or test speeds for the

indoor fan. Use the IDF SPEED TEST point to control the indoor

fan speed in terms of %, and use the CONVERTED IDF RPM

point as feedback to help set the fan speed settings in terms of

RPM. The indoor fan transition type point inform the test routine

how to handle the fans while running the cooling or heating tests.

Automatic will automatically transition the fans as the cooling or

heating tests change. While the Manual transition will only run the

fans as set by the test points.

R

system operation, power exhaust fans, economizer,

10

Page 11

Cooling Test

The COOL submenu is used to change output status for the

individual compressors and Humidi--MiZer system operation. The

HEAT submenu service test outputs are reset to OFF for the

cooling service test. Indoor fans and outdoor fans are controlled

normally to maintain proper unit operation when set for automatic

transition. The IDF SPEED TEST and ALL ODFSPD TEST can

be changed as needed for testing. These fans points show the

requested speed not actual speed. All normal cooling faults and

alerts are functional.

Heating Test

The HEAT submenu is used to change output status for the

individual heat stages, gas or electric. The COOL service test

outputs are reset to OFF for the heating service test. Indoor fan is

controlled normally to maintain proper unit operation when set for

automatic transition. The IDF S PEED TEST can be changed as

needed for testing and shows the requested speed not actual speed.

All normal heating faults and alerts are functional.

NOTE: When the IGC fan on command (IGC FAN REQUEST)

is active the fan may run when not expected.

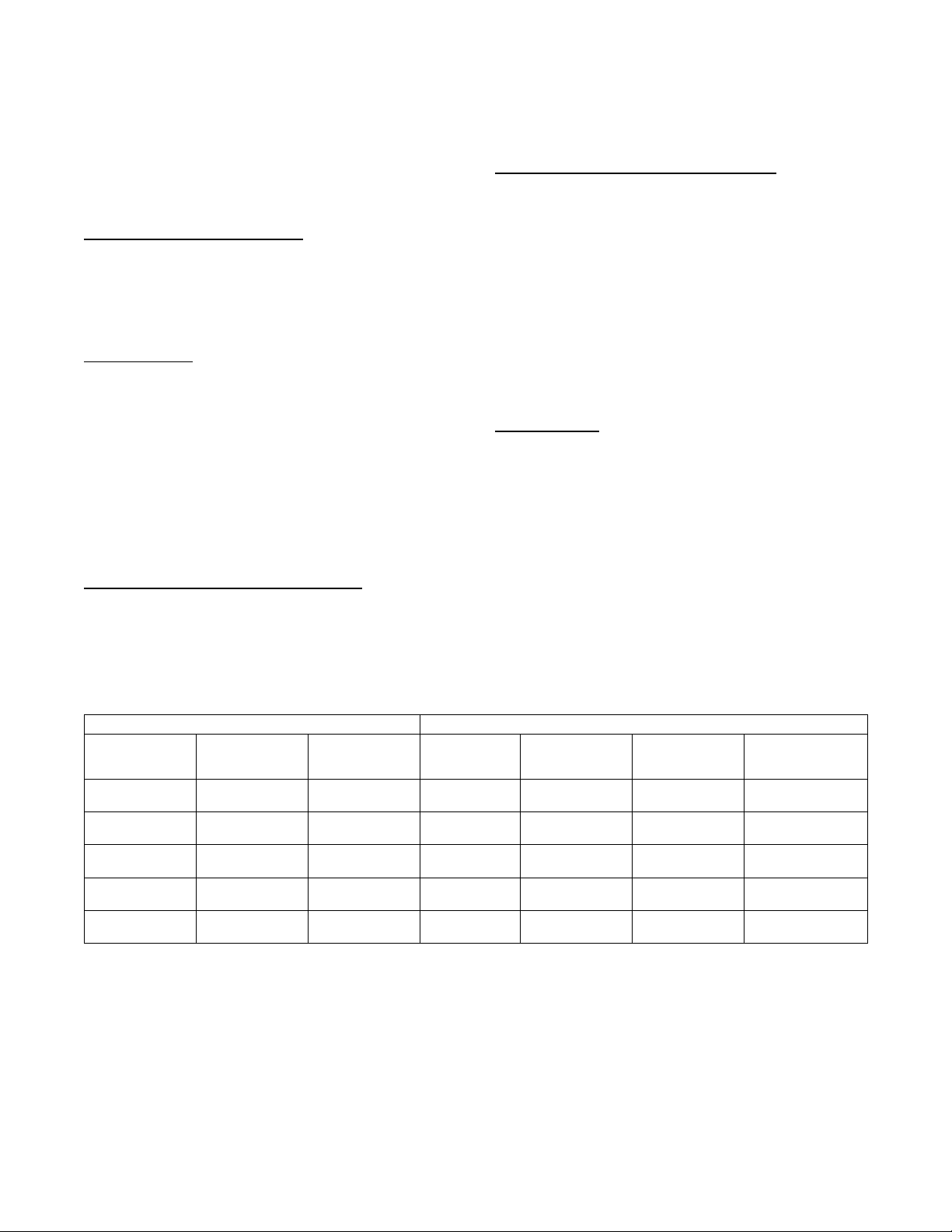

Table 4 – Test Mode Unit Test Directory

Display Menu/Sub menu/Name Expanded Name Values

UNIT TESTS Unit Tests Menu

TEST MODE ServiceTestModeEnable Off/On

SERVICE TEST Service Test Menu

INDEPENDENTS INDEPENDENT TEST MENU

ECON POS TEST Economizer Position Test 0 to 100

BUMP COMP A1 TEST Compressor Bump A1 Test Off/On

RH DIS VALVE TEST Rht Dischg Valve Rly Tst Off/On

RH LIQ VALVE TEST Reheat Liq Valv Rly Test Off/On

CL LIQ VALVE TEST Cooling Liq Valv Test Off/On

CCH RELAY 1 TEST Crankcase Heater 1 test Off/On

ALARM RELAY TEST Alarm Output Relay Test Off/On

PE1 RELAY TEST Power Exhaust 1 Test Off/On

PE2 RELAY TEST Power Exhaust 2 Test Off/On

2POS/ERV RLY TEST 2Position/ERV Relay Test Off/On

FAN TE STS Indoor and Outdoor Fan tests

IDF SPEED TEST Indoor Fan Speed Test 0 to 100

CONVERTED IDF RPM Converted IDF Speed XXXX

IDF MANUAL TRANS IDF Manual Transition Yes/ No

COOL Cooling Status Menu

COOL A1 TEST Cooling W/Comp.A1 Test Off/On

CIR A LOADER TEST Cooling W/Comp.ALD Test Off/On

IDF SPEED TEST Indoor Fan Speed Test 0 to 100

ODF RELAY TEST ODF Speed Relay Test Off/On

HUMIDIMIZER TEST Humidimizer Level Test 0=Off

HEAT Heating Status Menu

HEAT 1 TEST Heating Stage 1 Test Off/On

HEAT 2 TEST Heating Stage 2 Test Off/On

IDF SPEED TEST Indoor Fan Speed Test 0 to 100

AUTOMATIC TEST Automatic Test Menu

AUTO INDP TEST AUTO INDEPENDENT TEST Ye s/ N o

AUTO COOL TEST RUN AUTO COOLING TEST Ye s/N o

AUTO HEAT TEST RUN AUTO HEATING TEST Yes /N o

AUTO SYSTEM TEST RUN AUTO SYSTEM TEST Yes/N o

1 = SUBCOOL

2=REHEAT

Automatic Test

The AUTOMATIC TEST sub m en u is used to ex ecu te all the

applicable tests to the sy stem au to m atically. Th ese in clu d e

independent components, cooling, heating, and system. Table 5

shows the steps taken during the independent, cooling, and

heating auto m atic tests. The Hold time rep resen ts the time at

which that control waits before moving on to the next step.

The AUTO SYSTEM TEST will execute the independent auto

test, then the cooling auto test, then the heating auto test. At the end

of the system auto test a prompt will ask if you want to enter

measured data and complete a service report.

Table 5 – Independent, Cooling, and Heating Automatic Tests

AUTO INDP TEST

Step Action Hold (Sec)

1 Turn on Crankcase Heater Relay 0

2 Set IDF speed to 100% 30

3 Turn on 2 position damper/ERV relay 30

4 Set Economizer Damper to 100% 60

5 Turn o n p o w e r e x h a u s t 1 10

6 Turn o n p o w e r e x h a u s t 2 10

7 SetEconomizerDamperto0% 60

8 Turn off power exhau st 2 10

9 Turn off power exhau st 1 10

10 Set IDF to the ventilation speed 30

11 Turn off 2 position damper/ERV relay 0

12 Turn on alarm relay 10

13 Turn off alarm relay 10

14 Set IDF to 0% speed 30

15 Turn off Crankcase Heater relay 0

AUTO COOL TEST

Step Action Hold (Sec)

1 Set IDF auto transition 0

2 Turn o n C o o l A1 te s t 60

3 Turn on Compressor Loader test 30

4 Turn o f f OD F R e l a y t e st 10

5 Turn off Compressor Loader test 60

6 Turn off Cool A1 test 30

7 Turn on Hot Gas Reheat Test 60

8 Switch to Subcooling Test 30

9 Turn off Subcooling Test 30

AUTO HEAT TEST

Step Action Hold (Sec)

1 Set IDF auto transition 0

2 Turn o n H e a t 1 te s t 60

3 Turn o n H e a t 2 te s t 60

4 TurnoffHeat1andHeat2tests 20

11

Page 12

THIRD PARTY CONTROL

Third party controls may interface with the unit SystemVut

controller through the connections described below. See other

sections of these instructions for more information on the related

unit control and configurations.

Cooling/Heating Control

The thermostat inputs are provided on TB1 of the board. The

Unit Control Type configuration, UNIT CONTROL TYPE,

must be 0 (Tstat) to recognize the below inputs. Terminal R is

the 24--VAC source for the following:

Y1 = first stage cooling

Y2 = second stage cooling

W1 = first stage heating

W2 = second stage heating

G = Indoor fan

Dehumidification Control

For units with factory installed Humidi--MiZerRsystem option, the

humidistat input is defaulted for use on the Y3 thermostat input

screw terminal as a normally open switch. This can be changed

with the Humidistat Switch Channel configuration (HUMSTAT

CHANNEL) and the Humidistat switch type configuration

(HUMSTAT SW TYPE).

Remote Occupancy

The remote occupancy input can be provided on one of the

configurable inputs, most commonly TB3. The Remote

Occupancy Switch configuration, REMOTE OCC TYPE,

identifies the normally open or normally closed status of this input

when unoccupied. The Remote Occupancy Channel configuration,

REMOTE OCC CHAN, identifies the discrete input (DI) assigned

for this function.

Remote Shutdown

The remote shutdown input is provided for unit shutdown in response

to switch input configured most commonly on TB3. The Remote

Shutdown Swi t ch configuration, REM. SHUTDOWN TYPE,

identifies the normally open or normally closed status of this input

when there is no shutdown command. The Remote Shutdown

Channel configur ation, REM. SHUTDOWN CHAN, identifies the

discrete input (DI) assi gned for this function.

Alarm Output

The alarm output is provided on as a configurable relay, most

commonly on TB2, to indicate when a current alarm is active. The

output will be 24 --VAC if a current alarm exists. The Alarm Relay

Channel configuration, ALM RELY CHANNEL, identifies the

discrete output (DO) assigned for this function.

Economizer Damper Control

For units with the economizer option or accessory, the damper

position can be directly controlled through the IAQ sensor input.

The IAQ Analog Input configuration, IAQ LEVEL CONTROL

will have to set to 2 (CTL MINP). When IA.CF = 2, an external 4

to 20 mA source is used to move the damper 0% to 100% directly.

CONTROLS OPERATION

Display Configuration

The SETTINGSDISPLAY SETTINGS submenu is used to

configure the local display settings.

METRIC DISPLAY

This variable is used to change the display from English units to

Metric units.

LANGUAGE

This variable is used to change the language of the SystemVu

display. At this time, only English is available.

CONTRAST ADJUST

This is used to adjust the contrast of the SystemVu display.

PASSWORD ENABLE?

This variable enables or di sables the use of a user password. The

passw ord is used to rest r ict use of the control to change configurations.

VIEW USER PASSWORD

This menu allows the user to view the user password. The

password must be entered or disabled to view it.

CHANGE USER PASSWORD

This menu allows the user to change the user password. The

password must be entered or disabled to change it.

Unit Configuration

Many configurations that indicate what factory options and/or field

accessories are installed and other common operation variables are

included in SETTINGSUNIT CONFIGURATION submenu.

Some of these configurations will be set in the factory for the

factory--installed options (FIOPs). Field installed accessories and

custom control functions will require configuration changes. The

SETTINGSUNIT CONFIGURATIONGENERAL submenu

contains the following control configurations. Refer to other

specific sections for other configurations.

STARTUP DELAY

This configuration sets the control start-up delay after the power is

interrupted. This can be used to stagger the start-up of multiple

units.

UNIT CONTROL TYPE

This configuration defines if temperature control is based on

thermostat inputs or space temperature sensor input. TSTAT value

is when then unit determines cooling and heating demand by the

state of G, Y1, Y2, W1, and W2 inputs from a space thermostat.

This value is the factory default. SPACE SEN value is when the

unit determines cooling and heating demand based on the space

temperature and the appropriate set point. RAT SEN value is when

the unit determines cooling and heating demand based on the

return air temperature and the appropriate set point. SPACE SEN

or RAT SEN are also used as Linkage configuration.

THERMOSTAT TYPE

This configuration applies only if Unit Control Type is Thermostat.

The value determines how the inputs are interpreted. See the

specific operation sections for more information. The following

descriptions define what each value means.

0 = CONV 2C2H – Conventional Thermostat 2 stage cool and

2 stage heat.

1 = DIGI 2C2H – Digita l Thermos t at 2 stage cool and 2 stage heat.

2 = CONV 3C2H – Conventional Thermostat 3 stage cool and

2 stage heat. This is the default setting.

3 = DIGI 3C2H – Digital Thermostat 3 stage cool and 2 stage heat.

ADAPTIVE TSTAT

This configuration applies only if the Unit control type is

Thermostat. When this is YES the control will use Adaptive

Control for cooling and heating staging. When this is set to NO the

control will use the Traditional Thermostat Control, however

during integrated cooling Adaptive is always used.

DIRTY FILTER TIME

This configuration defines the life of the installed filter. A timer

will count down from this number while the indoor fan is running.

At the expiration of this timer, an alert will be activated to indicate

a filter change is required.

TEST MODE TIMEOUT

This configuration defines the time at which a test mode test has

not changed state will automatically disable test mode. This

configuration will disable the timeout when set to 0 (Disabled).

12

Page 13

CCH MAX TEMP

This configuration defines the temperature threshold for which the

crankcase heater is no longer required to heat the compressor shell.

STD BARO PRESSURE

This conf i guration is used to speci fy the job location’s s tandard

barometer pressure reading. This will feed the BAROMETRIC

PRESS when a network is not writing to it. This should be used to

account for job site eleva t ion if enthalpy calcula t ions are being used.

LINK STAGEUP TIME

This configuration sets the cooling and heating stage up time

during linkage operation.

Configurable Switches and Analog sensors

The SystemVut controll er has optional configurable inputs. These

consist of five physica l board switch inputs (disc r ete inputs) and three

physical board analog inputs. There are more functions allowed for

configuration than ther e are inputs. Each function will have a

configuration for which input channel it is assigned to. Each switch

function will als o have a switch type configuration which defines that

switches normal stat e. Table 6 shows the configurabl e functions and

what their normal and active states are. Ta ble 7 shows the configurable

analog input functi ons. The switc h configurations can be found in the

SETTINGSUNIT CONFIGURATIONSSWITCH INPUT

CONFIGS sub--menu. The analog input configura tions can be found

in the SETTINGUNIT CONFIGURATIONSSWITCH INPUT

CONFIGS sub--menu. The configurabl e input assignment can be

viewed in the SERVICEHARDWAREASSIGNED

INPUTS/OUTPUTS sub--menu.

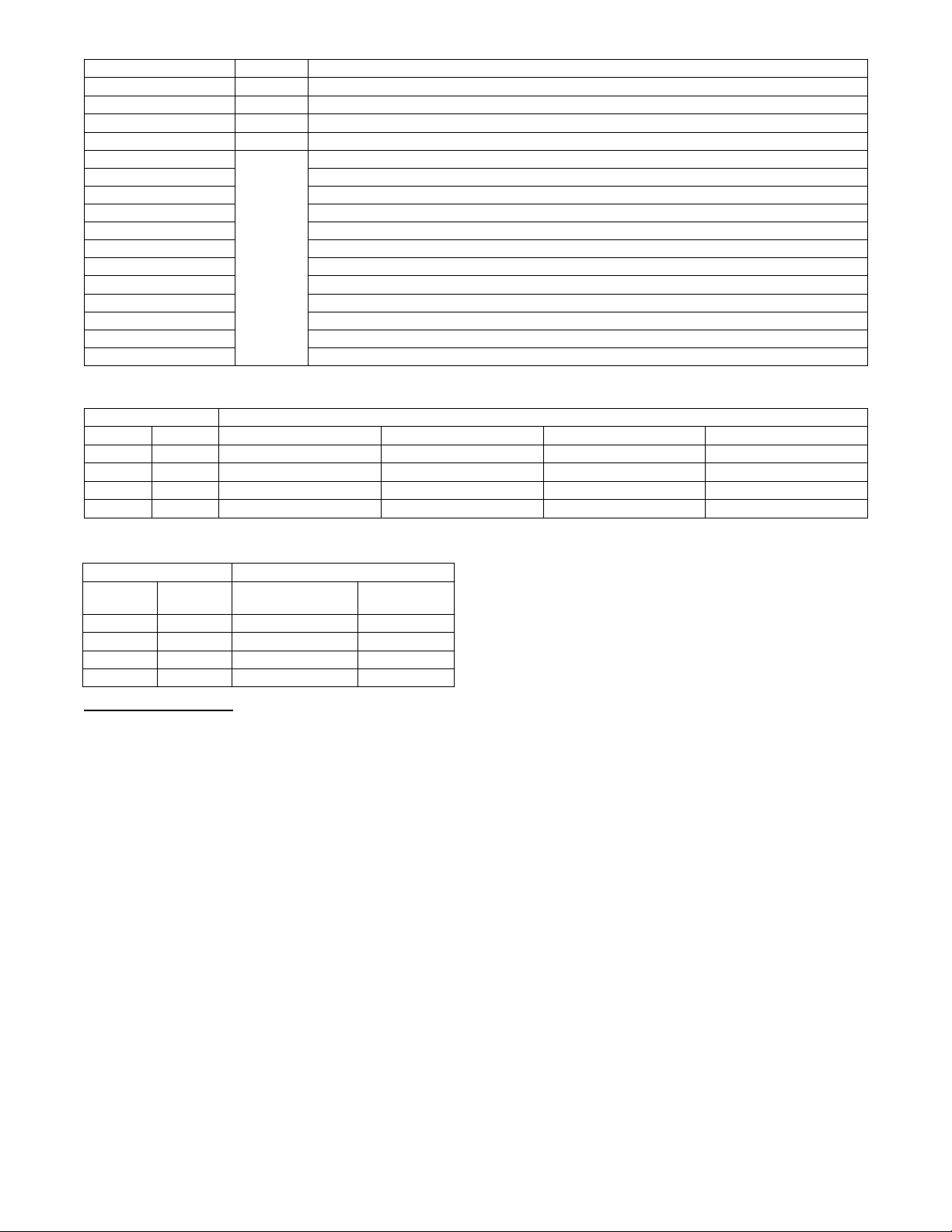

Table 6 – Configurable Switch Input Functions

Function Description Normal State Active State

Humidistat OFF ON

Condensate Overflow LOW HIGH

Phase Monitor NORMAL ALARM

Filter Status Switch CLEAN DIRTY

Remote Occupancy UNOCC OCCUPIED

Remote Shutdown RUN SHUTDOWN

Fan Status OFF ON

General Status Switch NORMAL ALARM

IAQ Override OFF ON

Enthalpy Switch Input LOW HIGH

Table 7 – Configurable Analog Input Functions

Function Description Sensor Type Sensor Values

Space Relative Humidity Sensor 0--- 2 0m A %RH

Outside Air Relative Humidity Sensor 0 --- 20 m A %RH

Return Air Relative Humidity Sensor 0 --- 20 m A %RH

Indoor Air CO2Sensor 0 --- 20 m A PPM

Outside Air CO2Sensor 0 --- 20m A PPM

Outdoor CFM Sensor 0 --- 2 0 m A CFM

General Operation

48/50FC and 48/50GC units can provide cooling,

dehumidification, heating, and ventilation. The operating mode

(MODE) shows the highest level of operation of the unit at any

given time. The operating sub--mode (SUB--MODE) shows the

detail operation occurring while under a specific mode. Fig. 8

shows the MODE and SUB--MODE values.

Each unit will operate under one of three basic types of control,

thermostat, space temperature sensor, or return air temperature

sensor. There are many inputs, configurations, safety factors, and

conditions that ultimately control the unit. Refer to the specific

operation sections for detail on a specific unit operation. The

control will set the demand based on these types of control and

conditions, which then drives the operating mode.

When thermostat control is enabled (UNIT CONTROL TYPE),

the unit will operate based on discrete input commands (G, Y1,

Y2, W1, and W2) and there is a one minute time delay between

modes and when re--entering a mode. The G command calls for

ventilation, the Y1 and Y2 commands call for cooling, and the W1

and W2 commands call for heating. Thermostat Control Type

(THERMOSTAT TYPE) affects how cooling operates based on

Y1 and Y2 commands and if cooling/heating stage time guards are

applied.

When space temperature sensor control in enabled (UNIT

CONTROL TYPE), the unit will try to maintain the Space

Temperature (SPACE TEMPERATURE) between the effective

cool and heat setpoints (EFF COOL SETPOINT and EFF HEAT

SETPOINT). However, to minimize unnecessary cool to heat and

heat to cool changes, there is a 10 minute delay after the last stage

turns off before the control will switch modes. Linkage operation

overrides the mode changeover delay to 15 seconds. The cooling

and heating Mode Select Time guards (COOL MODE T.GUARD

and HEAT MODE T.GUARD) show the remaining time before

allowing the respective mode to be entered.

Demand Determination

Based on the unit control type (UNIT CONTROL TYPE),alarm

conditions, and user interaction, the control will determine an

overall demand of the unit. Table 8 shows the possible system

demands with their priority level and summary description.

Thermostat Demand

When the unit control type is configured for thermostat (UNIT

CONTROL TYPE = TSTAT) the level 5 demand in Table 8 will be

determined by thermostat inputs and the Thermostat Type

configuration (THERMOSTAT TYPE) as shown in the tables

below. Table 9 shows the cooling thermostat inputs and how they

map to the system demand. Table 10 shows the heating thermostat

inputs and how they map to the system demand.

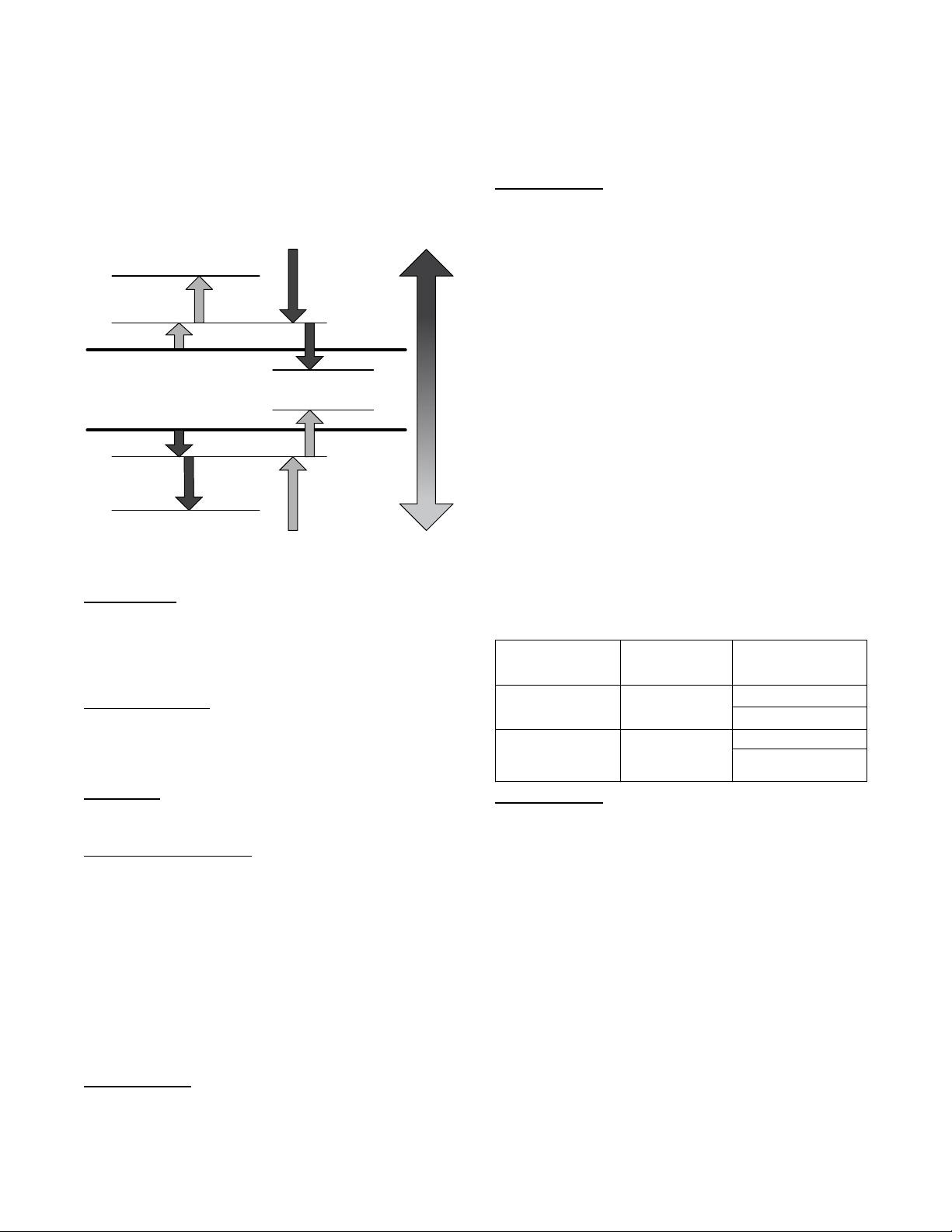

MODE OFF VENT COOL HEAT TEST

STARTING UP MODE TIMEGUARD ECON FREE COOLING HEATING MANUAL TEST

SUB-

MODE

IDLE - NO DEMAND

MODE TIMEGUARD MECH. COOLING

UNIT DISABLED ECON/MECH COOLING

URGENT SHUTDOWN DEHUMIDIFICATION

SAFETY CONTROL DEHUM/MECH COOL

SUPPLY FAN ON UNOCC. FREE COOL

DEHUM PREVENTED

COOLING PREVENTED

SHUTTING COOL OFF

OUTSIDE AIR TEMPERING

HEATING PREVENTED

SHUTTING HEAT OFF

AUTO TEST

SHUTTING TEST OFF

Fig. 8 -- Modes and Sub--Modes

13

a48--- 9374

Page 14

Table 8 – Demand List and Priority

DEMAND Priority Description

EMERGENCY 1 An emergency condition occurs which requires a unit shutdown

SAFETY FAULT 2 A safety diagnostic requires the unit to run in safety mode.

SERVICE TEST 3 User request test mode

SHUTDOWN 4 A minor or user condition requires the unit to shutdown

NO DEMAND

FAN ONLY Only circulation or ventilation is requested form the building

DEHUM A dehumidification load is present in the building

LOW COOL A low cooling load is present in the building

HIGH COOL A high coolin g load is present in the building

LOW COOL & DEHUM A low cooling and dehumidification load is present in the building

HIGH COOL & DEHUM A high cooling and dehumidification load is present in the building

UFC LOW COOL A low cooling load is present in the building due to the unoccupied free cooling algorithm

UFC HIGH COOL A high cooling load is present in the building due to the unoccupied free cooling algorithm

LOW HEAT A low heating load is present in the building

HIGH HEAT A high heating load is present in the building

SUPPLY AIR TEMPERING Due to outside air, supply air is uncomfortably cool during ventilation

5

There is no comfort demand from the building

Table 9 – Thermostat Cooling System Demands

Thermostat Inputs THERMOSTAT TYPE

Y1 Y2 CONV 2C2H* CONV 3C2H DIGI 2C2H DIGI 3C2H

0 0 No C ool No Cool No Cool No Cool

0 1 Alert & Low Cool Alert & Low Cool High C o ol High Cool

1 0 Low C ool Low Cool Low Cool Low Cool

1 1 High Cool High Cool High Cool High Cool

*SettheLOW COOL COMP as needed.

Table 10 – Thermostat Heating System Demands

Thermostat Input THERMOSTAT TYPE

W1 W2

0 0 No Heat No Heat

0 1 Alert & Low Heat High Heat

1 0 Low Heat Low Heat

1 1 High Heat High Heat

CONV 2C2H

CONV 3C2H

DIGI 2C2H

DIGI 3C2H

Space Sensor Demand

When the unit control type is configured for space sensor (UNIT

CONTROL TYPE = SPACE SEN) the level 5 demand in Table 8

will be determined by the space sensor inputs and setpoints as

described below. The Effective Demand Temperature (DEMAND

CTRL TEMP) represents the temperature which the control is

using to control the space. This would come from the space sensor,

building network, linkage, or the return air sensor.

Setpoint Determination

Setpoints are used to control the unit. The Cool Setpoint in Effect

(EFF COOL SETPOINT) and the Heat Setpoint in Effect (EFF

HEAT SETPOINT) are the points in which the unit is controlling

to at a specific time. These points are read only points and change

according to occupancy, the offset slider status, and network writes.

The setpoint configurations are in the SETTINGSSPACE SET

POINTS submenu.

If the building is in occupied mode, the Occupied Cool Setpoint

(OCC COOL SETPOINT) and the Occupied Heat Setpoint (OCC

HEAT SETPOINT) are active. When the building is in

unoccupied mode, the Unoccupied Cool Setpoint (UNOCC COOL

SETPNT) and the Unoccupied Heat Setpoint (UNOCC HEAT

SETPNT) are active. The heating and cooling set points are also

separated by a Heat-- Cool Set Point Gap (HEAT-COOL SP GAP)

that is user configurable from 2 to 10 degrees F. This parameter

will not allow the setpoints to be set too close together, it will

change the last setpoint adjusted if it is set within the GAP.

When the space sensor has a setpoint slider adjustment, the cool

and heat setpoints (occupied) can be offset by sliding the bar from

one side to the other. The SPT Offset Range (+/--) (SPT SLIDER

RANGE) sets the total positive or negative degrees that can be

added to the setpoints. With the slider in the middle, no offset is

applied. Moving the slider to the “COOL” side will subtract from

each setpoint, and sliding it to the “WARM” side will add to the

setpoints. The slider offset being applied at any given time is

displayed as Space Temperature Offset (SLIDER OFFSET VAL).

Temperature Demand

Space sensor staging control is an adaptive anticipation control that

weighs the actual space demand against the trend of that demand.

The control tries to anticipate the change in the space because of its

current stage status. This anticipation is based on the demand

trends. These trends will show the control how the space is reacting

to the current running conditions and help it decide when to

change the actual demand of the system. The following points are

in the RUN STATUSMODE submenu:

COOLING DEMAND — This is the difference between the Cool

Setpoint in Effect (EFF COOL SETPOINT) and the Effective

Demand Temperature (DEMAND CTRL TEMP) representing the

demand of the space for cooling.

COOL DEMAND TREND — This is the rate of change of the

cooling demand in degrees per minute, representing how the space

is changing its demand for cooling.

HEATING DEMAND — This is the difference between the Heat

Setpoint in Effect (EFF HEAT SETPOINT) and the Effective

Demand Temperature (DEMAND CTRL TEMP) representing the

demand of the space for cooling.

HEAT DEMAND TREND — This is the rate of change of the

heating demand in degrees per minute, representing how the space

is changing its demand for cooling.

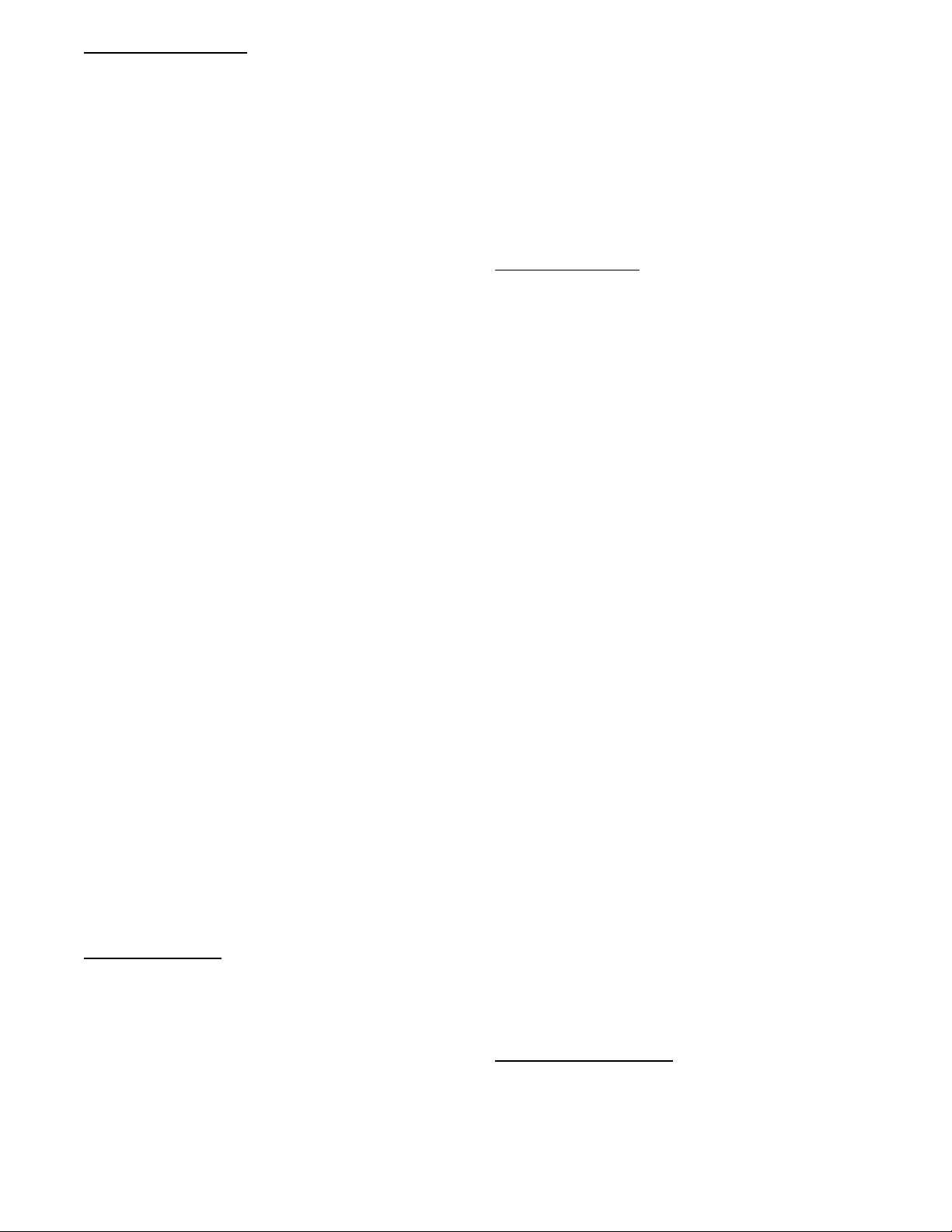

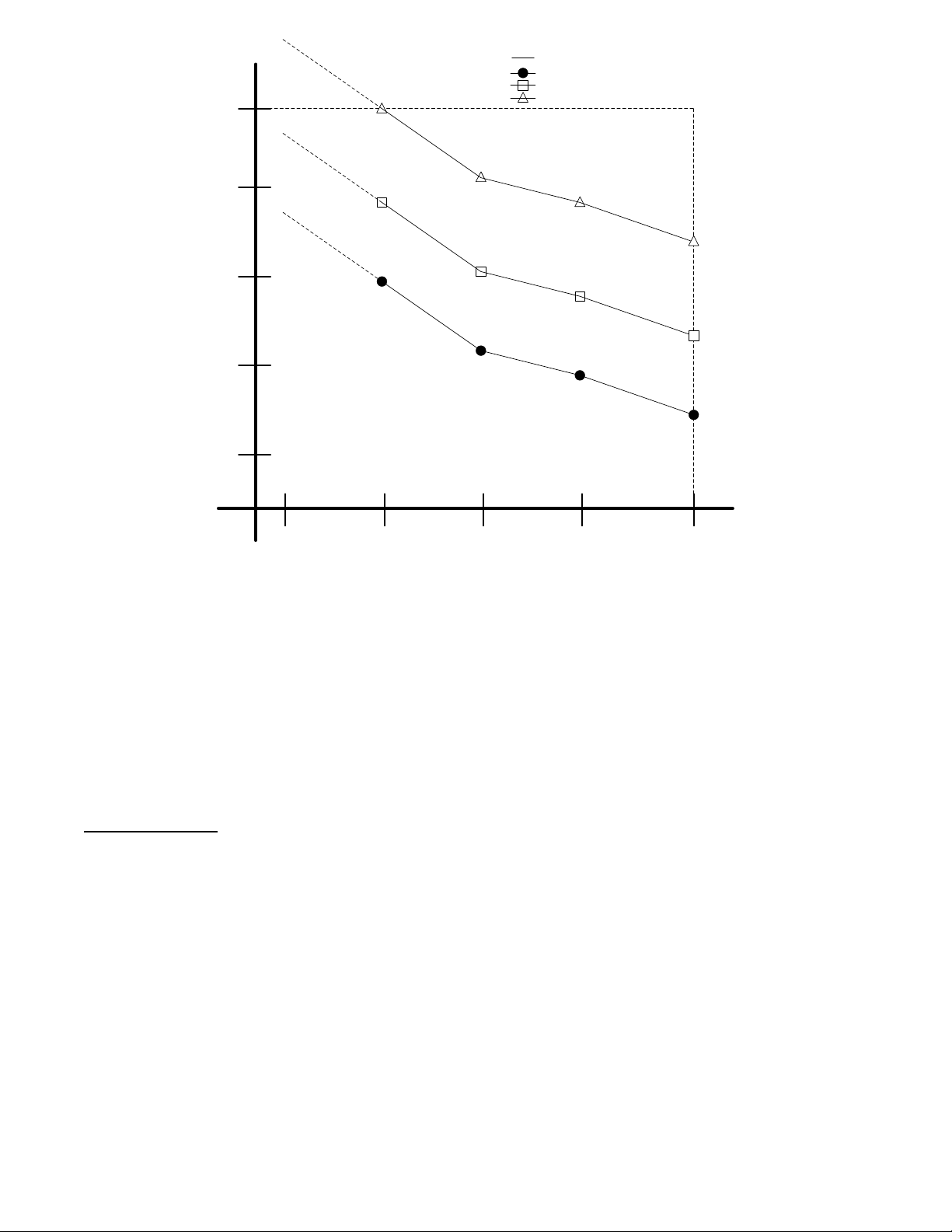

In general the system demand will increase based on the demand

compared to the demand switch states in Fig. 9. The demand

cannot increase until Time guard 1 (DEMAND TIMEGUARD1)

expires. The LCON and LHON thresholds will also cause the

14

Page 15

system demand to be reduced. When the demand hits the off switch

stages the system demand will be set to NO DEMAND. These

switch stages are in the SETTINGSSET POINTSTEMP

DEMAND CONFIG submenu.

The cooling and heating demand level up configurations (COOL

DMD LEVEL UP and HEAT DMD LEVEL UP) will restrict a

system demand increase if the demand trend is less than the level

up configuration. These level up configurations will also increase

the system demand if the demand trend is greater than it for greater

than the Time guard 2 (DEMAND TIMEGUARD2).

The system demand will increase if it has remained at the same

state for greater than Time Guard 3 (DEMAND TIMEGUARD3).

HCON

Decrease

LCON

Cool Setpoint

Heat Setpoint

LHON

HHON

Demand

LCOF

LHOF

Decrease

Demand

SPACE TEMP

a48--- 10313

Fig. 9 -- Space Sensor System Demand Switch States

RA T Demand

When the unit control type is configured for return air sensor

(UNIT CONTROL TYPE = RAT SEN) the level 5 demand in

Table 8 will be determined the same as space sensor but using the

return air temperature (RETURN AIR TEMP) instead of the space

temperature (SPACE TEMPERATURE).

Humidity Demand

When the unit is configured for either a Humidistat input

(HUMSTAT CHANNEL) or Space Humidity Sensor (SPRH

SENS CHANNEL) the level 5 demand in Table 8 will include a

determination of dehumidification demand.

Humidistat

When receiving an active input from the Humidistat

(HUMIDISTAT), dehumidification will be demanded.

Space Relative Humidity

On units with a relative humidity sensor, when the received value

of space relative humidity (SPRH LEVEL) has exceed the

humidity set point (SPRH SET POINT), dehumidification will be

demanded. This demand will remain until the space relative

humidity has fallen below the humidity set point by more than the

humidity set point deadband (SPRH DEADBAND). This would

come from the space humidity sensor, or building network.

Occupancy Determination

The building’s occupancy is affected by a number of different

factors. Occupancy affects the unit set points and the operation of

the economizer. The factors affecting occupancy are listed below

from highest to lowest priority.

Level 1 Priority

Level 1 classification is a force/write to occupancy and can occur

two ways. Listed in order of priority: force on OCCUPIED, and a

Linkage write. The CCN point OCCUPIED is forced via an

external device such as a ComfortIDt controller or a service tool:

when OCCUPIED is forced to YES, the unit is considered

occupied, when OCCUPIED is forced to NO, the unit is

considered unoccupied. If the unit is being controlled by Linkage,

the occupancy is communicated and mapped to OCCUPIED as an

input. Linkage does not force the point only write to it, therefore a

force applied to OCCUPIED will override it.

If OCCUPIED is not being forced or written to, proceed to the

level 2 priority.

Level 2 Priority

Level 2 is considered occupant interaction, and consists of Timed

Override and Remote Occupancy Switch. A timed override button

press will override a remote occupancy switch if both are installed

for operation.

While using the programmed schedule, occupancy can be

temporarily switched from unoccupied to occupied by pressing the

override button for approximately 3 seconds on the T--55, T--56, or

T--59 space temperature sensor. The length of the override period

when pressing the override button is determined by the Override

Time Limit (TIMED OVR LENGTH). The hours remaining in