42KC, 45UC, 45XC, 35BF

Access Floor Terminal Units

Installation, Operation and

Configuration Instructions

AXIS™

CONTENTS

Page

SAFETY CONSIDERATIONS...................... 1

GENERAL ...................................... 2-5

System Overview ................................ 2

System Architecture ............................. 3

PRE-INSTALLATION.............................. 6

Unpack and Inspect Units ........................ 6

Storage and Handling ............................ 6

Prepare Jobsite for Unit Installation.............. 6

45XC FAN-POWERED ZONE MIXING UNIT

INSTALLATION.............................. 6-27

45XC Hardware................................... 7

45XC Field-Supplied Hardware ................... 7

45XC Fan-Powered Zone Mixing Box

Installation ..................................... 9

45XC Sensor Installation ........................14

45XC Input and Output Connectors ............. 25

Connect to the CCN Communication Bus .......26

Connect Air Pressure Tubing.................... 26

45UC UNDERFLOOR SERIES FAN-POWERED

TERMINAL INSTALLATION ................. 27-35

45UC Hardware.................................. 27

45UC Field-Supplied Hardware .................. 27

45UC Underfloor Series Fan-Powered Unit

Installation ....................................29

45UC Sensor Installation ........................30

Connect to the CCN Communication Bus .......30

Modulating Baseboard Hydronic Heating........35

42KC PERIMETER FAN COIL UNIT

INSTALLATION............................. 36-45

42KC Hardware.................................. 36

42KC Field-Supplied Hardware .................. 37

42KC Perimeter Fan Coil Unit Installation ....... 37

Connect the Power Transformer................. 38

Fan Coil Controller Inputs and Outputs .........44

42KC Sensor Installation ........................44

35BF DIFFUSER INSTALLATION.............. 46-49

35BF-R Swirl Diffuser Installation ............... 46

35BF-CT,D,V Linear Diffuser Installation......... 46

OPERATION .................................. 50,51

Initial Start-Up Procedures ...................... 50

45XC Start-Up and Checkout Procedure......... 50

42KC Start-Up................................... 50

Page

CONFIGURATION ............................ 51-68

45XC Commissioning ........................... 51

45XC Set-Up and Configuration .................51

42KC Set-Up and Configuration .................57

42KC Fan Coil Airflow Adjustment .............. 57

Setting Fan Airflow with ECM ................... 57

Balancing Underfloor Fan Terminals ............ 57

Speed Controller ................................ 60

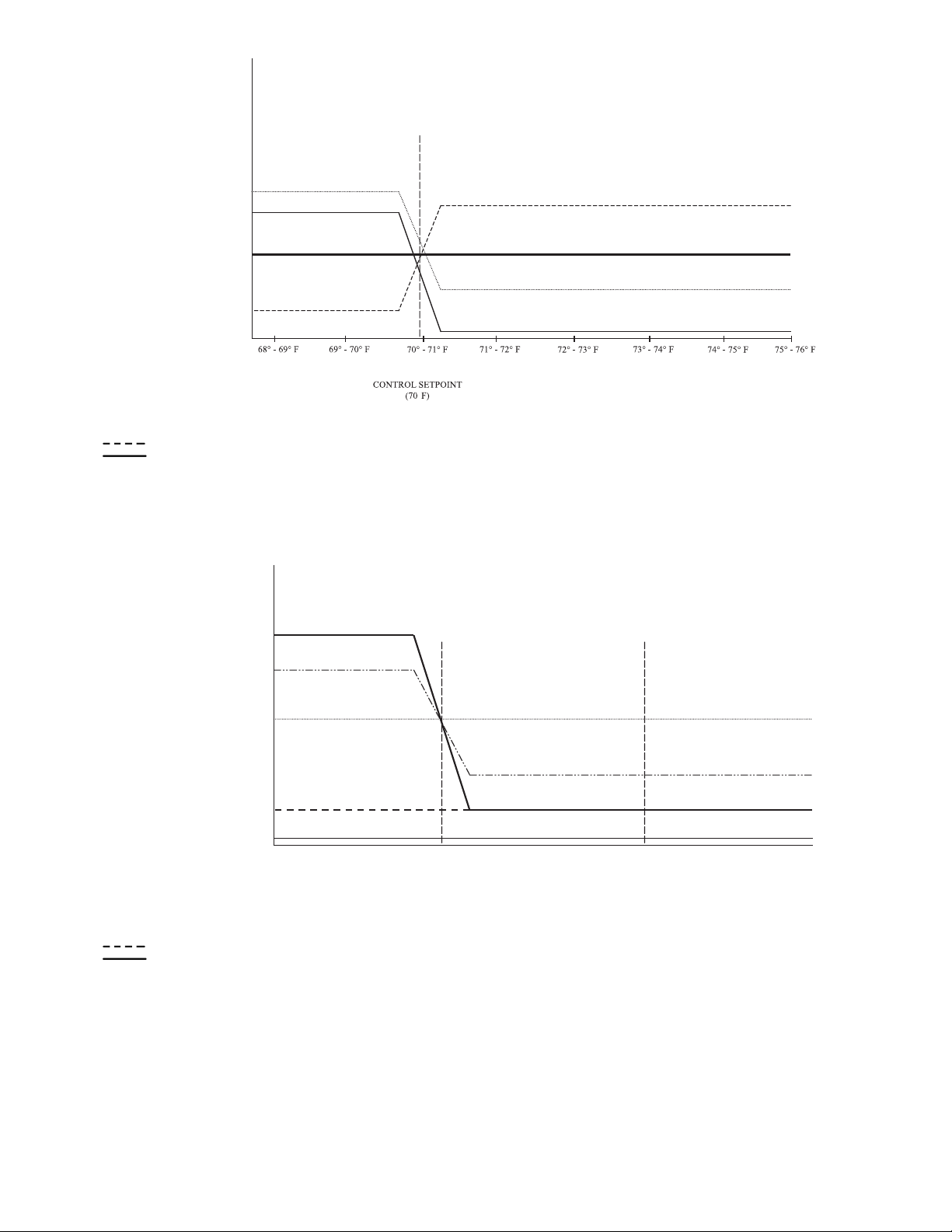

Set Points ....................................... 60

Testing and Start-Up ............................ 61

45XC Operation ................................. 62

42KC Fan Coil Sequence ........................ 66

45XC Application Considerations ............... 66

Maintenance ................................... 67

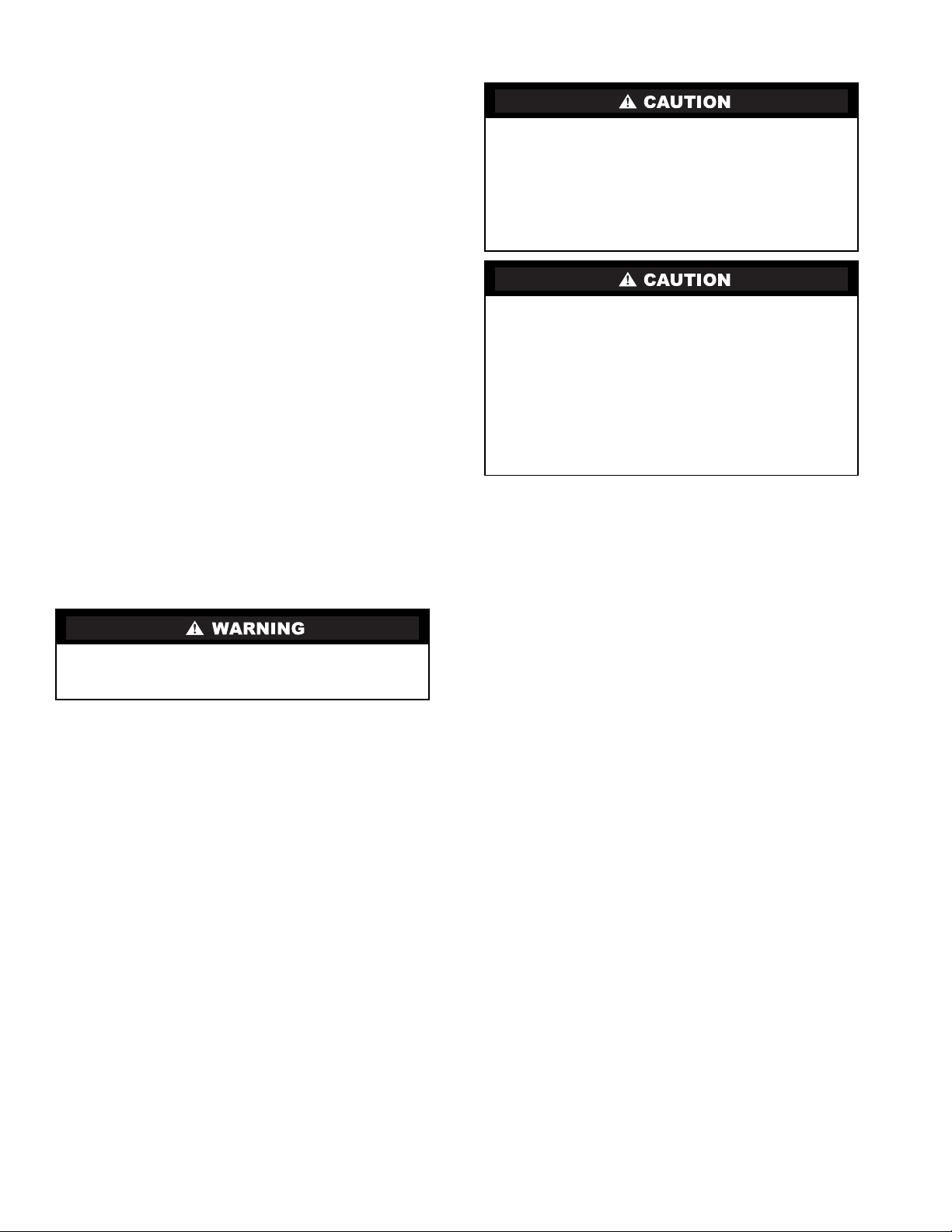

SAFETY CONSIDERATIONS

SAFETY NOTE

Air-handling equipment will provide safe and reliable

service when operated within design specifications. The

equipment should be operated and serviced only by

authorized personnel who have a thorough knowledge

of system operation, safety devices and emergency

procedures.

Good judgement should be used in applying any manufacturer’s instructions to avoid injury to personnel or

damage to equipment and property.

Disconnect all power to the unit before performing maintenance or service. Unit may automatically start if power is

not disconnected. Electrical shock and personal injury

could result.

If it is necessary to remove and dispose of mercury contactors in electric heat section, follow all local, state, and federal laws regarding disposal of equipment containing

hazardous materials.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3 3

Ta b 6 a 7 a

Catalog No. 04-53450001-01 Printed in U.S.A. Form 45-4SI Pg 1 11-05 Replaces: 45-2SI

GENERAL

The 45XC fan-powered mixing box provides plenum pressure and temperature control to the underfloor plenum. The

45XC mixing box is also equipped with a modulating primary

air damper and a variable speed fan. Together, these features

allow the 45XC unit to maintain plenum pressure at the desired

pressure set point while adjusting the plenum temperature to

match the load requirements.

The 45UC series underfloor fan-powered terminal and the

42KC fan coil unit are used to provide increased cooling or

supplemental heating to perimeter zones. These units are available with factory-installed electric or hot water heating coils.

The controllers are factory-mounted. The 33ZCPLNCTL

zone controller is supplied on the 45XC fan-powered mixing

box. The 33ZCFANTRM underfloor controller is supplied on

the 45UC underfloor fan-powered terminal. The 42KC fan coil

units contain the 33ZCFANCOL perimeter fan coil controller.

All are designed to be an integral part of the Carrier Direct Digital Controls (DDC) system. The controllers can communicate

on the Carrier Comfort Network® (CCN) system while completely integrating with the building’s heating, ventilation and

air conditioning (HVAC) system.

System Overview — Electronic control units feature a

factory-installed enclosure that provides easy access for field

connections.

The 45XC zone controller is factory-supplied and factoryconfigured, and consists of a processor, pressure transducer and

actuator. The controllers are configured to maintain the plenum

pressure between 0.01 and 1.0 in. wg and to control and maintain space temperature by measuring both plenum and space

temperature. The space temperature set point may be adjusted

by the user through the space temperature sensor without additional software.

Each 45XC zone controller also has the ability to function

as a linkage coordinator for systems with up to 128 zones. As a

linkage coordinator, a controller retrieves and provides system

information to the air-handling equipment and other zone

controllers. When a primary supply air sensor is installed, the

controller can function as a stand-alone device. See Fig. 1

and 2.

The controller monitors differential pressure from two pressure probes: one mounted in the space and one in the pressurized plenum. It compares the resulting signal to a plenum

pressure set point in order to provide pressure-independent

control of the air passing through the mixing box into the

plenum.

The controller is wired to a wall-mounted, field-supplied,

space temperature sensor (SPT) in order to monitor zone

temperature changes and satisfy zone demand.

The controller is designed to allow a service person or

building owner to configure and operate the unit through the

CCN user interface, however, a user interface is not required

for day-to-day operation. All maintenance, configuration, setup, and diagnostic information is available through the Level II

communications port to allow data access by an attached computer running Network Service Tool, ComfortVIEW™, or

ComfortWORKS® software.

PMET

S

S

FAN MOTOR

INTERFACE

(

ECAP

T

ERUTARE

ROSNE

ROOLFREDNU

MUNELP

NOC ENOZ ROOLFREDNU

)LTCNLPCZ33

SPACE

PRESSURE

SENSOR

R

ELLORT

PRIMARY AIR

TEMPERATURE

SENSOR

AIRFLOW

SENSOR

PRIMARY AIR

DAMPER

GIH

WOL

DAMPER

ACTUATOR

H

TROP

TROP

CONTROLS

ENCLOSURE

PRIMARY

P

IA

R

AIR DUCT

RAMIR

Y

ROSNES ERUSSERP MUNELP

EC

MIXED AIR

T

FAN

NRUTER / GNILI

RIA MUNELP

RETLIF

)deilppus-dleif(

RIA YLPPUS

ERUTAREPMET

FIELD-SUPPLIED

FILTER MONITOR

ERUSSERP

WS

HCTI

)deilppus-dleif(

RETURN

DUCT

3 equivalent diameters

of straight discharge duct

(minimum)

Fig. 1 — Typical Installation of Single 45XC Fan-Powered Mixing Unit

for Each Underfloor Zone

2

PMET

S

S

FAN MOTOR

INTERFACE

(

ECAP

T

ERUTARE

ROSNE

ROOLFREDNU

MUNELP

PRIMARY

RAMIR

TIC

)rosneS wolfriA(

Y

Y

than one

erom htiw snoitacilppa ni desu(

AIR DUCT

EC

EBORP

)munelp nommoc a gnizirusserp tinu CX54

MIXED AIR

T

FAN

NRUTER / GNILI

RIA MUNELP

RETLIF

)deilppus-dleif(

RIA YLPPUS

ERUTAREPMET

FIELD-SUPPLIED

FILTER MONITOR

ERUSSERP

WS

HCTI

)deilppus-dleif(

RETURN

DUCT

3 equivalent diameters

of straight discharge duct

(minimum)

P

IA

PRIMARY AIR

TEMPERATURE

SENSOR

AIRFLOW

SENSOR

PRIMARY AIR

DAMPER

DAMPER

R

NOC ENOZ ROOLFREDNU

ELLORT

)LTCNLPCZ33

ACTUATOR

HGIH

TROP

W

OL

R

TOP

CONTROLS

ENCLOSURE

R

OLEV DELLATSNI-DLEIF

Fig. 2 — Typical Installation for Multiple 45XC Fan-Powered Mixing Units

in a Larger Common Underfloor Zone (One 45XC Unit Shown)

System Architecture — Figure 3 shows the typical

control system architecture: a 45XC mixing box unit used to

provide the main plenum pressure and temperature control and

four 42KC fan coil units to provide supplemental heating and

cooling.

Figure 4 shows an arrangement of underfloor and zone

controllers and terminal units employed in the HVAC system

of a large building. Though all controllers are connected to the

same bus, controllers are configured to stand alone, satisfying

the needs of individual zones. These are commonly used in

perimeter zones. All underfloor controllers participate in linkage, with one configured as a linkage master; the rest are

configured as slaves.

This arrangement, from the software point of view, gives

the following information:

• All controllers may be configured to stand alone with their

own sensor OR they may share a temperature sensor

between themselves. The zone controllers do not share

sensor data with underfloor controllers.

• Controllers may have their own temperature sensor (located

near ceiling plenum) OR may share a single temperature

sensor.

• Controllers participate in linkage when sending the damper

position, occupancy, zone temperature and temperature set

point data to the master underfloor controller.

A bridge is recommended to isolate the underfloor control

system from the primary communication (comm) bus to:

• improve communication quality

• increase communication speed

Controllers use the underfloor plenum as the air source and

control the diffusers to satisfy the space temperature needs.

Controllers also make use of strip heaters for auxiliary heating.

POWER REQUIREMENTS — The power supply is 24 vac

± 10% at 40 va (50/60 Hz).

WIRING CONNECTIONS — Field wiring is 18-gage to

22-gage wire. The zone controller is a NEC (National Electrical

Code) Class 2 rated device.

INPUTS

• space temperature sensor

• primary air damper position

• plenum sensor (factory-installed)

• supply air temperature sensor

• optional primary air temperature sensor (required for sys-

tems which do not utilize a linkage compatible air source)

• optional CO

sensor

2

• optional relative humidity sensor

OUTPUTS

• internally factory-wired VAV (variable air volume) actuator

• internally factory-wired fan speed controller

3

ACCURACY — Terminal airflow pressure control is rated to

1 in. wg measured maximum pressure. The zone controller is

capable of controlling from as low as 0.01 in. wg to as high as

1.0 in. wg nominal pressure with an accuracy of ± 3% (nominal) at any point within the range.

HARDWARE (MEMORY) — The hardware consists of

FLASH EPROM memory.

DIFFERENTIAL PRESSURE SENSOR — Pressure range is

0.0 to 2.0 in. wg maximum for the onboard pressure sensor.

SPECIFIED SENSING TEMPERATURE RANGE — The

controller space temperature measuring range is –40 to 245 F.

This range applies to space temperature, supply-air temperature and primary air temperature sensors. The controller has an

allowable control set point range from 40 to 90 F for heating

and45to99Fforcooling.

COMMUNICATIONS — The maximum number of controllers is limited to 128 zones, with a limit of 8 systems (Linkage

Coordinator configured for at least 2 zones). Carrier Comfort

Network® (CCN) bus length may not exceed 4000 ft, with no

more than 60 devices on any 1000 ft section. Optically isolated

RS-485 repeaters are required every 1000 ft.

Exterior Zones

At 19,200 and 38,400 baud, the number of controllers is

limited to 128 maximum, with no limit on the number of Linkage Coordinators. Bus length may not exceed 1000 ft.

ENVIRONMENTAL RATINGS — Operating Temperature

is 32 to 140 F at 0 to 90% rh (relative humidity)

(non-condensing).

Shipping Temperature is –40 to 185 F at 0 to 90% rh

(non-condensing).

PERFORMANCE VIBRATION

• 0.014 in. peak-to-peak displacement measured at 5 to 31 Hz

• 0.75 G measured at 31 to 300 Hz

CORROSION — Equipment intended for indoor use only.

APPROVALS

• listed under UL 873

• conforms to requirements per European Consortium

standards EN50081-1 (CISPR 22, Class B) and EN50082-1

(IEC 801-2, IEC 801-3, and IEC 801-4) for CE mark

labeling

• UL94-5V plenum rated (housing and actuator)

35BF-D

42KC

42KC

Exterior Wall

LEGEND

42KC — Perimeter Fan Coil Unit with 33ZCFANCOL Fan Coil Controller

45XC — Fan-Powered Zone Mixing Unit with 33ZCPLNCTL Zone Controller

T—Wall-Mounted Temperature Sensor

35BF-D Linear Diffuser

35BF-R Swirl Diffuser

42KC

42KC

45XC

35BF-R

Interior Zones

Fig. 3 — Typical System Layout (45XC and 42KC)

4

CCN PRIMARY BUS (BUS 0)

CCN

SYSTEM

MONITORING

SOFTWARE

FAN COIL

CONTROLLER

45UC UNIT

(33ZCFANTRM)

FULLY CCN

COMPATIBLE CARRIER

AIR HANDLER

SECONDARY BUS

CC6400 OR CSAM

EQUIPPED

NON-CARRIER

AIR HANDLER

COMFORT ID™

EQUIPPED

AIR TERMINAL

(1 OF UP TO 128)

ADDRESSED

SEQUENTIALLY

45XC UNIT

(33ZCPLNCTL)

TYPICAL 42KC

FAN COIL UNIT

BRIDGE

(RECOMMENDED)

FAN COIL

CONTROLLER

(33ZCFANCOL)

TYPICAL 42KC

FAN COIL UNIT

LEGEND

CCN — Carrier Comfort Network®

CSAM — Comfort System

Air

Manager™

Fig. 4 — Control System Architecture with Underfloor Terminal Units

DATA

COLLECTION

OPTION

42KC UNIT

(33ZCFANCOL)

TO OTHER

CONTROLLERS

ON COMM BUS

5

PRE-INSTALLATION

Unpack and Inspect Units —

from all units. Check the shipment against shipping order.

Inspect for damage upon receipt. If shipment is damaged or

incomplete, file claim with transportation company and advise

Carrier immediately.

Remove shipping wraps

Storage and Handling — Store in a clean, dry and

covered location. Do not stack units. When unpacking units,

care should be taken that the inlet collars and externally mounted components do not become damaged. Do not lift units using

collars, sensors, or externally mounted components as handles.

If a unit is supplied with electric or hot water heat, care should

be taken to prevent damage to these devices. Do not lay uncrated units on end or sides. Do not stack uncrated units over 6 ft

high. Do not handle control boxes by tubing connections or

other external attachments.

PRIMARY

AIR DUCT

Prepare Jobsite for Unit Installation — To s av e t im e

and to reduce the possibility of costly errors, set up a complete

sample installation in a typical room at the jobsite. Check all

critical dimensions. Refer to job drawings and product dimension drawings as required.

45XC FAN-POWERED ZONE MIXING UNIT

INSTALLATION

Physical components of the 45XC fan-powered zone

mixing unit is detailed in Fig. 5. Figure 6 shows 45XC fanpowered zone mixing unit dimensions and weight data.

CEILING PLENUM

RETURN AIR

DUCT

CONTROL

ENCLOSURE

42 in. MINIMUM - SIZE 04

54 in. MINIMUM - SIZE 07

LOW AND HIGH

PRESSURE PORT*

RAISED FLOOR

*Installation is shown for a single unit in a multiple unit/common plenum application.

High and low pressure ports piped to a discharge plenum. Refer to Fig. 2.

SUPPLY AIR

TEMPERATURE

PROBE

SUPPLY DUCT

Fig. 5 — 45XC Fan-Powered Zone Mixing Unit Physical Details

6

1/2" DIA.

H

X

Y

D

PRIMARY

AIR INLET

W

DAMPER SHAFT

DD

1/2"

20"

ALLOW AT LEAST

24" CLEARANCE

FOR CONTROLS

J 11 7/8"

6 1/4"

A

B 1-1/2"

INLET VIEW

45XC UNIT SIZE UNIT WEIGHT (lb) FILTER SIZE (in.) FILTER P/N FILTER KIT P/N

4 209 17 x 17 x 1 102649-1717 3503341717

7 269 22 x 19 x 1 102649-2219 3503342219

INLET

UNIT

SIZE

*Estimated for rpm/torque controlled motor, at 0.1 in. wg static pressure under floor.

NOTE: Inlet Size: 6-10, DD = 3

SIZE

(in.)

4

7

PRI.

CFM

6 500 1200 1700

8900 1200 21001/2361/8361/8181/16151/815 77/811 14 9 631/831/

10 1400 1200 26001/2361/8361/8181/16151/815 97/811 14 9 731/831/

12 2100 1200 33001/2361/8361/8181/16151/815 117/811 14 9831/

10 1400 2500 3900 1 42

12 2100 2500 4600 1 421/8461/8201/16201/817 117/815 17 10 8 51/241/

14 2800 2500 5300 1 421/8461/8201/16201/817 137/815 17 10 10 51/

16 3700 2500 6200 1 421/8461/8201/16201/817 157/815 17 10 101/451/

FA N

CFM*

7

/8in. Inlet Size: 12-16, DD = 57/8in.

1-1/4"

MAX

FLOW

RECIRCULATED

AIR INLET

MOUNTING BRACKET - (4 PLCS)

SEE OPTIONAL FEATURES BELOW

PLAN VIEW – LEFT HAND UNIT

RIGHT HAND UNITS AVAILABLE - CONTROLS NOT SHOWN

HP

LWH

1

/2361/8361/8181/16151/815 57/811 14 9 631/831/

1

/8461/8201/16201/817 97/815 17 10 7 51/241/

L

Recirc. Air

AB FG

Fig. 6 — 45XC Fan Powered Zone Mixing Unit Physical Data and Dimensions

45XC Hardware — The 45XC fan-powered mixing unit

contains the 33ZCPLNCTL zone controller.

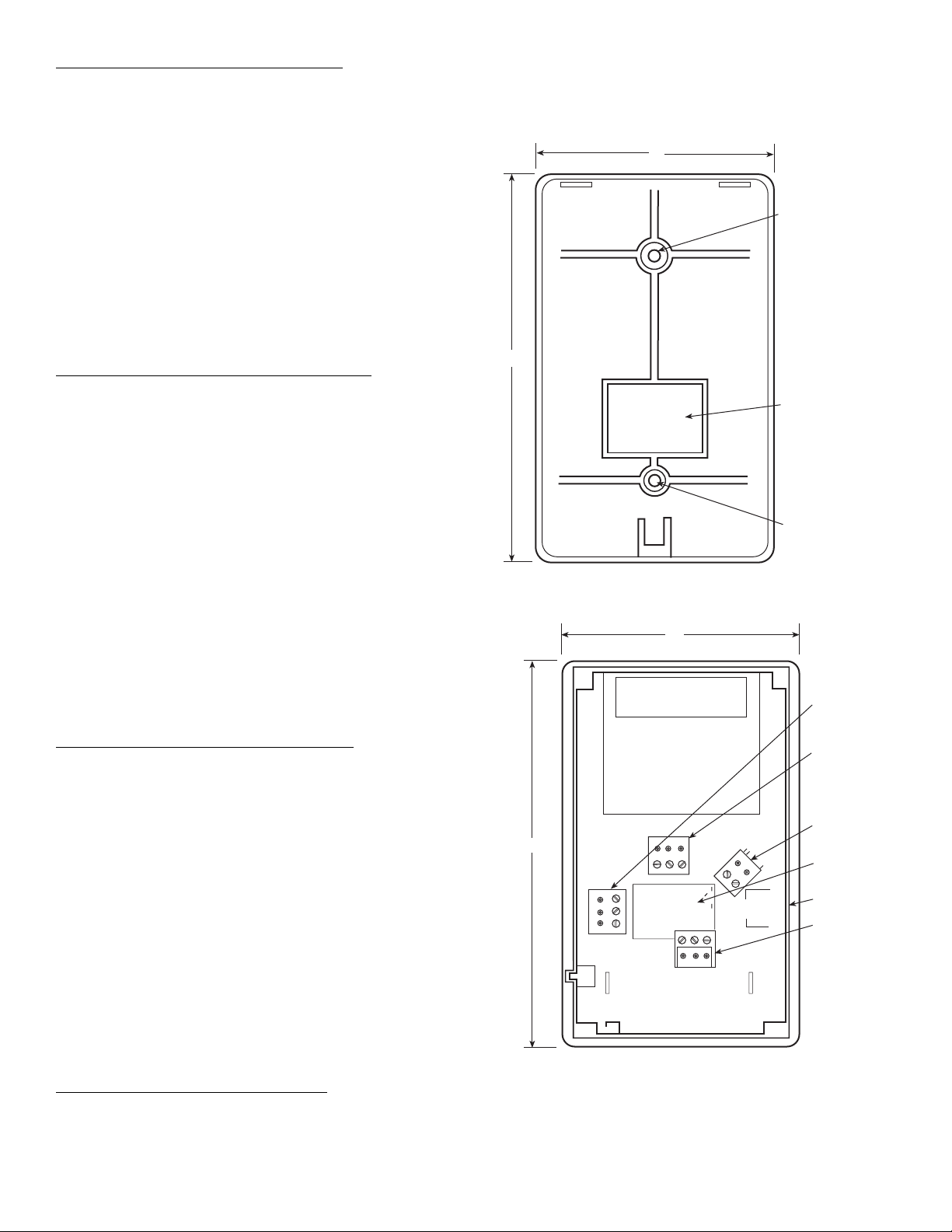

Figure 7 shows the zone controller physical details.

SUPPLY-AIR TEMPERATURE (SAT) SENSOR (Fig. 9) —

The zone controller must be connected to a field-supplied supply air temperature (SAT) sensor (P/N 33ZCSENSAT) to monitor the temperature of the air delivered by the fan coil.

45XC Field-Supplied Hardware — Each 45XC fan-

powered zone mixing unit requires the following field-supplied

components to complete its installation:

• transformer — 24 vac, 40 va (standard applications)

• contactors (as required for electric heat)

1

•

/4-in. OD flame retardant polyethylene tubing (length not

toexceed25ft)

• space temperature sensor (33ZCT55SPT, 33ZCT56SPT, or

33ZCT57SPT)

• supply-air temperature sensor (33ZCSENSAT) with two

no. 10 x

supply duct)

• primary-air temperature sensor

• indoor-air quality (CO

• relative humidity sensor (optional)

SPACE TEMPERATURE SENSOR (Fig. 8) — Each

33ZCPLNCTL zone controller requires a field-supplied

Carrier space temperature sensor. There are three sensors

available for this application:

• 33ZCT55SPT, space temperature sensor with override

button

• 33ZCT56SPT, space temperature sensor with override

button and set point adjustment

1

/2-in. sheet metal screws (to secure SAT sensor to

) sensor (optional)

2

PRIMARY-AIR TEMPERATURE SENSOR (PAT)

(Optional) — A field-supplied, primary air temperature (PAT)

sensor (P/N 33ZCSENPAT) is used on a zone controller that is

functioning as a linkage master for a non CCN/linkage compatible air source. See Fig. 10.

INDOOR-AIR QUALITY (CO

indoor air quality sensor is required for IAQ monitoring.

Three different CO2sensors are available for zone CO2level

monitoring.

• The 33ZCSENCO2 sensor is an indoor, wall-mounted sensor with an LED (light-emitting diode) display.

• The 33ZCT55CO2 sensor is an indoor, wall-mounted sensor without display. The CO

temperature sensor with override button.

• The 33ZCT56CO2 sensor is an indoor, wall-mounted sensor without display. The CO

temperature sensor with override button and temperature

offset.

RELATIVE HUMIDITY SENSOR (Fig. 12) — The relative

humidity sensor (P/N 33AMSENRHS000) is an indoor, wallmounted sensor and is required for zone humidity control

(dehumidification).

• 33ZCT57SPT, space temperature sensor with override button, set point adjustment, and manual fan speed control

DISCHARGE

DIMENSIONS (in.)

Discharge

D

G

Z

F 2 9/16"

DISCHARGE VIEW

XY Z J

8

8

8

31/

8

8

8

8

41/

8

2

41/

2

8

)SENSOR(Fig.11)—An

2

sensor also includes a space

2

sensor also includes a space

2

7

0

HF23BJ042

Made in Switzerland

by Belimo Automation

LR 92800

NEMA 2

LISTED

94D5

TENP IND &

REG. EQUIP.

Class 2 Supply

5K

WIP

yel

blu

ora

35 in-lb (4 Nm)

80...110s

24VAC/DC

50/60 Hz

3VA 2W

COM

1

2

red wht

blk

15

LOW

1

®

3

ZONE Controller

Part Number: 33ZCPLNCTL

S/N:

Bus#:

Element#:

Unit#:

HIGH

US

C

1

J6

2

1

J7

3

®

1

J8

3

SEC DMP

J6

1

CCW

COMCWHEAT1

24VAC

HEAT2

FAN AC

FAN

24VAC

N/A

HEAT3

CW

COM

COW

6

RH/IAQ

GND

SECFLOW

J4

+10V

DMPPOS

GND

TEST

GND

1

1

CCN

J2A

3

1

3

+

G

-

J1

+24V

SPT

GND

SAT

T56

GND

PAT

REMOTE

J3

24VAC

16

2

1

+

LEN

G

-

J2B

3

SRVC

+

-

G

Fig. 7 — 45XC Fan-Powered Zone Mixing Unit Controller Physical Details (33ZCPLNTCTL)

Cool

Warm

Fig. 8 — Space Temperature Sensor (P/N 33ZCT56SPT Shown)

.08

.39

FOAM GASKET

3.90

.40'' O.D.

.250 ±.01 Dia

.175 DIA

x .600

3.00

PLENUM RATED CABLE

114'' ±6

5.5 ±.5

NOTE: Dimensions are in inches.

Fig. 9 — Supply Air Temperature Sensor (33ZCSENSAT)

8

Fig. 10 — Primary Air Temperature Sensor

(33ZCSENPAT)

5.625

(14.3)

3.25

(8.3)

NOTE: Dimensions are in inches. Dimensions in () are in

centimeters.

1.125

(2.9)

5

(12.7)

0.25

(0.8)

Fig. 11 — Indoor Air Quality (CO2) Sensor

(33ZCSENCO2)

Fig. 12 — Wall-Mounted Relative Humidity Sensor

(33AMSENRHS000)

45XC Fan-Powered Zone Mixing Box Installation

STEP 1 — SELECT LOCATION

1. Units should be installed so that they do not come in contact with obstacles such as rigid conduit, sprinkler piping,

Greenfield flexible metal covering, or rigid pneumatic

tubing; such contact can transmit vibration to the building

structure, causing objectionable low frequency noise.

2. Units should never be installed tightly against concrete

slabs or columns, as vibration transmission is amplified in

this condition.

3. Fan-powered terminals require sufficient clearance for

servicing the blower/motor assembly from the bottom of

the unit, low voltage controls from the side and line

voltage motor controls or electric heat (if equipped) from

the rear (discharge end) of the unit. See Fig. 6.

Bottom access panel removal requires a minimum of

3-in. minimum clearance, in addition to substantial horizontal clearance, to slide the access panel out of the way

for service. Actual horizontal dimensions will vary due to

varying access panels for different sized units. See unit

submittal drawings for detailed information.

NOTE: Be certain that accommodations for panel removal of unit casings are large enough to allow adequate

internal service room once the panels are removed.

A clearance of 18 in. is recommended for control enclosure access. Unit control enclosure will vary depending

on which control package is used. Control enclosure

location is specified on unit submittals. Low voltage

enclosure covers are removable, not hinged.

A clearance of 36 in. is recommended for line voltage

motor controls and electric heat control access. High voltage motor controls or electric heat control access is

supplied with hinged access doors for units with fused

disconnect. Specific location is indicated on the unit

submittal.

These recommendations do not supersede NEC (National

Electrical Code) or local codes that may be applicable.

Adherence to these codes are the responsibility of the

installing contractor.

4. Whenever possible, fan-powered boxes should be

installed over halls or passageways (rather than over

occupied spaces) in order to limit the sound reaching

occupants.

STEP 2 — POSITION UNIT

1. When moving boxes, use appropriate material handling

equipment and avoid contact with shaft extensions, controls, wiring, piping, heaters, and control boxes.

2. Raise unit to position using safe mechanical equipment

and support until hanging means are attached and box is

level.

STEP 3 — INSTALL UNIT

1. Install field-supplied eyebolts, straphangers or bolt rod

supports as desired. Figure 13 illustrates possible 45XC

unit suspension methods. A typical underfloor installation

is shown in Fig. 14.

2. Care should be taken to use hanging materials of sufficient stiffness and strength, rigidly attached to the unit.

Straps should not be located on coil flanges, electric heat

sections, or control boxes. When using trapeze supports,

avoid areas where access is required to side mounted

controls, or side or bottom access doors. For best installation with trapeze supports, provide elastomeric material

between unit and supports.

3. Hangers should be securely attached to bar joist or

mounting anchors properly secured to building structure

with lugs or poured-in-place hangers. Percussion nails are

not considered adequate anchors.

9

STEP 4 — MAKE DUCT CONNECTIONS

1. Check that the pressure pick-up in primary air collar is

located properly and that air supply duct connections are

airtight. Install supply ductwork on unit inlet collar,

following all accepted medium-pressure duct installation

procedures. Seal joints against leakage.

NOTE: For maximum efficiency in controlling radiated

noise in critical applications, inlet ducts should be fabricated of 24-gage minimum sheet metal in place of flex

connections. Flex duct is extremely transparent to radiated sound; consequently high inlet static pressure (Ps) or

sharp bends with excessive pressure drop can cause a radiated noise problem in the space. If flex duct is used, it

should be limited to the connection between the distribution duct and the boot diffuser.

2. Install the discharge duct, being careful not to reduce the

face area of any electric heat section until several diameters away from the unit. It is strongly recommended that

lined discharge duct be used downstream of the unit.

Insulate duct as required.

3. Fan boxes should not be attached to octopus sections

immediately downstream of the unit.

4. Install optional return-air filters before operating the unit.

5. Leave construction filters supplied with the box in place

until installation is complete and building is cleared for

occupancy.

STEP 5 — POWER WIRING

Disconnect electrical power before wiring or servicing the

unit. All disconnect switches on the terminal (if equipped)

should be in the OFF position while making power connections. Electrical shock, personal injury, or damage to the

zone controller can result.

1. All power wiring must comply with local codes and with

NEC ANSI/NFPA (American National Standards

Institute/National Fire Protection Association) 70-1981.

Disconnect switches are optional equipment. Electrical,

control and piping diagrams are shown on the exterior

labeling or on a diagram inside the control and highvoltage enclosure covers, unless otherwise specified in

the order write-up. All units are wired for a single point

electrical connection to the fan and electric heater (if

equipped). Electric heaters provided by Carrier are

balanced by kW per stage. The installing electrician

should rotate incoming electric service by phase to help

balance overall building load.

2. All field wiring must be provided with a safety disconnect per NEC 424-19, 20, and 21.

3. Units with electric heat should use copper wires rated at

least 125% of rating plate amperage. Refer to the unit’s

rating label and minimum supply circuit amps.

4. Observe wiring diagram and instructions attached to the

unit. A Wye power source with a fourth (neutral) wire in

addition to the full sized ground wire is required for

480-v, 3-phase units. All units must be grounded as

required by NEC 424-14 and 250. See Fig. 15A and 15B.

ACCESSORY

HANGER

SUPPORT

ROD

FIELD-SUPPLIED

BRACKET

HANGER

DO NOT SUSPEND UNIT BY

TRAPEZE HANGERS THAT

INTERFERE WITH THE

UNIT ACCESS PANEL

Fig. 13 — Typical 45XC Support Methods

10

ROOM

SENSOR

45XC

FAN POWERED

ZONE MIXING

BOX

Fig. 14 — Typical Underfloor Installation — 45XC Fan-Powered Mixing Box

35 BF-R

SWIRL DIFFUSER

11

LEGEND

Factory Piping

Factory Wiring

Fig. 15A — 45XC Zone Controller Wiring — Control Package 4840

Field Wiring

to the fully closed position. Mount actuator over damper shaft and

secure to shaft enclosure. Engage clutch and rotate damper CCW to

AFS — Airflow Switch

COM — Common

CCW — Counterclockwise

CW — Clockwise

DMPPOS — Damper Position

ECM — Electronically Commutated Motor

GND — Ground

N.O. — Normally Open

PAT — Primary Air Temperature Sensor

SAT — Plenum Temperature Sensor

SPT — Space Temperature Sensor

UL — Underwriter’s Laboratories

NOTES:

the fully open position.

1. Verify actuator bushing is in the full CW position. Rotate damper CW

2. Use insulated quick connects.

Electric shock may result. Disconnect unit prior to servicing unit.

3. These controls have been wired to comply with UL-1995.

12

LEGEND

Factory Piping

Factory Wiring

Field Wiring

AFS — Airflow Switch

COM — Common

CCW — Counterclockwise

CW — Clockwise

DMPPOS — Damper Position

ECM — Electronically Commutated Motor

GND — Ground

N.O. — Normally Open

PAT — Primary Air Temperature Sensor

SAT — Plenum Temperature Sensor

SPT — Space Temperature Sensor

UL — Underwriter’s Laboratories

Electric shock may result. Disconnect unit prior to servicing

CW to the fully closed position. Mount actuator over damper

shaft and secure to shaft enclosure. Engage clutch and rotate

damper CCW to the fully open position.

NOTES:

1. Verify actuator bushing is in the full CW position. Rotate damper

2. Use insulated quick connects.

unit.

3. These controls have been wired to comply with UL-1995.

13

Fig. 15B — 45XC Zone Controller Wiring — Control Package 4841

45XC Sensor Installation

GENERAL SENSOR INSTALLATION — The sensor should

be mounted:

• on an internal wall near a return air grille or duct

• at least 3 ft from any corner, 2 ft from an open doorway and

4 to 6 ft from the floor

• proximal to the wiring egress on the wall

• where temperature operating limits are 32 to 122 F

The sensor should NOT be mounted:

• close to a window, on an outside wall, or next to a door

leading to the outside

• close to or in direct airflow of areas such as open windows,

drafts or over heat sources

• in areas with poor air circulation, such as behind a door or in

an alcove where there are dramatic temperature fluctuations

or moisture accumulation

• where it is influenced by supply air as the sensor will give

an inaccurate reading

• where it may be exposed to direct occupant breathing, such

as near water coolers or coffee machines.

SPACE TEMPERATURE SENSOR INSTALLATION —

A space temperature sensor must be installed for each zone

controller. There are three types of SPT sensors available used

with the 33ZCPLNCTL controller: 33ZCT55SPT space temperature sensor with timed override button, 33ZCT56SPT

space temperature sensor with timed override button and set

point adjustment, and 33ZCT57SPT space temperature sensor

with timed override button, set point adjustment, and manual

fan speed control. See Fig. 8 and 16.

The space temperature sensor is used to measure the build-

ing interior temperature and should be located on an interior

building wall. The sensor wall plate accommodates the NEMA

(National Electrical Manufacturers Association) standard 2 x

4 in. junction box. The sensor can be mounted directly on the

wall surface if acceptable by local codes.

Do not mount the sensor in drafty locations such as near air

conditioning or heating ducts, over heat sources such as baseboard heaters or radiators, or directly above wall-mounted

lighting dimmers. Do not mount the sensor near a window

which may be opened, near a wall corner, or a door. Sensors

mounted in these areas will have inaccurate and erratic sensor

readings.

The sensor should be mounted approximately 5 ft from the

floor, in an area representing the average temperature in the

space. Allow at least 4 ft between the sensor and any corner

and mount the sensor at least 2 ft from an open doorway.

The sensor consists of the following hardware:

1 — sensor top

1 — sensor base

1 — mounting plate

2 — machine screws (6 x 32)

2 — locking screws

Install the sensor as follows (see Fig. 16):

1. Locate the two Allen type screws at the bottom of the

sensor.

2. Turn the two screws clockwise to release the cover from

the sensor wall mounting plate.

3. Lift the cover from the bottom and then release it from

the top fasteners.

4. Feed the wires from the electrical box through the opening in the center of the sensor mounting plate.

5. Usingtwono.6-32x1machinescrews(providedwith

the sensor), secure the sensor to the electrical box.

NOTE: Sensor may also be mounted directly on the wall

using2plasticanchorsand2sheetmetalscrews

(field-supplied).

6. Use 20-gage wire to connect the sensor to the controller.

The wire is suitable for distances of up to 500 ft. Use a

three-conductor shielded cable for the sensor and set

point adjustment connections. The standard CCN communication cable may be used. If the set point adjustment

(slidebar) is not required, then an unshielded, 18-gage or

20-gage, two-conductor, twisted pair cable may be used.

The CCN service jack requires a separate, shielded CCN

communication cable. Always use separate cables

for CCN communication and sensor wiring. (Refer to

Fig. 17-19 for wire terminations.)

7. Replace the cover by inserting the cover at the top of the

mounting plate first, then swing the cover down over the

lower portion. Rotate the two Allen head screws counterclockwise until the cover is secured to the mounting plate

and locked in position.

NOTE: Clean sensor with damp cloth only. Do not use

solvents. See Table 1 for resistance vs temperature data.

Before performing service or maintenance operations on

the system, turn off main power switches to the unit.

Electric shock can cause personal injury.

NOTE: Dimensions are in inches.

Fig. 16 — Space Temperature Sensor and

Wall-Mounted Humidity Sensor Mounting

14

Wiring the Space Temperature Sensor

(33ZCT55SPT,

33ZCT56SPT, 33ZCT57SPT) — The sensor wiring has the

following requirements:

• Power requirements: 18 to 36 vac RMS 50/60 Hz at 4 va.

• All system wiring must be in compliance with all applicable

local and national codes.

• A dedicated power supply is required for this sensor.

• All sensor wiring should be color-coded for ease of mainte-

nance and service.

• Wiring should be 18 to 22 AWG (American Wire Gage)

stranded wire (20 AWG is recommended).

To wire the sensor, perform the following (see Fig. 17-19):

1. Identify which cable is for the sensor wiring.

2. Strip back the jacket from the cables at least 3 inches.

1

Strip

/4-in. of insulation from each conductor. Cut the

shield and drain wire from the sensor end of the cable.

3. Connect the sensor cable as follows:

a. Connect one wire from the cable (RED) to the SPT

terminal on the controller. Connect the other end of

the wire to the left terminal on the SEN terminal

block of the sensor.

b. Connect another wire from the cable (BLACK) to

the GND terminal on the controller. Connect the

other end of the wire to the remaining open terminal on the SEN terminal block (COM on

33ZCT57SPT).

c. On 33ZCT56SPT and 33ZCT57SPT thermostats,

connect the remaining wire (WHITE/CLR) to the

T56 terminal on the controller. Connect the other

end of the wire to the SET terminal on the sensor.

d. In the control box, install a no. 10 ring-type crimp

lug on the shield drain wire. Install this lug under

the mounting screw of the zone controller.

e. On 33ZCT56SPT thermostats, install a jumper

between the two center terminals (right SEN and

left SET). See Fig. 18.

f. On 33ZCT57SPT thermostats, a separate

3-conductor, shielded cable is used to connect the

fan speed wiring. Connect the SPD terminal on the

thermostat to the SPEED terminal on the zone controller. Use the white/clear wire. Connect the COM

terminal on the thermostat to the GND terminal on

the zone controller. Use the black wire. Connect

the 10V terminal on the thermostat to the +10V

terminal on the zone controller. Use the red wire.

In the control box, install a no. 10 ring-type crimp

lug on the fan speed wiring shield drain wire.

Install this lug under the mounting screw of the

zone controller.

Wiring the CCN Communication Service Jack

—See

Fig. 17-19. To wire the service jack, perform the following:

1. Strip back the jacket from the CCN communication

cable(s) at least 3 inches. Strip

1

/4-in. of insulation from

each conductor. Remove the shield and separate the drain

wire from the cable. Twist together all the shield drain

wires and fasten them together using a closed end crimp

lug or a wire nut. Tape off any exposed bare wire to

prevent shorting.

2. Connect the CCN + signal wire(s) (RED) to Terminal 5.

3. Connect the CCN – signal wire(s) (BLACK) to

Terminal 2 .

4. Connect the CCN GND signal wire(s) (WHITE/CLR) to

Terminal 4 .

Before wiring the CCN connection, refer to Connect the

CCN Communication Bus section for communication bus wiring and cable selection. The cable selected must be identical to

the CCN communication bus wire used for the entire network.

The other end of the communication bus cable must be

connected to the remainder of the CCN communication bus. If

the cable is installed as a T-tap into the bus, the cable length

cannot exceed 50 ft. No more than 10 T-taps are allowed

per bus. Wire the CCN service jack of the sensor in a daisy

chain arrangement with other equipment. See Fig. 20. Refer to

the Connect to the CCN Communication Bus section for additional details.

SW1

2

3

SEN

45

61

RED(+)

WHT(GND)

BLK(-)

BLK (GND)

RED (SPT)

CCN COM

SENSOR WIRING

Fig. 17 — Space Temperature Sensor Wiring

(33ZCT55SPT)

2

3

SEN

SW1

Cool Warm

45

61

RED(+)

WHT(GND)

BLK(-)

SET

WHT

(T56)

BLK (GND)

RED (SPT)

CCN COM

SENSOR WIRING

JUMPER

TERMINALS

AS SHOWN

Fig. 18 — Space Temperature Sensor Wiring

(33ZCT56SPT)

15

WHITE (SPEED)

3-CONDUCTOR

SHIELDED CABLE

LEGEND

CCN — Carrier Comfort Network®

SW1 — Switch

Set Point — Set Point Adjust

NOTE: Do not connect white wire to SET terminal if set point adjustment is not needed.

3-CONDUCTOR

SHIELDED CABLE

Fig. 19 — Space Temperature Sensor Wiring (33ZCT57SPT)

Table 1 — Thermistor Resistance vs Temperature Values for Space Temperature Sensor,

Return-Air Temperature Sensor, and Supply-Air Temperature Sensor

TEMP (C) TEMP (F) RESISTANCE (Ohms)

0 32 32,651

5 41 25,395

10 50 19,903

15 59 15,714

20 68 12,494

25 77 10,000

30 86 8,056

35 956,530

40 104 5,325

45 113 4,367

50 122 3,601

16

Wiring when distance between fan coil controller and space temperature sensor is 50 feet or less:

50 FT. MAXIMUM

FAN COIL

PERIMETER

CONTROLLER

3 COND COMM CABLE (TYP)

2 COND TWISTED

CABLE OR 3 COND

CABLE (TEMP

SENSOR WIRING) (TYP)

45KC

FAN COIL UNIT

CCN COMM BUS

Warm

Cool

SPACE

TEMPERATURE

SENSOR

Wiring when distance between fan coil controller and space temperature sensor is greater than 50 feet:

Warm

Cool

CCN COMM BUS

2 COND TWISTED

CABLE OR 3 COND

CABLE (TEMP

SENSOR WIRING) (TYP)

Warm

Cool

SPACE

TEMPERATURE

SENSOR

DISTANCE GREATER

THAN 50 FT.

Fig. 20 — Communication Bus Wiring (42KC Perimeter Fan Coil Zone Controller Shown)

Warm

Cool

17

SUPPLY-AIR TEMPERATURE (SAT) SENSOR INSTALLATION — The SAT sensor is required and must be installed

in the fan coil air outlet. The part number is 33ZCSENSAT.

The SAT sensor probe is 6 inches in length. See Fig. 9.

When using a ducted supply, the supply-air temperature

sensor should be located in the supply duct downstream of the

discharge of the fan coil to allow good mixing of the supply

airstream.

See Fig. 21 for mounting location. See Fig. 22 for mounting

hole requirements.

Disconnect electrical power before wiring the zone controller. Electrical shock, personal injury, or damage to the zone

controller can result.

Do not run sensor or relay wires in the same conduit or

raceway with Class 1 AC service wiring. Do not abrade,

cut, or nick the outer jacket of the cable. Do not pull or

draw cable with a force that may harm the physical or

electrical properties. Avoid splices in any control wiring.

Damage to the 33ZCPLNCTL zone controller can result.

Perform the following steps to connect the SAT sensor to

the zone controller:

1. Locate the opening in the control box. Pass the sensor

probe through the hole.

1

2. Drill or punch a

/2-in. hole in the fan coil unit. See

Fig. 22.

3. Use two field-supplied, self-drilling screws to secure the

sensor probe to the fan coil unit.

4. Connect the sensor leads to the zone controller’s wiring

harness terminal board at the terminals labeled SAT

(RED) and GND (BLK).

Perform the following steps if state or local code requires

the use of conduit, or if sensor installation requires a cable

length of more than 8 ft:

1. Secure the probe to the fan coil unit with two fieldsupplied self-drilling screws.

2. If extending cable length beyond 8 ft, use plenum rated,

20 AWG, twisted pair wire.

3. Connect the sensor leads to the zone controller’s wiring

harness terminal board at the terminals labeled SAT

(RED) and GND (BLK).

4. Neatly bundle and secure excess wire.

INDOOR-AIR QUALITY (CO

) SENSOR INSTALLA-

2

TION — The indoor-air quality (CO2) sensor accessory monitors carbon dioxide levels, which provide information used to

monitor indoor air quality. Three types of sensors are provided.

The wall sensor can be used to monitor the conditioned air

space. Sensors use infrared technology to measure the levels of

CO

present in the air. The wall sensor is available with or

2

without an LCD readout to display the CO

Fig. 11.

level in ppm. See

2

Sensor accessory descriptions and part numbers are shown

in Table 2. To mount the sensor, refer to the installation instructions shipped with the accessory kit.

Table 2 — CO

CO2SENSOR

ACCESSORY

PA RT N U MB ER S

33ZCSENCO2 Wall Mount Sensor (with display)

33ZCT55CO2

33ZCT56CO2

The CO

sensors listed in Table 3 are factory-set for a range

2

Sensor Accessories

2

DESCRIPTION

Wall Mount Sensor with 33ZCT55SPT

space temperature sensor (no display)

Wall Mount Sensor with 33ZCT56SPT

space temperature sensor and set point

adjustment (no display)

of 0 to 2000 ppm and a linear voltage output of 0 to 10 vdc.

Refer to the instructions supplied with the CO

sensor for

2

electrical requirements and terminal locations.

To accurately monitor the quality of the air in the conditioned air space, locate the sensor near a return air grille (if

present) so it senses the concentration of CO

leaving the

2

space. The sensor should be mounted in a location to avoid

direct breath contact.

Do not mount the CO

sensor in drafty areas such as near

2

supply ducts, open windows, fans, or over heat sources. Allow

at least 3 ft between the sensor and any corner. Avoid mounting

the sensor where it is influenced by the supply air; the sensor

gives inaccurate readings if the supply air is blown directly

onto the sensor or if the supply air does not have a chance

to mix with the room air before it is drawn into the return

airstream.

APROX

2 FT

SUPPLY

DUCT

TYPICAL

FAN COIL UNIT

HC

SUPPLY

AIR SENSOR

LEGEND

HC — Heating Coil

Fig. 21 — Supply Air Temperature Sensor

Mounting Location (42KC)

3.00

1.50

ø0.50

CLEARANCE HOLE

ENGAGEMENT HOLE FOR

#10 SHEET METAL SCREW (2)

Fig. 22 — Supply Air Temperature

Sensor Mounting

18

Indoor-Air Quality Sensor Wiring

— To wire the sensors

after they are mounted in the conditioned air space or outdoor

location, see Fig. 23 and the instructions shipped with the

sensors. For each sensor, use two 2-conductor 18 AWG

twisted-pair cables (unshielded) to connect the separate isolated 24 vac power source to the sensor and to connect the sensor

to the control board terminals. To connect the sensor to the

control board, identify the positive (0-10 VDC) and ground

(SIG COM) terminals on the sensor. Connect the –10 VDC terminal to terminal IAQ and connect the SIG COM terminal to

terminal GND.

RELATIVE HUMIDITY SENSOR (WALL-MOUNTED)

INSTALLATION — The relative humidity sensor accessory

is installed on an interior wall to measure the relative humidity

of the air within the occupied space. See Fig. 12.

Theuseofastandard2x4in.electricalboxtoaccommodate the wiring is recommended for installation. The sensor can

be mounted directly on the wall, if acceptable by local codes.

If the sensor is installed directly on a wall surface, install the

humidity sensor using 2 screws and 2 hollow wall anchors

(field-supplied); do not overtighten screws. See Fig. 16.

Do NOT clean or touch the sensing element with chemical

solvents; they can permanently damage the sensor.

The sensor must be mounted vertically on the wall. The

Carrier logo should be oriented correctly when the sensor is

properly mounted.

DO NOT mount the sensor in drafty areas such as near heating or air-conditioning ducts, open windows, fans, or over heat

sources such as baseboard heaters, radiators, or wall-mounted

light dimmers. Sensors mounted in those areas will produce

inaccurate readings.

Avoid corner locations. Allow at least 4 ft between the

sensor and any corner. Airflow near corners tends to be

reduced, resulting in erratic sensor readings.

Sensor should be vertically mounted approximately 5 ft up

from the floor, beside the space temperature sensor.

For distances up to 500 feet, use a 3-conductor, 18 or

20 AWG cable. A CCN communication cable can be used,

although the shield is not required. The shield must be removed

from the sensor end of the cable if this cable is used. See

Fig. 24 for wiring details.

The power for the sensor is provided by the control board.

The board provides 24 vdc for the sensor. No additional power

source is required.

FRESH

AIR

DAMPER

FAN

ON

FAN A C

LOW

MED

HIGH

24VAC

OAD

RH

GND

IAQ

+10V

SPEED

GND

CONDSW

GND

R

+

W

GND

B

-

+24V DC

SPT

GND

SAT

T56

GND

CNGOVR

RMT/FS

R

W

B

87

21

24VAC

LINE VOLTAGE

SEPARATE

POWER

SUPPLY

REQUIRED

NOT USED

CCN

COMMUNICATIONS

VALV E

DX1

COM

VALV E

DX2

HEAT1

24VAC

HEAT2

Fig. 23 — CO2Sensor Wiring (42KC Controller Shown)

19

CCN

COMMUNICATIONS

24 VAC

EQUIPMENT GROUND

LINE

VOLTAGE

To wire the sensor, perform the following:

1. At the sensor, remove 4-in. of jacket from the cable. Strip

1

/4-in. of insulation from each conductor. Route the cable

through the wire clearance opening in the center of the

sensor.

2. Connect the RED wire to the sensor screw terminal

marked (+).

3. Install one lead from the resistor (supplied with the sensor) and the WHITE wire into the sensor screw terminal

marked (–). After tightening the screw terminal, test the

connection by pulling gently on the resistor lead.

4. Connect the remaining lead from the resistor to the

BLACK wire and secure using a field-supplied closed

end type crimp connector or wire nut.

5. Using electrical tape, insulate any exposed resistor lead to

prevent shorting.

6. At the control box, remove the jacket from the cable.

7. Strip

1

/4-in. of insulation from each conductor.

8. Connect the RED wire to terminal 24 VDC on the control

board.

NOTE: The 24 VDC terminal is used for rh sensor wiring

only.

9. Connect the BLACK wire to terminal GND on the

control board.

10. Connect the WHITE/CLEAR wire to terminal RH on the

control board.

11. Connect shield to earth ground (if shielded wire is used).

HUMIDITY SENSOR

RED

WHITE

BLACK

SHIELD

(IF USED)

+24V DC

RH

SPT

GND

GND

IAQ

SAT

+10V

SPEED

GND

GND

R

+

W

GND

B

-

J1

T56

GND

CNGOVR

RMT/FS

R

W

B

1

2

3

VALVE

DX1

COM

VALVE

DX2

HEAT1

24VAC

HEAT2

FRESH

AIR

DAMPER

FAN

ON

FAN A C

LOW

MED

HIGH

24VAC

OAD

CONDSW

Fig. 24 — Humidity Sensor Wiring (42KC Controller Shown)

+

-

499

NOT USED

CCN

COMMUNICATIONS

CCN

COMMUNICATIONS

24 VAC

LINE

VOLTAGE

EQUIPMENT

GROUND

20

AND SPACE TEMPERATURE SENSORS (Optional) —

CO

2

The CO

and space temperature sensors are comprised of two

2

sensors housed in one unit. They are designed to monitor

carbon dioxide (CO2) levels in the air and measure the interior

building temperature.

Two models are available: P/N 33ZCT55CO2, and

P/N 33ZCT56CO2, which has a set point adjustment potentiometer. Both models include a push-button override that may

be disabled through controller software. See Table 3 for sensor

specifications. To convert the CO

CO

sensor, the duct-mounted aspirator (33ZCASPCO2) will

2

sensor into a duct-mounted

2

NOTE: There are 2 locking screws provided on the bottom of

the cover for security. A special tool is required to remove and

install the cover if the locking screws are used.

The sensor consists of the following hardware:

1 — sensor top

1 — sensor base

1 — mounting plate

2 — machine screws (6 x 32)

2 — locking screws

need to be purchased.

Refer to the instructions supplied with the CO

electrical requirements and terminal locations. The zone

controller requires 24 vac 25 va transformer to provide power

to the sensor.

sensor for

2

Before performing service or maintenance operations on

the system, turn off main power switches to the unit.

Electric shock can cause personal injury.

IMPORTANT: The CO2and space temperature sensor

should be wall-mounted in the occupied space to accurately measure the ventilation delivered to that zone.

Do NOT mount the sensor in the return air duct.

Table 3 — Performance Specification (P/N 33ZCT55CO2 and 33ZCT56CO2)

FEATURE SPECIFICATION

Sensing Method Single Beam Absor ption Infrared™

Sample Method Diffusion

Measurement Range 0to2000ppm

Sensitivity ± 20 ppm

Accuracy ± 100 ppm

Pressure Dependency 0.13% of reading per mmHg

Response Time 0 to 90% Step Change <2 minutes

Warm-Up Time at 77 F (25 C) <2 minutes

Operating Conditions 32 to 122 F (0° to 50 C)

Storage Temperatures –4 to +158 F (–20to70C)

Agency Certification FCC Part 15 Class B/CE/CA Energy Commission

Calibration/Interval Lifetime self-calibrating after 14 days of run time.*

Power 18-30 vac RMS, 50/60 Hz —halfwave rectified (dedicated)

Analog CO

Temperature Sensor 10 KΩ Thermistor, 10 KΩ ± 2.5% at 77 F (25 C)

Temperature Control (P/N 33ZCT56CO2 only) Equipped with a slide potentiometer.

Override Control Equipped with a push button that, when depressed, shorts out its internal thermistor.

Reliability Meets applicable Carrier reliability requirements

KΩ — Kilo-ohm (1000 ohms)

RH — Relative Humidity

RMS — Root Mean Square

TEMA — Time Extended Measurement

Output 4-20 mA (Rlmax = 500 Ohms) and 0-10 V(Source 100 mA, Sink 10 mA)

2

LEGEND *Automatic background calibration (ABC Logic™) is a patented self-

Patented TEMA self calibration software and 10K temperature sensor

60 to 90 F: 760 mmHg (15 to 32 C)

0to99% RH, non-condensing

18-42 VDC polarity protected (dedicated)

1.75 VA maximum average power

2.75 VA peak power

Positions Resistance

Left (Stop) 0 K(+5 K)

Right (Stop) 100 K±10 K

calibration procedure that is designed to be used in applications where

CO

concentrations will drop to outdoor ambient conditions (approxi-

2

mately 400 ppm) at least 3 times in a 14-day period (typically during

unoccupied periods).

21

Step 1 — Space Temperature Sensor Location

— The sensor

should be mounted:

• on an internal wall near a return air grille or duct

• at least 3 ft from any corner, 2 ft from an open doorway and

4 to 6 ft from the floor

• proximal to the wiring egress on the wall

• where temperature operating limits are 32 to 122 F

The sensor should NOT be mounted:

• close to a window, on an outside wall, or next to a door leading to the outside

• close to or in direct airflow of areas such as open windows,

drafts or over heat sources

• in areas with poor air circulation, such as behind a door or in

an alcove in areas where there are dramatic temperature

fluctuations or moisture accumulation

• where it is influenced by supply air as the sensor will give

an inaccurate reading

• where it may be exposed to direct occupant breathing, such

as near water coolers or coffee machines.

Step 2 — Mounting the Space Temperature Sensor

—The

sensor can be mounted on a surface, wall or in a junction box.

See Fig. 25-28.

NOTE: Before mounting the sensor, disassemble the sensor

into three parts. See Fig. 27.

Surface or Wall Mounting

1. Place the mounting plate on the wall. Mark the desired

location of the two mounting holes on the wall through

the holes in the mounting plate. See Fig. 25.

2. Pull the wires through the wire hole in the middle of the

mounting plate.

3. Drill two mounting holes in the wall in the location

marked in Step 1.

4. Mount the sensor mounting plate with two wood screws

and anchors (field-supplied).

Junction Box Mounting

1. Run wires through knockout in a 2x4in.junctionbox

(field-supplied).

2. Pull wires through the wire hole in the middle of the

mounting plate.

3. Secure the sensor mounting plate to the junction box

usingthetwo6x32machinescrews(included).

Step 3 — Wiring the Space Temperature Sensor

— Perform

the following procedure to wire the sensor:

1. Run the wall wiring through the wire hole in the sensor

base. See Fig. 26.

2. Align the top clips and secure the bottom clips of the

sensor base to the wall mount plate. See Fig. 27.

3. Gently rock the case from top to bottom, using minimal

pressure. A “snap” sound will indicate that the sensor is

secure. See Fig. 27.

4. Separate the wires into two bundles. One bundle should

contain the wires for the CO

sensor (J4 and J1) and the

2

other bundle should contain the wires for the temperature

sensor and CCN (J5 and J6). See Table 4 and Fig. 28.

5. Terminate the wires to J1, J4, J5, and J6. See Table 4 and

Fig. 28.

6. Push excess wire back through the hole. Align the sensor

top over the sensor base.

7. Install the cover on the sensor. Two Allen wrench locking

screws are provided to lock the cover onto the sensor for

security reasons. They are located on the bottom of the

cover. See Fig. 27.

Step 4 — Space Temperature Sensor Start-Up

— Perform the

following procedure to start up the sensor:

Once the installation is complete, apply power to the sensor.

A two-minute warm-up will take place. After two minutes, the

LED indicator light will be solid.

Measure and read the temperature and CO

sensor levels by

2

using a meter or checking the readings at the attached controller. Be sure the CO

maximum acceptable level in the range.

5.25”

levels are above the minimum, up to the

2

3”

Fig. 25 — CO2and Space Temperature Sensor

Mounting Plate

3”

3

2

5.25”

3

2

1

J5

OVERRIDE

B2

LEGEND

1—3-Pin Terminal Block — Signal Out

2—3-Pin Terminal Block — Temp Sensor

3—3-Pin Terminal Block — CCN

4—Wiring Access — 1.21 in. x .75 in.

5—2-Pin Terminal Block — Power In

6—RJ14 Connector — Service Communication

1

J4

J6

1

2

J3

Fig. 26 — CO2and Space Temperature

Sensor Base — Terminal Connections

22

MOUNTING

HOLE

WIRE HOLE

MOUNTING

HOLE

2

1

5

4

6

3

SENSOR

MOUNTING

PLATE

SENSOR

BASE

SENSOR

COVER

Fig. 27 — Sensor Assembly

ALLEN WRENCH

LOCKING SCREWS

(HIDDEN)

J1 J4

21 21

ISOLATED 24 VAC

OR 24 VDC

POWER SUPPLY

1

2

3 3

+

-

SHIELDED CABLE

GROUNDED AT

ONE LOCATION ONLY.

2

1

SHIELDED CABLE

GROUNDED AT

ONE LOCATION ONLY.

CCN (-)

CCN (GROUND)

CCN (+)

SETPOINT (T56)

COMMON

SENSOR

TO

TYPICAL

CARRIER

CONTROLLER

CO2

OUTPUT

4-20mA

GROUND

0-10 v

+

3

J6 J5

Fig. 28 — CO

and Space Temperature Sensors — Typical Field Wiring

2

(P/N 33ZCT55CO2, 33ZCT56CO2)

23

Table 4 — CO

and Space Temperature Sensors — Electrical Connections

2

(P/N 33ZCT55CO2, 33ZCT56CO2)

CONNECTOR TERMINAL DESIGNATION

J1 2-Pin Power Terminal

J3 RJ14 Connector

J4 3-Pin Terminal Signal Out

J5

J6

LEGEND

CCN — Carrier Comfort Network®

1—24VAC (+) (Dedicated Power Supply)

2—24VAC (–)(Dedicated Power Supply)

CCN Service Communication

1 — Not Used

2 — CCN (+)

3 — CCN Ground

4 — Not Used

5 — CCN (–)

6 — Not Used

1 — 4-20 mA CO

2 — Common CO2Output

3 — 0-10VDC CO

3-Pin Terminal Temp Sensor

1 — Thermistor

2—Common

3 — Temperature Offset

3-Pin Terminal CCN Communications

1 — CCN (–)

2 — CCN Ground

3 — CCN (+)

Output

2

Output

2

24

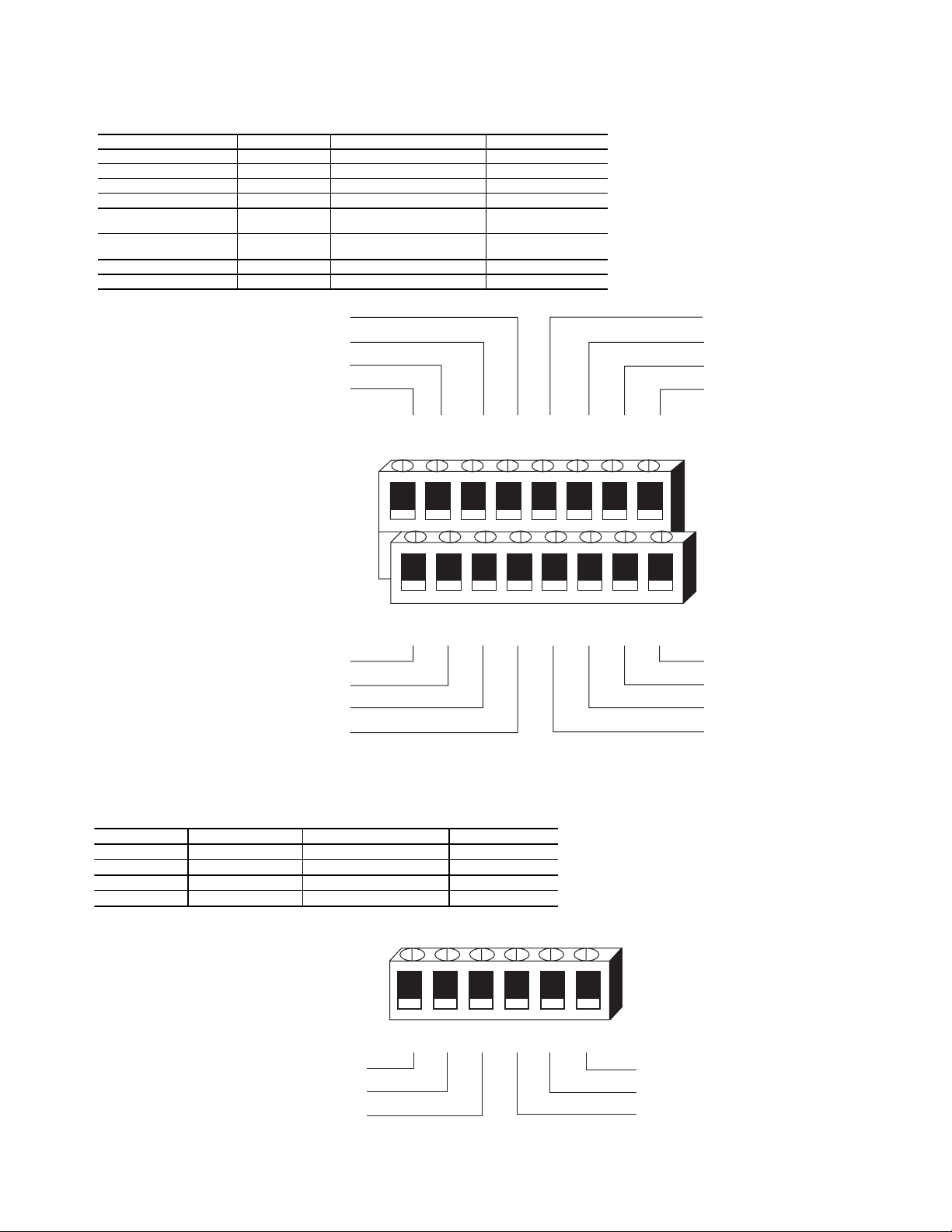

45XC Input and Output Connectors — The 45XC

zone controller inputs are shown in Fig. 29. Outputs (fan,

staged heat) are shown in Fig. 30. All available controller outputs are factory wired.

Inputs (J4)

CHANNEL J4 PINS (+,–) DESCRIPTION CONTROL DEVICE

SPT 4, 6 Space Temperature 10K Thermistor

SAT 6, 8 Supply Air Temperature 10K Thermistor

SP_OFFSET 10, 12 Set Point Offset Adjust 100K Pot en tiometer

PAT EM P 12, 14 Primary Air Temperature 10K Thermistor

RH/IAQ

DMPPOS

PRIFLO N/A Plenum Pressure Sensor 0-5 VDC

REMTCIN 2 (24 VAC),6(–) Unoccupied Override Input 0/24 VAC

PRIMARY DAMPER POSITION

16 (24 VDC),

15 (+),13(–)

9(10 VDC)

7 (W+),5(–)

GROUND

PLENUM PRESSURE

GROUND

RH/IAQ Sensor 2-10 VDC

Damper Position 0-10 VDC

5

3

1

9

7

11 13

LEGEND

IAQ — Indoor Air Quality

PAT EM P — Primary Air Temperature

RH — Relative Humidity

SAT — Supply-Air Temperature

SP — Set Point

SPT — Space Temperature

NOTE: The 24 v connection (J4-16) is required for

RH sensor only.

+10 VDC SUPPLY

NOT USED

GROUND

RH/IAQ

15

J4

2

46

REMTCIN/24 VAC

PATEMP

GROUND

T56 SETPOINT OFFSET

8

Fig. 29 — 45XC Input Connectors

Outputs (J5)*

CHANNEL J5 TERMINATIONS DESCRIPTION CONTROL DEVICE

DMPR_CCW 1, 2 Primary Damper CCW 24 VAC, 1A

DMPR_CW 2, 3 Primary Damper CW 24 VAC, 1A

HEAT_ST1 4, 5 Fan 1 (Increase) 24 VAC, 1A

HEAT_ST2 5, 6 Fan 1 (Decrease) 24 VAC, 1A

J5

PRIMARY DAMPER

ACTUATOR (OPEN)

PRIMARY DAMPER

ACTUATOR (CLOSED)

GROUND

1

2

34

Fig. 30 — 45XC Output Connectors

10

12 14

LEGEND

CCW — Counterclockwise

CW — Clockwise

* All outputs are factory wired.

6

5

HEAT CLOSE/

STAGE 2

COMMON (24VAC)

16

HEAT OPEN/

STAGE 1

+24VDC SUPPLY

SPT

GROUND

SAT

25

Connect to the CCN Communication Bus —

All controllers connect to the bus in a daisy chain arrangement.

The zone controller may be installed on a primary CCN bus or

on a secondary bus from the primary CCN bus. Connecting to

a secondary bus is recommended.

At any baud (9600, 19200, 38400 baud), the number of

controllers is limited to 239 zones maximum. When Carrier

linkage thermostats are used on the same bus as fan coil units,

no more than 128 fan coils and 12 linkage thermostats may be

on the same bus. Bus length may not exceed 4000 ft, with no

more than 60 total devices on any 1000 ft section. Optically

isolated RS-485 repeaters are required every 1000 ft.

NOTE: Carrier thermostats operate at 9600 band.

The first zone controller in a network connects directly to

the bridge and the others are wired sequentially in a daisy chain

fashion. Refer to Fig. 20 for an illustration of CCN communication bus wiring.

The CCN communication bus may also connect to the zone

controller space temperature sensor. Refer to the 45XC Sensor

Installation section for sensor wiring instructions.

COMMUNICATION BUS WIRE SPECIFICATIONS —

The CCN Communication Bus wiring is field-supplied and

field-installed. It consists of shielded three-conductor cable

with drain (ground) wire. The cable selected must be identical

to the CCN Communication Bus wire used for the entire network. See Table 5 for recommended cable.

Table 5 — Recommended Cables

MANUFACTURER CABLE PART NO.

Alpha 2413 or 5463

American A22503

Belden 8772

Columbia 02525

NOTE: Conductors and drain wire must be at least 20 AWG

(American Wire Gage), stranded, and tinned copper. Individual conductors must be insulated with PVC, PVC/nylon, vinyl, Teflon, or

polyethylene. An aluminum/polyester 100% foil shield and an outer

jacket of PVC, PVC/nylon, chrome vinyl, or Teflon with a minimum

operating temperature range of –20 Cto60 Cisrequired.

CONNECTION TO THE COMMUNICATION BUS

1. Strip the ends of the red, white, and black conductors of

the communication bus cable.

2. Connect one end of the communication bus cable to the

bridge communication port labeled COMM2 (if connecting on a secondary bus).

When connecting the communication bus cable, a color

code system for the entire network is recommended to

simplify installation and checkout. See Table 6 for the

recommended color code.

Table 6 — Color Code Recommendations

SIGNAL TYPE

+ Red 1

Ground White 2

– Black 3

CCN BUS WIRE

COLOR

3. Connect the other end of the communication bus cable to

the terminal block labeled CCN in the zone controller of

the first air terminal. Following the color code in Table 6,

PLUG PIN

NUMBER

connect the Red (+) wire to Terminal 1. Connect the

White (ground) wire to Terminal 2. Connect the Black (–)

wire to Terminal 3.

4. Connect additional zone controllers in a daisy chain fashion, following the color coded wiring scheme in Table 6.

Refer to Fig. 20.

NOTE: The communication bus drain wires (shield) must be

tied together at each zone controller. If the communication bus

is entirely within one building, the resulting continuous shield

must be connected to ground at only one single point. If the

communication bus cable exits from one building and enters

another building, connect the shields to ground at a lightning

suppressor in each building where the cable enters or exits (one

point only).

Connect Air Pressure Tubing

CONTROL PACKAGE 4840 — The underfloor controller

measures the pressure differential between the plenum high

and the occupied space low. See Fig. 1. The field-supplied and

field-installed piping are connected to barb fittings on the

underfloor controller with

tubing. All piping for this purpose must be plenum rated and

must conform to local codes.

Figure 15A indicates the positions of the two barb fittings.

Perform the following steps to install and connect the air

pressure tubing:

1. Select a location where the airflow tube will be installed.

The location should be one that is away from the unit’s

discharge into the plenum and halfway between that point

and the farthest diffuser. If this requirement is not met,

stable airflow measurements may not be possible.

2. Mount the tubing in the plenum securely.

3. Use field-supplied

to connect the high pressure airflow pickup to barb fitting

P1 on the pressure transducer. At the underfloor controller, be careful to avoid sharp bends in the tubing, because

malfunctions may occur if the tubing is bent too sharply.

Use at least 2 ft of tubing for reading stability.

4. Use field-supplied

to connect the low pressure fitting P2 on the pressure

transducer to the occupied space. Be careful to avoid sharp

bends in the tubing because malfunctions may occur if the

tubing is bent too sharply. Use at least 2 ft of tubing for

stability.

5. The

3

/8-in. OD tubing is limited to 25 ft maximum length

for accurate measurement and response. For lengths up to

50 ft, use

1

/4-in. OD tubing. Do not exceed 50 ft tube

lengths for either the low or high pressure connections.

CONTROL PACKAGE 4841 (Fig. 31) — Locate the airflow probe as shown in Fig. 15B. Perform the following steps

to install and connect the air pressure tubing:

1. Drill a rectangular shaped hole in the ductwork.

2. Securely mount the airflow probe with the high pressure

side (black and red tubing) facing into the airflow from

the 45XC terminal.

3. The probe is supplied with 10 ft of tubing from the

factory. If required, it may be extended up to 25 ft using

field-supplied

1

/4-in. flame retardant polyethylene

1

/4-in. tubing (rated for the application)

1

/4-in. tubing (rated for the application)

1

/4in. OD, flame retardant tubing.

26

AIR FROM 45XC

DISCHARGE

LEGEND

— Velocity Pressure

V

P

NOTE: Supply Duct View rotated to show component location.

Fig. 31 — Component Installation (Control Package 4841)

PLENUM

TEMPERATURE

SENSOR

24 in.

Size 04 - 34 in.

Size 07 - 46 in.

Size 04 - 42 in.

Size 07 - 54 in.

AIR INTO

PLENUM

CENTERLINE

LOW Vp PRESSURE

HIGH Vp PROBE

(Facing into Airflow)

NOTE - Supply Duct View

rotated to show component location

45UC UNDERFLOOR SERIES

FAN-POWERED TERMINAL INSTALLATION

Physical components of the 45UC underfloor series fanpowered terminal is detailed in Fig. 32. Figure 33 shows 45UC

underfloor terminal unit dimensions and weight data.

45UC Hardware — The 45UC underfloor fan-powered

unit contains the 33ZCFANTRM underfloor controller.

Figure 34 shows the underfloor controller physical details.

45UC Field-Supplied Hardware — Each 45UC un-

derfloor fan-powered unit requires the following field-supplied

components to complete its installation:

• transformer — 24 vac, 40 va (standard applications)

• contactors (as required for electric heat)

• space temperature sensor (33ZCT55SPT, 33ZCT56SPT, or

33ZCT57SPT)

• supply-air temperature sensor (33ZCSENSAT) with two

no. 10 x

supply duct)

• primary-air temperature sensor

• changeover sensor (required for 2-pipe applications)

• indoor-air quality (CO

• relative humidity sensor (optional)

• valve and actuator for hot water heat (optional)

SPACE TEMPERATURE SENSOR (Fig. 8) — Each under-

floor controller requires a field-supplied Carrier space

temperature sensor. There are three sensors available for this

application:

• 33ZCT55SPT, space temperature sensor with override

button

• 33ZCT56SPT, space temperature sensor with override

button and set point adjustment

1

/2-in. sheet metal screws (to secure SAT sensor to

) sensor (optional)

2

• 33ZCT57SPT, space temperature sensor with override

button, set point adjustment, and manual fan speed control

SUPPLY-AIR TEMPERATURE (SAT) Sensor (Fig. 9) — The

underfloor controller must be connected to a field-supplied

supply air temperature (SAT) sensor (P/N 33ZCSENSAT) to

monitor the temperature of the air delivered by the fan coil.

PRIMARY-AIR TEMPERATURE SENSOR (PAT) (Optional) —

A field-supplied, primary air temperature (PAT) sensor (P/N

33ZCSENPAT) is used on an underfloor controller that is functioning as a linkage master for a non CCN/linkage compatible air

source. See Fig. 10.

INDOOR-AIR QUALITY (CO

) SENSOR (Fig. 11) —

2

An indoor air quality sensor is required for indoor air quality

monitoring. Three different CO

level monitoring.

CO

2

sensors are available for zone

2

• The 33ZCSENCO2 sensor is an indoor, wall-mounted

sensor with an LED (light-emitting diode) display.

• The 33ZCT55CO2 sensor is an indoor, wall-mounted

sensor without display. The CO

sensor also includes a

2

space temperature sensor with override button.

• The 33ZCT56CO2 sensor is an indoor, wall-mounted

sensor without display. The CO

space temperature sensor with override button and tempera-

sensor also includes a

2

ture offset.

RELATIVE HUMIDITY SENSOR (Fig. 12) — The relative humidity sensor (P/N 33AMSENRHS000) is an indoor,

wall-mounted sensor and is required for zone humidity control

(dehumidification).

CHANGEOVER SENSOR — The underfloor controller uses

the changeover sensor (33ZCSENCHG) in 2-pipe applications

to determine if it is capable of providing heating or cooling to

the space based on the temperature of the heating and cooling

medium supplied to the unit from the building piping system.

This value may be broadcast to other units.

27

Fig. 32 — 45UC Series Fan-Powered Underfloor Unit Physical Detail

C

3

1

4

7

45UC

UNIT SIZE

7

6

8

8

1

2

2

1

2

2

INLET SIZE

(in.)

W

8

4

HI-VOLTAGE

CONTROL ENCLOSURE

Base

Unit

21

16

WEIGHT (lb)

With Hot Water Coil

1-Row 2-Row

L

6

OPTIONAL FILTER &

ACCESS DOOR

3 9 120 132 136 150

4

9 128 140 146 158

10 128 140 146 158

B

16

With Electric Heat

E

3

1/4 " TURN FASTENER

A

LO-VOLTAGE

CONTROL ENCLOSURE

INDUCED

AIR INLET

3

8

D

H

PRIMARY AIR INLET

WITH AeroCross

MULTIPOINT CENTER

AVERAGING FLOW

SENSOR

F

G

™

45UC

UNIT SIZE

INLET SIZE

ABCDE FGHLW