Page 1

40MBFQ

Floor Console Ductless System

Sizes 09 to 12

Product Data

INDUSTRY LEADING

FEATURES / BENEFITS

A PERFECT BALANCE BETWEEN

BUDGET LIMITS, ENERGY SAVINGS AND

COMFORT.

The 40MBFQ series ductless system are a matched combination

of an outdoor condensing unit and an indoor fan coil unit

connected only by refrigerant tubing and wires.

The fan coil is mounted on the floor, against the wall. This

selection of fan coils permits creative solutions to design problems

such as:

NOTE: Image for illustration purposes only. Actual model may

differ slightly.

S Add−ons to current space (an office or family room

addition)

S Special space requirements

S When changes in the load cannot be handled by the

existing system.

S When adding air conditioning to spaces that are heated

by hydronic or electric heat and have no ductwork.

S Historical renovations or any application where

preserving the look of the original structure is essential.

The ideal compliment to your ducted system when it is

impractical or prohibitively expensive to use ductwork.

These compact indoor fan coil units take up very little space in the

room and do not obstruct windows. The fan coils are attractively

styled to blend with most room decors. Advanced system

components incorporate innovative technology to provide reliable

cooling performance at low sound levels.

Page 2

LOW SOUND LEVELS

When noise is a concern, the ductless systems are the answer. The

indoor units are whisper quiet. There are no compressors indoors,

either in the conditioned space or directly over it, and there is

none of the noise usually generated by air being forced through

ductwork.

SECURE OPERATION

If security is an issue, outdoor and indoor units are connected only

by refrigerant piping and wiring to prevent intruders from

crawling through ductwork. In addition, since outdoor units can

be installed close to an outside wall, coils are protected from

vandals and severe weather.

FAST INSTALLATION

This compact ductless system is simple to install. A mounting

bracket is standard with the indoor units and only wire and piping

need to be run between the indoor and outdoor units. These units

are fast and easy to install ensuring minimal disruption to

customers in the home or workplace. This makes the ductless

systems the equipment of choice, especially in retrofit situations.

SIMPLE SERVICING AND MAINTENANCE

Removing the top panel on the outdoor units provides immediate

access to the control compartment, providing a service technician

access to check the unit’s operation. In addition, the draw−thru

design of the outdoor section means that dirt accumulates on the

outside surface of the coil. Coils can be cleaned quickly from the

inside using a pressure hose and detergent.

On all indoor units, service and maintenance expense is reduced

due to easy−to−use cleanable filters. In addition, these floor

console systems have extensive self−diagnostics to assist in

troubleshooting.

BUILT−IN RELIABILITY

Ductless system indoor and outdoor units are designed to provide

years of trouble−free operation.

The floor console indoor units include protection against freeze−up

and high evaporator temperatures on heat pumps.

The condensing units on heat pumps are protected by a three

minute time delay before the compressor starts the over−current

protection and the high temperature protection.

INDIVIDUAL ROOM COMFORT

Maximum comfort is provided because each space can be

controlled individually based on usage pattern. The air sweep

feature provided permits optimal room air mixing to eliminate hot

and cold spots for occupant comfort. In addition, year−round

comfort can be provided with heat pumps.

ECONOMICAL OPERATION

The ductless system design allows individual room heating or

cooling when required. There is no need to run large supply−air

fans or chilled water pumps to handle a few spaces with unique

load patterns. In addition, because air is moved only in the space

required, no energy is wasted moving air through ducts.

EASY−TO−USE CONTROLS

The floor console units have microprocessor−based controls to

provide the ultimate in comfort and efficiency. The user friendly

wireless remote control provides the interface between user and

the unit.

ACCESSORIES

Customizing these ductless systems to your application is easily

accomplished.

Adding a condensate pump accessory to the floor console fan coil

provides installation flexibility.

OPTIONAL WIRED CONTROLLER

AGENCY LISTINGS

All systems are listed with AHRI (Air Conditioning, Heating &

Refrigeration Institute), and ETL.

2

Page 3

MODEL NUMBER NOMENCLATURE

INDOOR UNIT

QF-

40= FAN COIL UNIT

MB = MODEL

INDOOR FAN COIL TYPE

F= FLOOR CONSOLE

40 MB 309

- -

VOLTAGE

3 = 208/230-1-60

SYSTEM TYPE

Q = HEAT PUMP

NOMINAL CAPACITY

09 - 3/4 TON

12 - 1 TON

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

NOT USED

NOT USED

3

Page 4

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Mounting Brackets S

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Wired Remote Control A

Wireless Remote Control S

Automatic Up-Down Air Sweep S

Air Direction Control S

Auto Restart Function S

Cold Blow Protection On Heat Pumps S

Freeze Protection Mode On Heat Pumps S

Turbo Mode S

Silence Mode S

Auto Changeover On Heat Pumps S

Follow Me S

Energy Saving Features

Sleep Mode S

Stop/Start Timer S

46°F Heating Mode (Heating Setback)

Safety And Reliability

Indoor Coil Freeze Protection S

Aluminum Blue Hydrophilic pre-coated fins S

Indoor Coil High Temp Protection in Heating Mode S

Ease Of Service And Maintenance

Cleanable Filters S

Diagnostics S

Liquid Line Pressure Taps S

Application Flexibility

Condensate Pumps A

Legend

S Standard

A Accessory

S

INDOOR UNITS

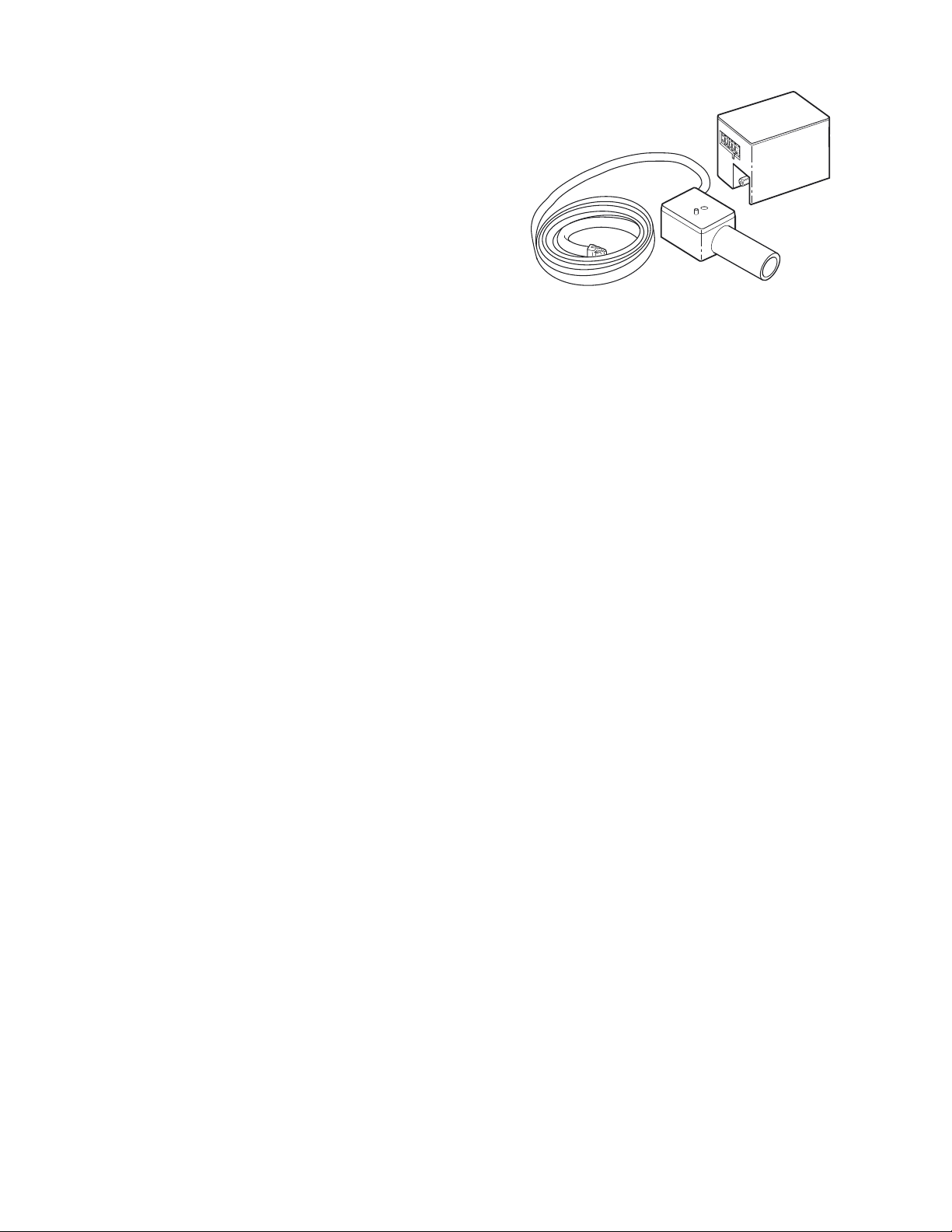

On the floor console fan coils, the condensate pump has a lift

capability of 12 ft. (3.6 m) on the discharge side with the pump

mounted in the fan coil or 6 ft. (1.8 m) on the suction side if the

pump is remote mounted.

The pump is recommended when an adequate drain line pitch

cannot be provided, or when the condensate must move up to exit.

Fig. 1 – Condensate Pump Accessory

ACCESSORIES

ORDERING NO. DESCRIPTION FOR MODELS

53DS-900---118 Condensate Pump (230v) All Sizes

KSACN0101AAA Wired Remote Control All Sizes

KSACN0401AAA

53DS-900---089

53DS-900---008

Wired Remote Control 7

Day Programmable

compatible with indoor units

starting with serial number

0217V10001

Insulated 25’

Line Set - 1/4” x 3/8”

Insulated 25’

Line Set - 1/4“ x 1/2”

All Sizes

Size 09

Size 12

4

Page 5

DIMENSIONS − INDOOR

23.62(600)

27.56(700)

Hanging arm

7.68(195)

0.63(16)

Drain pipe

8.27(210)

Unit: in (mm)

Fig. 2 – Indoor Unit

UNIT SIZE 9 12

Depth in (mm) 8.27 (210) 8.27 (210)

Width in (mm) 27.56 (700) 27.56 (700)

Height in (mm) 23.62 (600) 23.62 (600)

Weight-Net Lb (kg.) 32.41 (14.7) 32.41 (14.7)

5

Page 6

CLEARANCES − INDOOR

Fig. 3 – Indoor Unit Clearance

SPECIFICATIONS

Heat Pump

System

Electrical

Controls

Operating

Range

Piping

Indoor

Performance may vary based on the compatible outdoor units. See respective product data for performance data.

Size 9 12

Indoor Model 40MBFQ09---3 40MBFQ12---3

Voltage, Phase, Cycle V/Ph/Hz 208/230-1-60 208/230-1-60

Power Supply Indoor unit powered from outdoor unit

MCA A. 0.29 0.29

Wireless Remote Controller (°F/°C Convertible) Standard Standard

Wired Remote Controller (°F/°C Convertible) Optional Optional

Cooling Indoor DB Min -Max ° F (° C) 63~90 (17~32) 63~90 (17~32)

Heating Indoor DB Min -Max ° F (° C) 32~86 (0~30) 32~86 (0~30)

Pipe Connection Size - Liquid in (mm) 1/4 (6.35) 1/4 (6.35)

Pipe Connection Size - Suction in (mm) 3/8 (9.52) 1/2 (12.7)

Unit Width in (mm) 27.56 (700) 27.56 (700)

Unit Height in (mm) 23.62 (600) 23.62 (600)

Unit Depth in (mm) 8.27 (210) 8.27 (210)

Net Weight lbs (kg) 32.41 (14.7) 32.41 (14.7)

Number of Fan Speeds 3 3

Airflow (lowest to highest) CFM 220/250/280 220/250/280

Sound Pressure (lowest to highest) dB(A) 37/38/41 34/41/45

Field Drain Pipe Size O.D. in (mm) 1 (25.4) 1 (25.4)

COMPATIBILITY TABLE

Indoor Unit 40MBFQ09---3 40MBFQ12---3

Outdoor Unit Single Zone 38MAQB09R--3 38MAQB12R--3

Outdoor Unit Multi-zone

NOTE: Backward compatible with 38MAQ Single Zone and 38MGQ Multi−zone Systems.

6

38MGRQ18B--3

38MGRQ24C--3

38MGRQ30D--3

38MGRQ36D--3

38MGRQ48E--3

Page 7

APPLICATION DATA

UNIT SELECTION

Select equipment to either match or is slightly less than the

anticipated peak load. This provides better humidity control, fewer

unit cycles, and less part−load operation.

For units used in spaces with high sensible loads, base equipment

selection on unit sensible load, not on total anticipated load. Adjust

for anticipated room wet bulb temperature to avoid undersizing

equipment.

UNIT MOUNTING (INDOOR)

Refer to the unit’s Installation Instructions for further details.

Unit leveling − For reliable operation, units should be level in all

planes.

Clearance − Provide adequate clearance for airflow as shown in

Fig. 3.

Unit location − Select a location which provides the best air

circulation for the room.

These units should be positioned on the floor, against the wall for

the best air circulation. The unit return and discharge should not be

obstructed by furniture, curtains, or anything which may cause unit

short cycling or air recirculation. Place the unit in the middle of the

selected wall (if possible). Use an outside wall, if available, to

make piping easier, and place the unit so it faces the normal

location of room occupants.

UNIT MOUNTING (OUTDOOR)

Refer to the unit’s Installation Instructions for further details.

Do not install the indoor or outdoor units in a location with special

environmental conditions. For those applications, contact your

ductless representative.

MOUNTING TEMPLATE

Refer to the unit’s Installation Instructions for further details.

The fan coil units are furnished with mounting to mark the location

of the wiring, and refrigeration line hole locations.

SUPPORT

Adequate support must be provided to support the weight of all the

fan coils. Refer to th e Physical Data section for the fan coil weights,

and the base unit dimensional drawings for the mounting brackets

location.

SYSTEM OPERATING CONDITIONS

OPERATING RANGE

Min / Max °F (°C)

Cooling Heating

Indoor DB 63 / 90 (17 / 32) 32 / 86 (0 / 30)

Indoor WB 59 / 84 (15 / 29)

NOTE: Reference the Product Installation Instructions for more

information.

DRAIN CONNECTIONS

Install drains to meet the local sanitation codes. If adequate gravity

drainage cannot be provided, the unit should be equipped with an

accessory condensate pump. The floor console fan coil unit

condensate pumps have a maximum lift of 10’ (3.05 m).

See the physical dimension tables for the drain sizes.

NOTE: Floor console fan coil units have internal condensate

traps. A trap is not required.

REFRIGERANT LINES

General refrigerant line sizing:

1. The outdoor units are shipped with a full charge of R410A

refrigerant.

2. Refrigerant lines should not be buried in the ground. If it is

necessary to bury the lines, not more than 36−in (914 mm)

should be buried. Provide a minimum 6−in (152 mm)

vertical rise to the service valves to prevent refrigerant

migration.

3. Both lines must be insulated. Use a minimum of 1/2−in.

(12.7 mm) thick insulation. Closed−cell insulation is

recommended in all long−line applications.

4. Special consideration should be given to isolating the

interconnecting tubing from the building structure. Isolate

the tubing so that vibration or noise is not transmitted into

the structure.

7

Page 8

WIRING

All wires must be sized per NEC (National Electrical Code) or

CEC (Canadian Electrical Code) and local codes. Use the Electrical

Data table MCA (minimum circuit amps) and MOCP (maximum

over current protection) to correctly size the wires and the

disconnect fuse or breakers respectively.

Per the caution note, only Stranded copper conductors with a 600

volt rating and double insulated copper wire must be used.

NOTE: The use of BX cable is not recommended.

Recommended Connection Method for Power and

Communication Wiring −

Power and Communication Wiring:

The main power is supplied to the outdoor unit. The field supplied

14/3 power/communication wiring from the outdoor unit to the

indoor unit consists of four (4) wires and provides the power for

the indoor unit.

Two wires are high voltage AC power, one is communication

wiring and the other is a ground wire.

Recommended Connection Method for Power and

Communication Wiring (To minimize

communication wiring interference)

PowerWiring:

The main power is supplied to the outdoor unit. The field supplied

power wiring from the outdoor unit to the indoor unit consists of

three (3) wires and provides the power for the indoor unit. Two

wires are high voltage AC power and one is a ground wire.

To minimize voltage drop, the factory recommended wire size is

14/2 stranded with a ground.

Communication Wiring:

A separate shielded stranded copper conductor only, with a

minimum 600 volt rating and double insulated copper wire, must

be used as the communication wire from the outdoor unit to the

indoor unit. Please use a separate shielded 16GA stranded control

wire.

!

CAUTION

CONTROL SYSTEM

The unit is equipped with a microprocessor control to perform

two functions:

1. Provide safety for the system

2. Control the system and provide optimum levels of comfort

and efficiency

The main microprocessor is located on the control board of the

fan coil unit (outdoor units have a microprocessor too) with

thermistors located in the fan coil air inlet and on the indoor coil.

Heat pump units have a thermistor on the outdoor coil. These

thermistors monitor the system operation to maintain the unit

within acceptable parameters and control the operating mode.

WIRELESS REMOTE CONTROL

Fig. 4 – Wireless remote control

1. A wireless remote control is supplied for system operation

for system operation of all floor console units.

2. Each battery operated wireless (infrared) remote control

may be used to control more than one unit.

WIRED REMOTE CONTROL (OPTIONAL)

1. Optional wired remote controller used for system operation

of all floor console units.

2. Kit includes a wired remote controller and a connecting

cable.

3. Connect the wire terminal between the remote controller

and the indoor unit.

4. Display in _F or _C and temperature increments every 1_F

or every 1_C.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a 600 volt rating and

double insulated copper wire.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Be sure to comply with local codes while running wire

from indoor unit to outdoor unit.

S Every wire must be connected firmly. Loose wiring

may cause terminal to overheat or result in unit

malfunction. A fire hazard may also exist. Therefore,

be sure all wiring is tightly connected.

S No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

S Disconnecting means must be provided and shall be

located within sight and readily accessible from the air

conditioner.

S Connecting cable with conduit shall be routed through

hole in the conduit panel.

CAUTION

Fig. 5 – KSACN0101AAA (Timer Function)

Fig. 6 – KSACN0501AAA (7 Day Programmable)

8

Page 9

AIR FLOW DATA

SYSTEM SIZE 9 12

Indoor (CFM)

SOUND PRESSURE

SYSTEM SIZE 9 12

Cooling operation Indoor Sound

Pressure

Heating operation Indoor Sound

Pressure

Unit Outlet

High 280 280

Medium 250 250

Low 220 220

dBa (L/M/H) 37/38/41 34/41/45

dBa (L/M/H) 37/38/41 34/41/45

SOUND PRESSURE TESTING METHOD

Microphone

3.3ft (1m)

X

Indoor

Unit

Fig. 7 – Sound Pressure Testing Method

SOUND POWER

SYSTEM SIZE 9 12

Cooling operation Indoor Sound

Power

Heating operation Indoor Sound

Power

dBa (L/M/H) 46/47/50 44/51/55

dBa (L/M/H) 46/47/50 44/51/55

ELECTRICAL DATA

UNIT SIZE OPER. VOLTAGE MAX / MIN*

9

12

*Permissible limits of the voltage range at which the unit operates satisfactorily.

LEGEND

FLA - Full Load Amps

253 / 187 208-230/1/60

V-PH-HZ FLA HP W

INDOOR FAN

0.21 0.027 20

0.21 0.027 20

4.9 ft (1.5m)

MAX FUSE CB AMP

Refer to outdoor unit installation instructions –

Indoor unit powered by the outdoor unit

9

Page 10

FAN AND MOTOR SPECIFICATIONS

SYSTEM SIZE

material AS AS

Indoor fan

Indoor fan motor

Type LX-370*80*8-7JN LX-370*80*8-7JN

Diameter inch 14.6 14.6

Height inch 3.15 3.15

Model RD-280-20-8A RD-280-20-8A

Type DC DC

Phase 3 3

FLA 0.21 0.21

Insulation class E E

Safe class IPX0 IPX0

Input W 66.6 66.6

Output W 20 20

Range of current Amps 0.21±10% 0.21±10%

Rated current Amps 0.21 0.21

Rated HP HP 0.027 0.027

Speed rev/min 730/680/580/520 730/680/580/520

Rated RPM rev/min 1062 1062

Max. input W 66.6 66.6

9 12

(208-230V) (208-230V)

10

Page 11

WIRING DIAGRAM

FUNCTION OF SWITCHES

SWITCH BOARD

ON

ON

SW102

ON

1 2ON1 2

OFF

TEMP.ADJ

0 °C

FAN OFF

OFF

MO/MU FAN

2

°C

LOW

FAN SPEED

SW103

4

°C

SETTING

FAN SPEED

SWITCH BOARD

-2

°C

TERMAL

TO WIRE CONTROLLER

DISPLAY BOARD

CN10

CN15

J1

SW1

ON

ON

ON

ON

OFF

TYPE

SW2

1 2

1

OFF

MAIN CONTROL BOARD

L

NS

CN1

M1

CN3

XP4

XS4

M2

BLACK

XS1

XP1

RT2

PIPE

CN7

WHITE

XS2

XP2

RT1

ROOM

XS3

XP3

For outdoor power supply

L1 L2

S

XT1

TO OUTDOOR UNIT

Fig. 8 – Wiring Diagram − Sizes 9 and 12

CN2

L1 L2

S

For indoor power supply

L1 L2

TO OUTDOOR UNIT

WIRING DIAGRAM

CODE PART NAME

CN1-CN20

FAN

M1

XS5

XP5

EARTH

Y/G

XT1

S

FAN

Y/G Y/G

XT1

POWER

M2

RT1

RT2

XP1-XP5

XS1-XS5

XT1

J1

NOTICE 1:

THE TYPE_SELECTION AND MO/MU HAS BEEN SET

BEFORE LEAVING THE FACTORY,ANYONE CAN'T

MODIFY IT EXCEPT THE MAINTENANCE PER SON.

CN20

NOTICE 2:

PLEASE CUT OF F THE JUMPER IF YOU

CONNECT THE N ET MODULE

(INDOOR UNIT)

P.C BOARD SOCKETS

INDOOR DC FAN MOTOR

UPPER OUTLET SWING MOT OR

LOWER OUTLET SWING MOT OR

ROOM TEMPERATURE

PIPE TEMPERATURE

CONNECTORS

CONNECTORS

4-WAY TERMINAL

JUMPER

MODULE

TO WIRE

CONTROLLER

J1

INDOOR UNIT CONTROL BOARD

INDOOR UNIT

CODE PART NAME

CN1 Input: 230VAC High voltage Connection of the terminal

CN2 Input: 230VAC High voltage Connection of the terminal

CN3 Output: 24VDC Between CN2 Connection of the S signal

CN6 Output: 12VDC Connection of the Lower outlet swing motor

CN7 Output: 5VDC Connection of the Room and Pipe temperature

CN10 Output: 12VDC Connection of the Display board

CN13 Output: 12VDC Connection of the Upper outlet swing motor

CN15 Output: 1-5VDC Connection of the Switch board

CN16 Output: 320VDC Connection of the Fan high voltage

CN20 Output: 5VDC Connection of the Net module

CN23 Output: 1-12VDC Connection of the Remote switch

11

Page 12

GUIDE SPECIFICATIONS

INDOOR WALL−MOUNTED FLOOR CONSOLE DUCTLESS UNITS

Size Range: 3/4 to 1 Ton Nominal Cooling and Heating Capacity

Model Number: 40MBFQ

PART 1 − GENERAL

1.01 System Description

Indoor, wall−mounted floor console, direct−expansion fan coils are

matched with a cooling only or heat pump outdoor unit.

1.02 Agency Listings

Unit is rated per AHRI Standards 210/240 and listed in the AHRI

directory as a matched system.

1.03 Delivery, Storage, And Handling

Units are stored and handled per the unit manufacturer’s

recommendations.

1.04 Warranty (For Inclusion By Specifying

Engineer)

PART 2 − PRODUCTS

2.01 Equipment

A. General:

Indoor, direct−expansion, floor−mounted fan coil. Unit is complete

with a cooling/heating coil, fan, fan motor, piping connectors,

electrical controls, microprocessor control system, and integral

temperature sensing. Unit is furnished with an integral mounting

bracket and mounting hardware.

B. Unit Cabinet:

Cabinet discharge and inlet grilles are attractively styled,

high−impact polystyrene. Cabinet is fully insulated for improved

thermal and acoustic performance.

C. Fans:

1. Fan is the tangential direct−drive blower type with an air

intake in the center of the unit and discharge at the top and

bottom front. An automatic, motor−driven vertical air sweep

is provided standard.

2. Air sweep operation is user selectable. The vertical sweep

may be adjusted (using the remote control) and the

horizontal air direction may be set manually.

D. Coil:

Coil is a copper tube with aluminum fins and galvanized steel tube

sheets. Fins are bonded to the tubes by mechanical expansion and

specially blue hydrophilic pre−coated for enhanced wet−ability. A

drip pan under the coil shall has a drain connection for hose

attachment to remove condensate. The condensate pan has an

internal trap.

E. Motors:

The motors have an open drip−proof, permanently lubricated ball

bearing with inherent overload protection. The fan motors are

4−speed.

F. Controls:

Controls consist of a microprocessor−based control system which

controls the space temperature, determines the optimum fan speed,

and runs self diagnostics. The temperature control ranges from

62_F to 86_F (17_C to 30_C) in increments of 1_F or 1_C, and

have 46_F Heating Mode (Heating Setback). The wireless remote

controller has the ability to act as the temperature sensing location

for room comfort.

The unit shall have the following functions as a minimum:

1. An automatic restart after power failure at the same

operating conditions as at failure.

2. A timer function to provide a minimum 24−hour timer

cycle for system Auto Start/Stop.

3. Temperature−sensing controls to sense the return air

temperature.

4. Indoor coil freeze protection.

5. Wireless infrared remote control to enter set points and

operating conditions.

6. Automatic air sweep control to provide on or off activation

of air sweep louvers.

7. Dehumidification mode to provide increased latent removal

capability by modulating system operation and set point

temperature.

8. Fan−only operation to provide room air circulation when no

cooling is required.

9. Diagnostics to conduct continuous checks of unit operation

and warn of possible malfunctions. Error messages appear

on the unit.

10. Fan speed control is user−selectable: high, medium, low, or

microprocessor controlled automatic operation during all

operating modes.

11. Automatic heating−to−cooling changeover in heat pump

mode. Control includes a deadband to prevent rapid mode

cycling between heating and cooling.

12. Indoor coil high temperature protection is provided to detect

excessive indoor discharge temperature when the unit is in

heat pump mode.

G. Filters:

Unit has a filter track with factory−supplied cleanable filters.

H. Electrical Requirements:

Indoor fan motor to operate on 208−230V as specified. Power is

supplied from the outdoor unit.

I. Operating Characteristics:

The 40MBFQ system has a minimum SEER (Seasonal Energy

Efficiency Ratio) and HSPF at AHRI conditions, as listed on the

specifications table.

J. Refrigerant Lines:

All units should have refrigerant lines that can be oriented to

connect from the left, right or back of unit. Both refrigerant lines

need to be insulated.

K. Special Features (Field Installed):

1. Condensate Pump:

− The condensate pump removes condensate from the drain

pan when gravity drainage cannot be used. The pump is

designed for quiet operation. The pump consists of two

parts: an internal reservoir/sensor assembly, and a remote

sound−shielded pump assembly. A liquid level sensor in

the reservoir stops the cooling operation if the liquid level

in the reservoir is unacceptable.

Copyright 2017 Carrier Corp D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 02/17

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

12

Catalog No:40MBFQ-01PD

Replaces:NEW

Loading...

Loading...