Carrier 38TDB060310, 38TDB024300, 38TDB036300, 38TDB037300, 38TDB048300 Installation Guide

...

38TDB

HEAI1NG & COOLING

Visit WW w.calTit_r+com

Installation and Start-Up Instructions

NOTE: Read the entire instruction manual before starting the

installation.

This symbol --_ indicates a change since the last issue.

SAFETY CONSIDERATIONS

hnproper installation, adjustment, alteration, service, maintenance.

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized "kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safe_ codes. Wear safety, glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions thor-

oughly and follow all warnings or cautions included in literature

and attached to the unit. Consult local building codes and National

Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol z_ •

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, CAU-

TION, and NOTE. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which will

result in severe personal injury or death. WARNING signifies

haz,'u'ds which could result in personal injury or death. CAUTION

is used to identify unsat_ practices which would result in minor

personal injury or product and property damage. NOTE is used to

highlight suggestions which wUl result in enhanced installation.

reliability, or operation.

V_I

Before installing, modifying, or servicing system, main elec-

trical disconnect switch must be in the OPT position. There

may be more than 1 disconnect switch. Lock out and tag

switch with a suitable warning label. Electrical shock can

cause personal injury or death.

INSTALLATION RECOMMENDATIONS

NOTE: In some cases noise in the living m'ea has been traced to

gas pulsations from improper installation of equipment.

I. Locate unit away from windows, patios, decks, etc. where unit

operation sound may disturb customer.

2. Ensure that vapor and liquid tube diameters are appropriate to

capacity of unit.

WeatherMaker TMTwo-Speed

Air Conditioning Unit with Puron®

A98516

Fig. 1reModel 38TDB

3. Run refrigerant tubes as directly as possible by avoiding

unnecessary, turnsand bends.

4. When passing refrigerant tubes through the wall, seal opening

with RTV or other pliable silicon-based caulk. (See Fig. 2.)

5. Avoid direct tubing contact with water pipes, duct work, floor

joists, wall studs, floors, and walls.

6. Do not suspend refrigerant tubing from joists and studs with a

rigid wire or strap which comes in direct contact with tubing.

(See Fig. 2.)

7. Ensure that tubing insulation is pliable and completely sur-

rounds vapor tube.

8. When necessary, use hanger straps which are 1 in. wide and

conform to shape of tubing insulation. (See Fig. 2.)

9. Isolate hanger straps from insulation by using metal sleeves

bent to conform to shape of insulation.

Outdoor unit contains system refrigerant charge for operation with

indoor unit of the same size when connected by 15 fl of

field-supplied or factory accessory tubing. For proper unit opera-

tion, check refrigerant charge using charging information located

on control box cover.

IMPORTANT: Maximum liquid-line size is 3/8 in. O.D. for all

residential applications.

IMPORTANT: Only install the factory-supplied Puron® (R-

410At air conditioner liquid line filter drier. Obtain replacement

filter driers from your local distributor.

INSTALLATION

Step l_heck Equipment and Job Site

UNPACK UNIT

Move to final location. Remove carton, taking care not to damage

unit.

Manufacturer recycles the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 101 Catalog No. 533-80059 Pdnted in U.S.A. Form 38TDB-4SI 1 8-02

Pg

Replaces:

38TDB-3SI

3/8-1N.DIA TIEDOWN

KNOCKOUTS IN BASEPAN

INSU L/_TION

THROUGH THE WALL

STRAP----, _

(A_AONTU(NEB_

._ 0 _VAPOF1 TUBE

1 IQUID TUBE

I IJ_-J°'sT

SUSPENSION

- VAPOR TUBE

A01383

Fig. 2--Connecting Tubing Installation

INSPECT EQUIPMENT

File claim with shipping company prior to installation if shipment

is damaged or incomplete.

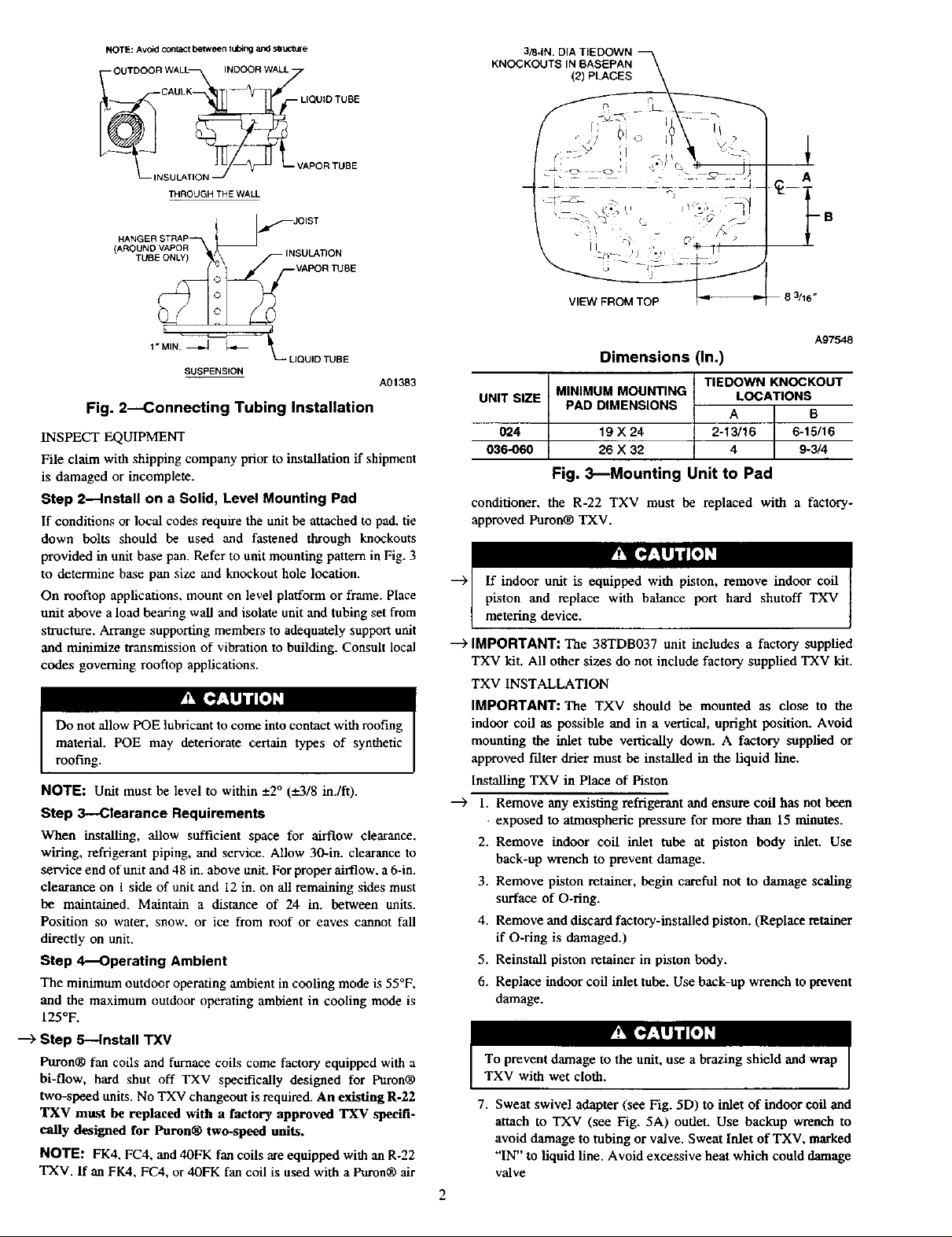

Step 2--Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad, tie

down bolts should be used and fastened through knockouts

provided in unit base pan. Refer to unit mounting pat_m in Fig. 3

to determine base pan size and knockout hole location.

On rooftop applications, mount on level platform or frame. Place

unit above a load bearing wall and isolate unit and tubing set from

structure. Arrange supporting members to adequately support unit

and minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

NOTE: Unit must be level to within _+2° (-+3/8 in.fit).

Step 3--Clearance Requirements

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Allow 30-in. clearance to

service end of unit and 48 in. above unit. For proper airflow, a 6-in.

clearance on l side of unit and i2 in. on all remaining sides must

be maintained. Maintain a distance of 24 in. between units.

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

Step 4_Operating Ambient

The minimum outdoor operating ambient in cooling mode is 55°F,

and the maximum outdoor operating ambient in cooling mode is

125°F.

Step 5--Install TXV

Puron® fan coils and furnace coils come factory equipped with a

bi-flow, hard shut off TXV specifically designed for Puron®

two-speed units. No TXV changeout is required. An existing R-22

TXV must be replaced with a factory approved TXV specifi-

cally designed for Puron® two-speed units.

NOTE: FK4, FC4, and 40FK fan coils are equipped with an R-22

TXV. If an FK4, FC4, or 40FK fan coil is used with a Puron® air

_L_ _ __ __ --2:_

8 3/16"

Dimensions (In.)

UNIT SIZE MINIMUM MOUNTING

024 19 X 24

036-060 26 X 32

PAD DIMENSIONS

TIEDOWN KNOCKOUT

LOCATIONS

A B

2-13/16 6-15/16

4 9-3/4

Fig. 3---Mounting Unit to Pad

conditioner, the R-22 TXV must be replaced with a factory-

approved Puron® TXV.

--_ IMPORTANT: The 38TDB037 unit includes a factory supplied

TXV kit. All other sizes do not include factory supplied TXV kit.

TXV INSTALLATION

IMPORTANT: The TXV should be mounted as close to the

indoor coil as possible and in a vertical, upright position. Avoid

mounting the inlet tube vertically down. A factory supplied or

approved filter drier must be installed in the liquid line.

Installing TXV in Place of Piston

---) I. Remove any existing refrigerant and ensure coil has not been

• exposed to atmospheric pressure for more than 15 minutes.

2. Remove indoor coil inlet tube at piston body inieL Use

back-up wrench to prevent damage.

3. Remove piston retainer, begin careful not to damage scaling

surface of O-ring.

4. Remove and discard factory-installed piston. (Replace retainer

if O-ring is damaged.)

5. Reinstall piston retainer in piston body.

6. Replace indoor coil inlet tube. Use back-up wrench to prevent

damage.

7. Sweat swivel adapter (see Fig. 5D) to inlet of indoor coil and

attach to TXV (see Fig. 5A) outlet. Use backup wrench to

avoid damage to tubing or valve. Sweat Inlet of TXV, marked

"IN" to liquid line. Avoid excessive heat which could damage

valve

2

A97548

BULB

TUBE

EXPANSION

VALVE

Fig. 4--TXV Installed

8. Install vapor elbow (see Fig. 5B) with equalizer adapter to

suction tube of line set and suction connection to indoor coil.

Adapter has a l/4-in, male connector or attaching equalizer

tube.

9. Connect equalizer tube of TXV to l/4-in, equalizer fitting on

vapor line adapter.

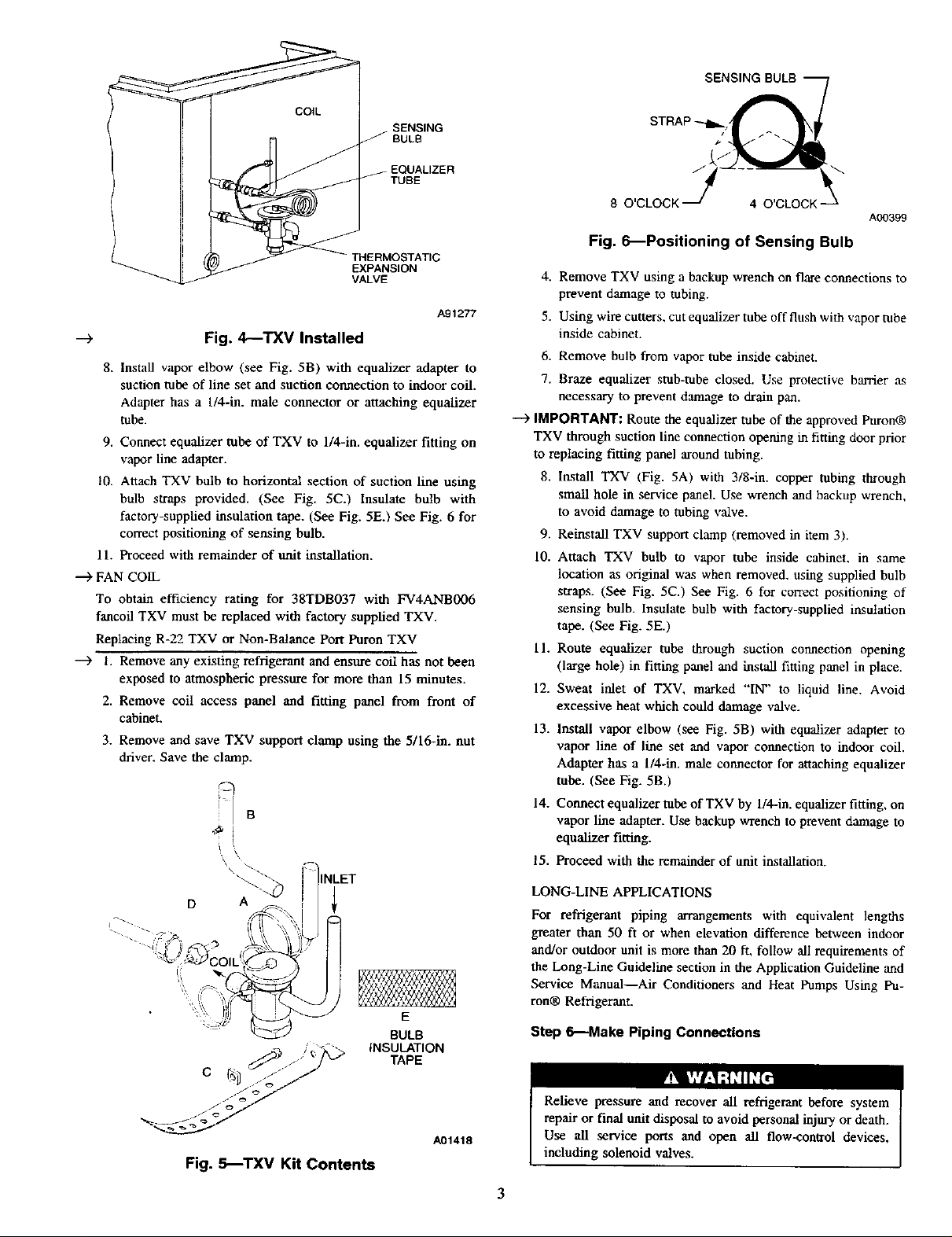

I0. Attach TXV bulb to horizontal section of suction line using

bulb straps provided. (See Fig. 5C.) Insulate bulb with

factory-supplied insulation tape. (See Fig. 5E.) See Fig. 6 for

correct positioning of sensing bulb.

11. Proceed with remainder of unit installation.

---)"FAN COIL

To obtain efficiency rating for 38TDB037 with FV4ANB006

fancoil TXV must be replaced with factory supplied TXV.

Replacing R-22 TXV or Non-Balance Port Puron TXV

l. Remove any existing refrigerant and ensure coil has not been

exposed to atmospheric pressure for more than 15 minutes.

2. Remove coil access panel and fitting panel from front of

cabinet.

3. Remove and save TXV support clamp using the 5/16-in. nut

driver. Save the clamp.

A91277

SENSING BULB --

8 O'CLOCK J 4 O'CLOCK--

A00399

Fig. 6_Positioning of Sensing Bulb

4. Remove TXV using a backup wrench on flare connections to

prevent damagetotubing.

5. Using wirecuUers, cutequalizertubeoffflushwithvaportube

inside cabinet.

6. Remove bulb from vapor mbe inside cabinet.

7. Braze equalizer stub-tube closed. Use protective barrier as

necessary to prevent damage to drain pan.

----)IMPORTANT: Route the equalizer tubeof the approved Puron®

TXV through suction line connection opening in fitting door prior

to replacing fitting panel around tubing.

8. Install TXV (Fig. 5A) with 3/8-in. copper tubing through

small hole in service panel. Use wrench and backup wrench,

to avoid damage to tubing valve.

9. Reinstall TXV support clamp (removed in item 3).

10.

Attach TXV bulb to vapor tube inside cabinet, in same

location as ori_nal was when removed, using supplied bulb

straps. (See Fig. 5C.) See Fig. 6 for correct positioning of

sensing bulb. Insulate bulb with factory-supplied insulation

tape. (See Fig. 5E.)

11. Route equalizer tube through suction connection opening

(large hole) in fitting panel and install fitting panel in place.

12. Sweat inlet of TXV, masked "IN" to liquid line. Avoid

excessive heat which could damage valve.

13. Install vapor elbow (see Fig. 5B) with equalizer adapter to

vapor line of line set and vapor connection to indoor coil.

Adapter has a l/4-in, male connector for attaching equalizer

tube. (See Fig. 5B.)

14. Connect equalizer tube of TXV by l/4-in, equalizer fitting, on

vapor line adapter. Use backup wrench to prevent damage to

equalizer fitting.

15. Proceed with the remainder of unit installation.

D

Fig. _TXV Kit Contents

E

BULB

iNSULATION

TAPE

LONG-LINE APPLICATIONS

For refrigerant piping arrangements with equivalent lengths

greater than 50 ft or when elevation difference between indoor

and/or outdoor unit is more than 20 ft, follow all requirements of

the Long-Line Guideline section in the Application Guideline and

Service Manual--Air Conditioners and Heat Pumps Using Pu-

ron® Refrigerant.

Step 6_Make Piping Connections

A01418

including solenoid valves.

3

To prevent damage to unit or service valves, observe the

following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. Tubing diameters listed in Table I ,are adequate

for equivalent lengths up to 50 ft. For tubing requirements beyond

50 ft. substantial capacity and performance losses will occur.

Follow the recommendations in the Application Guideline and

Service ManualIAir Conditioners and Heat Pumps Using Pu-

ron® Refrigerant to minimize losses.

Refer to Table 1 for field tubing diameters. Refer to Table 2 for

accessory requirements.

Do not bury lines over 36 in. long.

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

Table liRefrigerant Connections and

Recommended Liquid and Vapor Tube

Diameters (In.)

UNIT

SIZE Connection Tube Connection Tube Connection Tube

024 3/8 3/8 5/8 5/8 5/8 3/4

036 3/8 3/8 3/4 3/4 3/4 7/8

037, 048 3/8 3/8 7/8 7/8 7/8 7/8

060 3/8 3/8 7/8 1-1/8 7/8 1- 1/8

Notes:

1. Tube diameters are for lengths up to 50 equivalent ft.

2. Do not apply capillary tube indoor coils to these units.

OUTDOOR UNIT CONNECTED TO FACTORY-APPROVED

INDOOR UNIT

Outdoor unit contains correct system refrigerant charge for opera-

tion with indoor unit of same size when connected by 15 fi of

field-supplied or factory-accessory tubing. Check refrigerant

charge for maximum efficiency

Installation of filter drier in liquid line is required.

INSTALL LIQUID-LINE FILTER DRIER

Installation of filter drier in liquid line is required. Refer to Fig. 7

and install filter drier as follows:

LIQUID VAPOR VAPOR (LONG-LINE)

Diameter Diameter Diameter Diameter Diameter Diameter

LIQUID-LINE

FILTER-DRIER

SERVICE

VALVE

A01215

Fig. 7--Filter Drier with Sweat Adapter Tube and

Liquid Tube

1. Braze 5 in. connector tube to liquid line service valve. Wrap

filter drier with damp cloth.

2. Braze filter drier between connector tube and liquid tube to

indoor coil. Flow arrow must point tow,'u-d indoor coil.

REFRIGERANT TUBING

Connect vapor tube to fitting on outdoor unit vapor service valves.

Connect liquid tube to filter drier. (See Fig. 7and Table 1.)

SWEAT CONNECTION

Service valves are closed from factory, and ready for brazing. After

wrapping service valve and filter drier with a wet cloth, braze

sweat connections using industry accepted methods and materials.

Do not use soft solder (materials which melt below 800°F).

Consult local code requirements. Refrigerant tubing and indoor

coil are now ready for leak testing. This check should include all

field and factory joints.

LEAK CHECKING

Leak test all joints in indoor, outdoor, and refrigerant tubing.

EVACUATE REFRIGERANT TUBING AND INDOOR COIL

Reliigerant tubes and indoor coil should be evacuated to 500

microns. Always break a vacuum with dr3, nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of

pulling a minimum vacuum of 500 microns and a vacuum gage or

thermistor capable of accurately memsuring this vacuum depth. The

deep vacuum method is the most positive way of _ssuring a system

is free of air and liquid water. (See Fig. 8.)

Triple Evacuation Method

The triple evacuation method should only be used when vacuum

pmnp is capable of pumping down to 28 in. of mercury and system

does not contain any liquid water. Refer to Fig. 9 and proceed a.s

follows:

I. Pump system down to 28 in. of mercury and allow pump to

continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and open

until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr. During

this time, dry, nitrogen will be able to diffuse throughout the

system, absorbing moisture.

50oo--

4500I I

4000 I • _LEAK IN

35oo I I ._" LEA

o oooll -/

,25ooI|

_: 2000 t • ....... ....

1500 I I , VACUUM TIGHT

"1--1_ _ TOO WET

1000 I IF TIGHT

500 _TEM

0 1 2 3 4 5 6 7

MINUTES

Fig. 8---Deep Vacuum Graph

5. Repeat this procedure as indicated in Fig. 9. System will then

contain minimal amounts of contaminants and water vapor.

FINAL TUBING CHECK

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes ,'ue

not nabbing against each other or any sheet metal. Pay close

attention to feeder tubes, making sure wire ties on feeder tubes are

secure and tight.

Step 7_Make Electrical Connections

A95424

DISCONNECT

PER N. E. C. AND/OR

LOCAL CODES

CONTACTOR

[F,ELDPOWE.]

v3, fd A__

[

FIELD GROUND

WIRING j

Fig, 10_Line Power Connections

NOTE: Install branch circuit disconnect of adequate size per

NEC to handle unit starting curtera. Locate disconnect within sight

from and readily accessible from unit. per Section 440-14 of NEC.

ROUTE GROUND AND POWER WIRES

Remove access panel to gain access to unit wiring. Extend wires

from disconnect thl_ugh power wiring hole provided and into unit

control box. Size wires per NEC but not smaller than minimum

wire size shown in Product Data Digest.

The unit cabinet must have as uninterrupted or unbroken

ground to minimize personal injury if an electrical fault

should occur. The ground may consist of electrical wire or

metal conduit when installed in accordance with existing

electrical codes. Failure to follow this warning can result in an

electric shock, fee, or death.

-Q

GROUND

LUG

A91306

Be sure field wiring complies with local and national fire, safety,

and electrlzzal codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

in._tall unit in system where voltage may fluctuate above or below

permissible limits.

NOTEt Use copper wire only between disconnect switch and

unit.

IEVACUATE

IBREAK VACUUM WITH DRY NITROGEN [

_ACUATE]

IBREAK VACUUM WITH DRY NITROGEN [

_ACUATE]

CHECK FOR TIGHT, DRY SYSTEM

(|F IT HOLDS DEEP VACUUM) /

ICHARGESYSTEMI

1

A95425

Fig. 9--'rriple Evacuation Method

CONNECT GROUND AND POWER WIRES

Conae.ct ground _'ire to _ound connection in control box for

safety. Connect power wiring to leads provided as shown in Fig.

IO.

CONNECT CONTROL WIR[NG

Route 24v control wires through control wiring grommet and

counect to leads provided in control box. (See Fig. 11.)

Use No. 18 AWG color-coded, insulated (35°C minimum) wire. If

thermostat is located more than 100 ft from unit, as measured

along the control voltage wires, use No. 16 AWG color-coded wire

to avoid excessive voltage drop.

All wiring must be NEC Class i and must be separated from

incoming power leads.

The outdoor unit requires a minimum of 27va, 24vac control

power.

IMPORTANT: Check factory wiring and wire connections to

ensure temainations are secured properly. Check wire muting to

ensure ,,vires are not in contact with tubing, sheet metal, etc.

Step 8_lnstall Electrical Accessories

GENERAL

Refer to the individual instructions packaged with kits or acces-

sories when installing.

Available electrical accessories include latent capacity control. See

Fig. I i for typical accessory wiring diagrams.

LATENT CAPACITY CONTROL (LCC)

The purpose of an LCC is to provide a dehumidification mode to

assure a 75 percent or less system sensible heat ratio. If indoor unit

installed contains an ECM blower (such ax an FK4C. FV4A, or

40FK fan coil or a 58CVA or 58MVP gas furnace), no LCC is

Loading...

Loading...