Page 1

40MB*F

Floor Console Ductless Split System

Sizes 09 to 12

Installation Instructions

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS. . . . . . ....... . . . . . ...... . . 2

SYSTEM REQUIREMENTS . . . . . . . . . . . . . . ....... . . . . ..2

MODEL NUMBER NOMENCLATURE..... . . . ... ..... . . 3

PRECAUTIONS . . . . . . . . . . . . . . ....... . . . . . . . . ....... . 4

INSTALLATION INFORMATION . . . . . . . . . . . . . . ....... . 5

ACCESSORIES . . . . . . . . . . . . . . ....... . . . . . . . . . . . . . . . . 6

INSPECTING AND HANDLING THE UNIT . . . . . . . ...... 7

INDOOR UNIT INSTALLATION . . . . . . . . . . . . . . ....... . . 7

OUTDOOR UNIT INSTALLATION . . . . . . . . . . . . . . ..... . . 8

INSTALL THE CONNECTING PIPE . . . . . . . . . . . . . . ..... . 9

CONNECT THE DRAIN PIPE . . . . . . . . . . . . . . ....... . . . . . 12

WIRING . . . . . . . . . . . . . . ....... . . . . . . . . . . . . . . . . ..... . . 13

TEST OPERATION . . . . . . . . . . . . . . ....... . . . . . . . . ..... 14

NOTE: Read the entire instruction manual before starting the

installation.

Page 2

SAFETY CONSIDERATIONS

2

Installing, starting up, and servicing air-conditioning equipment

to

can be hazardous due

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as

cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes.

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and National Electrical Code

special requirements. Recognize safety information. This is the

safety-alert

in instructions or manuals, be alert

injury. Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to

identify unsafe practices which

injury or product and property damage. NOTE is used

suggestions which will result in enhanced installation, reliability, or

operation.

symbol&.

A.

ELECTRICAL

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

A.

system pressures, electrical components,

Wear

safety glasses and work gloves. Keep

(NEC) for

When you see this symbol on the unit and

to

the potential for personal

may

result in minor personal

to

WARNING

SHOCK

HAZARD

WARNING

EXPLOSION HAZARD

Failure

to

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures

oxygen can lead

follow this warning could

of

air or gases containing

to

an

explosion.

highlight

A.

EQUIPMENT DAMAGE HAZARD

Failure

to

damage or improper operation.

Do not bury more than 36 in. (914 mm)

in the ground.

6 in. (152 mm) vertical rise

a

the outdoor units.

buried, refrigerant may migrate

during extended periods

refrigerant slugging and could possibly damage the

compressor

follow this caution may result in equipment

CAUTION

If

any section

If

more than the recommended length is

of

at

start-up.

of

of

pipe is buried, there must be

to

the valve connections on

to

the cooler buried section

system shutdown. This causes

refrigerant pipe

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit. See Fig. 1

for minimum required distances between unit and walls or ceilings.

and

Recommended Connection Method for Power

cation Wiring

ence>

Power Wiring:

The main power is supplied

connecting cable from the outdoor unit

three (3) wires and provides the power for the indoor unit.

wires are high voltage AC power and one is a ground wire.

Consult your local building codes and the NEC (National

Electrical Code) or CEC (Canadian Electrical Code) for special

requirements.

All wires must be sized per NEC or CEC and local codes. Use

Electrical Data table MCA (minimum circuit amps) and MOCP

(maximum over current protection)

the disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300 volt

rating and 2/64-inch thick insulation must be used.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64-inch thick insulation, must be used

communication wire from the outdoor unit

To

minimize voltage drop

wire size and maximum lengths shown in the chart below:

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

• Wires should be sized based on NEC and local codes.

• Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

A.

ITo

minimize communication wiring interfer-

to

Wire Size

18AWG

16AWG

the outdoor unit. The field supplied

of

the control wire, use the following

to

indoor unit consists

to

correctly size the wires and

to

50 {15)

CAUTION

Communi-

the indoor unit.

Length

ft (m)

50 {15)

to

100 (30)

as

of

Two

the

4

Page 3

If usedasMULTIunit,please refer to the Installation& operation manuals packed with outdoorunit.

Unit Tons Unit Btuh

0.75 9,000

12,000

208/230-1 40MBQB09F--3

40MBQB12F--3208/230-11

Indoor Model

Number

Volt- Ph @

60Hz

Model Numbers

The first two digits indicate the equipment type.

40 = Indoor unit;

38 = Outdoor uni

Digit 5 indicates the system's type:

C = Cooling only;

Q = Heat pump

Maximum Number of fan coil units connected to the outdoor unit

B = 1:1

Digits 7, 8 indicate the system's capacity in 1000

BTU/Hr

Example: 09 = 9000 BTU/Hr

Digit 9 - Indoor Fan Coil Unit Type

B = High-Wall

C = Cassette

D = Ducted

F = Console

G = Underceiling

H = High Wall Color Variation

- = Outdoor

Digit 12 indicates voltage

1 = 115/l/60

3 = 208-230-1-60Hz

40 MA Q B 09 B -- 3

Digits 10, 11 - blank

Digits 3 and 4 represent the model

3

Page 4

Be sure to comply with the local, national and international

laws and regulations.

Read "PRECAUTIONS" carefully before installation.

The following precautions include important safety items.

Observe them and never forget.

Keep this manual with the owner's manual in a handy place

for future reference.

Installation must be performed in accordance with the

requirement of NEC and CEC by authorized personnel only.

(Applicable to the North American area only)

1. PRECAUTIONS

The safety precautions listed here are divided into two categories. In

either case, important safety information is listed which must be read

carefully.

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

on how to operate the unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

the owner's manual for future reference.

Only trained and qualified service personnel should

install, repair or service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to

the equipment.

Failure to observe a warning may result in death.

Failure to observe a caution may result in injury or

damage to the equipment.

Install the unit according to this installation instructions

found in this document.

If installation is defective, it will cause water leakage,

electrical shock or fire.

When installing the unit in a small space, take measures

to prevent refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information.

Excessive refrigerant in a closed space can lead to oxygen

deficiency.

Use the attached accessories parts and specified parts

for installation.

Failure to use the included parts will cause the set to fall,

water leakage, electrical shock or fire.

Install the unit in a strong and firm location which is able

to withstand the set' s weight.

If the installation site is not secure or the installation is not

properly done, the set will drop and possibly cause injury or

damage.

The appliance should not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked with

words, or with symbols, with the direction of the fluid

flow.

For electrical work, follow the local national wiring

standard, regulations and these installation instructions.

An independent circuit and single outlet must be used.

If electrical circuit capacity is insufficient or a defect exists in

the electrical work, it will cause an electrical shock or a fire.

Connect the specified cable tightly and then clamp the

cable so that no external force can act on the terminal.

If connection or fixing is not correct , it will cause a heat

build-up or fire at the connection.

Wiring routing must be properly arranged so the control

board cover is fixed properly.

If the control board cover is not fixed properly, it will cause a

heat build-up at the connection point of the terminal, which

may result in a fire or an electrical shock.

If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or similarly qualified

person in order to avoid a hazard.

An all-pole disconnection switch with a contact

separation of at least 3mm in all poles should be

connected in the fixed wiring.

When performing the piping connection, make sure that

air substances do not enter the refrigeration cycle.

If air substances enter the refrigeration cycle, it will reduce

capacity, abnormal high pressure in the refrigeration cycle,

explosion and injury.

Do not modify the length of the power supply cord or use

an extension cord, and do not share the single outlet

with other electrical appliances.

Failure to comply will cause fire or electrical shock.

Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

CAUTION

WARNING

WARNING

4

Page 5

To install properly, please read this "installation manual"

first.

The air conditioner must be installed by qualified persons.

When installing the indoor unit or its tubing, please follow

this manual closely.

If the air conditioner is installed on a metal part of the

building, it must be electrically insulated according to the

relevant standards to electrical appliances.

When all the installation work is finished, please turn on

the power only after a thorough check.

2. INSTALLATION INFORMATION

Ground the air conditioner.

Do not connect the ground wire to gas or water pipes,

lightning rod or a telephone ground wire.Incomplete

grounding may result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in

electric shocks.

Connect the outdoor unit wires , then connect the indoor

unit wires.

You should not connect the air conditioner with the power

source until wiring and piping the air conditioner is done.

While following the instructions in this installation

manual, install drain piping in order to ensure proper

drainage and insulate piping in order to prevent

condensation.

Improper drain piping may result in water leakage and

property damage.

Install the indoor and outdoor units, power supply wiring

and connecting wires at least 3.28ft (1m) meter away

from televisions or radios in order to prevent image

interference or noise.

Depending on the radio waves, a distance of 3.28ft (1m) may

not be sufficient enough to eliminate the noise.

The appliance is not intended for use by young children

or infirm persons without supervision.

Don't install the air conditioner in the following

locations:t

Near petroleum facilities.

Near coastal areas with any concentration of salty air.

Near caustic gases, like sulfide, especially when near hot

springs.

The volt vibrates violently (in the factories).

In buses or cabinets.

In kitchens with large amounts of oil gas.

Near a strong electromagnetic wave.

Near inflammable materials or gas.

Anywhere there is acid or alkaline liquid evaporating.

Other hazardous conditions.

If the refrigerant leaks during installation, ventilate the

area immediately.

Toxic gas may be produced if the refrigerant enters into the

area and comes in contact with fire.

The temperature of refrigerant circuit is high, please keep

the interconnection cable away from the copper tube.

After completing the installation work, ensure that the

refrigerant does not leak.

Toxic gas may be produced if the refrigerant leaks into the

room and comes into contact with a source of fire, such as a

fan heater, stove or cooker.

INSTALLATION ORDER

Select the location.

Install the indoor unit.

Install the outdoor unit.

Install the connecting pipe.

Connect the drain pipe.

Connect the wiring.

Test operation.

CAUTION

The appliance must be installed in accordance with

national wiring regulations.

Do not operate your air conditioner in a wet room such

as a bathroom or laundry room.

An all-pole disconnection device which has at least 3mm

clearances in all poles, and has a leakage current that

may exceed 10mA, and a residual current device (RCD)

which has a rated residual operating current not to

exceed 30mA, and a disconnection must be incorporated

in the fixed wiring in accordance with the wiring rules.

5

Page 6

SET TEMPERATURE」ィOC)

AUTO

COOL

DRY

HEAT

FAN

HIGH

MED

LOW

TEMP.

MODE

ON/OFF

FAN SPEED

SWING

ECONOMIC

TIMER ON

RESET

LOCK

TIMER OFF

AIR DIRECTION

POWERFUL

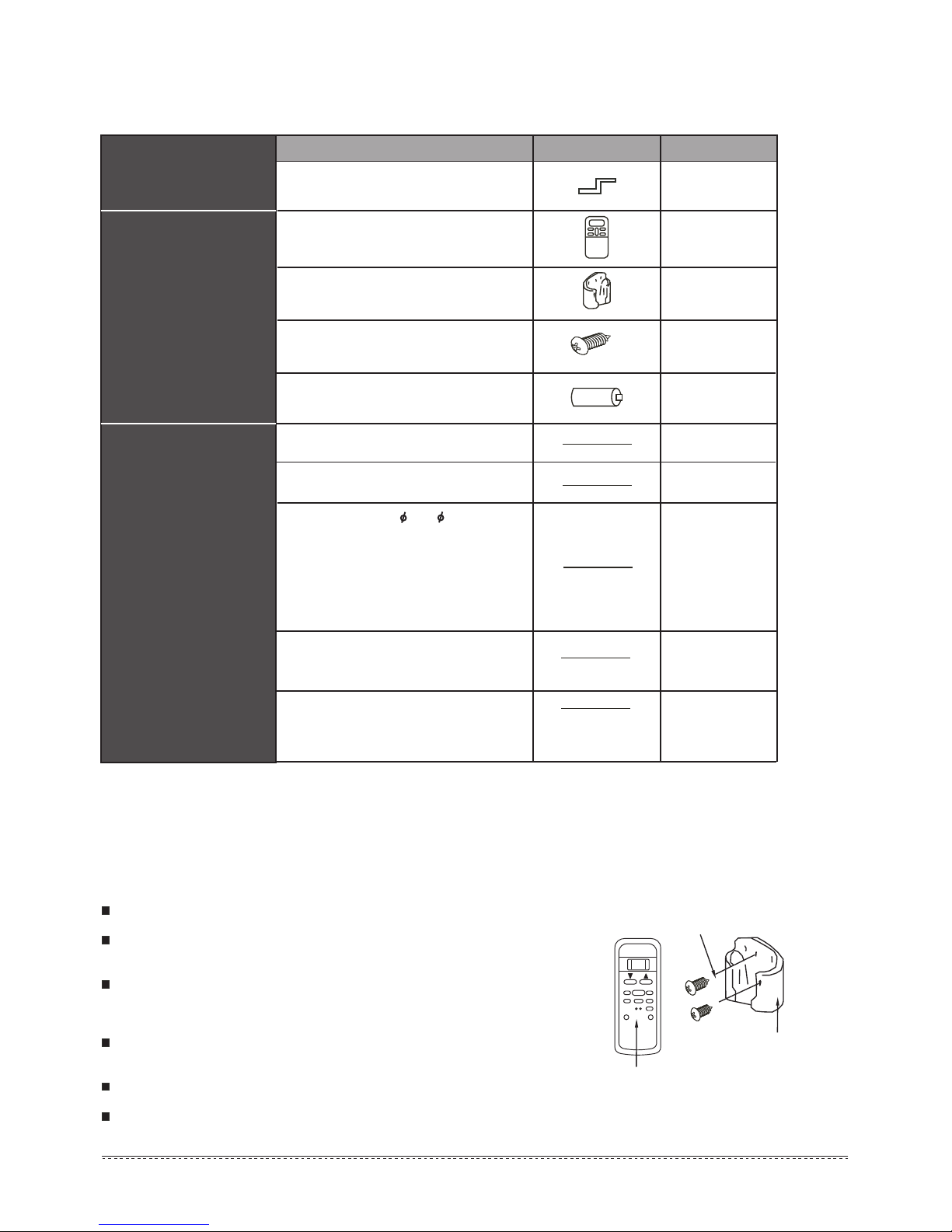

3. ACCESSORIES

Please check whether the following fittings are in scope. If there are some spare fittings , please restore them carefully.

Fig.3-1

Never throw or beat the controller.

Before installation, operate the remote controller to determine its location in a

reception range.

Keep the remote controller at least 3.28ft (1m) apart from the nearest TV set or

stereo equipment. (it is necessary to prevent image disturbances or noise

interferences.)

Do not install the remote controller in a place exposed to direct sunlight or close to a

heating source, such as a stove.

Note that the positive and negative poles are right positions when loading batteries.

This manual is subject to changes due to technological improvement without further

notices.

Cautions on remote controller installation:

Remote

controller

Remote controller

holder

Mounting screw B

ST2.9x10-C-H

Table 3-1

QUANTITYSHAPENAME

1.Hook

6. Owner's manual

7. Installation manual

2. Remote controller

3. Frame

5. Alkaline dry batteries (AM4)

2

1

1

2

2

1

1

(on some models)

1

Installation fittings

Remote controller and its

Frame

Others

4. Mounting screw(ST2.9×

10-C-H)

8 .Transfer connector( 9.52- 12.7)

(Packed with the indoor unit ,used for

multi-type models only )

(NOTE: Pipe sizes differ from appliance

to appliance.To meet different pipe size

requirements, sometimes the pipe

connections need the transfer connector

installed on the outdoor unit .)

9. Magnetic ring

(Hitch on the communication cable and

wind for two circles.)

10. Red short connected wire

(Applied to the W/L pin of outdoor unit

terminal block be short-circuited.)

1

(on some models)

1

(on some models)

6

Page 7

5. INDOOR UNIT INSTALLATION

4. INSPECTING AND HANDLING THE UNIT

At delivery, the package should be checked and any damage

should be reported immediately to the service agent.

When handling the unit, take into account the following:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

Determine before hand the path which the unit is to be

brought in.

Move this unit in the originally package is possible.

When lifting the unit , always use protectors to prevent

belt damage and pay attention to the position of the

unit’s centre of gravity.

1

2

3

4

Keep the indoor unit, the outdoor unit, the power

supply wiring and transmission wiring at least 3.28ft

(1m) away from televisions and radios. This is to

prevent image interference and noise in those

electrical appliances. (Noise may be generated

depending on the conditions under which the electric

wave is generated, even if a distance of 3.28ft (1m) is

maintained.)

There is enough room for installation and maintenance.

(Refer to Fig.5-1 and Fig.5-2)

The outlet and the inlet are not impeded, and the

influence of external air is minimal.

The air flow can reach throughout the room.

The connecting pipe and drainpipe could be extracted out

easily.

There is no direct radiation from heaters.

5.1 Installation place

5.2 Install the main body

The indoor unit should be installed in a location that meets

the following requirements:

CAUTION

Fig.5-1

Fig.5-2

Fig.5-3

Fig.5-4

Fix the hook with a tapping screw onto the wall.(Refer to

Fig.5-3)

Hang the indoor unit on the hook.

(The bottom of body can touch with floor or suspended,

however the body must install vertically.)

≥3.9in/100mm

≥39.4in/

1000mm

≥3.9in/100mm

≥3.9in/100mm

Hook

Hook

Tapping

screw

Washer

<0.24in/6mm

27.6in/700mm

8.3in/210mm

7.7in/195mm

7.7in/195mm

23.6in/600mm

7

Page 8

X

O

6.1 Installation Place

6. OUTDOOR UNIT INSTALLATION

There is enough room for installation and maintenance.

The air outlet and the air inlet are not impeded, and can

not be reached by strong wind.

The installation area must be a dry and well ventilated

place.

The support should be flat, horizontal and can with stand

the weight of the outdoor unit. There should be no

additional noise or vibration.

The unit or the placement of the unit should not impede

on the safety or disturb the comfort of others nearby.

The connecting pipes and cables are easy to install.

Determine the air outlet direction where the discharged

air is not blocked.

There is no danger of fire due to leakage of inflammable

gas.

The piping length between the outdoor unit and the indoor

unit may not exceed the allowable piping length.

In case the installation place is exposed to strong wind

such as a seaside, make sure the fan operates properly

by putting the unit lengthwise along the wall or use a dust

shield.(Refer to Fig.6-1)

If possible, do not install the unit where it is exposed to

direct sunlight.

If necessary, install a blind that does not interfere with the

air flow.

During the heating mode, the water drains off the outdoor

unit. The condensation should be drained away from the

unit through the drain hole to an appropriate location to

avoid contact with people, plants, or animals.

Select the position where the unit will not be subject to

snow drifts, accumulation of leaves or other seasonal

debris. If unavoidable, please cover it with a shelter.

Locate the outdoor unit as close to the indoor unit as

possible.

If possible, please remove the obstacles nearby to

prevent the unit's performance from being impeded by a

lack of air circulation.

The minimum distance between the outdoor unit and

obstacles described in the installation chart does not

mean that the same is applicable to the situation of an

airtight room. Leave open two of the three

directions.(Refore to Fig.6-3)

Fig.6-1

The outdoor unit should be installed in the location that

meets the following requiements:

All the pictures in this manual are for illustration

purposes only. They may differ slightly from the air

conditioner you purchased(depending on the model).

NOTE

Strong wind

Fig.6-2

Fig.6-3

Refore to Fig.6-2~Fig.6-3

Table 6-1 Unit:in/mm

(in=mm/25 .4)

32.0 (810) 22.0 (558) 82.5 (37.4)12.2 (310)

11.4 (290)

20.9 (530)

8

Page 9

Fig.6-4

NOTE

CAUTION

>11.8in/

30cm

>23.6in/

60cm

>11.8in/

30cm

>78.7in/

200cm

(Wall or obstacle)

Air outlet

Air inlet

M

P

Air inlet

Maintain channel

N

Side air outlet outdoor unit

Fig.6-5

6.2 Moving and installation

All the pictures in this manual are for illustration

purposes only. They may differ slightly from the air

conditioner you purchased(depending on model).

NOTE

All the pictures in this manual are for illustration

purposes only. They may differ slightly from the air

conditioner you purchased(depending on the model).

Since the gravity center of the unit is not at its physical

center, be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from

deforming.

Do not touch the fan with hands or other objects.

Do not lean the unit more than 45, and do not lay it sidelong.

Make a concrete foundation according to the specifications of

the outdoor units.(Refer to Fig.6-5)

Fasten the feet of this unit with bolts firmly to prevent it from

collapsing in case of earthquake or strong wind.(Refer to

Fig.6-5)

7. INSTALL THE CONNECTING PIPE

Check whether the height drop between the indoor unit and

outdoor unit, the length of refrigerant pipe, and the number of

the bends meet the following requirements:

All field piping must be provided by a licensed

refrigeration technician and must comply with the

relevant local and national codes.

Do not let air, dust, or other impurities fall in the pipe

system during the installation.

The connecting pipe should not be installed until the

indoor and outdoor units have been fixed already.

Keep the connecting pipe dry, and do not let moisture in

during installation.

Execute heat insulation work completely on both sides

of the gas piping and the liquid piping. Otherwise, this

can sometimes result in water leakage.

The Procedure of Connecting Pipes

7.1

Table 7-1

Capacity(Btu/h)

The max height drop

The length of refrigerant pipe

The number of bends

16.4ft/5m

Less than

32.8ft/10m

Less than 5

Fix with bolt

CAUTION

Drill a hole in the wall (suitable just for the size of the wall

conduit), then set on the fittings such as the wall conduit and

its cover.

Bind the connecting pipe and the cables together tightly with

binding tapes.

Pass the bound connecting pipe through the wall conduct

from outside. Be careful of the pipe allocation to avoid

damage to the tubing.

Connect the pipes. Refer to "How to Connect the pipes" for

details.

Expel the air with a vacuum pump. Refer to "How to expel the

air with a vacuum pump" for details.

Open the stop values of the outdoor unit to connect the

refrigerant pipe to the indoor unit with the outdoor unit in

fluent flow.

Check the leakage. Check all the joints with the leak detector

or soap water.

Cover the joints of the connecting pipe with the soundproof /

insulating sheath (fittings), and bind it well with tape to

prevent leakage.

1

2

3

5

6

7

4

Ensure that the insulating materials cover all the exposed

parts of the flare pipe joints and refrigerant pipe on the

liquid-side and the gas-side. Ensure there is no gap

between them.

Incomplete insulation may cause water condensation.

>23.6in/

60cm

9000~12000

9

Page 10

Fig.7-1

Open the front panel

1

Slide the two stoppers on the left and right sides inword

until they click .(Refer to Fig.7-1)

How to take indoor unit apart to connect

the pipes

Remove the front panel.

2

Remove the string.(Refer to Fig.7-2)

Allowing the front panel to fall forward will enable you to

remove it.

Remove the face plate .

3

Remove the four screws.(Refer to Fig.7-2)

Open the bottom of face plate to a 30 degree angle, then

you can remove the top of the face plate.(Refer to Fig.7-3)

Fig.7-2

Fig.7-3

How to take outdoor unit apart to connect

the pipes

Remove the water tray(Refer to Fig.7-4)

Flaring

1

Cut a pipe with a pipe cutter. (Refer to Fig.7-5)

Insert a flare nut into a pipe and flare the pipe.

Refer to Table 7-2 for the dimension of flare nut spaces.

90

Lean crude burr

Fig.7-5

Fig.7-4

How to Connect the pipes

Water tray

Table 7-2

0.33/8.3 0.34/8.7

0.47/12.0

0.61/15.4

Ø1/4in/6.35

Ø3/8in/9.52

Ø1/2in/12.7

R0.016~0.031

0.4~0.8

45

°

±

2

90

°

±

4

A

357~367 kgf.cm

(35~36 N.m)

255~265 kgf.cm

(25~26N.m)

153~163 kgf.cm

(15~16 N.m)

(in/mm)

min max

Pipe gauge

Tightening torque

Flare dimensin A

Flare shape

0.48/12.4

0.62/15.8

10

Page 11

2

Bend the tubing in the proper way.

Connect the indoor unit first, then the outdoor

unit.

Too much torque will harm the bellmouthing and an

inadequate amount of torque will cause leakage. Please

determine the torque according to Table 4.

After the connecting work is finished, be sure to check

that there is no gas leak.

The bending angle should not exceed 90.

The bending position is preferably in the middle of the

bendable pipe. The larger the bending radius the better it

is.

Do not bend the pipe more than three times.

When connecting the flare nut, coat the flare both inside

and outside with either oil or ester oil and initially tighten

by hand 3 or 4 turns before tighting firmly.

Bend the pipe with thumb

min-radius 100mm

How to expel the air with a vacuum pump

Stop valve operation introduction

1. Opening stop valve

1.

2.

3.

Remove the cap and turn the valve counter

clock-wise with the hexagon wrench.

Turn it until the shaft stops.Do not apply excessive force

to the stop valve. Doing so may break the valve body,

as the valve is not a backseat type. Always use the

special tool.

Make sure to tighten the cap securely.

Fig.7-6

Fig.7-7

Fig.7-8

Be sure to use both a spanner and torque wrench

together when connecting or disconnecting pipes to /from

the unit.

Make sure to tighten the cap securely.

For the tightening torque,refer to the table below.

2. Closing stop valve

1.

2.

Remove the cap and turn the valve clockwise with the

hexagon wrench.

Securely tighten the valve until the shaft contacts the

main bodyseal.

CAUTION

CAUTION

Always use a charge hose for service port connection.

After tightening the cap, check that no refrigerant leaks exist.

Table 7-3

Tightening torque N M (Turn clockwise to close)

Stop

Valve size Shaft (valve body)

Cap

(Valve lid)

Hexagonal

wrench

0.16in/4 mm

Maintenance nut

18~22

13.5~16.55.4~6.6

8.1~9.9

11.5~13.9

1

2

4

3

5

7

6

Using the vacuum pump

Loosen and remove the maintenance nuts of stop valves A

and B, and connect the charge hose of the manifold valve to

the service port of stop valve A. (Be sure that stop valves A

and B are both closed)

Connect the joint of the charge hose with the vacuum pump.

Open the Lo-lever of the manifold value completely.

Turn on the vacuum pump. At the beginning of pumping,

loosen the maintenance nut of stop valve B a little to check

whether the air comes in the (the sound of the pump

changes, and the indicator of compound meter turns below

zero). Then fasten the maintenace nut.

When the pumping has finished, close the Lo-lever of the

manifold valve completely and turn off the vacuum

pump.Continue pumping for 15 minutes or more and check

that the compound meter indicates -2.5ftHg/-76cmHg(-1 X10

Pa)

Loosen and remove the cap of stop valves A and B to open

stop valve A and B completely, then fasten the cap.

Disassemble the charge hose from the service port of stop

5

Fig.7-10

Fig.7-9

service port

cap

maintenance nut

Stop valve

Gas side

Liquid side

hexagon holeshaftseal

Outdoor

unit

Indoor

unit

A

C

D

B

Ø1/4in/6.35

Ø3/8in/9.52

Ø1/2in/12.7

11

Page 12

CAUTION

Additional Refrigerant Charge

7.2

Refrigerant cannot be charged until field wiring has been

completed.

Refrigerant may only be charged after performing the leak

test and the vacuum pumping.

When charging a system, care shall be taken that the

maximum permissible charge is not exceeded, in view of the

danger of liquid hammer.

Charging with an unsuitable substance may cause explosions

and accidents, so always ensure that the appropriate

refrigerant is charged.

Refrigerant containers shall be opened slowly.

Always use protective gloves and protect your eyes when

charging refrigerant.

Fig.7-11

NOTE

Pressure meterMulti-meter

Lo-lever

Lo-lever

Charge hose Charge hose

Vacuum pump

Hi-lever

Manifold valve

If a negative result is received for R from the formula at

right, no refrigerant needs to be added nor removed.

The outdoor unit is factory charged with refrigerant. Some

systems require additional charging of refrigerant depending

on pipe lengths. The additional refrigerant to be charged can

be calculated from the following formule:

The standard pipe length will vary according to the requirements of

your area. For example, in North America area, the standard pipe

length is 25ft(7.5m). While in the other areas, the standard pipe

length is 16ft(5m).

Inverter R410A:

Liquid side:φ1/4"(6.35) (Total pipe length - standard pipe length)x0.16oZ(15g)/m(ft)

Liquid side:φ3/8"(9.52) (Total pipe length - standard pipe length)x0.32oZ(30g)/m(ft)

CAUTION

The drain pipe of indoor unit must be heat insulated, or it will

condense dew, as well as the connections of the indoor unit.

Hard PVC binder must be used for pipe connection, and make

sure there is no leakage.

With the connection part to the indoor unit, be sure not to

impose pressure on the side of indoor unit pipes.

When the declivity of the drain pipe downwards is over 1/100,

there should not be any winding.

The total length of the drain pipe when pulled out traversely

shall not exceed 20m, when the pipe is over long, a prop stand

must be installed to prevent winding.

Refer to the figures on the right for the installation of the pipes.

8. CONNECT THE DRAIN PIPE

Install the drainpipe of the indoor unit

The outlet has PTI screw thread, Please use sealing materials

and pipe sheath(fitting) when connecting PVC pipes.

Drainage test

Ensure the drainpipe is unhindered.

The newly built housing should have this test preformed

before paving the ceiling.

4.9ft/1.5m~ 6.6ft/2m

Insulating

material

Downward declivity

lower than 1/100

Bend

S shape

VP30

Downward declivity

lower than 1/100

Put as deep as possible

(about 3.9in/10cm)

Fig. 8-1

Install the drain joint of the outdoor unit

Fit the seal into the drain joint, then insert the drain joint into the

base pan hole of outdoor, rotate 90 to securely assemble them.

Connect the drain joint with an extension drain hose (Locally

purchased), in case of the condensation draining off the outdoor

unit during the heating mode.(Refer to Fig.8-2)

-2.5ftHg/-76cmHg

12

Page 13

CAUTION

NOTE

NOTE

All the pictures in this manual are for illustration purposes only.

They may differ slightly from the air conditioner you

purchased(depending on model).

9. WIRING

The appliance shall be installed in accordance with

national wiring regualtions.

The air conditioner should use aseparate power supply

with rated voltage.

The external power supply to the air conditioner should

have a ground wiring, which is linked to the ground

wiring of the indoor and outdoor unit.

The wiring work should be done by qualified persons

according to circuit drawing.

An all-pole disconnection device which has at least 3mm

separation distance in all pole and a residual current

device(RCD)with the rating of above 10mA shall be

incorporated in the fixed wiring according to the national

rule.

Be sure to locate the power wiring and the signal wiring

well to avoid cross-disturbance.

Do not turn on the power until you have checked the

wiring carefully.

Remark per EMC Directive 89/336/EEC

To prevent flicker impressions during the start of the

compressor (technical process), the following installation

conditions apply.

The power connection for the air conditioner has to be

done at the main power distribution. The distribution must

have low impedance, normally the required impedance

reaches a 32 A fusing point.

No other equipment has to be connected with this power

line.

For detailed installation acceptance please refer to your

power supplier, for products like washing machines, air

conditioners or electrical ovens.

1

2

3

Seal

The base pan hole

of outdoor unit

Drain joint

Seal

The base pan

of outdoor unit

Drain

joint

Fig.8-2

NOTE

Dissemble the bolts from the cover.(If there isn't a cover on

the outdoor unit, disassemble the bolts from the maintenance

board, and pull it in the direction of the arrow to remove the

protection board.)

(Refer to Fig.9-2)

Rotate the installation bearer of the sensing device to the

other side, and then take off the cover of electrical box. (Take

off the electrical box if the capacity is 18000btu/h and its

using the network function.)

(Refer to Fig.9-1)

Connect the cable

9.1

Fig.9-2

Protection board

Cover

For power details of the air conditioner refer to the rating

plate of the product.

If you have any questions, contact your local dealer.

4

5

All the pictures in this manual are for illustration

purposes only. They may differ slightly from the air

conditioner you purchased(depending on the model).

Installation bearer

of sensing device

Fig.9-1

13

Page 14

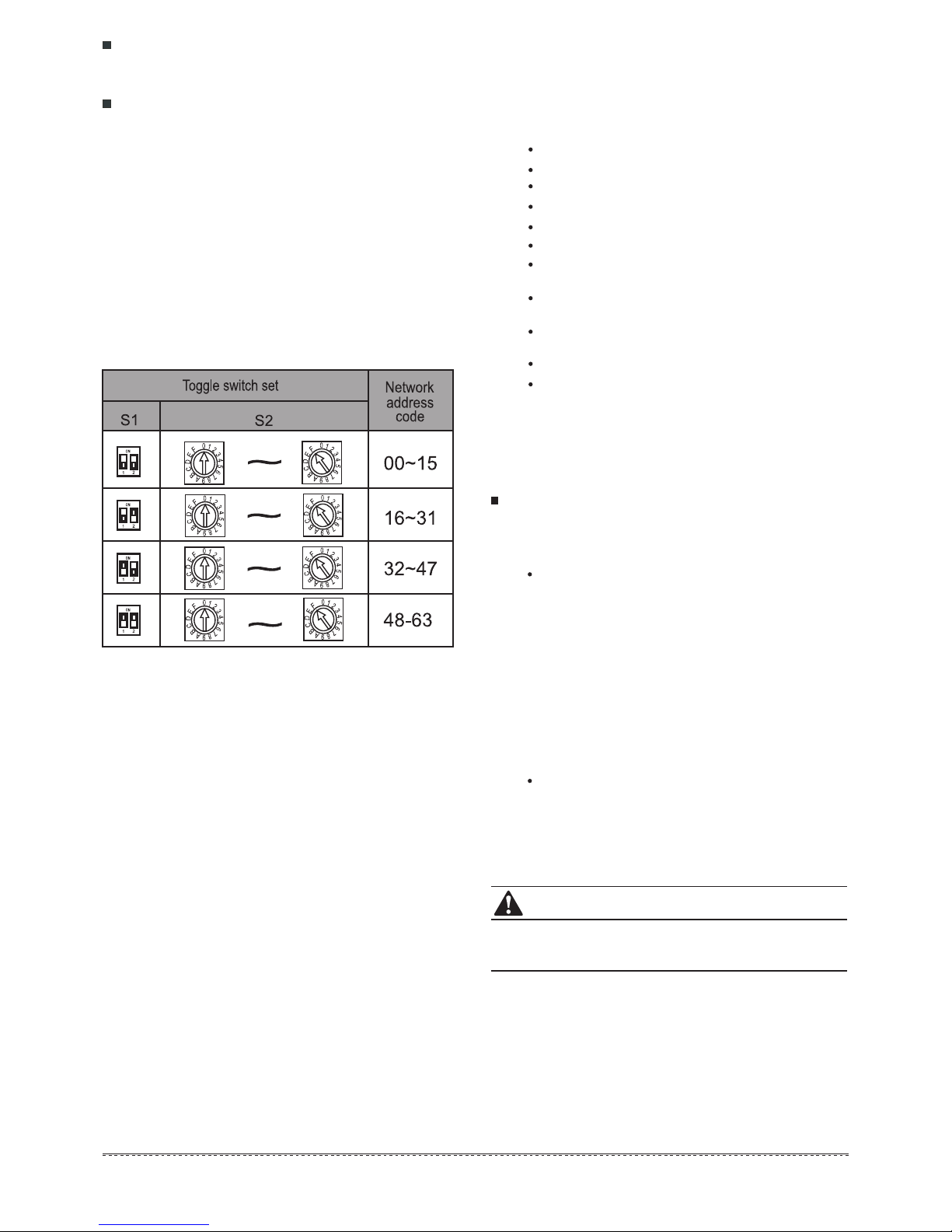

(Only 1800 BTU/h units have the network address set function.)

Every air conditioner in the network has one network address to

distinguish it from the other. The address code of the air conditioner

in LAN is set by code switches S1 & S2 on the Main Control Board

of the indoor unit, and the set range is 0-63.

Network address set

9.4

Table 9-1

Connect the connective cables to the terminals as identified

with their respective matched numbers on the terminal block

of the indoor and outdoor units.

Re-install the Indoor unit and outdoor unit

The Specification of Power

9.2

Wiring figure

9.3

(Refer to Table 9-2)

(Refer to Fig9-4~Fig9-7)

10. TEST OPERATION

The test operation must be performed after the entire

installation has been completed.

Please confirm the following points before the test operation:

2

1

According to the user's requirement, install the remote

controller frame where the remote controller's signal can best

reach the indoor unit.

Test the operation.

4

3

The indoor unit and outdoor unit are installed properly.

Tubing and wiring are correctly completed.

The refrigerant pipe system is leakage-checked.

The drainage is unimpeded.

The heating insulation works well.

The ground wiring is connected correctly.

The length of the tubing and the added stow capacity of

the refrigerant have been recorded.

The power voltage fits the rated voltage of the air

conditioner.

There is no obstacle at the outlet and inlet of the outdoor

and indoor units.

The gas-side and liquid-side stop valves are both opened.

The air conditioner is pre-heated by turning on the power.

Set the air conditioner to the "COOLING" mode with the

remote controller, and check the following points. If there is

any malfunction, please resolve it according to the

"Troubleshooting" chapter in the "Owner's Manual".

1) The indoor unit

a. Ensure the switch on the remote controller works well.

b. Ensure the buttons on the remote controller works well.

c. Ensure the air flow louver moves normally.

d. Ensure the room temperature is adjusted well.

e. Ensure the indicator lights normally.

f. Ensure the temporary buttons works well.

g. Ensure the drainage is normal.

h. Ensure there is no vibration or abnormal noise during

operation.

I. Ensure the air conditioner heats well in the case of the

HEATING/COOLING type.

2) The outdoor unit

a. Ensure there is no vibration or abnormal noise during

operation.

b. Ensure the generated wind, noise, or the unit's

condensation have not negatively effected the

surrounding environment

c. Ensure none of the refrigerant has leaked.

A protection feature prevents the air conditioner from being

activated for approximately 3 minutes when it is restarted

immediately after shut off.

CAUTION

14

Page 15

The Specification of Power

(A)

(sq in/mm2)

(sq in/mm²)

208-230V~, 50Hz/60Hz

TYPE

POWER

GROUND WIRING

OUTDOOR UNIT POWER

WIRING

STRONG ELECTRIC

SIGNAL

INDOOR/OUTDOOR

CONNECTING

WIRING

CIRCUIT BREAKER/FUSE

INDOOR UNIT POWER WIRING

PHASE 1-PHASE

FREQUENCY AND VOLT

20/16 20/16

12000Btu/h

(Cooling & Heating)

16000~

18000Btu/h

(Cooling & Heating)

208-230V~, 50Hz/60Hz

1-PHASE

0.06/1.5

0.1/2.5

0.12x0.1/3x2.5

0.12x0.06/3X1.5

0.16x0.04/4X1.0

WEAK ELECTRIC

SIGNAL

0.12x0.04/3x1.0

0.12x0.02/3x0.5

Table 9-2

Wiring figure

The power supply included in the power supply mentioned above can be applied to the table.

Before obtaining access to terminals, all supply circuits must be disconnected.

CAUTION

Fig.9-4

Ground wiring

Ground wiring

Power supply

Switch/Fuse

(Available locally)

Power wiring (indoor)

Power linking wiring (Outdoor)

Strong elec-signal link wiring

Weak elec-signal link wiring

Indoor

Unit

Outdoor

Unit

Ground the air conditioner properly in case to affect its anti-interference function

15

Page 16

Fig.9-5

Ground wiring

Ground wiring

Power supply

Switch/Fuse

(Available locally)

Power wiring (outdoor)

Power linking wiring (indoor)

Strong elec-signal link wiring

Weak elec-signal link wiring

Indoor

Unit

Outdoor

Unit

Ground the air conditioner properly.

Fig.10-6

Ground wiring

Ground wiring

Power supply

Switch/Fuse

(Available locally)

Power wiring (indoor)

Power linking wiring (Outdoor)

Weak elec-signal link wiring

Indoor

Unit

Outdoor

Unit

Power supply

Ground the air conditioner properly.

---

---

---

---

Magnetic ring(optional)

Connect the communication cable and wind for two circles.

16

Page 17

A disconnection device with a air gap contact separation in all active conductors should be

incorporated in the fixed wiring according to the National Wiring Regulation.

When wiring, please choose the corresponding chart, or it may cause damage.The signs of the

indoor terminal block in the some of following figures may be replaced by L N L1 N1.

CAUTION

Fig.9-7

Ground wiring

Ground wiring

Power supply

Switch/Fuse

(Available locally)

Power wiring (outdoor)

Strong elec-signal link wiring

Weak elec-signal link wiring

Indoor

Unit

Outdoor

Unit

Ground the air conditioner properly.

17

Page 18

Copyright 2014 Carrier Corporation S 7310 W. Morris St. S Indianapolis, IN 46231

Manufacturer reserves the right to change, at any time, s pecifications and designs without notice and without obligations.

Edition Date: /1411

Replaces: New

Loading...

Loading...