Page 1

HEATING & COOLING

Heat Pumps—Outdoor Section

Installation and Start-Up Instructions

NOTE: Read entire instruction before beginning installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock or other condi

tions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions pack

aged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warning or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special require

ments.

It is important to recognize safety information. This is the

safety-alert symbol ^ . When you see this symbol on the unit and

in instructions or manuals, be alert to the potential for personal

injury.

Understand the signal word— DANGER, WARNING, or CAU

TION. These words are used with the safety- alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards that

could result in personal injury or death. CAUTION is used to

identify unsafe practices, which would result in minor personal

injury or product and property damage.

38QRA

Й1

À WARNING

Before installation or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Turn off accessory heater power if applicable. Elec

trical shock can cause personal injury or death.

INSTALLATION

Step 1—Check Equipment

Unpack unit and move to final location. Remove carton taking care

not to damage unit.

Inspect equipment for damage prior to installation. File claim with

shipping company if shipment is damaged or incomplete. Locate

rating plate on unit. It contains information needed to properly

install unit. Check rating plate to be sure unit matches job

specifications.

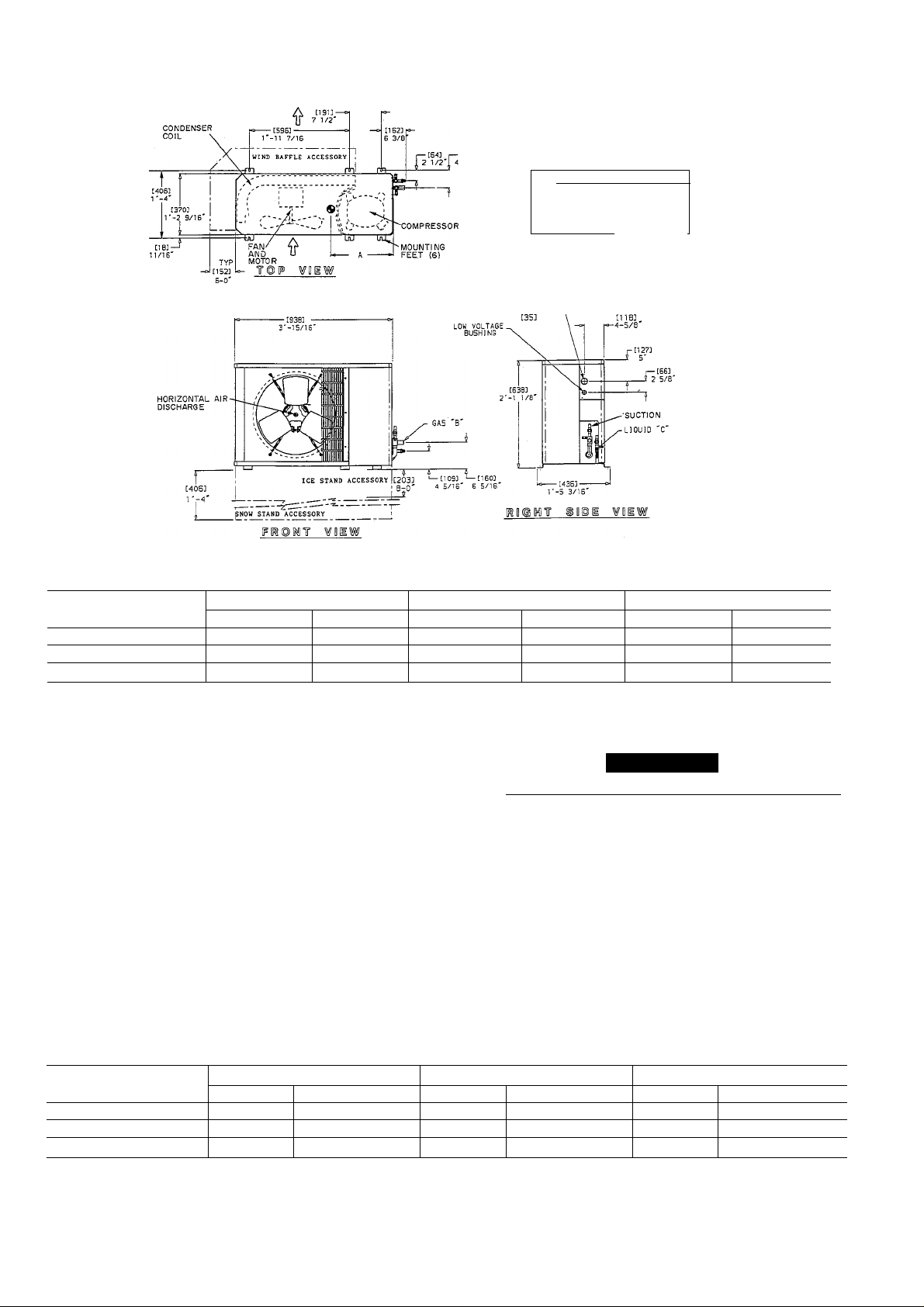

Step 2—Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad,

tiedown bolts should be used and fastened through mounting feet

provided in unit base. Refer to unit mounting pattern to determine

base size and knockout hole locations. (See Fig. 2.)

Allow sufficient space for airflow clearance, wiring, refrigerant

piping and servicing of unit. Locate unit so condenser airflow is

unrestricted on both sides. A minimum 6-in. (152mm) clearance

above and 6 ft (1.83m) between units must be maintained. (See

Fig. 2.)

Fig. 1—Model 38QRA

be mounted on a level pad directly on base legs or

g m>mt( ШОП accessory snow stand at support points. See Fig. 2 and

4^^Р^ВДег of gravity. Position unit so water or ice from roof

i^aqjpt drop directly onto unit.

levate Unit

: drainage the heat pump must be raised off the mounting

surface? Use accessory snow rack or ice stand where prolonged

subfreezing temperatures or heavy snow occur. Refer to separate

installation instructions packaged with these accessories.

In rooftop applications, locate unit at least 6 in. (152mm) above

roof surface on a level platform or frame. Place unit above a loadbearing wall and isolate unit and tubing set from structure. Arrange

supporting members to adequately support unit and minimize

transmission of vibration to building. Consult local codes govern

ing rooftop applications.

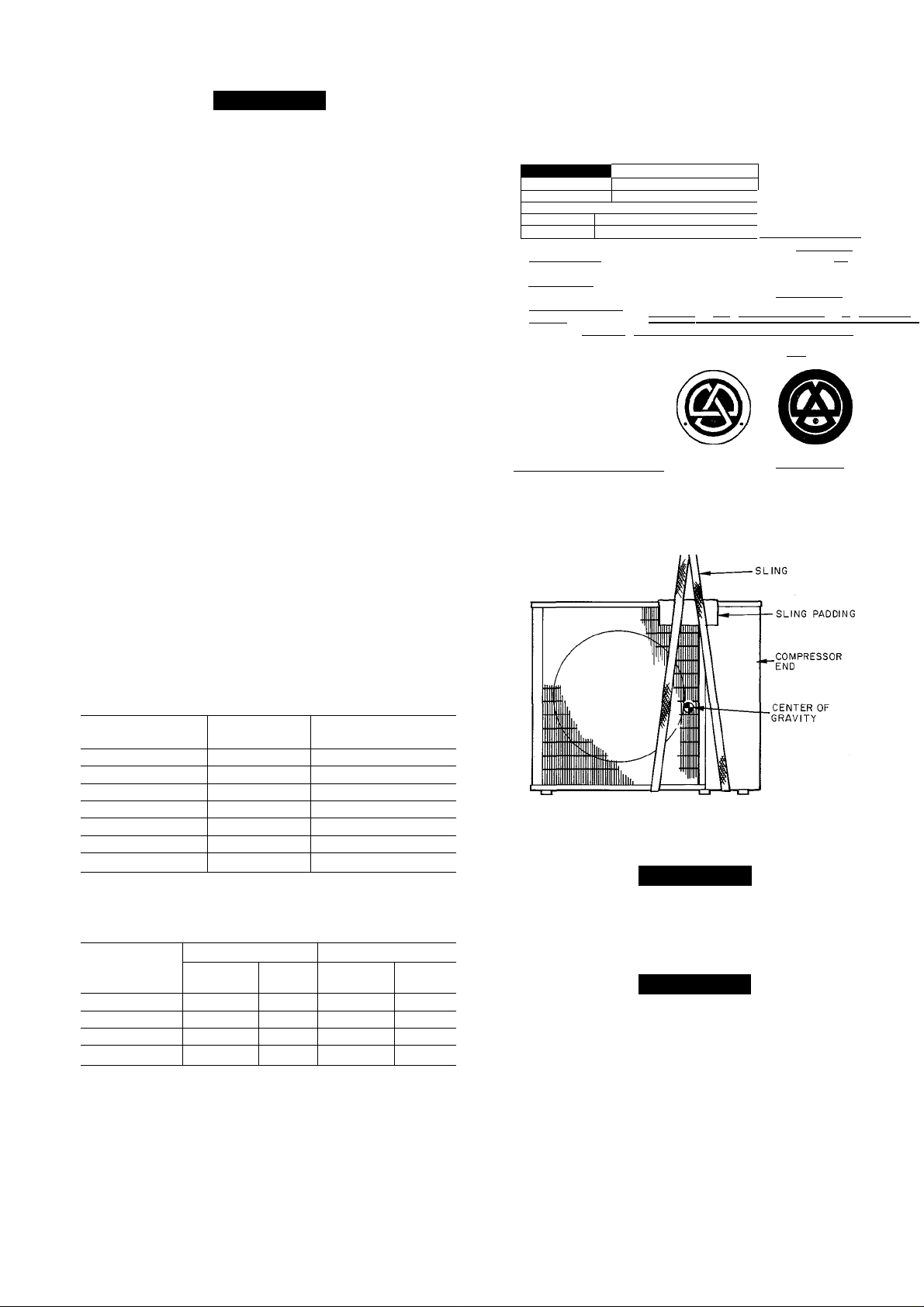

RIGGING

When lifting unit for rooftop mounting, keep unit upright. Lift unit

using a sling. Use cardboard or padding under sling, and spreader

bars to prevent sling damage to unit. (See Fig. 4.) See Figs. 2 and

4 for center of gravity reference. Install unit so that coil does not

face into prevailing winds. If this cannot be done, and constant

A90280

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 1 4

Tab 5a 5a

PC 101 Catalog No. 533-858

Printed in U.S.A. Form 38QRA-1SI

Pg 1

10-91

Replaces: New

Page 2

1-6

HIGH VOLTAGE

1-1/8' DIA.

CLEARANCES FOR SERVICE AND AIRFLOW.

ALLOW 6 IN. ABOVE UNIT.

T

SIN.

i

TOP VIEW

,1

\

B'i i COMPr'i

3FT

Jl

V J* ' - - '

~UU LfCr

A90304

UNIT SIZE

018—036 10

036 30

048-060 1 & 30

In.

16 406.4

18-7/16

18-7/16

A

(mm)

468.3

468.3

Fig. 2—Dimensional Drawing—38QRA018—060

winds above 25 mph are expected, use Accessory Wind Baffle,

part number KSAWBOIOIAAA or KSAWB0201AAA. See in

structions provided with accessory kit for installation.

B

In. (mm)

36-15/16 938.2

In-. (mm)

23-7/16 595.3

C

44-9/16 1131.9 30-1/2 774.7

44-9/16 1131.9 30-1/2 774.7

A CAUTION

I Be sure unit panels are securely in place prior to rigging. [

Step A—Replace Indoor AccuRater® Piston, if required

Check indoor coil piston to see if it matches the required piston

shown on unit rating plate. If it does not match, replace indoor coil

piston with piston shipped with this unit. (See Fig. 5.) The piston

shipped with outdoor unit is correct for any approved indoor coil

combination. Note that Type A pistons are used on indoor units

and Type B pistons are used on 38QRA outdoor units. Do not

interchange piston types. (See Fig. 5.) For optimum cyclic perfor

mance, installation of liquid solenoid valve is recommended.

Consult local distributor for liquid solenoid valve kit and hard start

kit part number, if required.

UNIT SIZE

018—036 1 0 23x42

036 3 0 24 X 50

048—060 1 and 3 0

SUPPORT FEET

In.

24 X 50

Table 1—Minimum Mounting Pad Dimensions

SNOW STAND

(mm)

584.2 X 1066.8

609.6x 1270.0 28 X 50 711.2 X 1270.0

609.6 X 1270.0

In. (mm)

26 X 42

660.4 X 1066.8 26 X 42

28 X 50 711.2 X 1270.0

ICE STAND

In.

(mm)

660.4 X 1066.8

26x50 660.4 X 1270.0

26x50

660.4 X 1270.0

Page 3

A CAUTION

DO NOT BURY MORE THAN 36 IN. (914mm) OF RE

FRIGERANT TUBING IN GROUND. If any section of

tubing is buried, there must be a 6-in.(152mm) vertical rise to

the valve connections on the outdoor unit. If more than the

recommended length is buried, refrigerant may migrate to

cooler buried section during extended periods of unit shut

down, causing refrigerant slugging and possible compressor

damage at start-up.

Step 5—Make Piping Connections

Outdoor units may be connected to indoor sections using accessory

tubing package or field-supplied tubing of refrigerant grade,

correct size, and condition. The liquid- and vapor-tube diameters

can be determined by using Table 3. For tubing requirements

beyond 50 ft (15.24m), obtain information from your local

distributor.

If either refrigerant tubing or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 1000

microns to eliminate contamination and moisture in the system.

Run refrigerant tubes as directly as possible, avoiding unnecessary

turns and bends. Suspend refrigerant tubes so they do not damage

insulation on vapor tube and do not transmit vibration to the

structure. Also, when passing refrigerant tubes through the wall,

seal opening so vibration is not transmitted to stmcture. Leave

some slack in refrigerant tubes between structure and unit to

absorb vibration.

OUTDOOR UNIT CONNECTED TO FACTORY APPROVED

INDOOR UNIT — Outdoor unit contains holding refrigerant

charge only. See Table 2 for correct system charge when con

nected by 25 ft (7.62m) of field-supplied or factory accessory

tubing. Add charge as required to achieve correct total. For long

line application information, contact your local distributor.

CARRIER CORP.

MODEL N0.

SERIAL N0.

1 DF.SIGN/TEST PRESSURE GAGE 1

HIGH PSI 300 kPa 2068

TSEZ'PSl

COMPRESSOR

FAN MOTOR

powgPi Supply

VOLTAGE RAN5F

MIN ¿I

SYSTEM

IN 46206

150 TPo 1034

VOLTS AC

EHÜI £LA

VOLTS

MAX MIN

IMAX■ FU5E/HASR TyRE'';CB; AHPT

PER Installation InSFRuCHW

V MADE IN MEXICO

Fig. 3—Unit Rating Piate

SUITABLE FOR

OUTDOOR USE

REFRIGERANT:

R-22

HOLDING CHARGE

PI5T0N

nn

Phi Ih7I

CERTIFICATION APPLIES QH.Y

IKN THE CO(f>LETE SYSTD1

IS LISTED WITH ARI

I 317204-401 REV.

LBS kg

OP

A90282

Table 2—Refrigerant Charge

OUTDOOR

UNIT

018

024 1

030

036

036

048

060

PHASE

1

1

1

3

1 &3 9.44

1 &3

CHARGE (LB)

4.25

4.75

6.00

7.00

11.63

11.75

Table 3—Refrigerant Connections and Recom

mended Liquid and Vapor Tube Diameters (In.)

UNIT

SIZE

018,024,030 3/8

036 3/8 3/8

048 3/8 3/8 7/8

060 3/8 3/8 7/8

Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50

ft, consult Long-Line Application Guideline.

LIQUID

Connect

Dia

Tube

Dia

3/8

REFRIGERANT TUBING — Connect tubing to fittings on out

door unit vapor and liquid service valves. (See Fig. 2.) Remove

brass piston retainer. Insert outdoor piston shipped in bag with

indoor piston in the liquid service valve, replace brass piston

retainer and connect sweat adapter provided. (See Fig. 5.)

VAPOR

Connect

Dia

5/8

3/4

Tube

Dia

5/8

3/4

7/8

1-1/8

Fig. 4—Rigging

A90285

A CAUTION

A brazing shield MUST be used when tubing sets ate being

brazed to the service valves to prevent damage to the painted

unit surface.

A CAUTION

To avoid valve damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet cloth.

FILTER DRIER — Install in field liquid line, if used.

SWEAT CONNECTION — Use refrigerant grade tubing. Service

valves are closed from factory and ready for brazing. After

wrapping the service valve with a wet cloth, the tubing set can be

brazed to the service valve using either silver bearing or non-silver

bearing brazing material. Consult local code requirements. Refrig

erant tubing and indoor coil are now ready for leak testing. This

check should include all field and factory joints.

Page 4

NOTE: Unit is shipped with R-22 factory holding charge indi

cated on unit rating plate.

TYPE A

A90287

TYPE B

A90300

Fig. 5—AccuRater® (Bypass Type Component)

Step 6—Make Electrical Connections

Be sure field wiring complies with local and national fire, safety

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device and minimum circuit amps for wire size.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

NOTE: Use copper wire only between disconnect switch and

unit.

BRANCH CIRCUIT DISCONNECT - Install branch circuit dis

connect per NEC of adequate size to handle unit starting current.

Locate disconnect within sight from and readily accessible from

unit, per Section 440-14 of NEC.

A WARNING

According to NEC, ANSI/NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken ground, to

minimize personal injury if an electrical fault should occur.

The ground may consist of electrical wire or metal conduit

when installed in accordance with existing electrical codes.

Failure to follow this warning could result in an electric

shock, fire, or death.

GROUND AND POWER WIRES — Route power wires through

opening in unit side panel and connect in unit control box as shown

on unit wiring label and Fig. 6. Unit must be grounded.

Factory Wiring

Fig. 6—Line Power Connections

A91315

CONTROL CIRCUIT WIRING - Control voltage is 24 volts (40

va minimum). See Fig.. 7 and unit wiring label for field-supplied

wiring details. Route control wires through opening in unit side

panel to connection in unit control box. Use furnace or fan coil

transformer as 24 volt (40 va minimum) supply for system or use

accessory transformer.

NOTE: Use No. 18 AWG color-coded, insulated (35 C mini

mum) wires. If thermostat is located more than 100 ft from unit (as

measured along the control voltage wires), use No. 16 AWG

color-coded wires to avoid excessive voltage drop.

NOTE: The defrost timer is factory set for 90-minute cycles. The

timer can be field set for 30- and 50-minute cycles depending on

defrost conditions in your geographical location.

Step 7—Install Electrical Accessories

Refer to the individual instructions packaged with kits or acces

sories when installing.

See your local distributor or dealer for specific component

information.

Step 8—Start-Up

1. When equipped with a crankcase heater, energize crankcase

heater a minimum of 24 hours before starting unit. To energize

heater only, set thermostat at OFF position and close electrical

disconnect to outdoor unit.

2. Fully back seat (open) liquid- and vapor-tube service valves.

3. Unit is shipped with valve stem(s) front seated and caps

installed. Replace stem caps after system is opened to refrig

erant flow (back seated). Replace caps finger tight plus

1/6-tum.

4. Close electrical disconnects to energize system.

5. Set room thermostat at desired temperature.

6. Set room thermostat at HEAT or COOL and fan switch at ON

or AUTO, as desired. Operate unit for 15 minutes.

SEQUENCE OF OPERATION — With power supplied to indoor

and outdoor units, transformer and crankcase heater are energized.

Page 5

SYSTEMS WITHOUT OUTDOOR THERMOSTATS

Thermostat Indoor Outdoor

Subbase ^ . ,

SYSTEMS WITH ONE OUTDOOR THERMOSTAT

Thermostat Indoor

Subbase

Splice Terminal

Connection Board

D VWTH FF1A, 40nc FAN COIL

Terminal

Board

! V FIELO SPLICE

Thermostat

Subbase

SYSTEMS WITH TWO OUTDOOR THERMOSTATS

Terminal

Board

USED WITH FD3A, FB4A. FB5A. FK4A,

40AQ, 40DQ, 40QBAÎH OR 40YAWYZ

Terminal

Board

A88285

When the thermostat is satisfied, its contacts open, de-energizing

the contactor and sequencer. All heaters and motors should stop.

Defrost

The defrost control is a time/temperature control which includes a

field-selectable time period between defrost cycles (30, 50 and 90

minutes, factory set at 90 minutes). Quick connects are located at

board edge.

The electronic timer and the defrost cycle will start only when the

contactor is energized, defrost thermostat is closed and the timing

device has completed one cycle.

The defrost mode is identical to the cooling mode except that the

outdoor fan motor stops and second stage heat is turned on to

continue warming the conditioned space.

A WARNING

Service valve gage ports are not equipped with Schrader

valves. To prevent personal injury, make sure gage manifold

is connected to the valve gage ports before moving valves off

fully back seated position. Wear safety glasses and gloves

when handling refrigerant.

ik CAUTION

Compressor damage may occur if system is overcharged. |

USED WITH {?1A. 4QRC FAN COIL

REMOVE FAaORYINSTAUEO JUMPERS ON INDOOR FAN COIL TERMINAL BOARD WHEN INSTALUNSOUTDOORTHERMOSTATS

- FACTOflVVVIRlNG

■ FIEIOWIRING

OU'BOORTHERMOSTAT

SUPPIEUENTAI. HEAT RELAV

A88286

Fig. 7—Typical Circuit Connections

Cooling

On a “call for cooling”, the thermostat “makes” circuits R- O,

R-Y and R-G. Circuit R-0 energizes the reversing valve, switching

it to cooling position. Circuit R-Y energizes the contactor, starting

outdoor fan motor and compressor circuit. R-G energizes the

indoor unit blower relay, starting the indoor blower motor on high

speed.

When the thermostat is satisfied, its contacts open, de-energizing

the contactor and blower relay. Compressor and motors should

stop.

Heating

On a “call for heating”, the thermostat “makes’ ’ circuits R- Y and

R-G. Circuit R-Y energizes contactor, starting outdoor fan motor

and compressor. Circuit R-G energizes the indoor blower relay,

starting the blower motor on high speed.

Should the temperature continue to fall, R-W2 is made through the

second-stage room thermostat bulb. Circuit R-W2 energizes a

sequencer, bringing on the first bank of supplemental electric heat

and providing electrical potential to the second heater sequencer (if

used). If the outdoor temperature falls below the setting of the

outdoor thermostat, (field-installed operation) the contacts close to

complete the circuit and bring on the second bank of supplemental

electric heat.

Step 9—Refrigerant Charging

NOTE: See Table 2 for correct system charge of tested combi

nation.

Cooling

To check and adjust charge during cooling season, use Tables 4

and 5 and the following procedure:

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suction valve

service port.

Table 4—Superheat Charging Table

(Superheat Entering Suction Service Valve)

OUTDOOR

TEMP

—Do not attempt to charge system under these conditions or refrigerant

slugging may occur.

50

55

9

60 7 10 12 15 18

65

70

75

80 — — — — 5 8

85

90

95

100 8 12 15 20

105 5 9 13

110

115 8

—

_

3. Measure suction line temperature by attaching a service

thermometer to unit suction line near suction valve. Insulate

thermometer for accurate readings.

4. Measure outdoor coil inlet air dry-bulb temperature with a

second thermometer.

5. Measure indoor coil inlet air wet-bulb temperature with a sling

psychrometer.

INDOOR COIL ENTERING AIR (F) WB

52 54 56 58 60

17

12 14

6 10 13

7 10 13 16

— —

6 9

62 64 66

23 26 29

20

24 27

21

16 19 21

19 21

12 15 18 21 24 28 31

12

8

5 9 13 16 20

68 70

32

35 37 40

30

33 35

24 27 30

24 27

21

15 18

11

15 19 22 26 30

6 10 14

6 11

72

38 40 43

33 36 38

33 36 39

30

25 28

24 27 31

22 25 29

18

17 22 26

15

14 18 23

74

42

34 37

31 35

23 27

20 25

76

45

41

33

Page 6

6. Using Table 4, find air temperature entering outdoor coil and

wet-bulb temperature entering indoor coil. At this intersection

note the superheat.

Table 5—Required Suction Tube Temperature (F)

(Entering Suction Service Valve)

A CAUTION

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system. This

can cause compressor flooding.

A CAUTION

Service valves must be fully back seated to close service port.

There is no Schrader valve at the service port and failure to

back seat the valve could result in loss of system charge or

personal injury.

7. Using Table 5, find superheat temperature and suction pres

sure; note suction line temperature.

8. If unit has higher suction line temperature than charted

temperature, add refrigerant until charted temperature is

reached (+/- 3 F).

9. If unit has lower suction line temperature than charted

temperature, bleed refrigerant until charted temperature is

reached (+/- 3 F).

10. If air temperature entering outdoor coil or pressure at suction

valve changes, charge to new suction line temperature indi

cated in chart.

11. This procedure is valid, independent of indoor air quantity.

TEMP(F)

0

2

4

6

8 43

10

12

14 49 51

16

18 53 55

20

22

24

26

28

30

32

34 69 71

36

38

40 75 77

64.2 67.1

61.5

37

35

37

39

39 41

41

43 45

45 47

45 47

47 49

51

53 55

55 57 59

57

59 61 63

59 61

61

63 65 67 69

63 65 67

65 67

67

69

71

73 75 77 79 81 83

73 75 77

70.0

39 41

41

43

43 45

47 49 51

49

49 51

51 53

53 55

57 59 61 63 65

57

59

61

63 65

69

71 73 75 77

69

71

73 75

73 75

79

79 81

73.0 76.0

43 45 47

45 47

47

'51 53 55 57 59

53

55

57

61 63 65 67 69

63 65

65

67

71

77

81 83

83 85 87

79.2 82.4 85.7

49 51 53

49 51

53 55

55 57

57

, 59

59 61

67

67

69 71 73

69 71

71

73 75

73 75

77

79 81

79

81 83

85

49 51

53 55

59

61 63

63

69

73

77 79

79 81

85 .

87 89

89 91

57

61

65

67

71

75

77

83

85

87

Heating

To check system operation during heating cycle, use Table 6. This

table indicates whether a correct relationship exists between

system operating pressure and air temperatures entering indoor and

outdoor units. In heating mode, check should be made approxi

mately 15 minutes after defrost with unit running with a clean coil.

If pressure and temperature do not match on chart, system

refrigerant charge may not be correct or other system abnormali

ties may exist. Do not use table to adjust refrigerant charge.

When recharging is necessary during heating season, weigh in total

charge as indicated in Table 2. Remove or recycle any refrigerant

remaining in system before recharging. If the system has lost

complete charge, evacuate and recharge by weight. Service port

connections are provided on liquid- and suction-line service

valves. For evacuation and recharging, Dial-a-Charge charging

cylinder, or similar device, is an accurate device for recharging

system by weight.

CARE AND MAINTENANCE

For continuing high performance, and to minimize possible

equipment failure, it is essential that periodic maintenance be

performed on this equipment. Consult your servicing contractor or

users manual for the proper frequency of maintenance. Frequency

of maintenance may vary depending upon geographic areas, such

as coastal applications.

Page 7

Unit

38QRA

018

024

030

036 1 Phase

036 3 Phase

(HIGH PRESSURE AT !

Indoor D17

Bulb

Temp (F)

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

Table 6—Heating Check Chart

HEATING OPERATION PRESSURE TABLE, FIXED RESTRICTOR

Outdoor Temperature (F) Dry Bulb

60

High

Low

Suction 66.8

High

Low

Suction

High 288.0

Low

Suction 73.4

High

Low

Suction

High 254.2

Low

Suction

High 279.9

Low 85.7

Suction 72.7

High 157.7

Low

Suction 48.2

High 186.6

Low

Suction 52.7

High

Low

Suction 56.2

High 226.1

Low

Suction

High 252.0

Low 130.2

Suction

High

Low

Suction

High 193.7 180.4

Low 71.4

Suction 58.1

High 227.8

Low

Suction 65.7

High 235.4

Low 106.7

Suction 72.7

231.0

80.4

257.0

84.5

70.5

87.6

226.9

79.1

67.2

83.1

70.7

64.9 58.9 53.0 46.8 40.1

70.0 62.1 54.2

216.0 205.3

74.5 65.0 55.6 45.8 39.9 34.1 28.0

117.7

65.3 55.4 45.6 35.4 30.2 25.0 19.6

65.8

282.3 241.3 200.3

144.8 121.4 97.9

67.3 56.9 46.4 35.7 31.5 27.3 23.0

79.7

50

208.3 185.6

70.6

57.9

231.6

73.2

60.0

260.0

75.6

62.5

203.2

67.8 56.5 44.9 40.0 35.2 30.2

56.9

222.1 189.9 156.8 155.3 153.8 152.3

65.8

55.1 39.5

251.3

70.9

59.4 46.2

151.3 144.9 138.3

43.1

177.5

45.8 38.9

48.0 39.9 31.5 26.9 22.3 17.6

219.6 213.0 206.3 183.0 159.6 135.6

110.8 103.9 96.8 84.6

230.3 208.5 186.1 177.2 168.3 159.1

118.3

56.5

64.4 57.5

52.3 46.6

200.1

94.6 109.5 124.9

61.1 56.6

222.6

88.3 69.9 50.9 42.9 34.9

62.9 53.0 42.9 35.5 28.1 20.5

40

60.8 53.7 46.6

49.0 42.9 36.8 30.7 24.6

206.1

61.9

49.5 43.2 36.8 30.5

232.0 218.8 205.5 192.3 179.0

63.6

51.6 44.7 37.9

179.4

46.7

48.5

222.6

56.2

37.9

168.4

194.7 183.7 177.4 171.2 164.7

106.4

47.3 37.7 32.2

167.0 153.3 145.8 138.3 130.6

172.4

209.9 196.7

30 20

174.2

194.1 182.1

54.4

55.6

155.0

36.1 31.9 ,

30.6

23.4 22.7

193.1

41.0

32.5

32.6 27.3 22.0

159.0

46.0

31.8

94.2 85.3 76.4 67.3

158.0

73.8 74.8 75.8 76.9

50.3

40.6

143.9 144.9 145.8 146.8

51.9

162.8 151.4

46.8 39.3

47.6

148.2

29.6 28.6 27.5

153.7

36.5 32.1 27.5

28.8 25.1

132.2

153.4

40.4

27.4

167.5

42.1

33.6 26.7 19.5

92.4

41.4 30.8 20.0

187.5

10

140.0

39.5

170.0 158.0

39.6

31.0

141.5 134.5

27.7 23.4

21.9

114.4

126.0

33.4

147.8

34.7 28.9

23.0

72.4

26.6 20.9

177.0

33.9

59.8 26.3

178.4

32.4

31.7

24.1

31.6

24.1

21.2

73.8

21.4

119.7

26.5

16.5

142.1

18.4

59.8

186.8

25.5

168.9

26.7

0

Page 8

Table 6—Heating Check Chart Cont’d

HEATING OPERATION PRESSURE TABLE, FIXED RESTRICTOR

Unit

38QRA

048

060

Indoor Dry

Bulb

Temp (F)

60

70

80

60

70

80

High

Low

Suction

High

Low

Suction

High

Low

Suction

High

Low

Suction

High

Low

Suction

High

Low

Suction

Outdoor Temperature (F) Dry Bulb

60

273.5

82.9

68.3

295.2 256.7

85.2 71.1

69.5 56.9

314.5

87.2

70.6

228.9 210.7

85.9

63.3

258.3

86.9

65.1

290.0

88.4

66.5 57.3 48.2

50

239.3 205.2 170.0 170.0 170.1 170.1

71.3 59.7 47.7 42.2 36.6

57.6 47.0 36.0

218.2 178.5

57.1

44.3 31.3

274.0

70.9

56.1 41.7

74.1

54.6

238.7

74.9 62.9

56.1 47.0

268.7

76.0

233.5 191.8

54.6 37.8

192.5 173.8

62.2 50.0

45.8

219.2 199.0 184.9 170.9

247.4 225.5 209.6

63.7 50.9 42.2 33.5 24.5

40

30 20 10 0

30.9

31.8 2.6 23.2

178.7 179.0 179.2

42.6

26.8

36.8

50.5 41.8 33.0 24.0

37.7

38.7

38.7

28.5

194.3 196.9

35.6

25.5

161.5 149.2 136.6

41.3 32.5 23.5

30.2 23.6

31.0

31.9

34.9 30.9

25.8

33.4

24.2

24.4

193.6 177.2

25.2 18.2

22.9

199.5

31.1

22.9

16.8

156.4

17.5

Copyright 1991 Carrier Corporation Indpis, IN 46206 13015

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

BookI 1 I 4 PC 101 Catalog No. 533-858 Printed in U.S.A. Form 38QRA-1SI Pg 8 10-91 Repiaces: New

Tab I5a|5a

Loading...

Loading...