Page 1

38MVC/40MVC

38MVQ/40MVQ

Comfortt S e r i e s H i g h --- W a l l D u c t --- F r e e S p l i t S y s t e m

Sizes 009 --- 024

Service Manual

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

STANDARD FEATURES AND ACCESSORIES 2...........

SPECIFICATIONS -- COOLING ONLY 3..................

SPECIFICATIONS -- HEAT PUMP UNITS 4...............

DIMENSIONS 5......................................

SERVICE VALVE LOCATIONS 5........................

CLEARANCES 6.....................................

SYSTEM OPERATING ENVELOPE 7....................

ELECTRICAL DATA 7................................

WIRING 8...........................................

CONNECTION DIAGRAMS 9..........................

WIRING DIAGRAMS 10 -- 16...........................

REFRIGERATION CYCLE DIAGRAM 17.................

REFRIGERANT LINES 18.............................

SYSTEM EVACUATION AND CHARGING 19.............

CONTROL SYSTEM 20...............................

SYSTEM SAFETIES 20................................

3MINUTETIMEDELAY 20............................

COMPRESSOR OVERCURRENT PROTECTION 20 -- 21....

SEQUENCE OF OPERATION 21........................

MODES OF OPERATION 22 -- 24........................

TROUBLESHOOTING 25 -- 37..........................

APPENDIX 38 -- 43...................................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-- authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes and

National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious h azards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

WARNING

!

!

INTRODUCTION

Section 1 of this Service Manual provides the necessary

information to service, repair, and maintain the EEZ family of

Puron air conditioners and heat pumps. Section 2 of this manual is

an appendix with data required to perform troubleshooting. Use

the Table of Contents to locate a desired topic.

Page 2

MODEL NUMBER NOMENCLATURE

INDOOR UNIT

40 MVC 3--- 01

Fan Coil Unit

Unit Type

MVC --- Co o l i n g On l y

MVQ --- H e a t Pu m p

018

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 To n

018 --- 1 --- 1 / 2 To n

024 --- 2 To n s

---

Volt age

--- --- 3 0 V D C

1 --- 1 1 5 --- 1 --- 6 0

3 --- 208/230 ---1 ---60

38/40MVC, MVQ

A i r --- C o o l e d C o n d e n s e r

OUTDOOR UNIT

38 MVC 3--- 01

Unit Type

MVC --- Co o l i n g On l y

MVQ --- H e a t Pu m p

018

Nominal Capacity

009 --- 3 / 4 To n

012 --- 1 To n

018 --- 1 --- 1 / 2 To n

024 --- 2 To n s

---

SERIAL NUMBER NOMENCLATURE

Week of Manufacture

01 06

V

00001

Serial Number

Volt age

1--- 11 5 --- 1 --- 6 0

3--- 208/230 --- 1 ---60

Year of Manufacture

Manufacturing Site

2

Page 3

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Mounting Brackets S

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Wireless Remote Control S

Automatic Air Sweep S

Air Direction Control S

Auto Restart Function S

Cold Blow Protection On Heat Pumps S

Turbo M o d e O n Si z e s 9K a n d 1 2 K S

Auto Changeover On Heat Pumps S

Energy Saving Features

Sleep Mode S

Stop/Start Timer S

Safety And Reliability

3MinuteTimeDelayForCompressor S

Over Current Protection For Compressor S

Indoor Coil Freeze Protection S

Indoor Coil High Temperature Protection On Heat Pumps S

Condenser High Temperature Protection On heat Pumps{ S

Accumulator On Heat Pumps S

Ease Of Service And Maintenance

Cleanable Filters S

Diagnostics S

Liquid Line Pressure Taps S

Suction And Discharge Pressure Taps (Sizes 18 and 24K) S

Application Flexibility

Low Ambient Controls ( --- 20˚F) A

Condensate Pumps A

Crankcase Heater A

Wind Baffles F

Warranty

5 --- Year Compressor Warranty S

1 --- Parts Warranty S

Compressor Extended Warranty Years 6 Thru 10 O

All Parts And Labor Years 2 Thru 5 O

All Parts And Labor Years 2 Thru 5, Compressor Years 6

Thru 10

{ Sizes 18k & 24k

Legend

SStandard

A Accessory

OOptional

F Field Fabricated

O

INDOOR UNITS

On high wall fan coils, the condensate pump has a lift capability of

18 ft (5.5 m) or the discharge side with the pump mounted in the

fan coil or 6 ft (1.8 m) on the suction side if the pump must be

remote mounted. The pump mounts inside the unit with quick

plug--in connections, and is recommended when adequate drain

line pitch cannot be provided, or when the condensate must move

up to exit.

NOTE: An external 115v power source will be required to run the

pump on unit sizes 9k and 12k.

OUTDOOR UNITS

LOW AMBIENT KIT

The kit controls condenser fan cycling using a pressure switch. It is

specifically designed to control fan--motor cycles in response to

saturated condensing pressure. This device maintains a constant

saturated condensing temperature of 100 _F ± 10 _F (37.78_C ±

--12.22 _C) at outdoor--air temperatures between 55 _F and --20 _F

(12.78_C ± --12.22_C), and can be used on all outdoor units

without changing the outdoor fan motor.

CRANKCASE HEATER

Available for units with rotary compressors. Heater clamps around

compressor oil sump. Recommended for low-- ambient applications

on sizes 9, 12 , 18, 24 and long line applications.

A07892

Fig. 1 – Condensate Pump

38/40MVC, MVQ

3

Page 4

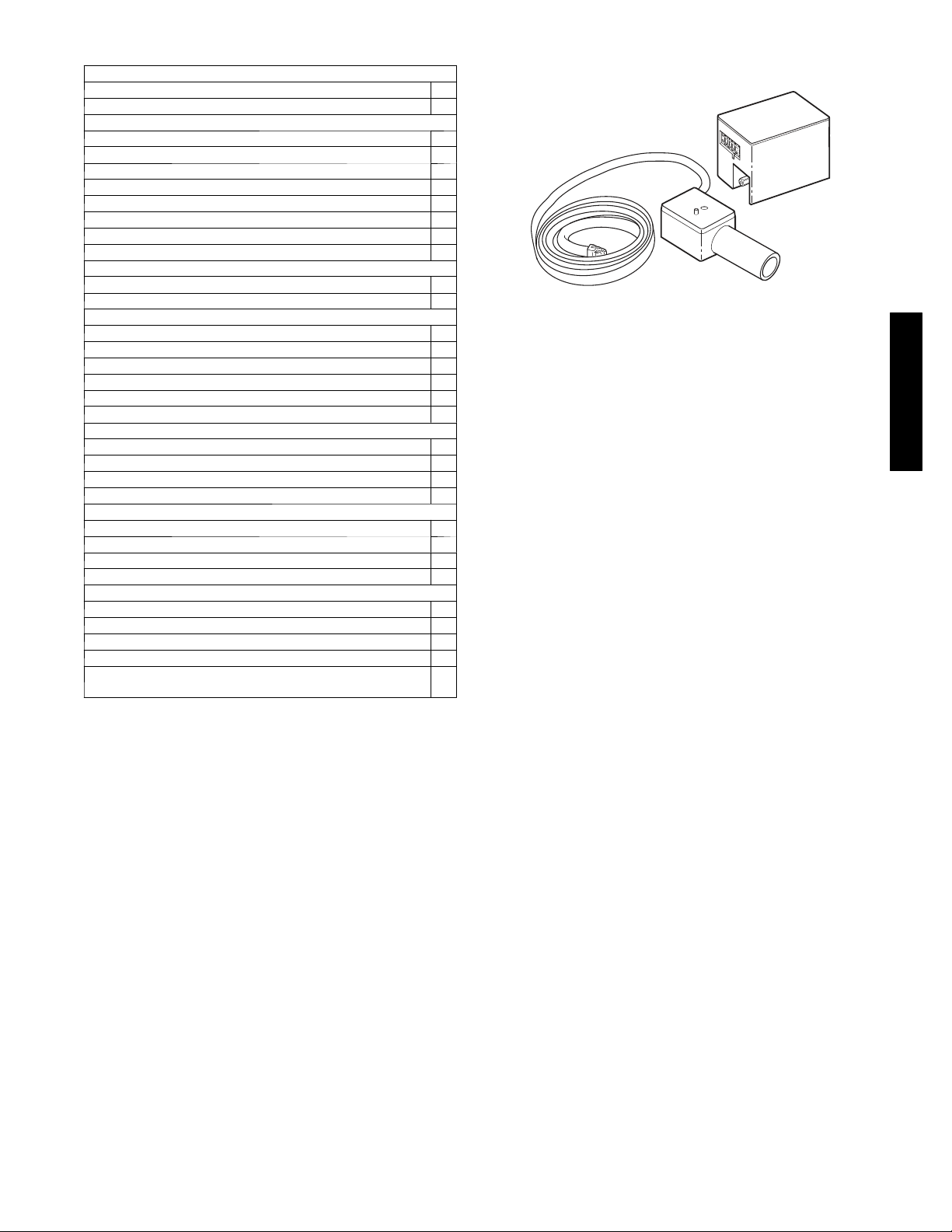

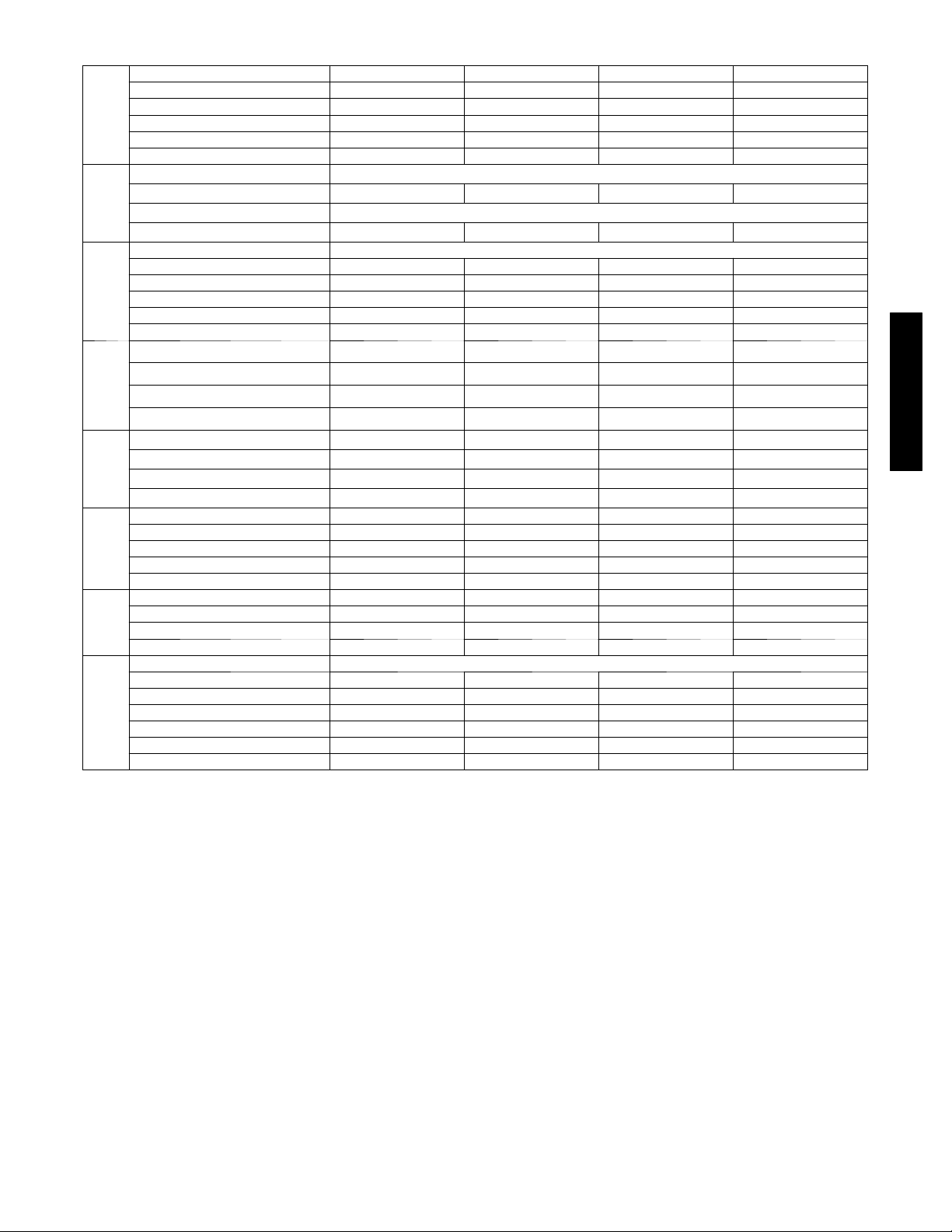

SPECIFICATIONS -- COOLING ONLY UNITS

System Model Number 5 3 M V C 0 0 9 --- --- --- 1 5 3 M V C 0 1 2 --- --- --- 1 5 3 M V C 0 1 2 --- --- --- 3 5 3 M V C 0 1 8 --- --- --- 3

System Voltage 115 V 115 V 208/230 208/230

Control Voltage 0 --- 1 2 P u l s e D C 0 --- 1 2 P u l s e D C 0 --- 1 2 P u l s e D C Pulse DC

Capacity (Btuh) 9000 12000 12000 18000

System

SEER 13.0 13.0 13.0 13.0

Refrigerant Typ e R--- 410A

Design Pressure (PSIG) 550 550 550 550

Metering Device Capillary Tube in Outdoor Unit

Charge (lb) 2.3 2.9 3.0 4.4

Refrigerant

Type Rotary

Model EA82X1C --- 1FZDU1 EA108X1C--- 1FZDU1 PA108X1C--- 3FZDU PA150X2C S--- 3KUU

O i l C h a r g e ( P O E --- o z ) 11.8 11.8 11.8 25.4

Capacitor 45µF/250VAC 45µF/250VAC 35µF/370VAC 40µF/370VAC

Rated Current (RLA) 7.5 9.9 5.2 7.3

Compressor

Locked Rotor Amp (LRA) 40 47 21 32.6

Rpm/CFM 900/1060 900/1090 900/1120 840/1470

Diameter (in) .. No. of Blades 15.8 … 3 15.8 … 3 15.8 … 3 18.1 … 3

Motor (hp) 0.102 0.102 0.102 0.224

Motor

Outdoor

Capacitor 6.5µF/260VAC 6.5µF/260VAC 2.5µF/450VAC 3µF/450VAC

Face A rea (sq. f t) 4.05 3.94 3.94 5.51

38/40MVC, MVQ

No. Rows 2 2 2 4

Fins per inch 17 17 17 18

Circuits 4 4 4 4

Outdoor Coil

Motor Watts/HP 20/.034 20/.034 20/.034 25/.044

Rpm/Cfm (High) 1250/325 1270/425 1270/425 1070/630

Rpm/Cfm (Medium) 1000/260 1100/365 1100/365 1000/570

Rpm/Cfm (Low) 800/190 1000/340 1000/340 960/500

Indoor Motor

Blower Diameter … Length (in) 3.84 … 25.87 4.17 … 25.2 4.17 … 25.2 4.21 … 37.6

Face A rea (sq. f t) 2.15 2.54 2.54 4.36

No. Rows 2 2 2 2

Coil

Fins per inch 19.5 19.5 19.5 19.5

Indoor

Circuits 2 3 3 6

Connection Type Flare

Liquid (Mix Phase) (in) OD 1/4” 1/4” 1/4” 1/4”

Vapor Line (in) OD 3/8” 1/2” 1/2” 1/2”

Condensate Drain (in) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID)

Lines

Maximum Length (ft) 65 65 65 100

Refrigerant

Max Lift (Fan Coil Above) (ft) 35 35 35 50

Max Drop (Fan Coil Below) (ft) 35 35 35 50

4

Page 5

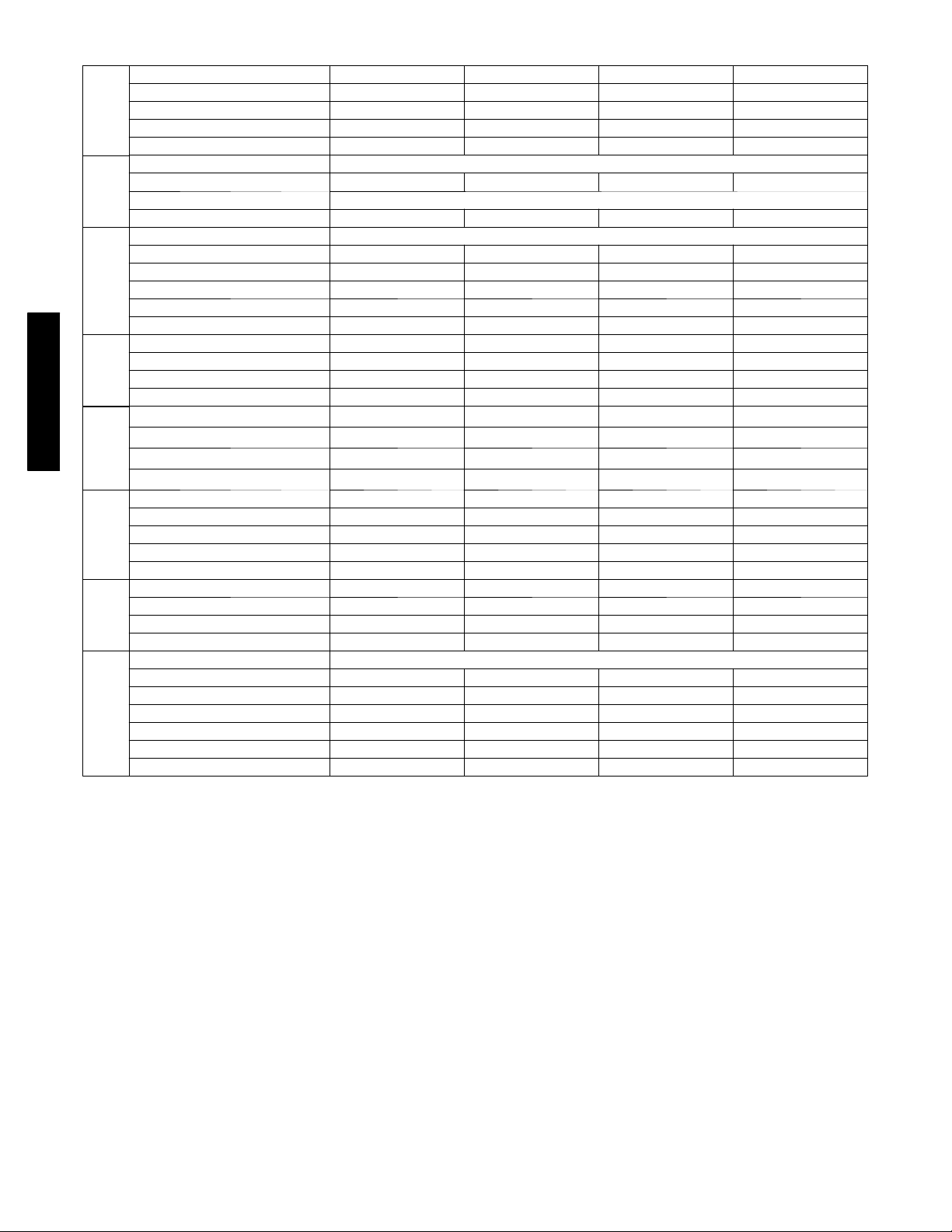

SPECIFICATIONS -- HEAT PUMP UNITS

System Model Number 5 3 M V Q 0 0 9 --- --- --- 1 5 3 M V Q 0 1 2 --- --- --- 1 5 3 M V Q 0 1 2 --- --- --- 3 5 3 M V Q 0 1 8 --- --- --- 3

System Voltage 115 V 115 V 208/230 208/230

Control Voltage 0 --- 1 2 P u l s e D C 0 --- 1 2 P u l s e D C 0 --- 1 2 P u l s e D C Pulse DC

Capacity (Btuh) 9000 12000 12000 18000

System

SEER 13.0 13.0 13.0 13.0

HSPF 7.7 7.7 7.7 7.7

Refrigerant Typ e R--- 410A

Design Pressure (PSIG) 550 550 550 550

Metering Device Capillary Tubes in Outdoor Unit

Charge (lb) 2.35 3.0 3.0

Refrigerant

Type Rotary

Model EA82X1C --- 1FZDU1 EA108X1C--- 1FZDU1 PA108X1C--- 3FZDU PA150X2C S--- 3KUU

O i l C h a r g e ( P O E --- o z ) 11.8 11.8 11.8 25.4

Capacitor 45µF/250VAC 45µF/250VAC 35µF/370VAC 40µF/370VAC

Rated Current (RLA) 7.5 9.9 5.2 7.3

Compressor

Locked Rotor Amp (LRA) 40 47 21 32.6

Rpm/CFM 900/1060 900/1090 900/1120 840/1470

Diameter (in) .. No. of Blades 15.8 … 3 15.8 … 3 15.8 … 3 18.1 … 3

Motor (hp) 0.102 0.102 0.102 0.224

Capacitor 6.5µF/260VAC 6.5µF/260VAC 2.5µF/450VAC 3µF/450VAC

Outdoor Motor

Face A rea (sq. f t) 4.05 3.94 3.94 5.51

No. Rows 2 2 2 4

Fins per inch 17 17 17 18

Circuits 4 4 4 4

Outdoor Coil

Motor Watts/HP 20/.034 20/.034 20/.034 25/.044

Rpm/Cfm (High) 1250/325 1270/425 1270/425 1070/630

Rpm/Cfm (Medium) 1000/260 1100/365 1100/365 1000/570

Motor

Indoor

Rpm/Cfm (Low) 800/190 1000/340 1000/340 960/500

Blower Diameter … Length (in) 3.84 … 25.87 4.17 … 25.2 4.17 … 25.2 4.21 … 37.6

Face A rea (sq. f t) 2.15 2.54 2.54 4.36

No. Rows 2 2 2 2

Coil

Fins per inch 19.5 19.5 19.5 19.5

Indoor

Circuits 2 3 3 6

Connection Type Flare

Liquid (Mix Phase) (in) OD 1/4” 1/4” 1/4” 1/4”

Vapor Line (in) OD 3/8” 1/2” 1/2” 1/2”

Condensate Drain (in) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID) .65 (OD) .53 (ID)

Maximum Length (ft) 65 65 65 100

Lines

Refrigerant

Max Lift (Fan Coil Above) (ft) 35 35 35 50

Max Drop (Fan Coil Below) (ft) 35 35 35 50

38/40MVC, MVQ

5

Page 6

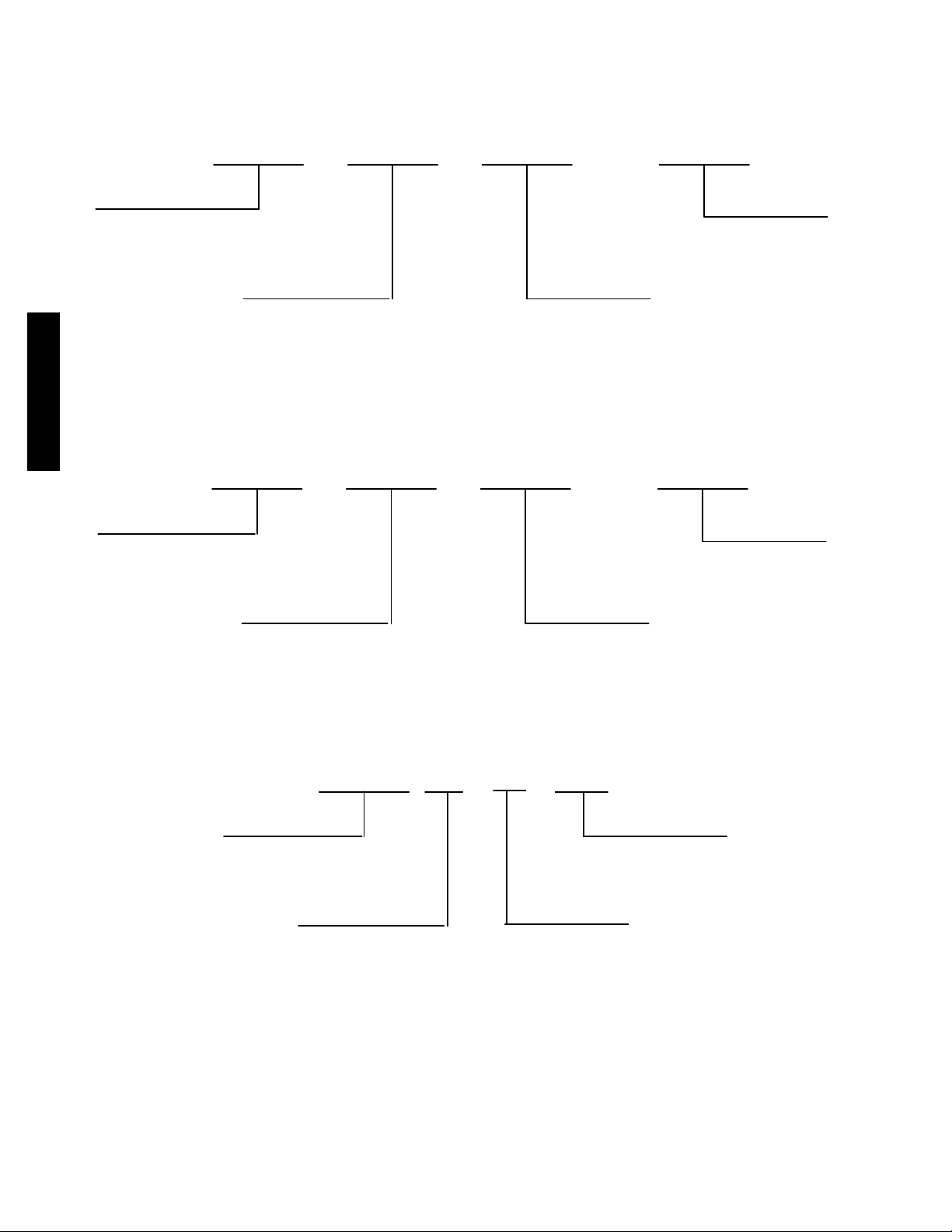

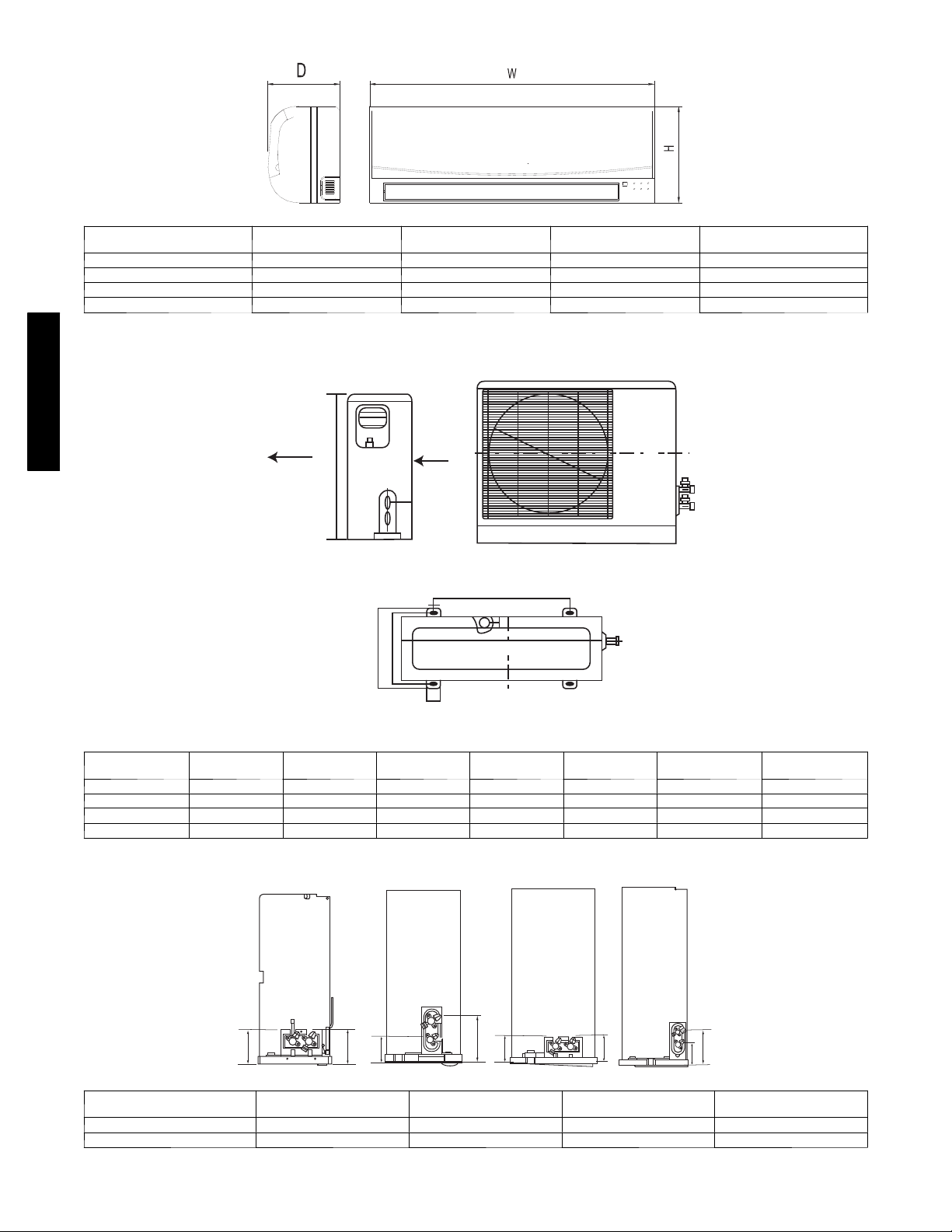

DIMENSIONS -- INDOOR

Model Size

9K 32.09 (815) 11.02 (280) 7.68 (195)

12K 35.67 ( 906) 11.26 (286) 9.25 (235)

18K 49.21 (1250) 12.80 (325) 9.06 (230)

24K 49.21 (1250) 12.80 (325) 9.06 (230)

in. (mm)

DIMENSIONS -- OUTDOOR

A07336

W

H

in. (mm)

D

in. (mm)

Weight lb (kg)

24.2 (11)

33.0 (15)

55.0 (25)

55.0 (25)

38/40MVC, MVQ

Model Size

9K 30.71 (780) 21.26 (540) 21.61 ( 549) 11.81 (300) 10.87 (276)

12K 29.92 (760) 23.23 (590) 20.87 (530) 12.40 (315) 11.42 (290)

18K 33.07 (840) 27.36 (695) 22.05 (560) 14.17 (360) 13.19 (335)

24K 31.16 (893) 33.86 (860) 23.11 (588) 13.98 (355) 13.11 (333)

Air Flow

W

in. (mm)

SERVICE VALVE LOCATI ONS

9K

H

H

in. (mm)

L2

L3

in. (mm)

12K

L1

W

L1

35

A07337

L2

in. (mm)

18K

L3

in. (mm)

24K

Weight lb (kg)

Cooling Only

77.0 (35) 79.2 (36)

85.8 (39) 90.2 (41)

125.4 (57) 125.4 (57)

159.5 (72) 160.6 (73)

Weight lb (kg)

Heat Pumps

Service Valve Locations

J 3.46 (88) 3.19 (81) 3.46 (88) 4.02 (102)

K 3.46 (88) 5.63 (143) 3.62 (92) 6.57 (167)

K

12K

in. (mm)

J

K

18K

in. (mm)

K

J

A07376a

24K

in. (mm)

J

9K

in. (mm)

J

K

6

Page 7

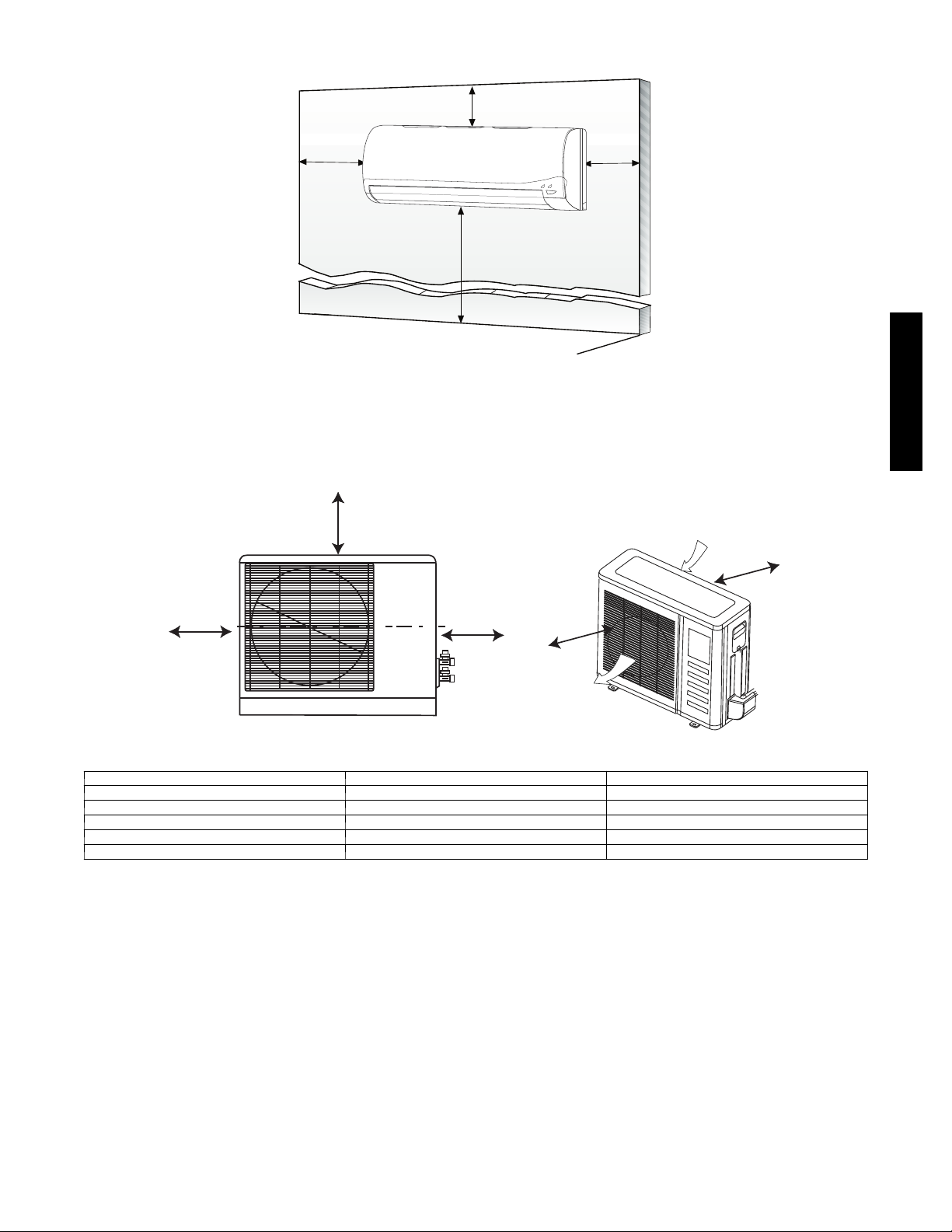

CLEARANCES -- INDOOR

5

"

(0.13m)

min.

6" (0.15m) min.

(1.8m)

6'

Fig. 2 – Indoor unit clearance

5

"

(0.13m)

min.

A07891

CLEARANCES -- OUTDOOR

D

UNIT 9k and 12k in. (mm)

A 24 (610)

B 24 (610)

C 24 (610)

D 4 (102)

E 12 (305)

A

B

Fig. 3 – Outdoor Unit Clearance

38/40MVC, MVQ

Air-inlet

E

C

Air-outlet

A07894

18k and 24k in. (mm)

24 (610)

36 (914)

24 (610)

12 (305)

12 (305)

7

Page 8

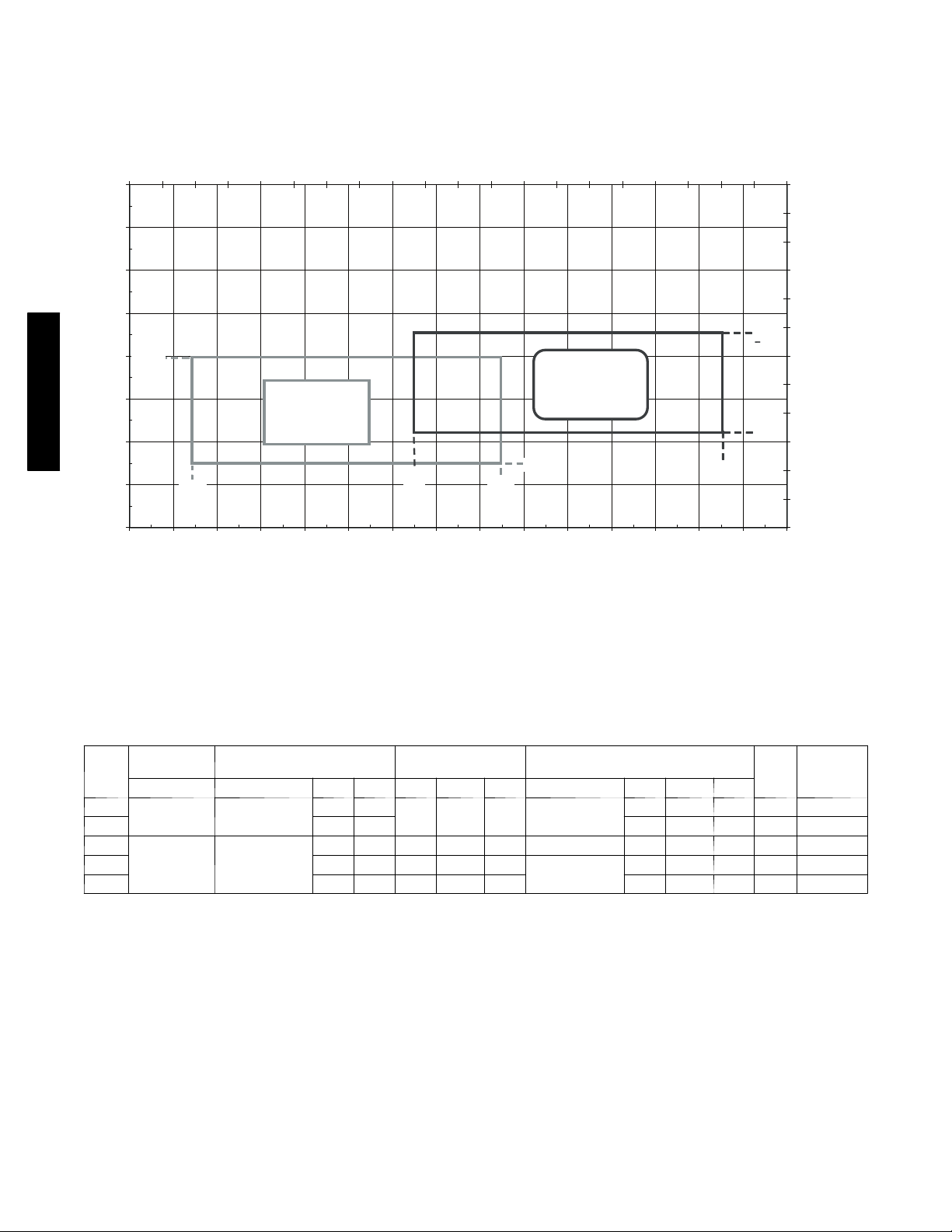

SYSTEM OPERATING ENVELOPE

53MVC/MVQ System Operating Envelope Chart

40

50

60

70

80

90

100

110

120

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Outdoor Temperature (ºF)

Indoor Temperature (ºF)

0

5

10

15

20

25

30

35

40

45

50

55

60

-40-35-30-25-20-15-10-5 0 5 1015202530354045505560

Outdoor Temperature (ºC)

Indoor Temperature (ºC)

Cooling

Continuous

Operation

Heating

Continuous

Operation

85º

62ºF

55º

75ºF

55ºF

5ºF

80ºF

125º

38/40MVC, MVQ

Use low ambient control if the unit will operate in cooling at ambient conditions below 55_F (12.78_C).

Fig. 4 – System Operating Enevelope

ELECTRICAL DATA

OPERATING

UNIT

SIZE

*Permissible limits of the voltage range at which the unit will operate satisfactorily

LEGEND

FLA --- Fu l l L o a d A m p s

LRA --- L o c k e d R o t o r A m p s

MCA - -- Minimum Circuit Amps

RLA ---RatedLoadAmps

VOLTAGE*

MAX/MIN V O L T S --- P H --- H Z RLA LRA FLA HP W VOLTS FLA HP W

009

012 9.9 47 1.18 0.044 25 15 25

012

018 7.3 32.6 0.78 0.224 53

024 9.7 34.8 0.62 0.218 100 0.39 0.112 50 14 25

127/104 1 1 5 --- 1 --- 6 0

253/187 208/230---1 ---60

COMPRESSOR OUTDOOR FAN INDOOR FAN

7.5 40

5.2 21 0.38 0.116 36 35 DC 1.18 0.044 25 9 15

0.60 0.102 23 35 DC

208/230---1---60

1.1 0.034 20 12 20

0.26 0.075 31 11 20

A08180

MCA

MAX

FUSE/CB

AMP

8

Page 9

WIRING

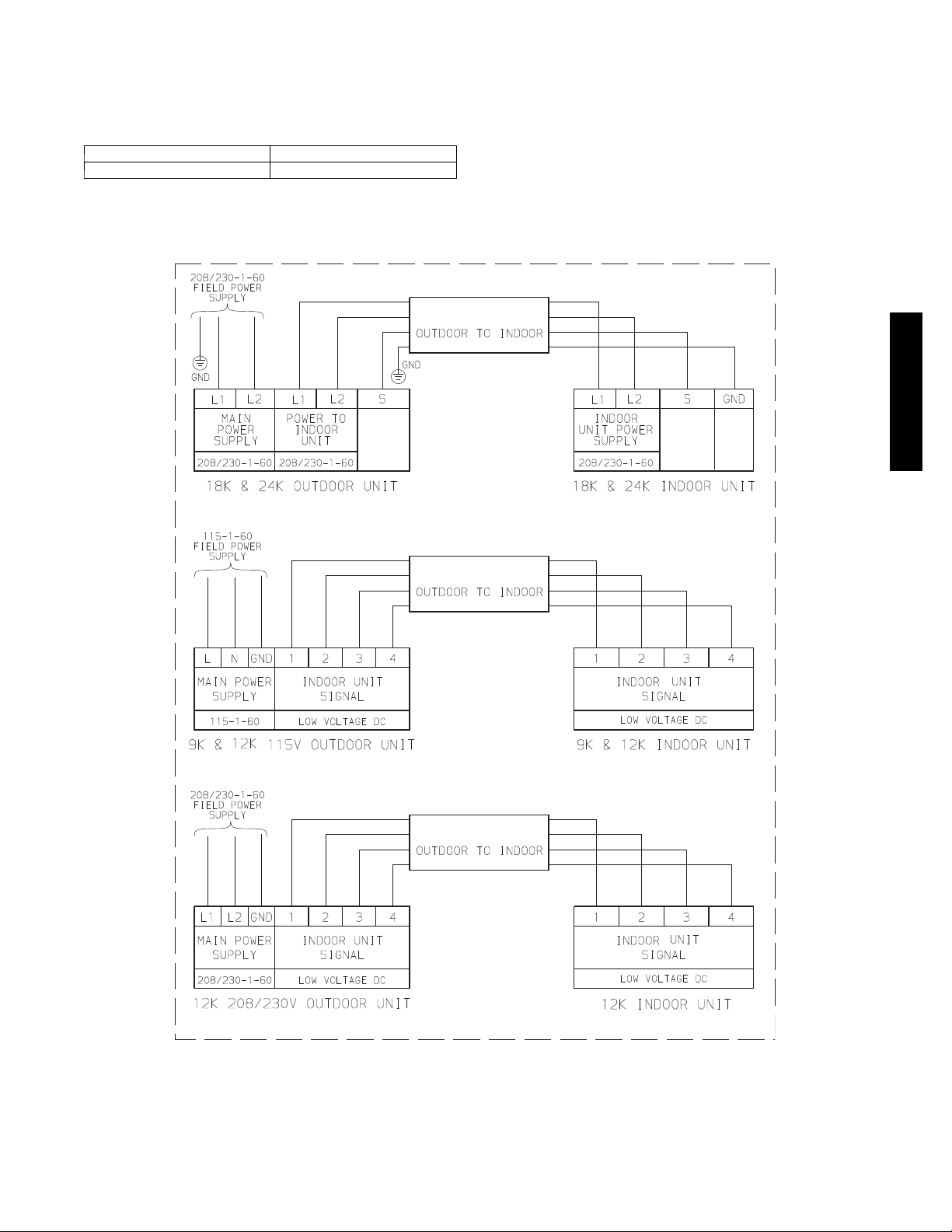

The main power is supplied to the outdoor unit. The field supplied connecting cable from the outdoor unit to indoor unit consists of four

wires and provides the power for the indoor unit as well as the communication signal between the outdoor unit and indoor unit.

Voltage drop on the connecting cable should be kept to a minimum. Use cable size and max length below:

18 AWG 50 ft. (16 m)

16 AWG 100 ft. (33 m)

CONNECTION DIAGRAMS

CONNECTING CABLE

CONTROL

CONNECTING CABLE

CONNECTING CABLE

CONTROL

38/40MVC, MVQ

Notes:

1. Do not use thermostat wire for any connection between indoor and outdoor units.

2. All connections between indoor and outdoor units must be as shown. The connections are sensitive to polarity.

3. On the 18k and 24k units, the “S” terminal “CONTROL” output is pulse DC with a potential AC voltage shock hazard.

Fig. 5 – Connection Diagrams

9

A07654

Page 10

38/40MVC, MVQ

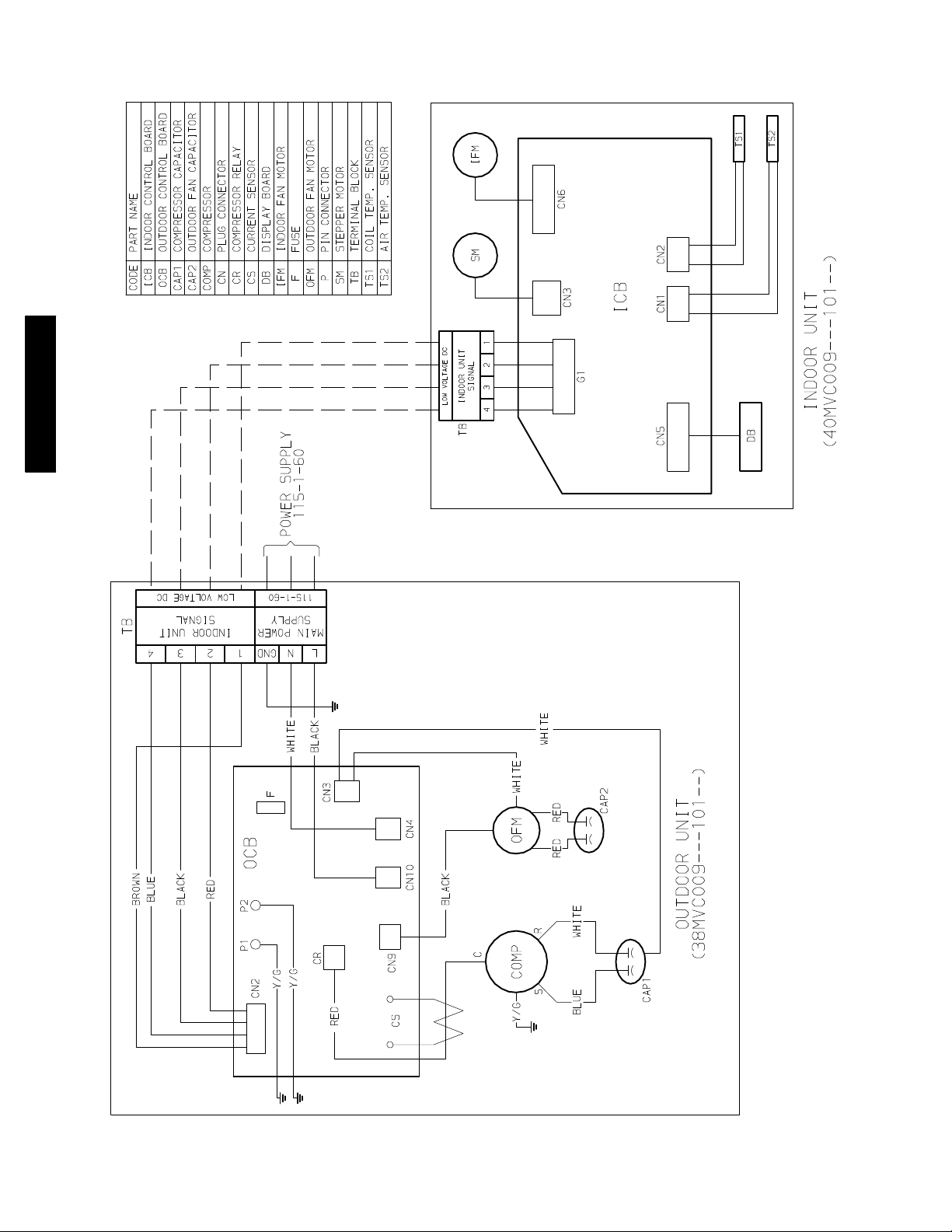

Fig. 6 – Wiring Diagram 38MVC009------ 1 W/ 40MVC009-- -- --1

WIRING DIAGRAMS

10

Page 11

38/40MVC, MVQ

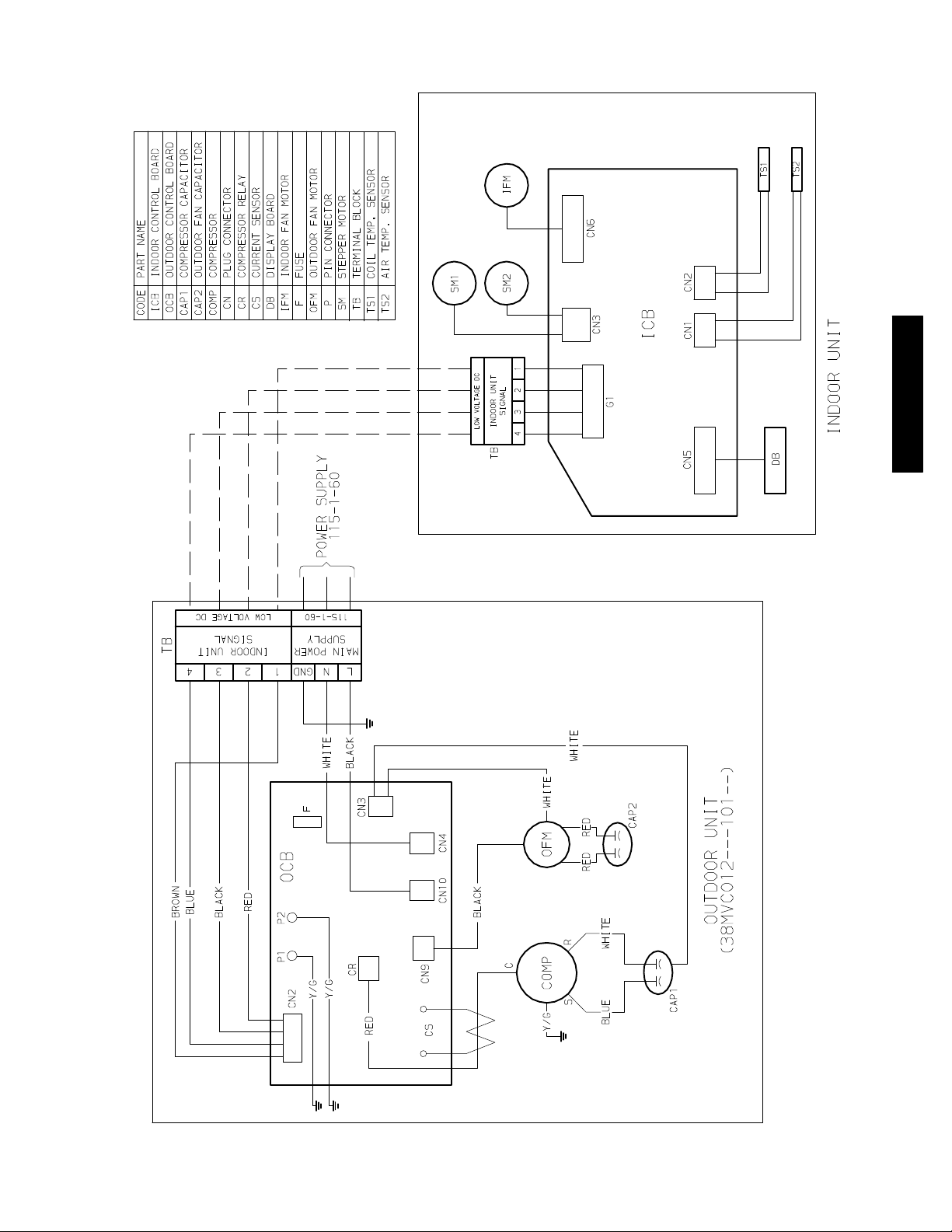

Fig. 7 – Wiring Diagram 38MVC012------ 1 W/ 40MVC012-- -- --1

WIRING DIAGRAMS (CONT.)

11

Page 12

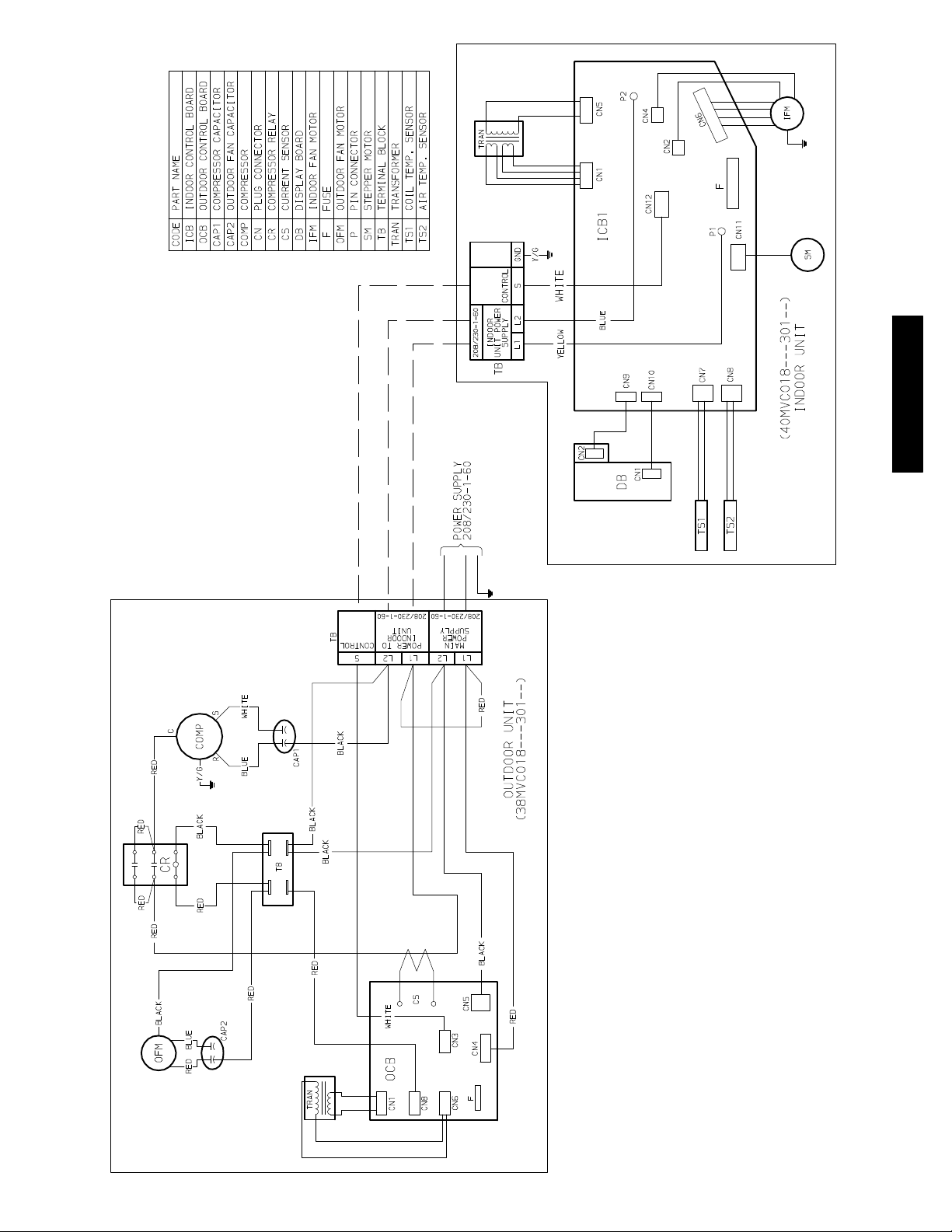

38/40MVC, MVQ

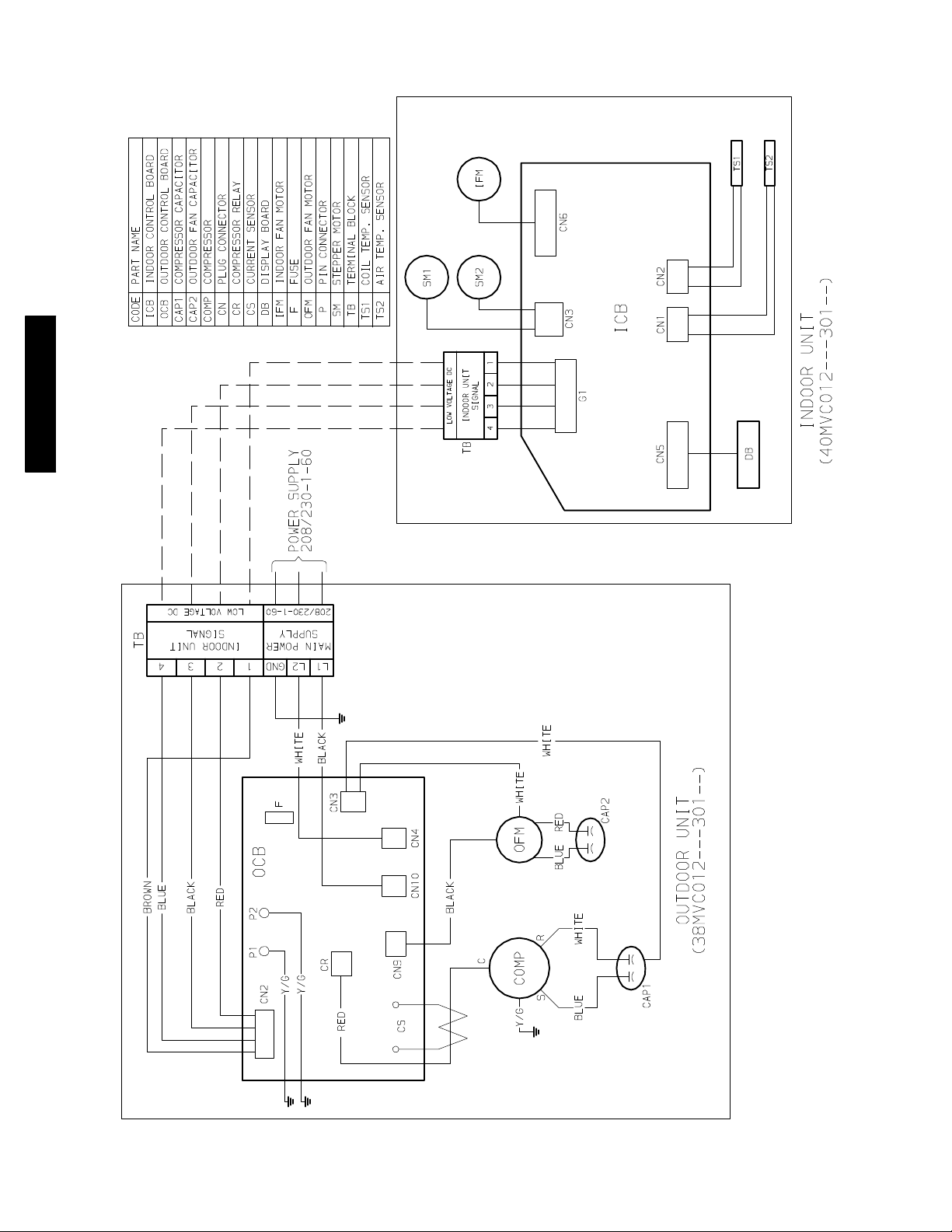

Fig. 8 – Wiring Diagram 38MVC012------ 3 W/ 40MVC012-- -- --3

WIRING DIAGRAMS (CONT.)

12

Page 13

38/40MVC, MVQ

Fig. 9 – Wiring Diagram 38MVC018------ 3 W/ 40MVC018-- -- --3

WIRING DIAGRAMS (CONT.)

13

Page 14

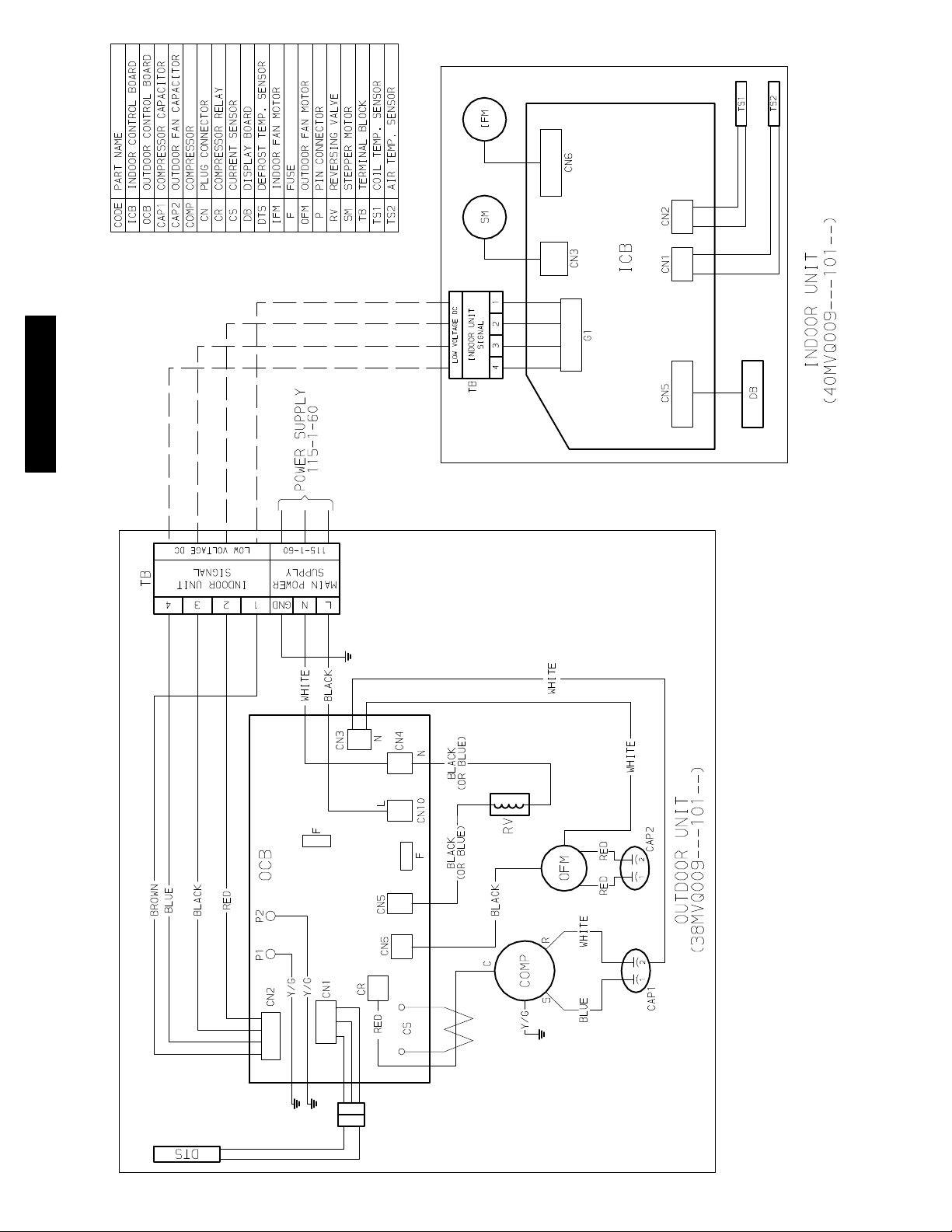

38/40MVC, MVQ

Fig. 10 – Wiring Diagram 38MVQ009------ 1 W/ 40MVQ009-- -- --1

WIRING DIAGRAMS (CONT.)

14

Page 15

38/40MVC, MVQ

Fig. 11 – Wiring Diagram 38MVQ012-- -- --1 W/ 40MVQ012-- ----1

WIRING DIAGRAMS (CONT.)

15

Page 16

38/40MVC, MVQ

Fig. 12 – Wiring Diagram 38MVQ012------ 3 W/ 40MVQ012-- -- --3

WIRING DIAGRAMS (CONT.)

16

Page 17

REFRIGERATION CYCLE DIAGRAM

FIELD

PIPING

FLARE CONNECTION

TWO PHASE LIQUID LINE

SERVICE VALVE

CAPILLARY TUBE

HEAT

EXCHANGER

(EVAPORATOR)

FLARE CONNECTION

INDOOR UNIT OUTDOOR UNIT

FLARE CONNECTION

SERVICE VALVE W/GUAGE PORT

SUCTION LINE

FIELD

PIPING

Fig. 13 – Cooling

LIQUID HTG

SERVICE VALVE

COMPRESSOR

CHECK VALVE

(HEATING MODEL ONLY)

CAPILLARY TUBE

HEAT

EXCHANGER

(CONDENSER)

38/40MVC, MVQ

A08104

TWO PHASE

LIQUID

HEAT

EXCHANGER

(EVAPORATOR)

FLARE CONNECTION

SERVICE VALVE

W/ GUAGE PORT

ACCUMULATOR

FIELD

PIPING

Fig. 14 – Heat Pumps

SUCTION

SUCTION

DISCHARGE

COMPRESSOR

HEAT

EXCHANGER

(CONDENSER)

REVERSING

VALVE

(HEAT PUMP ONLY)

COOLING

HEATING

A08105

17

Page 18

REFRIGERANT LINES

General refrigerant line sizing:

1. The 38MVC/MVQ units are shipped with a full charge of

R410A refrigerant. All charges, line sizing, and capacities

are based on runs of 25 ft (7.6 m). For runs over 25 ft (7.6

m), consult long--line section on this page for proper charge

adjustments.

2. Minimum refrigerant line length between the indoor and

outdoor units is 10 ft. (3 m).

3. Refrigerant lines should not be buried in the ground. If it is

necessary to bury the lines, not more than 36--in (914 mm)

should be buried. Provide a minimum 6--in (152 mm)

vertical rise to the service valves to prevent refrigerant

migration.

4. Both lines must be insulated. Use a minimum of 1/2--in.

(12.7 mm) thick insulation. Closed-- cell insulation is

recommended in all long--line applications.

5. Special consideration should be given to isolating

interconnecting tubing from the building structure. Isolate

the tubing so that vibration or noise is not transmitted into

the structure.

S The following maximum lengths are allowed:

38/40MVC, MVQ

Unit Size

S The following are the piping sizes.

Refrigerant Charge

S Above charge is for piping runs up to 25 ft. (7.6 m).

S For piping runs greater than 25 ft. (7.6 m), add 0.1 oz. of

refrigerant per foot of extra piping up to the allowable

length.

REFRIGERANT LINE LENGTHS ft. (m)

Max Line

Length

Max Elevation

(ID over OD)

9K 65 (20) 35 (11) 35 (11)

12K 65 (20) 35 (11) 35 (11)

18K 100 (30) 50 (15) 50 (15)

24K 100 (30) 60 (18) 60 (18)

PIPE SIZES

Unit Size Mix Phase Vapor

9K 1/4” 3/8”

12K 1/4” 1/2”

18K 1/4” 1/2”

24K 3/8” 5/8”

REFRIGERANT CHARGE lb. (kg)

Unit Size Air Conditioner

Heat Pump

9K 2.3 (1.0) 2.4 (1.1)

12K 2.9 (1.3) 3.0 (1.4)

18K 4.4 (2.0) TBD

24K TBD TBD

Max Elevation

(OD over ID)

Long Line Applications, 38MVC

Units:

1. A crankcase heater should be added for line lengths longer

than 25 ft (7.62 m) to prevent the migration of refrigerant to

the compressor during the “OFF” cycle.

2. A field fabricated wind baffle is recommended.

3. No change in line sizing is required.

4. Add refrigerant per table below.

ADDITIONAL CHARGE TABLE

Unit

Size

9K

cool

only

9K

hp

12K

cool

only

12K

hp

18K

cool

only

Tot a l

Line Length,

ft

Min. Max.

65

10

100

10 --- 25 ft

(3.05 --- 7.62m)

Additional Charge, oz.

none

> 2 5 --- 6 5 f t

(7.62 ---19.81m)

0.1 oz per

foot

> 6 5 --- 1 0 0 f t

(19.81 ---30.48m)

0.1 oz. per

foot

5. Reduction in capacity due to long lines can be calculated

from the chart below.

CAPACITY LOSS

Capacity,%Loss

Line Length, ft

Cooling: 25 45 65 100

9&12KBTU/Hmodels 0% 2% 5%

18 & 24 KBTU/H models 0% 2% 4% 7%

Heating:

9&12KBTU/Hmodels 0% 7% 11%

18 & 24 KBTU/H models 0% 7% 11% 15%

18

Page 19

SYSTEM EVACUATION AND

t

CHARGING

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed. Always break a vacuum with dry nitrogen.

SYSTEM VACUUM AND CHARGE

Using Vacuum Pump

1. Completely tighten flare nuts A, B, C, D, connect manifold

gage charge hose to a charge port of the low side service

valve. (See Fig. 15.)

2. Connect charge hose to vacuum pump.

3. Fully open the low side of manifold gage. (See Fig. 16)

4. Start vacuum pump

5. Evacuate using either deep vacuum or triple evacuation

method.

6. After evacuation is complete, fully close the low side of

manifold gage and stop operation of vacuum pump.

7. The factory charge contained in the outdoor unit is good for

up to 25 ft. (8 m) of line length. For refrigerant lines longer

than 25 ft (8 m), add 0.1 oz. per foot of extra piping up to

the maximum allowable length.

8. Disconnect charge hose from charge connection of the low

side service valve.

9. Fully open service valves B and A.

10. Securely tighten caps of service valves.

Outdoor Unit

Service Valve

CAUTION

Refrigerant

Low Side

A

High Side

B

Fig. 15 – Service Valve

Manifold Gage

Indoor Uni

C

D

A07360

Deep Vacuum

Method

The deep vacuum method requires a vacuum pump capable of

pulling a vacuum of 500 microns and a vacuum gage capable of

accurately measuring this vacuum depth. The deep vacuum method

is the most positive way of assuring a system is free of air and

liquid water. (See Fig. 17)

5000

4500

4000

3500

3000

2500

2000

MICRONS

1500

1000

500

01234567

MINUTES

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

A95424

Fig. 17 – Deep Vacuum Graph

Triple Evacuation

Method

The triple evacuation method should only be used when vacuum

pump is only capable of pumping down to 28 in. of mercury

vacuum and system does not contain any liquid water.

Refer to Fig. 18 and proceed as follows:

1. Pump system down to 28 in. of mercury and allow pump to

continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allo w system to stand for 1 hr. During this time, dry nitrogen will be able to diffuse throughout

the system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 18. System will

then be free of any contaminants and water vapor.

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

38/40MVC, MVQ

500 microns

Low side valve

Charge hose

Low side valve

High side valve

Charge hose

Fig. 16 – Manifold

Vacuum pump

A07361

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

RELEASE CHARGE INTO SYSTEM

A95425

Fig. 18 – Triple Evacuation Method

Final Tubing

Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any sheet

metal. Pay close attention to feeder tubes, making sure wire ties

on feeder tubes are secure and tight.

19

Page 20

CONTROL SYSTEM

The 40MVC/MVQ unit is equipped with a microprocessor control to perform two functions:

1. Provide safety for the system

2. Control the system and provide optimum levels of comfort and efficiency

The main microprocessor is located on the control board of the fan coil unit (outdoor units have a microprocessor too) with thermistors

located in the fan coil air inlet and on the indoor coil. Heat pump units have a thermistor on the outdoor coil. These thermistors monitor the

system operation to maintain the unit within acceptable parameters and control the operating mode.

SYSTEM SAFETIES

Safety

3MinTimeDelay X X X X X X X X

Over Current Protection On Compressor X X X X X X X X

Indoor Coil Freeze Protection X X X X X X X X

Condenser High Temperature Protection X X X X

Indoor Evaporator High Temperature X X X X

9K 012K 018K 024K 09K 012K 018K 024K

Cooling Only Heat Pump

3MINUTETIMEDELAY

In order to protect the compressor, there is a 3 minute delay on break even if the control is calling for heating or cooling.

38/40MVC, MVQ

COMPRESSOR OVERCURRENT PROTECTION

Overcurrent protection can result due to any of the following:

S The ambient temperature is to high

S Locked rotor on the compressor

S Blockage in refrigeration circuit (cap tubes, for example)

S Outdoor air is blocked or restricted

The compressor current is monitored continuously and protection is provided as shown below:

3 sec

5 min

1 sec

Normal

Current down

Indoor fan: On

compressor: On

outdoor fan: On

Compressor off

(after 5 minutes)

Outdoor fan

off (heating)

Indoor fan low

speed (cooling)

Compressor off

(after 3 seconds)

Current up

A08117

Fig. 19 – Compressor Overcurrent Protection

If the compressor is stopped 4 times at the 5 minute limit or 1 time at the 3 second limit, the system will be locked off and the main power will

have to be reset before the system can be restarted.

Time Limit

3SEC 14 A 18 A 11 A 14 A 23 A

5MIN 12 A 16A 9A 12 A 21 A

ISEC 10.5 A 14 A 7A 11 A 18 A

NORMAL 9A 12.5 A 6A 10 A 16 A

38MVC(Q)009---1 38MVC(Q)012--- 1 38MVC(Q)012--- 3 38MVC(Q)018---3 38MVC(Q)024--- 3

Compressor Current

20

Page 21

Indoor Coil Freeze

Protection

The indoor coil can freeze due to any of the following:

S Low system charge

S Reduced indoor airflow

S Restricted refrigerant flow

S Low ambient temperature (outdoor)

S Low load (indoor)

In cooling mode, the thermistor located on a return bend of the

indoor coil monitors the coil temperature continuously. Any time

the coil temperature drops below the TE5 limit for five consecutive

minutes, the compressor and outdoor fan will be switched off until

the coil temperature rises above the TE6 as shown below:

Compressor and

outdorr fan on

EVAP temp. down

Compressor and outdoor

fan off (after 5 mins)

TE5 TE6

EVAP temp. up

T

(Evap Temp.)

A08118

Fig. 20 – Indoor Coil Freeze Protection

Parameter

TE5 39 (4) 41 (5) 36 (2) 36 (2)

TE6 50 (10) 54 (12) 54 (12) 54 (12)

40MVC(Q)

009--- 1

Coil Temperature ˚F(˚C)

40MVC(Q)

012--- 1

40MVC(Q)

018--- 3

40MVC(Q)

024--- 3

Condenser High Temperature Protection

Condenser high temperature can occur due to any of the following

conditions:

S High outdoor ambient

S Outdoor fan blocked

S Outdoor coil blocked

The outdoor coil thermistor on a heat pump unit continuously

monitors the temperature of the outdoor coil. Anytime the coil

temperature exceeds the TE10 limit, the compressor is switched off

and the outdoor fan continues running to reduce the coil

temperature. When the coil temperature drops below the TE11

limit, the compressor is switched back on as shown below:

Compressor off

Outdoor fan on

COND temp. down

Compressor on

Outdoor fan on

TE11 TE10 T

COND temp. up

A08119

Fig. 21 – Condenser High Temp Protection

Condenser Temp.

Parameter

38MVQ018 --- 3 38MVQ024--- 3

TE10 149 (63) 158 (70)

TE11 131 (55) 149 (65)

˚F(˚C)

Indoor High Temperature Protection

High indoor coil temperature (in heating mode) can occur due to

any of the following:

S High outdoor ambient temperature

S Indoor fan blocked

S Indoor coil blocked (including dirty filters)

The indoor coil thermistor on a heat pump unit continuously

monitors the temperature of the indoor coil during heating

operation. Anytime the coil temperate exceeds the TE8 limit, the

outdoor fan is switched off. If the coil temperature continues to

climb and exceeds the TE7 limit, the compressor is switched off.

When the coil temperature drops below the TE9 limit, the

compressor and outdoor fan are switched back on as shown

below:

Compressor off

Fan off

Compressor on

Fan off

T temp. down

Compressor on

Fan on

TE9 TE8 TE7 T

T temp. up

A08120

Fig. 22 – Indoor High Temperature Protection

Condenser Coil Temp.

Parameter

TE7 140 (60) 140 (60) 145 (63) 145 (63)

TE8 129 (54) 129 (54) 129 (54) 129 (54)

TE9 118 (48) 118 (48) 122 (50) 122 (50)

40MVQ

009--- 1

40MVQ

012--- 1

˚F(˚C)

40MVQ

018--- 3

40MVQ

024--- 3

SEQUENCE OF OPERATION

Interface

A wireless remote control, supplied with the unit, is the interface

between the fan coil and the user. The wireless remote control has

the following characteristics:

S Capable of displaying _Cand_F with _C being the default

setting. To change the default setting, refer to the Owner’s

Manual or push the recessed F/C button once using a paper

clip or similar object*.

S The remote control setpoint range is from 62_F(17_C) to

88_F(30_C) in increments of 2_F(1_C).

S There is a dedicated cooling only and heat pump remote

control.

S The wireless remote control has an operating range of 25 ft.

(7.62 m).

S The same remote control can be used to control more than one

unit.

S If the remote control is lost, damaged, or the batteries are

exhausted, the system can be operated by using the manual

button (forced Auto) located under the front panel.

38/40MVC, MVQ

Manual button

Fig. 23 – Manual Button Location on Unit

* On units produced during week 12 (2008) and later. Units

produced before week 12 have dedicated _Cor_F controls.

21

A07364

Page 22

MODES OF OPERATION

The units have 5 main operating modes:

1. Fan Only

2. Cooling

3. Heating (heat pumps only)

4. Auto

5. Dehumidification (Dry)

The units have 2 other modes (manual operation) that are operated

in unique situations:

1. Auto Forced Mode (Emergency)

2. Test Mode

Fan Mode

In this mode, the system circulates the room air without changing

the room air temperature.

Cooling

In this mode, the system cools and dries the room air with the fan

running continuously, either at a selected fan speed or Auto fan

speed. The fan runs even when the compressor cycles off. This

feature enhances room comfort and efficiency of the system.

When the unit is operating in cooling, two sub modes can also be

selected:

38/40MVC, MVQ

Compressor and Outdoor Fan

The compressor and outdoor fan motor cycle on and off based on

the conditions of the set point and the room temperature as shown

below. There is no minimum run time.

Indoor Fan

When in cooling mode, the fan runs continuously either at the

chosen set speed , or in Auto mode, where the speed is determined

by the microprocessor based on the difference between the room

temperature and the temperature set point as shown below:

Room temp. down

Only

Mode

1. Sleep Mode is an energy saving feature that changes the set

point automatically.

2. Turbo Mode is a comfort feature on the 9k and 12k units

where the set point is reached quickly by having the fan run

on high speed regardless of the speed that has been selected.

Operation

Compressor and

outdoor fan on

Room temp. down

T = Room Temperature

Ts = Set Point Temperature

Compressor off

fan off

0 1.8°FT-Ts

Room temp. up

Fig. 24 – Compressor and Outdoor Fan -- Cooling Mode

Operation

Med fan

Room temp. up

High fan

A08106

Sleep

Mode

When in cooling mode, additional energy savings can be realized

by selecting the Sleep setting. When the Sleep setting is selected,

the temperature set point is adjusted automatically as shown below:

Set point

1.8

°

F

°

F

1.8

Time (hour)12

A08108

Fig. 26 – Sleep Mode

The unit will shut off 7 hours after the Sleep Mode is selected.

Mode

Turbo

When in cooling mode, selecting Turbo will allow the indoor unit

to satisfy the temperature set point as quickly as possible. In Turbo

Mode, the indoor fan will shift to high speed and either run

continuously for 20 minutes or until the user pushes the Turbo

button again, at which point the fan speed will return to the original

setting.

Heating

Mode

In this mode, the system heats the room air with the indoor fan

running at either the selected speed or on Auto. As in the cooling

mode, the indoor fan will run continuously unless interrupted by

the cold blow algorithm. This algorithm will not allow the fan to

run if the indoor coil temperature drops below a preset value.

The sleep function can be selected while the unit is running in the

Heating Mode. Defrost is controlled by the on --board

microprocessor.

Compressor and Fan

Operation

The compressor and outdoor fan cycle on and off based on the

actual room temperature versus the set point as shown below.

When the compressor starts, it will run continuously for 7 minutes

even if the set point condition is satisfied.

The 4--way value is energized in heating and will stay energized for

2 minutes after the mode is changed into a non--heating mode.

Compressor on

outdoor fan off

Room temp. down

T = Room Temperature

TS = Set Point Temperature

* For 9k & 12k Units Only. For 18k and 24k units, numbers will be 5.4 and 7.2 respectively.

Compressor off

outdoor fan on

Ts+5.4*Ts+3.6*Ts T

Room temp. up

A08109

Fig. 27 – Compressor and Outdoor Fan -- Heating Mode

Low fan

T= Room Temperature

Ts = Set Point Temperature

Fig. 25 – Auto Fan -- Cooling Mode

9.0 °F7.2 °F1.8 °F T-Ts

A08107

22

Page 23

Fan

Auto

When the fan speed is set to Auto, the fan will run at either the

medium or low speed based on the difference between the room

temperature and the set point temperature as shown below:

Low. Speed

Room temp. down

T = Room Temperature

Ts = Set Point Temperature

Med. Speed

0

3.6°F

Room temp. up

T-Ts

A08112

Fig. 28 – Auto Fan -- Heating Mode

Manual Indoor

Fan

The indoor fan will run continuously in heating at the set fan speed

(even if the compressor cycles off) unless the indoor coil

temperature begins to drop. When the coil temperature drops to

the TE3 limit, the 18k and 24k unit indoor fan switches to low

speed. On the 9k and 12k unit the indoor fan switches to ultra low

speed. When the coil temperature drops to the TE4 limit, the

indoor fan on all systems shuts off to prevent cold blow as shown

below. The cold blow algorithm also applies to the auto fan

setting.

Set fan speed

Low Speed /

Ultra Low Speed

T temp. down

Fan o ff

TE4 TE1 TE3 TE2 T

T temp. up

(Coil temp.)

A08111

Fig. 29 – Manual Indoor Fan -- Heating Mode

Parameter

TE1 88 (31) 88 (31) 77 (25) 82 (28)

TE2 93 (34) 91 (33) 90 (32) 93 (34)

TE3 86 (30) 81 (27) 86 (30) 90 (32)

TE4 72 (22) 68 (20) 68 (20) 75 (24)

40MVQ

009--- 1

Indoor Coil Temperature ˚F(˚C)

40MVQ

012--- 1

40MVQ

018--- 3

40MVQ

024--- 3

Sleep Mode

When in heating mode additional energy savings can be realized

by selecting the Sleep setting. When the Sleep setting is selected,

the temperature set point is adjusted automatically as shown below:

Set Point

Defrost

Defrost on heat pump units is controlled by the microprocessor and

is initiated if either of the following conditions occur:

1. The outdoor coil temperature is lower than 32_F(0_C) for

more than 40 minutes and during that period, the coil

temperature is continuously lower than 26.6_F(--3_C) for 3

minutes.

2. If the first condition does not occur within 90 minutes of

termination of the last defrost cycle.

The defrost cycle will terminate 10 minutes after initiation or when

the coil temperature reaches 68_F(20_C). At the end of the

Defrost cycle the timer resets automatically.

The cycles of defrost algorithm are shown below:

Defrost 10 or 6 minutes

10s

On

Off

5s

25s

2s

A08114

Compressor

4-way valve

Outdoor fan

Indoor fan

Fig. 31 – Defrost Cycle

Mode

Auto

When the Auto setting is selected, the microprocessor looks at the

difference between the room temperature (T) and the set point

(TS). The algorithm determines which mode the unit will run in as

shown below:

Heating (fan only in cooling) Fan only Cooling

°

F 3.6°F

-1.8

T-TS

A08115

Fig.32–AutoMode

When the unit shifts modes, it will remain in that mode for at least

15 minutes while the algorithm ignores the difference between T

and TS. This ensures that the unit cannot change modes too

frequently.

38/40MVC, MVQ

1.8ºF

1.8ºF

Time (hour)12

Fig. 30 – Sleep Mode -- Heating

The unit will shut off 7 hours after the Sleep mode is selected.

A08110

23

Page 24

Dry (Dehumidification)

Mode

When more humidity control is desired, the Dry setting can be

selected. Lower humidity is achieved when the microprocessor

adjusts the indoor fan speed and compressor cycling by comparing

the room temperature (T) and the set point temperature (TS).

There are two different control algorithms:

Size 9k and 12 k

units:

T = TS + 3.6 -- the compressor will run for 6 minutes and the

indoor fan will run at low speed. The compressor will be off for 4

minutes and the indoor fan will run in ultra low speed.

TS = T < TS + 3.6 -- The compressor will run for 5 minutes and the

indoor fan will run at low speed. The compressor will be off for 5

minutes and the indoor fan will run in ultra low speed.

T < TS -- The compressor will run for 4 minutes and the indoor

fan will run at low speed. The compressor will be off for 6 minutes

and the indoor fan will run in ultra low speed.

Size 18k and 24k

units:

These units do not have ultra low speed. When set for

dehumidification, the indoor fan runs at low speed and the

compressor cycles based on the difference between T and TS.

Manual Operation

The unit can be set for Forced Auto or Forced Cooling manually

by pushing the Manual button once or twice as shown below:

38/40MVC, MVQ

Push 3 Times

Remote

mode

Push Once Push Twice

Forced

auto

Forced

cooling

Forced Auto (Emergency

Operation)

Forced Auto option allows operation of the unit if the remote

control is lost or the batteries have expired. When the system is in

Forced Auto, it will run with a default set point of 75.2_F. While

in Forced Auto, the system will respond to signals from the remote

control.

Forced Cooling

Operation

This option is used for diagnostic purposes. The system is forced

to run in cooling for 30 minutes.

After 30 minutes, the 9k and 12k systems will switch to Dry mode

with a default set point of 75.2_F. The 18k and 24k systems will

switch to Forced Auto mode. When the system is in Forced

Cooling mode, it will not respond to signals from the remote

control. The only way to exit the Forced Cooling mode is to push

the manual button once to switch the system to remote control

mode.

Fig. 33 – Manual Operation

A08116

24

Page 25

TROUBLESHOOTING

This section provides the required flow charts to troubleshoot problems that may arise.

NOTE: Information required in the diagnoses can be found either on the wiring diagrams or in the appendix.

Required

Tools:

The following tools are needed when diagnosing the units:

S Digital multimeter

S Screw drivers (Phillips and straight head)

S Needle--nose pliers

Recommended

Steps

1. Refer to the diagnostic hierarchy chart below and determine the problem at hand.

2. Go to the chart listed in the diagnostic hierarchy and follow the steps in the chart for the selected problem.

DIAGNOSTIC HIERARCHY

Unit has a problem

Unit has a problem

Unit displays a

Unit displays a

diagnostic code

diagnostic code

Unit not running and

Unit not running and

no diagnostic code

no diagnostic code

Unit running but not

Unit running but not

optimally

optimally

38/40MVC, MVQ

Refer to page ---

Refer to page A8 & A9

identify error code*

appropriate diagnostic chart

* For EEROM error, replace the indoor microprocessor board

* For EEROM error, replace the indoor microprocessor board

and use

Go to chart # 7 Go to chart # 8 & 9

Go to chart Go to chart #

For the ease of service, the systems are equipped with diagnostic

code display LED’s on both the indoor and outdoor units. The

outdoor diagnostic display is an LED on the outdoor unit board

and is limited to very few errors. However, it is useful in

identifying special error codes like a failure of the outdoor coil

sensor on heat pumps. The indoor diagnostic display is a

combination of flashing LED’s on the display panel on the front of

the unit. If possible always check the diagnostic codes displayed on

the indoor unit first.

The diagnostic codes for the indoor and outdoor units are listed in

appendix A8 and A9.

Problems may occur that are not covered by a diagnostic code, but

are covered by the diagnostic flow charts starting with the

diagnostic hierarchy. These problems will be typical air

conditioning mechanical or electrical issues that can be corrected

using standard air conditioning repair techniques.

A08165

For problems requiring measurements at the control boards please

note the following:

1. Always disconnect the main power.

2. When possible check the outdoor board first.

3. Start by removing the outdoor unit top cover.

4. Reconnect the main power

5. Probe the outdoor board inputs and outputs with a digital

multi--meter referring to the wiring diagrams and

input/output charts found in the appendix.

6. Connect the red probe to hot signal and the black probe to

the ground or negative.

7. Note that some of the DC voltage signals are pulse will give

continuously variable readings.

8. If it is necessary to check the indoor unit board you must

start by disconnecting the main power.

9. Next remove the front cover of the unit and then control

box cover.

10. Carefully remove the indoor board from the control box,

place it face up on a plastic surface (not metal).

11. Reconnect the main power and repeat steps 5,6, and 7.

12. Disconnect main power before reinstalling board to avoid

shock hazard and board damage.

25

Page 26

CHART 1 -- I NDOOR FAN SPEED OUT OF CONTROL

Reset main power and

Reset main power and

restart system using remote.

restart system using remote.

Problem persists?

Problem persists?

Yes

Yes

Check motor connection.

Check motor connection.

Connection good?

Connection good?

Yes

Yes

No

No

No

No

No further action is

No further action is

required

required

Fix connection

Fix connection

38/40MVC, MVQ

Check IFM output and input

on indoor board.

Values good?

Yes

Yes

Replace indoor fan motor

Replace indoor fan motor

No

No

Replace indoor board

Replace indoor board

A08166

26

Page 27

CHART 2 -- TEMPERATURE SENSOR

Reset main power and

restart system using remote.

Problem persists?

Yes

Yes

Check sensor connector

at ID or OD board

Connection good?

Yes

Yes

Check input and output

on indoor or outdoor board.

Yes

Yes

Check sensor resistance.

Appendix 6

YesYes

No

No

No

No

No

No

No

No

No further action is

required

Fix connection

Replace board

38/40MVC, MVQ

Replace sensor

Double check connection,

for corrosion or high

resistance.

A08167

27

Page 28

CHART 3 -- COMPRESSOR OVERCURRENT PROTECTION

Is unit running in outdoor

Is unit running in outdoor

ambient higher than

ambient higher than

125 °F?

125 °F?

No

No

Outdoor coil clean?

Outdoor coil clean?

Yes

Yes

Check connections from

Check connections from

OD board. Corrosion, or

OD board. Corrosion, or

high resistance

high resistance

No

No

Outdoor fan Ok?

Outdoor fan Ok?

Yes

Yes

Yes

Yes

Beyond operating range

Beyond operating range

No No

No No

No

No

Clean coil.

Clean coil.

Problem persists?

Problem persists?

Yes

Yes

Clean/repair connection

Clean/repair connection

Problem persists?

Problem persists?

Yes

Yes

Change outdoor motor

Change outdoor motor

No

No

Problem solved

Problem solved

Problem solved

Problem solved

38/40MVC, MVQ

Replace compressor

Replace compressor

Connect gauges to unit.

Connect gauges to unit.

pressures ok?

pressures ok?

Yes

Yes

Check amp draw to

Check amp draw to

No

No

compressor? Values within

compressor? Values within

range?

range?

Yes

Yes

Replace outdoor board

Replace outdoor board

No

No

High head, high suction? High head, low suction?

High head, high suction? High head, low suction?

Yes

Yes

Unit is overcharged.

Unit is overcharged.

Reclaim charge and weigh

Reclaim charge and weigh

in correct charge.

in correct charge.

No

No

Yes

Yes

Restriction in refrigeration

Restriction in refrigeration

circuit.

circuit.

A08168

28

Page 29

CHART 4 -- INDOOR UNIT COMMUNICATION ERROR SIZ E 9K AND 12K

Notes:

Check the wires and

Check the wires and

connections between

connections between

Indoor and outdoor units*

Indoor and outdoor units*

Yes

Yes

Reset main power and

Reset main power and

restart system using remote.

restart system using remote.

Problem persists?

Problem persists?

Yes

Yes

Measure Volts DC on

Measure Volts DC on

outdoor TB between 1 & 3.

outdoor TB between 1 & 3.

Ok?**

Ok?**

No

No

No

No

Yes

Yes

Fix connection or

Fix connection or

replace wiring

replace wiring

No further action is

No further action is

required

required

Measure Volts DC on

Measure Volts DC on

indoor TB between 1 & 3.

indoor TB between 1 & 3.

Ok?**

Ok?**

Notes:

Before measuring the Volts DC on outdoor TB,

Before measuring the Volts DC on outdoor TB,

disconnect the field wire on terminal 1.

disconnect the field wire on terminal 1.

Before measuring the Volts DC on Indoor TB,

Before measuring the Volts DC on Indoor TB,

disconnect the field wire on terminal 1.

Have the red probe of the meter on terminal 1

and the black probe on terminal 3. Reconnect

wiring when measurements are complete.

Recheck wiring and

Recheck wiring and

connections

connections

No

No

.

Replace outdoor board.

Replace outdoor board.

* Make sure wires are connected per connection diagrams. Failing to do that will result in a communication error.

** There is a 2 to 3 minute window to take the measurement before the diagnostic light is on again.

** There is a 2 to 3 minute window to take the measurement before the diagnostic light is on again.

.

Replace indoor board.

Replace indoor board.

No

No

38/40MVC, MVQ

A08181

29

Page 30

Outdoor coil clean?

Outdoor coil clean?

CHART 5 -- OUTDOOR UNIT PROTECTS

Clean coil. Problem

No No

Clean coil. Problem

No No

persists?

persists?

Problem solved

Problem solved

Yes

Yes

Check outdoor unit

Check outdoor unit

board. Indicator light

board. Indicator light

flashing twice?

flashing twice?

No

No

Connect gauges to

Connect gauges to

unit. Pressures ok?

unit. Pressures ok?

No

No

Suction and head

Suction and head

equal?

38/40MVC, MVQ

equal?

Yes

Yes

Check compressor

Check compressor

* Restriction in system. Check capillary tube, check for moisture, and check for damage to liquid line between indoor and

* Restriction in system. Check capillary tube, check for moisture, and check for damage to liquid line between indoor and

outdoor units.

outdoor units.

Yes

Yes

Yes

Yes

No No No

No No No

Check sensors.

Check sensors.

Flow Chart #2

Flow Chart #2

Check application

Check application

Normal suction,

Normal suction,

Non condensables

Non condensables

in sys. Pump down

in sys. Pump down

and recharge unit

and recharge unit

Yes

Yes

limits

limits

high head?

high head?

Yes Yes

Yes Yes

Unit is overcharged.

Unit is overcharged.

Reclaim charge and

Reclaim charge and

weigh in correct charge

weigh in correct charge

High head, high

High head, high

suction?

suction?

High head, low

High head, low

suction?

suction?

Yes

Yes

See note below

See note below

*

*

A08182

30

Page 31

CHART 6 -- INDOOR UNIT COMMUNICATION ERROR SIZE 18K AND 24K

Check the wires and

Check the wires and

Check the wires and

connections between

connections between

connections between

Indoor and outdoor units*

Indoor and outdoor units*

Indoor and outdoor units*

Yes

Yes

Yes

Reset main power and

Reset main power and

Reset main power and

restart system using remote.

restart system using remote.

restart system using remote.

Problem persists?

Problem persists?

Problem persists?

Yes

Yes

Yes

Measure VDC reading on

Measure VDC reading on

Measure VDC reading on

outdoor between S and G.

outdoor between S and G.

outdoor between S and G.

Reading positive? **

Reading positive? **

Reading positive? **

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

Fix connection or

Fix connection or

Fix connection or

replace wiring

replace wiring

replace wiring

No further action is

No further action is

No further action is

required

required

required

Replace outdoor board

Replace outdoor board

Replace outdoor board

Notes:

Notes:

Notes:

When unit is operating normally and a DC

When unit is operating normally and a DC

When unit is operating normally and a DC

voltage reading is taken between the S and

voltage reading is taken between the S and

voltage reading is taken between the S and

G terminal on the outdoor unit (or indoor

G terminal on the outdoor unit (or indoor

G terminal on the outdoor unit (or indoor

unit) positive and negative readings will

unit) positive and negative readings will

unit) positive and negative readings will

fluctuate between 0 and 24V DC.

fluctuate between 0 and 24V DC.

fluctuate between 0 and 24V DC.

If indoor board is bad, only a positive

If indoor board is bad, only a positive

If indoor board is bad, only a positive

readings will be registered between

readings will be registered between

readings will be registered between

terminals S and G on the outdoor unit. The

terminals S and G on the outdoor unit. The

terminals S and G on the outdoor unit. The

reverse will apply if outdoor board is bad

reverse will apply if outdoor board is bad

reverse will apply if outdoor board is bad

(only negative readings will register).

(only negative readings will register).

(only negative readings will register).

Above data is obtained by having the red

Above data is obtained by having the red

Above data is obtained by having the red

probe of the meter on the S terminal and

probe of the meter on the S terminal and

probe of the meter on the S terminal and

the black probe on the G terminal.

the black probe on the G terminal.

the black probe on the G terminal.

.

.

Replace indoor board.

Replace indoor board.

Replace indoor board.

* Make sure wires are connected per connection diagrams i.e. L1 to L1 and L2 to L2. Failing to do that will result in a

* Make sure wires are connected per connection diagrams i.e. L1 to L1 and L2 to L2. Failing to do that will result in a

communication error.

communication error.

** There is a 2 to 3 minute window to take measurements before the diagnostic light is on again.

** There is a 2 to 3 minute window to take measurements before the diagnostic light is on again.

.

A08183

38/40MVC, MVQ

31

Page 32

Reset circuit breaker. Is unit

Reset circuit breaker. Is unit

38/40MVC, MVQ

running?

running?

Problem solved

Problem solved

CHART 7 -- UNIT NOT RUNNING, NO DIAGNOSTIC CODE

Use auto forced function.

Use auto forced function.

Unit runs?

Unit runs?

Yes

Yes

Reset remote and restart

Reset remote and restart

the unit. Is unit running?

the unit. Is unit running?

Yes Yes

Yes Yes

Problem solved

Problem solved

Is there power to outdoor

Is there power to outdoor

unit?

unit?

Yes

Yes

Check fuse on outdoor

Check fuse on outdoor

board. Ok?

board. Ok?

Yes

Yes

Check input and output on

Check input and output on

outdoor board. Ok?

outdoor board. Ok?

Yes

Yes

Check components. Ok?

Check components. Ok?

Flow charts 10 thru 12

Flow charts 10 thru 12

No

No

Replace defective

Replace defective

component

component

No No

No No

No

No

No

No

Yes

Yes

Check batteries. OK? Replace battery

Check batteries. OK? Replace battery

Go to chart #13

Check wiring and circuit

Check wiring and circuit

breaker and fix

breaker and fix

Replace fuse

Replace fuse

Replace outdoor board

Replace outdoor board

Check fuse(s) on indoor

Check fuse(s) on indoor

board. Ok?*

board. Ok?*

No

No

Replace fuse

Replace fuse

Yes

Yes

Replace indoor board

Replace indoor board

Check input and output on

Check input and output on

indoor board. Ok?

indoor board. Ok?

Determine defective

Determine defective

component and replace

component and replace

Yes

Yes

No

No

No No

No No

No

No

* For sizes 18 and 24 K units only. For sizes 9 and 12K units proceed to check inputs and outputs on indoor boards.

* For sizes 18 and 24 K units only. For sizes 9 and 12K units proceed to check inputs and outputs on indoor boards.

A08169

32

Page 33

Outdoor coil clean?

Outdoor coil clean?

CHART 8 -- UNIT NOT RUNNING OPTIMALLY

No No

No No

Clean coil. Problem

Clean coil. Problem

persists?

persists?

Problem solved

Problem solved

Yes

Yes

Indoor filter clean?

Indoor filter clean?

Yes

Yes

Check indoor fan

Check indoor fan

motor

motor

Yes

Yes

Connect gauges to

Connect gauges to

unit. Pressures ok?

unit. Pressures ok?

No

No

Suction and head

Suction and head

equal?

equal?

Yes

Yes

Check compressor

Check compressor

Yes

Yes

Clean filter. Problem

No No

Clean filter. Problem

No No

persists?

persists?

Yes

Yes

No

No

Replace indoor fan

Replace indoor fan

motor.

motor.

Yes

Yes

Check application

Check application

limits.

limits.

No No No

No No No

Normal suction,

Normal suction,

high head?

high head?

Yes Yes

Yes Yes

Non condensables

Non condensables

in sys. Pump down

in sys. Pump down

and recharge unit

and recharge unit

Problem solved

Problem solved

High head, high

High head, high

suction?

suction?

Unit is overcharged.

Unit is overcharged.

Reclaim charge and

Reclaim charge and

weigh in correct charge

weigh in correct charge

High head, low

High head, low

suction?

suction?

Yes

Yes

See note below*

See note below*

38/40MVC, MVQ

* Restriction in system. Check capillary tube, check for moisture, and check for damage to liquid line between indoor and

* Restriction in system. Check capillary tube, check for moisture, and check for damage to liquid line between indoor and

outdoor units.

outdoor units.

A08170

33

Page 34

CHART 9 -- UNIT NOT RUNNING OPTIMALLY (HP IN HEATING)*

No

Visually check outdoor

Visually check outdoor

Unit for ice blockage. **

Unit for ice blockage. **

Yes

Yes

Check defrost sensor. Ok?

Check defrost sensor. Ok?

Go to flow chart #2

Yes

Yes

Check application limits.

Check application limits.

Ok?

Ok?

No

No

No

No

No

Check reversing valve.

Check reversing valve.

Go to flow chart #12

Replace sensor

Replace sensor

Beyond operating range

Beyond operating range

38/40MVC, MVQ

Yes

Yes

Check ambient conditions.

Check ambient conditions.

Prime icing?

Prime icing?

Yes

Yes

Explain to customer

Explain to customer

* To supplement flow chart #8

** Check for blockage on outdoor coil and drain pan. Are the holes in drain pans blocked?

es in drain pans blocked?

A08184

34

Page 35

CHART 10 -- COMPRESSOR

Trace connections from

Trace connections from

OD board. Connections

OD board. Connections

ok?

ok?

Yes

Yes

Check contactor.*

Check contactor.*

Contactor ok?

Contactor ok?

Yes

Yes

Check capacitor.

Check capacitor.

Capacitor ok?

Capacitor ok?

Yes

Yes

No

No

No

No

No

No

No fix connection

No fix connection

Replace contactor

Replace contactor

Replace capacitor

Replace capacitor

No

Check compressor

Check compressor

windings. Ok?

windings. Ok?

No

No

Compressor ok.

Compressor ok.

* For size 9 and 12k units contactor is on outdoor board.

Check contactor output on outdoor board if not done already.

If bad, replace outdoor board.

No

Replace compressor

Replace compressor

38/40MVC, MVQ

A08171

35

Page 36

38/40MVC, MVQ

CHART 11 -- OUTDOOR MOTOR

Visually confirm that fan

Visually confirm that fan

blades and outdoor coil

blades and outdoor coil

are not blocked.

are not blocked.

Yes

Yes

Trace connections from

Trace connections from

OD board. Connections

OD board. Connections

ok?

ok?

Yes

Yes

Check capacitor.

Check capacitor.

Capacitor ok?

Capacitor ok?

Yes

Yes

Check motor windings.

Check motor windings.

Ok?

Ok?

No

No

No

No

No

No

No

No

Clear blockage

Clear blockage

Fix connection

Fix connection

Replace capacitors

Replace capacitors

Replace motor

Replace motor

Yes

Yes

Motor ok.

Motor ok.

A08172

36

Page 37

CHART 12 -- REVERSING VALVE

No

Check RV connection on

Check RV connection on

outdoor board. Ok?

outdoor board. Ok?

Yes

Yes

Check RV output on outdoor

Check RV output on outdoor

board. Ok?

board. Ok?

Yes

Yes

Check RV solenoid. Ok? Replace solenoid

Check RV solenoid. Ok? Replace solenoid

Yes

Yes

Replace reversing valve.

Replace reversing valve.

No

No

No

No

No

Clean or repair the

Clean or repair the

connection

connection

Replace outdoor board

Replace outdoor board

38/40MVC, MVQ

CHART 13 -- RECEIVER BOARD

Check wiring and

Check wiring and

connection between

connection between

receiver and ID board. Ok?

receiver and ID board. Ok?

Yes

Yes

Check input and output

Check input and output

on ID and receiver

on ID and receiver

boards. Ok?

boards. Ok?

Yes

Yes

Replace remote control

Replace remote control

No

No

No

No

Fix wiring or

Fix wiring or

connection

connection

Replace receiver board

Replace receiver board

A08173

37

Page 38

APPENDIX

APPENDIX TABLE OF CONTENTS

DESCRIPTION NUMBER

Control Boards Input/Output tables for 53MVC009(12)------1 A1...................................................

Control Boards Input/Output tables for 53MVQ009(12)------1 A2...................................................

Control Boards Input/Output tables for 53MVC012-- -- --3 A3.......................................................

Control Boards Input/Output tables for 53MVQ012-- -- --3 A4......................................................

Control Boards Input/Output tables for 53MVC018-- -- --3 A5.......................................................

Temperature Sensor V alues (Temperature vs. Resistance) A6.......................................................

Fuse Chart A7...........................................................................................

Indoor Unit Diagnostic Codes A8...........................................................................

Outdoor Unit Diagnostic Codes A9..........................................................................

38/40MVC, MVQ

38

Page 39

A 1 -- 5 3 M V C 0 0 9 -- -- -- 1 / 5 3 M V C 0 1 2 -- -- -- 1

3 8 M V C 0 0 9 --- --- --- 1 / 3 8 M V C 0 1 2 --- --- --- 1 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN2 OUT: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

CN3 OUT: Neutral

CN4 IN: Neutral

CN9 OUT: L 115 Volt s AC

CN10 IN: L 115 Volts AC

P1 GND

P2 GND

4 0 M V C 0 0 9 --- --- --- 1 / 4 0 M V C 0 1 2 --- --- --- 1 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN : 0 --- 5 V o l t D C

CN2 IN : 0 --- 5 V o l t D C

CN3 Pulse drive output: 0 --- 17 Volts DC(Pin 5: GND All other Pins are 0 to 17 Volt DC) All relative to Pin 5)

CN5

CN6

G1 IN: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

Power Output: (Pin 1: GND) (Pin 2: 5 Volts DC) Input: (Pin 3: Pulse 0 to 5 Volts DC) Output:(Pin 4~ Pin 10: Pulse 0 to 5

Volt DC) All relative to Pin 1

Out: (Pin 1: 35 Volt DC) ( Pin 2: Empty) (Pin 3: GND) (Pin 4: 5 Volt DC) (Pin 5: Pulse 0--- 5 Volt DC) IN: (Pin 6: Pulse 0 to 5

Volt DC) All relative to Pin 3

38/40MVC, MVQ

A 2 -- 5 3 M V Q 0 0 9 -- -- -- 1 / 5 3 M V Q 0 1 2 -- -- -- 1

38MVQ009--- 1/38MVQ012--- --- --- 1 CONTROL BOARD

CONNECTOR INPUT or OUTPUT VALUE

CN1 OUT: (Pin 1: GND, Pin 2: 5 Volts DC, Pin 3: Empty) IN: (Pin 4: 0 to 5 Volts DC) All relative to Pin 1

CN2 OUT: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

CN3 OUT: Neutral

CN4 IN: Neutral

CN5 OUT: L 115 Volt AC

CN6 OUT: L 115 Volt AC

CN10 IN: L 115 Volt AC

P1 GND

P2 GND

40MVQ009--- 1/40MVQ012--- --- --- 1 CONTROL BOARD

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN : 0 --- 5 V o l t D C

CN2 IN : 0 --- 5 V o l t D C

CN3 Pulse drive output: 0 --- 17 Volts DC(Pin 5: GND All other Pins are 0 to 17 Volt DC) All relative to Pin 5)

CN5

CN6

G1 IN: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

Power Output: (Pin 1: GND) (Pin 2: 5 Volts DC) Input: (Pin 3: Pulse 0 to 5 Volts DC) Output:(Pin 4~ Pin 10: Pulse 0 to 5

Volt DC) All relative to Pin 1

Out: (Pin 1: 35 Volt DC) ( Pin 2: Empty) (Pin 3: GND) (Pin 4: 5 Volt DC) (Pin 5: Pulse 0--- 5 Volt DC) IN: (Pin 6: Pulse 0 to 5

Volt DC) All relative to Pin 3

39

Page 40

A 3 -- 5 3 M V C 0 1 2 -- -- -- 3

3 8 M V C 0 1 2 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN2 OUT: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

CN3 OUT: L2 208/230 Volt AC

CN4 IN: L2 208/230 Volt AC

CN9 OUT: L1 208/230 Volt AC

CN10 IN: L1 208/230 Volt AC

P1 Ground

P2 Ground

4 0 M V C 0 1 2 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN : 0 --- 5 V o l t D C

CN2 IN : 0 --- 5 V o l t D C

CN3 Pulse drive output: 0 --- 17 Volts DC(Pin 5: GND All other Pins are 0 to 17 Volt DC) All relative to Pin 5)

Power Output: (Pin 1: GND) (Pin 2: 5 Volts DC) Input: (Pin 3: Pulse 0 to 5 Volts DC) Output:(Pin 4~ Pin 10: Pulse 0 to 5

Volt DC) All relative to Pin 1

Out: (Pin 1: 35 Volt DC) ( Pin 2: Empty) (Pin 3: GND) (Pin 4: 5 Volt DC) (Pin 5: Pulse 0--- 5 Volt DC) IN: (Pin 6: Pulse 0 to 5

Volt DC) All relative to Pin 3

38/40MVC, MVQ

CN5

CN6

G1 IN: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

A 4 -- 5 3 M V Q 0 1 2 -- -- -- 3

3 8 M V Q 0 1 2 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 OUT: (Pin 1: GND, Pin 2: 5 Volts DC, Pin 3: Empty) IN: (Pin 4: 0 to 5 Volts DC) All relative to Pin 1

CN2 OUT: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

CN3 OUT: L2 208/230 Volt AC

CN4 IN: L2 208/230 Volt AC

CN5 OUT: L1 208/230 Volt AC

CN6 OUT: L1 208/230 Volt AC

CN10 IN: L1 208/230 Volt AC

P1 Ground

P2 Ground

4 0 M V Q 0 1 2 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN : 0 --- 5 V o l t D C

CN2 IN : 0 --- 5 V o l t D C

CN3 Pulse drive output: 0 --- 17 Volts DC(Pin 5: GND All other Pins are 0 to 17 Volt DC) All relative to Pin 5)

CN5

CN6

G1 IN: (Pin 1: Pulse 0 to 12 Volts DC) (Pin2: 35±2 Volts DC) (Pin 3: GND) (Pin 4: 13±4 Volts DC) all relative to Pin 3

Power Output: (Pin 1: GND) (Pin 2: 5 Volts DC) Input: (Pin 3: Pulse 0 to 5 Volts DC) Output:(Pin 4~ Pin 10: Pulse 0 to 5

Volt DC) All relative to Pin 1

Out: (Pin 1: 35 Volt DC) ( Pin 2: Empty) (Pin 3: GND) (Pin 4: 5 Volt DC) (Pin 5: Pulse 0--- 5 Volt DC) IN: (Pin 6: Pulse 0 to 5

Volt DC) All relative to Pin 3

40

Page 41

A 5 -- 5 3 M V C 0 1 8 -- -- -- 3

3 8 M V C 0 1 8 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN: 14.5±5V Volts AC

CN3 Pulse Signal 0 to 24 Volts DC (Relative to ground)

CN4 IN: L1 208/230 Volts AC

CN5 IN: L2 208/230 Volts AC

CN6 OUT: 208/230 Volts AC

CN8 OUT: 208/230 Volts AC

4 0 M V C 0 1 8 --- --- --- 3 C O N T R O L B O A R D

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN:11.0±3VoltsAC(Pin1toPin2); 9.5±2VoltsAC(Pin3toPin4)

CN2 OUT: IFM Capacitor Terminal 1

CN4 OUT: IFM Capacitor Terminal 2

CN5 OUT: 208/230 Volts AC

CN6 OUT: 208/230 Volts AC (Pin 1 to Pin 2, Pin 1 to Pin 3, Pin 1 to Pin4)

CN7 IN: 0---5VoltDC(Notincluding0Vand5V)

CN8 IN: 0---5VoltDC(Notincluding0Vand5V)

CN9 OUT: (Pin 1: Ground, Pin 2: 5 Volts DC) IN: (Pin 1: Ground, Pin 3: 0 to 5 Volts DC) Pulse relative to Pin 1

CN10 OUT: (Pin 1: Ground, Pin 2 ~ Pin 5: 0 to 5 Volts DC) Pulse relative to Pin 1

CN11 OUT: (Pin 5: Ground, all other Pins are 0 to 17 Volts DC) Pulse relative to Pin 5

CN12 Two way signal, 0 to 24 Volts DC, Pulse relative to Ground

P1 IN: L1 208/230 Volts AC

P2 IN: L2 208/230 Volts AC

INDOOR UNIT DISPLAY BOARD

CONNECTOR INPUT or OUTPUT VALUE

CN1 IN: (Pin 1: Ground, Pin 2 ~ 5: 0 to 5 Volts DC) Pulse relative to Pin 1

CN2 IN: (Pin 1: Ground, Pin: 5 Volts DC) OUT: (Pin 3: 0 to 5 Volts DC) Pulse relative to Pin 1

38/40MVC, MVQ

41

Page 42

A6 -- Characteristics of Temperature Sensor

Tem p . ˚F/˚C Resistance KΩ Te m p . ˚F/˚C Resistance KΩ Te m p . ˚F/˚C Resistance KΩ

14/--- 10 62.2756 62.6/17 14.6181 111.2/44 4.3874

15.8/--- 9 58.7079 64.4/18 13.918 113/45 4.2126

17.6/--- 80 56.3694 66.2/19 13.2631 114.8/46 4.0459

19.4/--- 7 52.2438 68/20 12.6431 116.6/47 3.8867

21.2/--- 6 49.3161 69.8/21 12.056 118.4/48 3.7348

23/--- 5 46.5725 71.6/22 11.5 120.2/49 3.5896

24.8/--- 4 44 73.4/23 10.9731 122/50 3.451

26.6/--- 3 41.5878 75.2/24 10.4736 123.8/51 3.3185

28.4/--- 2 39.8239 77/25 10 125.6/52 3.1918

30.2/--- 1 37.1988 78.8/26 9.5507 127.4/53 3.0707

32/0 35.2024 80.6/27 9.1245 129.2/54 2.959

33.8/1 33.3269 82.4/28 8.7198 131/55 2.8442

35.6/2 31.5635 84.2/29 8.3357 132.8/56 2.7382

37.4/3 29.9058 86/30 7.9708 134.6/57 2.6368

39.2/4 28.3459 87.8/31 7.6241 136.4/58 2.5397

41/5 26.8778 89.6/32 7.2946 138.2/59 2.4468

42.8/6 25.4954 91.4/33 6.9814 140/60 2.3577

44.6/7 24.1932 93.2/34 6.6835 141.8/61 2.2725

38/40MVC, MVQ

46.4/8 22.5662 95/35 6.4002 143.6/62 2.1907

48.2/9 21.8094 96.8/36 6.1306 145.4/63 2.1124

50/10 20.7184 98.6/37 5.8736 147.2/64 2.0373

51.8/11 19.6891 100.4/38 5.6296 149/65 1.9653

53.6/12 18.7177 102.2/39 5.3969 150.8/66 1.8963

55.4/13 17.8005 104/40 5.1752 152.6/67 1.83

57.2/14 16.9341 105.8/41 4.9639 154.4/68 1.7665

59/15 16.1156 107.6/42 4.7625 156.2/69 1.7055

60.8/16 15.3418 109.4/43 4.5705 158/70 1.6469

42

Page 43

A7 -- Fuse Chart

r

Unit Size

Indoor Outdoor Outdoor

Fuse Rating (Amps/Volts)

009 --- 3.15A/250V 2A/250V

012 --- 3.15A/250V 2A/250V

018 3.15A/250V 3.15A/250V ---

024 3.15A/250V 3.15A/250V ---

The 3.15A fuses protect the board against the indoor or outdoor fan motors.

The 2A fuses protect the board against a Class II circuit board failure.

A8 -- Indoor Unit Diagnostic Guides

9K & 12K Units

Operation

Lamp

l X Indoor fan speed has been out of control for over 1 minute 1

l On Indoor room temp. or evaporator sensor is open circuit or short circuited 2

X l Compressor over--- current protection has been activated four times 3

On l EPROM error* ---

l l Indoor unit communication error (Illuminates simultaneously) 4

Opera-

tion

Lamp

l l l l Over- -- current protection of the compressor occurs four times 3

X l X X Indoor room temp. sensor is open circuit or short circuited 2

l X X X Temp. sensor on indoor evaporator is open circuit or short circuited 2

X X l X

X X l l Outdoor unit protects (outdoor temp. sensor, phase order, etc.) 5