39LA,LB,LC,LD,LF,LG,LH03-25

Indoor Air-Handling Units

Installation, Start-Up and

Service Instructions

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,3

Unit Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PREINSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Suspended Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Service Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

External Vibration Isolators. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Mixing Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Inlet Guide Vane Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Install Sheaves on Motor and Fan Shafts . . . . . . . . . . . . . .11

Install V-Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water and Steam Piping Recommendations . . . . . . . . . . 14

Coil Freeze-Up Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Refrigerant Piping, Direct Expansion

(DX) Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

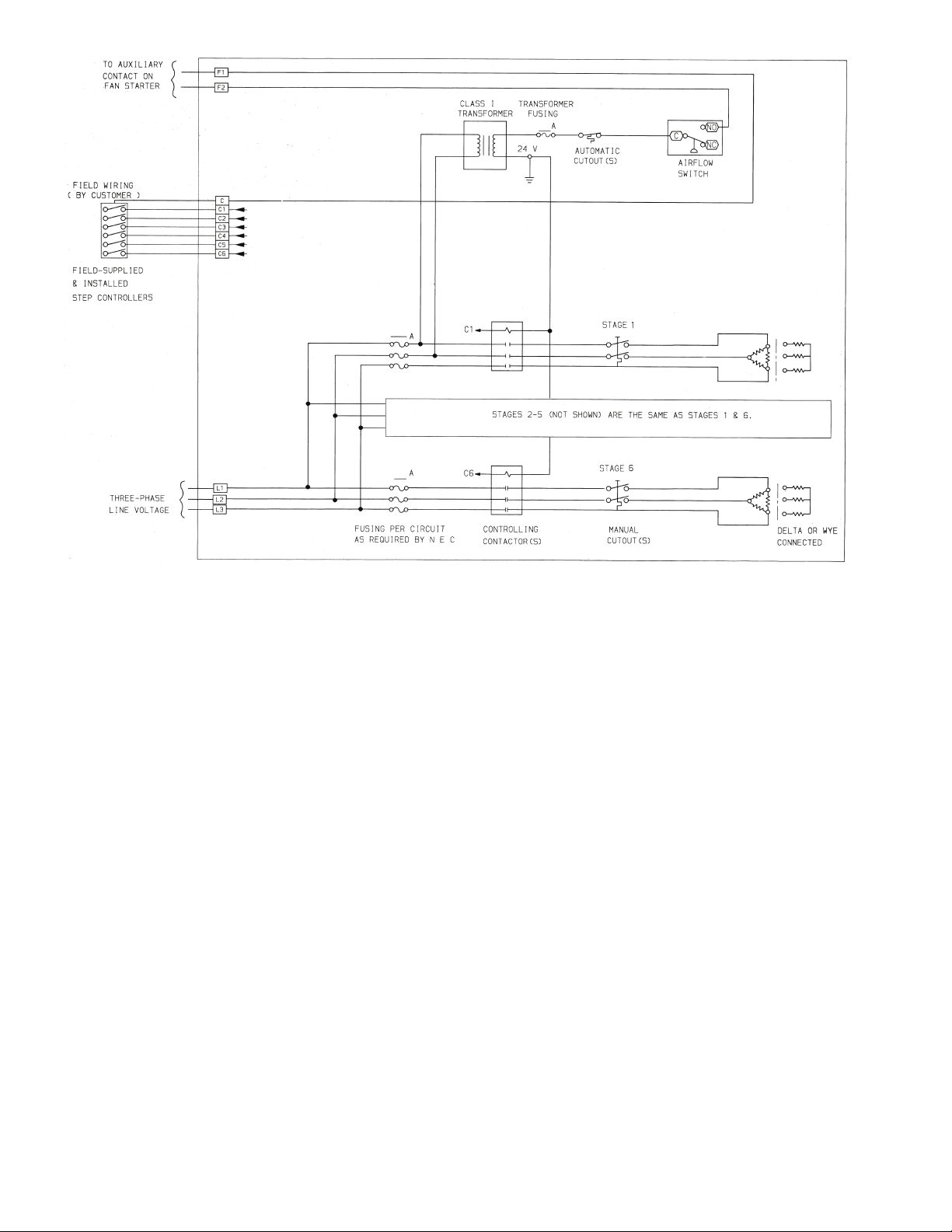

Electric Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Discharge Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,30

Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-38

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Winter Shutdown (Chilled Water Coil Only) . . . . . . . . . . . 30

Field-Installed Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coil Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Changing Coil Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fan Shaft Bearing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fan and Shaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

METRIC CONVERSION CHART . . . . . . . . . . . . . . . . . . . . . . . 39

Air-handling equipment is designed to provide safe and

reliable service when operated within design specifications. To

avoid injury to personnel and damage to equipment or property

when operating this equipment, use good judgment and follow

safe practices as outlined below.

NEVER enter an enclosed fan cabinet or reach into a unit

while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect

switch before working on a fan. Take fuses with you and

note removal on tag. Electric shock can cause personal

injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near heaters.

SAFETY CONSIDERATIONS

Page

CHECK the assembly and component weights to be sure

that the rigging equipment can handle them safely. Note

also, the centers of gravity and any specific rigging

instructions.

CHECK for adequate ventilation so that fumes will not

migrate through ductwork to occupied spaces when welding or cutting inside air-handling unit cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that the area

is clear of personnel.

DO NOT attempt to handle access covers and removable

panels on outdoor units when winds are strong or gusting

until you have sufficient help to control them. Make sure

panels are properly secured while repairs are being made to

a unit.

DO NOT remove access panel fasteners until fan is completely stopped. Pressure developed by a moving fan can

cause excessive force against the panel which can injure

personnel.

DO NOT work on dampers until their operators are

disconnected.

BE SURE that fans are properly grounded before working

on them.

SECURE drive sheaves with a rope or strap before working on a fan to ensure that rotor cannot free-wheel.

DO NOT restore power to unit until all temporary walkways inside components have been removed.

NEVER pressurize equipment in excess of specified test

pressures.

PROTECT adjacent flammable material when welding or

flame cutting. Use sheet metal or asbestos cloth to contain

sparks. Have a fire extinguisher at hand and ready for

immediate use.

IMPORTANT: The installation of air-handling units and all

associated components, parts, and accessories which make

up the installation and subsequent maintenance shall be in

accordance with the regulations of ALL authorities having

jurisdiction and MUST conform to all applicable codes. It

is the responsibility of the installing contractor to determine

and comply with ALL applicable codes and regulations.

Field-supplied motors should be Underwriters Laboratories

(UL) or Canadian Standards Association (CSA) approved.

Field wiring must comply with National Electrical Code

(NEC) and all local requirements.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 533-932 Printed in U.S.A. Form 39L-6SI Pg 1 1110 2-04 Replaces: 39L-5SI

INTRODUCTION

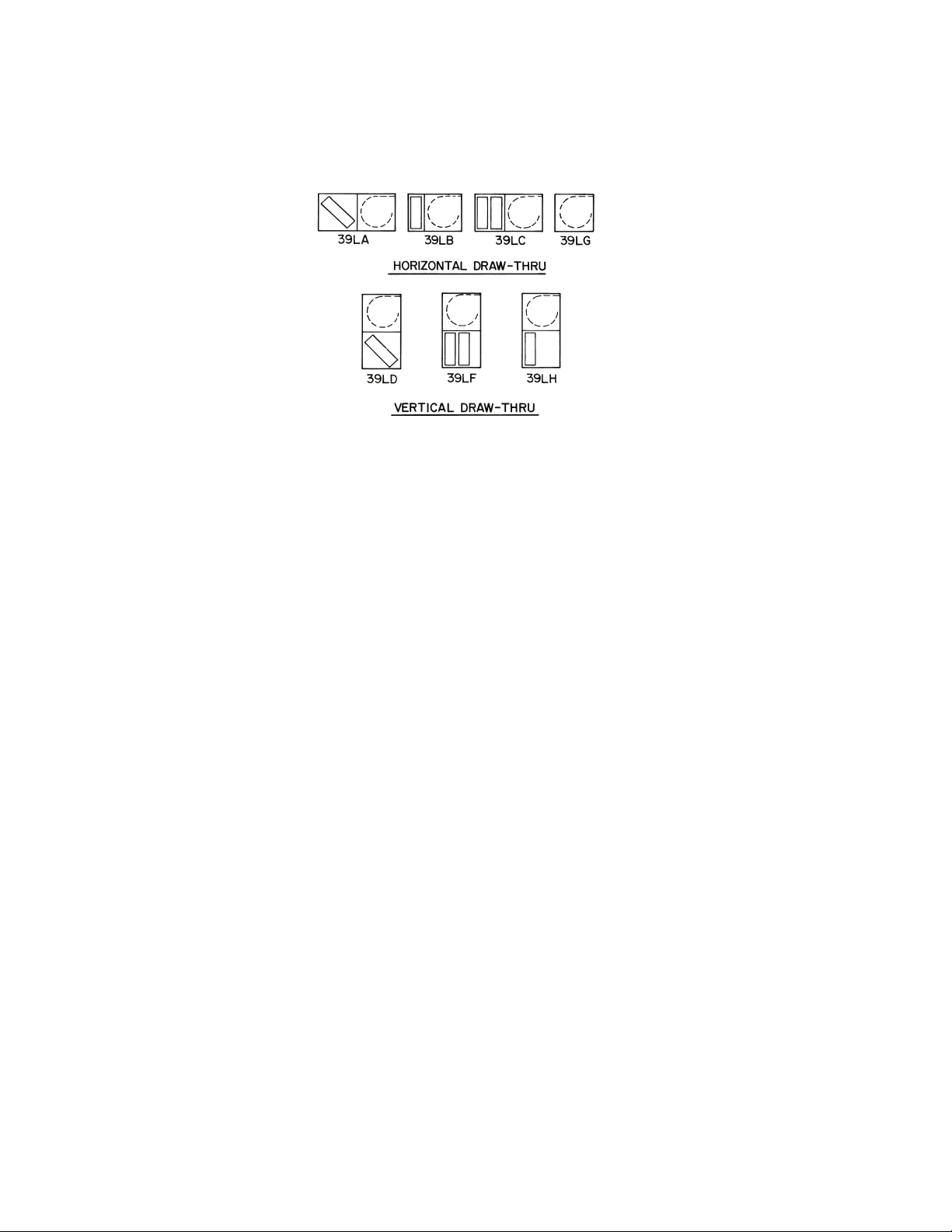

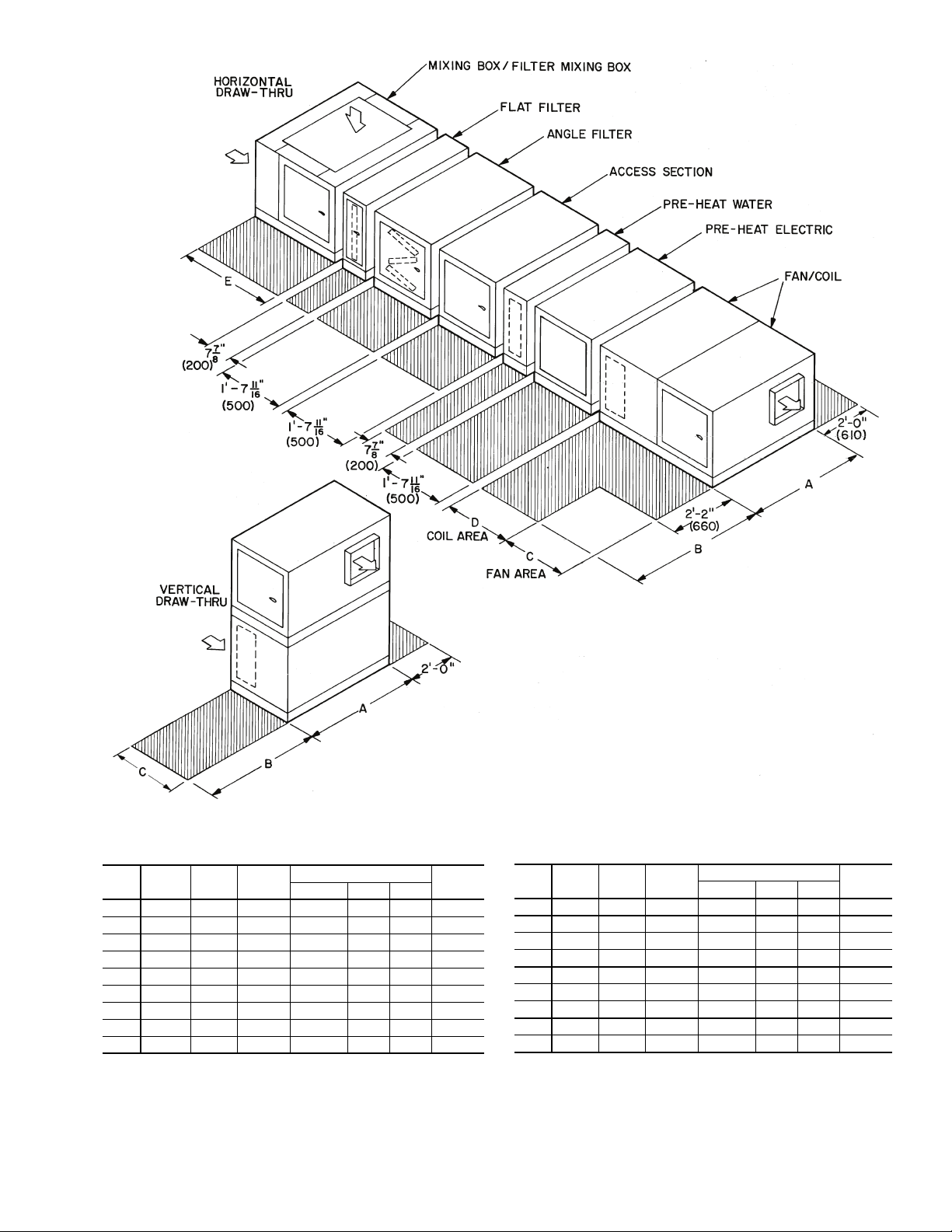

Fig. 1 — Unit Identification

LEGEND

Fig. 2 — 39L Model Number

CV — Constant Volume

DX — Direct Expansion

VAV — Var iab le Air Vol um e

39L C 10 GK C H E A C G - A

Due to the complexity of the (18 position) 39L model number, use the “verify model number”

function in the AHUBuilder® software for a detailed model explanation. The description below

can be used as a general model guide.

Pos. 1-3: Unit Type — 39L Air Handler

Pos. 4: Unit Model — how the unit is configured. Refer to Fig. 3.

Pos. 5-6: Unit Size — Ranges from 03 to 25.

Pos. 7-8: Draw-Thru Options — Includes the sections that will make up the unit.

Pos. 9-12: Coil Type and Arrangement — Describes the coil type (chilled water, CX, heating

only, etc.), fins, rows and circuit information.

Pos. 13-15: Fans — Describes fan discharge, fan speed, and motor information.

Pos. 16: Controls — Describes the AirManager™ control offering (CV, VAV) and the

components that they include.

Pos. 17: F1/F2 Motors — Depending upon positions 13 and 17, F1 or F2 motors may be

substituted for top mounted motor conduit boxes.

Pos. 18: Special Order — Allows copper fin coils and/or .025 in. wall tubes.

Unit Identification —

the 18-digit part number listed on the serial plate. The part

number describes all component, coil, motor, drive, and control

selections. See Fig. 1-3 for unit identification.

The 39L units are identified by

2

LEGEND

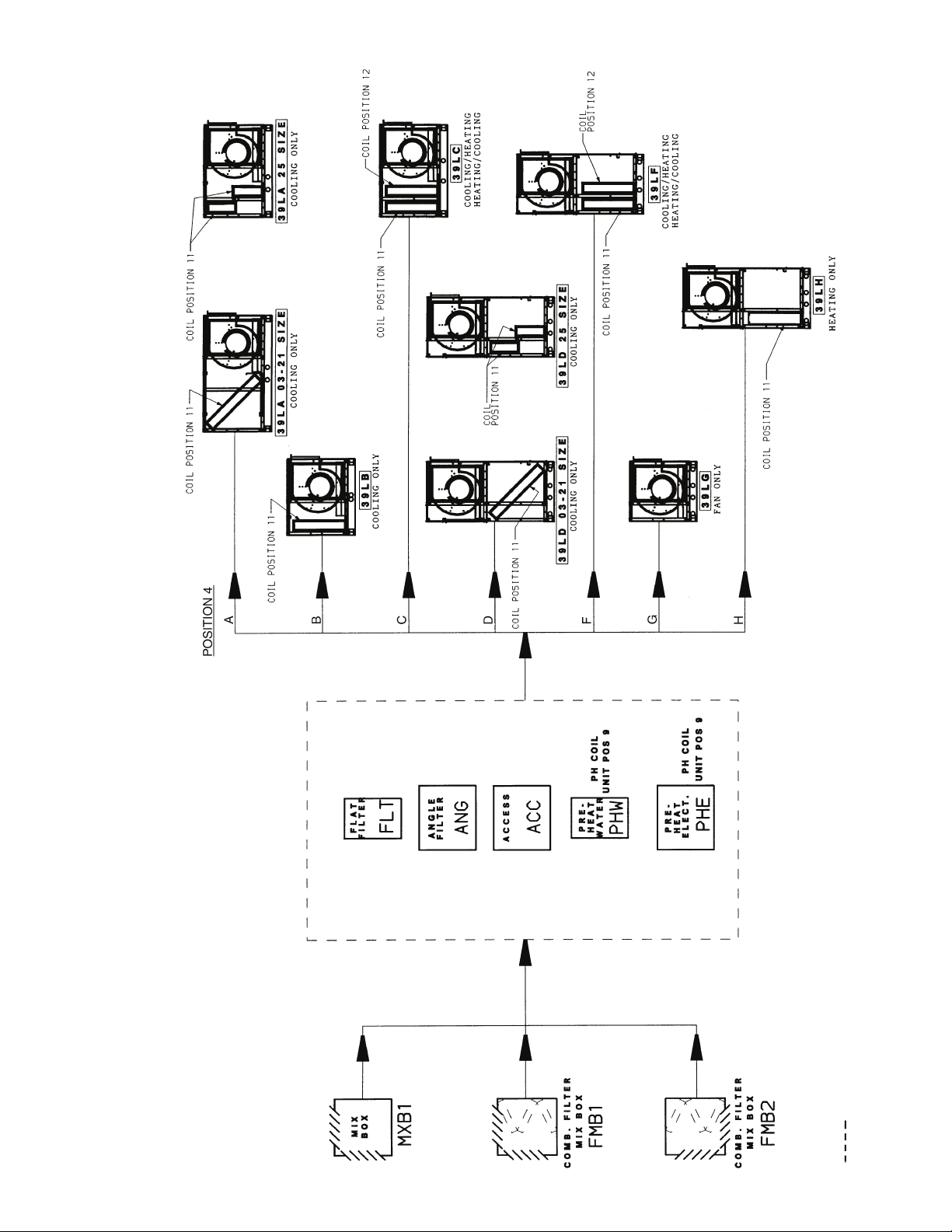

Fig. 3 — Position 4, Unit Configuration Model

(Component Sequence Also Shown)

COMB. — Combination

PH — Preheat

POS. — Positi on

Factory-installed option components

3

PREINSTALLATION

1. Check items received against packing list. Notify Carrier

of any discrepancy.

2. Refer to Fig. 4 for service area requirements.

3. To transfer unit from truck to storage site, refer to rigging

details in Fig. 5 and section on unit rigging for proper

handling. See Table 1 for component weights.

If a fork lift truck is used, lift only from heavy end of skid.

Minimum recommended fork length is 48 inches.

4. Do not stack unit components or accessories during storage. Stacking can cause damage or deformation.

5. If unit is to be stored for more than 2 weeks prior to installation, observe the following precautions:

a. Choose a dry storage site that is reasonably level

and sturdy to prevent undue stress or permanent

damage to the unit structure or components. Do not

store unit on vibrating surface. Damage to stationary bearings can occur. Set unit off ground if in

heavy rain area.

b. Remove all fasteners and other small parts from

jobsite to minimize theft. Tag and store parts in a

safe place until needed.

c. Cover entire unit with a tarp or plastic coverall.

Extend cover under unit if stored on ground.

Secure cover with adequate tiedowns or store

indoors. Be sure all coil connections have protective shipping caps.

d. Monthly — Remove tarp from unit, enter fan

section through access door or through fan inlet,

and rotate fan and motor slowly by hand to redistribute the bearing grease and to prevent bearing

corrosion.

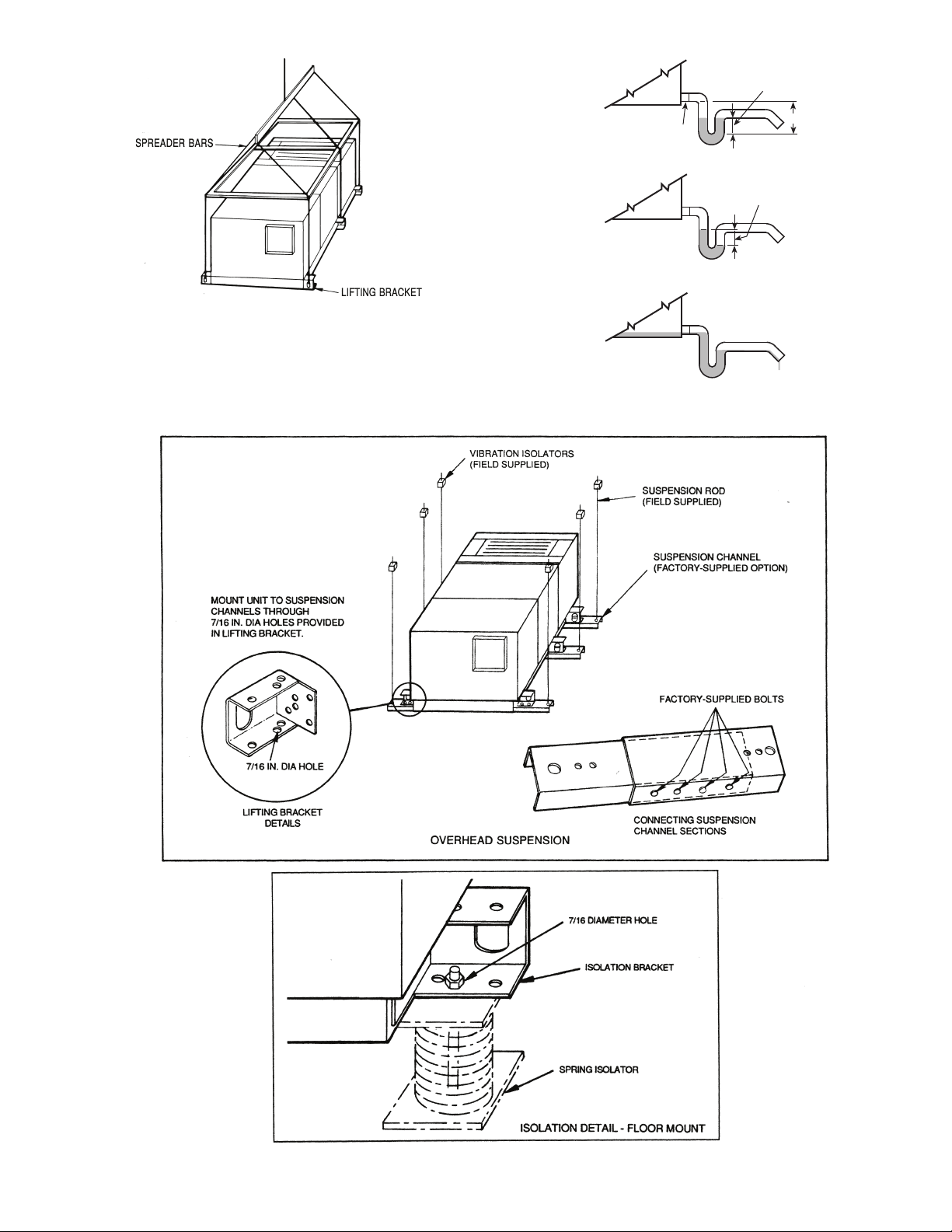

Rigging (Fig. 5) — All 39L units can be rigged by means

of the lifting brackets on bottom of unit.

Units are shipped fully assembled. Do not remove shipping

skids or protective covering until unit is ready for final placement. Use slings and spreader bars as applicable to lift unit. Do

not lift unit by coil connections or headers.

Do not remove protective caps from coil piping connections

until ready to connect piping.

Do not remove protective cover or grease from fan shaft until ready to install sheave.

Lay rigid temporary protection such as plywood walkways

in unit to prevent damage to insulation or bottom panel during

installation.

Suspended Units — Figure 6 shows overhead suspen-

sion of unit using optional factory-supplied suspension

channels.

Each support channel consists of 2 pieces, the smaller of

which fits inside the larger one. This allows the channel to be

adjusted to the required length for installation.

Channels are shipped on top of the unit. The 2 sections of

each channel are shipped one inside the other, and are held in

place during shipping by the panel screws in the top panel.

Hardware required for installation of suspension channels is

shipped in a package inside the fan section.

At least 2 suspension channels are shipped with each fan

and coil unit. One or more extra channels will be supplied

depending on the number of accessories ordered. Be sure to

install all the suspension channels shipped with a unit. Refer to

39L Isolator Mounting (Suspended Unit) certified drawing for

details.

To install suspension channels:

1. Remove panel screws to free suspension channels for installation. Replace screws in top panel.

2. Adjust channel to required length by sliding one channel

section inside the other. The channel must extend at least

9 in. but not more than 12 in. beyond the edge of the unit.

Set length of channel by installing factory-supplied bolts

through the overlapping channel sections.

3. Mount unit to suspension channel using factory-supplied

nuts and bolts through

ing bracket.

4. Install field-supplied suspension rods through

ameter holes provided at outer edges of channel. Be sure

hanger rods are securely fastened in place.

7

/16-in. diameter holes in unit lift-

9

/16-in. di-

Service Clearance — Provide adequate space for unit

service access (fan shaft and coil removal, filter removal, motor access, damper linkage access, etc.) as shown in Fig. 4.

Condensate Drain — To prevent excessive build-up of

condensate in drain pan, adequate trap clearance must be provided beneath the unit as indicated in Fig. 7. See Installation,

Condensate Drain section (page 8) for additional details.

External Vibration Isolators — Install vibration iso-

lators per certified drawings, and in accordance with the job

specifications and the instructions of the vibration isolator

manufacturer. The coil piping must be isolated or have a flexible connection to avoid coil header damage because of unit

motion. A flexible connection should be installed at the fan discharge.

Figure 6 shows isolation location for floor mounting or

overhead suspension of unit.

4

NOTE: Dimensions in ( ) are in mm.

DIMENSIONS (ft-in.)

SIZE A B C

D

E

39LA 39LB 39LC

03 3-17/83-13/41-91/41- 711/160-77/81-33/42- 39/

16

06 3-93/43-95/82-13/161-115/80-77/81-33/42- 39/

16

08 4-111/164-19/162-51/82- 39/160-77/81-33/42- 39/

16

10 4-99/164-97/162-51/82- 39/160-77/81-33/42- 39/

16

12 5-51/165-55/162-51/82- 39/160-77/81-33/42- 39/

16

15 5-51/165-55/163-1 2-119/160-77/81-33/42- 39/

16

18 5-51/165-55/163-415/163- 33/80-77/81-33/42-117/

16

21 6-51/46-51/83-415/163- 33/80-77/81-33/42-117/

16

25 6-51/46-51/84-015/162- 39/160-77/81-33/42-117/

16

DIMENSIONS (mm)

SIZE A B C

D

E

39LA 39LB 39LC

03 952 959 540 500 200 400 700

06 1162 1159 640 600 200 400 700

08 1262 1259 740 700 200 400 700

10 1462 1459 740 700 200 400 700

12 1653 1659 740 700 200 400 700

15 1653 1659 940 900 200 400 700

18 1653 1659 1040 1000 200 400 900

21 1962 1959 1040 1000 200 400 900

25 1962 1959 1240 700 200 400 900

Fig. 4 — Service Area Requirements

5

Table 1 — Physical Data

UNIT SIZE 03 06 08 10 12 15 18 21 25

UNIT WEIGHTS (lb)*

39LA 200 280 411 470 540 620 695 740 820

39LB 150 210 308 352 405 465 521 555 615

39LC 170 238 349 400 459 527 590 629 697

39LD 230 322 472 540 621 713 799 851 943

39LF 230 322 472 540 621 713 799 851 943

39LG 120 168 246 282 324 372 417 444 492

39LH 220 308 452 517 594 682 764 814 902

COMPONENT WEIGHTS (lb)

Mixing Box Section 139 164 193 219 226 244 283 272 311

Filter Mixing Box 150 173 208 227 245 279 327 340 395

Angle Filter Section 75 82 97 107 114 134 140 159 185

Flat Filter Section 37 43 48 50 55 74 75 86 90

Access Section 48 55 60 64 68 74 77 87 92

Preheat (Water) Section 36 42 43 46 49 52 54 53 57

Preheat (Electric) Section 49 56 61 66 72 74 76 87 89

TYPICAL DRY COIL WEIGHTS (lb)

Large Face Area Cooling Coils,

1

/

-in. OD (Chilled Water & DX)†

2

4-Row 56 84 98 109 137 178 198 251 280

6-Row 63 95 123 138 174 234 270 327 363

Small Face Area Cooling Coils,

1

/

-in. OD (Chilled Water & DX)†

2

4-Row 45 72 91 105 133 161 182 211 238

6-Row 53 85 113 129 162 197 225 270 307

8-Row 61 92 129 143 189 228 263 324 377

Hot Water Coils,

1-Row 19 34 38 48 58 62 77 86 95

2-Row 28 43 51 61 76 89 104 117 130

Steam Coils, 1-row, 1-in. OD

6-FPI 50 70 85 95 110 135 150 180 215

9-FPI 55 80 100 115 125 155 175 214 256

12-FPI 60 85 115 130 145 180 205 248 297

FAN

Wheel Diameter (in.) 9

Wheel Width (in.) 7

Shaft Diameter (in.) 3/4 1

Maximum Fan Rpm 2500 2000 2000 1600 1600 1400 1300 1100 1000

OPERATING CHARGE, R-22 (lb)

4-Row Coil 1-2 2-3 3-4 4-5 4-5 5- 6 6- 7 6- 8 6- 9

6-Row Coil 1-2 2-4 5-6 5-6 6-8 8-10 9-11 11-13 11-16

8-Row Coil 2-3 3-5 5-6 5-7 7-9 10-12 12-14 13-19 16-24

COIL VOLUME (gal. water)

Chilled Water,

Large Face Area

4-Row 2.5 3.5 4.5 5.2 5.6 7.3 8.5 10.4 12.0

6-Row 3.2 4.7 6.0 6.8 7.7 10.1 11.7 14.2 16.3

Chilled Water,

Small Face Area

4-Row 2.1 3.3 3.9 4.1 5.1 6.3 7.3 8.7 9.8

6-Row 2.4 3.7 5.1 5.9 6.6 8.3 9.5 11.8 13.5

8-Row 2.7 4.1 6.4 7.4 8.4 10.7 12.1 14.7 17.2

Hot Water,

1-Row 0.5 0.8 1.0 1.3 1.5 1.8 2.1 2.5 2.9

2-Row 0.7 1.3 1.6 2.0 2.4 2.9 3.4 4.0 4.8

COOLING COILS

Chilled Water

(4, 6 Row) Large Face Area

Face Area (sq ft) 3.63 5.90 7.90 9.54 11.18 14.91 17.71 21.6 25.0

Number of Tubes/Face 16 20 24 24 24 32 38 38 44

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

Chilled Water

(4, 6, 8 Row) Small Face Area

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Number of Tubes/Face 12 16 20 20 20 26 30 30 36

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

1

DX

/

-in. OD Tube

2

(4, 6 Row) Large Face Area

Face Area (sq ft) 3.63 5.90 7.90 9.54 11.18 14.91 17.71 21.6 25.0

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

1

/

-in. OD Tube

DX

2

(4, 6, 8 Row) Small Face Area

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

HEATING COILS

Hot Water

U-Bend (1, 2 Row)

Face Area (sq ft) 2.72 4.72 6.58 7.95 9.32 12.12 13.98 17.1 20.5

Number Tubes/Face 12 16 20 20 20 26 30 30 36

Finned Tube Length (in.) 26.1 34.0 37.9 45.8 53.7 53.7 53.7 65.5 65.5

Steam 1-in. OD (1 Row)

Face Area (sq ft) 2.13 4.18 6.22 7.53 8.85 11.06 13.28 16.2 18.9

Number Tubes/Face 4688 8 10121214

Finned Tube Length (in.) 25.5 33.4 37.3 45.2 53.1 53.1 53.1 53.1 64.9

LEGEND *Less coil.

DX — Direct Expansion

FPI — Fins Per Inch

1

/

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube

2

1

/

-in. OD Tube,

2

1

/

-in. OD Tube

2

1

/

-in. OD Tube,

2

-in. OD†

1

/

2

1

/

8

5

12

/

1

9

/

2

3

/

16

5

12

/

8

1

11

3

1

/

15 15 18

8

/

16

1

11

8

/

8

3

1

/

16

15 15 13

3

1

/

16

1

/

7

1

/

16

20 20 25

8

1

/

2

7

1

/

16

18 15

7

1

/

16

11

1

/

16

†Coils have 14 aluminum fins per inch on copper tubes.

6

DIFFERENTIAL

NOTE: Lift in one piece. Use slings and spreader bars at each lifting

bracket.

Fig. 5 — Unit Rigging Details

Fig. 7 — Condensate Drain

Fig. 6 — Unit Support Details

1

DRAIN NIPPLE

FAN OFF

TRAP CONDITION WHEN FAN STARTS

COOLING COIL

DRAIN PAN

FAN RUNNING AND CONDENSATE DRAINING

H

DIFFERENTIAL

2

7

INSTALLATION

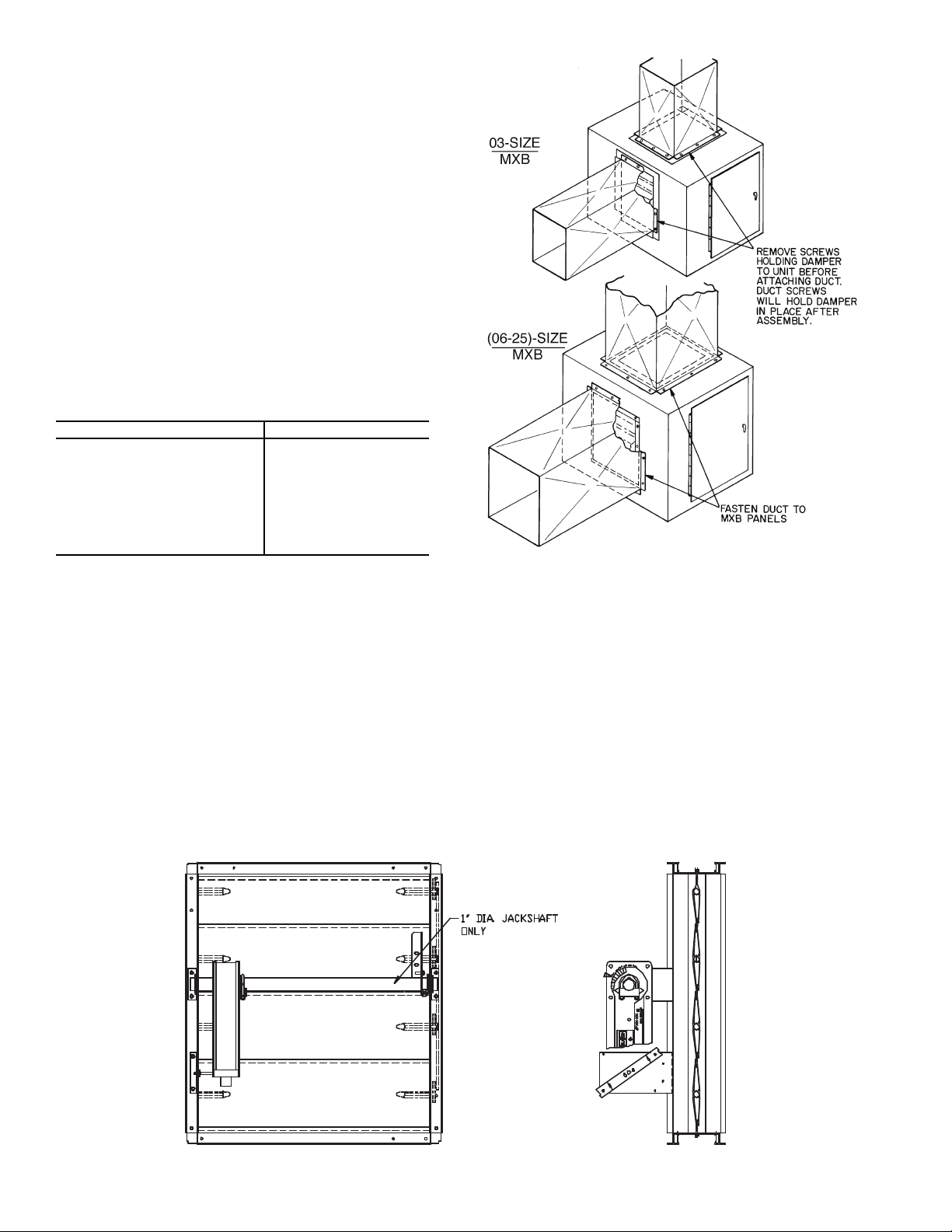

MXB — Mixing Box

Fig. 9 — Mixing Box Ductwork Attachment

Fig. 8 — Typical Mixing Box Actuator Mounting

Mixing Box

DAMPER ACTUATORS — The 39L mixing boxes are supplied with low leak dampers and blade and edge seals. Damper

operating torques are shown in Table 2.

The actuator and mounting brackets are field supplied and

may be mounted inside or outside the unit. A typical inside

mounting bracket is shown in Fig. 8. For external mounting of

actuators, drill or punch a hole in the exterior panel.

NOTE: If the unit is shipped with AirManager™ controls,

actuator(s) are factory-supplied. Refer to Table. 3.

To ensure torque is transmitted equally to both damper sections, actuator must be connected to the 1-in. hollow jackshaft

that drives the interconnecting linkage bar. Connection to any

other shaft is not recommended.

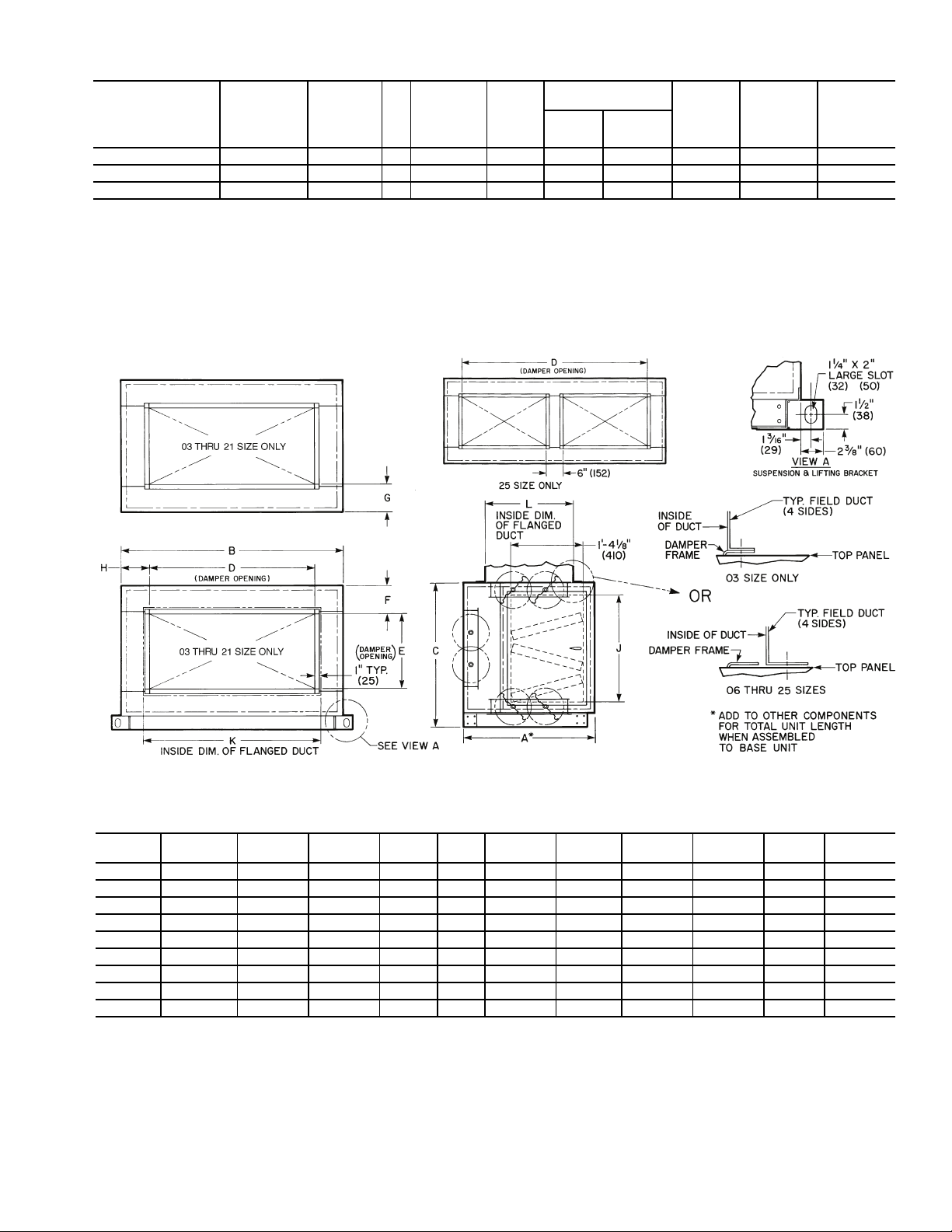

DUCTWORK ATTACHMENT — Ductwork should be

flanged out and attached to the mixing box panels as shown in

Fig. 9. See Fig. 10 for duct connection sizes.

Table 2 — Mixing Box Damper Operating Torque

(in.-lb)

39L UNIT SIZE TORQUE

03 20

06 20

08 26

10 29

12 33

15 41

18 52

21 56

25 76

NOTES:

1. Torque values are based on interconnected dampers driven by

one operator. For units with separate operators for each

damper, calculate torque as follows: Table values x .80 = torque

per damper section.

2. Damper shaft moves 90 degrees from open to closed position.

Condensate Drain — Install a trapped condensate drain

line at unit drain connection. Use 1-in. standard pipe.

Measure maximum design negative static pressure upstream from the fan. Referring to Fig. 7, height “H” must be

equal to or larger than negative static pressure at design operating conditions. Prime enough water in trap to prevent losing

seal (Differential 1). When the fan starts, Differential 2 is equal

to the maximum negative static pressure.

Provide freeze-up protection as required.

8

Table 3 — Recommended Actuators

NOTES:

1. Hand is determined by the location of the fan drive and/or coil connection when viewed while facing the direction toward which air is flowing.

2. Dimensions in ( ) are in millimeters.

DIMENSIONS (ft-in.)

Fig. 10 — Mixing Box Duct Connections

UNIT

39L-

A B C D E F G H J K L

03 2- 39/

16

3-17/

8

2-01/

4

1- 5 1-5 0- 15/

8

0-61/

16

0-101/

2

1-43/

4

1-51/

4

1- 51/

4

06 2- 39/

16

3-93/

4

2-43/

16

1-11 1-5 0- 41/

8

0-61/

16

0-113/

8

1-811/

16

2-11/

4

1- 71/

4

08 2- 39/

16

4-111/

16

2-81/

8

3- 1 1-5 0- 61/

16

0-61/

16

0- 63/

8

2-05/

8

3-31/

4

1- 71/

4

10 2- 39/

16

4-99/

16

2-81/

8

3- 5 1-5 0- 61/

16

0-61/

16

0- 85/

16

2-05/

8

3-71/

4

1- 71/

4

12 2- 39/

16

5-57/

16

2-81/

8

3-11 1-5 0- 61/

16

0-61/

16

0- 91/

4

2-05/

8

4-11/

4

1- 71/

4

15 2- 39/

16

5-57/

16

3-4 3-11 1-9 0- 8 0-41/

16

0- 91/

4

2-81/

2

4-11/

4

1-111/

4

18 2-117/

16

5-57/

16

3-715/

16

3-11 2-3 0- 7 0-5 0- 91/

4

3-07/

16

4-11/

4

2- 51/

4

21 2-117/

16

6-51/

4

3-715/

16

3-11 2-5 0- 6 0-4 1- 31/

8

3-07/

16

4-11/

4

2- 71/

4

25 2-117/

16

6-51/

4

4-313/

16

5- 4 2-5 0- 97/

8

0-4 0- 65/

8

3-85/

16

5-61/

4

2- 71/

4

ACCESSORY

PACKAGE

NO.

ACTUATOR

PART N O.

VOLTAGE

(50/60 Hz)

VA

ROUND

SHAFT

SIZE

MIN-MAX

(in.)

TIMING

(sec)

DAMPER AREA

(sq ft)

Parallel Opposed

TORQUE

(in.-lb)

MAXIMUM

STROKE

(degrees)

MAXIMUM

LENGTH

33AMACTDMP133 HF27BJ035* 24 10 .750-1.050 150 44 53 133 90 300

33AMACTGV-133 HF27BJ033 24 4 .375- .625 < 150 N/A N/A 133 90 725

33AMACTGV-266 HF27BJ034 24 6 .475- .750 135 N/A N/A 266 90 450

*Actuator is spring-return type.

NOTES:

1. All actuators are direct coupled type, designed to be directly

mounted into jackshaft assembly.

2. All actuators are equipped with a plenum rated cable, factoryterminated to the actuator. Part No. HF27BB035 and 034 are

16 ft, HF27BB033 is 9.5 ft.

3. Damper areas are nominal and based on low leakage type

dampers.

4. For larger damper assemblies, multiple activators may be used.

5. Part No. HF27BB033 and 034 are designed for inlet guide vane

and face and bypass applications, but may be used for external

relief dampers if spring return is not required.

WIRE

(ft)

9

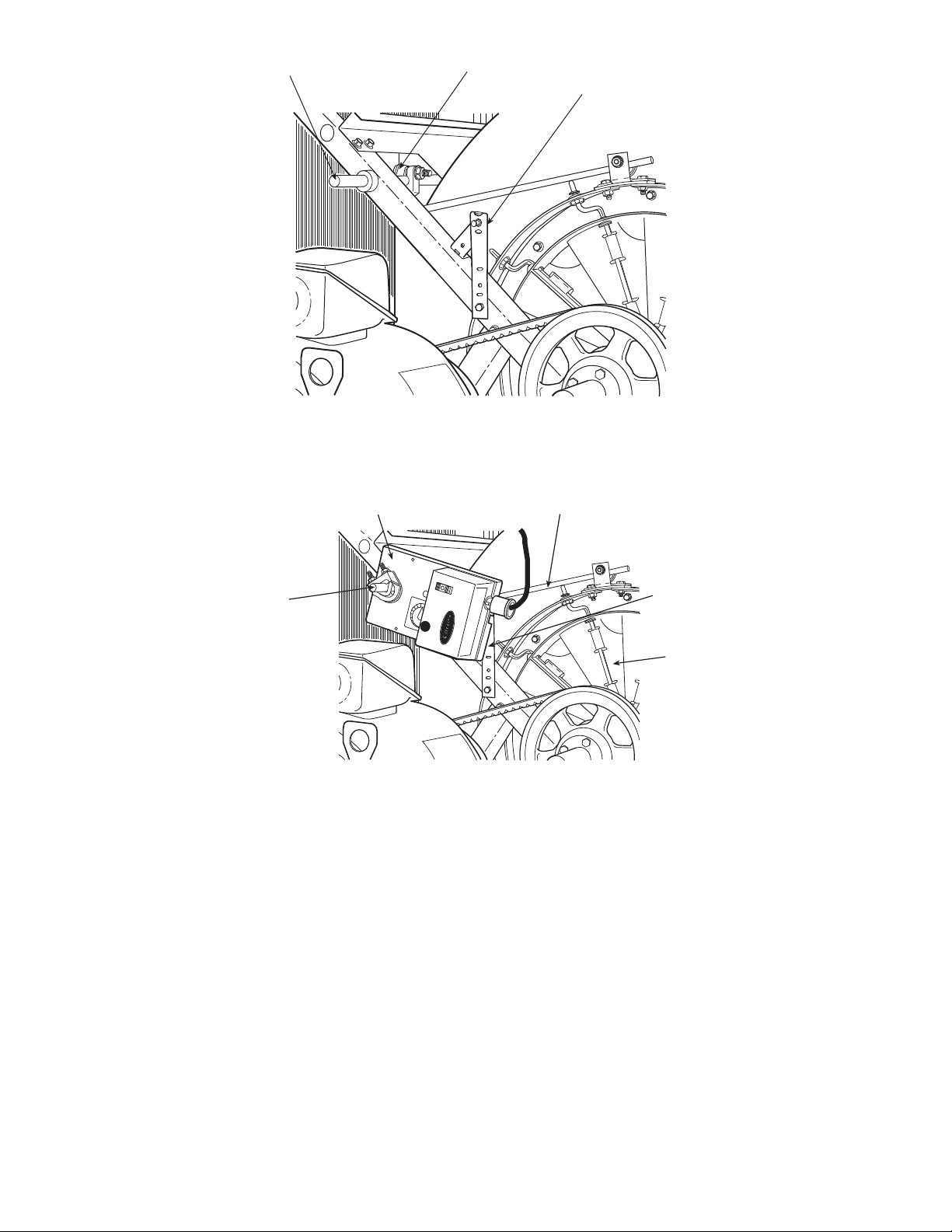

Inlet Guide Vane (IGV) Actuators — The control

board positions the unit IGVs in order to maintain the duct static pressure, as measured by the static pressure transducer, at the

required set point. The IGV actuator is electrically connected to

the control board and receives a signal whenever the guide

vane position needs to be adjusted. The guide vane actuator is

mounted to the IGV jackshaft, and secured to the jackshaft

mounting member in order to prevent rotation.

For factory-installed controls which are ordered with the

unit, the IGV actuator is properly sized and factory mounted to

the IGV jackshaft. The actuator wiring is routed across the fan

section to a junction box which is mounted to the exterior of

the unit. Two compatible actuators are available for field

installation. Both actuators are supplied with a length of

plenum rated cable to facilitate installation inside the unit. See

Table 3 for actuator specifications and typical applications.

Jackshaft and IGV linkage setup adjustments are extremely

important for proper IGV performance and static pressure control. Closely follow all instructions.

To install the IGV actuators, perform the following:

1. Disconnect power to the fan motor prior to performing

the installation.

2. Open the fan access door and locate the IGV jackshaft.

Measure the IGV jackshaft diameter. Verify that the size

is within the range of the actuator chosen. See Table 3.

3. Loosen the U-bolt locking nuts on the actuator.

4. Slip the actuator over the IGV jackshaft. Align the actuator parallel with the frame member which supports the

jackshaft.

5. Take the anti-rotation bracket supplied with the actuator

and, with the center locking pin pointed outward, slip the

pin into the slot at the far end of the actuator. Seat the pin

into the center of the groove provided. If the anti-rotation

bracket is not seated against the frame member, measure

the distance from the member and remove the antirotation bracket from the actuator. Bend the bracket to the

required offset. See Fig. 11.

6. With the anti-rotation bracket installed in the actuator

groove, locate the hole in the bracket, closest to the pin,

which is fully in contact against the frame. Mark this hole

location on the frame. Trace the outline of the bracket on

the frame so that it can be re-aligned again when

removed.

7. Remove the bracket and actuator. Drill a pilot hole at the

location marked from Step 6. Install one screw through

the hole. Re-align the bracket with the outline made previously and tighten the screw.

8. Locate and mark the hole on the opposite end of the

bracket, closest to the pin, which contacts the frame. Drill

a pilot hole in this location and install the remaining

screw. Remove the first screw.

9. Install the actuator on the jackshaft and while moving

into position, adjust the free end of the anti-rotation

bracket so that the pin fully locks into the slot provided in

the actuator. Once the actuator is adjusted into position,

install the remaining screw into the anti-rotation bracket.

See Fig. 12.

10. Rotate the jackshaft to fully close the IGVs. Press the

release button (BLACK) on the face of the actuator, and

rotate the clamp in the same direction that closed the

IGVs, until the actuator stop is reached. With the release

still pressed, rotate the actuator clamp from the full closed

position to the .1 mark and release the actuator release

button. Lock the U-bolt clamp into position to secure the

actuator to the IGV jackshaft.

11. If a second actuator is required, repeat the process for a

second actuator. The second actuator mounts on the opposite side of the fan on the opposite end of the jackshaft.

ACTUATOR WIRING — To wire the actuator, perform the

following:

1. Each actuator is supplied with a length of plenum rated

cable. Route the cable from the actuator to the exterior of

the unit. Allow a sufficient service loop to provide free

movement of the fan sled.

2. At the desired location for field connection, drill a

hole (two holes within a

7

/8-in. diameter are required if

3

/8-in.

two actuators are used) through the unit and route the cable through the hole.

3. Install a field-supplied bushing to protect the cable and

seal the hole, using a suitable silicone sealer such as

Form-A-Gasket® by Permatex to secure the cable and

prevent air leakage.

4. Remove the center back plug from a field supplied 2 x

4-in. electrical junction box. Route the cable(s) through

the hole and secure the box to the unit using 2 fieldsupplied no. 10 drill/tap screws.

5. Use a 3 or 4-conductor, 18 AWG cable or individual

18 AWG wiring using RED, WHITE, and BLACK color

coding to connect the actuator to the control box.

6. Inside the control box, connect all RED wire(s)

together. Secure with wire nuts or closed end crimp type

connectors.

7. Inside the control box, connect all BLACK wire(s) together. Secure with wire nuts or closed end crimp type

connectors.

8. Inside the control box, connect all WHITE wire(s) together. Secure with wire nuts or closed end crimp type

connectors.

9. At the control box, strip

conductor. Equip each conductor with a

1

/4-in. of insulation from each

1

/4-in. female

spade type crimp connector.

10. Connect the RED wire to terminal T37 on the control

board.

11. Connect the WHITE wire to terminal T39 on the control

board.

12. Connect the BLACK wire to terminal no. 3 on the TB2

terminal block in the control box.

13. Check the rotation of the actuator. The switch is factory

set in the A position which provides clockwise rotation to

open the IGVs. If counterclockwise rotation is required to

open the IGVs, reset the actuator switch to the B position.

To adjust the jackshaft linkage, perform the following:

1. Refer to Fig. 12. Close the IGVs fully.

2. Loosen the crankarm and rods. Press the release button

on the actuator and rotate it to the .9 mark for right hand

units or the .1 mark for left hand units. Rotate the crankarm on the jackshaft to a position which is about 30 degrees from parallel alignment with the rod connecting the

IGV.

3. Tighten the crankarm into this position.

4. Close the IGVs fully by hand. Tighten the rod into

position.

5. Test the actuator and IGV operation. Be sure the IGVs

fully close and open. Re-adjust the position of the swivel

joint outward if full IGV travel is not reached with the

actuator 90 degree rotation. If the IGVs reach the end of

full travel in less than 90 degrees of actuator rotation,

adjust the swivel joint inward toward the jackshaft. After

making any adjustment, repeat Steps 2-5.

10

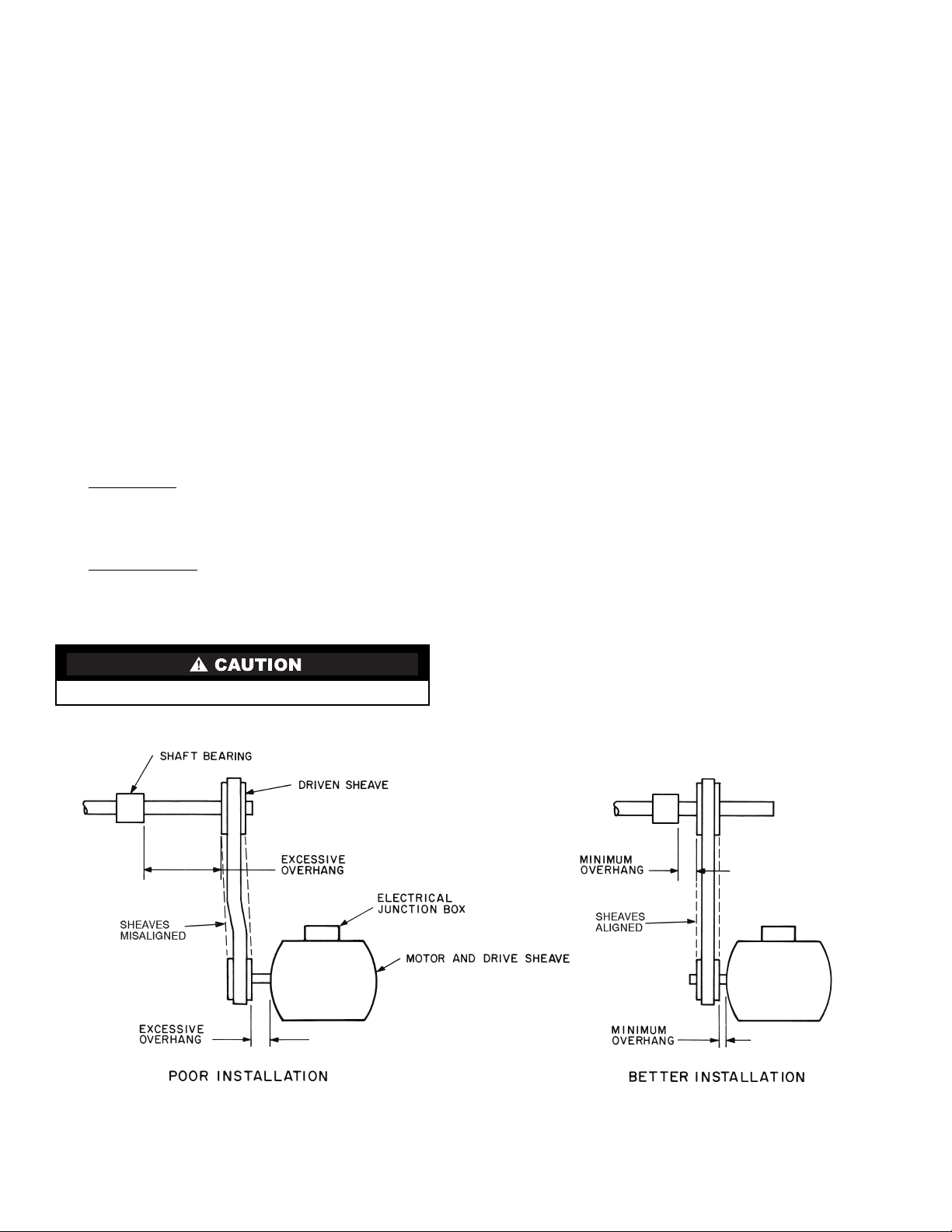

Install Fan Motor — For field installation of motors, be

JACKSHAFT CRANKARM

ANTIROTATION STRAP

INSTALLED (ACTUATOR

NOT SHOWN FOR

CLARITY)

IGV ACTUATOR

CONNECTING ROD

ANTIROTATION

STRAP

INLET GUIDE

VANES (IGV)

IGV

JACKSHAFT

Fig. 11 — IGV Actuator Bracket Installation

Fig. 12 — IGV Actuator Mounting

sure electrical junction box is toward the center of the unit.

This is necessary for drive and belts to be properly tightened.

Use smallest slots in motor mounting base that will accommodate motor and allow minimum overhang (Fig. 13). Be sure

that motor holddown bolts are tight on field-installed motor.

JUNCTION BOX CONDENSATE PREVENTION — When

air handlers are installed outdoors in a high humidity environment or indoors where the apparatus room is used as a fresh air

plenum, precautions must be taken to prevent condensation

from forming inside the junction box of the internally mounted

motor.

Standard installation practice is to mount the motor starter

or fused disconnect box adjacent to the air handler and enclose

the power wiring to the motor in flexible conduit.

The sheet metal housing of the disconnect switch or motor

starter is not airtight (even when a box meeting NEMA

[National Electrical Manufacturers Association] IV standards

is used). Thus, warm moist air can migrate through the flexible

conduit to the junction box on the motor. With the motor

located inside the unit, the motor temperature is that of the cool

11

supply air; thus, condensate can form inside the junction box

and, possibly, on the live terminal lugs.

To prevent the moist air from migrating through the conduit

to the motor, seal the power wires inside the flexible conduit at

the motor starter or fused disconnect.

Use a nonconductive, nonhardening sealant. Permagum

(manufactured by Schnee Morehead) or sealing compound,

thumb grade (manufactured by Calgon), are acceptable

materials.

POWER KNOCKOUTS — Panels are not provided with

knockouts for the fan motor power wiring. Openings must be

drilled or punched in the exterior panels of the unit. It is recommended that power wiring be routed through the discharge

panel whenever possible, as this panel is rarely removed for

service access.

Install Sheaves on Motor and Fan Shafts —

Factory-supplied drives are prealigned and tensioned, however,

Carrier recommends that you check the belt tension and alignment before starting the unit. Always check the drive alignment after adjusting belt tension.

When field installing or replacing sheaves, install sheaves

Fig. 13 — Determining Sheave-Shaft Overhang

on fan shaft and motor shaft for minimum overhang. (See

Fig. 13.) Use care when mounting sheave on fan shaft; too

much force may damage bearing. Remove rust-preventative

coating or oil from shaft. Make sure shaft is clean and free of

burrs. Add grease or lubricant to bore of sheave before

installing.

The 39L fan, shaft, and drive pulley are balanced as a complete assembly to a high degree of accuracy. If excessive unit

vibration is present after fan pulley replacement, the unit must

be rebalanced. For drive ratio changes, always reselect the motor pulley — do not change the fan pulley.

ALIGNMENT — Make sure that fan shafts and motor shafts

are parallel and level. The most common causes of misalignment are nonparallel shafts and improperly located

sheaves. Where shafts are not parallel, belts on one side are

drawn tighter and pull more than their share of the load. As a

result, these belts wear out faster, requiring the entire set to be

replaced before it has given maximum service. If misalignment

is in the sheave, belts will enter and leave the grooves at an

angle, causing excessive belt cover and sheave wear.

1. Shaft alignment can be checked by measuring the

distance between the shafts at 3 or more locations. If the

distances are equal, then the shafts will be parallel.

2. Sheave alignment:

Fixed sheaves

— To check the location of the fixed

sheaves on the shafts, a straightedge or a piece of string

can be used. If the sheaves are properly lined up the string

will touch them at the points indicated by the arrows in

Fig. 14.

Adjustable sheave

— To check the location of adjustable

sheave on shaft, make sure that the centerlines of both

sheaves are in line and parallel with the bearing support

channel. See Fig. 14. Adjustable pitch drives are installed

on the motor shaft.

3. Rotating each sheave a half revolution will determine

whether the sheave is wobbly or the drive shaft is bent.

Correct any misalignment.

4. With sheaves aligned, tighten cap screws evenly and

progressively.

NOTE: There should be a

1

/8-in. to 1/4-in. gap between

the mating part hub and the bushing flange. If gap is

closed, the bushing is probably the wrong size.

5. With taper-lock bushed hubs, be sure the bushing bolts

are tightened evenly to prevent side-to-side pulley wobble. Check by rotating sheaves and rechecking sheave

alignment. When substituting field-supplied sheaves for

factory-supplied sheaves, consider that the fan shaft

sheave has been factory balanced with fan and shaft as an

assembly. For this reason, substitution of motor sheave is

prefer-able for final speed adjustment.

Install V-Belts — When installing or replacing belts, al-

ways use a complete set of new belts. Mixing old and new belts

will result in the premature wear or breakage of the newer

belts.

1. Always adjust the motor position so that V-belts can be

installed without stretching over grooves. Forcing belts

can result in uneven stretching and a mismatched set of

belts.

2. Do not allow belt to bottom out in sheave.

3. Tighten belts by turning motor-adjusting jackscrews.

Turn each jackscrew an equal number of turns.

4. Equalize belt slack so that it is on the same side of belt for

all belts. Failure to do so may result in uneven belt

stretching.

5. Tension new drives at the maximum deflection force

recommended (Fig. 15).

With adjustable sheave, do not exceed maximum fan rpm.

12

Fig. 14 — Sheave Alignment

PD — Pitch Diameter, inches

Fig. 15 — Fan Belt Tension Data

BELT

CROSS

SECTION

SMALL

SHEAVE

PD RANGE

(in.)

DEFLECTION FORCE — LB

Super

Belts

Notch

Belts

Steel Cable

Belts

Min Max Min Max Min Max

A

3.0- 3.6 3 4

1

/437/851/234

3.8- 4.8 3

1

/2541/261/433/443/

4

5.0- 7.0 4 51/2567/841/451/

4

B

3.4- 4.2 4 5

1

/253/4841/251/

2

4.4- 5.6 51/871/861/291/853/471/

4

5.8- 8.6 63/883/473/8101/8783/

4

C

7.0- 9.4 11

1

/4143/8133/4177/8111/414

9.6-16.0 14

1

/8181/2151/4201/4141/4173/

4

3V

2.65-3.65 3

1

/2537/851/2——

4.12-6.90 4

3

/467/851/477/8——

5V

4.40-6.70 — — 10 15 — —

7.1-10.9 10

1

/2153/4127/8183/4——

11.8-16.0 13 19

1

/215 22 — —

8V

12.5-17.0 27 40

1

/2——— —

18.0-22.4 30 45 — — — —

Fig. 16 — Fan Section Label

NOTICE

TENSION BELTS TO SPECIFICATION

SHOWN ON DRIVE LABEL. OVER

TENSIONING BELTS WILL SEVERELY

REDUCE BELT AND BEARING LIFE.

REPLACEMENT PARTS

BEARINGS

DRIVE _______________________

FREE ________________________

SHAFT ________________________

WHEEL ________________________

INLET CONE ____________________

TO ORDER REPLACEMENT PARTS,

CONTACT: RCD

(REPLACEMENT COMPONENTS DIVISION)

1-800-443-4410

6. To determine correct belt tension, use the deflection

formula given below and the tension data from Fig. 15 as

follows:

EXAMPLE:

Given

Solution

1. From Fig. 15 find that deflection force for type A, super

belt with 5-in. small sheave PD is 4 to 5

2.

3. Increase or decrease belt tension until force required for

1

Check belt tension at least twice during first operating

day. Readjust as required to maintain belt tension within

the recommended range.

With correct belt tension, belts may slip and squeal

momentarily on start up. This slippage is normal and disappears after unit reaches operating speed. Excessive belt tension

shortens belt life and may cause bearing and shaft damage.

After run-in, set belt tension at lowest tension at which belts

will not slip during operation.

Record information on the label (Fig. 16) found on the door

of the fan section.

Belt Span 16 in.

Belt Cross-Section A, Super Belt

Small Sheave PD 5 in.

Deflection =

(Belt Span)

64

Deflection =

/4-in. deflection is 51/2 lb.

16

64

1

/2 lb.

13

Water and Steam Coil Piping Recommendations

Fig. 17 — Coil Connections and Lifting Points

GENERAL — Use straps around the coil casing or the lifting

holes (see Fig. 17) to lift and place the coil.

To prevent damage to the coil or coil headers: Do not use

the headers to lift the coil. Support the piping and coil connections independently. Do not use the coil connections to

support piping. When tightening coil connections, use a

backup wrench on the nozzles.

Piping practices are outlined in the Carrier System Design

Manual, Part 3, Piping Design. See Tables 4-6 for circuiting data.

WATER COILS — Typically, coils are piped by connecting

the supply at the bottom and the return at the top. See Fig. 17.

This is not always the case, especially if the coil hand has been

changed in the field. Coils must be piped for counterflow; otherwise, a capacity reduction of 5% for each coil row will result.

To ensure counterflow, chilled water coils are piped so that the

coldest water meets the coldest air. Hot water coils are piped so

that the warmest water meets the warmest air.

STEAM COILS — Position the steam supply connection at

the top of the coil, and the return (condensate) connection at the

bottom. The coil tubes must incline downwards toward

the return header connection for condensate drainage. See

Fig. 18-22.

Figure 18 illustrates the normal piping components and the

suggested locations for high, medium, or low-pressure steam

coils. The low-pressure application (zero to 15 psig) can

dispense with the ¼-in. petcock for continuous venting located

above the vacuum breaker (check valve).

Note the horizontal location of the 15-degree check valve,

and the orientation of the gate/pivot. This valve is intended to

relieve any vacuum forming in the condensate outlet of a

condensing steam coil, and to seal this port when steam

pressure is again supplied to the coil. It must not be installed in

any other position, and should not be used in the supply line.

For coils used in tempering service, or to preheat outside air,

install an immersion thermostat in the condensate line ahead of

the trap. This will shut down the supply fan and close the outdoor damper whenever the condensate falls to a predetermined

point, perhaps 120 F.

NOTE: Do NOT use an immersion thermostat to override a

duct thermostat and open the steam supply valve.

For vacuum return systems, the vacuum breaking check

valve would be piped into the condensate line between the trap

and the gate valve instead of open to the atmosphere.

Figure 19 illustrates the typical piping at the end of every

steam supply main. Omitting this causes many field problems

and failed coils.

Figure 20 shows the typical field piping of multiple coils.

Use this only if the coils are the same size and have the same

pressure drop. If this is not the case, an individual trap must be

provided for each coil.

Figure 21 shows a multiple coil arrangement applied to a

gravity return, including the open air relief to the atmosphere,

which DOES NOT replace the vacuum breakers.

Figure 22 illustrates the basic condensate lift piping.

Following the piping diagrams in Fig. 18-22, make all connections while observing the following precautions:

• Install a drip line and trap on the pressure side of the

inlet control valve. Connect the drip line to the return

line downstream of the return line trap.

• To prevent scale or foreign matter from entering the con-

trol valve and coil, install a

3

/32-in. mesh strainer in the

steam supply line upstream from the control valve.

• Provide air vents for the coils to eliminate noncondens-

able gases.

• Select a control valve according to the steam load, not

the coils supply connection size. Do not use an oversized

control valve.

• Do not use bushings that reduce the size of the header

return connection. The return connection should be the

same size as the return line and reduced only at the

downstream trap.

• To lift condensate above the coil return line into over-

head steam mains, or pressurized mains, install a pump

and receiver between the condensate trap and the

pressurized main. Do not try to lift condensate with

modulating or on-and-off steam control valves. Use only

15-degree check valves, as they open with a lower water

head. Do not use 45-degree or vertical-lift check valves.

• Use float and thermostatic traps. Select the trap size

according to the pressure difference between the steam

supply main and the return main.

• Load variations can be caused by uneven inlet air distri-

bution or temperature stratification.

• Drain condensate out of coils completely at the end of

the heating season to prevent the formation of acid.

Coil Freeze-Up Protection

WATER COILS — If a chilled water coil is applied with outside air, provisions must be made to prevent coil freeze-up.

Install a coil freeze-up thermostat to shut down the system if

any air temperature below 36 F is encountered entering the

water coil. Follow thermostat manufacturer’s instructions.

14

When a water coil is applied downstream of a direct-

NOTES:

1. Flange or union is located to facilitate coil removal.

2. Flash trap may be used if pressure differential between steam

and condensate return exceeds 5 psi.

3. When a bypass with control is required.

4. Dirt leg may be replaced with a strainer. If so, tee on drop can

be replaced by a reducing ell.

5. The petcock is not necessary with a bucket trap or any trap

which has provision for passing air. The great majority of high

or medium pressure returns end in hot wells or deaerators

which vent the air.

Fig. 18 — Low, Medium or

High Pressure Coil Piping

expansion (DX) coil, a freeze-up thermostat must be installed

between the DX and water coil and electrically interlocked to

turn off the cooling to prevent freeze-up of the water coil.

For outdoor-air application where intermittent chilled water

coil operation is possible, one of the following steps should be

taken:

• Install an auxiliary blower heater in cabinet to maintain

above-freezing temperature around coil while unit is

shut down.

• Drain coils and fill with an ethylene glycol solution suit-

able for the expected cold weather operation. Shut down

the system and drain coils. See Service section, Winter

Shutdown, page 30.

STEAM COILS — When used for preheating outdoor air in

pressure or vacuum systems, an immersion thermostat to control outdoor-air damper and fan motor is recommended. This

control is actuated when steam supply fails or condensate temperature drops below an established level, such as 120 to 150 F.

A vacuum breaker should also be used to equalize coil pressure

with the atmosphere when steam supply throttles close. Steam

should not be modulated when outdoor air is below 40 F.

On low-pressure and vacuum steam-heating systems, the

thermostat may be replaced by a condensate drain with a thermal element. This element opens and drains the coil when condensate temperature drops below 165 F. Note that condensate

drains are limited to 5 psig pressure.

INNER DISTRIBUTING TUBE STEAM COILS — The

inner distributing tube (IDT) steam coil used in the Carrier

39M air-handling units has an inner tube pierced to facilitate

the distribution of the steam along the tube's length. The outer

tubes are expanded into plate fins. The completed assembly

includes the supply and condensate header and side casings

which are built to slant the fin/tube bundle back toward the

condensate header. The slanting of the assembly ensures that

condensate will flow toward the drains. This condensate must

be removed through the return piping to prevent premature

failure of the coil. The fin/tube bundle is slanted vertically for

horizontal airflow coils, and horizontally for vertical airflow coils.

IDT Steam Coil Piping

— The following piping guidelines

will contribute to efficient coil operation and long coil life:

1. Use full size coil outlets and return piping to the steam

trap. Do not bush return outlet to the coil. Run full size to

the trap, reduce at the trap.

2. Use float and thermostatic (F & T) traps only for condensate removal. Trap size selection should be based on the

difference in pressure between the steam supply main and

the condensate return main. It is good practice to select a

trap with 3 times the condensate rating of the coil to

which it is connected.

3. Use thermostatic traps for venting only.

4. Use only

1

/2-in., 15-degree swing check valves installed

horizontally, piped open to atmosphere, and located at

least 12 in. above the condensate outlet. Do not use

45-degree, vertical lift and ring check valves.

5. The supply valve must be sized for the maximum anticipated steam load.

6. Do not drip steam mains into coil sections. Drip them on

the pressure side of the control valve and trap them into

the return main beyond the trap for the coil.

7. Do not use a single trap for two or more coils installed in

series. Where two or more coils are installed in a single

bank, in parallel, the use of a single trap is permissible,

but only if the load on each coil is equal. Where loads in

the same coil bank vary, best practice is to use a separate

trap for each coil.

Variation in load on different coils in the same bank may

be caused by several factors. Two of the most common

are uneven airflow distribution across the coil and stratification of inlet air across the coil.

8. Do not try to lift condensate above the coil return into an

overhead main, or drain into a main under pressure with a

modulating or on/off steam control valves. A pump

and receiver should be installed between the coil condensate traps and overhead mains and return mains under

pressure.

9. Use a strainer (

3

/32-in. mesh) on the steam supply side,

as shown in the piping diagrams, to avoid collection of

scale or other foreign matter in the inner tube distributing

orifices.

NOTE: IDT coils must be installed with the tubes draining

toward the header end of the coil. Carrier's IDT steam coils

are pitched toward the header end as installed in the unit.

10. Ensure the AHU (air-handling unit) is installed level to

maintain the inherent slope. Also ensure the unit is installed high enough to allow the piping to be installed correctly, especially the traps which require long drip legs.

11. Do not fail to provide all coils with the proper air vents to

eliminate noncondensable gasses.

12. Do not support steam piping from the coil units. Both

mains and coil sections should be supported separately.

IDT Steam Coil Installation

— Refer to drawings to position

the coils properly with regard to the location of the supply and

return connections. Ensure that the IDT coil is pitched with the

tubes draining toward the header. Carrier’s AHUs provide

proper coil pitch when the AHU is installed level.

Refer to schematic piping diagrams and piping connection

notes for the recommended piping methods.

15

NOTES:

1. A bypass is necessary around trap and valves when continuous operation is necessary.

2. Bypass to be the same size as trap orifice but never less than

1

/2 inch.

Fig. 19 — Dripping Steam Supply to

Condensate Return

NOTES:

1. Flange or union is located to facilitate coil removal.

2. When a bypass with control is required.

3. Flash trap can be used if pressure differential between supply

and condensate return exceeds 5 psi.

4. Coils with different pressure drops require individual traps. This

is often caused by varying air velocities across the coil bank.

5. Dirt leg may be replaced with a strainer. If so, tee on drop can

be replaced by a reducing ell.

6. The petcock is not necessary with a bucket trap or any trap

which has provision for passing air. The great majority of high

pressure return mains terminate in hot wells or deaerators

which vent the air.

Fig. 20 — Multiple Coil High Pressure Piping

NOTES:

1. Flange or union is located to facilitate coil removal.

2. When control valve is omitted on multiple coils in parallel air

flow.

3. When a bypass with control is required.

4. Coils with different pressure drops require individual traps. This

is often caused by varying air velocities across the coil bank.

Fig. 21 — Multiple Coil Low Pressure

Piping Gravity Return

NOTES:

1. Flange or union is located to facilitate coil removal.

2. To prevent water hammer, drain coil before admitting steam.

3. Do not exceed one foot of lift between trap discharge and

return main for each pound of pressure differential.

4. Do not use this arrangement for units handling outside air.

Fig. 22 — Condensate Lift to Overhead Return

16

Refrigerant Piping, Direct-Expansion (DX)

Fig. 23 — Typical Direct-Expansion

Row Split Coil

Coils (Fig. 23) —

2 or 4 splits depending upon the unit size and coil circuiting.

See Table 7 for coil circuiting data. Each split requires its own

distributor nozzle, expansion valve, and suction piping. Suction

connections are on the air entering side when the coil is properly installed. Matching distributor connections for each coil split

are on the air leaving side. See unit label or certified drawing to

assure connection to matching suction and liquid connections.

See Table 8 for distributor part numbers.

Direct-expansion coils are shipped pressurized with dry

air. Release pressure from each coil split through valves in

protective caps before removing caps.

Do not leave piping open to the atmosphere unnecessarily. Water and water vapor are detrimental to the refrigerant

system. Until the piping is complete, recap the system and

charge with nitrogen at the end of each workday. Clean all

piping connections before soldering joints.

The lower split of face split coils should be first on, last

off.

Row split coils utilize special intertwined circuits (as

shown in Fig. 23); either split of these row split coils can be

first on, last off.

Direct-expansion coils are divided into

Table 4 — Hot Water Coil Circuiting Data

39L UNIT SIZE 03 06 08 10 12 15 18 21 25

1-ROW H 6 81010 101315 15 13

2-ROW H

F

LEGEND NOTE: All hot water coils have 11/2-in. MPT.

F—Full Circuit

H—Half Circuit

6 8 10 10 10 13 15 15 13

12 16 20 20 20 26 30 30 36

No. of Circuits

Table 5 — Chilled Water Coil Circuiting Data

LARGE FACE AREA (39LA, 39LD)

03 06 08 10 12

COIL

TYPE

4-ROW

6-ROW

CIRCUIT

Circuits

Q 41

H 81

F 16 11/

D ——————————

H 81

F 16 11/

D ————362

3.63 5.90 7.90 9.54 11.18

No.

Connection

Size

1

/

2

1

/

2

2

1

/

2

2

No.

Circuits

Connection

Size

51

10 11/

20 11/

10 11/

20 11/

1

/

2

2

2

2

2

LARGE FACE AREA (39LA, 39LD)

UNIT SIZE

15 18 21 25

COIL

TYPE

4-ROW

6-ROW

CIRCUIT

Q ————————

H 16 11/

F 32 21/

D ————762

H 16 11/

F 32 21/

D 48 21/

14.91 17.71 21.60 25.00

No.

Circuits

Connection

Size

2

2

2

2

2

No.

Circuits

19 11/

38 21/

19 11/

38 21/

57 21/

Face Area (sq ft)

Connection

Size

2

2

2

2

2

LEGEND NOTES:

D—Double Circuit

F—Full Circuit

H—Half Circuit

Q—Quarter Circuit

UNIT SIZE

Face Area (sq ft)

No.

Circuits

Circuits

Connection

Size

——————

12 11/

24 21/

12 11/

24 21/

No.

19 11/

38 21/

19 11/

38 21/

57 21/

1. Connection sizes are MPT — inches.

2. Sizes 21-25 have 2 coils.

2

2

2

2

1

/

2

Connection

Size

2

2

1

/

2

2

2

2

No.

Circuits

Circuits

Connection

Size

12 11/

24 21/

12 11/

24 21/

36 21/

No.

22 11/

44 21/

88 21/

——

44 21/

66 21/

2

2

2

2

2

Connection

Size

2

2

2

2

2

No.

Circuits

12 11/

24 21/

12 11/

24 21/

36 21/

Connection

Size

2

2

2

2

2

17

03 06 08 10 12

COIL

TYPE

4-ROW

6-ROW

8-ROW*

CIRCUITING

Circuits

Q 31

H 61

F 12 11/

D ——————————

H 61

F 12 11/

D ————302

H 61

F 12 11/

D ————402

2.72 4.72 6.58 7.95 9.23

No.

15 18 21 25

COIL

TYPE

4-ROW

6-ROW

8-ROW*

CIRCUITING

Q ————————

H 13 11/

F 26 21/

D ————602

H 13 11/

F 26 21/

D 39 21/

H 13 11/

F 26 21/

D 52 21/

12.12 13.98 17.10 20.50

No.

Circuits

LEGEND

D—Double Circuit

F—Full Circuit

H—Half Circuit

Q—Quarter Circuit

*Not available on 39LB units.

NOTE: Connection sizes are MPT - inches.

Table 5 — Chilled Water Coil Circuiting Data (cont)

SMALL FACE AREA (39LB, 39LC, 39LF)

UNIT SIZE

Face Area (sq ft)

Connection

Size

1

/

2

1

/

2

2

1

/

2

2

1

/

2

2

SMALL FACE AREA (39LB, 39LC, 39LF)

Connection

Size

2

2

2

2

2

2

2

2

No.

Circuits

Circuits

Connection

Size

41

81

16 11/

81

16 11/

81

16 11/

No.

Connection

Size

15 11/

30 21/

15 11/

30 21/

45 21/

13 11/

30 21/

60 21/

No.

1

1

1

1

Circuits

/

2

/

2

2

/

2

2

/

2

2

——————

10 11/

20 21/

10 11/

20 21/

10 11/

20 21/

UNIT SIZE

Face Area (sq ft)

No.

Circuits

2

2

2

2

2

2

2

2

15 11/

30 21/

15 11/

30 21/

45 21/

—1

30 21/

60 21/

Connection

Size

2

2

2

2

1

/

2

2

2

1

/

2

Connection

Size

2

2

1

/

2

2

2

2

1

/

2

2

2

No.

Circuits

10 11/

20 21/

10 11/

20 21/

30 21/

10 11/

20 21/

40 21/

No.

Circuits

18 11/

36 21/

72 21/

—1

36 21/

54 21/

—1

36 21/

72 21/

Connection

Size

2

2

2

2

2

2

2

2

Connection

Size

2

2

2

1

/

2

2

2

1

/

2

2

2

No.

Circuits

10 11/

20 21/

10 11/

20 21/

30 21/

10 11/

20 21/

40 21/

Connection

Size

2

2

2

2

2

2

2

2

Table 6 — Steam Coil Connection Sizes

39L UNIT SIZE FACE AREA COIL TYPE CIRCUITING CONNECTION CONNECTION SIZE

03-25 Small 1-Row F

LEGEND

F—Full Circuit

NOTE: Connection sizes are MPT - inches.

Inlet

Outlet 11/

21/

2

2

18

SUCTION PIPING — Connect suction piping as shown in

TXV — Thermostatic Expansion Valve

Fig. 24 — Face Split Coil Suction Line Piping

TXV — Thermostatic Expansion Valve

Fig. 25 — Row Split Coil Suction Line Piping

Fig. 26 — Suction Line Riser Piping

Fig. 24 for face split coil or Fig. 25 for row split coil.

Suction line from coil connection to end of the 15-diameterlong riser should be same tube size as coil connection to ensure

proper refrigerant velocity.

Refer to Carrier System Design Manual, Part 3, and size remaining suction line to compressor for a pressure drop equivalent to 2.0 F. This will provide a total suction line header pressure drop equivalent to approximately 2.5 F. Refer to Fig. 26

for piping risers to the compressor.

To minimize the possibility of flooded starts and compressor damage during prolonged light load operation, install an accumulator in the suction line or a solenoid in the liquid line of

last-on, first off split in row-split applications.

EXPANSION VALVE PIPING — Distributor nozzles sized

for acceptable performance for a range of conditions are factory supplied. Use the AHU (Air-Handling Unit) selection program in the Carrier electronic catalog to select optimal nozzle

sizes. Replace factory nozzle as necessary for best performance. See Fig. 27.

Thermostatic expansion valves are field supplied. See

Fig. 27.

NOTE: Be sure that correct nozzle is installed in each distributor before installing expansion valve. Before installing fieldsupplied nozzles, remove nozzle retainer rings and factoryinstalled minimum-sized nozzles from distributors.

Install expansion valve (Fig. 27) as follows:

1. Wrap wet cloths around valve body to prevent excessive

heat from reaching diaphragm and internal parts. Do not

allow water to enter system. Disassemble expansion

valve before soldering, if accessible, for easy reassembly.

Use 95-5 tin-antimony soft solder.

2. Solder expansion valve outlet directly to distributor unless:

a. An adapter bushing or coupling is supplied by the

factory (solder adapter to distributor first, then to

expansion valve).

b. Hot gas bypass is required. (See Hot Gas Bypass

section, below.)

3. Solder expansion valve equalizer line to suction line and

locate control bulb on suction line as in Fig. 24 or 25.

4. Insulate expansion valve body, diaphragm assembly and

control bulb area to prevent charge migration and excessive condensation.

5. Install filter drier ahead of expansion valve to ensure satisfactory valve operation.

HOT GAS BYPASS — When low-load operation requires

use of hot gas bypass, hot gas must be introduced between expansion valve and distributor. See Table 9.

Install hot gas bypass connector (Fig. 28) in coil split that is

first on, last off as follows:

1. Remove distributor nozzle and retainer ring (area A) from

distributor and reinstall in inlet (area B) of side connector.

2. Solder side connector outlet to distributor inlet, using

silver solder or equivalent with 1300 to 1500 F melt

temperature.

3. Silver-solder expansion valve outlet to side connector

inlet.

4. If required, install factory-supplied adapter bushing or

coupling to connector inlet before soldering to expansion

valve outlet.

19

Table 7 — Direct Expansion Coil Circuiting Data

LARGE FACE AREA (39LA, 39LD)

UNIT SIZE 03 06 08 10 12

CIRCUITING TYPE Qtr Half Full Qtr Half Full Qtr Half Full Qtr Half Full Half Full

CFM AT 550 FPM 1996 3245 4345 5247 6149

FACE AREA (sq ft) 3.63 5.90 7.90 9.54 11.18

TUBE FACE 16 20 24 24 24

TUBE LENGTH (in.) 26.1 34.0 37.9 45.8 53.7

NUMBER OF CIRCUITS 4 8 16—1020 —1224—12241224

NUMBER OF TXVs 222—22—22—2222

NUMBER OF CIRCUITS/TXV† 2 4 8— 510— 612— 612612

SUCTION CONNECTIONS

(in. OD)

DISTRIBUTOR CONNECTIONS

(in. OD)

4-ROW COIL

Circuit Equivalent Length (ft) 52 26 — — 32 — — 34 18 — 40 20 45 23

Distributor Tube Length (in.)

Face Split 11 11 — — 11 — — 13 15 — 13 15 13 15

Row Split 13 15 — — 16 — — 18 18 — 18 18 18 18

Distributor Nozzle Size** 22——3——44— 5566

6-ROW COIL

Circuit Equivalent Length (ft) — 39 20 — 47 24 — 51 26 — 59 30 67 34

Distributor Tube Length (in.)

Face Split — 11 11 — 11 13 — 13 15 — 13 15 13 15

Row Split — 15 16 — 16 18 — 18 21 — 18 21 18 21

Distributor Nozzle Size** —2 3— 33—44— 5566

UNIT SIZE 15 18 21 25

CIRCUITING TYPE Half Full Half Full Half Full Double Half Full Double

CFM AT 550 FPM 8200 9740 11,880 13,750

FACE AREA (sq ft) 14.91 17.71 21.6 25.0

TUBE FACE 32 38 38 22U-22L

TUBE LENGTH (in.) 53.7 53.7 65.5 65.5

NUMBER OF CIRCUITS 16 32 19 38 19 38 — 22 44 88

7

7

/

8

/

8

11/813/

7

/

11/

8

—11/813/

8

—

8

7

/

11/

8

—11/815/

8

—

8

LARGE FACE AREA (39LA, 39LD)

7

/815/

—11/815/811/815/

8

7

—

8

/

15/

8

8

7

/811/

8

8

NUMBER OF TXVs 24* 2 4* 2 4* — 2 22244

NUMBER OF CIRCUITS/TXV† 8 8 9-10 9-10 9-10 9-10 — 5-6 5-6 11 11 11 11

SUCTION CONNECTIONS

(in. OD)

DISTRIBUTOR CONNECTIONS

(in. OD)

3

1

/

13/813/

8

1

1

/

11/811/

8

8

8

13/813/

11/811/

11/

8

11/

8

—11/811/813/813/815/815/

8

7

—

8

7

/

/813/813/813/813/

8

8

8

4-ROW COIL

Circuit Equivalent Length (ft) 45 23 45 23 54 26 — 54 54 26 26 — —

Distributor Tube Length (in.)

Face Split 15 16 16 16 16 16

Row Split 26 16 28 16 28 16

Distributor Nozzle Size** 84105105 — 8855——

3

/

— 12121515— —

4

3

/

— 21212323— —

4

6-ROW COIL

Circuit Equivalent Length (ft) 67 34 67 34 81 40 — — — 40 40 — —

Distributor Tube Length (in.)

Face Split 15 16 16 18 16 18

Row Split 23 16 28 18 28 18

Distributor Nozzle Size** 84105105 — ——55——

LEGEND

AHU — Air-Handling Unit Selection Program

TXV — Thermostatic Expansion Valve (Field-supplied)

*May be field manifolded for either face split or row split.

†Where each TXV has the same number of circuits, that number is

shown once. When coil has an uneven number of circuits per TXV,

both values are shown.

1

/

———1515——

2

1

/

———2222——

2

**Factory-supplied distributors have factory-selected nozzle sizes

shown. If necessary, replace factory-supplied nozzles with fieldsupplied and installed nozzles. Consult Electronic Catalog AHU

selection program for correct nozzle selection.

††Not available on 39LB units.

20

Table 7 — Direct Expansion Coil Circuiting Data (cont)

SMALL FACE AREA (39LB, 39LC, 39LF)

UNIT SIZE 03 06 08 10 12

CIRCUITING TYPE Qtr Half Full Qtr Half Full Qtr Half Full Qtr Half Full Half Full

CFM AT 550 FPM 1496 2596 3619 4372 5126

FACE AREA (sq ft) 2.72 4.72 6.58 7.95 9.32

TUBE FACE 12 16 20 20 20

TUBE LENGTH (in.) 26.1 34.0 37.9 45.8 53.7

NUMBER OF CIRCUITS 4 6 — 4 8 16— 1020 —10201020

NUMBER OF TXVs 22—222—22—2222

NUMBER OF CIRCUITS/TXV† 23—248—510—510510

SUCTION CONNECTIONS

(in. OD)

DISTRIBUTOR CONNECTIONS

(in. OD)

4-ROW COIL

Circuit Equivalent Length (ft) 52 26 — 62 32 — — 34 18 — 40 20 45 23

Distributor Tube Length (in.)

Face Split 11 11 — 11 11 — — 11 18 — 11 18 11 18

Row Split 11 11 — 11 15 — — 16 18 — 16 18 16 18

Distributor Nozzle Size** 1

6-ROW COIL

Circuit Equivalent Length (ft) 58 39 — — 47 24 — 51 26 — 59 30 67 34

Distributor Tube Length (in.)

Face Split 11

Row Split 11

Distributor Nozzle Size** 11/211/

8-ROW COIL††

Circuit Equivalent Length (ft) —52— —6332 —6834—78398945

Distributor Tube Length (in.)

Face Split —11

Row Split —13——1516—1618

Distributor Nozzle Size** —11/

7

/

11/

8

7

/

8

1

/211/

1

1

8

7

/

8

2

/2111/2——111/2111/2—111/213 — 111/213 111/213

/213 — — 15 16 — 16 181/2—16181/216 181/

2

1

/2——111/2111/2—111/213 — 111/213 111/213

2

7

—

—

/811/813/

7

/

8

—21/221/

——21/

——21/

—11/813/

8

7

/811/

8

—— 44—5555

2

3—44— 5555

2

3—44— 5555

2

7

—

/

8

—11/813/811/813/

8

7

/

—

8

1

/2—16181/216 181/

7

7

/

/

8

8

7

/

8

8

7

/

8

2

2

SMALL FACE AREA (39LB, 39LC, 39LF)

UNIT SIZE 15 18 21 25

CIRCUITING TYPE Half Full Half Full Half Full Half Full Double

CFM AT 550 FPM 6666 7689 9405 11,275

FACE AREA (sq ft) 12.12 13.98 17.1 20.5

TUBE FACE 26 30 30 36

TUBE LENGTH (in.) 53.7 53.7 65.5 65.5

NUMBER OF CIRCUITS 16 26 15 30 15 30 18 36 72

NUMBER OF TXVs 2 4* 2 4* 2 4* 2 4* 4*

NUMBER OF CIRCUITS/TXV† 6-7 6-7 7-8 7-8 7-8 7-8 9 9 18

SUCTION CONNECTIONS

(in. OD)

DISTRIBUTOR CONNECTIONS

(in. OD)

4-ROW COIL

Circuit Equivalent Length (ft) 45 23 45 23 54 26 54 26 —

Distributor Tube Length (in.)

Face Split 13 16 13 16 13/15 16 16 15 —

Row Split 21 16 23 16 23

Distributor Nozzle Size** 63848484—

6-ROW COIL

Circuit Equivalent Length (ft) 67 34 67 34 81 40 — 40 —

Distributor Tube Length (in.)

Face Split 13 16 13 16 13/15 16 — 16

Row Split 21 16 23

Distributor Nozzle Size** 638484—4 —

8-ROW COIL

Circuit Equivalent Length (ft) 89 45 89 45 — 54 — 54 26

Distributor Tube Length (in.)

Face Split 13 16 15 16 — 16 — 16

Row Split 21 16 23

Distributor Nozzle Size** 6384—4— 4 8

LEGEND

AHU — Air-Handling Unit Selection Program

TXV — Thermostatic Expansion Valve (Field-supplied)

*May be field manifolded for either face split or row split.

†Where each TXV has the same number of circuits, that number is

shown once. When coil has an uneven number of circuits per TXV,

both values are shown.

3

1

/

8

7

/

8

13/

7

/8-11/

13/

8

1

/

2

1

/

2

8

7

/

8

8

13/

8

7

/8-11/

16 231/

13/

8

7

/8-11/

8

1

/

13/

8

7

/8-11/

8

2

2

8

16 26 15 —

16 — 163/

16 — 16 — 163/

**Factory-supplied distributors have factory-selected nozzle sizes

shown. If necessary, replace factory-supplied nozzles with fieldsupplied and installed nozzles. Consult Electronic Catalog AHU

selection program for correct nozzle selection.

††Not available on 39LB units.

13/

11/

8

8

13/

11/

8

8

3

/

4

4

3

/

4

4

15/

13/

—

—

16

16

8

8

21

Table 8 — Distributor Part Numbers

Fig. 27 — Expansion Valve Piping

Fig. 28 — Distributor and Hot Gas Bypass

Auxiliary Side Connector

PART N O.

Sporlan Carrier Type Size

1

1112-2-

/4EA07NC261 2

1

/4EA07FC027 3

1112-3-

1

/4EA07NC262 4

1112-4-

1

1112-5-

/4EA07NC263 5

1

1112-6-

/4EA07NC264 6

1

/4EA07HC207 7

1113-71113-8-1/4EA07HC208 8

1

/4EA07KC240 8

1115-8-

1

/4EA07KC241 9

1115-91115-101116-11-

1117-111117-121117-131126-141126-151126-161126-17-

1

/4EA07KC242 10

1

/4EA07HC011 11

1

/4EA07LC510 11

1

/4EA07HC012 12

1

/4EA07HC013 13

1

/4EA07TC290 14

1

/4EA07HC015 15

1

/4EA07TC207 16

1

/4EA07HC017 17

NO.

OF

TUBES

CONNECTION

OD (in.)

0.88 G

1.12 E 3 to 30

1.38 C 3 to 50

SPORLAN

NOZZLE

3

/4 to 12

Table 9 — Side Connector (Hot Gas Bypass) Data

SPORLAN

TYPE

ASC-5-4 —

ASC-7-4 EA19BA504

ASC-9-5 EA19BA705 1

ASC-11-7 EA19BA905 1

ASC-13-9 — 1

CARRIER

PART N O.

Inlet — ODM Solder Outlet — ODF Solder Auxiliary — ODF Solder

5

/

8

7

/

8

1

/

8

3

/

8

5

/

8

CONNECTION SIZES (in.)

5

/

8

7

/

8

11/

8

13/

8

15/

8

SPORLAN

ASC-5-4

ASC-7-4

ASC-9-5 1

ASC-11-7 1

ASC-13-9 1

LEGEND

ODF — Outside Diameter, Female

ODM — Outside Diameter, Male

TYPE

11/

USED WITH

DISTRIBUTOR TYPE

1

/

2

1

/

2

5

/

8

7

/

8

8

1620, 1622 J

1112, 1113 G

1115, 1116 E

1117, 1126 C

1125, 1127, 1143 A

NOZZLE

SIZE

DIMENSIONS (in.)

ABCDEF

5

/8 ODM5/8 ODF 1.88 0.95 1.251/2 ODM

7

/8 ODM7/8 ODF 2.25 1.06 1.381/2 ODM

1

/8 ODM 11/8 ODF 2.81 1.47 1.62 15/8 ODM

3

/8 ODM 13/8 ODF 3.53 1.89 2.19 17/8 ODM

5

/8 ODM 15/8 ODF 3.72 1.83 2.75 11/8 ODM

22

UNLOADING CONSIDERATIONS — Direct expansion coils

can have two intertwined refrigerant circuits. In addition, quarter, half, full and double circuiting configurations are offered to

allow optimum system performance and oil return at full and

part-load operation.

Circuiting selection should result in a circuit loading of 0.8

to 2.0 tons per circuit at design load. Circuit loading must be

evaluated at minimum load to ensure that it does not drop

below 0.6 tons per circuit. Solenoid valves may be used, if necessary, to shut off the refrigerant supply to individual expansion

valves to maintain adequate coil circuit loading.

Compressor minimum unloading and TXV quantity is necessary to determine minimum tonnage per circuit.

Minimum Unloading Equation: