Page 1

38QN

HEATING & COOLING

Heat Pumps—Outdoor Section

Installation and Start-Up Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be

hazardous due to system pressure and electrical compo

nents. Only trained and qualified service personnel should

install or service air conditioning equipment.

Untrained personnel can perform basic maintenance, such

as cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working

on air conditioning equipment, observe precautions in litera

ture and on tags emd labels attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available. Read these instructions thor

oughly. Consult local building codes and National Electrical

Code (NEC) for special installation requirements.

A WARNING

Before installing or servicing unit, always turn off main

power to system. There may be more than one discon

nect switch. Turn off accessory heater power if applica

ble. Electrical shock can cause personal injury.

INSTALLATION

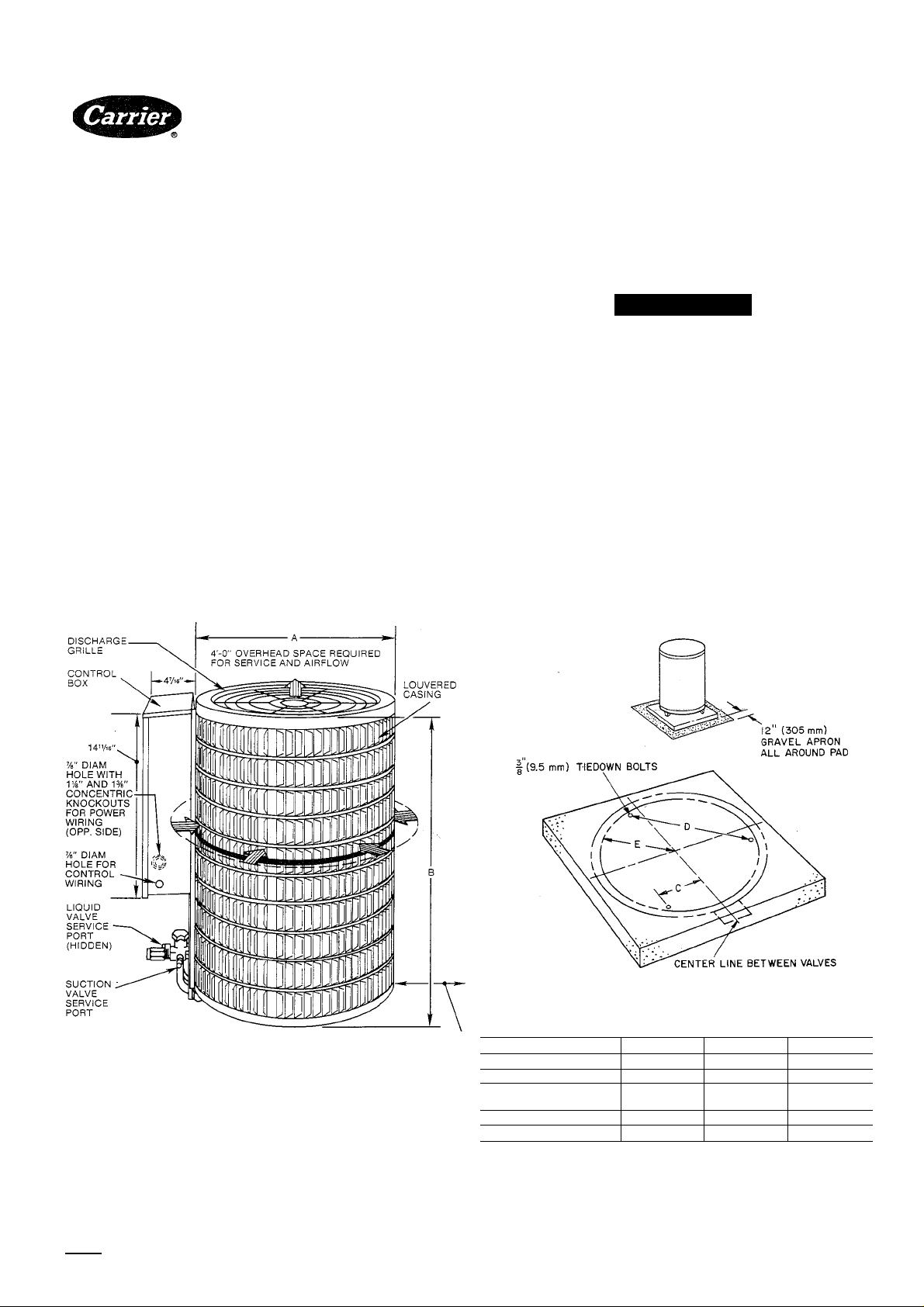

Step 1—Check Equipment and Jobsite—Install on a sohd,

level mounting pad. It is recommended that unit be

attached to pad using tiedown bolts. Fasten unit to pad

using holes provided in unit mounting feet. See Fig. 1.

A87150

Dimensions (ft-in.)

AIRFLOW

A86167

r-6" AIRFLOW AND

SERVICE CLEARANCE

AROUND UNIT — 12"

ON VALVE SIDE

Model 38QN 015-030 036-048 060

Diameters

Squares (minimum)

Tiedown Bolt

Locations C

1-9’2

1-11

0-6=4

D

1-4

E 0-9V

Fig. 1—Dimensions, Connections and Mounting Pad (Refer to Tabie 1)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book| 1 I 4

Tab l5al5a

PC 101 Cataiog No. 533-820 Printed in U.S.A. Form 38QN-10Si 10-87 Pg 1 Repiaces: 38QN-9Si

2-5\ 3-3

2-6 3-4

0-9’'2

1-10^2

1-1

1-T=16

2-7

1-5^8

Page 2

Table 1—Physical Data

MODEL 38QN

OPER WT (lb)* 132

REFRIGERANT

Control

CONDFAN

Air Discharge

AirQty(Cfm)

Mtr Rpm (60 Hz)

CONDCOIL(fins/in.)

Tube Diam

Rows

Refrig Ckts

Face Area (sq ft)

DIMENSIONS (ft-in.)

Diameter A

Height B

CONNECT, (in. ODF)

Suction

Liquid

REFRIG LINES

(in. ODF)

Suction

Liquid

♦Weight increases slightly with addition of any accessories.

t38QN048-060 require lYs-in. suction line for optimum perform

ance. A %- X 17s-in. connection adapter accessory (Carrier Part

No. 28AU900061) is available. If a 7s-in. accessory tubing pack

age is used, expect a slight capacity loss.

015 018

1850 1 2400 1 3100 1 3800 | 4000 | 5000

Compatible Fitting (Suction) & Flare (Liquid)

When installing, allow sufiBcient space for edrflow clearance,

wiring, refrigerant piping and servicing. Maintain a mini

mum of 4 ft clearance from obstructions above and 18 in.

around unit (12 in. on valve side). Maintedn a distance of 24

in. between heat pumps. Position so water or ice from roof

or eaves cannot fall directly on unit.

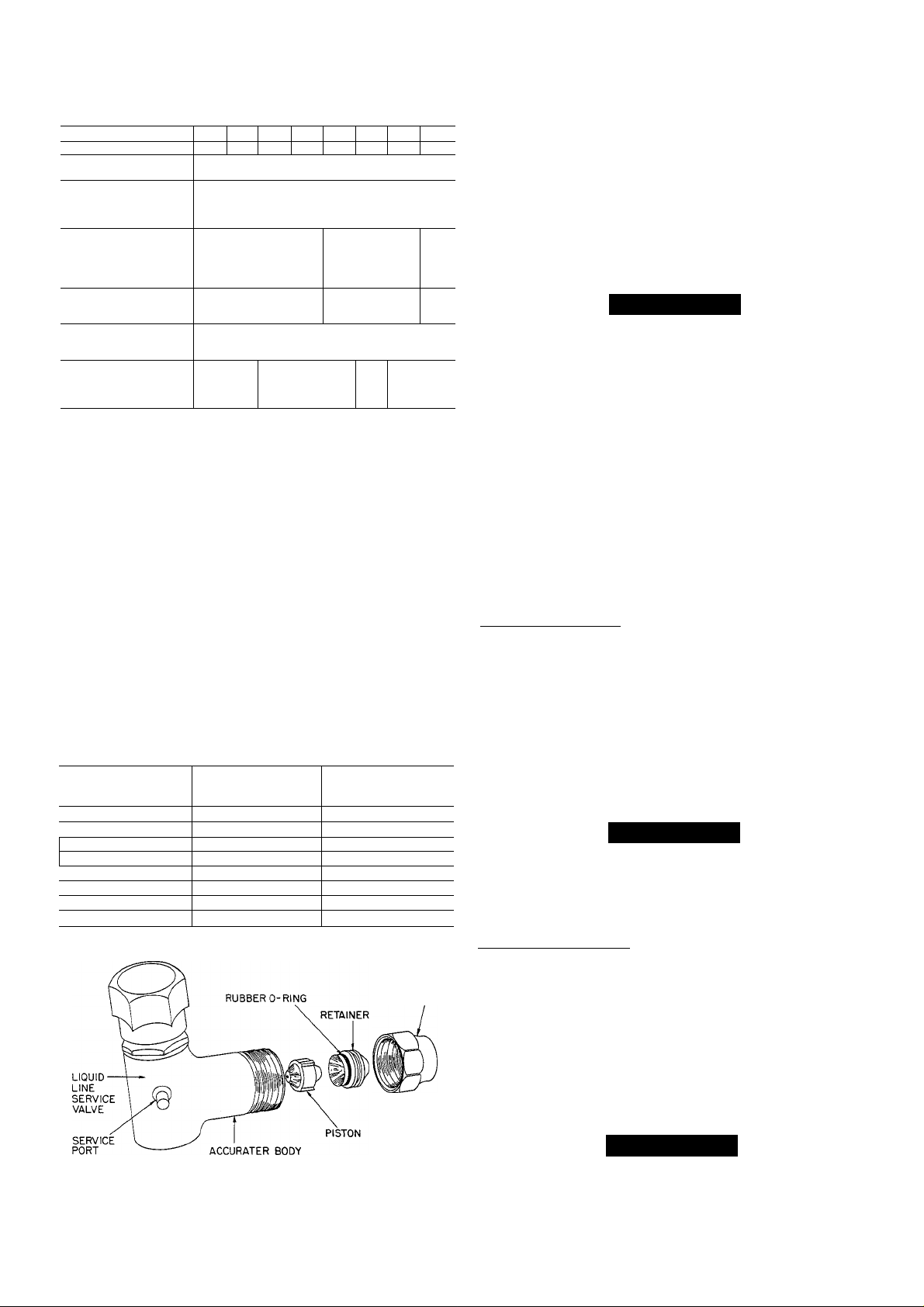

Step 2—Replace Indoor AccuRater™ Piston, if Required-

Check indoor cod piston to see if it matches the required pis

ton listed in Table 2. If it does not match, replace indoor cod

piston with piston shipped with this outdoor unit (located in

plastic bag taped to valves). See Fig. 2.

024

151 155 180 195

830 1 1075 850 | 1075 | 840

2 2

12.77

1-9%

% 1 %

%

030 036 042

1

Vertical

Vin.

22

1

%

%

6

E-Coil

AccuRater'^'^ (Bypass Type)

Propeller Type, Direct Drive

189 235 270

2 1 3 1

17.33

2-574

2-7

% 1%t

048 060

)

21.88

3-2%

Table 2—AccuRater™ Chart

OUTDOOR

UNIT

38QN

015 35 46

018 40

024

030 55 65

036

042 67 73

048 73 82

060

OUTDOOR

PISTON

46 59

61

78

INDOOR

PISTON

49

73

101

FLARE NUT

Step 3—Make Piping Connections—Outdoor units may be

connected to indoor sections using Carrier accessory tubing

package or field-supplied tubing of refrigerant grade, cor

rect size and condition (Table 1). For tubing requirements

beyond 50 ft, obtain information from local Carrier

distributor.

Outdoor Units Connected to Carrier-Approved Indoor

Units—Outdoor units contain correct system refrigerant

charge for operation with indoor unit of the same size when

connected by 25 ft of field-supplied or Carrier accessory tub

ing. Check refrigerant charge for maximum efficiency.

A CAUTION

DO NOT BURY MORE THAN 3 FT OF REFRIGER

ANT TUBING IN GROUND. If any section of tubing

is buried, there must be a 6-in. vertical rise to valve con

nections on outdoor unit. If more than the recom

mended length is buried, refrigerant may migrate to

cooler buried section during extended periods of unit

shutdown. This causes refrigerant slugging and possi

ble compressor damage at start-up.

CONNECT REFRIGERANT LINES to fittings on unit

suction and liquid service valves (Fig. 1). Liquid service

valve has flare fitting; suction service valve has Compatible

Fitting. Make suction line connection first. Slide flare nut

on liquid line, then flare and connect liquid line. Use a maxi

mum torque of 15 ft-lb to tighten flare nut. (Do not disas

semble AccuRater.) Unit Compatible Fitting permits

mechanical or sweat connection as described below.

Models 38QN048,060—When using iVs in. field-supplied

refrigerant suction line, sweat-connect suction line to lYs in.

end of required connection adapter. Be sure to provide a

heat sink at the service valve to prevent damage during

sweating operation. Connect %-in. end of adapter to unit suc

tion line Compatible Fitting. Connect liquid refrigerant line

to unit. When a 7s-in. field-supplied suction hne is used, pro

vide a field-supplied %-in. to 7s-in. suction line adapter (not

necessary if 38LS accessory tube is used).

NOTE: Compatible Fitting on outdoor section has alumi

num plug located beneath compatible nut on suction valve.

Plug keeps contaminants out of Compatible Fitting.

A CAUTION

When removing compatible nut, be careful pressure

build-up does not cause aluminum plug to blow and

cause personal injury. After tubing is hooked up, dis

card plug.

Mechanical Connection—Mate one set of connections at a

time.

1. Remove nut on Compatible Fitting.

2. Remove plug and be sure 0-ring is in the groove inside

the Compatible Fitting.

3. Cut tubing to correct length. Deburr and size as neces

sary. Slide nut onto tube.

4. Insert tube into Compatible Fitting until it bottoms.

Tighten nut until it bottoms on shoulder of fitting or

valve. Keep tube bottomed in Compatible Fitting while

tightening nut.

A87151

Fig. 2—AccuRater (Bypass Type) Components

A CAUTION

If undersized, damaged or eUipticaUy-shaped tubing is

used when making Compatible Fitting, leaks may

result.

Page 3

Sweat Connection—Use refrigerant grade tubing.

1. Remove locking nut, plug, rubber 0-ring and Schrader

core and cap from valve service port.

2. Cut tubing to correct length. Deburr and size as

necessary.

3. Insert tube in Compatible Fitting until it bottoms.

NOTE: Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with lowtemperature (430 F) silver edloy solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system with field-supplied

refrigerant.

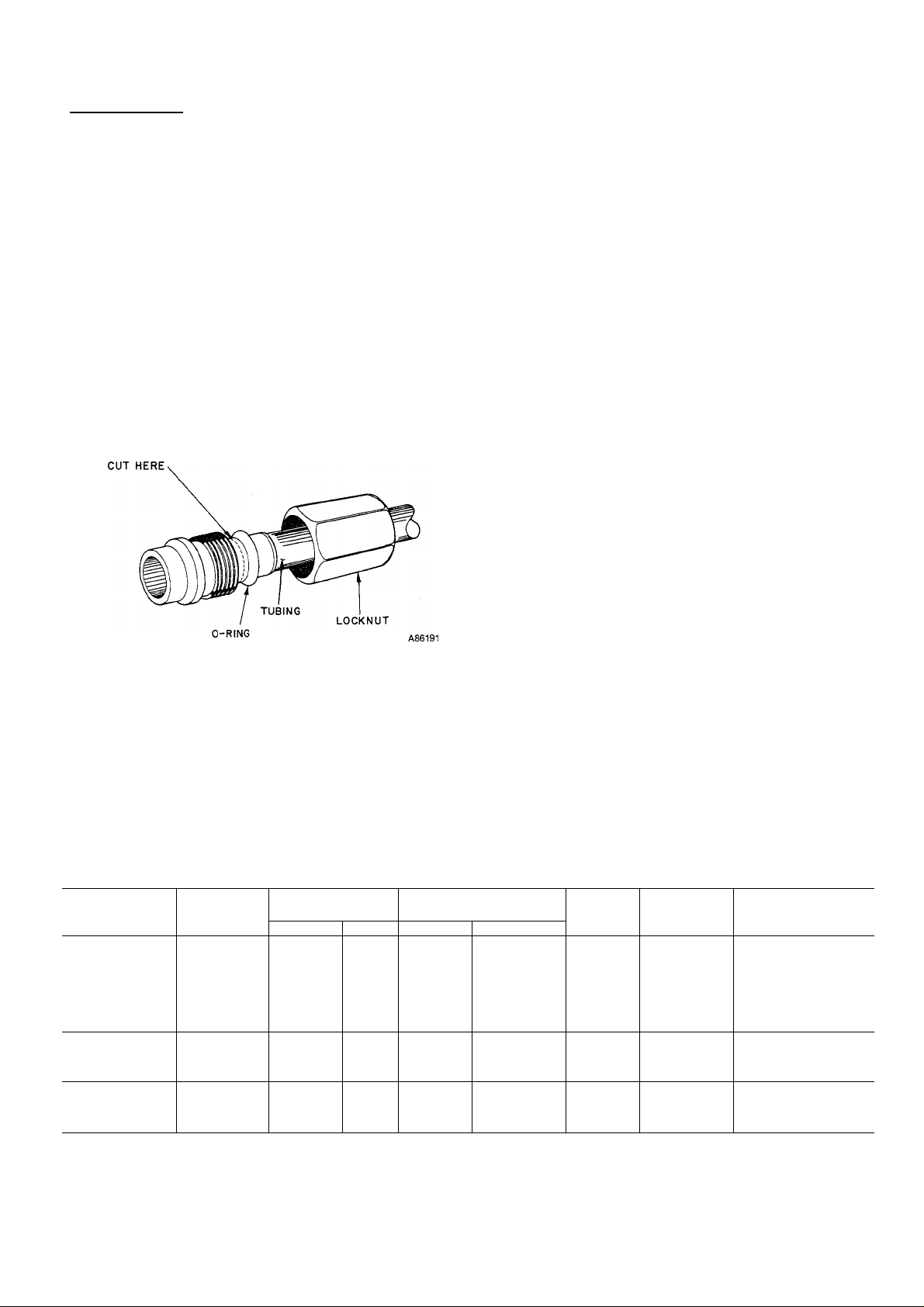

Compatible Fitting Repair

MECHANICAL CONNECTION-Frontseat unit service

valves. Relieve refrigerant pressure from tubing. Back off

locknut from Compatible Fitting onto tube. Cut fitting

between threads and 0-ring. See Fig. 3. Remove tubing sec

tion remaining in threaded portion of fitting. Discard

locknut.

COMPATIBLE FITTING

Clean, flux and insert new tube end into remaining portion

of Compatible Fitting. Wrap valve in wet rag to prevent

damaging factory-made joints. Heat and apply low-tempera

ture (430 F) solder.

SWEAT CONNECTION-Frontseat unit service valves.

Relieve refrigerant pressure from tubing. Clean and flux

around leak. Repair, using low-temperature (430 F) solder.

Evacuate or purge evaporator coil and tubing system. Add

refrigerant charge. See Refrigerant Charging.

Step 4—Make Electrical Connections—Be sure field wir

ing comphes with local and national fire, safety and electri

cal codes, and voltage to system is within limits shown in

Table 3. Contact local power company for correction of

improper fine voltage.

NOTE: Operation of unit on improper line voltage consti

tutes abuse and could affect Carrier warranty. See Table 3.

Do not install unit in system where voltage may fluctuate

above or below permissible limits.

See Table 3 for recommended fuse sizes. When making elec

trical connections, provide clearance at unit for refrigerant

piping connections.

INSTALL BRANCH CIRCUIT DISCONNECT PER NEC

of adequate size to handle unit starting current. Locate dis

connect within sight from and readily accessible from unit,

per Section 440-14 of National Electrical Code (NEC).

ROUTE LINE POWER LEADS-Extend leads from dis

connect through power wiring hole provided (see Fig. 1) and

into unit splice area. Remove control box cover to gain

access to unit wiring.

Fig. 3—-Repair of Mechanicai Connection

Tabie 3—Eiectricai Data (60 Hz)

Three-phase availabie with 036-060 sizes

OUTDOOR

UNIT 38QN

015-32

018-33 49.0

024-32 53.0

030-34 208-230/1 253 197 70.0

036-31

042-31 108.0

048-31 110.0

060-31

036-51 65.0 11.5 0.9 15.3

042-51

048-51 92.0 14.7 1.9 20.2

060-51 130.0 21.4 2.1

036-61

042-61 460/3 506 414

048-61 46.0 7.0 1.6 10.4

060-61 65.0 9.6 1.6 13.9

FLA —Full Load Amps

HACR—Heating, Air Conditioning, Refrigeration

LRA —Locked Rotor Amps

MCA —Minimum Circuit Amps

RLA —Rated Load Amps

NOTE: Control circuit is 24 v on all units and requires external power source.

V/PH OPER VOLTS* COMPR

208/230/3

Max

254 187 80.0 13.3 2.5 19.1

Min

LRA

35.0

86.7

142.0 33.0

32.8

35.0

FAN

RLA

7.2

10.5

13.2

17.6 1.9

18.9

21.8

27.3

5.1 1.6 8.0

7.2 1.6 10.6

♦Permissible limits of the voltage range at which unit will operate

satisfactorily.

tTime-delay fuse.

FLA

0.7

0.7 13.8

2.1 18.6

0.9 24.5

2.6 29.9

1.9 36.0

2.1 43.4

MCA

9.7

24.1

28.9

MAX FUSEt OR

HACR TYPE

CKTBKRAMPS

15

20

30

40

40

50

60

60

25

30

30

, 45

15

15

15

20

Page 4

CONNECT GROUND LEAD AND POWER WIRINGConnect ground lead to ground connection in control box for

safety. Then connect power wiring. See Fig. 4. Splice line

power leads to yellow and black pigtails. Use wire nuts and

tape at each connection. Connect unit wiring to copper

power wiring only.

CONNECT CONTROL POWER WIRING-Route 24-v

control wires through control wiring hole and channel and

connect leads to control wiring terminal board. See Fig. 1

and 6.

Use furnace or fan coil transformer as 24-v (40-va minimum)

supply for system as shown in Fig. 6, or use accessory

transformer.

MOUNT OUTDOOR THERMOSTAT in control box.

Attach brackets with short sheet metal screws to avoid con

tact with coH. Leave capUlary tube coiled in control com

partment making sure it is clear of aU electrical connections

and sharp metal edges.

MOUNT SUPPLEMENTAL HEAT RELAY in convenient

location on indoor unit. Attach with sheet metal screw.

To Start Unit

1. Energize crankcase heater a minimum of 24 hours

before starting unit. To energize heater only, set ther

mostat at OFF position and close electrical disconnect

to outdoor unit.

2. Backseat (open) liquid and suction line service valves.

l-PHASE

CONN. TO

DISCONNECT

PER NEC

'---GROUND LEAD-

----.---------

----------------

---------------

3-PHASE

CONN. TO

DISCONNECT

PER NEC

--------------Field Wiring

--------------

SPLICE CONNECTIONS

FIELD WIRING

FACTORY WIRING

--GROUND LEAD -

Factory Wiring

-[Hgroundin'g lug

— YEL

-------------------

I- PHASE

COND UNIT

-UlGROUNDING LUG

3-PHASE UNIT

Fig. 4—Line Power Connections

Step 5—Start-Up—Heat Anticipator Settings for Room

Thermostat. To set the heat anticipator, move the heat

anticipator to the maximum setting. Determine which ter

minal powers the electric heater controls. With the heaters

energized, measure the amperage between the appropriate

W terminal and R and set the anticipator to the same valve.

Fig. 5 illustrates an easy method of obtaining the actual

amp draw.

Accessory Outdoor Thermostat provides adjustable out

door control of accessory electric heater. This thermostat

makes contact when a drop in outdoor temperature occurs.

It energizes a stage of electric heat when the outdoor tem

perature setting is reached, provided the room thermostat

is on the second stage of heating. One outdoor thermostat is

recommended for each stage of electric heat after the first

stage. Set the outdoor thermostat(s) progressively lower for

each stage. Refer to heat load of building and unit capacity

to determine the correct outdoor thermostat settings.

The accessory supplemental heat relay is required when 2

outdoor thermostats are used. It is automatically energized

by the manually operated supplemental heat switch in the

indoor thermostat subbase. The thermostat locks out com

pressor and the relay bypasses the outdoor thermostats for

electric heater operation during heat pump shutdown. When

one outdoor thermostat is used, a supplemental heat relay is

not required. The supplemental heat switch in the indoor

thermostat subbase bypasses outdoor thermostat, locks out

compressor and activates electric heater.

Unit is shipped with valve stem(s) frontseated, and

caps installed. Replace stem caps after system is

opened to refrigerant flow (backseated). Replace caps

finger tight and tighten additional % turn with wrench.

See sticker on valve cap.

Turn on main disconnect switch(es) to indoor and out

4.

door units.

Set fan switch as desired (ON or AUTO).

5.

Set thermostat dial at desired temperature.

6.

Set selector switch at HEAT or COOL. Operate unit

7.

for 15 minutes.

Check system refrigerant charge. See Refrigerant

8.

Charging.

Motors and controls are designed to operate satisfactorily

in the voltage range shown in Table 3. If necessary to use

manifold gages for servicing, refer to Carrier Standard Serv

ice Techniques Manual, Chapter 1, Refrigerants, Pages 1-5,

Fig. 8 for bypass method of returning charge to system.

Removal of liquid line charging hose without following

these precautions could result in some loss of charge.

Refrigerant Charging (Fig. 7 through 14)

A CAUTION

To prevent personal injury, wear safety glasses and

gloves when handling refrigerant. Do not overcharge

system. This can cause compressor failure.

THERMOSTAT I—^ A

TERMINALS"

---

® 0 ® ©

10 TURNS AROUND JAWS

0.5 AMPS FOR THERMOSTAT SETTING

Fig- 5—Determining Amp Draw

HOOK'AROUNO

VOLT/AMMETER

Page 5

THERMOSTAT

SUBBASE

HH93AZIT3

OR HH93AZI75

(38QN/40AQ 0R40QB WITHOUT ELECTRIC HEATER)

40AQ OR 40QB FAN COIL

COOLING CONTROL KIT

TERMINAL BOARD

38QN

TERMINAL

BOARD

THERMOSTAT

SUBBASE

HH93AZI73 OR

HH93AZI75

COOLING AND TWO-STAGE HEATING

SUPPLEMENTAL HEAT, TWO OUTDOOR THERMOSTATS)

EQUIPPED WITH ELECTRIC HEATER;

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

(38QN WITH 40FS/28HQ.VQ

38QN

TERMINAL

BOARD

A87154

THERMOSTAT

SUBBASE

HH93AZI73

ORHH93AZI75

THERMOSTAT

SUBBASE

HH93AZI73

OR HH93AZI75

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

COOLING AND TWO-STAGE HEATING

(38QN WITH 40AQ,40QB OR 40FS/28HQ,VQ

SUPPLEMENTAL HEAT, NO OUTDOOR THERMOSTATS)

EQUIPPED WITH ELECTRIC HEATER;

B

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

380N

TERMINAL

BOARD

38QN

TERMINAL

BOARD

A87152

TH ERMOSTAT H H07AT17I 40DQ ELEC. HEATER

WITHHH93AZI73(AUT0. (ALL MODELS) 38QN

CHANGEOVER) OR HH93AZI75 LOW VOLTAGE TERM. TERMINAL

(MAN. CHANGEOVER) SUBBASE. SPLICE CONNECTIONS BOARD

SUPPLEMENTAL HEAT, NO OUTDOOR THERMOSTATS)

A87156

(38QN WITH 40AQ,40QB OR 40FS/28HQ.VQ

EQUIPPED WITH ELECTRIC HEATER;

SUPPLEMENTAL HEAT, ONE OUTDOOR THERMOSTAT)

Fig. 6—Control Circuit Connections

A87155

ODT — Outdoor Thermostat

SHR — Supplemental Heat Relay

------------

------------

Factory Wiring

Field Wiring

'Transformer (60 va) located in cooling control kit or electric

heater.

fRemove factory-installed jumper (Connection B) when

installing outdoor thermostats (ODT).

5

Page 6

HEATING CYCLE CHECK CHARTS

PSIG

(kPa)

10

(69)

20

(138)

SUCTION PRESSURE AT SERVICE PORT

30

(207)40(276)

50

(345)

Fig. 7—38QN015 Heating Cycie Check Chart

60

(414)

SUCTION PRESSURE AT SERVICE PORT

Fig. 8—38QN018 Heating Cycie Check Chart

PSIG

(kPa)

(69)

lO

20

(138)

SUCTION PRESSURE AT SERVICE PORT

30

(207)

40

(276)50(345)

Fig. 9—38QN024 Heating Cycle Check Chart

60

(4I4)

A87158

PSIG

(kPa)

lO

(69)

20

(138)

SUCTION PRESSURE AT SERVICE PORT

30

(207)40(276)50(345)

A87159

Fig. 10—38QN030 Heating Cycie Check Chart

60

(4I4)

Page 7

HEATING CYCLE CHECK CHARTS (cont)

PRESS. AT SUCT. SERVICE PORT psig

Fig. 11—38QN036 Heating Cycie Check Chart

SUCTION PRESSURE AT SERVICE PORT

A87160

Fig. 12—38QN042 Heating Cycie Check Chart

Fig. 13—38QN048 Heating Cycle Check Chart

SUCTION PRESSURE AT SERVICE PORT

a87161

Fig. 14--38QN060 Heating Cycie Check Chart

Page 8

To check system operation during heating cycle, use correct

Heating Cycle Check Chart (Fig. 7 through 14). These

charts indicate whether a correct relationship exists

between system operating pressure and air temperatures

entering indoor and outdoor units. If pressure and tempera

ture lines do not intersect on chart, system refrigerant

charge may not be correct or other system abnormalities

may exist. Do not use Heating Cycle Check Charts to adjust

refrigerant charge.

When recharging is necessary during heating season, weigh

in total charge as indicated on unit rating plate. Remove

any refrigerant remedning in system before recharging. If

the system has lost complete charge, evacuate and recharge

by weight. Service port connections are provided on liquid

and suction line service valves. For evacuation and recharg

ing, Dial-A-Charge charging cylinder is an accurate device

for recharging systems by weight.

To check and adjust charge during cooling season, use

Tables 4 and 5 and the following procedure:

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suc

tion valve service port.

3. Measure suction line temperature by attaching a serv

ice thermometer to unit suction line near suction valve.

Insulate thermometer for accurate readings.

4. Measure outdoor coil inlet air dry-bulb temperature

Table 4—Superheat Charging Table

(Superheat Entering Suction Service Valve)

OUTDOOR

TEMP(F)

55

60

65

70

75

80

85

90

95

100

105

110

115

-Do not attempt

refrigerant slugg

50

INDOOR COIL ENTERING AIR (F) WB

52

54

56

12

14

17

10

to charge system

ing may occur.

20

12

15

10

13

10

58

18

16

13

62

60

64

23

26

29

21

24

27

19

21

24

16

19

21

12

15

18

12

15

11

under these conditions or

21

18

15

13

10

66

32

30

27

24

70 72 74 76

68

37

35

33

35

33

30

27

30

24

28

25

21

19

22

16

20

14

18

12

15

13

11

40

42

38

40

36

38

33

36

34

31

28

31

26

30

24

27

22

25

20

23

17

22

15

20

8 14 18 23

45

43

41

39

37

35

33

31

29

27

26

25

with a second thermometer.

5. Measure indoor coü inlet air wet-bulb temperature with

a sling psychrometer.

6. Refer to Table 4. Find air temperature entering outdoor

coil and wet-bulb temperature entering indoor coil. At

this intersection, note the superheat.

7. Refer to Table 5. Find superheat temperature and suc

tion pressure, and note suction line temperature.

8. If unit has higher suction line temperature than

charted temperature, add refrigerant until charted tem

perature is reached.

9. If unit has lower suction line temperature them charted

temperature, bleed refrigerant until charted tempera

ture is reached.

10. If air temperature entering outdoor coU or pressure at

suction valve changes, charge to new suction line tem

perature indicated on chart.

11. This procedure is valid, independent of indoor air

quantity.

NOTE: For service data, refer to separate service manual

for Models 38EH,EN,ES,QH,QN,QS.

Table 5—Required Suction-Tube Temperature (F)

(Entering Suction Service Vaive)

51

53

59

79

82.4 85.7

51 53

53 55

57

55

57 59

59 61

63

61

67

65

67 69

71

69

71 73

73 75

77

77 79

81 83

83 85

85 87

87 89

89 91

TEIWP(F) 61.5 64.2 67.1 70.0 73.0

0

2

4 39 41 43 45 47 49

6

8

10

12

14 49 51 53 55 57 59 61 63 65

16 51

18

20

22

24

26 61

28

30

32

34

36

38

40

35 37 39 41 43 45 47 49 51

37 39 41

41

43 45 47 49 51

43

45 47 49 51 53 55

45 47

47

49 51 53 55 57

53

53

55 57 59 61 63 65

55 57 59 61 63

57 59

59 61

63

63

65 67 69 71

65 67

67

69 71

69 71

71 73

73

75 77 79 81 83 85

75 77

43 45 47 49

49 51 53 55 57

57 59

55

63

61

63 65

65 67 69 71 73 75

69 71 73 75 77 79 81

73 75

73 75

77

75

79 81 83 85 87

76.0 79.2

61 63

65 67

65 67 69

67

69 71

73 75

77

77

79 81

79 81 83

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

^ I

^ PC 101 Catalog No. 533-820 Printed in U.S.A. Form 38QN-10SI 10-87 Pg 8

Tab 15a 15a

Replaces: 38QN-9SI

Loading...

Loading...