Page 1

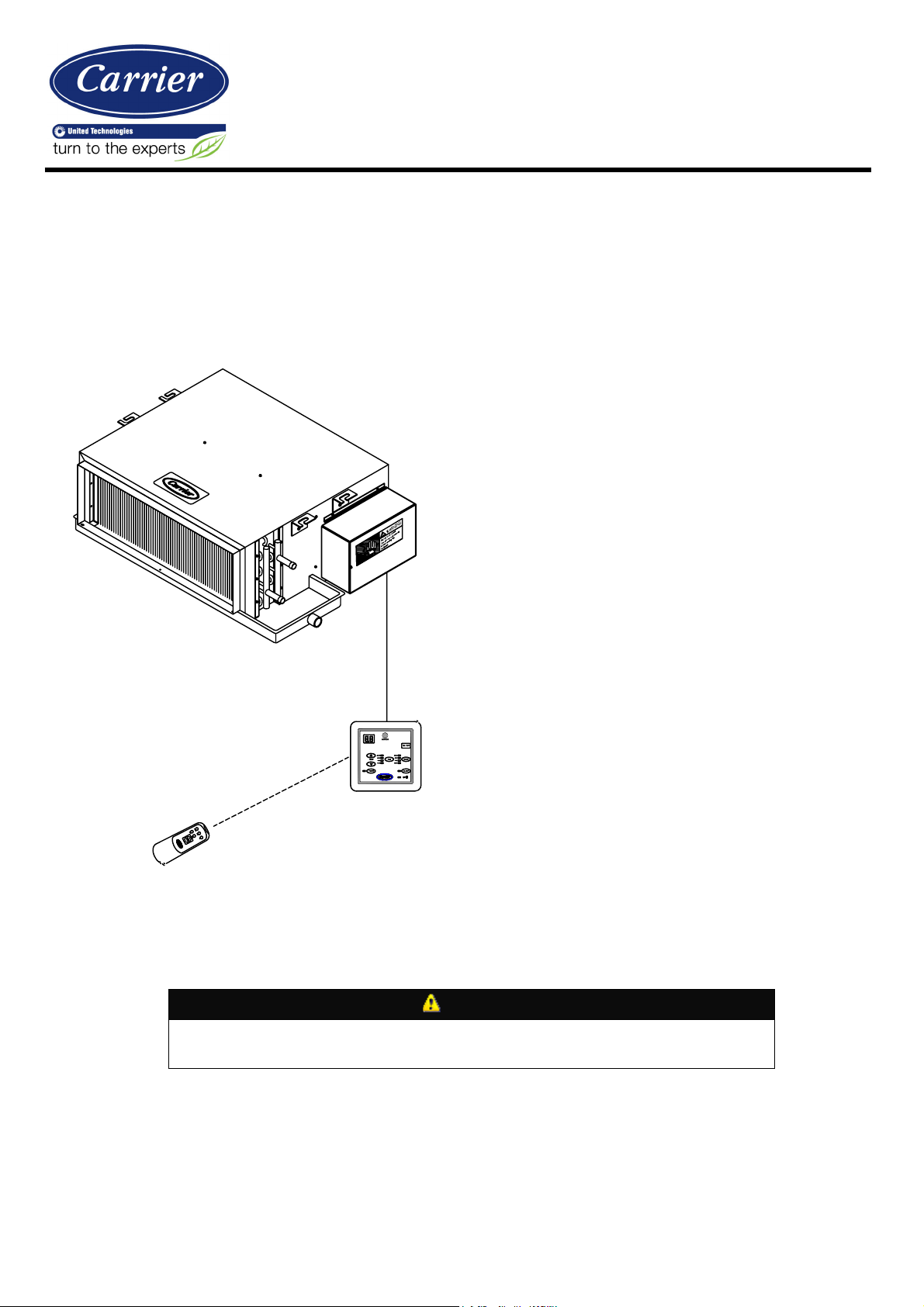

42TW/TD

Chilled Water

Fan Coil unit

with Remote Control

(50/60 Hz)

Insta

llation,

Se

ervice I

Start-

Instruct

Installation and servicing air-conditioning

equipment can be hazardous due to system

pressure and electrical components. Only trained

and qualified service personnel should install,

repair, or service air conditioning equipment.

Untrained personnel can perform basic

maintenance functions of cleaning coils and filters

and replacing filters.

All other operations should be performed by trained

service personnel When working on airconditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for un-brazing

operations. Have fire extinguishers available for all

brazing operations.

Up

and

tions

SAFETY CONSIDERATIONS

REMOTE CONTROL

Fig. 1 - 42TW Unit

ELECTRIC SHOCK HAZARD To avoid the possibility of electrical shock, open and tag all

service switches before installing this equipment.

CONTROL BOARD

WARNING

CONTENTS

Safety Consideration

Introduction

Receiving

Inspection

Protection

Preliminary Check

Physical Data

Sound Data

Fan Performance Data

Base Unit Dimensions

Prepare Jobsite

Identify and Prepare Units

Unit Configuration

Rigging and Unpacking

Installation

Page Page

1

Placing unit in position

2

Making Piping Connections

2

Electrical Heater Option

2

Test and Insulate

2

Make Electrical Connections

2

Make Duct Connections

2

Make Final Preparation

4

Control Board & Remote control

5

Typical wiring digram

6

Start-up

7

Service

7

Start-up Checklist

7

7

7

7

7

8

8

8

8

8

9,10

11,12

13

13

14

-1-

Page 2

- 2 -

INTRODUCTION

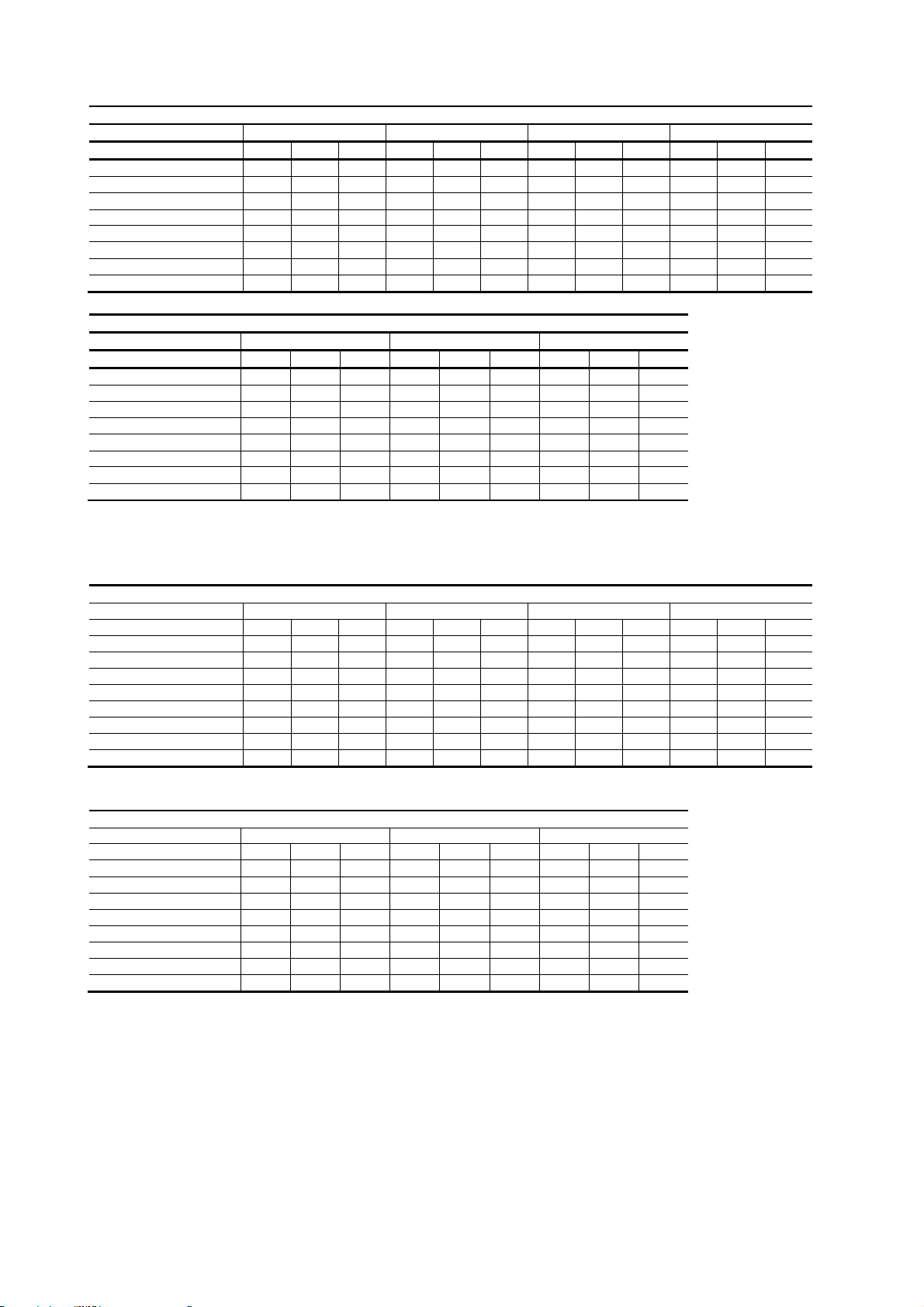

Size

03 05 06

07

09

11

12 16

CFM*

348

592

692

780

883

1181

1385

1572

Cooling Capacity (kw)*

3.4 6.1 7.5

8.9

9.9

11.5

14.5

16.9

Colling Capacity

(kbtuh)

11.7

20.7

25.6

30.4

33.8

39.2

49.5

57.7

SHR

0.75

0.74

0.72

0.71

0.71

0.75

0.73

0.73

Power Supply

208-230, 1 ph, 60 Hz / 220-240, 1 ph, 50 Hz / 110-127, 1 ph, 60 Hz

Motor HP(

Nominal)

1/15 1/10

1/15

1/10

Input W atts ( Med Speed, 25 Pa ESP)

56 64 70 80 80 130

146

160

Number of

Motors

1, 3

Speed

2, 3 Speed

Coil

Material

Smooth copper tubes/ Aluminum fins with double wavey fin

Coil Face Area,

m^2

0.11

0.15

0.21

0.26

0.31

0.31

0.44

0.52

Coil

Connection

Type

Sweat

Type

Coil

Connection Size

5/8

Inch

7/8

Inch

Number of

Rows

3

Fin Denisty/ Inch

14

Drain

Diameter

5/8

Inch

Blower type

Direct drive forward curved centerifugal fan

Blower

Number

1

2 4

Blower Diameter / Width, mm

156/220

156/170

156/220

156/170

156/220

Filter

Type

Washable Aluminum Filter

Width, mm

640

800

1010

1220

1430

1430

1430

1640

Depth, mm

590

Height, mm

275

375

Net Weight, kg

18 23 28 32 39 43 49 56

This document contains general installation

instructions for the 42TW unit Fan Coils. Refer

to the unit-wiring diagram installed on the

blower housing or specific manufacturer

literature for any other type of factory-mounted

controls.

See drawings for unit configurations,

dimensions, clearances, and pipe

connections. Refer to unit wiring label for all

electrical connections; follow NEC (National

Electrical Code) and local codes.

RECEIVING

42TW fan coil units are shipped individually

packed in carton boxes. When cartons are

individually off loaded from the truck, do not

roll, nor throw, or drop the carton to avoid

damage to the contents. Store boxes upright

as the symbols on the boxes indicated. Do

not stack units more than 6 units high for size

11-16 and 8 units high for other sizes.

INSPECTION

Check the shipment against shipping list and

remove unit from the carton and take off

protective covering. If the unit has been

Table.1 -

Physical

Model 42TW3

Model

42T

Data - 42TW3, 42TD3 – 2 Pipe

D3

damaged, file claim with transportation

company and notify Carrier immediately.

PROTECTION

Protection unit from damage caused by job

site debris. Do not allow dust, debris and

water to get into the unit. These will damage

unit’s component and unit’s performance will

be affected.

PRELIMINARY

Following is a checklist which should be

checked before the installation is started. The

installer should be familiar with each of the

following requirements before the actual

installation.

- Space requirement and clearance, See

Fig.3.

- Ceiling or mounting strength.

- Piping connections.

- Condensate drain connection.

- Power supply and wiring.

- Air duct connections.

System

CHECK

* At 26.7/19 c approch 6.7c water inlet/12.7c water outlet, High speed @ 0 Static

Page 3

- 3 -

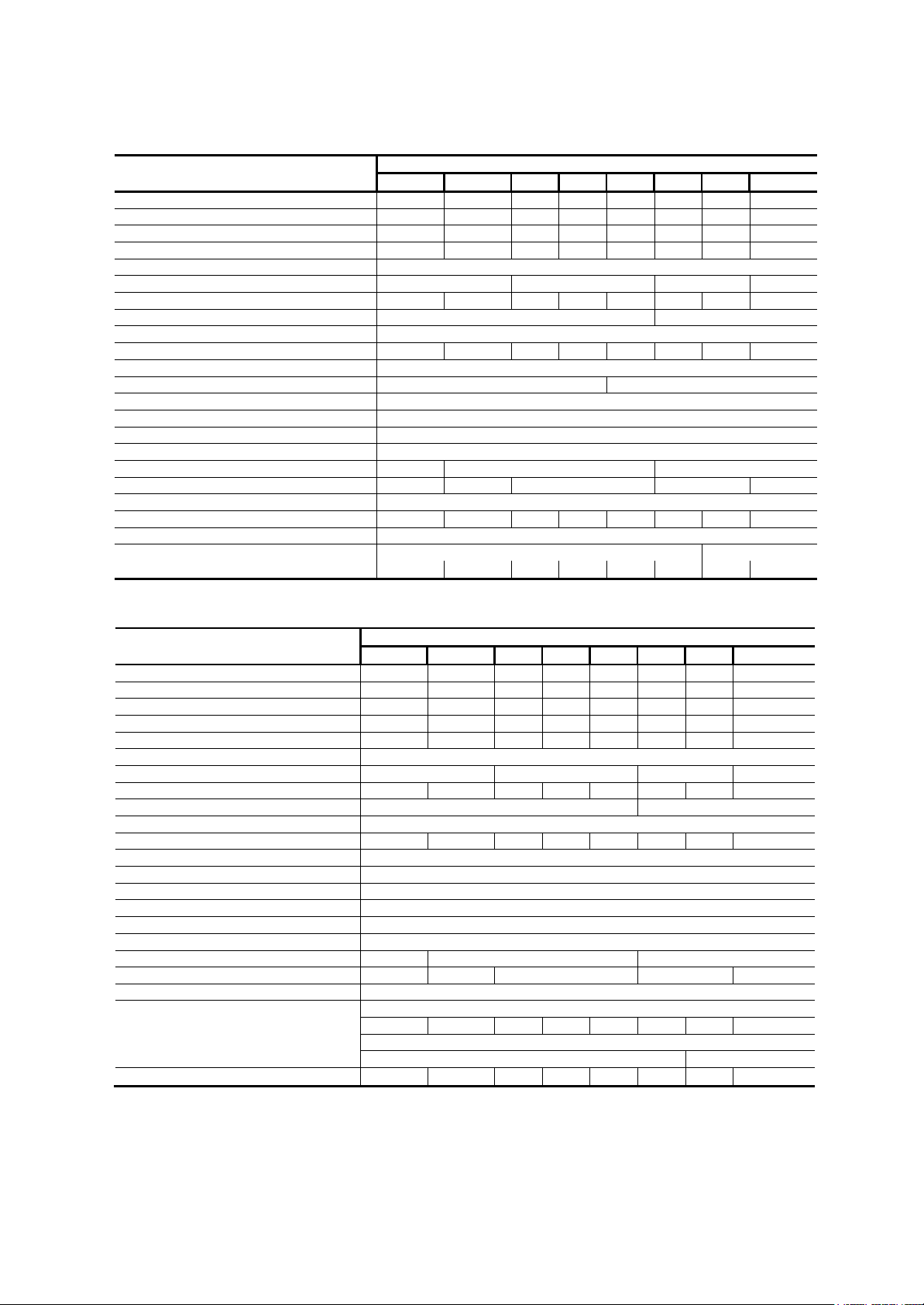

Model 42TD 4

Size

03 04 05

06

08

10

11 14

CFM*

313

533

623

702

795

1065

1247

1416

Cooling Capacity (kw)*

3.8 6.2 7.7

9.0

9.9

12.7

15.7

17.6

Colling Capacity

(kbtuh)

13.0

21.0

26.3

30.8

33.7

43.3

53.6

60.1

SHR

0.69

0.71

0.69

0.69

0.69

0.7

0.68

0.69

Power Supply

208-230, 1 ph, 60 Hz / 220-240, 1 ph, 50 Hz / 110-127, 1 ph, 60 Hz

Motor HP

(Nominal)

1/15 1/10

1/15

1/10

Input W atts ( Med Speed, 25 Pa ESP)

52 60 65 75 75 121

136

150

Number of

Motors

1, 3

Speed

2, 3 Speed

Coil

Material

Smooth copper tubes/ Aluminum fins with double wavey fin

Coil Face Area

0.11

0.15

0.21

0.26

0.31

0.31

0.44

0.52

Coil

Connection

Type

Sweat

Type

Coil

Connection Size

5/8

Inch

7/8

Inch

Number of

Rows

4

Fin Denisty/ Inch

14

Drain

Diameter

5/8

Inch

Blower type Direct drive forward curved centerifugal fan

Blower

Number

1

2 4

Blower Diameter /

Width

156/220

156/170

156/220

156/170

156/220

Filter

Type

Washable Aluminum Filter

Width 640

800

1010

1220

1430

1430

1430

1640

Depth

590

Height

275

375

19 24 29 33 41 45 51 58

Model 42TW4

Size

03 04 05

06

08

10

11 14

CFM*

313

533

623

702

795

1065

1247

1416

Cooling Capacity (kw)*

3.4 5.3 6.9

8.0

8.9

11.2

14.1

15.9

Colling Capacity

(kbtuh)

11.6

18.1

23.5

27.3

30.4

38.2

48.1

54.3

Heating Capacity (kw)**

2.9 5.5 6.8

7.9

9.4

12.2

13.9

17.5

Heating Capacity

(kbtuh)

9.9 18.8

23.2

27.0

32.1

41.6

47.4

59.7

Power Supply

208-230, 1 ph, 60 Hz / 220-240, 1 ph, 50 Hz / 110-127, 1 ph, 60 Hz

Motor HP

(Nominal)

1/15 1/10

1/15

1/10

52 60 65 75 75

121

136

150

Number of

Motors

1, 3

Speed

2, 3 Speed

Coil

Material

Smooth copper tubes/ Aluminum fins with double wavey fin

Coil Face Area

0.11

0.15

0.21

0.26

0.31

0.31

0.44

0.52

Coil

Connection

Type

Sweat

Type

Coil

Connection

Size Cool & Heat

3/4 Inch & 5/8

Inch

Number of

Rows

4

Fin Denisty/ Inch

14

Drain

Diameter

5/8

Inch

Blower type

Direct drive forward curved centerifugal fan

Blower

Number

1

2 4

Blower Diameter /

Width

156/220

156/170

156/220

156/170

156/220

Filter

Type

Washable Aluminum Filter

Unit

Dimensions

640

800

1010

1220

1430

1430

1430

1640

590

275

375

Net

Weight

19 24 29 33 41 45 51 58

Table.2 -

Physical

Data - 42TW4,42TD4 – 2 Pipe

System

Model 42TW4

Net

Weight

* At 26.7/19 c approch 6.7c water inlet/12.7c water outlet, High speed @ 0 Static

Table.3 -

Physical

Data - 42TW4, 42TD4 – 4 Pipe

System

Model 42TD4

Width,

Depth,

mm

mm

Height, mm

* At 26.7/19 c approch 6.7c water inlet/12.7c water outlet, High speed @ 0 Static

** At 20 /14 c approch 70c water inlet/61.6c water outlet, High speed @ 0 Static

Page 4

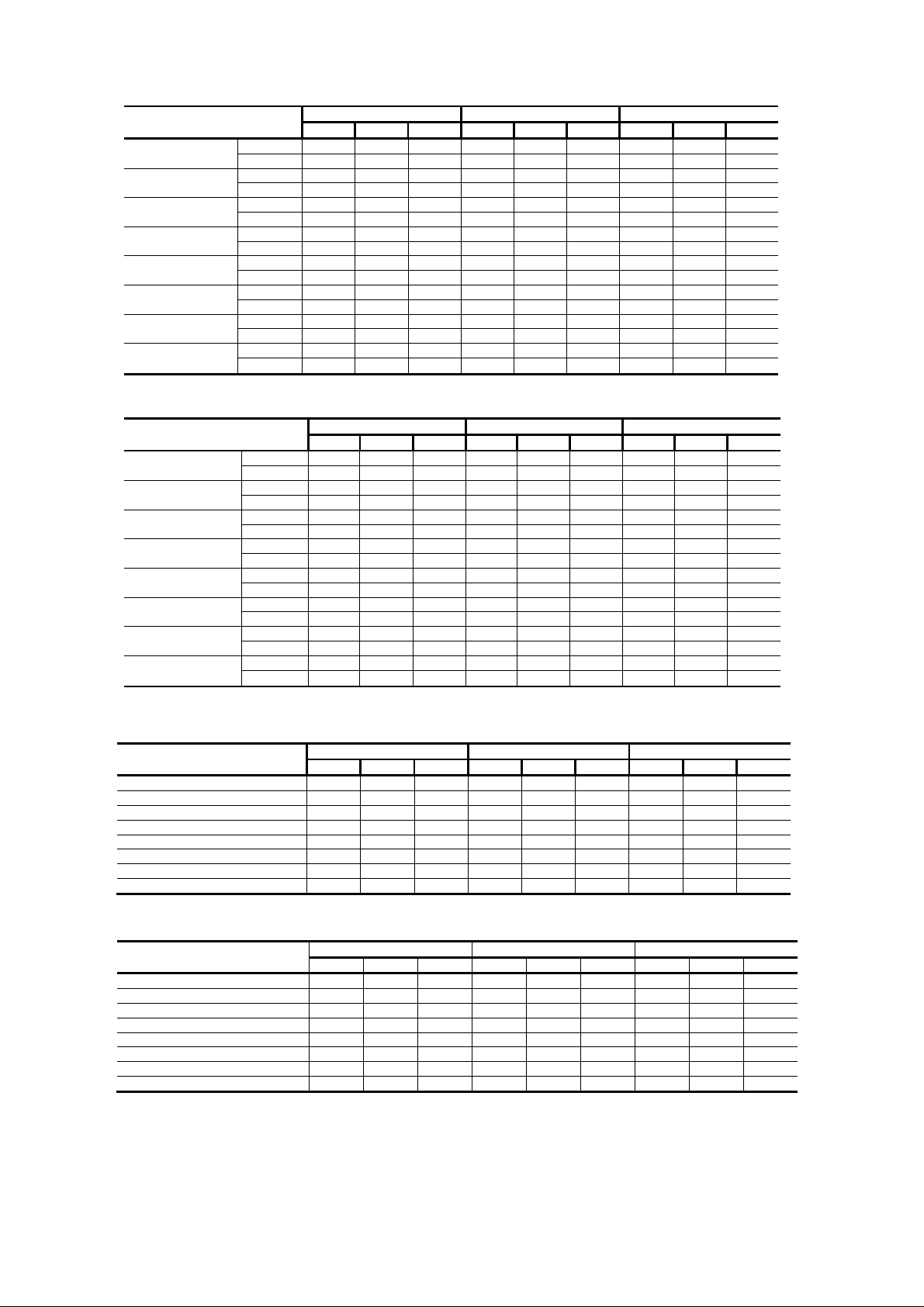

Table.4 a - POWER CONSUMPTION 42TW,42TD 3ROW

42TW,42TD ± 3Row

-03

-05

-06

-07

-09

-11

-12

-16

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

@ 0 Pa ESP @ 25 Pa ESP @ 50 Pa ESP

Hi Med Low Hi Med Low Hi Med Low

0.40 0.35 0.30 0.34 0.28 0.24 0.30 0.25 0.20

80 70 60 68 56 48 60 50 40

0.45 0.40 0.35 0.37 0.32 0.27 0.33 0.28 0.22

90 80 70 74 64 54 66 56 44

0.55 0.45 0.35 0.45 0.35 0.27 0.40 0.30 0.22

110 90 70 90 70 54 80 60 44

0.60 0.50 0.40 0.50 0.40 0.30 0.45 0.35 0.25

120 100 80 100 80 60 90 70 50

0.60 0.50 0.40 0.50 0.40 0.30 0.45 0.35 0.25

120 100 80 100 80 60 90 70 50

0.90 0.80 0.70 0.75 0.65 0.55 0.65 0.55 0.45

180 160 140 150 130 110 130 110 90

1.10 0.90 0.70 0.90 0.73 0.55 0.80 0.62 0.45

220 180 140 180 146 110 160 124 90

1.20 1.00 0.80 1.00 0.80 0.62 0.80 0.70 0.50

240 200 160 200 160 124 160 140 100

Table.4 b

42TW,42TD ± 4Row

-03

-04

-05

-06

-08

-10

-11

-14

Note: For 220V, 1 Phase Motor.

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

Amps

Watts

@ 0 Pa ESP @ 25 Pa ESP @ 50 Pa ESP

Hi Med Low Hi Med Low Hi Med Low

0.37 0.33 0.28 0.33 0.27 0.23 0.29 0.24 0.20

73 64 55 64 52 45 57 48 38

0.42 0.37 0.33 0.36 0.31 0.26 0.32 0.27 0.22

82 73 64 69 60 50 63 53 42

0.51 0.42 0.33 0.43 0.34 0.26 0.39 0.29 0.22

100 82 64 84 65 50 76 57 42

0.56 0.47 0.37 0.48 0.38 0.29 0.44 0.34 0.24

109 91 73 93 75 56 86 67 48

0.56 0.47 0.37 0.48 0.38 0.29 0.44 0.34 0.24

109 91 73 93 75 56 86 67 48

0.84 0.75 0.65 0.72 0.62 0.53 0.64 0.54 0.44

164 145 127 140 121 103 124 105 86

1.03 0.84 0.65 0.86 0.70 0.53 0.78 0.61 0.44

200 164 127 168 136 103 152 118 86

1.12 0.93 0.75 0.96 0.77 0.60 0.78 0.68 0.49

218 182 145 187 150 116 152 133 95

Table.5 a -SOUND PRESSURE

42TW,42TD ± 3Row

42TW3-03

42TW3-05

42TW3-06

42TW3-07

42TW3-09

42TW3-11

42TW3-12

42TW3-16

@ 0 Pa ESP @ 25 Pa ESP @ 50 Pa ESP

Hi Med Low Hi Med Low Hi Med Low

47.5 45.5 43.5 46.5 44.0 42.5 45.5 42.5 41.0

48.5 46.5 44.5 47.5 45.0 43.5 46.5 43.5 42.0

50.0 48.0 46.0 49.0 46.5 45.0 48.0 45.0 43.5

50.5 48.5 46.5 49.5 47.0 45.5 48.5 45.5 44.0

50.0 48.0 46.0 49.5 47.0 45.5 48.5 45.5 43.5

51.0 49.0 47.0 50.0 47.5 46.0 49.0 46.0 44.0

51.0 49.0 47.0 50.0 47.5 46.0 49.0 46.0 44.5

51.5 49.5 47.5 50.5 48.0 46.5 49.5 46.5 45.0

Table.5 b

42TW ± 4Row

42TW4-03

42TW4-04

42TW4-05

42TW4-06

42TW4-08

42TW4-10

42TW4-11

42TW4-14

Note: Assumes "standard room ", 3 meters from exit, no ducts, ducts will further reduce sound

@ 0 Pa ESP @ 25 Pa ESP @ 50 Pa ESP

Hi Med Low Hi Med Low Hi Med Low

46.5 44.5 42.5 46.0 43.5 42.0 45.0 42.0 40.5

47.5 45.5 43.5 47.0 44.5 43.0 46.0 43.0 41.5

49.0 47.0 45.0 48.5 46.0 44.5 47.5 44.5 43.0

49.5 47.5 45.5 49.0 46.5 45.0 48.0 45.0 43.5

49.0 47.0 45.0 49.0 46.5 45.0 48.0 45.0 43.0

50.0 48.0 46.0 49.5 47.0 45.5 48.5 45.5 43.5

50.0 48.0 46.0 49.5 47.0 45.5 48.5 45.5 44.0

50.5 48.5 46.5 50.0 47.5 46.0 49.0 46.0 44.5

-4-

Page 5

Table.6 a - Fan Performance ± 42TW-3-SI

L

423

629

845

938

1011

1257

1690

1876

L

383

572

769

854

919

1144

1538

1707

42TW3 Air Flow (m3/hr)

Ex. Static Pres. Pa 0 12.5 25 37.5

Unit Size H M L H M

03

05

06

07

09

11

12

16

592 515 466 568 481

1005 846 694 940 761

1176 995 931 1132 943

1325 1174 1031 1284 1090

1500 1285 1120 1420 1178

2007 1690 1385 1879 1521

2353 1991 1862 2265 1886

2671 2349 2062 2569 2180

42TW3 Air Flow (m3/hr)

Ex. Static Pres. Pa 50 62.5 75

Unit Size H M L H M L H M L

03

05

06

07

09

11

12

16

H ± At High Fan Speed.

M ± At Medium Fan Speed.

L ± At Low Fan Speed.

460 358 250 380 270 ± 305 ±±

718 541 389 625 439 ± 524 ±±

919 715 499 737 541 ± 559 ±±

1031 788 634 890 651 ± 769 ±±

1120 865 650 1000 740 ± 862 ±±

1437 1082 777 1251 879 ± 1048 ±±

1839 1430 997 1437 1055 ± 1091 ±±

2062 1575 1268 1770 1295 ± 1530 ±±

HML HML

544 446 380 502 402 315

875 676 564 794 600 473

1088 891 759 1024 791 634

1243 1006 845 1158 896 752

1340 1071 902 1230 968 776

1751 1352 1129 1589 1200 946

2177 1781 1518 2048 1582 1268

2467 2011 1690 2315 1791 1504

Table.6 b - Fan Performance ± 42TW - 4 - SI

42TW4 Air Flow (m3/hr)

Ex. Static Pres. Pa 0 12.5 25 37.5

Unit Size H M L H M

03

05

06

07

09

10

11

14

532 463 419 517 437

905 764 625 855 693

1059 896 840 1030 858

1192 1058 931 1168 992

1350 1156 1007 1291 1072

1809 1524 1249 1710 1384

2119 1793 1679 2061 1716

2406 2118 1859 2338 1984

42TW4 Air Flow (m3/hr)

Ex. Static Pres. Pa 50 62.5 75

Unit Size H M L H M L H M L

03

05

06

07

09

10

11

14

H ± At High Fan Speed.

M ± At Medium Fan Speed.

L ± At Low Fan Speed.

433 336 235 363 279 ± 296 ±±

675 509 366 594 417 ± 503 ±±

864 672 469 700 514 ± 537 ±±

969 741 596 846 618 ± 738 ±±

1063 813 602 950 715 ± 825 ±±

1351 1017 730 1188 835 ± 1006 ±±

1729 1344 937 1365 1002 ± 1047 ±±

1938 1481 1192 1682 1230 ± 1469 ±±

HML HML

502 411 350 467 373 292

805 622 519 738 558 440

1001 820 698 952 736 590

1144 926 777 1077 833 699

1232 987 831 1148 900 717

1611 1244 1039 1478 1116 880

2003 1639 1397 1905 1471 1179

2270 1850 1555 2153 1666 1399

-5-

Page 6

Page 7

PREPARE JOSITE FOR UNIT INSTALLATION

To save time and to reduce the possibility of

costly errors, set up a complete sample

installation in a typical room at jobsite. Check all

critical dimensions such as pipe, wire, and duct

connection requirements. Refer to job drawings

and product dimension drawings as required.

Instruct all trades in their part of the installation.

IDENTIFY AND PREPARE UNITS

Be sure power requirements match available

power source. Refer to unit nameplate and

wiring diagram.

1. Check all tags on unit to determine if shipping

screws are to be removed. Remove screws as

directed.

2. Rotate the fan wheel by hand to ensure that

the fan is unrestricted and can rotate freely.

Check for shipping damage and fan

obstructions.

UNIT CONFIGURATION

The piping connections, drain pan outlet and control

box are located on the right side of the unit facing the

airflow direction as factory standard as shown in the

unit picture. Left hand side connection is factory

option. However, the connections side can be

relocated at site.

RIGGING AND UNPACKING

Unit should not be removed from carton until reaching

final location to avoid damage. Inspect unit for

shipping damage and file claim with transportation

company if necessary, check nameplate voltage

against available power supply. For special installation,

consult local building and electrical codes.

INSTALLATION

PLACING UNIT IN POSITION

1. Select the unit location. Allow adequate space

for free air circulation, service clearances, piping

and electrical connections, and any necessary

ductwork, see fig.2. For specific unit dimensions,

refer to the submittal drawings. Allow clearances

according to the local and national electrical

codes.

2. Be sure either the ceiling is able to support the

weight of the unit. See Table 1-3 for nominal unit

weight.

3. Move unit into position. Ensure unit is level or

pitched towards drain to ensure proper drainage

and operation.

4. Mounting units to the ceiling - When unit is

lifted, access to the. mounting holes is on the top

panel of the unit. Hanger rods, fasteners, and

other required hardware must be field-supplied.

MAKING PIPING CONNECTONS

Qualified personnel in accordance with local and

national codes must perform all piping

connections. Refer to Fig.2 for piping

connections.

NOTE: It is important to have a common

understanding of which side of the unit is the right

hand side and which is the left hand side. When

facing the supply air outlet from the front of the

unit (air blowing in your face), your right hand will

be on the right side of the unit and your left hand

will be on the left side of the unit. See Fig. 5.

Fig.3 ± Minimum clearance required. Fig4- Changing the coil connection side

Fig.5 ± Unit end reference

-7-

Page 8

Table.7 - ELECTRIC HEATER OPTION

(2 Pipe System)

42TW 3 Ro

ws Models 42TW 4 Rows Models Heater option, watts

42TW3-03

42TW3-05

42TW3-06

42TW3-07

42TW3-09

42TW3-11

42TW3-12

42TW3-16

42TW4-03 2000

42TW4-04 2000

42TW4-05 2000

42TW4-06 2500

42TW4-08 2500

42TW4-10 4000

42TW4-11 4000

42TW4-14 4000

TEST AND INSULATE

When all joints are complete, perform hydrostatic

test for leaks. Vent all coils at this time. Check

interior unit piping for signs of leakage from

shipping damage or mishandling. If leaks are

found, notify a Carrier representative before

initiating any repairs. Release trapped air from

system (refer to Make Final Preparations section).

MAKE ELECTRICAL CONNECTIONS

Refer to unit nameplate for required supply

voltage, fan and heater amperage and required

circuit ampacity. Refer to unit wire diagram for unit

and field wiring; see fig.6 . Make sure all electrical

connections are in accordance with unit wiring

diagram and all applicable codes. The fan

motor(s) should never be controlled by any wiring

or device other than the factory-supplied control

board and remote control.

All field wiring must be in accordance with

governing codes and ordinances. Any modification

of unit wiring without factory authorization will

invalidate all factory warranties and nullify any

agency listings.

- Select proper wall location to fix display pad

- Connect communication cable end to its

location in the PCB as shown in the wiring

diagram.

IMPORTANT

Wiring diagrams shown depict typical control

functions. Refer to unit wiring label for specific

functions.

minimize duct-to-unit alignment problems and

noise transmission where specified.

Set unit markings for minimum clearance to

combustible materials and first 3 ft of

ductwork. Install ductwork, accessory grilles

and plenums so that they do not restrict

access to filter.

Cut openings for supply-air and return-air

grilles. Be careful not to cut wires, piping or

structural supports.

CAUTION

Prevent dust and debris from settling in

unit. If wall finish or color is to be spray

applied, cover all openings to prevent

spray from entering unit. Unit efficiency

will be reduced.

MAKE FINAL PREPARATIONS

1. Turn off power to the unit (open unit

electrical disconnect).

3. Clean dirt, dust, and other construction

debris from unit interior. Be sure to check fan

wheel and housing.

4. Rotate fan wheel by hand to be sure it is

free and does not rub housing. Check that

wing nuts securing fan assembly to fan deck

are tight.

5. Ensure all panels and filters are installed

before checking fan operation. Turn on power

to the unit.

MAKE DUCT CONNECTIONS

Install all ductwork to and from unit in

accordance with all applicable codes. Duct

construction must allow unit to operate within

duct external static pressure limits as shown

on job submittals. Units designed to operate

with ductwork may be damaged if operated

without intended ductwork attached.

Units provided with outside air should have

some method of low-temperature protection

to prevent freeze-up. Insulate ductwork as

required. Use flexible connections to

IMPORTANT

Do not start-up or operate unit without

filter. Be sure filter and unit interior are

clean.

8. Be sure drain line is properly and securely

positioned and that the line is clear. Pour

water into drain to check operation.

- 8 -

Page 9

Controller For Ducted Fan Coil Units

DIP Switch

On

Off

SW1

Cool

Cool-Heat

SW2

Water System

DX System

Room sensor fault

E1

Indoor coil sensor fault

E2

Comp fault

E4

“COOL” Led

Lights on when selecting COOL mode.

“DRY” Led

Lights on when selecting DRY mode.

“HEAT” Led

Lights on when selecting Heat mode.

“FAN” Led

Lights on when selecting FAN mode.

Wired Room

Notes: The wired room controller is mounted on the wall and can control all system functions without wireless remote control.

Wired Room Controller

Wireless Room Controller

- 9 -

Features: The controller is used to control air cooled ducted split unit, supports the following functions:

- Modes: Cool, Dry, Fan, Heat

- Indoor fan speed: Auto, High, Medium, Low

- Sleep mode

- Compressor protections:

Comp 3 minutes restart protection

Indoor coil anti-freeze

Room sensor and indoor coil sensor failure monitoring

- Non volatile memory – keep system settings

- Programmable On/Off timer

- Random restart to minimize voltage dip during compressor first cut in cycle upon power up.

Hardware Setting: A 2 way DIP switch is used to configure:

Error Code: If multiple faults happen at the same time, the corresponding error code will be shown one after

another

Split System Description

1) On/Off Key: If you press this key, the system will begin operation, Press the key again, and operation stops.

(You can hear a receiving beep). If you press this key immediately after turning off the system, the compressor will

not operate for 3 minutes to prevent overloading.

2) Operation Mode Selection Key: Toggles the operation mode: Cool, Dry, Heat, or Fan only

3) Fan Speed Selection Key: Toggles the fan speed: Auto, High, Medium, or Low, Note: Fan key is invalid in Dry

mode.

4) Temperature Up Key:

press.

5) Temperature Down Key: By pressing temperature down key, the setting temperature decreases by 1ºC with

each press. If you set the desired room temperature, then system will maintain the room temperature as set. Upon

setting the desired room temperature the system will maintain the room temperature

Controller (Standard)

Fault Error code

By pressing Temperature up Key, the setting temperature increases by 1ºC with each

Page 10

Cool Mode

FAN

Menu

Parameter

Set Range

Default value

Remarks

1: Disable room temp display

2: Enable room temp display

1: Comp OFF, Fan ON

2: Comp OFF, Fan OFF

1: Heater OFF, Fan ON

2: Heater OFF, Fan OFF

- 10 -

: If the room temperature is higher than the setting, the compressor will automatically turn on provide a

cooling effect. On the hand, if the room temperature is lower than the setting, the compressor will automatically turn

off to stop cooling operation. If indoor fan is programed to be turned off with comp signal, it will turn off once comp

is cut off

Heat Mode: If the room temperature is lower than the setting, the Electric heater will automatically turn on to

provide a heating effect. If the room temperature is higher than the setting, the heater will automatically turn off to

stop heating operation. If indoor fan is programed to be turned off with heater signal, it will turn off once heater is

cut off but subject to 30 sec dispersing remaining heat timing.

Dry Mode: The fan speed runs automatically at low speed and compressor stopping and running is controlled by

the difference between room and setting temperatures and by continuous running time. If indoor fan is programed

to be turned off with comp signal, it will turn off once comp is cut off

- In Dry mode, the humidity is reduced in the space to be air-conditioned.

Fan Mode: There will be no cooling or heating effects; only the fans of indoor unit will run for ventilation at the

selected speed (High, Med, and Low).

- In COOL or HEAT mode and if AUTO fan speed is selected; Fan speed is automatically selected by controller

according to the difference between setting temperature and room temperature, fan will be continuously

running at low speed after setting temperature is achieved.

Notes:

a) Temperature setting range is 16ºC to 30ºC or 60ºF to 85ºF.

b) Hold down at the same time for about 5 seconds, Temp down and fan keys will toggle the temperature

setting from degree C to degree F and vice versa.

c) Press any temperature key will flash the current setting temperature for 4 seconds, Should there be no

further key press, it will revert to room temperature display. Temperature display range is 0 C to 50 C or 32 F

to 99 F.

d) Temp keys are invalid in Fan mode.

6) Sleep Key: Press this key to set the SLEEP timer and then the sleep led will light on, to cancel the sleep timer

press this key again.

- Sleep function for healthy sleep to control automatically the room temperature and stop automatically the

operation of the air conditioner after certain set off time.

- Sleep mode is valid in cool or heat mode and invalid in Fan mode.

7) Timer Key: Upon count down of the set hours, the system will switch from OFF to ON or vice-versa.

- OFF Timer Function to stop automatically, the air conditioner after certain set OFF time.

- ON Timer Function to start automatically, the air conditioner after certain set ON time.

* Timer setting is 1 Hour to 24 Hour. The timer led will light on when operating the Timer Function

First key press will flash the digital display and Timer Led for 3 seconds.

Notes:

a) The digital displays show the number of hours previously set, only the Timer Led flashes.

b) Subsequent 3 seconds will show the number of hours previously set; only the timer led flashes.

c) Should there be no further key press, it will revert to normal mode.

d) Should Timer key is not released timer setting will increase automatically every 0.5-second.

8) Sensor: Receives the remote controller’s signal

9) Display Screen:

Displays the set temperature and displays also the TIMER settings when adjusting it.

10) Key Lock Mode: To activate key lock mode, hold down for 3 seconds, temp. Down Key (5) and Mode Key (2).

In key lock mode, all keys are not valid except ON/OFF Key (1) to turn ON/OFF the system.

Notes:

a) Hold down Temp Down and Sleep button for one second to enter into coil temperature display mode.

Press Temp Up key to display indoor coil temperature, High Fan LED flashes. With the same sequence to

exit coil temperature display mode. Temperature display range is -9C to 78 ºC.

b) Hold down

to activate temperature display setting and auto fan LED flashes. Repeat the same sequence to cancel

this function. Press

temperature display and “2” means enable room temperature display.

Temperature display, Auto fan

1

LED flashing

Cool mode fan control function,

2

Auto & High fan LED flashing

Heat mode fan control function,

3

Auto & Medium fan LED flashing

and

buttons for only 1 second ( 5 sec to toggle between ºC and ºF temperature )

or button to change the setting from 1 to 2. “1” means disable room

1~2 1

1~2 1

1~2 1

Page 11

WIRING SCHEMATIC 42TW/TD COOL/HEAT

-11-

Page 12

WIRING SCHEMATIC 42TW/TD COOL/HEAT WITHOUT CONTROL

-12-

Page 13

START-UP

42TW unit is designed to operate in hot and

humid conditions without condensation

problem because of the rubber insulated

drain pan. Refer to the startup checklist in

page 11 for startup procedure.

SERVICE

TO CLEAN COIL

1. Be sure electrical service switch is open,

locked, and tagged while working on unit.

2. Remove supply-air grille access panel and

brush between coil fins with stiff wire brush.

Follow-up by cleaning with vacuum cleaner. If

coil is cleaned with air hose and nozzle, take

care not to drive dirt and dust into other

components.

CHECK DRAIN

Lock open and tag unit electrical service

switch.

Check drain pan, drain line and trap at start

of each cooling season. A standard type pipe

cleaner for 5/8-in. ID pipe can be used to

ensure that pipe is clear of obstruction so that

condensate is carried away.

CLEAN FAN WHEEL

Lock open and tag unit electrical service

switch.

For access to fan assembly, remove front or

bottom panel.

Fan assembly may be removed from its

tracks if unit has a long conduit lead. Use a

stiff brush or vacuum to remove dirt and

debris from scroll.Wipe all fan surfaces with a

damp cloth.

CLEAN ELECTRIC HEATER

Lock open and tag unit electrical service

switch.

1. Remove dust, dirt, or foreign material

before start-up. Do not block normal airflow to

and from units; blockage may damage

electric heaters.

2. Clean heater elements with soft brush or

vacuum cleaner as necessary.

CLEAN OR REPLACE AIR FILTERS

Lock open and tag unit electrical service

switch.

At the start of each cooling season and after

each month of operation (more or less

depending on operating conditions) replace

throwaway filter or clean permanent filter.

THROWAWAY FILTER ² Replace filter with

a good quality filter. Do not attempt to clean

and reuse disposable filters.

PERMANENT FILTER

1. Tap on solid surface to dislodge heavy

particles.

2. Wash in hot water.

3. Set filter on end so that water drains out

through slots in frame. Allow filter to dry

thoroughly.

See Fig.7 for filter access.

Fig.7 ± Filter Access.

-13-

Page 14

START-UP CHECKLIST FOR 42TW SERIES FAN COIL UNIT

I. Project Information

Job Name

_______________________________________________________________________

Address ________________________________________________________________________

City ______________________________________________State __________ Zip __________

Installing Contractor

_______________________________________________________________

Sales Office _____________________________________________________________________

Start-up Performed By

_____________________________________________________________

INSPECTION, INSTALLATION, & START-UP CHECKLIST

ITEM COMPLETE ITEM COMPLETE

Receiving & Inspection

1. Unit received undamaged

2. Unit received complete as ordered

3. Unit arrangement/hand correct

4. Unit structural support complete &

correct

Handling & Installation

5. Mounting grommets / isolators

used

6. Proper access provided for unit &

accessories

9. Proper electrical service provided

7. Proper overcurrent protection

provided

8. Proper service switch / disconnect

provided

9. Proper refrigerant line sizes to unit

10. All service to unit in code

compliance

11. All shipping screws & braces

removed

12. Unit protected from direct &

foreign matter

Cooling / Heating Connections

13. Connect field piping to unit

14. Pressure test all piping for leaks

15. Install drain line & traps as

required

16. Insulate all piping as required

Ductwork Connections

17. Install ductwork, Fittings, &

Grilles as required

18. Flexible duct connections at unit

19. Proper supply & return grille type

& size used

20. Insulate all ductwork as required

Electrical Connections

21. Refer to unit wiring diagram

22. Connection incoming power

service(s)

23,QVWDOOFRQQHFWLRQ³IXUQLVKRQO\´

parts

24. All field wiring in code compliance

Unit Startup

25. General visual unit & system

inspection

26. Check for proper fan belt tension

27. Check for proper fan rotation

28. Record electrical supply voltage

29. Record ambient temperatures

30. Check all wiring for secure

connections

31. Close all unit isolation valves

32. Flush water systems

33. Fill systems with water /

refrigerant

34. Vent water systems as required

35. All ductwork & grilles in place

36. All unit panels & filters in place

37. Start fans, pumps, chillers, etc.

38. Check for overload condition of all

units

39. Check all ductwork & units for air

leaks

40. Balance air systems as required

41. Record all final settings for future

use

42. Check piping & ductwork for

vibration

43. Verify proper cooling operation

44. Verify proper heating operation

45. Reinstall all covers & access

panels

-14 -

Page 15

NOTES

Page 16

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

2015

42TW/TD - 05 - IOM

Loading...

Loading...