Carrier 40MBCQ123 Installation Manual

40MB*C

Cassette Ductless System

Sizes 09 to 18

Installation Instructions

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 2.........................

PARTS LIST 3.......................................

SYSTEM REQUIREMENTS 4...........................

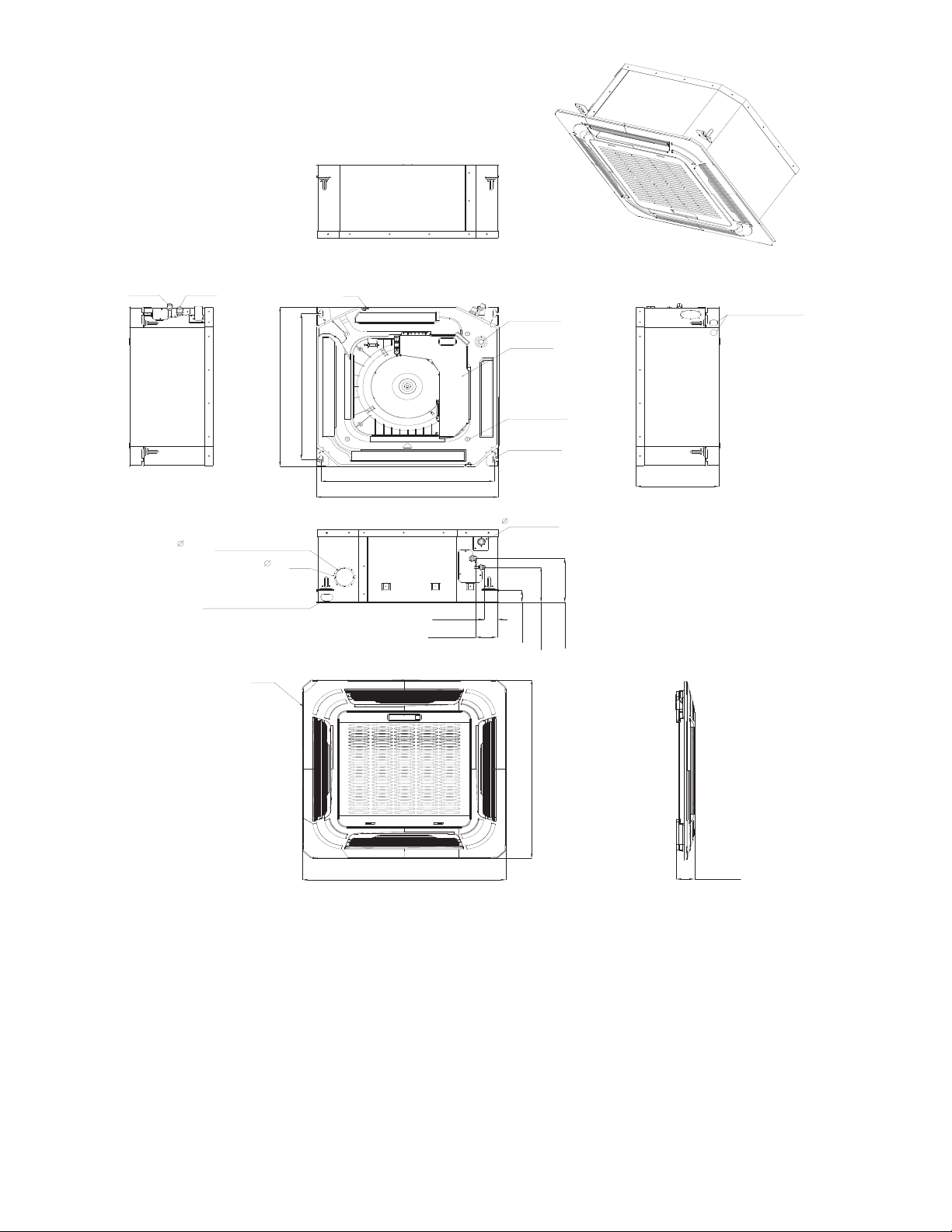

DIMENSIONS − INDOOR 5............................

CLEARANCES − INDOOR 6...........................

INSTALLATION TIPS 7................................

INDOOR UNIT INSTALLATION 7.......................

ELECTRICAL DATA 13...............................

CONNECTION DIAGRAMS 13.........................

START−UP 15........................................

TROUBLESHOOTING 16..............................

NOTE: The images in this manual are for illustration purposes

only. The actual model may differ slightly.

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air−conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start−up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should only be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

a quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in the literature and attached to the unit. Consult

the local building codes and National Electrical Code (NEC) for

special requirements. Recognize safety information.

!

!

This is the safety−alert symbol

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand these signal words: DANGER,

WARNING, and CAUTION. These words are used with the

safety−alert symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in

minor personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

. When you see this symbol on

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, the

main electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

a 6 in. (152 mm) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start−up.

WARNING

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

CAUTION

2

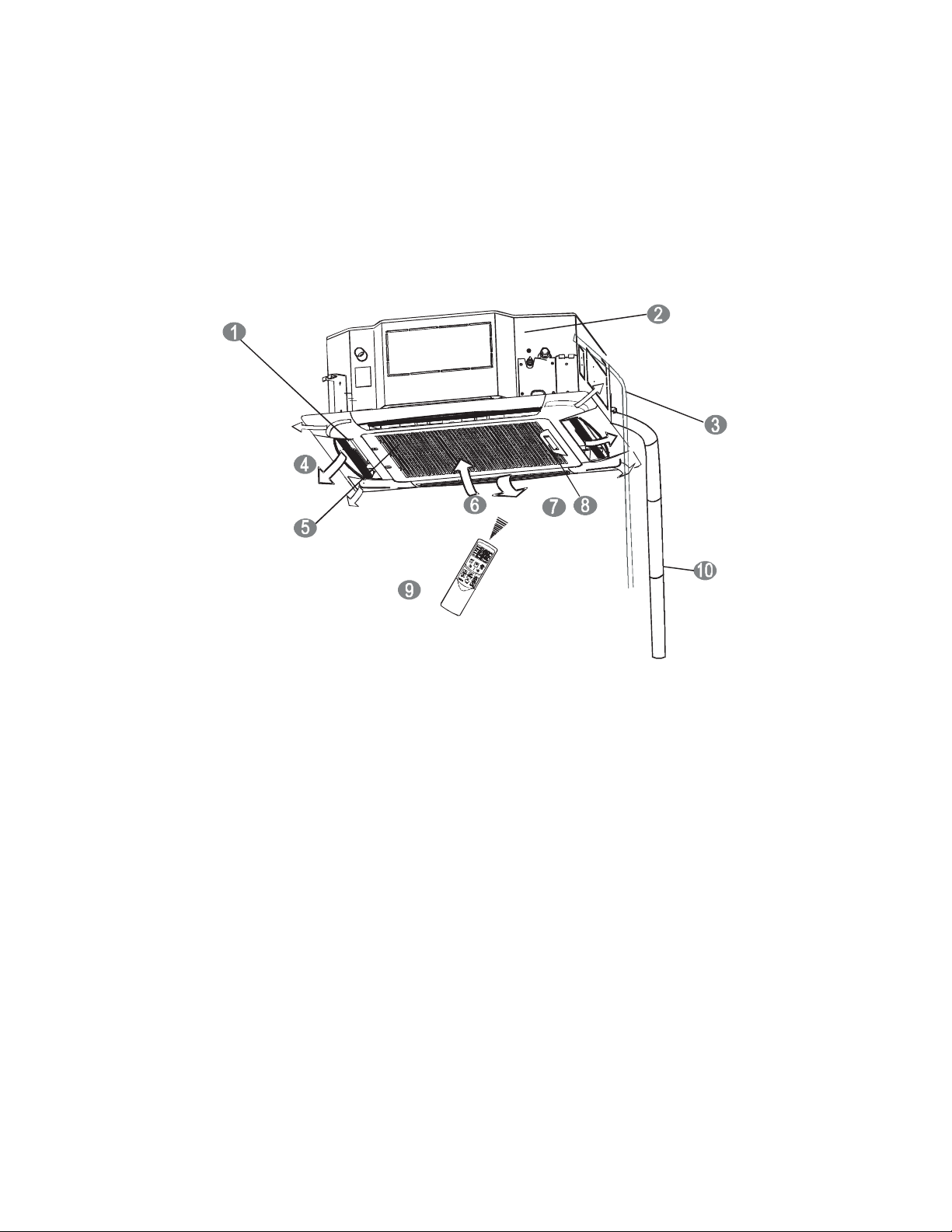

PARTS LIST

Table 1—Parts List

PART NO. PART NAME

1 Air flow louver (at air outlet)

2 Drain pump (drain water from the indoor unit)

3 Drain pipe (Field Supplied)

4 Air outlet

5 Air filter (inside grille/ceiling panel)

6 Air inlet

7 Grille/Ceiling panel (Required - sold separately)

8 Display panel

9 Remote controller

10 Refrigerant pipe (Field Supplied)

Fig. 1 - Parts List

Note:

- If the outdoor unit is higher than the indoor unit, prevent rain from flowing into the indoor unit, along the connection pipe, by creating a downward arc

in the connection pipe before it enters the wall to the indoor unit. This ensures that rain drips from the connection pipe before entering the wall.

- Piping and the interconnecting wiring are field supplied.

- Fig.1 is only a sketch. Different models may differ slightly.

See Table 2 for the units covered in these installation instructions.

Table 2—Indoor Units

kBTUh V-Ph-Hz ID Model No.

9 208/230-1-60 40MBQB09C--3

12 208/230-1-60 40MBQB12C--3

18 208/230-1-60 40MBQB18C--3

3

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and unit servicing. See Fig. 3 for the minimum required distances between the unit and the walls or ceilings.

PIPING

IMPORTANT: Both refrigerant lines must be insulated separately.

S Minimum refrigerant line length between the indoor and outdoor units is 10 ft. (3 m).

S Table 3 lists the pipe sizes for the indoor unit. Refer to the outdoor unit installation instructions for other allowed piping lengths and

refrigerant information.

Table 3—Indoor Unit Pipe Sizes

SYSTEM SIZE 9K 12K 18K

Piping

Gas Pipe (size - connection type) In (mm) 3/8 (9.52) 1/2 (12.7) 1/2 (12.7)

Liquid Pipe (size - connection type) In (mm) 1/4 (6.35) 1/4 (6.35) 1/4 (6.35)

WIRING

All wires must be sized per NEC (National Electrical Code) or

CEC (Canadian Electrical Code) and local codes. Use the

Electrical Data table MCA (minimum circuit amps) and MOCP

(maximum over current protection) to correctly size the wires and

the disconnect fuse or breakers respectively.

Per the caution note, only stranded copper conductors with a 600

volt rating and double insulated copper wire must be used. The

use of BX cable is not recommended.

IMPORTANT: The use of BX cable is not recommended.

Recommended Connection Method for Power and

Communication Wiring − Power and Communication Wiring:

The main power is supplied to the outdoor unit. The field

supplied 14/3 power/communication wiring from the outdoor unit

to the indoor unit consists of four (4) wires and provides the

power for the indoor unit. Two wires are high voltage AC power.

One wire is communication wiring and the other is a ground wire.

Recommended Connection Method for Power and

Communication Wiring (To minimize communication wiring

interference)

Power Wiring:

The main power is supplied to the outdoor unit. The field

supplied connecting cable from the outdoor unit to the indoor unit

consists of three (3) wires and provides the power for the indoor

unit. Two wires are high voltage AC power and one is a ground

wire.

Communication Wiring:

A separate shielded stranded copper conductor only, with a 600

volt rating and double insulated copper wire, must be used as the

communication wire from the outdoor unit to the indoor unit.

Please use a separate shielded 16GA stranded control wire.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

S Wires should be sized based on NEC and local codes.

S Use copper conductors only with a 600 volt rating and

double insulated copper wire.

CAUTION

4

DIMENSIONS − INDOOR

Liquid side

Gas side

)

(

6

5

.

6

5

2

Outside Air Intake

Wiring connection port

Panel

20.59(523)

22.44(570)

5

.

(7

2

5

9

Body

21.46(545)

22.44(570)

)

1.65(42)

2.67(68)

Drain hole

( for Service )

E-parts box

4-Screw hole

(for install panel)

4-install hanger

)

5

(2

.

8

0

9

Drain pipe

1.73(44)

6.18(157)

4.96(126)

Wiring connection port

10.24(260)

25.47(647)

25.47(647)

1.97(50)

Fig. 2 - Indoor Unit

Table 4—Dimensions Indoor

UNIT SIZE

BODY PANEL BODY PANEL BODY PANEL

Height in(mm) 10.24 (260) 1.97 (50) 10.24 (260) 1.97 (50) 10.24 (260) 1.97 (50)

Width in(mm) 22.44 (570) 25.47 (647) 22.44 (570) 25.47 (647) 22.44 (570) 25.47 (647)

Depth in(mm) 22.44 (570) 25.47 (647) 22.44 (570) 25.47 (647) 22.44 (570) 25.47 (647)

Height in(mm) 11.42 (290) 4.84 (123) 11.42 (290) 4.84 (123) 11.42 (290) 4.84 (123)

Width in(mm) 25.79 (655) 28.15 (715) 25.79 (655) 28.15 (715) 25.79 (655) 28.15 (715)

Depth in(mm) 25.79 (655) 28.15 (715) 25.79 (655) 28.15 (715) 25.79 (655) 28.15 (715)

Weight-Gross lbs(kg) 41.88 (19) 9.92 (4.5) 41.88 (19) 9.92 (4.5) 46.3 (21) 9.92 (4.5)

Weight-Net lbs(kg) 35.27 (16) 5.51 (2.5) 35.27 (16) 5.51 (2.5) 39.68 (18) 5.51 (2.5)

9 12 18

DIMENSIONS

PACKING

5

Loading...

Loading...