Product

Data

AIRSTREAM™

42BHC,BVC

System Fan Coils

600to4000Cfm

Carrier’s versatile belted fan coil units

satisfy design requirements:

• A selection of 8 sizes covers

capacities from 600 to 4000 cfm

• Choice of motors, from

eliminates oversizing

• Wide range of coil options for 2-pipe

or 4-pipe systems

• Optional DX coils with expansion

valve and distributor

• Single and three-phase electric

heat (1.0 to 40 kW)

1

/4to 5 hp,

42BHC UNIT

Features/Benefits

The 42BHC, BVC belt drive

fan coil units provide yearround comfort air

conditioning with central

station operating economy.

A variety of coil options

reduces first cost

Four, 6 or 8-row cooling coils combine

needed capacities with the most efficient heat transfer surface. For

4-pipe systems, select either of two

split-coil options. Coils consist of aluminum fins securely bonded to

OD seamless copper tubes. Each fin’s

aluminum collar ensures accurate control of the fin spacing, while completely covering the tubes to lengthen coil

life. All coils also feature manual air

vents, with automatic air vent available

as an option.

1

/2-in.

42BVC UNIT

Copyright 2005 Carrier Corporation Form 42B-1PD

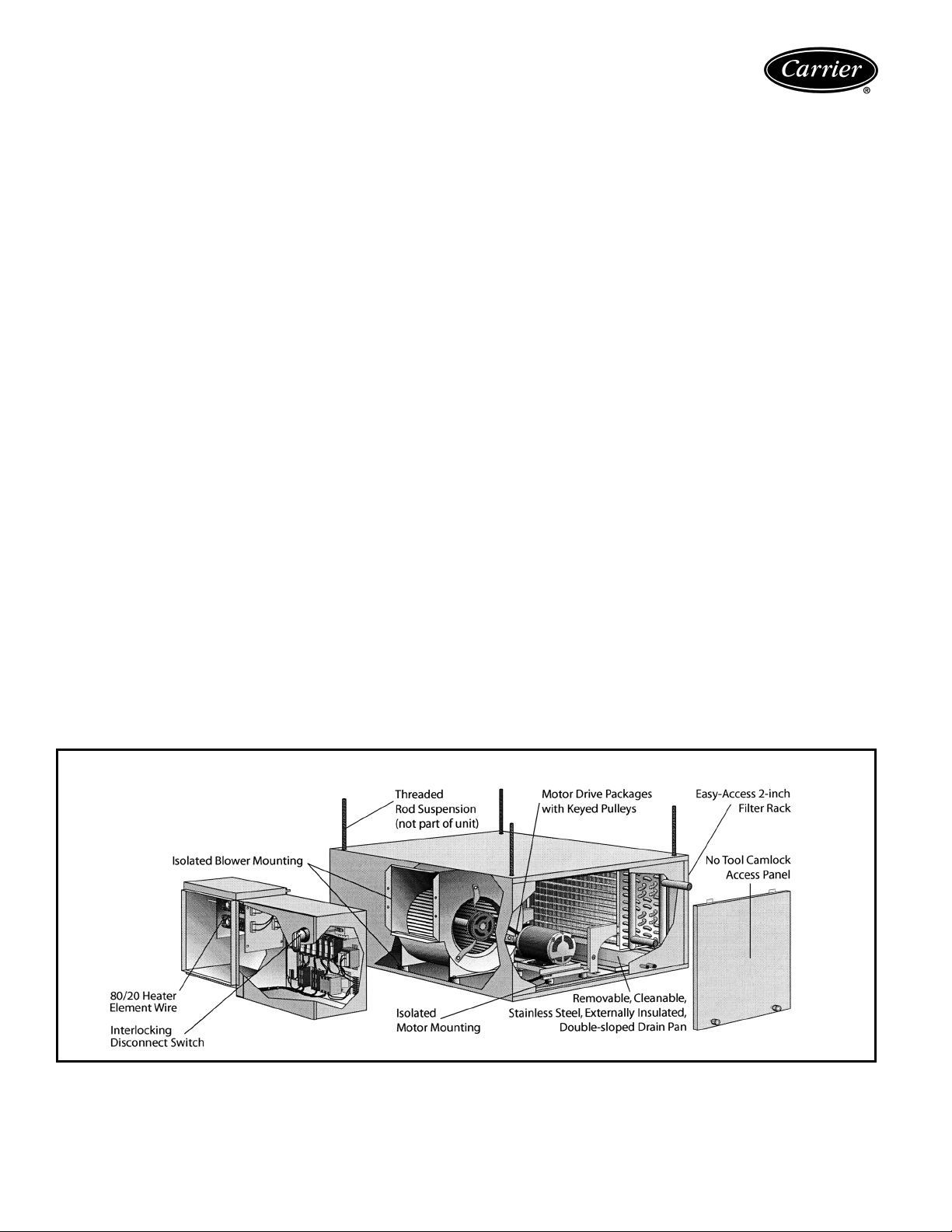

Fan wheels are designed to

provide low operating costs

The forward-curved, centrifugal,

double-inlet fans are statically and

dynamically balanced at the factory to

minimize transmission of vibration

to the building structure.

The belt-driven motor (single or

three phase) has a variable-pitch pulley

which adjusts at the jobsite to accommodate limited ranges of air quantities

and pressures.

All motors (single and three phase)

are UL listed, factory wired, single

speed with thermal overload protection and are continuous duty rated.

Motors are supplied with permanently

lubricated bearings, class-B insulation

and are open drip-proof. The motor

mount has an adjustable platform for

easy belt adjustment. The motor and

its mounting are independently isolated

from the cabinet and the blower. An

adjustable pitch pulley allows cfm balancing to meet system requirements.

Motor drive packages are provided

with keyed pulleys.

Complete factory assembly

minimizes on-the-jobsite costs

and problems

Compact, lightweight units are designed

for easy mounting. Knockouts designed

to accept

3

/8-in. threaded rods are

provided on the top and bottom of each

corner of the unit One-in. duct collars

on discharge and on return are furnished standard. These integral duct

collars cut installation time and labor

expense.

Durable construction means

easy-to-maintain units

The 42BHC,BVC fan coils casings are

fabricated from heavy-gage galvanized

G90 steel, reinforced for maximum

rigidity and structural strength. Removable side panels with tool-less camlock

fasteners allow easy access for servicing interior components.

One-inch matte surface, fiberglass

thermal/acoustical insulation lines the

fan coil cabinets to prevent sweating

and to muffle sound transmission.

The stainless steel, double-sloped

condensate drain pan extends under

full coil surface to cut maintenance

costs.

Slide-in return-duct collar filter

makes it possible to remove and

replace the filter without disturbing

return air ductwork.

Table of contents

Page

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-18

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-21

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-33

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-36

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39,40

INTERNAL FEATURES OF A 42BHC FAN COIL UNIT

2

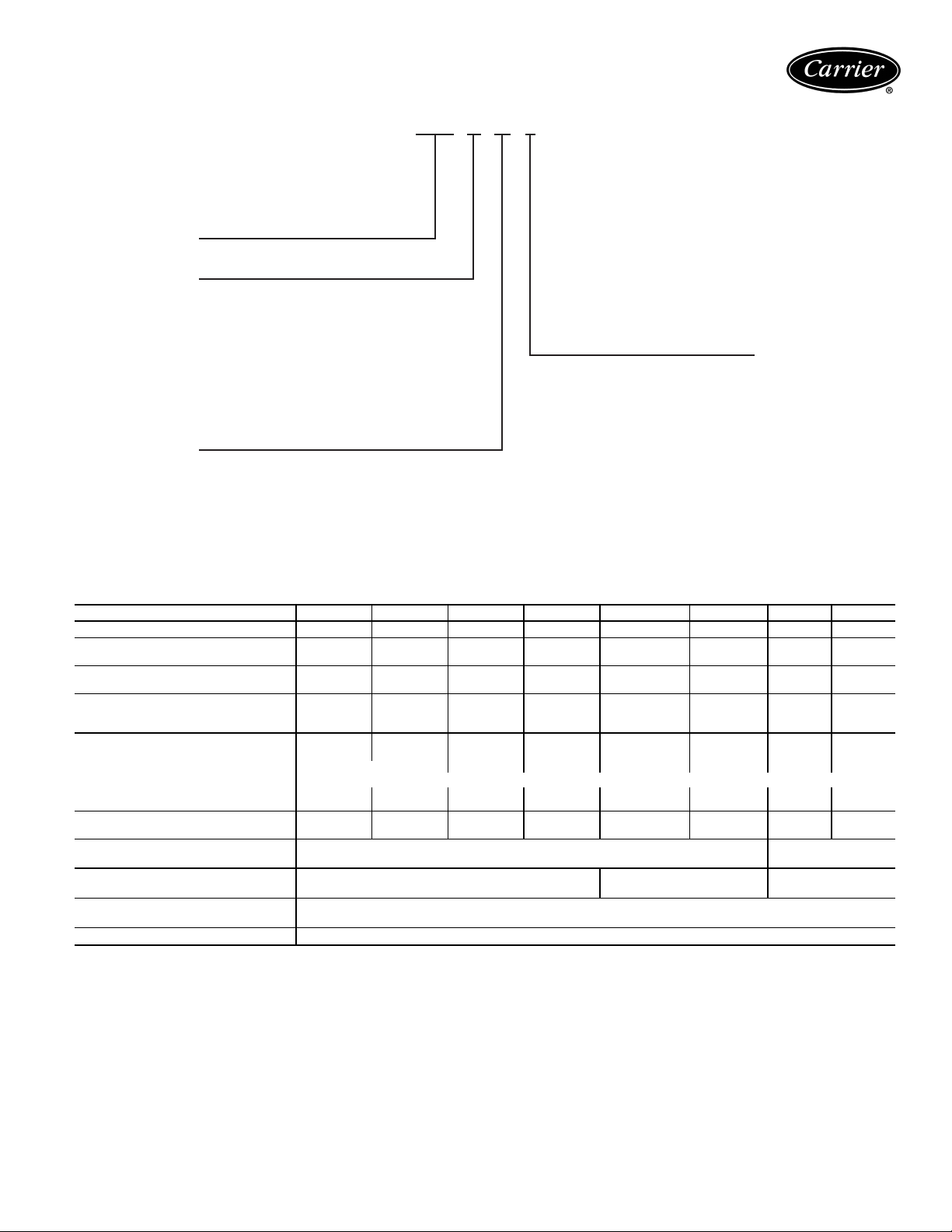

Model number nomenclature

42BH C 08 L

42BH — Vertical Belt Drive Fan Coil Unit

42BV — Vertical Belt Drive Fan Coil Unit

C — Design

Coil —

Rows

B — 4, 2-Pipe

6, 2-Pipe

L —

H — 4/1, Same End Conn.

K — 4/2, Same End Conn.

N — 6/1, Same End Conn.

Q — 6/2, Same End Conn.

R — 8, 2-Pipe

1 — 4 With Electric Heat

Size — Nominal

—

06

600

—

08

800

—

1000

10

12 — 1200

Cfm

2 — 6 With Electric Heat

3 — 8 With Electric Heat

16 — 1600

20 — 2000

30 — 3000

40 — 4000

NOTE: Refer to current 42 Series Master Prices for

complete model definition, including motor, cfm and

total static pressure.

Physical data

UNIT SIZE 42BHC, BVC 06 08 10 12 16 20 30 40

NOMINAL CFM 600 800 1000 1200 1600 2000 3000 4000

42BHC SHIPPING WT (lb)

(no heat/ with heat)

42BVC SHIPPING WT (lb)

(no heat/ with heat)

FILTERS (2 in. pleated)

Number...Size (in.) 1...16

Face Area (sq ft) 2.8 2.8 4.2 4.2 5.5 6.3 8.9 11.7

COILS

Size (in.) 15 x 20 15 x 20 15 x 29 15 x 29 15 x 39 18 x 40 27 x 40 27 x 54

Face Area (sq ft) 2.1 2.1 3.0 3.0 4.1 4.9 7.7 10.3

Fins per inch

Coil Water Weight (approx. lb per

row of coil)

FANS

Number...Size (in.) 1...9 x 4 1...9 x 6 1...10 x 4 1...10 x 7 1...11 x 10 1...12 x 9 1...12 x 12 1...15 x 12

COPPER COIL CONN. 8 ROW

(in.) (Cooling)

COPPER COIL CONN. 4 AND 6 ROW

(in.) (Cooling)

COPPER COIL CONN. 1 AND 2 ROW

(in.) (Heating)

DRAIN CONN. SIZES (in.)

203/234 205/236 253/287 256/290 312/346 344/380 437/474 553/590

200/231 202/233 243/277 247/281 289/323 351/387 436/473 522/559

1

/2x 24 1...161/2x 24 1...181/4x 33 1...181/4x 33 2...181/4x211/22...203/4x 22 2...29 x 22 2...29 x 29

10

0.240 0.240 0.324 0.324 0.420 0.492 0.768 1.020

1OD 1

3

/4OD 1 OD 11/2OD

1

/2OD

3

/4MPT

1

/2OD

3

Options and accessories

42BHC, BVC OPTIONS AND ACCESSORIES

ITEM OPTION* ACCESSORY†

Automatic Air Vents X

Controls X

Electric Heat X

Filters X

Heating/Cooling Coils X

Insulation X

Mixing Boxes X

Motors X

Thermostats X

Valve Packages X

*Factory-installed option.

†Field-installed accessory.

The 42BHC and 42BVC fan coil units are designed to

offer maximum flexibility in an application, accessibility for

service, quiet operation and durability.

Factory-installed options

Automatic air vents — Automatic air vents have fiber-

washers, which allow air in the pipes to pass through,

automatically bleeding the system. The fiber washers eliminate the need to manually remove air from the system.

When wet, washers swell and seal the system.

Coils — Coils are available in a choice of two-pipe system

with 4-row cooling/heating or four-pipe system with 4, 6

or 8-row cooling and 1 or 2 row heating.

Reheat operation is standard. Preheat is available as an

option.

Controls

• Interlocking disconnect switch

• Heater power fusing

• 24 v Class 2 transformer (40 va)

• 8-pole control terminal strip

• Auto reset temperature limit switch

• Airflow safety switch

• Motor power fusing

• Motor control contactor

• 24 v condensate overflow switch

Electric heat — Total electric heat eliminates the require-

ment for a boiler. Heating and/or cooling may be available

on an individual basis throughout the year. Resistance

electric heat is available from 1.0 kW to 40.0 kW (refer to

electric heater data table for availability per unit) with

single-stage or multiple-stage, single power source.

Voltages:

• 115 v, 208 v, 230 v and 277 v single-phase 60 Hz

• 208 v, 230 v and 480 v three-phase 60 Hz

Electric heat is available with the following staging options

(3-phase staging is balanced).

• 1 to 12 kW 1 stage only — single phase

• 3 to 12 kW 1 or 2 stage only — single phase

• 1 to 40 kW 1 stage only — 3 phase

• 4 to 40 kW 1 or 2 stage only — 3 phase

• 12 to 40 kW 1, 2, or 3 stage — 3 phase

Heater coils are constructed of high-grade resistance

wire that is supported by ceramic insulators on plated steel

brackets. These heat elements are suspended directly in

front of the outlet after the blower and the coil. High limit

thermal cutouts protect the heater in the event of air

failure.

Filters — Two in. pleated filters are standard. One-in.

pleated, two 1-in. throwaway, or 2-in. MERV (minimum

efficiency reporting value) 11 filters with 2-in. pleated

pre-filter are available. The 2-in. MERV 11 filters with 2-in.

pleated pre-filter include a filter rack.

Insulation — Tuf-Skin™ II (1-in. thick) insulation is

standard. Units are available with ¾-in. closed cell, 1-in.

Tuf-Skin Rx™ edge sealed, or 1-in. foil-faced insulation.

Motors — A wide selection of standard motors provides

efficient operation in ducted applications with excellent

performance with up to 2 inches of total static pressure.

Available motor options:

• 115 v, 208 v, 230 v and 277 v single-phase 60 Hz

• 208 v, 230 v and 460 v three-phase 60 Hz

• Open drip-proof motors

• External junction box

Field-installed accessories

Mixing boxes — Mixing boxes can be used when outside

air is required for ventilation. Preassembled at the factory

and shipped separately with base rails for field installation,

mixing boxes include a linkage kit consisting of two crank

arms, 2 swivels and either a 25 in. long (for sizes 06-16) or

a 84 in. long (for sizes 20-40) rod for field installation of an

actuator.

4

Thermostats — Three thermostats are available for field

installation:

Honeywell T834C manual changeover, single-stage heat

thermostat features:

• off-cool-heat system switch

• on-auto fan mode switch

• single-stage electric heat

• outside air signal

Honeywell T8500 digital, automatic/manual changeover,

2-stage heat thermostat features:

• digital display of temperatures and all functions

• off-cool-heat-auto system mode buttons

• single speed fan operation

• on-auto fan mode button

• single or two stage electric heat signal

• outside air signal

• remote temperature sensor available

Sunne T170 single-stage heat, 2-pipe heat/cool auto

changeover thermostat features:

• digital display of ambient temperature and operating

mode

• single fan speed operation, power and operating mode

buttons

• continuous fan operation, cycling water control valve

• 4-pipe ACO/MCO (automatic changeover/manual

changeover) with “on-auto” fan mode button

• one or 2 stage electric heat signal available

• purge cycle and temperature sensor for 2-pipe cold

water/hot water systems

• programmable operating range, dead band, digital display, temperature set-back

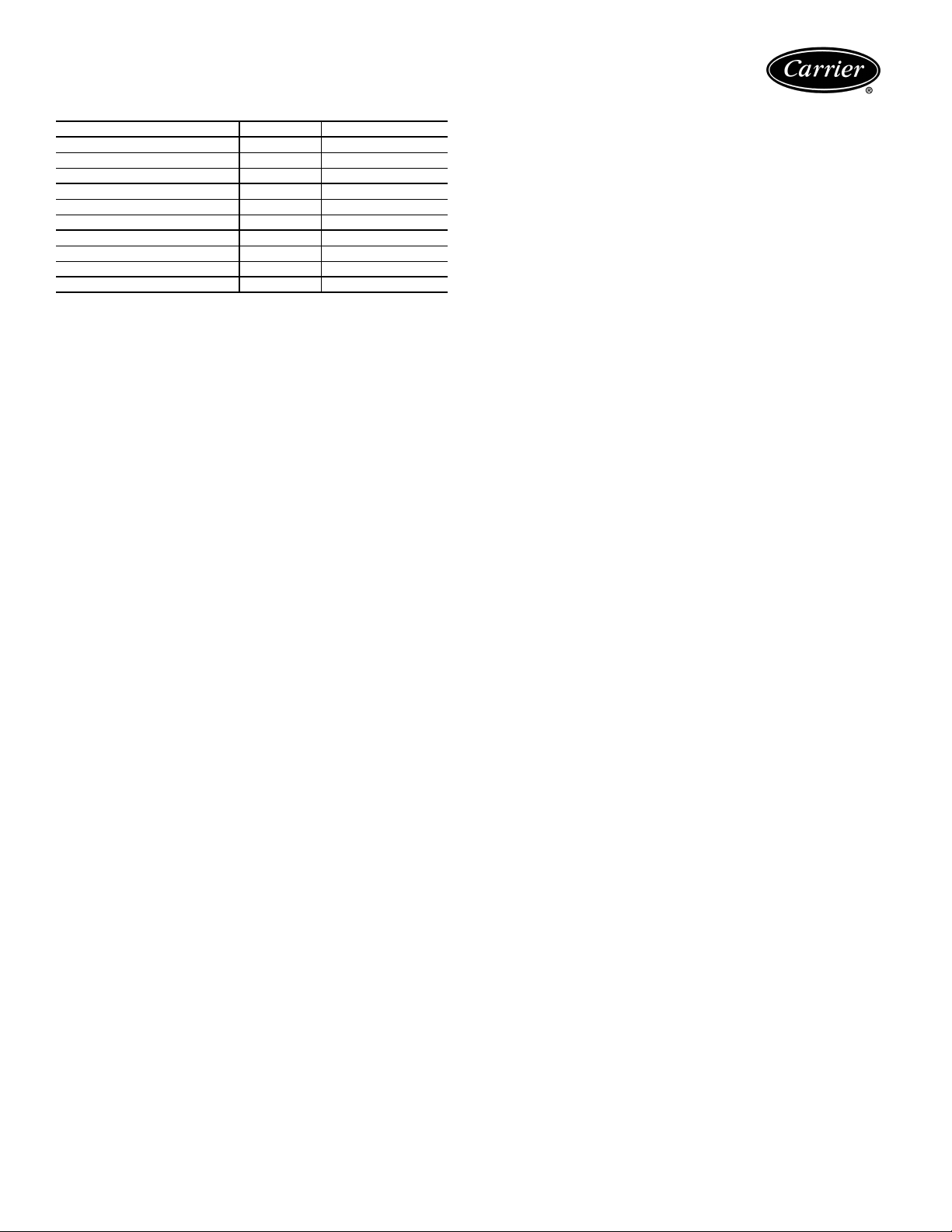

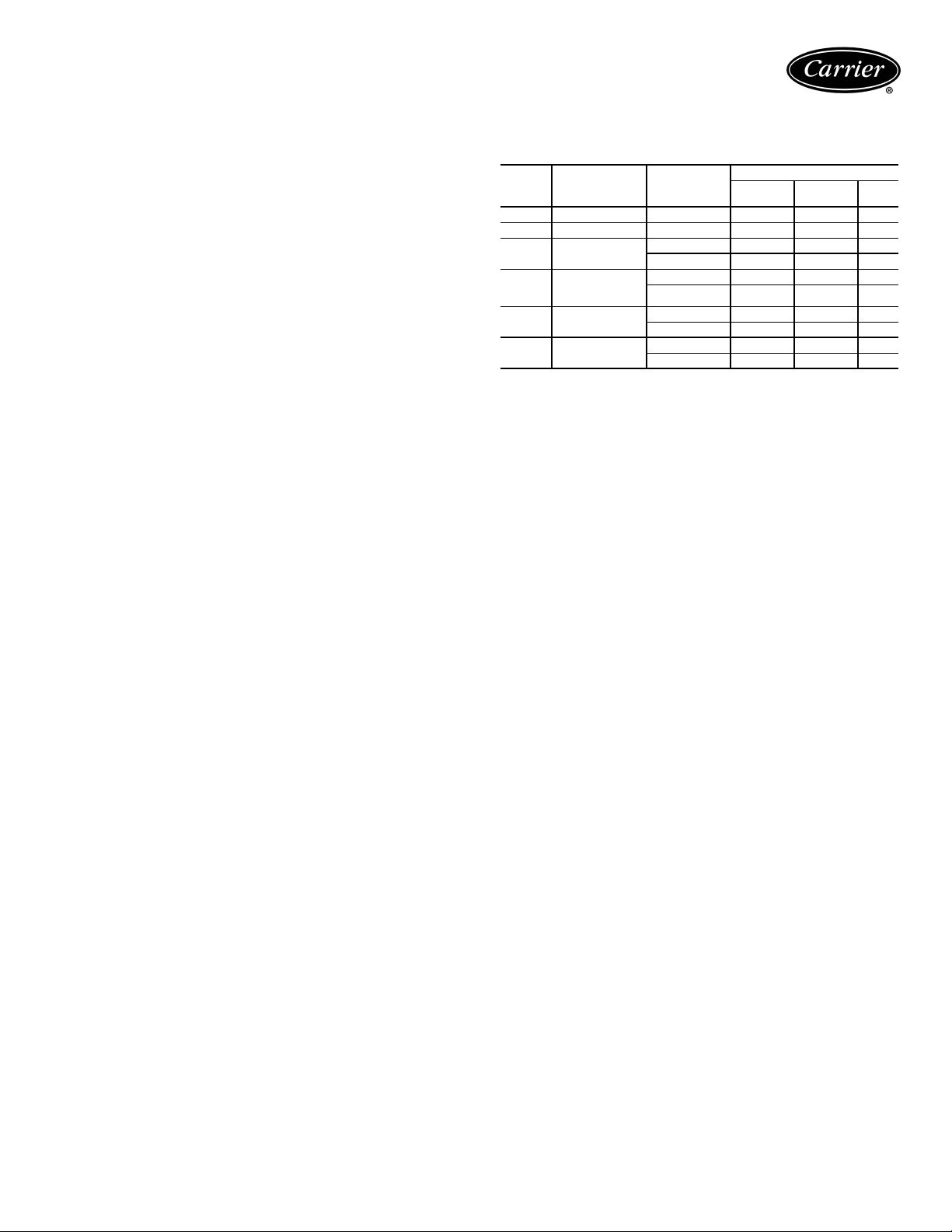

THERMOSTAT FUNCTIONS

SYSTEM FUNCTION CHANGEOVER

2Pipe HW-Heat Only ACO — XX

2 Pipe CW-Cool Only ACO — XX

2Pipe

2Pipe

2Pipe

4Pipe

ACO — Automatic Changeover

Aux — Auxiliary

CW — Chilled Water

HW — Hot Water

MCO — Manual Changeover

CW/HW

Heat/Cool

CW/HW

Heat/Cool with

Aux. Electric Heat

CW-Cooling with

To t al Electric Heat

CW/HW

Heat/Cool

LEGEND

MCO ——X

ACO ——X

MCO ——X

ACO ——X

MCO X X X

ACO — XX

MCO X X X

ACO — XX

THERMOSTATS

Honeywell

T834C

Honeywell

T8500

Sunne

T170

Valve packages — Valve packages are factory assembled

for field installation. Motorized valves (24 v) can be operated with power on with spring return or power off/power

on.

It is recommended that basic motor controls are ordered

when valve packages are ordered.

5

Base unit dimensions

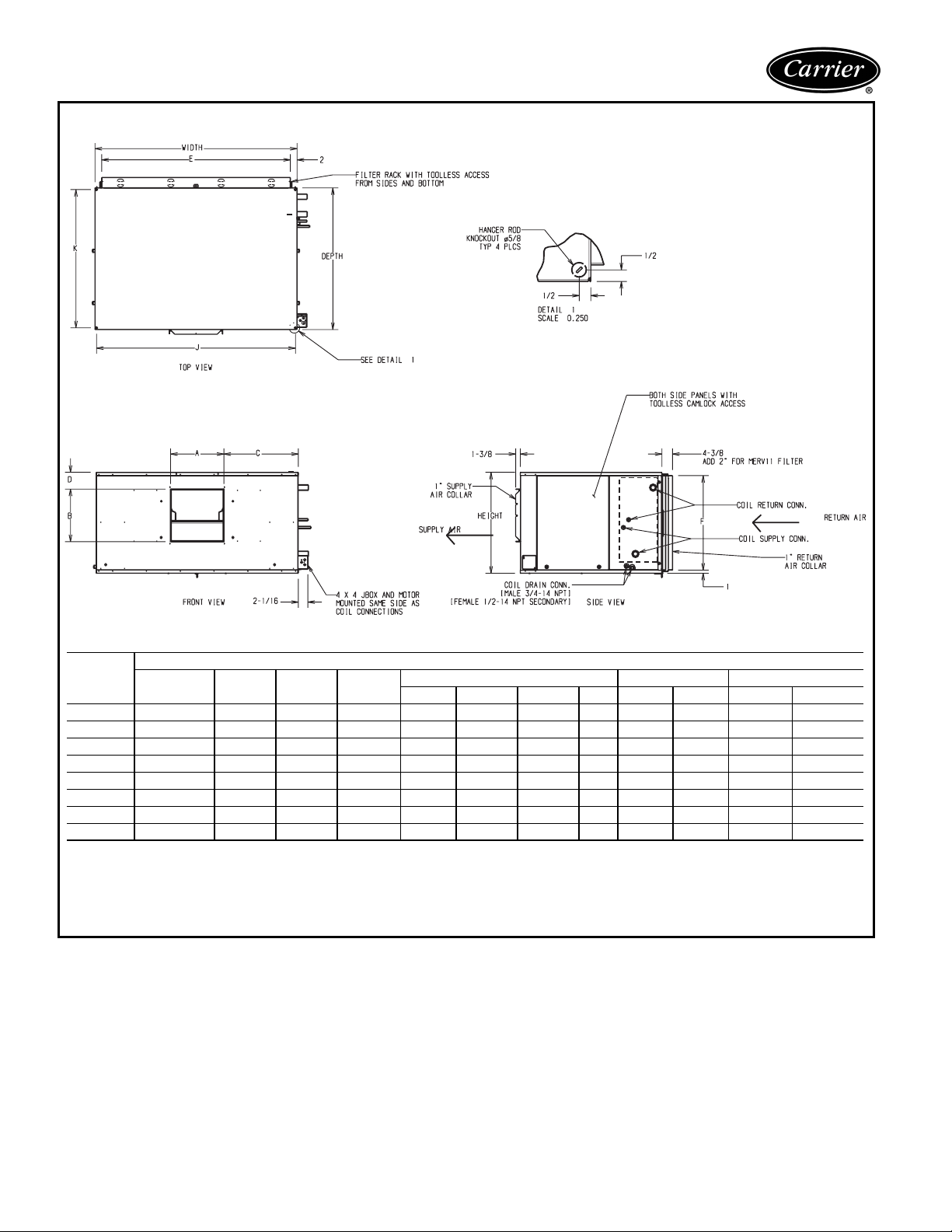

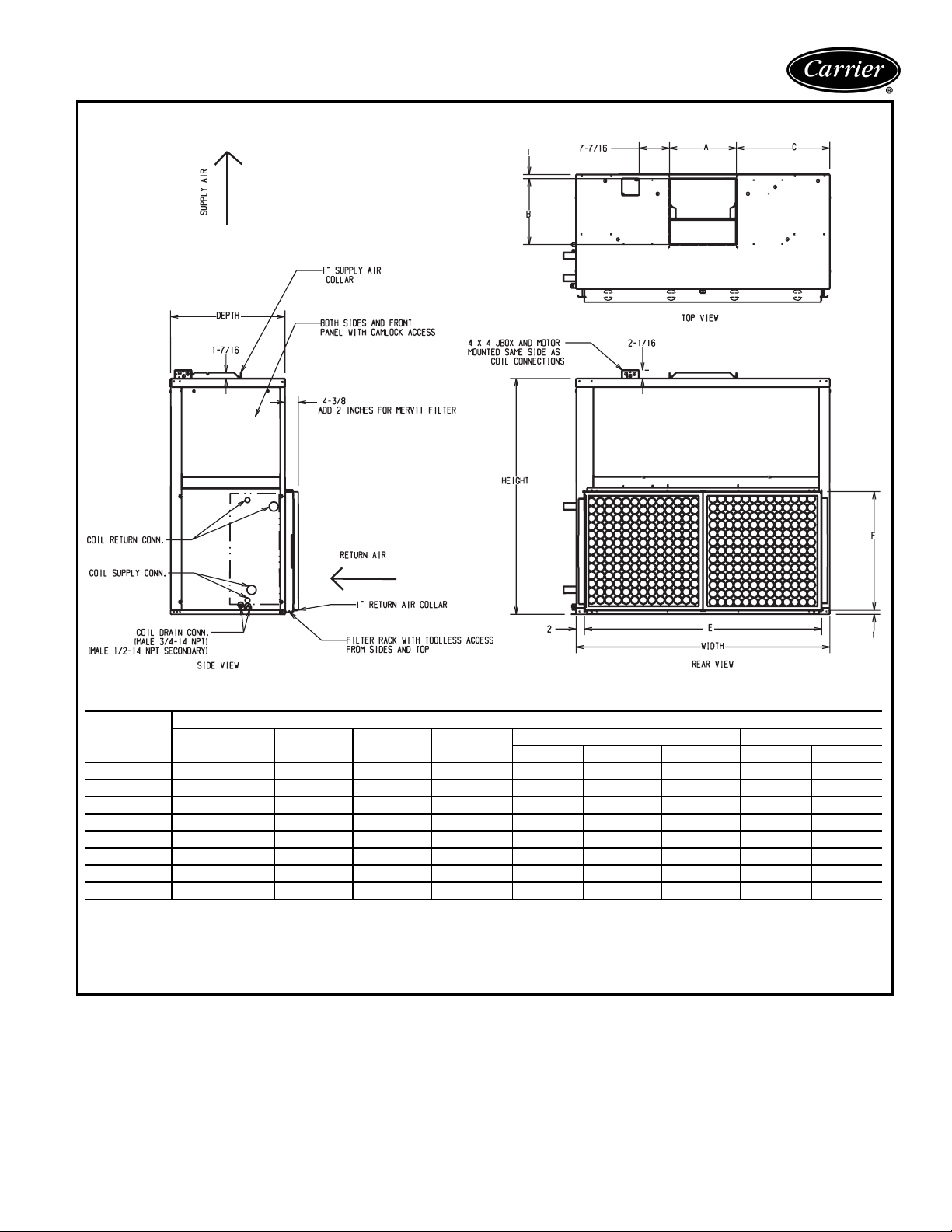

42BHC FAN COIL BASE UNIT (NO CONTROLS)

UNIT

42BHC

06 9x 4 36

08 9x 6 363/

10 10 x 4 373/

12 10 x 7 373/

16 11 x 10 3715/

20 12 x 9 40

30 12 x 12 403/

40 15 x 12 439/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

Fan Size Depth Width Height

3

/

2811/

16

2811/

16

371/

4

371/

4

471/

16

3

/

481/

8

481/

8

621/

16

1

/4in.).

16

16

16

16

16

16

16

16

181/

2

181/

2

201/

4

201/

4

201/

4

223/

4

31 157/

31 167/

DIMENSIONS (in.)

Supply Duct Return Duct Mounting Holes

AB CDEF J K

71/

89/

71/

915/161111/

135/

121/

109/

8

109/

16

1111/

2

1211/

16

133/

2

133/

8

161/

16

137/

16

137/

16

137/

16

137/

16

1613/

16

173/

4

161/

4

2213/

16

8

8

8

8

16

4

16

16

11/8241/

11/8241/

11/8331/

11/8331/

11/8431/

11/8441/

61/8441/

51/8581/

167/

16

167/

16

183/

16

183/

16

183/

16

2011/

16

2815/

16

2815/

16

273/

16

273/

16

363/

16

363/

16

463/

16

473/

16

473/

16

613/

16

351/

16

16

16

16

16

16

16

16

351/

3613/

3613/

37

397/

397/

425/

4

4

16

16

8

change without notice.

3. Right hand shown, left hand opposite.

4. Hanger rods, which are field-supplied, are shown for reference only.

16

16

6

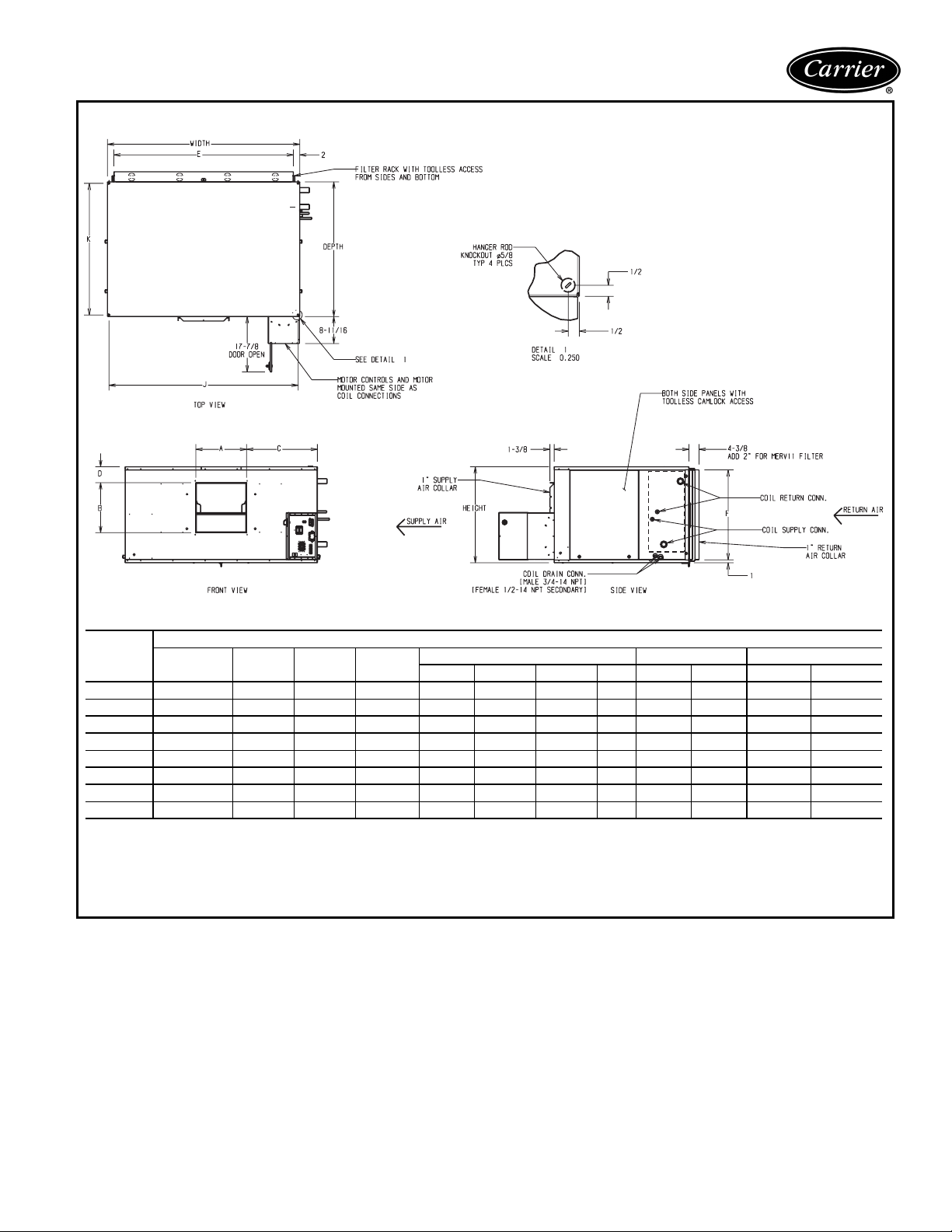

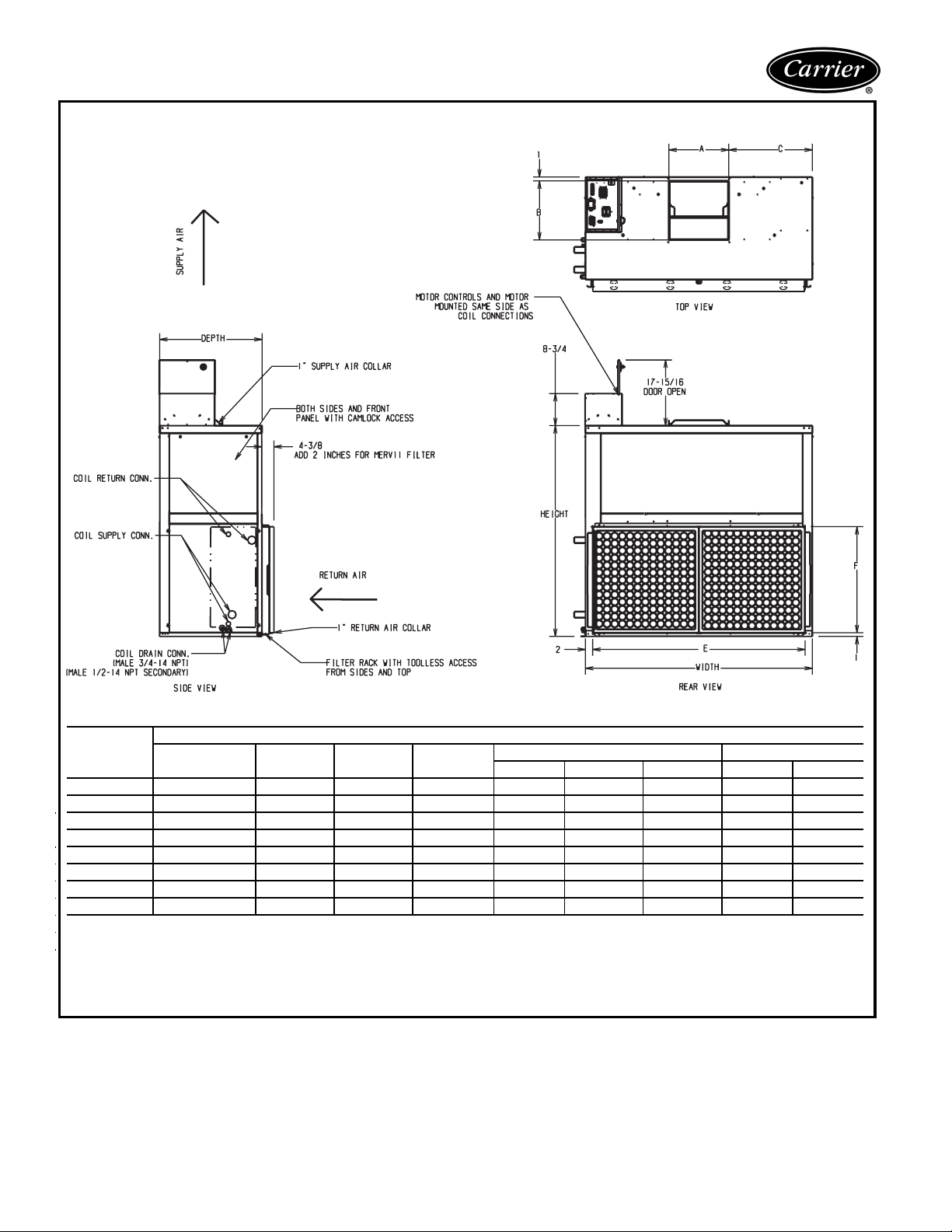

42BHC FAN COIL WITH MOTOR CONTROL OPTION

UNIT

42BHC

06 9x 4 36

08 9x 6 363/

10 10 x 4 373/

12 10 x 7 373/

16 11 x 10 3715/

20 12 x 9 40

30 12 x 12 403/

40 15 x 12 439/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

Fan Size Depth Width Height

3

/

2811/

16

2811/

16

371/

4

371/

4

471/

16

3

/

481/

8

481/

8

621/

16

1

/4in.).

16

16

16

16

16

16

16

16

181/

2

181/

2

201/

4

201/

4

201/

4

223/

4

31 157/

31 167/

DIMENSIONS (in.)

Supply Duct Return Duct Mounting Holes

AB CDEF J K

71/

89/

71/

915/

135/

121/

109/

8

109/

16

1111/

2

1111/

16

1211/

16

133/

2

133/

8

161/

16

137/

16

137/

16

137/

16

137/

16

1613/

16

173/

4

161/

4

2213/

16

8

8

8

8

16

4

16

16

11/8241/

11/8241/

11/8331/

11/8331/

11/8431/

11/8441/

61/8441/

51/8581/

167/

16

167/

16

183/

16

183/

16

183/

16

2011/

16

2815/

16

2815/

16

273/

16

273/

16

363/

16

363/

16

463/

16

473/

16

473/

16

613/

16

351/

16

16

16

16

16

16

16

16

351/

3613/

3613/

37

397/

397/

425/

4

4

16

16

16

16

8

change without notice.

3. Right hand shown, left hand opposite.

4. Hanger rods, which are field-supplied, are shown for reference only.

7

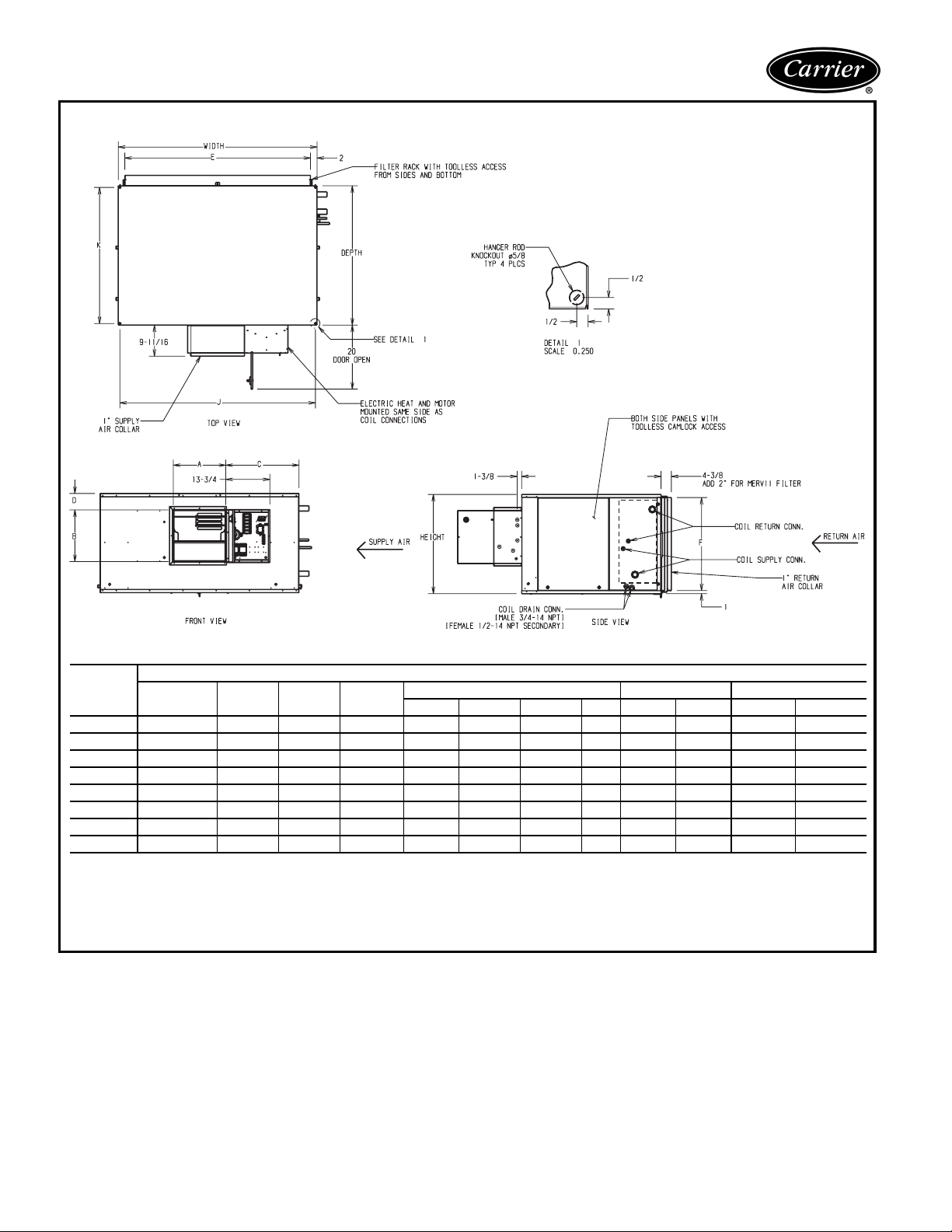

Base unit dimensions (cont)

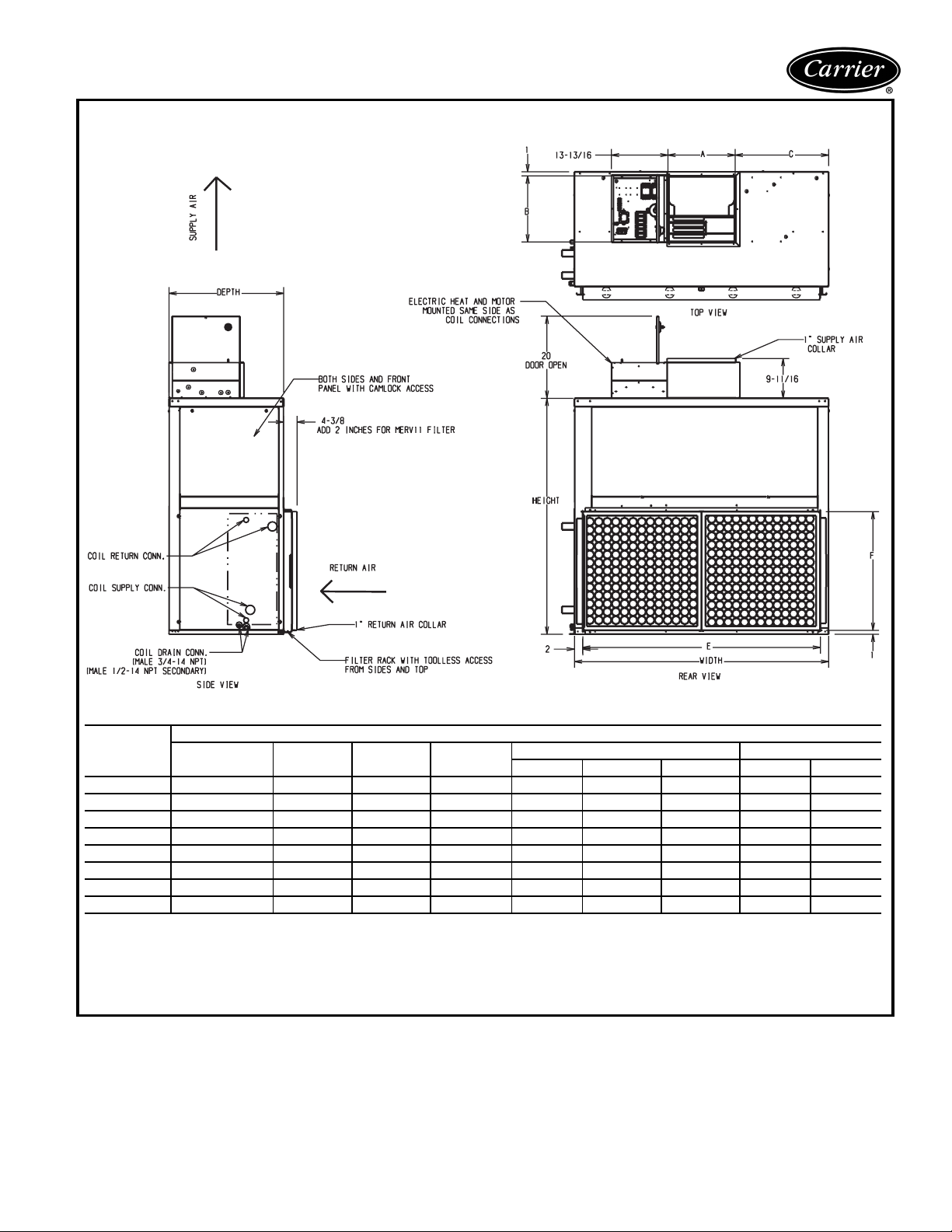

42BHC FAN COIL WITH ELECTRIC HEAT OPTION

UNIT

42BHC

06 9x 4 36

08 9x 6 363/

10 10 x 4 373/

12 10 x 7 373/

16 11 x 10 3715/

20 12 x 9 40

30 12 x 12 403/

40 15 x 12 439/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

change without notice.

Fan Size Depth Width Height

3

/

2811/

16

2811/

16

371/

4

371/

4

471/

16

3

/

481/

8

481/

8

621/

16

1

/4in.).

16

16

16

16

16

16

16

16

181/

181/

201/

201/

201/

223/

31 157/

31 167/

2

2

4

4

4

4

DIMENSIONS (in.)

Supply Duct Return Duct Mounting Holes

AB CDEF J K

71/

89/

71/

915/

135/

121/

109/

8

109/

16

1111/

2

1111/

16

1211/

16

133/

2

133/

8

161/

16

137/

16

137/

16

137/

16

137/

16

1613/

16

173/

4

161/

4

2213/

16

8

8

8

8

16

4

16

16

11/8241/

11/8241/

11/8331/

11/8331/

11/8431/

11/8441/

61/8441/

51/8581/

167/

16

167/

16

183/

16

183/

16

183/

16

2011/

16

2815/

16

2815/

16

273/

16

273/

16

363/

16

363/

16

463/

16

473/

16

473/

16

613/

16

351/

16

16

16

16

16

16

16

16

351/

3613/

3613/

37

397/

397/

425/

4

4

16

16

8

3. Right hand shown, left hand opposite.

4. Hanger rods, which are field-supplied, are shown for reference only.

16

16

8

42BVC FAN COIL BASE UNIT (NO CONTROLS)

UNIT

42BVC

06 9x 4 20 28

08 9x 6 20 281/

10 10 x 4 22 371/

12 10 x 7 22 371/

16 11 x 10 22 471/

20 12 x 9 24 481/

30 12 x 12 28 481/

40 15 x 12 28 621/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

change without notice.

Fan Size Depth Width Height

1

/

16

16

16

16

16

16

16

16

1

/4in.).

DIMENSIONS (in.)

361/

2

361/

2

393/

8

393/

8

393/

451/

543/

575/

8

8

16

8

135/

121/

157/

167/

Supply Duct Return Duct

AB CEF

71/

89/

71/

915/

8

16

2

16

16

2

8

16

109/

109/

1111/

1111/

1211/

133/

133/

161/

16

16

16

16

16

4

4

16

33/

33/

51/

51/

167/

1713/

161/

227/

4

4

2

2

8

16

8

8

241/

241/

331/

331/

431/

441/

441/

581/

167/

16

16

16

16

16

16

16

16

167/

183/

183/

183/

2011/

2815/

2815/

16

16

16

16

16

3. Right hand shown, left hand opposite.

4. Hanger rods, which are field-supplied, are shown for reference only.

16

16

16

9

Base unit dimensions (cont)

42BVC FAN COIL WITH MOTOR CONTROL OPTION

UNIT

42BVC

06 9x 4 20 28

08 9x 6 20 281/

10 10 x 4 22 371/

12 10 x 7 22 371/

16 11 x 10 22 471/

20 12 x 9 24 481/

30 12 x 12 28 481/

40 15 x 12 28 621/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

NOTES:

change without notice.

1. All dimensions are in inches (±

3. Right hand shown, left hand opposite.

2. Any modifications to product specifications by any person are

4. Hanger rods, which are field-supplied, are shown for reference only.

subject to acceptance of the factory. Product specifications are

subject to change without notice.

3. RH shown, LH opposite.

Fan Size Depth Width Height

1

/

16

16

16

16

16

16

16

16

1

/4in.).

1

/4in.).

DIMENSIONS (in.)

361/

2

361/

2

393/

8

393/

8

393/

451/

543/

575/

8

8

16

8

135/

121/

157/

167/

Supply Duct Return Duct

AB CEF

71/

89/

71/

915/

8

16

2

16

16

2

8

16

109/

109/

1111/

1111/

1211/

133/

133/

161/

16

16

16

16

16

4

4

16

33/

33/

51/

51/

167/

1713/

161/

227/

4

4

2

2

8

8

8

241/

16

241/

16

331/

16

331/

16

431/

16

441/

16

441/

581/

16

16

16

4. Hanger rods, which are field-supplied, are shown for reference

only.

167/

167/

183/

183/

183/

2011/

2815/

2815/

16

16

16

16

16

16

16

16

10

42BVC FAN COIL WITH ELECTRIC HEAT OPTION

UNIT

42BVC

06 9x 4 20 28

08 9x 6 20 281/

10 10 x 4 22 371/

12 10 x 7 22 371/

16 11 x 10 22 471/

20 12 x 9 24 481/

30 12 x 12 28 481/

40 15 x 12 28 621/

NOTES:

1. All dimensions are in inches (±

2. Any modifications to product specifications by any person are subject to acceptance of the factory. Product specifications are subject to

Fan Size Depth Width Height

1

/

16

16

16

16

16

16

16

16

1

/4in.).

DIMENSIONS (in.)

361/

2

361/

2

393/

8

393/

8

393/

451/

543/

575/

8

8

16

8

135/

121/

157/

167/

Supply Duct Return Duct

AB CEF

71/

89/

71/

915/

8

16

2

16

16

2

8

16

109/

109/

1111/

1111/

1211/

133/

133/

161/

16

16

16

16

16

4

4

16

33/

33/

51/

51/

167/

1713/

161/

227/

4

4

2

2

8

16

8

8

241/

241/

331/

331/

431/

441/

441/

581/

16

16

16

16

16

16

16

16

167/

167/

183/

183/

183/

2011/

2815/

2815/

change without notice.

3. Right hand shown, left hand opposite.

4. Hanger rods, which are field-supplied, are shown for reference only.

16

16

16

16

16

16

16

16

11

Base unit dimensions (cont)

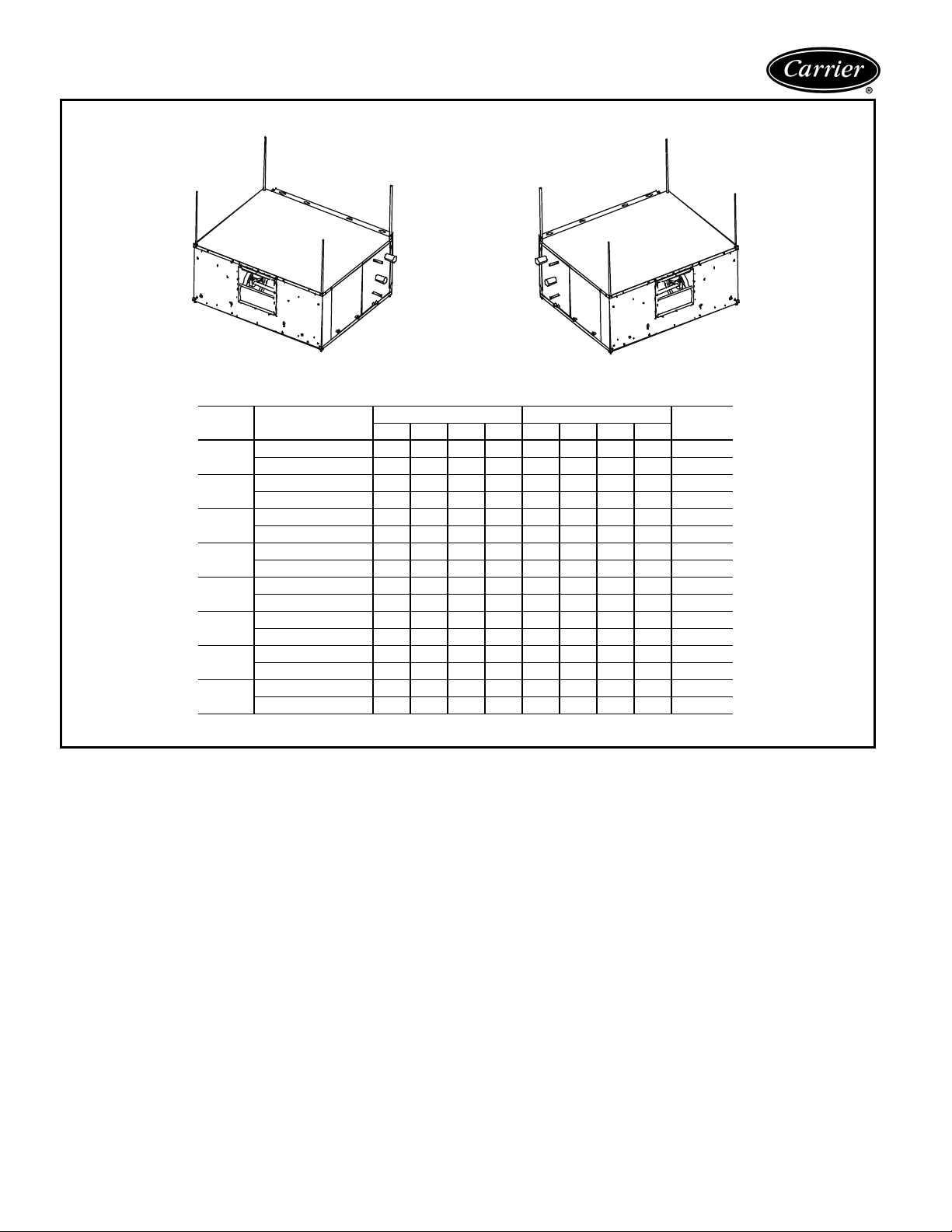

42BHC UNIT CORNER WEIGHTS (lb)

1

3

4

RIGHT HAND UNIT

UNIT

42BHC

NOTE: Unit weights (shown in pounds) ±10%, are based on the 8-row coil and 1 Hp motor.

CONFIGURATION

06

08

10

12

16

20

30

40

No Heat 50 55 47 51 55 50 51 47 203

With Heat 50 58 59 67 58 50 67 59 234

No Heat 51 55 47 52 55 51 52 47 205

With Heat 50 59 59 68 59 50 68 59 236

No Heat 63 71 55 63 71 63 63 55 253

With Heat 62 76 68 81 76 62 81 68 287

No Heat 64 72 56 64 72 64 64 56 256

With Heat 63 76 68 82 76 63 82 68 290

No Heat 80 87 69 76 87 80 76 69 312

With Heat 79 91 82 95 91 79 95 82 346

No Heat 90 98 74 82 98 90 82 74 344

With Heat 90 102 88 100 102 90 100 88 380

No Heat 118 127 92 100 127 118 100 92 437

With Heat 118 131 106 119 131 118 119 106 474

No Heat 155 162 114 122 162 155 122 114 553

With Heat 155 166 129 140 166 155 140 129 590

2

RIGHT-HAND UNITS LEFT-HAND UNITS

12341234

1

3

LEFT HAND UNIT

2

4

TOTAL

WEIGHT

12

42BVC UNIT CORNER WEIGHTS (lb)

1

3

2

4

1

3

1

3

2

4

RIGHT HAND UNIT

UNIT

42BVC

06

08

10

12

16

20

30

40

NOTE: Unit weights (shown in pounds) ±10% are based on the 8-row coil and 1 Hpmotor.

CONFIGURATION

No Heat 52 54 51 43 54 52 43 51 200

With Heat 58 65 61 47 65 58 47 61 231

No Heat 53 55 51 43 55 53 43 51 202

With Heat 58 66 62 47 66 58 47 62 233

No Heat 63 69 61 50 69 63 50 31 243

With Heat 69 81 72 54 81 69 54 72 277

No Heat 64 70 62 51 70 64 51 62 247

With Heat 70 82 73 55 82 70 55 73 281

No Heat 74 85 72 58 85 74 58 72 289

With Heat 80 98 84 61 98 80 61 84 323

No Heat 90 108 86 68 108 90 68 86 351

With Heat 95 123 99 71 123 95 71 99 387

No Heat 110 139 106 81 139 110 81 106 436

With Heat 115 155 120 83 155 115 83 120 473

No Heat 131 172 125 94 172 131 94 125 522

With Heat 135 190 140 95 190 135 94 140 559

RIGHT-HAND UNITS LEFT-HAND UNITS

12341234

1

3

LEFT HAND UNIT

2

2

WEIGHT

4

4

TOTAL

TOTAL WEIGHT UNIT CORRECTION FACTOR (lb)

Corner weights on pages 12 and 13 are for 8-row water filled coils. For a different number of rows, total unit weight

can be determined by the following procedure:

• Identify the number of rows and the size of the unit.

• Determine the total weight of the unit from the Corner Weight tables.

• From the table below, identify the correction factor (for size of unit and number of rows) and subtract this from the

total weight.

UNITS

42BHC,BVC

06 21 16 11 5

08 21 16 11 5

10 28 21 14 7

12 28 21 14 7

16 39 29 20 10

20 46 35 23 12

30 74 55 37 18

40 98 74 49 25

4ROWS 5ROWS 6ROWS 7ROWS

Correction Factors (lb)

13

Accessory dimensions

MIXING BOX

1

2.4

A

C

BOTTOM/REAR INLET

WB

2

B

2

W

TOP VIEWS

A

3

A

H

2.4

4

2.4

1

4

2.4

H

A

3

C

TOP/REAR INLET

14

NOTE: All dimensions in inches.

RIGHT HAND SIDE VIEWS

42BHC,BVC

UNIT SIZE

06 18.5 28 6 24 11

08 18.5 28 6 24 11

10 20.25 37 8 33 13

12 20.25 37 8 33 13

16 20.25 47 8 43 13

20 22.75 48 8 44 13

30 31.0 481044 15

40 31.0 481044 15

DIMENSIONS (in.)

HWABC

MIXING BOX RAILS

W

FRONT VIEW

NOTE: All dimensions in inches.

UNIT

42BHC06 28 51.6 16.1

42BHC08 28 51.6 16.1

42BHC10 37 55.2 18.1

42BHC12 37 55.2 18.1

42BHC16 47 55.4 18.1

42BHC20 48 57.8 18.1

42BHC30 48 59.8 20.1

42BHC40 62 63.0 20.1

DIMENSIONS (in.)

WD A

1

1

D

A

3

SIDE VIEW

UNIT

42BVC06 28 35.5 16.1

42BVC08 28 35.5 16.1

42BVC10 37 39.5 18.1

42BVC12 37 39.5 18.1

42BVC16 47 39.5 18.1

42BVC20 48 41.5 18.1

42BVC30 48 47.5 20.1

42BVC40 62 47.5 20.1

DIMENSIONS (in.)

WD A

15

Accessory dimensions (cont)

VALVE PACKAGES

Basic — Basic valve package includes 2 or 3-way

valves with balancing valves and 2 ball valvs.

B

A

D

Deluxe — Deluxe valve package includes a circuit

setter and a strainer in addition to the components

listed under basic valve package.

F

E

D

A

B

NOTE: All dimensions in inches.

CONTROL VALVE

Normal Close Off

Spring Return

High Close Off

Power On/

Power Off

PIPING

PACKAGE

2-way

3-way

2-way

3-way

C

E

F

SIZEABCDE FCv

1

/2in. 12.45 2.285 — — 15.25 7.41 3.5 25 psig

3

/4in. 12.71 3.156 — — 17.71 7.936 5 20 psig

1 in. 14.88 3.38 — — 20.81 9.6 8 17 psig

1

/2in. 12.99 14.7 1.823 5.805 16.29 19.32 4 25 psig

3

/4in. 12.84 16.24 2.318 7.411 17.34 21.02 5 20 psig

1 in. 14.72 19.38 2.774 8.247 20.65 25.19 8 17 psig

1

/2in. 13.29 2.285 — — 16.09 7.41 3.5 60 psig

3

/4in. 13.59 3.156 — — 18.59 7.936 4.6 60 psig

1 in. 14.97 3.38 — — 20.90 9.6 6.6 60 psig

1

/2in. 13.41 15.54 2.031 6.014 16.71 20.16 3.8 60 psig

3

/4in. 13.03 16.62 2.219 7.313 17.53 21.4 5.9 60 psig

1 in. 14.77 19.47 2.731 8.248 20.70 25.28 9 60 psig

CLOSE

C

OFF

16

PIPING CONNECTION LOCATION DIAGRAM*

HWS

HWR

D

C

B

A

2(51)

1-5/8(41)

RH Tell-Tale

CWR

CWS

Drain

0

)462(8/3-01

E

)912(8/5-8

F

)571( 8/7-6

G

H

0

LH Tell-Tale

LEGEND

CWR — Cold Water Return

CWS — Cold Water Supply

HWR — Hot Water Return

HWS — Hot Water Supply

LH — Left Hand

RH — Right Hand

SO — Stub Out

*Right-hand unit with re-heat coil shown.

42BHC,BVC

UNIT SIZE

06 1 0.75 0.75 0.5

08 1 0.75 0.75 0.5

10 1 0.75 0.75 0.5

12 1 0.75 0.75 0.5

16 11 1 0.5

20 11 1 0.5

30 1.5 1.5 1.5 0.5

40 1.5 1.5 1.5 0.5

8RowCoilSO

Nominal

Use the table on the next page to determine the location of the piping

connections. For example, on a size 20 unit with 4 rows and a right

hand connection, the location of the chilled water supply line is determined by G (6 in.) and B (7

HEAD STUB OUT SIZES (in.)

6RowCoilSO

Nominal

4RowCoilSO

Nominal

4

/5in.).

Heating 1 or 2 SO

Row Coil Nominal

17

Accessory dimensions (cont)

HEAT OPTIONS

Re-heat

Pre-heat*

*Factory-installed option.

42BHC,BVC

UNIT SIZE

06/08

10/12

16

20

30/40

06/08

10/12

16

20

30/40

COIL ROWS DIMENSIONS (in.)

0—

4

13

23

0— ———

6

13

23

80 — — ——10

4

0—

15

25

6

0— ———

15

25

80 — — ——10

4

0—

1

25

0— ———

6

1

25

80 — — ——10

4

0—

1

25

0— ———

6

1

25

80 — — ——10

4

0—

1

23

0— ———

6

1

23

80 — — ——10

4

6

80 — 6

0—6

13

23

0—6

13

23

0—7

4

15

25

0—7

6

15

25

80 — 7

4

0—7

15

25

6

0—7

15

25

80 — 7

4

6

80 — 7

0—7

15

25

0—7

15

25

0—5

4

13

23

0—5

6

13

23

80 — 5

A BCDEFGHCool Heat

1

/

13

/

1

/

13

/

1

/

7

/

16

1

/

27

/

LH 105/

RH 133/

7

/

16

LH 105/

RH 133/

7

/

16

LH 1115/

RH 1411/

1

/

LH 1115/

RH 1411/

1

/

LH 141/

RH 1813/

5

/

LH 141/

RH 1813/

5

/

1

/

13

/

1

/

13

/

1

/

7

/

16

1

/

7

/

16

1

/

7

/

16

1

/

7

/

16

3

/

16

1

/

3

/

16

1

/

5

/

16

5

/

5

/

16

5

/

———

2

16

2

16

8

8

61

61/

8

73/

4

123/

143/

4

8

151/

2

1513/

16

151/

2

1513/

16

———

171/

8

177/

16

171/

8

177/

16

77

79/

16

93/

16

93/

4

77

79/

16

93/

16

93/

4

———

8

8

73/

8

8

4

155/

8

177/

177/

12

16

12

16

95/

95/

79/

1113/

1113/

93/

8

8

16

16

16

4

———

16

16

2

16

16

2

713/

16

183/

16

135/

201/

135/

201/

16

16

16

16

95/

95/

79/

1113/

1113/

93/

8

8

16

16

16

4

———

16

16

8

16

16

8

2

16

2

16

8

8

8

8

2

2

8

8

515/

87/

713/

87/

713/

69/

515/

69/

515/

16

1

/

8

63/

4

61/

8

1

/

8

63/

4

61/

8

1

/

8

3

/

4

83/

8

73/

4

3

/

4

83/

8

73/

4

3

/

4

3

/

4

83/

8

73/

4

3

/

4

83/

8

73/

4

3

/

4

13

/

16

16

16

13

/

16

16

16

13

/

16

15

/

16

16

16

15

/

16

16

16

15

/

16

265/

16

123/

4

133/

8

123/

4

123/

4

133/

8

123/

4

123/

4

143/

8

15 171/

143/

8

143/

8

15 171/

143/

8

143/

8

155/

8

161/

4

155/

8

155/

8

161/

4

155/

8

155/

8

183/

16

1813/

16

183/

16

183/

16

1813/

16

183/

16

183/

16

265/

16

2615/

16

265/

16

265/

16

2615/

16

265/

16

265/

16

167/

16

281/

8

167/

16

281/

8

———5

151/

2

1513/

16

———8

151/

2

1513/

16

———10

———5

8

177/

16

———8

8

177/

16

———10

———5

171/

8

177/

16

———8

171/

8

177/

16

———10

———5

193/

4

201/

16

———8

193/

4

201/

16

———10

———5

2713/

16

281/

8

—3

2713/

16

281/

8

—3

95/

8

95/

8

79/

16

1113/

16

1113/

16

93/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

211/

16

31/

4

——73

211/

16

1

/

4

——9

211/

16

1

/

4

515/

79/

93/

79/

93/

79/

93/

93/

79/

93/

93/

79/

103/

103/

211/

93/

93/

7

7

93/

7

7

93/

8

8

93/

31/

16

16

81/

8

16

4

1

/

4

515/

16

16

81/

8

16

4

1

/

4

515/

16

16

16

81/

8

1

/

4

515/

16

81/

8

1

/

4

515/

16

81/

8

1

/

4

15

/16211/

733/

81/847/

1

/8211/

211/

16

4

16

16

16

4

16

16

16

4

16

4

211/1693/1633/

31/4101/447/

211/

31/

211/1693/1633/

31/4101/447/

211/

31/

211/1693/1633/

31/4101/447/

211/

31/

1

/4211/

15

/16211/

733/

16

81/847/

4

1

/8211/

1

/4211/

15

/16211/

733/

16

81/847/

4

1

/8211/

1

/4211/

15

/16211/

733/

16

81/847/

4

1

/8211/

211/1693/1633/

31/4101/447/

211/

31/

211/16101/447/

1

/4211/

15

/16211/

81/847/

16

81/8211/

4

3

/1633/

31/4101/4211/

16

16

4

8

16

4

8

16

16

4

8

16

4

8

16

16

4

8

16

4

8

16

16

4

8

16

4

8

16

16

3

/

4

8

16

4

8

16

18

Application data

Basic definitions

Unit hand — When facing the supply air outlet from the

front of the unit (air blowing in your face), your right hand

will be the right hand side of the unit and your left hand the

left hand side of the unit.

PIPING COMPONENTS

SYMBOL/SKETCH DESCRIPTION

MANUAL AIR VENT: Threaded brass needle valve

with screwdriver slot for adjustment.

Application — Body brazed into high point of heat-

ing and cooling coils for bleeding air from coil. Standard item on all hydronic coils (not used on steam

or DX coils). Should not be used in lieu of main system air vents.

AUTOMATIC AIR VENT: Nickel plated brass valve,

fiber-disc type, with positive shut-off ballcheck and

quick vent feature via knurled vent screw.

Application — Optional replacement for manual air

vent. Automatically passes minute quantities of air

through the fiber discs which expand upon contact

with water, completely sealing the valve. As air

accumulates, the fiber discs dry and shrink, repeating the cycle. Not recommended for removing large

quantities of air encountered during initial start-up

or subsequent draining and refilling. Should not be

used in lieu of main system air vents.

SWAGE: Copper tube end expanded to accept a

copper tube of the same size for factory or field

brazing.

Application — Used where possible for all tubing

joints for best joint integrity.

CIRCUIT SETTER: Variable water flow balancing

valve with manual adjustment knob, pointer, percent-open scale, memory stop and integral pressure read-out ports.

Application — Used for close tolerance water flow

balancing. Positive shut-off ball valve feature allows

usage as combination balancing and shut-off valve.

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

*Check all system component pressure ratings (coils, values, pumps,

etc.) with manufacturer and any applicable local or national piping

codes prior to specifying system pressure rating.

UNIT HAND

CVFACTOR RATING*

1

/

2

N/A N/A 400 100

N/A N/A 125 240

N/A N/A 300 200

2.12 3.9 300 250

3

/

4

PSI F

19

Application data (cont)

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

BALANCE VALVE: Variable water flow manual bal-

ancing valve with screwdriver slot adjustment

screw.

Application — Often used in conjunctionwithtest

port fittings for water flow balancing. Balance by

temperature differential or coil pressure drop

(check specifications for service fittings required if

balancing by pressure drop). May be used in 3-way

valve bypass line to permit equal flow balancing.

STRAINER: Y-type body with 50 mesh stainless

steel screen.

Application — Used for removal of small particles

from system water during normal system operation.

Should not be used in lieu of main system strainers. Strainer screen may have to be removed during initial high pressure system flushing during

start-up. Screen should be removed and cleaned

per normal maintenance schedule (provisions for

strainer blow-down not provided).

BALL VALVE: Manual balance and shut-off valve.

Application — Used for unit isolation and water flow

balancing. Without memory stop feature water balance point must be marked by installer (if necessary). Check specifications for service fittings

required when used for water balancing.

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

*Check all system component pressure ratings (coils, values, pumps,

etc.) with manufacturer and any applicable local or national piping

codes prior to specifying system pressure rating.

CVFACTOR RATING*

1

/

2

3

/

4

PSI F

3.0 8.9 150 200

9.0

Clean

19.0

Clean

400 250

4.0 7.5 400 200

20

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

2-WAY MOTORIZED VALVE: Electric

2-position flow control valve (open/closed).

Normally closed body with manual override

lever. Installed in supply line to unit.

Application — All standard control and valve

packages are based upon normally closed

valves (valve electrically powered open and

closed by spring return when electric power

removed). Manual override lever allows valve

to be placed in the open position for secondary (unit) flushing, constant water flow prior to

start-up, etc. Manual override is automatically

disengaged when valve is electrically activated. Consult factory for normally open

valve applications.

3-WAY MOTORIZED VALVE: Electric

2-position flow control valve (closed to coil/

open to bypass or open to coil/closed to

bypass). Normally closed with manual override lever. Installed in supply line to unit.

Application — Same comments as 2-way

motorized valve except with manual override

lever engaged the valve is open to both ports

and water flow will take the path of least resistance through the valve package (not necessarily 100% through the coil).

C

FACTO R

V

1

/

2

3

/

4

1 PSI F

3.5 5.0 8.0

SPRING RETURN

3.5 4.6 6.6

POWER ON/OFF

4.0 5.0 8.0

SPRING RETURN

3.8 5.9 9.0

RATING

300 200

300 200

LEGEND

Cv — Coefficient of Velocity

DX— Direct Expansion

NOTES:

1. Motorized spring return 2-way valves have a maximum close-off differential of 25 psi.

2. Motorized spring return 3-way valves have a maximum close-off differential of 25 psi.

POWER ON/OFF

21

Selection procedure

This selection procedure provides a guide to determine

unit performance of the 42BHC, BVC units. Capacity

tables (in Performance Data) are based on nominal cfm.

Correction factors are provided for other operating conditions as explained in the following selection example.

For applications outside the range provided in this

catalog, please consult the factory.

FORMULAS:

TC = TCb x Ct x Et

SC = SCb x Cs x Es

Where:

Cs = Sensible Airflow Correction Factor

Ct = Total Airflow Correction Factor

Es = Sensible Elevation Correction Factor

Et = Total Elevation Correction Factor

SC = Sensible Capacity

SCb = Base Sensible Capacity from Base Cooling Capaci-

ties by gpm charts

TC = Total Capacity

TCb = Base Total Capacity from Base Cooling Capacities

by gpm charts

EXAMPLE:

I Rate unit performance.

To rate the performance at sea level for a 42BHC16

unit with a four-row coil at 80 F/67 F EAT, 45 F EWT,

7 gpm water flow, and 1500 cfm:

a) Enter the Base Cooling Capacities by Gpm, 4-Row

Capacity Units table at 80 F/67 F EAT and

45 F EWT.

b) Locate the appropriate row for unit size 16 and

7 gpm.

Record the tabulated base performance.

TCb = 42.0 MBtuh

SCb = 34.2 MBtuh

∆T = 12.0 F

c) Divide CFM Actual by CFM Nominal to determine

Cfm Ratio.

Cfm Ratio = 1500/1600 =.9375

II Select CFM correction factors.

Select the Cfm correction factors, Ct and Cs, from the

Airflow Correction Factors table. (Interpolation may be

required.)

Ct = .9625

Cs = .96

Select the elevation correction factors, Et and Es, from

the Elevation Correction Factors table. (No correction

necessary in this example, unit is at sea level.)

Et = 1.00

Es = 1.00

III Calculate actual performance.

TC = TCb x Ct x Et

= 42.0 x .9625 x 1.00

= 40.42 MBtuh

SC = SCb x Cs x Es

= 34.2 x .96 x 1.00

= 32.83 MBtuh

a) Calculate water pressure drop (or refer to the Water

Pressure Drop for Cv Factor and Water Flow Rate

table on page 33). From the Cv Factor by Coil and

Unit Size table on page 32, find the Cv value for

unit size 16 with four rows.

Cv = 7.2

P = [GPM/(0.658 x Cv)]2

= [7.0/(0.658 x 7.2)]2

= 2.18 feet of H

b) For selections other than those listed here, please

contact the factory.

IV Determine motor.

To determine motor and drive selection requirements

and obtain the cfm for a specific application, the

total static pressure (TSP) for that application must be

determined.

The TSP is the sum of the internal static pressure

(ISP) and the external static pressure (ESP) measured in

inches of water column. Internal static pressure is the

sum of the static resistance of the unit’s components

— the cabinet, coil and filter. The ESP is the static

resistance of the unit’s external components, including,

but not limited to, ductwork, grilles and additional

filtration. For non-ducted applications, the ESP is

0 in. wg.

After the TSP has been calculated (see the following

example), use the motor horsepower table on pages 30

and 31 to determine actual horsepower (hp) for the belt

drive unit. Horsepower offerings are limited to

1

/2, 3/4, 1, 11/2, 2, 3 and 5.

The standard selection is the nearest offering above

the actual hp shown in the table.

Using the TSP of the table, match the unit size with

the cfm row to determine the correct motor for the

specific application. Drive sheaves and the required

belt assembly will be provided to meet specific design

requirements. Drive sheaves are set at the factory.

Calculate the hp and drive selection required to deliver 1500 cfm on a 42BHC16 unit equipped with a

4-row hydronic cooling coil and a 2-in. pleated filter in

a ducted application at .38 in. ESP, including duct and

grille losses.

Using the Component Static Resistance table on

page 32, the ISP is calculated as follows:

Cabinet .09-in. wg

4-row Wet Coil .30-in. wg

2-in. Pleated Filter .12-in. wg

ISP .51-in. wg

ESP .38-in. wg

TSP .89-in. wg

O

2

1

/4, 1/3,

22

Performance data

42BHC,BVC AIRFLOW CORRECTION FACTORS

CFM RATIO

(Actual/Base)

1.40 1.25 1.26

1.35 1.22 1.23

1.30 1.19 1.20

1.25 1.16 1.17

1.20 1.13 1.14

1.15 1.10 1.11

1.10 1.07 1.08

1.05 1.04 1.04

1.00 1.00 1.00

0.95 0.97 0.97

0.90 0.94 0.93

0.85 0.90 0.89

0.80 0.86 0.85

0.75 0.82 0.81

0.70 0.78 0.77

0.65 0.74 0.72

0.60 0.70 0.67

0.55 0.66 0.62

0.50 0.62 0.57

0.45 0.58 0.52

0.40 0.53 0.47

0.35 0.48 0.42

0.30 0.43 0.38

0.25 0.38 0.33

NOTE: Use Sensible Heat correction factors when calculating heating

capacity.

TOTAL (Ct) SENSIBLE (Cs)

DIRECT EXPANSION (DX) CORRECTION FACTORS

%OF

NOMINAL CFM

80 0.95 0.93

90 0.97 0.96

100 1.00 1.00

110 1.02 1.04

120 1.05 1.08

Consult factory for values outside of table.

DX Total Capacity (MBtuh) = Base Et x Total Correction Factor

DX Sensible Capacity (MBtuh) = Base Es x Sensible Correction Factor

% of Nominal Cfm = Actual Cfm (from Fan Performance table)

÷ Nominal Cfm

CORRECTION FACTOR

Total Sensible

ALTITUDE COOLING CORRECTION FACTORS

ELEVATION (ft) TOTAL HEAT (Et) SENSIBLE HEAT (Es)

1000 0.99 0.96

2000 0.98 0.93

3000 0.97 0.89

4000 0.96 0.86

5000 0.94 0.83

6000 0.93 0.80

7000 0.92 0.77

8000 0.91 0.75

9000 0.90 0.73

42BHC,BVC HOT WATER CAPACITY CORRECTION FACTORS

ENTERING AIR

TEMPERATURE (F)

50 0.455 0.545 0.636 0.727 0.818 0.909 1.000 1.091 1.182 1.273 1.364

55 0.409 0.500 0.591 0.682 0.773 0.864 0.955 1.045 1.136 1.227 1.318

60 0.363 0.455 0.545 0.636 0.727 0.818 0.909 1.000 1.091 1.182 1.273

65 0.318 0.409 0.500 0.591 0.682 0.773 0.864 0.955 1.045 1.136 1.227

70 0.272 0.363 0.455 0.545 0.636 0.727 0.818 0.909 1.000 1.091 1.182

75 0.227 0.318 0.409 0.500 0.591 0.682 0.773 0.864 0.955 1.045 1.136

80 0.182 0.272 0.363 0.455 0.545 0.636 0.727 0.818 0.909 1.000 1.091

NOTES:

1. Leaving air temperature not to exceed 104 F with standard motor.

2. Base capacity ratings based on 180 F entering water temperature

and 70 F entering air temperature.

3. Hot Water Heating Capacity (MBtuh) =Rated Heating Capacity x

Hot Water Capacity Correction Factor x Sensible Airflow Correction Factor.

100 110 120 130 140 150 160 170 180 190 200

ENTERING WATER TEMPERATURE (F)

23

Performance data (cont)

42BHC, BVC NOMINAL COOLING CAPACITIES

UNIT SIZE

42BHC,BVC

06 600

08 800

10 1000

12 1200

16

20 2000

30 3000

40 4000

EWT — Entering Water Temperature

MBtuh — Capacity (Btuh in thousands)

*Based on entering air temperature of 67 F wb, 80 F db and temperature rise of 10

degrees F.

NOTE: All ratings at sea level. Ratings in accordance with ARI (Air Conditioning &

Refrigeration Institute).

NOMINAL

LEGEND

CFM

1600

COIL

ROWS

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

EWT

(F)

40 23.3 16.0

45 17.9 13.8

50 12.8 12.0

40 31.0 19.8

45 24.5 17.0

50 18.0 14.5

40 33.8 21.2

45 26.7 18.1

50 19.4 15.2

40 28.4 20.0

45 21.9 17.5

50 15.3 15.3

40 38.4 25.1

45 30.3 21.7

50 22.5 18.6

40 42.6 27.2

45 33.7 23.3

50 24.7 19.8

40 40.5 27.3

45 31.6 23.7

50 23.4 20.6

40 52.2 33.3

45 41.7 28.7

50 31.2 24.5

40 57.7 36.0

45 46.4 31.0

50 34.6 26.2

40 45.4 31.2

45 35.5 27.2

50 26.5 23.8

40 59.6 38.4

45 47.4 33.2

50 35.5 28.5

40 66.6 42.0

45 53.3 36.1

50 39.9 30.7

40 59.7 41.2

45 46.4 35.9

50 34.4 31.4

40 78.7 50.9

45 62.6 44.1

50 46.8 37.8

40 89.0 56.0

45 71.3 48.3

50 53.3 41.0

40 75.2 51.6

45 59.0 45.1

50 44.1 39.5

40 99.0 63.8

45 78.7 55.2

50 59.0 47.4

40 111.8 70.3

45 89.9 60.6

50 67.6 51.6

40 112.5 77.6

45 87.6 67.6

50 65.0 59.1

40 148.5 95.8

45 117.8 82.8

50 88.1 71.1

40 168.0 105.5

45 135.0 91.0

50 101.2 77.4

40 157.7 106.7

45 123.6 92.9

50 92.6 81.1

40 204.0 130.5

45 162.6 112.7

50 122.3 96.7

40 230.1 143.5

45 185.6 123.8

50 140.2 105.2

COOLING*

Tot al

Capacity

(MBtuh)

Sensible

Capacity

(MBtuh)

42BHC,BVC NOMINAL HEATING CAPACITIES

UNIT SIZE

42BHC,BVC

06 600

08 800

10 1000

12 1200

16 1600

20 2000

30 3000

40 4000

NOTES:

1. Ratings are based on 180 F Entering Water Temperature (EWT) and 70 F

Entering Air Temperature (EAT ) .

2. Leaving-air temperature is not to exceed 104 F with the standard motor.

Consult the factory for higher temperature motor applications.

3. For information on four and six-row heating coil capacities and applications,

consult the factory.

4. For all application ratings, use the quick-selection ratings provided in this

catalog, or contact the factory.

NOMINAL CFM ROWS

127.0

246.9

127.0

246.9

127.0

246.9

138.5

268.5

148.0

287.7

158.7

2104.9

178.0

2149.2

192.3

2182.4

HEATING CAPACITY

(MBtuh)

24

UNIT

SIZE

GPM

42BHC,BVC

06

08

10

12

16

20

30

40

DB — Dry Bulb Temperature

EWT — Entering Water Temperature

MBtuh — Btuh in Thousands

SCb— Base Sensible Capacity at Nominal Cfm

TCb— Base Total Capacity at Nominal Cfm

WB — Wet Bulb Temperature

∆T—Change in Water Temperature (F)

LEGEND NOTE: All capacities are given in thousands of Btuh (MBtuh).

40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT

∆TTC

3 10.9 16.3 13.2 9.0 13.5 12.1 7.2 10.7 10.7 13.0 19.5 14.5 11.1 16.6 13.4 9.1 13.7 12.3 15.3 22.9 15.7 13.3 19.9 14.6 11.2 16.9 13.5

4 9.1 18.3 14.0 7.5 15.0 12.7 5.7 11.5 11.5 11.0 22.0 15.5 9.3 18.6 14.1 7.6 15.2 12.8 13.1 26.2 16.9 11.3 22.6 15.5 9.5 18.9 14.2

5 7.9 19.7 14.6 6.4 16.1 13.1 5.0 12.5 11.6 9.6 23.9 16.3 8.0 20.1 14.7 6.5 16.2 13.2 11.4 28.5 17.8 9.8 24.5 16.3 8.2 20.4 14.8

3 12.2 18.3 16.0 10.0 15.0 15.0 8.4 12.7 12.7 14.5 21.7 17.4 12.4 18.7 16.3 10.2 15.2 15.2 16.9 25.4 18.8 14.8 22.2 17.7 12.6 19.0 16.6

4 10.4 20.8 17.0 8.6 17.2 15.6 6.9 13.8 13.8 12.4 24.9 18.6 10.6 21.1 17.2 8.7 17.4 15.8 14.6 29.2 20.2 12.7 25.4 18.8 10.7 21.4 17.4

5 9.0 22.6 17.7 7.4 18.6 16.1 5.8 14.5 14.5 10.8 27.1 19.5 9.2 22.9 17.9 7.5 18.7 16.3 12.9 32.1 21.3 11.1 27.7 19.6 9.3 23.2 18.0

6 8.0 23.9 18.3 6.5 19.5 16.5 5.0 14.9 14.9 9.6 28.9 20.3 8.1 24.3 18.4 6.6 19.7 16.7 11.5 34.4 22.1 9.8 29.5 20.3 8.2 24.6 18.5

3 15.4 23.1 20.2 12.7 19.0 19.0 10.6 16.0 16.0 18.2 27.2 22.0 15.6 23.4 20.6 12.8 19.2 19.2 21.1 31.7 23.7 18.5 27.8 22.3 15.8 23.8 21.0

4 13.2 26.4 21.6 11.0 21.9 19.8 8.8 17.5 17.5 15.7 31.5 23.6 13.4 26.8 21.8 11.1 22.1 20.1 18.4 36.9 25.5 16.0 32.0 23.8 13.6 27.1 22.1

5 11.5 28.8 22.6 9.5 23.7 20.5 7.4 18.5 18.5 13.8 34.6 24.9 11.7 29.2 22.8 9.6 23.9 20.8 16.3 40.7 27.0 14.1 35.2 24.9 11.8 29.6 22.9

6 10.2 30.6 23.4 8.4 25.1 21.1 6.4 19.1 19.1 12.3 36.9 25.8 10.4 31.1 23.5 8.4 25.3 21.3 14.6 43.8 28.2 12.6 37.7 25.8 10.5 31.5 23.6

3 16.4 24.6 22.8 13.8 20.7 20.7 11.6 17.4 17.4 19.3 28.9 24.7 16.7 25.0 23.3 14.0 20.9 20.9 22.3 33.5 26.5 19.6 29.5 25.1 16.9 25.4 23.8

4 14.2 28.4 24.3 11.9 23.7 22.4 9.7 19.3 19.3 16.8 33.6 26.5 14.4 28.8 24.6 11.6 23.2 23.2 19.6 39.2 28.5 17.1 34.2 26.7 14.5 29.1 25.0

5 12.4 31.1 25.4 10.3 25.8 23.2 8.2 20.5 20.5 14.8 37.1 27.8 12.6 31.5 25.7 10.4 26.0 23.6 17.4 43.6 30.1 15.1 37.8 28.0 12.7 31.9 25.9

6 11.1 33.2 26.3 9.1 27.3 23.9 7.1 21.4 21.4 13.3 39.8 28.9 11.2 33.7 26.5 9.2 27.5 24.2 15.6 46.9 31.4 13.5 40.5 29.0 11.3 34.0 26.7

5 14.2 35.4 31.4 11.7 29.3 29.3 9.9 24.7 24.7 16.8 41.9 34.2 14.4 36.1 32.0 11.9 29.7 29.7 19.5 48.8 36.8 17.1 42.8 34.7 14.7 36.6 32.6

7 11.8 41.3 33.8 9.8 34.3 31.0 7.8 27.4 27.4 14.1 49.4 37.1 12.0 42.0 34.2 9.9 34.6 31.5 16.6 58.0 40.1 14.4 50.3 37.3 12.1 42.5 34.6

9 10.1 45.3 35.5 8.3 37.2 32.2 6.4 28.9 28.9 12.1 54.4 39.1 10.2 46.0 35.8 8.3 37.5 32.6 14.3 64.4 42.5 12.3 55.5 39.2 10.3 46.5 36.0

11 8.7 48.1 36.7 7.1 39.3 33.0 5.4 29.9 29.9 10.6 58.3 40.7 8.9 48.8 36.9 7.2 39.5 33.3 12.6 69.3 44.4 10.8 59.4 40.6 9.0 49.5 37.0

5 16.5 41.3 37.9 13.8 34.6 34.6 11.6 29.1 29.1 19.4 48.6 41.2 16.8 42.0 38.7 14.0 35.0 35.0 22.5 56.3 44.2 19.8 49.5 41.8 17.0 42.6 39.5

7 13.9 48.5 40.8 11.6 40.5 37.6 9.3 32.7 32.7 16.5 57.6 44.6 14.0 49.2 41.4 11.7 40.8 38.3 19.2 67.4 48.1 16.7 58.6 45.0 14.2 49.7 41.9

9 11.9 53.5 42.9 9.8 44.1 39.1 7.7 34.8 34.8 14.2 64.0 47.1 12.0 54.1 43.3 9.9 44.4 39.6 16.7 75.2 51.0 14.5 65.0 47.3 12.2 54.7 43.6

11 10.4 57.1 44.4 8.5 46.8 40.1 6.6 36.1 36.1 12.5 68.6 48.9 10.5 57.8 44.7 8.5 47.0 40.6 14.8 81.3 53.3 12.7 69.9 49.0 10.6 58.4 44.9

7 15.9 55.6 55.6 13.9 48.5 48.5 11.7 41.0 41.0 19.0 66.5 59.7 16.2 56.8 56.8 14.1 49.4 49.4 22.0 77.0 64.0 19.5 68.2 61.0 16.5 57.9 57.9

9 14.6 65.5 58.6 12.1 54.4 54.4 10.2 45.8 45.8 17.2 77.4 63.7 14.8 66.8 59.8 12.2 55.1 55.1 20.0 90.1 68.5 17.6 79.0 64.7 15.1 67.8 60.9

11 13.1 72.3 61.3 11.0 60.5 56.6 8.9 49.1 49.1 15.6 85.9 67.0 13.4 73.5 62.2 11.1 61.1 57.7 18.3 100.5 72.2 15.9 87.6 67.6 13.5 74.5 63.1

14 11.4 79.9 64.5 9.4 66.1 58.8 7.5 52.3 52.3 13.7 95.6 70.7 11.6 81.1 65.1 9.5 66.6 59.7 16.1 112.5 76.6 13.9 97.4 71.1 11.7 82.1 65.7

17 11.4 85.5 66.8 8.3 70.2 60.5 6.4 54.5 54.5 12.1 102.8 73.6 10.2 86.8 67.3 8.3 70.7 61.2 14.3 121.8 80.1 12.3 104.9 73.8 10.3 87.9 67.7

11 16.4 90.5 79.5 13.5 74.4 74.4 11.4 62.5 62.5 19.4 106.8 86.4 16.7 91.8 80.8 13.7 75.1 75.1 22.6 124.1 92.8 19.7 108.5 87.4 16.9 92.8 82.1

14 14.4 100.9 83.7 12.0 84.0 76.8 9.6 67.4 67.4 17.1 119.9 91.4 14.6 102.1 84.6 12.1 84.6 78.2 20.0 140.2 98.6 17.4 121.8 92.0 14.7 103.2 85.6

17 12.8 108.7 87.0 10.6 89.7 79.2 8.3 70.6 70.6 15.3 129.9 95.4 12.9 110.0 87.6 10.6 90.2 80.2 18.0 152.6 103.2 15.5 132.0 95.7 13.1 111.1 88.3

21 11.1 116.5 90.2 9.1 95.5 81.5 7.0 73.6 73.6 13.3 140.0 99.4 11.2 118.0 90.7 9.1 95.9 82.3 15.8 165.5 108.1 13.6 142.4 99.4 11.3 119.2 91.1

25 9.8 122.3 92.7 8.0 99.8 83.2 6.0 75.6 75.6 11.8 147.9 102.7 9.9 124.0 93.0 8.0 100.3 84.0 14.1 175.8 112.1 12.0 150.4 102.4 10.0 125.5 93.3

75 F DB/ 63 F WB 80 F DB/67 F WB 85 F DB/71 F WB

∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSC

bSCb

42BHC,BVC 4-ROW COOLING CAPACITY (by Gpm)

b

UNIT

SIZE

42BHC,BVC

06

08

10

12

16

20

30

40

DB — Dry Bulb Temperature

EWT — Entering Water Temperature

MBtuh — Btuh in Thousands

SCb— Base Sensible Capacity at Nominal Cfm

TCb— Base Total Capacity at Nominal Cfm

WB — Wet Bulb Temperature

∆T—Change in Water Temperature (F)

LEGEND NOTE: All capacities are given in thousands of Btuh (MBtuh).

40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT

GPM

∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSCb∆TTCbSC

3 13.5 20.2 15.4 11.1 16.7 13.9 8.8 13.2 12.5 16.1 24.2 16.9 13.7 20.6 15.5 11.2 16.8 14.0 19.0 28.4 18.3 16.5 24.7 16.9 13.9 20.8 15.5

4 11.3 22.6 16.4 9.2 18.5 14.6 7.2 14.4 12.9 13.6 27.2 18.2 11.5 23.0 16.4 9.3 18.6 14.7 16.1 32.2 19.8 13.9 27.9 18.1 11.7 23.4 16.4

5 9.7 24.2 17.1 7.9 19.7 15.1 6.1 15.1 13.3 11.7 29.2 19.1 9.9 24.6 17.1 7.9 19.9 15.2 13.9 34.8 20.9 12.0 30.0 19.0 10.0 25.1 17.1

3 15.3 22.9 18.7 12.8 19.2 17.2 10.2 15.3 15.3 18.1 27.2 20.4 15.5 23.3 18.9 12.9 19.3 17.4 21.2 31.8 22.0 18.5 27.7 20.5 15.7 23.6 19.1

4 13.0 26.0 20.0 10.7 21.4 18.1 8.3 16.5 16.5 15.5 31.1 22.0 13.2 26.4 20.1 10.8 21.6 18.3 18.3 36.5 23.8 15.8 31.7 22.0 13.4 26.7 20.2

5 11.3 28.1 20.9 9.2 23.1 18.7 7.2 18.0 16.7 13.5 33.8 23.1 11.4 28.6 21.0 9.3 23.2 18.9 16.0 40.0 25.2 13.8 34.6 23.1 11.6 29.0 21.0

6 9.9 29.7 21.6 8.1 24.3 19.2 6.3 18.8 17.0 12.0 35.9 24.0 10.1 30.2 21.6 8.2 24.5 19.3 14.2 42.6 26.2 12.2 36.7 23.9 10.2 30.7 21.6

4 16.2 32.3 25.0 13.4 26.8 22.7 10.4 20.8 20.8 19.2 38.5 27.4 16.4 32.7 25.1 13.5 26.9 22.9 22.5 45.0 29.6 19.5 39.1 27.4 16.5 33.1 25.2

5 14.1 35.3 26.3 11.6 29.0 23.6 9.1 22.8 21.1 16.9 42.3 29.0 14.3 35.8 26.3 11.7 29.2 23.8 19.9 49.8 31.5 17.2 43.0 28.9 14.5 36.2 26.3

6 12.5 37.5 27.2 10.2 30.6 24.3 7.9 23.8 21.5 15.0 45.1 30.2 12.7 38.1 27.2 10.3 30.8 24.4 17.8 53.3 32.9 15.4 46.1 30.0 12.9 38.6 27.2

8 10.1 40.5 28.6 8.2 32.9 25.3 6.3 25.3 22.1 12.3 49.1 31.9 10.3 41.3 28.5 8.3 33.2 25.3 14.6 58.5 35.0 12.6 50.3 31.7 10.5 41.9 28.4

6 13.7 41.0 30.8 11.2 33.6 27.7 8.8 26.5 24.8 16.4 49.1 33.9 13.8 41.5 30.9 11.3 33.8 27.9 19.3 57.8 36.8 16.6 49.9 33.8 14.0 41.9 30.9

8 11.2 44.7 32.4 9.1 36.4 28.9 7.1 28.2 25.5 13.5 53.9 35.9 11.3 45.4 32.4 9.2 36.7 29.0 16.0 63.9 39.3 13.8 55.0 35.8 11.5 46.0 32.4

10 9.4 47.1 33.5 7.7 38.3 29.7 5.9 29.4 26.0 11.5 57.3 37.4 9.6 48.0 33.5 7.7 38.6 29.7 13.6 68.2 41.1 11.7 58.6 37.2 9.8 48.8 33.4

7 14.6 51.2 39.6 12.1 42.3 35.9 9.4 32.8 32.8 17.5 61.1 43.5 14.8 51.9 39.8 12.2 42.6 36.3 20.5 71.7 47.0 17.8 62.1 43.5 15.0 52.4 40.0

9 12.5 56.1 41.7 10.2 46.0 37.4 8.0 36.0 33.3 15.0 67.4 46.0 12.6 56.9 41.8 10.3 46.2 37.6 17.7 79.5 50.1 15.3 68.7 45.9 12.8 57.6 41.8

11 10.8 59.5 43.2 8.8 48.5 38.5 6.8 37.6 34.0 13.1 71.8 47.9 11.0 60.5 43.2 8.9 48.9 38.6 15.5 85.2 52.4 13.3 73.4 47.7 11.1 61.3 43.2

13 9.5 62.0 44.4 7.8 50.5 39.3 6.0 38.8 34.5 11.6 75.3 49.4 9.7 63.2 44.3 7.8 50.9 39.4 13.8 89.6 54.2 11.8 76.9 49.1 9.9 64.2 44.2

7 17.0 59.6 47.6 14.2 49.5 43.4 11.2 39.2 39.2 20.2 70.7 52.0 17.2 60.3 47.9 14.2 49.8 44.0 23.6 82.5 56.0 20.5 71.7 52.1 17.4 60.8 48.2

9 14.6 65.9 50.2 12.0 54.2 45.3 9.2 41.5 41.5 17.5 78.7 55.2 14.8 66.6 50.4 12.1 54.5 45.7 20.5 92.4 59.8 17.8 79.9 55.1 14.9 67.3 50.5

11 12.8 70.4 52.2 10.5 57.6 46.7 8.2 45.0 41.6 15.4 84.6 57.6 13.0 71.3 52.2 10.5 57.9 47.0 18.1 99.8 62.7 15.6 86.1 57.4 13.1 72.1 52.2

13 11.4 73.8 53.7 9.3 60.2 47.8 7.2 46.6 42.3 13.7 89.0 59.5 11.5 74.9 53.6 9.3 60.5 48.0 16.2 105.3 64.9 14.0 90.8 59.2 11.7 75.9 53.6

15 10.2 76.5 54.9 8.3 62.2 48.7 6.4 47.9 42.8 12.3 92.6 61.0 10.4 77.8 54.8 8.4 62.6 48.8 14.7 110.2 67.0 12.6 94.6 60.7 10.5 78.9 54.7

11 16.3 89.4 71.5 13.5 74.4 65.3 10.7 59.0 59.0 19.3 106.2 78.1 16.5 90.6 72.1 13.6 75.0 66.2 22.5 124.0 84.3 19.6 107.9 78.4 16.7 91.6 72.7

14 14.1 98.9 75.5 11.6 81.5 68.2 8.9 62.5 62.5 16.9 118.2 83.0 14.3 100.2 75.8 11.7 82.0 68.8 19.8 138.9 90.0 17.2 120.3 82.9 14.5 101.3 76.0

17 12.4 105.8 78.5 10.2 86.7 70.3 8.0 67.8 62.7 15.0 127.2 86.7 12.6 107.3 78.6 10.3 87.2 70.8 17.6 150.0 94.3 15.2 129.6 86.4 12.8 108.6 78.7

21 10.7 112.5 81.5 8.7 91.7 72.4 6.8 71.0 63.9 12.9 135.8 90.4 10.9 114.3 81.4 8.8 92.3 72.7 15.4 161.2 98.8 13.2 138.8 89.9 11.0 115.9 81.3

17 15.6 132.8 101.1 12.9 109.4 91.3 10.2 86.6 82.1 18.7 158.6 111.1 15.8 134.3 101.4 12.9 109.9 92.0 21.9 185.9 120.3 18.9 160.8 110.8 15.9 135.4 101.6

21 13.6 142.7 105.4 11.1 116.8 94.3 8.7 91.3 83.9 16.3 171.3 116.4 13.8 144.5 105.4 11.2 117.3 94.8 19.2 201.8 126.5 16.6 174.2 115.8 13.9 145.9 105.3

25 12.0 150.0 108.6 9.8 122.3 96.6 7.6 94.8 85.3 14.5 180.8 120.4 12.2 152.2 108.5 9.8 123.0 97.0 17.1 213.8 131.4 14.7 184.4 119.7 12.3 154.1 108.3

75 F DB/63 F WB 80 F DB/67 F WB 85 F DB/71 F WB

42BHC,BVC 6-ROW COOLING CAPACITY (by Gpm)

b

25

Performance data (cont)

42BHC,BVC 8-ROW COOLING CAPACITY (by Gpm)

UNIT

SIZE

42BHC,BVC

06

08

10

12

16

20

30

40

DB — Dr y Bulb Temperature

EWT — Entering Water Temperature

MBtuh — Btuh in Thousands

SCb— Base Sensible Capacity at Nominal Cfm

TCb— Base Total Capacity at Nominal Cfm

WB — Wet Bulb Temperature

∆T—Change in Water Temperature (F)

42BHC,BVC

DB — Dry Bulb Temperature

EWT — Entering Water Temperature

MBtuh — Btuh in Thousands

SCb— Base Sensible Capacity at Nominal Cfm

TCb— Base Total Capacity at Nominal Cfm

WB — Wet Bulb Temperature

∆T—Change in Water Temperature (F)

LEGEND NOTE: All capacities are given in thousands of Btuh (MBtuh).

UNIT

SIZE

06

08

10

12

16

20

30

40

LEGEND NOTE: All capacities are given in thousands of Btuh (MBtuh).

40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT

GPM

∆TTC

4 11.8 23.6 17.0 9.7 19.4 15.2 7.6 15.1 13.4 14.2 28.4 18.9 12.1 24.1 17.1 9.8 19.6 15.3 16.8 33.6 20.6 14.6 29.2 18.8 12.3 24.6 17.1

5 10.2 25.6 17.9 8.4 20.9 15.8 6.4 16.1 13.8 12.4 30.9 20.0 10.5 26.2 17.9 8.5 21.2 15.9 14.7 36.7 21.9 12.7 31.9 19.9 10.7 26.7 17.9

6 9.0 27.0 18.6 7.3 22.0 16.3 5.6 16.8 14.1 10.9 32.7 20.8 9.2 27.6 18.5 7.4 22.3 16.3 13.0 39.0 22.9 11.3 33.8 20.6 9.4 28.3 18.5

7 8.0 28.0 19.0 6.5 22.8 16.7 5.0 17.3 14.3 9.7 34.1 21.4 8.2 28.7 19.0 6.6 23.1 16.7 11.6 40.7 23.6 10.1 35.2 21.2 8.4 29.4 18.9

4 13.6 27.2 20.8 11.3 22.5 18.8 9.0 18.0 17.0 16.2 32.5 22.8 13.8 27.7 20.9 11.4 22.8 19.0 19.0 38.1 24.7 16.6 33.2 22.9 14.1 28.1 21.0

5 11.9 29.9 21.9 9.8 24.6 19.7 7.7 19.3 17.5 14.4 35.9 24.2 12.2 30.4 22.0 9.9 24.8 19.8 16.9 42.3 26.4 14.7 36.7 24.2 12.4 30.9 22.0

6 10.6 31.9 22.8 8.7 26.1 20.3 6.7 20.2 17.9 12.8 38.4 25.3 10.8 32.5 22.8 8.8 26.4 20.4 15.2 45.5 27.7 13.1 39.4 25.2 11.0 33.1 22.8

7 9.5 33.4 23.5 7.8 27.2 20.8 6.0 21.0 18.2 11.5 40.4 26.2 9.7 34.1 23.5 7.9 27.6 20.9 13.7 47.9 28.7 11.9 41.5 26.1 9.9 34.8 23.5

8 8.6 34.6 24.1 7.0 28.2 21.2 5.4 21.6 18.4 10.5 41.9 26.9 8.8 35.4 24.0 7.1 28.5 21.2 12.5 50.0 29.6 10.8 43.2 26.7 9.0 36.1 24.0

6 13.3 40.0 28.6 10.9 32.8 25.5 8.5 25.5 22.5 16.0 48.1 31.7 13.6 40.7 28.6 11.0 33.1 25.6 18.9 56.8 34.6 16.4 49.2 31.6 13.8 41.3 28.6

7 12.0 42.1 29.6 9.8 34.4 26.2 7.6 26.5 22.9 14.5 50.8 32.9 12.3 42.9 29.5 9.9 34.7 26.2 17.2 60.2 36.0 14.9 52.1 32.7 12.5 43.6 29.4

8 10.9 43.7 30.3 8.9 35.6 26.7 6.8 27.3 23.2 13.2 52.9 33.8 11.2 44.6 30.3 9.0 36.0 26.7 15.7 62.8 37.2 13.6 54.4 33.6 11.4 45.5 30.1

9 10.0 45.0 31.0 8.1 36.6 27.2 6.2 28.0 23.5 12.1 54.6 34.6 10.2 46.0 30.8 8.2 37.1 27.2 14.5 65.1 38.1 12.5 56.2 34.4 10.4 47.0 30.7

7 13.2 46.4 33.6 10.9 38.0 30.0 8.5 29.7 26.5 15.9 55.7 37.1 13.5 47.1 33.6 10.9 38.3 30.1 18.8 65.7 40.5 16.3 56.9 37.0 13.6 47.8 33.5

9 11.1 50.1 35.3 9.1 40.8 31.2 7.0 31.5 27.3 13.5 60.5 39.2 11.3 51.0 35.2 9.2 41.2 31.2 15.9 71.7 43.0 13.8 62.0 39.0 11.5 51.9 35.1

11 9.6 52.6 36.4 7.8 42.8 32.0 5.9 32.7 27.8 11.6 63.8 40.7 9.8 53.7 36.3 7.9 43.2 32.0 13.8 76.1 44.8 11.9 65.5 40.4 10.0 54.8 36.1

13 8.4 54.4 37.2 6.8 44.2 32.6 5.2 33.6 28.1 10.2 66.3 41.8 8.6 55.6 37.1 6.9 44.7 32.6 12.2 79.1 46.2 10.5 68.2 41.5 8.7 56.9 37.0

9 13.6 61.0 44.5 11.1 50.1 39.7 8.7 39.2 35.3 16.3 73.3 49.1 13.8 62.1 44.5 11.2 50.6 39.9 19.2 86.4 53.5 16.6 74.9 48.9 14.0 63.0 44.4

11 11.9 65.3 46.4 9.7 53.3 41.1 7.5 41.2 36.1 14.3 78.8 51.5 12.1 66.5 46.3 9.8 53.8 41.2 16.9 93.2 56.3 14.7 80.6 51.2 12.3 67.5 46.1

13 10.5 68.3 47.7 8.6 55.7 42.1 6.6 42.7 36.7 12.7 82.7 53.2 10.7 69.7 47.6 8.6 56.2 42.1 15.1 98.2 58.4 13.1 84.9 52.9 10.9 70.9 47.4

15 9.4 70.6 48.8 7.7 57.4 42.9 5.8 43.9 37.1 11.4 85.8 54.6 9.6 72.2 48.6 7.7 58.0 42.9 13.6 102.3 60.1 11.7 88.1 54.2 9.8 73.6 48.4

10 14.9 74.6 54.8 12.3 61.3 49.1 9.6 48.1 43.7 17.9 89.4 60.4 15.1 75.7 54.8 12.3 61.7 49.3 21.0 105.1 65.6 18.2 91.0 60.1 15.3 76.5 54.7

12 13.2 79.4 56.9 10.8 64.9 50.6 8.4 50.4 44.6 15.9 95.6 63.0 13.4 80.6 56.8 10.9 65.4 50.7 18.8 112.8 68.8 16.3 97.5 62.6 13.6 81.7 56.6

14 11.9 83.0 58.6 9.7 67.7 51.8 7.4 52.2 45.3 14.3 100.3 65.1 12.1 84.5 58.4 9.7 68.2 51.8 17.0 118.7 71.2 14.6 102.6 64.6 12.2 85.7 58.1

16 10.7 85.8 59.8 8.7 69.8 52.7 6.7 53.5 45.8 13.0 103.9 66.7 10.9 87.5 59.6 8.8 70.4 52.7 15.4 123.5 73.3 13.3 106.5 66.2 11.1 89.0 59.3

13 16.1 104.3 78.9 13.3 86.4 71.3 10.6 68.7 64.2 19.2 124.5 86.7 16.3 105.9 79.2 13.4 87.1 72.0 22.4 145.9 93.8 19.5 126.8 86.6 16.5 107.2 79.5

16 14.2 113.6 83.0 11.7 93.3 74.2 9.1 73.1 65.9 17.0 136.3 91.6 14.4 115.4 83.0 11.8 94.0 74.6 20.1 160.5 99.6 17.4 139.0 91.2 14.6 116.9 82.9

19 12.7 120.5 86.1 10.4 98.5 76.4 8.0 76.4 67.3 15.3 145.2 95.4 12.9 122.6 85.9 10.5 99.4 76.6 18.1 171.6 104.2 15.6 148.4 94.8 13.1 124.4 85.7

22 11.4 125.8 88.5 9.3 102.6 78.2 7.2 79.0 68.3 13.8 152.0 98.4 11.6 128.1 88.2 9.4 103.5 78.2 16.4 180.2 107.8 14.2 155.7 97.7 11.8 130.2 87.9

25 10.4 129.9 90.3 8.5 105.7 79.5 6.5 81.0 69.1 12.6 157.4 100.8 10.6 132.5 90.0 8.5 106.7 79.5 15.0 187.2 110.8 12.9 161.5 100.0 10.8 134.9 89.6

19 15.9 151.5 110.7 13.1 124.5 99.0 10.3 97.7 88.0 19.1 181.4 122.0 16.1 153.4 110.5 13.2 125.2 99.4 22.4 213.0 132.5 19.4 184.3 121.2 16.3 155.0 110.3

22 14.5 159.4 114.3 11.9 130.4 101.5 9.2 101.4 89.5 17.4 191.6 126.4 14.7 161.7 113.8 11.9 131.2 101.7 20.5 225.8 137.7 17.7 195.1 125.4 14.9 163.6 113.4

25 13.3 165.7 117.1 10.8 135.2 103.6 8.4 104.4 90.7 16.0 199.7 129.9 13.5 168.3 116.6 10.9 136.1 103.6 18.9 236.1 142.0 16.3 203.9 128.8 13.6 170.6 116.0

28 12.2 170.8 119.3 9.9 139.0 105.2 7.6 106.9 91.7 14.7 206.4 132.8 12.4 173.8 118.8 10.0 140.1 105.2 17.5 244.4 145.5 15.1 211.1 131.7 12.6 176.4 118.2

40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT 40 F EWT 45 F EWT 50 F EWT

∆T

GPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSCbGPM TCbSC

10 3.5 17.3 13.6 2.5 12.5 11.7 3.5 17.3 13.6 4.7 23.3 16.0 3.6 17.9 13.8 2.6 12.8 12.0 6.0 30.0 18.5 4.8 24.2 16.2 3.7 18.3 14.0

12 2.5 14.9 12.6 — — — 2.5 14.9 12.6 3.5 20.8 15.0 2.6 15.5 12.9 — — — 4.6 27.7 17.5 3.6 21.7 15.2 2.7 16.0 13.2

14 — — — — — — — — — 2.6 18.1 13.9 — — — — — — 3.5 24.8 16.4 2.7 19.0 14.2 — — —

16— — ————— — —— — —— — — ——— 2.721.815.3— — —— — —

10 4.3 21.3 17.2 3.0 15.1 15.1 4.3 21.3 17.2 5.7 28.4 20.0 4.4 21.9 17.5 3.1 15.3 15.3 7.3 36.4 22.9 5.8 29.2 20.2 4.5 22.3 17.7

12 3.1 18.6 16.1 2.2 13.3 13.3 3.1 18.6 16.1 4.2 25.5 18.9 3.2 19.3 16.5 2.3 13.7 13.7 5.6 33.5 21.8 4.4 26.4 19.1 3.3 19.8 16.8

14 2.3 15.8 15.0 — — — 2.3 15.8 15.0 3.2 22.5 17.7 2.4 16.5 15.5 — — — 4.3 30.2 20.6 3.3 23.4 18.1 2.5 17.2 16.0

16 — — — — — — — — — 2.4 19.3 16.5 — — — — — — 3.4 27.0 19.3 2.5 20.3 17.0 — — —

18— — ————— — —— — —— — — ——— 2.623.418.1— — —— — —

10 6.2 30.9 23.5 4.6 23.1 20.3 6.2 30.9 23.5 8.1 40.5 27.3 6.3 31.6 23.7 4.7 23.4 20.6 10.2 51.2 31.1 8.4 41.8 27.4 6.4 32.2 23.9

12 4.7 28.1 22.3 3.4 20.7 19.3 4.7 28.1 22.3 6.2 37.3 26.0 4.8 28.8 22.6 3.5 21.0 19.7 8.0 47.9 29.8 6.4 38.5 26.1 4.9 29.4 22.9

14 3.6 25.2 21.1 2.5 17.6 17.6 3.6 25.2 21.1 4.9 34.3 24.8 3.7 25.9 21.5 2.6 18.1 18.1 6.4 44.7 28.5 5.0 35.4 25.0 3.8 26.5 21.9

16 2.8 22.0 19.8 — — — 2.8 22.0 19.8 3.9 31.0 23.5 2.9 22.9 20.4 — — — 5.2 41.2 27.2 4.0 32.1 23.8 2.9 23.5 20.9

18 — — — — — — — — — 3.1 27.5 22.1 — — — — — — 4.2 37.7 25.8 3.2 28.6 22.6 2.2 19.5 19.5

10 7.0 34.8 27.0 5.2 26.2 23.4 7.0 34.8 27.0 9.1 45.4 31.2 7.1 35.5 27.2 5.3 26.5 23.8 11.5 57.5 35.5 9.3 46.8 31.3 7.2 36.1 27.4

12 5.3 31.8 25.7 3.9 23.6 22.4 5.3 31.8 25.7 7.0 41.9 29.8 5.4 32.5 26.0 3.8 22.9 22.9 9.0 53.8 34.0 7.2 43.1 29.9 5.5 33.0 26.3

14 4.1 28.6 24.4 2.9 20.4 20.4 4.1 28.6 24.4 5.5 38.6 28.4 4.2 29.4 24.9 3.0 20.9 20.9 7.2 50.1 32.6 5.7 39.7 28.7 4.3 29.9 25.3

16 3.2 25.3 23.0 2.2 17.8 17.8 3.2 25.3 23.0 4.4 35.1 27.0 3.3 26.1 23.7 2.3 18.5 18.5 5.8 46.3 31.1 4.5 36.1 27.4 3.4 26.8 24.2

18 2.3 21.0 21.0 — — — 2.3 21.0 21.0 3.5 31.4 25.6 2.4 21.9 21.9 — — — 4.7 42.4 29.7 3.6 32.5 26.2 2.5 22.6 22.6

10 9.1 45.4 35.6 6.8 33.9 30.8 9.1 45.4 35.6 11.9 59.7 41.2 9.3 46.4 35.9 6.9 34.4 31.4 15.2 75.8 47.0 12.3 61.4 41.4 9.5 47.3 36.3

12 6.8 40.9 33.7 4.8 28.9 28.9 6.8 40.9 33.7 9.1 54.7 39.2 7.0 41.9 34.2 4.9 29.5 29.5 11.8 70.6 44.9 9.4 56.3 39.5 7.1 42.8 34.7

14 5.1 35.9 31.6 3.6 25.2 25.2 5.1 35.9 31.6 7.1 49.6 37.2 5.3 37.2 32.4 3.7 26.2 26.2 9.3 65.3 42.9 7.3 51.3 37.7 5.5 38.2 33.2

16 3.6 28.9 28.9 — — — 3.6 28.9 28.9 5.5 44.1 35.1 3.8 30.3 30.3 — — — 7.4 59.6 40.7 5.7 45.9 35.8 4.2 33.4 31.6

18 — — — — — — — — — 4.2 38.0 32.8 — — — — — — 6.0 53.7 38.5 4.5 40.1 33.8 — — —

10 11.6 57.9 44.8 8.7 43.7 38.9 11.6 57.9 44.8 15.0 75.2 51.6 11.8 59.0 45.1 8.8 44.1 39.5 19.1 95.4 58.8 15.5 77.6 51.9 12.0 60.0 45.5

12 8.9 53.2 42.8 6.6 39.5 37.2 8.9 53.2 42.8 11.6 69.9 49.4 9.0 54.2 43.3 6.7 40.1 38.0 14.9 89.6 56.5 12.0 71.7 49.7 9.2 55.1 43.8

14 6.9 48.1 40.7 4.9 34.2 34.2 6.9 48.1 40.7 9.2 64.6 47.3 7.0 49.3 41.4 5.0 35.0 35.0 11.9 83.4 54.1 9.5 66.3 47.7 7.2 50.2 42.1

16 5.3 42.8 38.5 3.8 30.0 30.0 5.3 42.8 38.5 7.4 59.0 45.1 5.5 44.1 39.5 3.9 31.2 31.2 9.7 77.4 51.8 7.6 60.7 45.7 5.6 45.2 40.4

18 3.9 35.4 35.4 — — — 3.9 35.4 35.4 5.9 53.1 42.8 4.1 36.9 36.9 — — — 7.9 71.3 49.5 6.1 54.8 43.7 4.2 38.0 38.0

10 17.2 85.8 66.9 12.8 64.1 58.0 17.2 85.8 66.9 22.5 112.5 77.6 17.5 87.6 67.6 13.0 65.0 59.1 28.6 142.8 88.4 23.1 115.8 77.8 17.8 89.2 68.2

12 12.9 77.4 63.4 9.1 54.7 54.7 12.9 77.4 63.4 17.2 103.3 73.8 13.2 79.4 64.5 9.3 55.8 55.8 22.1 132.7 84.4 17.7 106.4 74.4 13.5 81.0 65.3

14 9.8 68.3 59.7 6.8 47.9 47.9 9.8 68.3 59.7 13.4 94.0 70.1 10.1 70.6 61.2 7.1 49.8 49.8 17.6 123.3 80.7 13.9 97.0 71.0 10.4 72.5 62.5