Page 1

42VMC

T

h

e

S

t

a

n

d

a

r

d

s

I

n

s

t

i

t

u

t

i

o

n

o

f

I

s

r

a

e

l

Q

u

a

l

i

t

y

A

s

s

u

r

e

d

F

i

r

m

SI

ISO 9001

Console

INST ALLATION MANU AL

Page 2

42VMC

Split system “Console night & day” indoor unit

The operation and maintenance instructions for the indoor unit and the installation instructions

for the indoor and the outdoor unit are given in the manuals for each unit. These are supplied

with the unit.

Contents

Page

Dimensions and weight.... ........................................................................... 2

Nominal data.... .... .... .... .... ........................................................................... 2

Minimum clearances....... .... ........................................................................ 2

Connections................................................................................................ 3

Material supplied .... .... .... .... ........................................................................ 3

Operating limits..... .... ... .... .... ....................................................................... 3

General information.... .... .... .... .... ................................................................ 4

Warnings: av oid .. .... .... .... ............................................................................ 5

Installation .................................................................................................. 6/7

Refrigerant connections .. .... ....................................................................... 8

Electrical connection .... ... ........................................................................... 9/11

System configuration... .... ........................................................................... 12

Operating test .... .... .... .... .... ......................................................................... 13

Address selector.... ... .... .... .... ...................................................................... 13

Fault code .... .... ... .... .... .... ............................................................................ 13

Guide for the owner........ .... ......................................................................... 13

Accessories ................................................................................................ 13

Air delivery ........ .... .... .... .... .......................................................................... 14

Fresh air rene wal ...... .... .... .......................................................................... 14

ENGLISH

Cooling only and

Power supply

heat pump models

42VMC009

42VMC012

42VMC014 230V ~ 50Hz

42VMC018

42VMC024

GB - 1

Page 3

42VMC

50 min

500 min

50 min

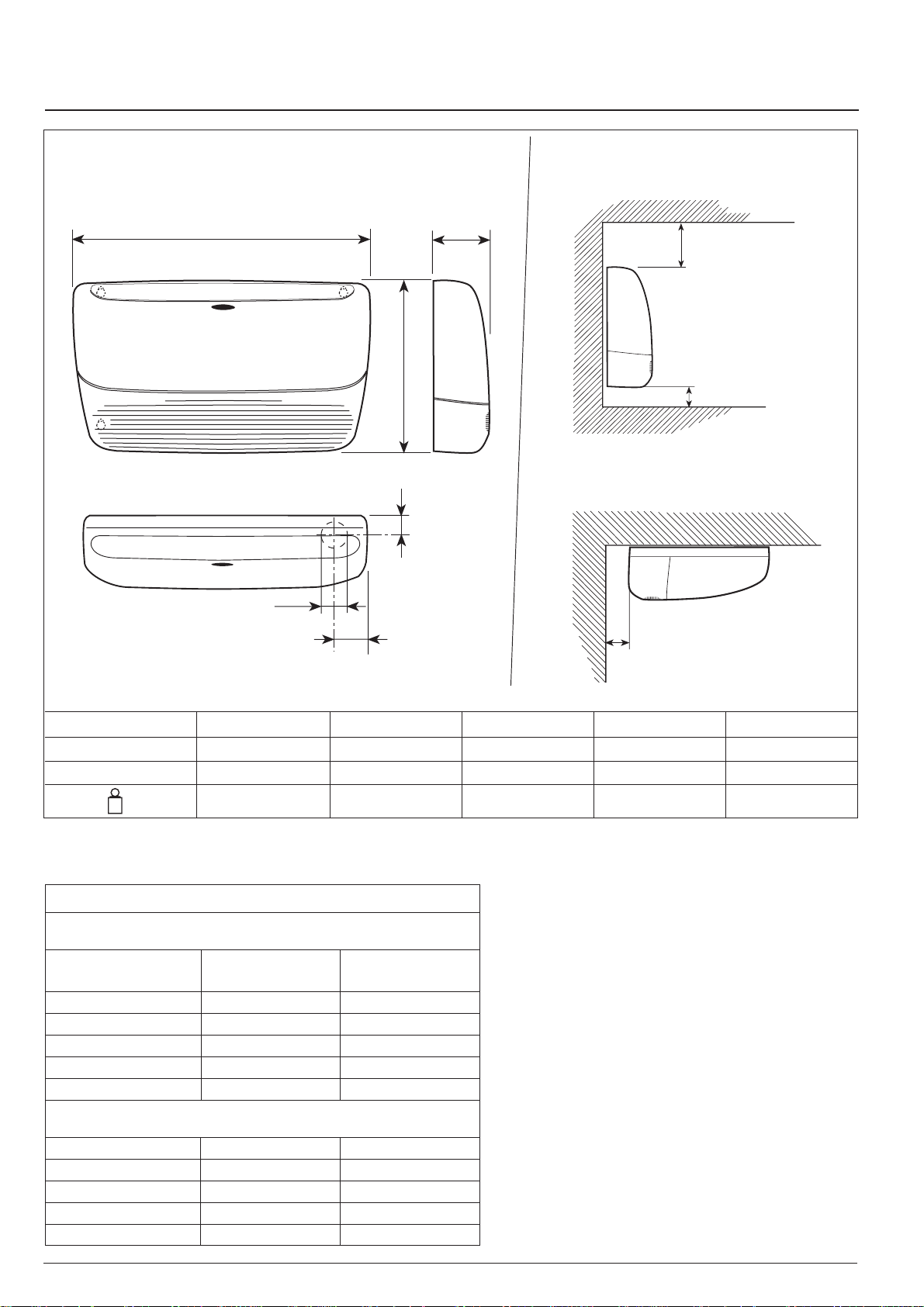

Dimensions and weights - Minimum c learances (mm)

Dimensions and weights Minimum clearances

Wall installation

A

B

200

Ceiling installation

40

Ø 80

50

Model 42VMC009 42VMC012 42VMC014 42VMC018 42VMC024

A mm 850 850 1000 1000 1000

B mm 540 540 600 600 600

kg

42VMC 009 25 –

42VMC 012 30 –

42VMC 014 55 –

42VMC 018 55 –

42VMC 024 80 –

42VMC 009 25 25

42VMC 012 30 30

42VMC 014 55 55

42VMC 018 55 55

42VMC 024 80 80

kg 15 16 18 18 20

POWER INPUT

Cooling only

Cooling Heating

WW

Heat pump

Table I: Nominal data

• Unit is not suitable for operation in laundry premises.

• For sizing of power supply wires and delay type fuses, refer to

the outdoor unit installation instructions.

GB - 2

Page 4

42VMC

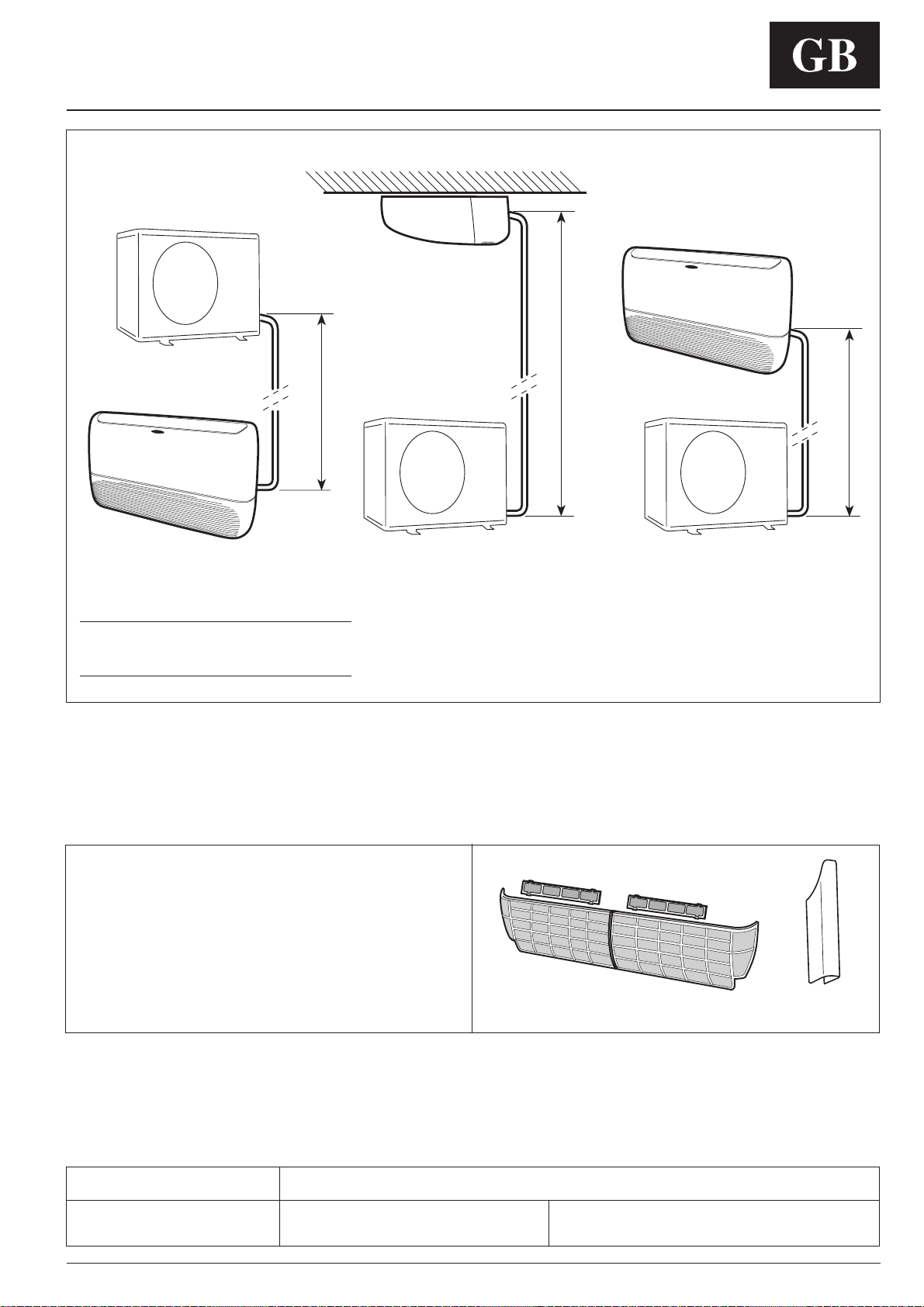

Connections

햳

햲

햴

햳

햲

ENGLISH

햳

햴

햴

햲

Note:

Height difference / Connection length / Pipe bends:

See outdoor unit installation manual.

Table II: Material supplied

햵 Photocatalytic filter

햶 Acrylic-fibre filter

햷 Condensate drain pipe cover

(use for horizontal installation)

• Drilling template

• Installation manual

• Owner’s manual

• Wireless infrared remote control kit

햲 Outdoor unit

햳 Indoor unit

햴 Height difference

햵

햷

햶

Table III: Operating limits

Cooling / Heating Refer to outdoor unit installation manual.

Mains power supply

Nominal single-phase voltage 230V ~ 50Hz

Operating voltage limits min. 198V – max. 264V

GB - 3

Page 5

42VMC

General information

Unit installation

Read this instruction manual thoroughly before starting the

installation.

• This unit complies with low-voltage (EEC/73/23) and electromagnetic compatibility (EEC/89/336) directives.

• The installation must be carried out by a qualified installer.

• Follow all current national safety code requirements. In particular

ensure that a properly sized and connected ground wire is in place.

• Check that voltage and frequency of the mains power supply are

those required for the unit to be installed; the available power

must be adequate to operate any other possible appliances

connected to the same line.

Also ensure that national safety code requirements have been

followed for the mains supply circuit.

• The mains supply must be connected as follows:

Models 42VMC 009, 012, 014: to the indoor unit.

Models 42VMC 018, 024: to the outdoor unit.

• Connect indoor and outdoor units with field-supplied copper pipes

by means of flare connections. Use insulated seamless

refrigeration grade pipe only, (Cu DHP type according to ISO 1337),

degreased and deoxidized, suitable for operating pressures of at

least 4200 kPa.

Under no circumstances must sanitary type copper pipe be used.

• Failure to observe electric safety codes may cause a fire hazard in

case of short circuits.

• Inspect equipment for damage due to improper transportation or

handling: file an immediate claim with the shipping company.

Do not install or use damaged units.

• In case of any malfunctioning turn the unit off, disconnect the

mains power supply and contact a qualified service engineer.

• This equipment contains R-410A refrigerant, a substance that is

not depleting the ozone layer.

• All of the manufacturing and packaging materials used for

your new appliance are compatible with the environment and

can be recycled.

• Dispose of the packaging material in accordance with local

requirements.

• This equipment contains refrigerant that must be disposed of in

the proper manner.

When disposing of the unit after its operational life, remove it

carefully.

The unit must then be delivered to an appropriate disposal centre

or to the original equipment dealer, for proper environmentally

friendly disposal.

• Use field-supplied 16 mm I.D. PVC pipe of appropriate length and

with the correct thermal insulation for the condensate drain.

• After installation thoroughly test the system operation and explain

all system functions to the owner.

• Leave this manual with the owner for consultation during future

periodic maintenance.

• Use this unit only for factory approved applications: the unit

cannot be used in laundry or steam pressing premises.

IMPORTANT:

During the unit installation make first refrigerant connections

and then electrical connections. When disassembling first

disconnect electrical cables, then refrigerant connections.

WARNING:

Disconnect the mains power supply switch before servicing

the system or handling any internal parts of the unit.

• Do not open the remote controller to avoid possible damage.

In case of malfunctioning contact a qualified service engineer.

• This installation manual describes the installation procedures of

the indoor unit of a residential split system consisting of two units

manufactured by Carrier.

Consult factory or a qualified system engineer prior to connecting

this unit to any other manufacturer's outdoor unit.

Coupling units which have different control systems, may cause

irreversible damage and void the warranty protection.

The manufacturer declines any liability for system malfunction

resulting from unapproved coupling.

• Operating conditions outside the operating range

(“Connections”), will cause safety device tripping or damage to

unit components.

• The manufacturer declines any liability for damage resulting from

modifications or errors in the electrical or refrigerant connections.

Failure to observe the installation instructions or use of the unit

under conditions other than those indicated in Table III (operating

limits) of the outdoor unit installation manual, will immediately

void the unit warranty.

Choosing the installation site

Positions to avoid:

• Exposed to direct sun.

• Too close to heat sources.

• On humid walls or positions with water hazard, e.g. laundry premises.

• Where curtains or furniture may obstruct free air circulation.

Recommendations:

• Choose an area free from obstructions which may cause irregular

air distribution and/or return.

• Check that the wall surface is flat enough to allow easy and safe

installation.

The wall structure should be strong enough to carry the unit

weight and avoid deformation, rupture or vibration during

operation.

• Consider using an area where installation is easy.

• Choose a position that allows for the clearances required (see drawing).

• Look for a position in the room which assures the best possible air

distribution.

• Install the unit in a position where condensate can easily be piped

to an appropriate drain.

GB - 4

Page 6

42VMC

Warnings: a void…

...any obstruction of the unit air outlet or return.

...exposure to oil vapours.

ENGLISH

...exposure to direct sunshine, when unit is operating in cooling

mode; always use shutters or shades..

...positions too close to heating sources which may damage the unit.

...connecting condensate piping to sewage system drain without

appropriate trap. Trap height must be calculated according to the unit

discharge head in order to allow sufficient and continuous water evacuation.

...installation in areas with high frequency waves.

...

any rise in the condensate drain piping.

...horizontal condensate drain piping with less than 2% slope.

.

...only partial insulation of the piping.

...installation not correctly levelled which will cause condensate

dripping.

...flattening or kinking the refrigerant pipes or condensate pipes.

...excessive height difference between outdoor and indoor units

(see installation manual of outdoor unit).

...slack on electrical connections. ...disconnecting refrigerant

connections after installation: this will cause refrigerant leaks.

...unnecessary turns and bends in interconnecting tubing. ...excessive

interconnecting tube length (see installation manual of outdoor unit).

GB - 5

Page 7

42VMC

Installation

Vertical wall-mounting

• The preferred arrangement is generally under a window sill on an

external wall.

This makes it easier to install the interconnecting tubing,

electrical connections and condensate pipework to the outdoor

unit.

The indoor unit can also be installed against an internal partition

if the connections to the outdoor unit can be concealed.

• For better operation of the thermostat located on the unit, it is

advisable to avoid unit installation in enclosed spaces.

Hole

Plate

T emplate

Ceiling installation

• Using the template supplied, drill the four holes in the ceiling and

position four tie rods (not supplied).

• Attach the unit to the tie-rods, as shown in the illustration.

• There are three alternatives for the connections to the unit:

parallel to the wall, through the wall or through the side.

Preparation

• Unpack the unit.

• Open and remove the suction grille.

To remove suction grille, remove the central lock using a pliers,

then with a screwdriver remove the two side screws fixing the

fasteners.

• Locate the mounting template, supplied with the unit.

• Ensure a minimum slope of 5 mm (refrigerant connection side

must be lower) by modifying on the tie-rod fixing.

C

D

A

B

Installation

• Use the template supplied, and drill the four fixing holes in the

wall. Use the four dowels provided.

• Fix the attachment plate (using the two upper holes).

• Attach the unit.

• Fix the unit to the wall, using the two holes, positioned in the lower

part.

• Verify that the unit is level.

GB - 6

42VMC 009 012 014 018 024

A mm 850 850 1000 1000 1000

B mm 786 786 940 940 940

C mm 237 237 250 250 250

D mm 237 237 285 285 285

Page 8

42VMC

Installation

Drilling the hole in the wall for the

connection of the pipes

Ø 80 mm

75 mm

50 mm

The pipes can exit the unit to three different directions (see illustration). For exit to the rear, the wall hole must be made in the position

shown in the illustration.

ENGLISH

For horizontal installation

To allow the condensate drain pipe to correctly come out of the unit,

proceed as follows:

5-10 mm

햲

햲 Indoors

햳 Outdoors

Drill a 70 or 80 mm diameter hole. The hole must have a 5-10 mm

downward slope towards the outside. Insert the plastic conduit

provided.

Pass the electrical connecting wires through the conduit (see

electrical connections).

Ø 70 / 80 mm

햳

Condensate drain pipe

For vertical installation

Connect the PVC pipe to the connection on the drain pan.

A Refrigerant connections

B Condensate drain pipe

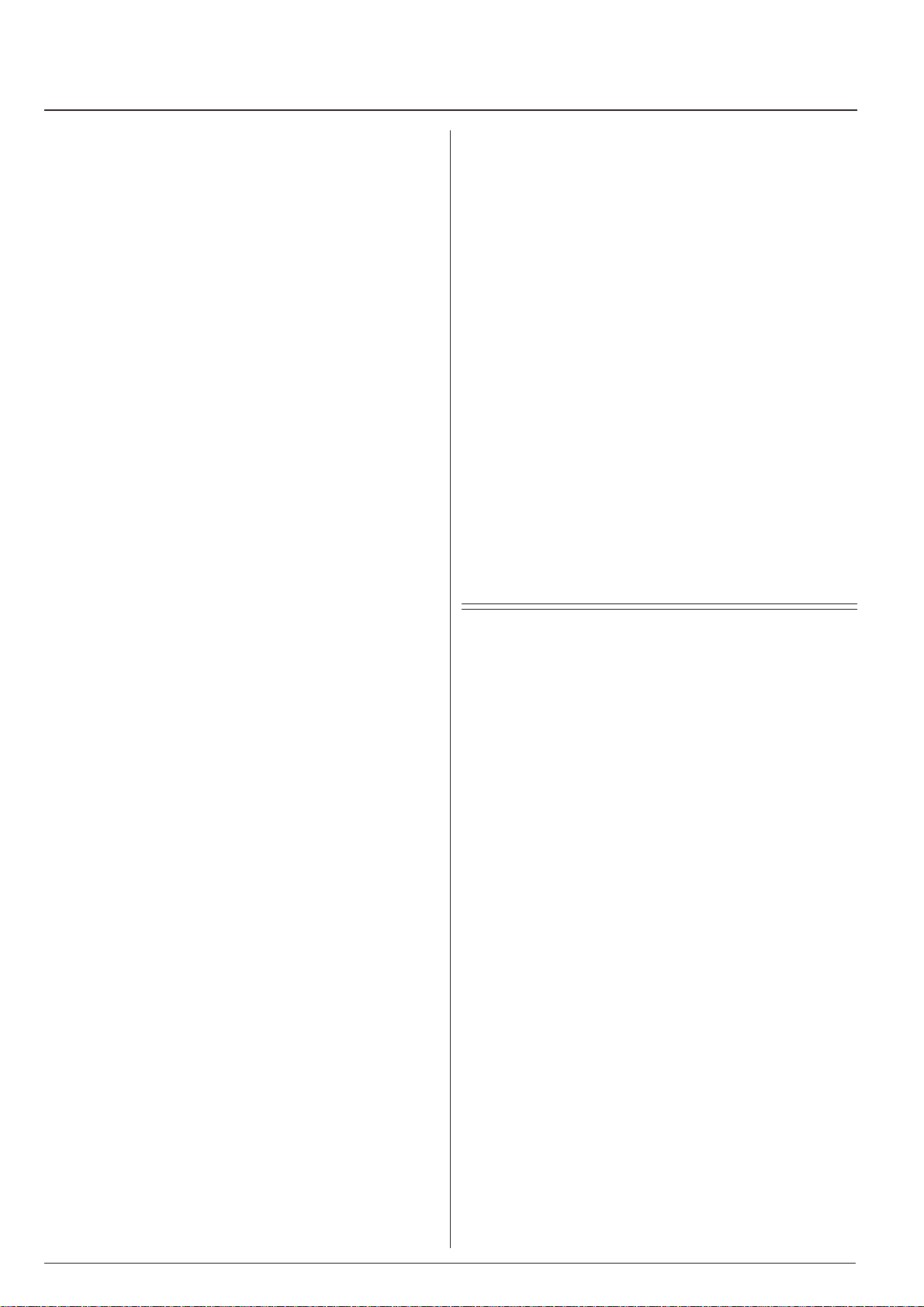

• Remove from suction grille, the part of grille fixed tonguing,

pressing it until tabs is unhooked.

햷

A

B

IMPORTANT:

The outdoor unit is designed to operate without the use of

condensate water to cool the condenser coil.

It is necessary to discharge the condensate directly into the

sewer system, downpipes or to disperse it outside.

Mount condensate drain pipe cover 햷 supplied, fitting it as

necessary.

In the event of condensate discharge pump is used

(accessory), the condensate drain pipe can exit together with

the refrigerant pipes.

GB - 7

Page 9

42VMC

햲햳

햴

Refrigerant connections

Make refrigerant connections before connecting the system to

the power supply.

Refer to the outdoor unit installation manual for tube sizing,

and limitations (slopes, length, number of curves allowed,

refrigerant charge, etc.)

Tubing diameter

Gas Liquid

Model (Suction) (Discharge)

mm (inches) mm (inches)

009 9.52 (3/8”)6.35(1/4”)

012 12.70 (1/2”)6.35(1/4”)

014 12.70 (1/2”)6.35(1/4”)

018 12.70 (1/2”)6.35(1/4”)

024 12.70 (1/2”)6.35(1/4”)

• For refrigerant tubes use seamless, insulated refrigeration grade

tube, (Cu DHP type according to ISO 1337), degreased and

deoxidized, suitable for operating pressures of at least 4200 kPa.

Under no circumstances use sanitary type copper pipe.

Note:

• Do not kink or flatten the tubes.

• Avoid bends with a bending radius of less than 100 mm.

• Do not bend copper tubes more than three times at the same point.

• Do not remove flare fittings from unit tubes before actually making

the connections.

• Do not fasten the insulation too tightly to the tubes with straps or

tape.

Connection to the unit

Insufficient tightening torque will cause gas leaks.

Overtightening the fittings will damage the tube flaring and cause

gas leaks.

햲 Adijustable wrench or

torque wrench

햳 Connecting pipes

햴 Unit connections

Tubing diameter Torque

mm (inches) Nm

6.35 (1/4”)18

9.52 (3/8”)42

12.70 (1/2”)55

햶

Flaring the end of the tubing

Remove protective caps from the copper tube ends. Position tube

end downward, cut the tube to the required length and remove the

burrs with a reamer.

Remove flare nuts from the unit connections and place them on the

tube end.

Flare the tube with a flaring tool.

L

Flare end must not have any burrs or imperfections.

The length of the flared walls must be uniform.

L

햵

햵 Tube insulation

햶 Fastening tape

Once all connections have been completed, check for leaks by

applying soapy water to them.

If incorrect connection or removal of the unit results in a refrigerant

gas leak, check the refrigerant charge as indicated in the

“OUTDOOR UNIT INSTALLATION MANUAL”.

Finally wrap connections with anti-condensate insulation and

tighten with tape, without exerting great pressure on the insulation.

Repair and cover any possible cracks in the insulation.

Connection pipes and electric cables between indoor and outdoor

units must be fixed to the wall with appropriate conduits.

Check

Finger-tighten the fitting several turns, then tighten it fully with two

wrenches by applying the tightening torque indicated in the table.

GB - 8

Pour water into the condensate drain pan and check that it flows

freely to the drain.

Page 10

42VMC

Electrical connections

ENGLISH

The mains supply must be connected as follows:

Models 42VMC 009, 012, 014: to the indoor unit.

Models 42VMC 018, 024: to the outdoor unit.

• Make electrical connections between units prior to proceeding

to mains supply unit connection.

• Before proceeding with the unit connection to the mains supply

locate live L and neutral N, then make connections as shown

in the wiring diagram.

• Ensure that mains supply connection is made through a switch

that disconnects all poles, with contact gap of a least 3 mm.

• The indoor - outdoor unit connecting wires must be A07 RN-F type

(or higher), with synthetic rubber insulation with Neoprene coating,

according to EN 60335-2-40 and HD277.S1 codes.

• The mains supply connecting cable for 42VMC 009, 012, 014

units, must be H07 RN-F type (or higher), with synthetic rubber

insulation with Neoprene coating, according to EN 60335-2-40

and HD277.S1 codes.

• Ground connection between indoor and outdoor unit is made

via the refrigerant pipes.

• With the cable clamp supplied, secure the connecting cable

between the two units.

Jumper positioning:

Units are equipped with a jumper inside the electric control box, to

make them suitable for the two installation typologies:

Wall vertical installation: jumper inserted.

Ceiling horizontal installation: jumper removed.

To reset incorrect jumper positioning, proceed as follows:

• Disconnect the power supply.

• Reposition the jumper correctly.

• Connect the power supply.

• Fasten the electric connecting wires with refrigerant tubes together.

Allow an additional length to the electric wires for easy connection

to the unit connectors.

Notes:

• For sizing of power supply wires and delay type fuses, refer

to the outdoor unit installation instructions.

• All field electrical connections are the responsibility of the

installer.

IMPORTANT:

The units are provided with electronic control.

A time-delay device provides a 3 minute starting delay of the

compressor every time the unit is stopped or when it is initially

switched on.

Control and safety devices

The following control and safety devices are built into the indoor

units (see wiring diagrams):

• Room air thermostat adjustable from 18°C to 32°C.

• Motor with overheat/overcurrent protection.

IMPORTANT:

• Make refrigerant connections before electrical

connections.

When disconnecting, disconnect electrical connections before

refrigerant connections.

• Make ground connection prior to any other electrical

connections.

GB - 9

Page 11

42VMC

LYN

쐃

쐇

YN

230V ~ 50Hz

쐋

쐏

N O

W

2

쐃

쐇

RLCYN

230V ~ 50Hz

쐋

쐏

RYCSO

W

2

Electrical connections

Cooling only

햲

Unit System

L

Y

42VMC 009, 012, 014

ON NW2

햳

42VMC 018, 024

Unit System

R

Model L N N R C Y

42VMC 009 2.5 2.5 1.5 ––1.5

42VMC 012, 014 2.5 2.5 2.5 ––2.5

42VMC 018, 024 –––1.5 1.5 1.5

OC YW

2

S

햳

Minimum connection wire size between

indoor and outdoor units (mm

2

)

Terminal box legend

Earth.

L Live power supply.

N Neutral power supply.

N Neutral connection indoor/outdoor unit.

R Live connection indoor/outdoor unit.

C Neutral connection indoor/outdoor unit.

Y Compressor interlocking contact.

GB - 10

10

10

120

100

햲

햳

햲 Mains supply connecting cable

(field wiring).

햳 Connecting cable, indoor-outdoor units

(field wiring).

쐃 Indoor unit

쐇 Outdoor unit

쐋 Main switch

쐏 Time-delay fuse or circuit breaker

(see outdoor unit installation manual)

Page 12

42VMC

LYN

쐃

쐇

YN

230V ~ 50Hz

쐋

쐏

N O

W

2

O

W

2

쐃

쐇

230V ~ 50Hz

쐋

쐏

RLCYN

O

W2

RYOC

W2

S

S

Electrical connections

Unit System

L

햲

Y

Heat pump

42VMC 009, 012, 014

ON NW

2

햳

ENGLISH

Terminal box legend

L Live power supply.

N Neutral power supply.

N Neutral connection indoor/outdoor unit.

R Live connection indoor/outdoor unit.

C Neutral connection indoor/outdoor unit.

Y Compressor interlocking contact.

O Reversing valve control.

W2 Outdoor fan signal.

S Defrost end signal.

Unit System

R

햳

Model L N N R C Y O W2 S

42VMC 009 2.5 2.5 1.5 ––1.5 1.5 1.5 –

42VMC 012, 014 2.5 2.5 2.5 ––2.5 2.5 2.5 –

42VMC 018, 024 –––1.5 1.5 1.5 1.5 1.5 1.5

Earth.

OC YW2

42VMC 018, 024

S

햳

10

120

10

100

Minimum connection wire size between

indoor and outdoor units (mm

햲 Mains supply connecting cable

햲

햳

(field wiring).

햳 Connecting cable, indoor-outdoor units

(field wiring).

쐃 Indoor unit

쐇 Outdoor unit

쐋 Main switch

쐏 Time-delay fuse or circuit breaker

(see outdoor unit installation manual)

2

)

GB - 11

Page 13

42VMC

System configuration

System configuration

Units are factory configured as heat pumps.

When a cooling only system is installed, it is necessary to change

the factory configuration.

Such operation must be performed by the installer as follo ws:

Cooling only configuration (of the system)

• Check all electrical connections (instructions and wiring diagram).

• Insert the batteries into the remote control and leave it OFF.

• Energise the system, turning the power supply ON.

• Press the

hold them pressed for more than 5 seconds.

• The display will be cleared, the time segments will display the first

configuration item (rAdr = remote address) and the temperature

segments will display the default value of this configuration item

(Ab = control of both indoor units).

• Press button

• Press either the

to the new value (A C).

• Press

• Press

For other available configuration options, see table IV.

Note:

When 30 seconds have elapsed and no buttons have been

pressed, the remote controller will automatically exit the

configuration menu and the procedure has to be restarted.

and buttons of the infrared remote control and

repeatedly until “UCFG” is displayed.

or button to change the default value (HP)

button to transmit the new configuration to the unit.

button to leave the configuration menu.

Cooling only configuration (of the remote controller)

• Insert the batteries into the remote controller and leave it OFF.

• Energize the system, turning the power supply ON.

• Press the

hold them pressed for more than 5 seconds.

• The display will be cleared, the temperature segments will display

the first configuration item (CH = remote address) and the time

segments will display the default value of this configuration item

(Ab = control of both indoor units).

• Press button

• Press either the

to the new value (A C).

• Press

• Press

For other available configuration options, see table V.

Note:

When 30 seconds have elapsed and no buttons have been

pressed, the remote controller will automatically exit the

configuration menu and the procedure has to be restarted.

and buttons of the infrared remote control and

repeatedly until “rc” is displayed.

or button to change the default value (HP)

button to transmit the new configuration to the unit.

button to leave the configuration menu.

Table IV

Item Shown on Explanation Description

display

1 “rAdr”“b”:

2 “UCFG”

3 “UAdr”

4 “ZONE”

5 “GFdn”

6 “A St”

“A”: remote unit A Remote address indoor unit A.

remote unit

“Ab”:

remote units

“HP”: heat pump Default address is heat pump.

“AC”: cooling only Change address for cooling only.

40 with increase of 1 CCN unit address.

1-

2

40 with increase of 1 Number of zone.

1-

2

40 with increase of 1 Number of GFD.

1-

2

“OF”: unit in stop mode Choose of operating mode after a power supply

“On”: automatic restart interruption.

B

A and B Default address is both indoor units.

Remote address indoor unit

Default = 1.

Default = 0.

Default = 1.

T able V

Shown on Explanation Description

display

“CH”“b”: unit B

“tU”

“rc”

“HR”

“CR”

“CL”

“A”: unit A Address indoor unit A.

Address indoor unit

“Ab”: units A and B Default address is both indoor units.

“C”: Degrees Celsius Temperature.

“F”: Degrees Fahrenheit Default is °C.

“HP”: heat pump Default address is heat pump.

“AC”: cooling only Change address for cooling only.

17 – 32: 17°C ÷ 32°C Heating temperature range °C min. and max.

63 – 90: 63°F ÷ 90°F Heating temperature range °F min. and max.

17 – 32: 17°C ÷ 32°C Cooling temperature range °C min. and max.

63 – 90: 63°F ÷ 90°F Cooling temperature range °F min. and max.

12 : 12: 12 hour clock (AM/PM) Time format (AM = morning; PM = afternoon).

24 : 24: 24 hour clock Default is 12 : 12.

B.

B.

NOTE: If the selection is changed from “rc” (HP operation) to

cooling only and the remote control operating mode is auto or

heating, the operating mode is set to cool.

GB - 12

NOTE: If the “HR” is set to a value that is lower than “CR” and the

remote control operating mode is auto, the operating mode is set to

cooling.

Page 14

42VMC

Operating test, address selector , fault code,

guide for the owner and accessories

Operating test

• Perform the operating test after the units have been installed in

position and the gas leak test has been completed.

• Check all electrical connections (instructions and wiring diagram).

• Insert the batteries into the remote control and leave it OFF.

• Energise the system, turning the power supply ON.

• Press the

hold them pressed for more than 5 seconds.

The display will be cleared, the time segments will display the icon

(Src = service test).

• After test has been completed, press

menu.

Note:

When 30 seconds have elapsed and no buttons have been

pressed, the remote control will automatically exit the test menu

and resume its normal operation.

and buttons of the infrared remote control and

button to leave the test

Address selector

If you are installing two indoor units in the same room and you want

them to operate in independent mode, it is necessary to assign

each unit its own address so that each unit can operate via its own

remote control.

For configuration, proceed as follows:

Fault code

Once a failure occurs with the indoor unit in operation, the green

unit LED flashes at intervals of 0.5 seconds.

The fault code is deduced from the number of times the green LED

flashes, blocking unit operation.

Between one flash cycle and the next one, a pause of 5 seconds

elapses.

Table VI: Fault code

ENGLISH

Code Description

3 Room air sensor f ault

4 Indoor unit coil sensor fault

6 Filter dirty

7 Outdoor unit failure

10 EEPROM corrupt

11 Unit address incomplete

12 Address / zone incomplete

13 Gas flow distributor corrupt

Configuration (of the unit)

• Press the and buttons of the infrared remote control and

hold them pressed for more than 5 seconds.

• The display will be cleared, the time segments will display the first

configuration item (rAdr = remote address) and the temperature

segments will display the default value of this configuration item

(Ab = control of both indoor units).

• Press either the

the new value (A) or (b).

• Press

• Press

button to transmit the new configuration to the unit.

button to leave the configuration menu.

or button to change the default value (Ab) to

Configuration (of the remote controller)

• Press the and buttons of the infrared remote control and

hold them pressed for more than 5 seconds.

• The display will be cleared, the temperature segments will display

the first configuration item (CH = remote address) and the time

segments will display the default value of this configuration item

(Ab = control of both indoor units).

• Press either the

the new value (A) or (b).

• Press

• Press

Note:

When 30 seconds have elapsed and no buttons have been

pressed, the remote control will automatically exit the configuration

menu and the procedure has to be restarted.

button to transmit the new configuration to the unit.

button to leave the configuration menu.

or button to change the default value (Ab) to

Guide for the owner

When installation and tests are completed explain the Operation

and Maintenance Manual to the owner, with particular attention to

the main operating modes of the air conditioner, such as:

• Turning the unit on and off.

• Functions of the remote control.

• Removal and cleaning of the air filters.

Leave the two installation manuals for the indoor and outdoor units

with the owner for future use during maintenance operations or for

any other needs.

T able VII: Accessories

Description Part number

Condensate discharge pump 230V ~ 50Hz 42VKG9002

Cable cover kit 42VKG9003

42VMC

009 012 014 018 024

앬앬앬앬 앬

앬앬앬앬 앬

GB - 13

Page 15

42VMC

Air delivery and fresh air renewal

Air delivery direction

Wall installation, cooling

Ceiling installation, cooling

Wall installation, heating

Ceiling installation, heating

“No draught”

(guide vane fully open)

(position recommended for ceiling installation in

cooling mode, to avoid draughts)

IMPORTANT:

Air is supplied into the room through the grilles located on top

of the cabinet; air from the room is drawn into the unit through

the grilles and filter at the bottom of the unit.

Fresh air renewal

Units are prearranged for introduction of renewal air through a

prepunched hole located on back side.

Back knockout allows connection of fresh air inlet duct.

Model 009 - 012 Model 014 - 018 - 024

Make absolutely sure that the above parts are not obstructed

(even partially).

• To complete the installation, all non-insulated ducts must be

covered with anti-condensate insulation (ex. expanded neoprene,

6 mm thickness).

Not observing of these instructions may cause condensate

dripping; the manufacturer will not be held responsible for any

damage caused.

• The supplementary fan motor for outside air intake has to be

supplied separately and controlled by a bipolar ON-OFF switch

with safety fuses (field-installed).

To adjust the fan motor air flow to the required values it is

advisable to install a speed controller.

Fresh air flow must be less than 10% of the total air flow, to

avoid operating problems.

For fresh air ventilation rates higher than 10%, a primary air

treatment system with separate deflectors is recommended.

• Use locally purchased material, suitable for operating

temperatures of 60 °C (continuous).

Conduits can be of flexible polyester (with spiral core) or

corrugated aluminium, externally covered with anti-condensate

material (fibre glass from 12 to 25 mm thickness).

GB - 14

• Install an air inlet grille with filter inspection port to prevent

dust and dirt from entering and fouling the indoor unit heat

exchanger.

Filter installation also makes the installation of a duct closing

damper during shutdown periods unnecessary.

Page 16

L010125H33 - 0402

Via R. Sanzio, 9 - 20058 Villasanta (MI) Italy - Tel. 039/3636.1

The manufacturer reserves the right to change any product specifications without notice.

Order No. 14489-74, April 2002. Supersedes Order No. 14489-74, January 2002. Printed in Italy

Loading...

Loading...