Page 1

40KMC------301

40KMQ------301

OWNER’S MANUAL

Page 2

40KMC------310/ 40KMQ------310

Split system “Global cassette” indoor unit

IR Remote Control “Room Controller” “Zone Manager”

The unit can be used with infrared Remote Control, with the Carrier “Room

Controller” or “Zone Manager” remote control.

Carrier “Room controller” control instructions are contained in the present manual.

Infrared Remote and “Zone Manager” controls instructions are contained in the relevant

manuals.

The installation instructions for both the indoor and the outdoor unit are given in the

manuals for each unit.

Contents

Page

General information .................................................................................... 2

System description ..................................................................................... 2

Unit LEDs and controls ............................................................................... 3

Periodical checks ........................................................................................ 3

Optimum comfort and minimum power consumption ................................. 4

Correct cleaning.......................................................................................... 4

Before a long shutdown period .................................................................. 4

“Room controller” general information and characteristics ............................ 5

Unit protection devices ............................................................................... 5

ENGLISH

“Room controller” wired control .................................................................. 6/7

Troubleshooting.......................................................................................... 8

GB - 1

Page 3

40KMC------310/ 40KMQ------310

General information

Unit operation and maintenance

Read this instruction manual thoroughly before using the unit.

• This unit complies with UL 1995 directive (Usa and Canada).

• Check that the main power supply voltage and frequency are as

required for the unit; the power source must be sufficient to

operate all other appliances connected to the same line.

Also ensure that local building codes and NEC (National electrical

code) requirements have been followed for the main supply circuit.

• To avoid personal injury or damage to unit,do not service until all

power sources are shut down, locked out, and tagged out.

Failure to do so could result in personal injury or unit damage.

WARNING:

!

To prevent fire, explosion or injury, do not operate the unit near

dangerous substances or esposed to lighting equipment.

• All operation and maintenance manuals must be carefully looked

after and kept with the equipment, should the unit change owners.

• Check that local building codes and NEC (National electrical code)

requirements for the installation have been followed. In particular,

ensure that a properly sized and connected ground wire is in place.

• Only use the unit for factory approved applications: the unit

cannot be used in laundry premises.

• Do not use damaged equipment. In case of malfunction, turn the

unit OFF and disconnect the main supply.

• Disconnect the main power supply prior to any maintenance

operations or prior to handling any internal unit parts.

• The manufacturer declines any liability for damage resulting from

modifications or errors in the electrical or refrigerant connections,

made during the installation, or from improper use of this equipment.

This will invalidate the unit warranty conditions immediately.

• This unit will only work safely and correctly, if installed and tested

by qualified personnel.

• Do not open the remote control to avoid possible damage.

In case of malfunction contact a qualified service engineer.

• This unit contains moving parts. Ensure that these parts are kept

out of the reach of children.

• Maintain the room temperature at general comfort conditions,

especially when children, elderly or handicapped persons are present.

• In order to ensure correct use, the air conditioner must operate

within the temperature limits indicated in the “Operating Limits”

table, included in the Technical manual. Failure to observe these

limits may cause unit malfunction or water leakage.

• In order to avoid electric shock, fire or injury, stop the unit and

disconnect the safety switch in case of abnormal events (such as

smell of burning) and call Carrier Service for further instructions.

•

A routine maintenance should be carried out on the unit to check the

correct operation of the electric connections and protection devices.

• Extraordinary maintenance operations must be carried out by

specially trained personnel.

• Do not attempt to repair, move, modify or re-install the unit on your

own. To avoid electric shock or fire make sure these operations

are carried out by qualified personnel only.

•

Contact the qualified service if one of the following events takes place:

- hot or damaged power supply cable;

- unusual noise during operation;

- frequent operation of the protection devices;

- unusual smell (such as smell of burning).

WARNING:

!

Never operate unit without a filter or with grille removed. Damage

to the unit or personal injury may result.

WARNING:

!

If air filter is not replaced in the unit, dust and dirt gather in air

conditioner and operation becomes impaired.

• A mist or cloud of vapor may be emitted from the unit, when

switching from a cooling operation to a reverse cycle heating

operation. This will occur when the unit has been operating in

cooling mode for awhile and then is switched to heating. The

combination of the evaporated indoor coil condensate and the dry

room air, may result in a cloud of vapor being emitted from the

unit. There is no need for concern.

• Inspect equipment for damage during transport. In case of

damage file an immediate claim with the shipping company.

• Non-routine maintenance of the refrigerant circuit must only be

carried out by qualified personnel.

• All of the manufacturing and packaging materials used for

this appliance are biodegradable and recyclable.

• Dispose of the packaging material and of the remote control

batteries in accordance with local requirements.

• This equipment contains refrigerant that must be disposed of

correctly. When disposing of the unit at the end of its operational

life, take the unit to an authorised waste disposal centre, for

correct disposal procedures.

WARNING:

!

The unit must always be switched OFF using the Room

Controller. Do not switch OFF the split system by

disconnecting the electric power supply.

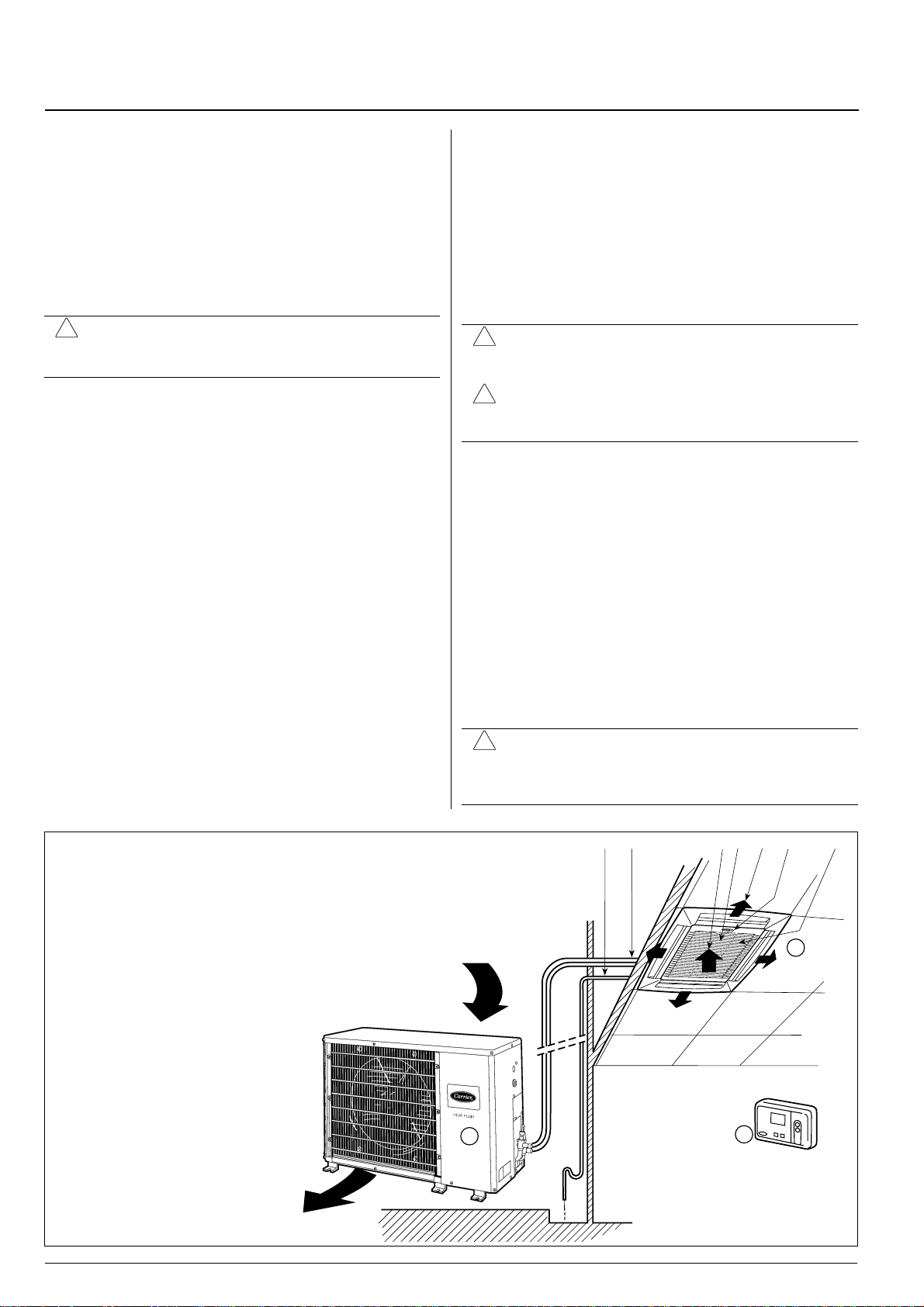

System description

A. Outdoor unit

B. Indoor unit

C. Room Controller

(if foreseen)

1. Air return

2. Air filters

3. Air supply

4. Operation indicator light

and receiver of remote

control signals (if foreseen)

5. Nameplate

6. Interconnecting tubing

7. Condensate drain (open)

GB - 2

1 234 567

B

A

C

Page 4

40KMC------310/ 40KMQ------310

Unit warning lights and controls - Fault code

Indoor unit LEDs

Information concerning indoor unit operation, timer status and

diagnostic is given by 3 LEDs located on the unit.

• THE GREEN LED (P) shows the following conditions:

- Fault codes (diagnostic);

- During normal operation, the LED is lit.

Once a failure occurs, the LED flashes at intervals of 0.5

seconds. The fault code is deduced from the number of times

the LED flashes. Between one flash cycle and the next a pause

of 5 seconds elapses.

• THE RED LED (Q) gives the following information:

- During normal operation, the LED is OFF;

- During defrost the LED is lit;

- During the test for wired connection, the LED flashes at 0.1

second intervals.

• THE YELLOW LED (R) shows the operation in timer mode.

During this operation the LED is lit.

If the timer mode is active and the unit is immediately

restarted after a stop, this LED flashes until a new signal is

sent to the unit.

In case the Room Controller is not working, obtain a qualified

service personnel.

Fault code

Once a failure occurs with the indoor unit in operation, the green

unit LED flashes at intervals of 0.5 seconds.

The fault code is deduced from the number of times the green

LED flashes, blocking unit operation.

Between one flash cycle and the next one, a pause of 5 seconds

elapses.

Table IX: Fault code

Code Description

3 Room air sensor fault

2 Condensate discharge pump

4 Indoor unit coil sensor fault

6* Filter dirty

7 Outdoor unit failure

10 EEPROM corrupt

11 Card serial number damaged

12 Address / zone incomplete

13 Gas flow distributor corrupt

14 Outdoor air thermistor

* with enabled code

ENGLISH

P : Green LED

Q : Red LED

R : Yellow LED

S : Remote control

signal receiver

Table II: Periodical checks

Indoor unit Every month Every 4 months Every year

Clean air filter (2) •

Clean drain pipe (2) •

Outdoor unit Every month Every 4 months Every year

Clean outdoor coil from outside •

Clean outdoor coil from inside (2) •

Blow air over electric parts (2) •

Check electric connection tightening (2) •

Clean fan wheel (2) •

Check fan tightening (2) •

Clean drain pan (2) •

(1)

For a good operation of the

air conditioner it is

recommended to carry out

checks and maintenance

as indicated.

Recommended

maintenance intervals may

vary depending on the

installation environment,

e.g. dusty zones, etc.

(1) Increase frequency in

dusty zones.

(2) Operations to be

carried out by qualified

service personnel.

Refer also to

“Installation Manual”.

GB - 3

Page 5

40KMC------310/ 40KMQ------310

Optimum comfort... - Correct cleaning - Before a long shutdown period

Optimum comfort and minimum power

consumption

Keep room temperature at a comfortable level.

Only open doors and windows when strictly necessary.

Correct cleaning

• Turn the unit OFF and switch the main supply OFF.

Use only a clean, damp cloth and a mild detergent.

Do not use flammable liquids, solvents or abrasive powders that

may result in damage to the panels.

Use only a dry cloth to clean the remote control.

Before a long shutdown period

Ask to clean the filter and replace it in the unit.

When cooling, avoid direct sunlight in the room: if possible, draw

the curtains or close the shades.

Do not obstruct the air intake or outlet of the indoor unit.

Obstructions will cause a reduction in the air flow and the

conditioning effect, resulting in unit malfunction.

Ensure that the air filters are clean.

Ensure that the air distribution in the room is uniform by properly

adjusting the air flow direction.

12 h

Keep the unit in operation for half a day in the ventilation

(fan only) mode in order to dry all internal parts.

Switch the unit OFF and wait for at least 3 minutes before switching OFF the main electric supply.

Periodically clean the area surrounding the outdoor unit and the

air intake, in order to avoid reduced air circulation.

Keep heat sources away from the unit: panels may be damaged.

GB - 4

Clean indoor and outdoor units.

Page 6

40KMC------310/ 40KMQ------310

“Room controller” general information and characteristics

Characteristics

• Single unit operation:

Ability to control one unit only.

• Grouping:

Ability to control 2 to 6 units with one Room Controller.

• Operating modes:

A

B

A = Display readout

B = Increase

temperature /

change louvre

setting button

C = Decrease

temperature /

change louvre

setting button

D = Fan selection

button

E = Mode selection

button

CDE

Display of selected functions

Off, Heat, Cool, Dry, Auto, and Fan only.

• Fan speeds:

Low, Medium, High, and Auto.

• Louver control:

Auto and swing.

• Desired temperature:

Range between 17 and 32 °C (63 and 90 °F).

• Room Thermistor Override:

Allows to use air sensor located in the Room Controller instead

of the one located into the unit.

• Diagnostics:

Detects the fault of air sensor in the Room Controller.

“A1” shown on the screen indicates this anomaly.

up

down

ENGLISH

Automatic

Off

Temperature

selected / room

temperature

Table I: Unit protection devices

System Type of protection Effect of protection Operation mode When on

Heat pump

Set temperature

Operating

position of the air

louvre

Fan speed

Cold draft prevention Indoor fan off

Defrost cycle Indoor fan off

Heating

Cooling

Dehumidification

only

“

UP” and “DOWN” buttons

Buttons for raising or lowering the temperature or for selecting

the “

AUTO” or “SWING” louver mode.

MODE

Button for operation mode selection.

FAN

Button for fan or louvre selection.

Heating in

heat pump mode

Heating in

heat pump mode

During unit operation

During unit operation

Cooling only freeze protection

and

heat pump Against frequent Compressor Cooling or heating At unit start-up or

WARNING:

During heat pump operation the unit will undergo several defrost cycles to remove ice that might collect on the outdoor unit in very low ambient

temperatures. In these cycles, the indoor fan will be automatically off and cannot operate until defrost cycle is completed.

Indoor coil

compressor cycling time delay in heat pump mode

Compressor off Cooling During unit operation

change of operating mode

GB - 5

Page 7

40KMC------310/ 40KMQ------310

“Room controller” wired control

Power up

All segments of the LCD should be energized for five seconds.

The mode, fan, louver, desired temperature and configuration

information should be read from the EEPROM.

If the EEPROM values are not valid, the following should be used

as defaults.

Operating Mode = AUTO

Fan Speed = AUTO

Desired Temperature = 72°F

°F o °C=F

Louver = AUTO

Room Thermistor Override = OFF

Cooling only vs Heat/Cool Remote

Example of normal operation

When switched on, the control display appears.

= Heat/Cool

AUTO, HEAT, COOL and DRY Modes:

ICONS Energized:

• Operation Mode ICON.

• Room Temperature if configured for Room Thermistor Override

(operated by Room Controller), otherwise user selected

temperature with the “

• FAN/LOUVER Icon with the user selected Fan and Louver

settings.

Buttons available:

• All Buttons are available.

AUTO Automatic operation

NOTE:

The compressor and electric heater must be off for at least 30

Minutes, this time being necessary to pass from Heating to

Cooling, or Cooling to Heating.

This will prevent the system from switching between Heating

and Cooling continuously.

SET TEMP” Icon.

Setting mode operation

“MODE” button

Pressing the “

The “

MODE” button must be released and then pressed again in

order to change to the next mode.

The active mode will always be lit in normal operation.

Available modes to select are:

Heat/Cool Remote:

OFF, COOL, DRY, FAN ONLY, AUTO, HEAT

Cooling Only Remote:

When the “

press will always switch the mode to OFF.

MODE” button will cause the mode to change.

OFF, COOL, DRY and FAN ONLY

MODE” button is not pressed for 15 seconds, the next

OFF Mode:

ICONS Energized:

• OFF Mode

• Room Temperature if configured for Room Thermistor Override,

otherwise nothing

Buttons available:

•“

MODE” button

COOL Cooling operation

DRY Drying operation.

GB - 6

HEAT Heating operation.

Page 8

40KMC------310/ 40KMQ------310

“Room controller” wired control

FAN ONLY Mode:

ICONS Energized:

• Room Temperature if configured for Room Thermistor Override

(operated by Room Controller), otherwise nothing.

• FAN/LOUVER Icon with the user selected Fan and Louver

settings.

Buttons available:

•“

MODE” and “FAN ” buttons are available.

fan only Ventilation operation only.

“UP” and “DOWN” button

(Selecting the desired temperature)

up

down

Pressing either the “UP” or “DOWN” buttons will modify the desired

temperature.

The maximum desired temperature is 32°C (90°F) and the

minimum desired temperature is 17°C (63°F).

Whenever the setpoint is being displayed, the “

illuminated.

Whenever the display mode is changed from C to F, the setpoint is

set to the default start-up values of 22°C for “C” mode and 72°F for

“F” mode.

SET TEMP” icon is

ENGLISH

Auto mode setting will be displayed by blinking the fan Medium

speed and High speed icons in order (Med then Hi then repeat).

Low

Medium

High

Automatic

(Fan speed will automatically switch to the

value required for optimum comfort).

When this function is activated, the dotted

symbols will flash.

Louver mode selection

To enter louver mode selection, make sure the Room Controller is

on and hold the “

After 5 seconds, the selected louver setting will be displayed.

By pressing the up and down buttons the user can modify

the louver desired configuration.

The two settings will be displayed in the following way:

“S” with Swing Louver Icon - represents Swing Louver.

“A” with Auto Louver Icon - represents Auto Louver.

Press “

FAN ” button to exit LOUVER Mode Selection.

This mode will exit automatically after 10 seconds if no buttons are

pressed.

The only way to change the operation mode, is to go back to this

menu.

FAN” button down for 5 seconds.

If the air sensor built in the Room Control is enabled, the

display will indicate the room temperature after few seconds.

“FAN ” button

(Adjusting the ventilation speed)

Pressing the “FAN ” button will cause the fan speed to change.

The “

FAN ” SPEED button must be pressed and then released

to reach the desired speed (Low, Medium, High or Auto).

The icon on the display indicates that change has occurred.

NOTE:

• If units are grouped to one Room Controller , all units will end

up having the same louver value.

• Louver Mode selection is not available during OFF mode.

:AUTO Automatic louvre positioning to the best position

for the selected operating mode.

:SWING Louvres swing continuously.

GB - 7

Page 9

40KMC------310/ 40KMQ------310

Troubleshooting

No Room controller LCD display:

• Mis-wiring of the 12 volt power to Room Controller control;

verify that + 12 V and Ground are connected to the proper

terrminals of the Controller (Reference Installation wiring

section for correct connections): after disconnecting the

power, correct the wiring problem and re-cycle power.

• Power not online; check that the units main power is

connected.

The main control board should be operating normally: after

verifing the wiring to the Room Controller, re-cycle the unit

power.

• No 12 volts between P and G of terminal block; check the

installation of the J6 plug on the main control board: after

disconnecting the power, correct the wiring problem and

re-cycle power.

Note

: Those verifications need to be carried out by qualified

personnel only.

+12 volts applied to Room Controller at the correct terminals

and still does not operate:

• The Room Controller is damaged; change the Room

Controller and re-cycle power.

Note

: This operation needs to be carried out by qualified

personnel only.

Air conditioner will not start:

• The main switch is switched OFF, place the switch in the ON

position.

• The fuses on the main switch are burnt out; replace the fuses.

( this operation need to be carried out by qualified personnel only).

• Wait for 3 minutes: protection against frequent compressor

cycling is ON.

• Selected temperature is higher than the room temperature (or

lower in the heating mode).

Air conditioner is not supplying enough cooling (or heating):

• Air cannot circulate freely.

• Dirty filter reduces air quantity circulating.

Filter must be cleaned by skilled personnel only.

• Doors and/or windows are open.

• Fan speed has been set to ‘low’.

• Air flow direction is not correct for optimum ventilation.

• Selected temperature is not correct.

service, please refer to the installation instructions.

Restart air conditioner after having corrected the faults.

Q (Red LED) indicator is illuminated:

• In the heating mode, the LED switches on to indicate an active

defrost condition.

The unit emits unpleasant smells:

• Unpleasant smells can accumulate on the air filters and then be

dispersed into the room during air conditioner operation.

Switch the unit OFF and contact an authorised service centre to

have the filters cleaned.

Restart unit in the ventilation (fan only) mode and open windows

to change room air.

The unit makes strange noises:

• Occasionally the unit makes strange noises at start-up, during

operation or when it has stopped.

These are generally due to the effect of temperature changes on

the plastic parts.

Mist or Vapor Cloud emitted at start-up of Heating operation:

• A mist or cloud of vapor may be emitted from the unit, when

switching from a cooling operation to a reverse cycle heating

operation. This will occur when the unit has been operating in

cooling mode for awhile and then is switched to heating. The

combination of the evaporated indoor coil condensate and the dry

room air, may result in a cloud of vapor being emitted from the

unit. There is no need for concern.

WARNING:

(models with electric heaters):

• If the manual reset, thermal trip device cuts out, switch the unit

OFF and ON again at the main switch to reset.

If the malfunction persists, contact your local authorised dealer.

A slight mist is emitted from the unit:

• A slight mist, coming out of the unit air outlet, is sometimes

noticed during cooling operation. This is due to the cool air

coming into contact with the room air.

A slight whistling noise is heard when the air conditioner

starts or stops:

• This is due to the refrigerant beginning to circulate or an

adjustment of the refrigerant pressures. This is a normal

operating condition.

P (Green LED) indicator is flashing:

System malfunction.

Contact service organisation after having ensured that:

• Air circulation is not obstructed.

• Outdoor unit coil is not obstructed and causing severe reduction

of air circulation.

• Condensate drainage tube is not obstructed.

As regards fault codes to be communicated to the after-sales

GB - 8

Page 10

L010127H09 - 0306

Via R. Sanzio, 9 - 20058 Villasanta (MI) Italy - Tel. 039/3636.1

The manufacturer reserves the right to change any product specifications without notice.

March, 2006. Printed in Italy

Loading...

Loading...