Page 1

38QE/40QE

KEATING A COOLING

Installation Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS

GENERAL OPERATION AND USAGE

APPLICATION LIMITATIONS

ORIENTATION AND LOCATION OF EQUIPMENT

Step 1 Inspect equipment and job site

Step 2 Install outdoor fan coil section (38QE924 or

38QE936)

Step 3 Install indoor compressor section (38QE024 or

38QE036) '

Step 4 Install domestic water heating control box

Step 5 Install domestic water heating tank temperature

fitting

Step 6 Install thermostat

Step 7 Install indoor fan coil (40QE024, 40QE036 or

40QEH036)

(refer to installation instruction supplied with

indoor unit)

Step 8 Install other accessories

PIPING CONNECTIONS

Step 9 Install refrigerant piping

Step 10 Install domestic hot water piping

ELECTRICAL CONNECTIONS

Step 11 Install control and sensor wiring

Step 12 Install thermostat wiring

Step 13 Install power wiring

SYSTEM SET-UP ADJUSTMENTS

Step 14 Inspect Indoor blower speed settings

Step 15 Adjust domestic water heating tank thermostat

settings

Step 16 Configure thermostats

Step 17 Adjust Refrigerant Charge

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be

hazeurdous due to system refrigerant pressures and electrical

components. This is especially true with variable speed type

equipment, since HIGH VOLTAGE COMPONENTS

REMAIN ENERGIZED AFTER THE UNIT MAIN DIS

CONNECT IS OPENED!

Advanced Technology

Heat Pump System

For the above reasons, installation and servicing MUST BE

conducted only by a Carrier installer/dealer specifically

trained to service variable speed equipment. Improper

installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock or other

conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency or your

distributor or branch for information or assistance. The

qualified installer or agency must use factory authorized

kits or accessories when modifying this product. Refer to

the individual instructions packaged with the kits or acces

sories when instalhng.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available. Read these instructions thor

oughly and follow all warnings or cautions attached to<the

unit. Consult local building codes and NEC (National Elec

trical Code) for special installation requirements.

A WARNING

Before installing or servicing, turn off main power to

indoor and outdoor units. There may be more than one

disconnect switch. Turn off accessory heater power if

apphcable. Electric shock can cause personal injury or

death.

GENERAL OPERATION AND USAGE

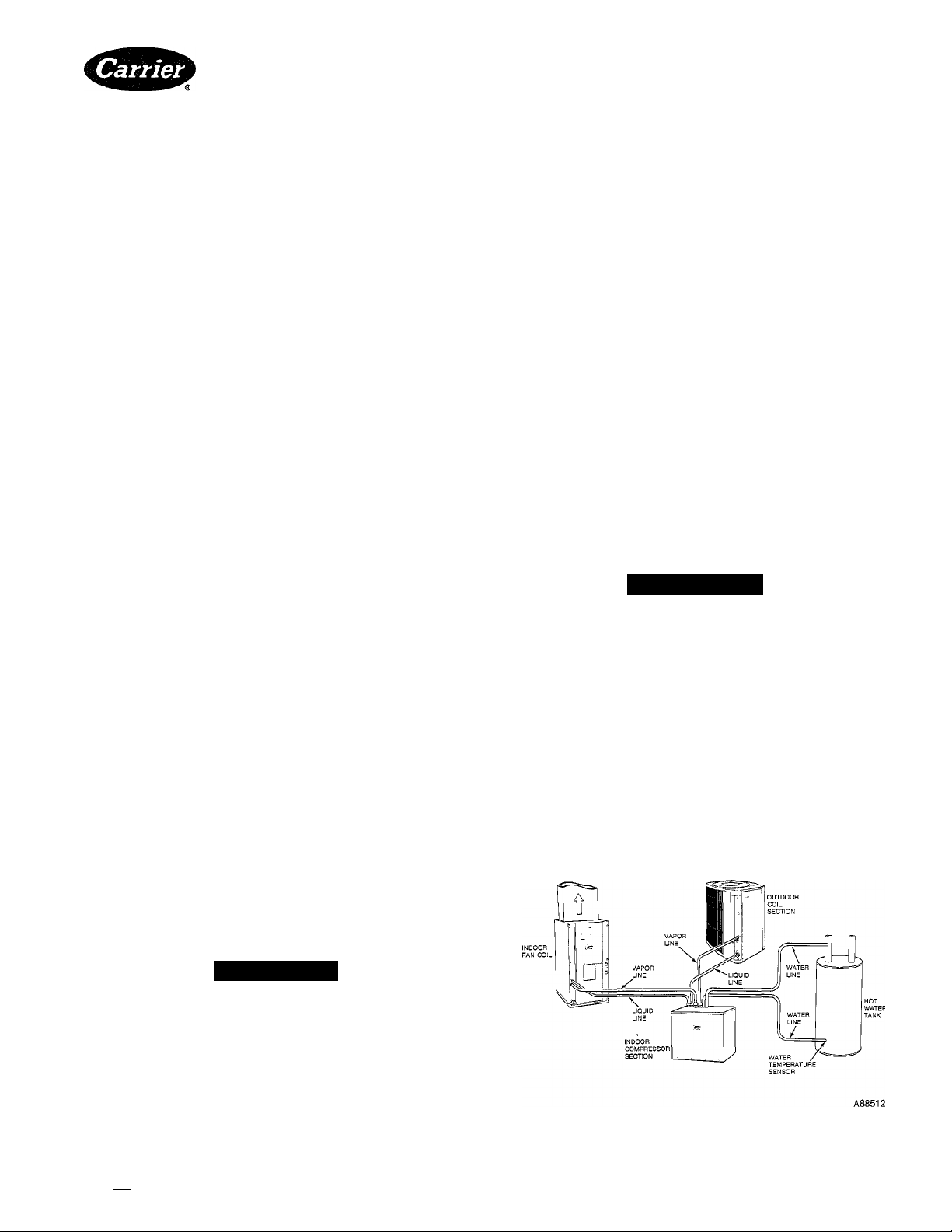

The HydroTech 2000 advanced variable speed heat pump

system is designed to provide heating and cooling, as weU

as provide a majority of the year round domestic hot water

requirements. The system is composed of three main sec

tions, indoor compressor section, outdoor fan cofi. section

and the indoor fan coil section (see Fig. 1). Additionally a

A DANGER

A high-voltage (300-VDC) circuit remains energized

after the main disconnect is opened. The normal capaci

tive discharge time is 10 minutes, but this period may

be extended indefinitely by component failure. Before

servicing components within the compressor section

power box, always check with a DC voltmeter across

the D.C. Capacitor. Electrical shock can cause personal

injury or death.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

^ I PC 101 Catalog No. 563-964 Printed in U.S.A. Form 38QE-3SI Pg 1 5-90 Replaces: 38QE-2SI

Tab I5al5a

Fig. 1—38QE/40QE Advanced Heat Pump System

Page 2

domestic water heating control box emd domestic water

heating tank temperature sensor are supplied to control the

electric domestic water heating tank. The water heating is

accomphshed by pumping cold water from the cold water

inlet pipe at the top of the domestic water tank, through the

38QE refrigerant-to-water heat exchanger, and back into

the bottom of the tank.

The variable speed compressor operation allows the 38QE

system to control its output capacity to match the required

load through a wide range of outdoor temperatures and

operating modes.

Specially designed mating 40QE indoor units provide vari

able airflow control which is increased and decreased along

with the compressor speed. This feature, along with an elec

tronic expansion device, provide a level of comfort pre

viously unavailable for the home. It also enhances system

efficiency and provides much quieter operation them conventioneil systems during most periods of operation.

The 38QE/40QE system has many other designed in com

fort and efficiency features including:

Carrier/Parker Home-Zone® thermostat and damper

options—to provide separate temperature control in up to

four areas.

Humidity control—add the optional humidistat to activate

special compressor and fan control which improves moisture

removal as needed. Humidistat plus humidifier also controls

moisture addition in the heat mode.

Air cleaning—connections provided for automatic control of

optional electronic air cleaner.

Utility demand limit interface—allows owner participation

in incentive programs offered by utilities for peak load con

trol, where available.

Unique defrost—the high temperature of the water in the

home’s hot water tank is used as the heat source for the

defrost cycle, rather than cooling the indoor air as with tra

ditional units. In addition, demand type defrost control pro

vides defrost when, and only when, it is required.

The 38QE/40QE system is available in capacity sizes shown

in Table 1. Accessories supplied with the system and other

available accessories are shown in Table 2.

APPLICATION LIMITATIONS

The 38QE system software and safety devices Eire designed

to prevent equipment operation under conditions that do

not comply with the application hmitations.

The 38QE product has certEun application hmitations which

are hsted below:

The 38QE compressor section and outdoor section are

1.

to be matched to the specifically designed 40QE indoor

fan coil section. Permitted system configurations are

shown in Table 1.

Table 1—Carrier Approved 38QE Systems

SYSTEM CAPACITY

INDOOR COMPRESSOR SECTION 38QE024300 38QE036300

OUTDOOR FAN-COIL SECTION

INDOOR FAN-COIL SECTION

25 ft maximum vertical rise allowable

The 38QE can only be used with Carrier/Parker Home-

2.

2 TON 3TON

38QE924300 38QE936300

40QE024300 40QE036300

Zone® thermostats. Monitor thermostat and slave ther

mostat model requirements are given in Table 2. All

thermostats must be properly configured and pro

grammed in order to obtain normal system operation.

The 38QE should not be used with systems containing

3.

more than four (4) independently dampered zones. Use

<@)

of the bypass controUer accessory is required for aU

zone apphcations.

4. The system wiU not operate in the cool mode at outdoor

temperatures below 45 F, and is not compatible with

tie Carrier Motormaster low-ambient control

; accessory. /

5, §The systern wiU not operate in the heat mode at out

door ternperatures above 75 F.

The compressor section must be located in a non-

6.

freezing area because of water containing components.

Maximum air temperature surrounding the compressor

section must not exceed 105 F because of cooing

required for electronic controls.

The compressor section is designed to be installed on a

7.

sohd mounting pad such as concrete. Do not install

compressor section in an attic, on a wall, or suspended

from a ceiling.

Refrigerant line lengths are hmited to 50 ft total maxi

8.

mum, with 25 ft maximum vertical rise between indoor

and outdoor units.

9. For improved domestic water heating, locating the

compressor section within 15 ft of the domestic water

tank is desirable.

Table 2—Accessory Parts List

ACCESSORIES SUPPLIED WITH COMPRESSOR SECTION

ORDERING NUMBER

313204-701

313288-710

313243-201

ACCESSORIES REQUIRED OR RECOMMENDED

ORDERING NUMBER

HT2000

HZS (Version 2.7 or

higher)

ZD-06,08,10,12,14,16

RD0810,0814,0818,0824

BCE

TSR01

PS02/PS01

PSPOO

RDS

RRS

PCA-223

PCA-225

HL38MG026 Humidistat

—

__

38TH900011

38YH900011

38YH900021

P504-8163S

HT01AX220 Transformer 40va

RQ—Required for installations.

RC—Recommended for installations.

DESCRIPTION

Water Heater Control Box

Water Temperature Sensor

Assembly

Comp. Section Base Pad

Zones

DESCRIPTION Singl

Homezone Monitor Stat w/

clock RQ

Homezone Slave Stat RQ

Round Dampers 6" thru 16"

Rectangular Damper 8x10

thru 24

Bypass Controller

Relay Pack-Power Supply

Duct Pressure Sensor RQ

Static Pressure Plok-up RQ

Remote Duct Sensor OP

Remote Room Sensor OP

Plenum Cable—22 AWG, 3

conduc

Plenum Cable—22 AWG, 5

conduc

Humidifier (49BF/FH/WS) RC RC

Electronic Air Cleaner (31MPI

SX)

Outdoor Support Foot Kit, 4

in.

Outdoor Snow Rack, 18 in.

(024)

Outdoor Snow Rack, 18 in. OP

(036)

Bi-flow Filter-Drier

OP—Optional for installations.

Mult

RQ

RQ

RQ

RQ

RQ

OP

OP

)

RC RC

RC RC

RC

RC

RC RC

OP

OP

OP

OP

OP

RQ RQ

RQ

—

10. System is designed to work with conventional residen

tial sized electric water heating tanks only. NOTE: The

38QE should be installed with electric water heater

tanks that have two connections leading to the bottom

of the tank, as shown in Fig. 7a (cold water in, drain). If

only one connection to bottom of tank, install a preheat

tank, as for gas water heaters. Fig. 7b. For installation

with a gas water heater, a water preheat tank must be

installed.

i ;

Page 3

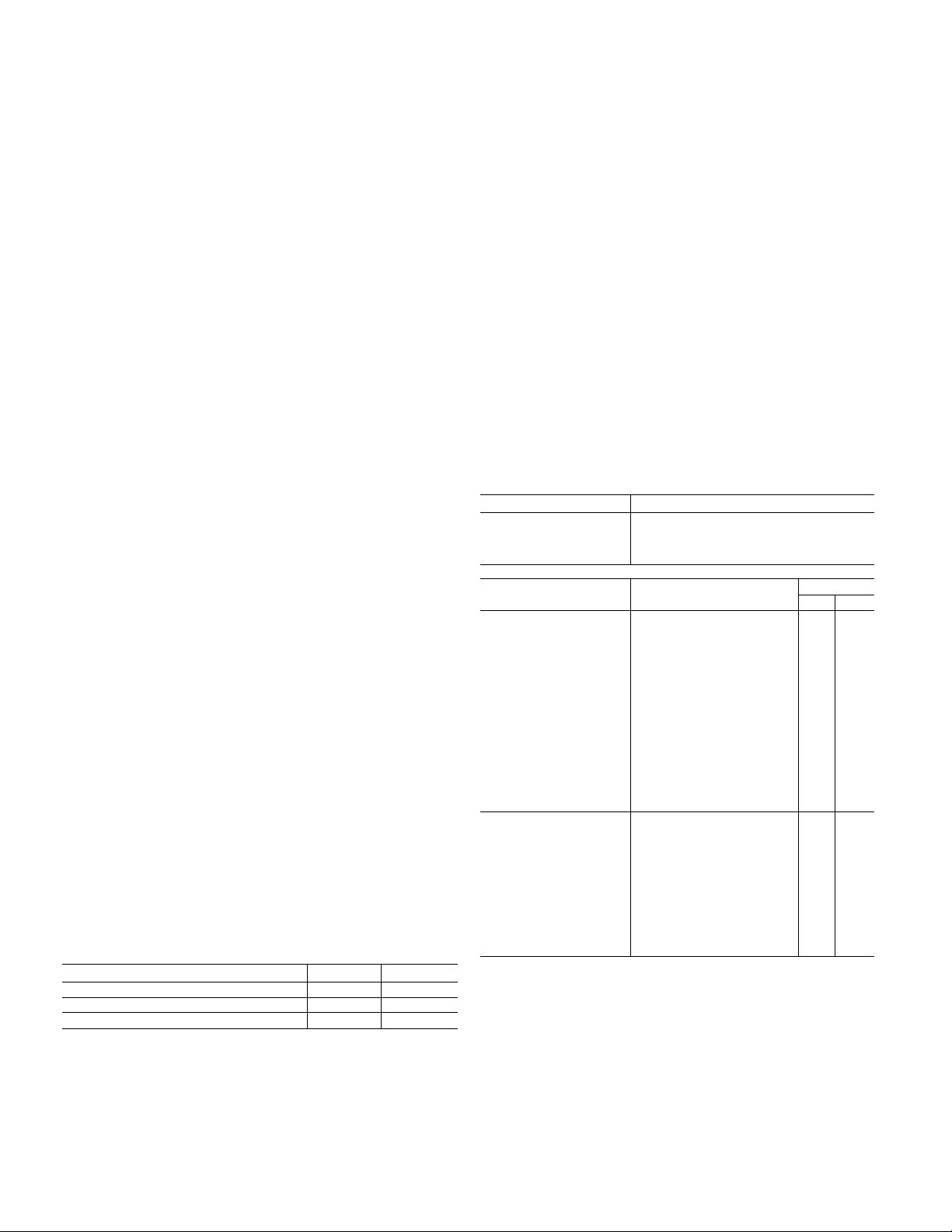

Fig. 2—Outdoor Section Dimensions

Dimensions

UNIT A B C D E

SIZE*

38Q E924

38Q E936 3 1-7/8 " 809 .6

(mm )

(IN.)

809 .6 30" 762.0 34 -15/1 6"

31-7/8" •

(IN.)

38-5/8"

(mm )

391 .0 45"

(IN.)

(mm )

887 .4

114 3.0

(mm )

(IN.)

4" 101 .6 9-3/4" 247 .6

5-15/16" 150.8

(IN.)

11-13/16 "

(mm )

300 .0 21-1 /2" 54 6.1 27-7/8" 7 08.0

F

(mm )

(IN.)

21-1/2" 546.1

G

(mm )

(IN.)

27-7/8" 708.0 8-3/16" 207 .9

A90214

H

(IN.) (mm )

8-9/16" 217.4

ORIENTATION AND LOCATION OF EQUIPMENT

Step 1—Inspect Equipment and Job Site.

A complete single zone system wül consist of the following:

1. Compressor Section

2. Outdoor Section

3. Indoor Section

4. Domestic Water Heater Control Box

5. Domestic Water Heater Tank Sensor

6. Homezone Monitor Thermostat

7. Homezone Power Supply Relay Pack

Unpackage and inspect imits for any damage. Füe claims

with shipper if necessary.

The compressor section package wül include an installation

packet, domestic water heater control box and tank temper

ature sensor.

The outdoor fan coü section will include an instaUation

packet. The indoor fan coü section wül include an instaUa

tion packet.

Consult local buüding codes and the National Electrical

Code (NEC) for special requirements.

When installing, aUow sufficient space for airflow clearance

(outdoor fan-coü section), wiring, refrigerant and water pip

ing and servicing unit. Position the outdoor section so water

or ice from roof cannot drop directly on top of unit. Position

the compressor section indoors and adjacent to the domes

tic water heating tank.

Step 2—Install Outdoor Fan-Coü Section (38QE924 or

38QE936).

The instaUation data, dimensions, and connection for the

38QE924,936 outdoor section are shown in Fig. 2.

InstaU on a solid, level mounting pad—If conditions or local

codes require the unit be attached to pad, tiedown bolts

should be used and fastened thru knockouts provided in

unit base pan. Refer to unit mounting pattern in Fig. 2.

Position so snow or ice from roof or eaves cannot faU

directly on unit. Position to minimize direct sunlight on air

temperature sensor above service valves.

On rooftop applications, locate unit at least 6 ins. above roof

surface. Place xmit above a load-bearing waU and isolate

unit and tubing set from structure.

Arrange supporting members to adequately support unit

and minimize transmission of vibration to buüding. Consult

local codes governing rooftop applications.

For proper drainage the outdoor section must be raised off

the mounting surface. Fig. 3 shows unit with accessory sup

port feet installed. Use accessory snow rack in areas where

prolonged subfreezing temperatures or heavy snow occur.

Refer to separate instaUation instructions packaged with

the accessories.

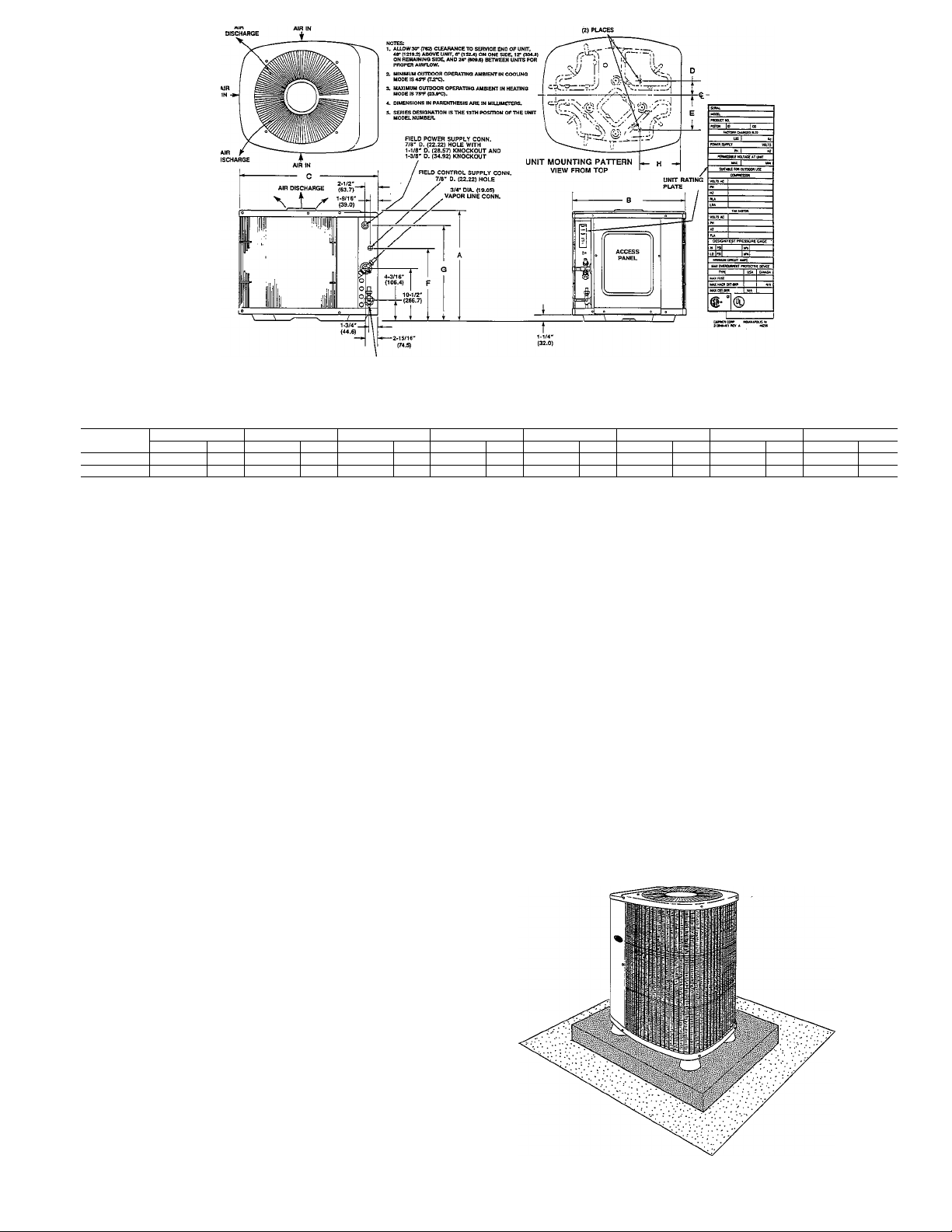

Step 3—Install Indoor Compressor Section (38QE024 or

38QE036).

The instaUation data, dimensions, and connection for the

38QE024, 036 compressor sections are shown in Fig. 4.

Locate unit in non-freezing area such as a basement, garage

or utility room. Indoor locations within the living space are

not recommended. Basement instaUations also require care

ful planning to avoid areas directly under or adjacent to

bedrooms, living rooms, etc. Locate unit near the domestic

water heater. AUow space for refrigerant and water piping.

A88277

Fig. 3—Outdoor Accessory Support Feet

Page 4

UNIT

38QE024

38QE036

SHIPPING WGT. A B

SERIES LBS.

230 104.3 3/8

0

0 240

108.8 3/8 9.53

Kg.

(IN.)

(mm)

9.53

(IN.) (mm)

3/8 9.53

3/8 9.53

C

(mm)

(IN.)

3/4 19.05

3/4 19.05 3/4

(IN.)

3/4

Fig. 4—Indoor Compressor Section

D

(mm)

19.05 7/8 22.23 7/8

19.05 7/8 22.23 7/8 22.23 38QE936

(IN.)

E

(mm) (IN.)

F

(mm)

22.23 38QE924

USE WITH

OUTDOOR SECTION

wiring and for servicing the unit (see Fig. 4). Do not exceed

maximum total pipe lengths.

Mount indoor compressor section on a rigid, sohd platform

or concrete floor. Insert the asphalt impregnated felt pad

(factory supplied in container) between the unit basepan and

moimting surface to provide fuU unit support and for vibra

tion attenuation. Do not use vibration isolators under cor

ners of basepan.

Install unit to permit adequate clearance for service on all

sides of the unit. A heat sink which is used to provide elec

tronic component cooling is located at the lower right side

of the rear panel. This heat sink protrudes from the rear

panel. This area should always remain clear of obstructions.

Do not enclose this area, in any manner. Failure to provide

proper ventilation can cause equipment to malfunction.

A CAUTION

To prevent freezing of water piping, do not expose the

38QE indoor compressor section to ambient tempera

tures below freezing.

Step 4—Install Domestic Water Heater Control Box.

The domestic water heater control box allows the 38QE

heat pump to control the domestic water heating function.

The tank elements are controlled by the 38QE such that the

water heating is performed by the heat pump when possible

and the tank elements are disabled.

Locate the control box adjacent to the Domestic water heat

ing tank. The box will be wired in the branch circuit that

»!

Page 5

supplies the power for the Electric Water Heater Tank. Con

trol and sensor wiring will also be connected to the control

box. Refer to wiring section of this manual for description of

the wiring required.

Step 5—Install Domestic Water Heating Tank Tempera

ture Sensor Fitting.

The tank temperature sensor is used to provide the 38QE

with the tank water temperature. This temperature is used

to control and terminate the water heating mode.

The water temperature sensor fitting is installed into the

tank drain-out fitting. Details describing the piping are con

tained within the piping section of this manual.

Step 6—Install the Thermostat(s).

The system is designed to operate with Carrier/Parker

Home-Zone® model thermostats and zoning deunpers. Refer

to the installation instructions shipped with the Carrier/

Parker Home-Zone® accessories.

Step 7—Install Indoor Fan-Coil Section (40QE024,

40QE036 or 40QEH036).

Refer to the installation instruction shipped with the 40QE

unit.

Step 8—Install Other Electrical Accessories, if any.

Refer to the individual instructions packaged with optional

accessories (humidistat, humidifier, air cleaner, zone ther

mostats and dampers).

Also refer to the installation instructions supplied with the

40QE indoor unit.

PIPING CONNECTIONS

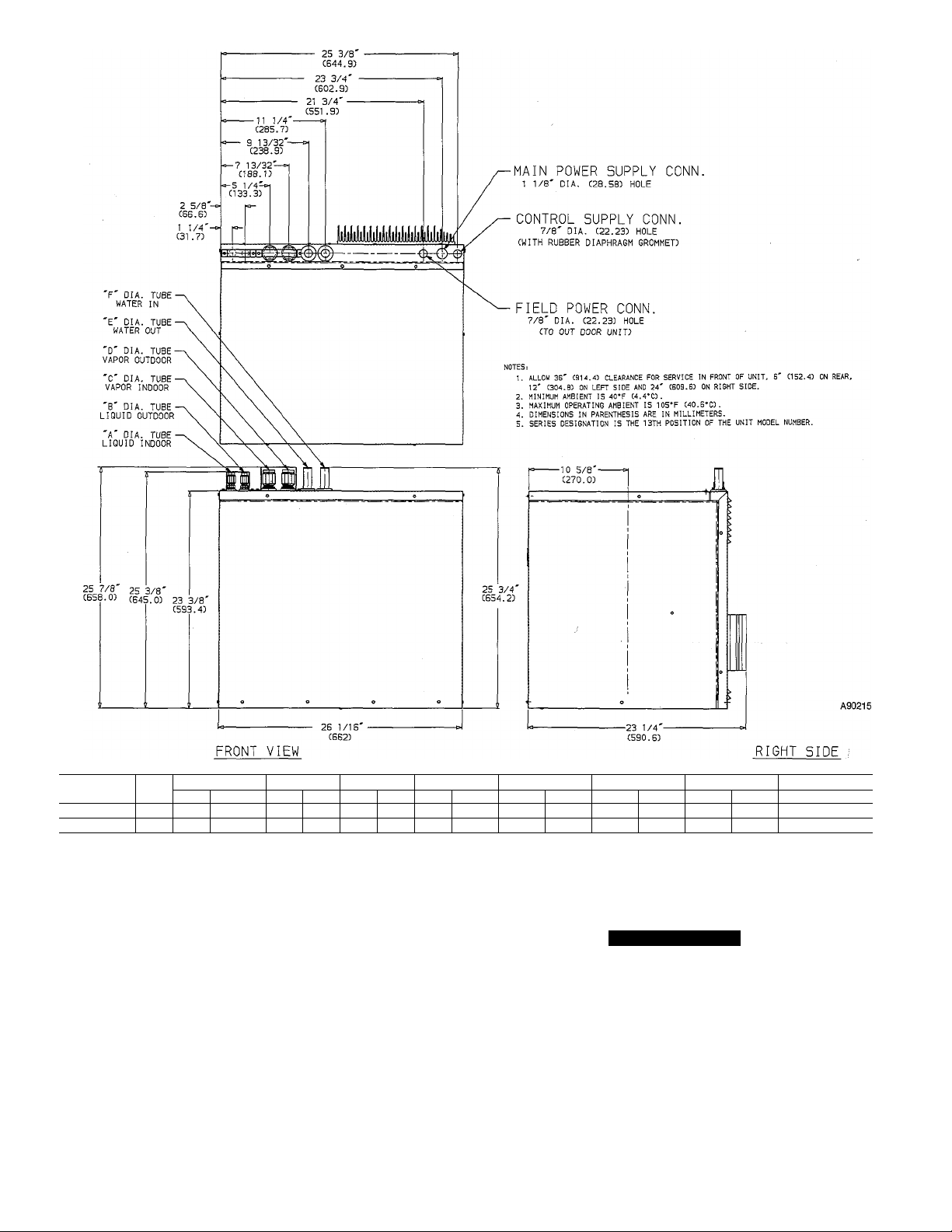

A system piping schematic is shown in Fig. 5 which illus

trates both the refrigerant and domestic water heating con

nections that are required.

Isolate interconnecting tubing from the framing and duct

work or where tubing runs through stud spaces, enclosed

ceiling or pipe chases. Use isoiation type hangers, since

rigid fastening transmits pulsation to structure, creating

objectionable sound.

Step 9—Install Refrigerant Pipes

NOTE: Before making the 3/8" O.D. refrigerant line connec

tions at the indoor coil verify that the fittings do not con

tain an AccuRater piston.

The 38QE system employes a unique electronic bi

directional expansion valve, located within the compressor

section, and does not require AccuRaters in either the

indoor or outdoor section..

Refrigerant piping between sections may be made using

accessory tubing packages or field-supplied tubing of refrig

erant grade, correct size and condition.

If either refrigerant tubing or unit piping is exposed to

atmospheric conditions for longer than 5 minutes, it must

be evacuated to 1000 microns to eliminate contamination

and moisture in the system.

All refrigerant tubes must be insulated with closed-ceU foam

type insulation with a minimum waU thickness of 3/8". Fail

ure to properly insulate refrigerant tubes adequately wUl

degrade system performance and efficiency, as well as per

mitting moisture or frost to form on the tubing surfaces

during some operating modes. Insulation on the refrigerant

lines at the compatible fittings should extend over the com

patible fitting to prevent moisture from collecting on the

fitting surface and freezing during low outdoor temperature

operation. Freezing of the moisture on the compatible fit

ting may cause damage to the fitting and refrigerant

leakage.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes so

they do not damage insulation on liquid and vapor tubes

and do not transmit vibration to structure. Also, when pass

ing refrigerant tubes through walls, seal opening so vibra

tion is not transmitted to structure. Leave some slack in

refrigerant tubes between structure and units to absorb

vibration.

A CAUTION

DO NOT BURY MORE THAN 3 FT OF REFRIGER

ANT TUBING IN GROUND. If any section of tubing

is buried, there must be a 6-in. vertical rise to valve con

nections on outdoor unit. If more than the recom

mended length is buried, refrigerant may migrate to the

cooler buried section during extended periods of shut

down. This causes refrigerant slugging and possibly

compressor damage at start-up.

Compressor Section

Refrigerant piping on the 38QE differs from other Carrier

triple split type systems. The refrigerant piping requires the

installation of two (one 3/4-in. O.D. copper tube and one

3/8-in. O.D. copper tube) tubes between the compressor sec

tion and each of the indoor and outdoor sections. A filterdrier, specified in Table 2 or supplied with unit, must be

installed in the 3/8-in. indoor liquid fine within 12 ins. of the

compressor section for noise control. Fig. 5 illustrates the

various refrigerant tube connections on the compressor

section.

3/4-in. O.D. refrigerant vapor tube to indoor coil

3/4-in. O.D. refrigerant vapor tube to outdoor coü

3/8-in. O.D. refrigerant liquid tube to indoor coil

3/8-in. O.D. refrigerant liquid tube to outdoor coü

The total refrigerant fine distance from the indoor fan coü to

the outdoor unit shaU not exceed 50 equivalent ft (see

Fig. 6).

Both the liquid and vapor connections have compatible fit

tings. Compatible fittings permit mechanical (quickconnect), or sweat connections.

A. Mechanical connection (mate one set of connections at a

time.)

1. Loosen nut on compatible fitting one turn. Do not

remove.

2. Remove plug and be sure 0-ring is in groove inside

compatible fitting.

3. Cut tubing to correct length. Deburr and size as

necessary.

4. Insert tube into compatible fitting untü it bottoms.

TIGHTEN NUT UNTIL IT BOTTOMS ON SHOUL

DER OF FITTING OR VALVE. Keep tube bottomed

in compatible fitting whüe tightening nut. Do not over

tighten.

A CAUTION

If undersized, damaged or eUiptically-shaped tubing is

used when making Compatible Fitting, leeiks may

result.

B. Sweat connection—Use refrigerant grade tubing.

1. Remove locknut, and rubber 0-ring from inside of com

patible fitting.

2. Cut tubing to correct length.

3. Insert tube into compatible fitting until it bottoms.

Page 6

A89059

(Top)

Fig. 5—38QE/40QE System Piping Schematic

A89059

(Bottom)

Fig. 6—Maximum Refrigerant Line Length

4. After wrapping the service valve with a wet cloth, the

tubing set can be brazed to the service valve using

either silver bearing or non-silver bearing brazing

material. Consult local code requirements.

Outdoor Fan Coil Section

Jk CAUTION

A brazing shield MUST be used when tubing sets are

being brazed to the service valves to prevent damage to

the painted unit surface.

A CAUTION

To avoid damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet

cloth.

Both the liquid emd vapor lines require sweat connections.

Use proper equipment and safety precautions when making

the sweat connection. The service valves on this unit are

both front and backseating. The service port does not con

tain a Schrader fitting. Do not attempt to connect manifold

until valve is fully backseated.

Service valves are closed from factory and ready for braz

ing. After wrapping the service valve with a wet cloth, the

tubing set can be brazed to the service valve using either sil

ver bearing or non-silver bearing brazing material. Consult

local code requirements.

Outdoor units contain correct system refrigerant charge for

operation with indoor unit of the same size when connected

by 25 ft of field-supplied or factory accessory tubing. Check

refrigerant charge for maximum efficiency (see Refrigerant

charging).

Indoor Fan Coil Section

The liquid and vapor tube fittings are flare and compatible,

respectively on the 40QE units. Use proper equipment and

safety precautions when making the flare connections.

Refer to the 40QE Installation Instructions.

Step 10—Install Domestic Hot Water Piping

A CAUTION

Use only water piping, fittings and brazing material

that are suitable for Potable Water systems when con

necting the heat pump to the household water system.

Consult local codes.

The compressor section and domestic water heater should

be located as near as possible to each other. Total length of

interconnecting water piping between the compressor sec

tion and water heater should not exceed the lengths shown

in Table 3. The number of bends and pipe fittings should be

kept to a minimum. The use of shut-off valves in the water

lines between the domestic water tank and the compressor

section are not recommended as they may adversely affect

the system performance. (If valves are used, use only Ball or

Gate type). However compliance with local codes should be

followed. Failure to insulate pipes will result in performance

degradation..

Domestic Water Heating Tank

The 38QE can be installed with a conventional electric

water heater or with a gas water heater system. The basic

installation procedures are the same. However in the instal

lation with the gas water heater an insulated preheat tank

Table 3—Recommended Water

Piping Size

PIPE SIZE

1/2" nom (5/8" OD)

3/4" nom (7/8" OD) 50

♦Length can increase by 1.6 ft for each elbow less than 6.

♦♦Length can increase by 2.0 ft for each elbow less than 6.

tTotal length of cold and hot water pipes.

ALLOWABLE TOTAL

PIPING LENGTH (Ft)t

20

ALLOWABLE TOTAL

PLUS

PIPING ELBOWS

6^

6**

must be used. The preheat tank is essentially an electric

water tank without the electric heating elements.

Installation of the 38QE with a conventional electric water

heater is shown in Fig. 7a. Installation with a gas water

heater and preheat tank is shown in Fig. 7b.

Tank Water Temperature Sensor

The connection of the water heating lines to the tank

includes the installation of the tank water temperature sen

sor. The tank water temperature sensor is located within the

drain fitting of the tank. The fitting location is shown in

Fig. 7a,b. The detail for instaUing the sensor is shown in

Fig. 8.

Water connection tubes on the 38QE compressor section are

identified in Fig. 4. The two tubing stubs require fieldsupplied sweat couplings or reducing couplings for connec

tion to water lines.

A CAUTION

A brazing shield must be used when tubing and fittings

are being brazed to the water stub tubes to prevent

damage to the painted unit surface.

Page 7

Fig. 7a—Installation with Conventional

Electric Water Heater

7. Insulate all water pipes with closed-cell foam type insu

lation with a nunimum wall thickness of 3/8 in.

8. If shut off valves have been installed in the water lines

between the tank and compressor section, slowly open

all valves. Bleed air from the heat pump water circuit

and circulating pump. First loosen the threaded union

on the pump outlet untU water flows out and no air is

present. Retighten union. Repeat process with xmion on

pmnp inlet. Then loosen air bleed screw in the center of

the circulating pump. The air bleed screw should only

be loosened, not totally removed, enough to allow air to

bleed. Retighten screw after system has been bled.

A CAUTION

Failure to bleed air from the water pump before energiz

ing will cause immediate pump failure. The pump

employs water-cooled and lubricated bearings; and if air

is left in the vicinity of the bearing, insufficient cooling

and lubrication will be available and bearing failure will

result.

ELECTRICAL CONNECTIONS

NOTE: This equipment generates and uses radio frequency

energy. If not installed properly in strict accordance with

these installation instructions, it may cause interference

with televisions and/or radio reception. It has been tested

and foxmd to comply with the limits for a Class B comput

ing device in accordance with the specifications in Subpart

J of Part 15 of FCC rules (which are designed to provide pro

tection against such interference in a residential installa

tion). However, there is no guarantee that there will not be

interference in a particular installation. If this equipment

does cause interference to television and/or radio reception,

which can be determined by turning the equipment off and

on, the installer or serviceman should refer to “38QE Start

up, Troubleshooting and Service Guide.”

Fig. 7b—Installation with Gas Water Heater

and Preheat Tank

Tank Water Temperature Thermostat

Adjust the lower electric heater thermostat to the minimum

setting.

Water Piping Installation

1. Shut off all electrical power to domestic water heater.

2. Shut off water supply to domestic water heater and

drain tank.

Remove drain valve from bottom of tank which

3.

requires sensor (Fig. 7a or 7b). Install pipe nipples and

tee and insteJl tank water temperature sensor as shown

in Fig. 8. Bend sensor up to avoid hitting water tanks

that have dome shaped bottoms.

4.

Install second tee into tank sensor tee as shown in

Fig. 8. Install drain valve and connect water piping

between second pipe tee and hot water outlet connec

tion on the compressor section.

5. Install a tee fitting on the cold city water supply as

shown in Fig. 7. Install the water piping between the

tee fitting and the cold water inlet connection on the

compressor section.

6. Refill the hot water pipes and tank, purge air, and

check aff water connections for leaks.

HOT WATER FROM 38QE

COMPRESSOR SECTION

Fig. 8—Hot Water Inlet Connection

to Hot Water Tank

A90213

Page 8

Compressor section to indoor fan coil section ;

38QE

Compressor Section

Terminal Board

Compressor section to outdoor fan coil section:

38QE

Compressor Section

Terminal Board

0

0

40QE

Indoor Section

Terminal Board

38QE

Outdoor Section

Terminal Board

0

"0

0

Domestic water heater control box and temperature sensor (Electric water heater)

Water Heater

Control Box

Terminal Board

Water Temperature

Sensor

A

0.

0

0-

-

0

Water Temperature Sensor (Gas water heater and preheat tank)

38QE

Compressor Section

Terminal Board

0

0

(w^

0

38QE

Compressor Section

Terminal Board

A

0

Water Temperature

Sensor

0.

0

A

Splice Connection

-- Field Wiring

~ Factory Wiring

Fig. 9—System Control and Sensor Connections

8

0

0

Page 9

A CAUTION

Avoid running control and sensor wiring in parallel

bundles, conduit or pipe chases with the power wiring.

Power wiring can cause interference with the control

and sensor wiring. Maintain a minimum of 6 ins. of sep

aration between the control and sensor and power wir

ing. Control wiring should be secured to the refrigerant

piping between the compressor, indoor and outdoor

units.

A CAUTION

To prevent interference avoid running control and sen

sor wires in parallel with antenna emd telephone cables.

IMPORTANT: The use of aluminum wire for any power or

control wiring is not allowed, all electrical wiring must be

copper; and all wiring specifications pertaining to the 38QE

system are specified as copper wire using American Wire

Gauge (AWG) sizing system

Step 11 —Install Control and Sensor Wiring

The control wiring consists of connections between the com

pressor section, water heater control box, indoor fan coil

and the thermostat. Sensor wiring is connected between the

outdoor fan coil and the compressor section. Sensor wiring

is also connected between the water heater tank and the

domestic water heating control box.

Control and sensor wiring requires standeird "thermostat

type and gauge of wire. The plenum cable listed in Table 2 is

recommended.

Compressor Section to Indoor Fan Coil Section

Run one length of 3 conductor wire. See Fig. 9 for connec

tion schematic. These three wires are used to control com

munications. To reduce the possibihty of electrical interfer

ence, route this cable along the refrigerant tubes and attach

with wire ties.

Compressor Section to Outdoor Fan Coil Section

Run one length of 3 conductor wire. See Fig. 9 for connec

tion schematic. These wires are used for outdoor unit tem

perature sensors. To reduce the possibility of electrical

interference, route this cable along the refrigerant tubes and

attach with ties.

Domestic Water Heater Control Box to Compressor Section

Run one length of 4 conductor wire. See Fig. 9 for connec

tion schematic. Two wires will be used to power the water

heater contactor. The other two wires will be used for the

tank sensor connections. Do not interconnect the contactor

and sensor wires as immediate damage will result.

Domestic Water Tank Temperature Sensor to Water Heater

Control Box

See Fig. 9 for connection schematic. Use 2 conductor wire, if

extra length is required to make the connection.

NOTE: For installations with a gas hot water heater and a

preheat tank, the water heater control box may be omitted.

Wire tank water temperature sensor directly to compressor

section as shown in Fig. 9.

Step 12—Install Thermostat Wiring

The thermostat connections are described below for both

single and multiple zone installations.

The single zone instaRation requires a Parker relay pack

power supply accessory to provide power for the single zone

thermostat.

Single Zone—Fig. 10

Connect 3 wires from indoor fan coil section to monitor ther

mostat. Connect 5 wires from thermostat to power supply

module. Connect 2 wires from the power supply module to

the indoor fan coU section terminals R and C or an auxiliary

transformer that is capable of supplying 24 VAC. These

connections are shown schematically in Fig. 10. AH connec

tions within the indoor fan coU are described in the 40QE

Installation Instructions.

Multiple Zone (option)—Fig. 11

Connect 3 wires from indoor fan coil section to Monitor

Thermostat. AU additional zones are to be connected as

shown in Fig. 11 in parallel. All connections within the

indoor fan con and for each additional zone are described in

the 40QE Installation Instructions.

Other Accessories

Refer to the individual instructions packaged with optional

accessories for their control wiring. Also refer to the instal

lation instructions supplied with the 40QE indoor unit.

Step 13—Install Power Wiring

The 38QE system requires three branch circuits for power.

These include the compressor section, domestic water

heater and the indoor fan coil. The outdoor fan coil section

receives power from the indoor compressor section. The

electrical data for the 38QE system is shown in Table 4.

NOTE: Be sure field wiring comphes with local emd national

fire, safety and electrical codes, and voltage to system is

within limits shown in Table 4 or on unit rating plate. Con

tact local power company for correction of improper volt

age. See Table 4 for recommended circuit protection device.

NOTE: Operation of unit on improper line voltage consti

tutes abuse and could affect unit reliability. Do not install

unit in system where voltage may fluctuate above or below

permissible limits.

Install all branch circuits and disconnect switches in accord

ance with National Electric Codes (NEC) and appMcable

local codes. Locate disconnect(s) within sight from and read

ily accessible from the unit, per section 440-14 of the

National Electric Code (NEC).

208 Volt Operation

Model 38QE and 40QE units are factory wired for nominal

Page 10

TSR-01 Relay Pack Circuit Board

24 VAC

R and C on

'40QE

Terminal

Board

Fig. 10—Thermostat Wiring Diagram

(Singie Zone)

Fig. 11—Thermostat Wiring Diagram

(Multipie-Zone)

10

A89057

Page 11

Table 4—Electrical Data

OPERATING

INDOOR COMPRESSOR SECTION

38QE024300 208/230/1

38QE036300 208/230/1 187 254

OUTDOOR FAN-COIL SECTION

38QE924300 208/230/1

38QE936300 208/230/1 187 254

WATER HEATER CONTROL BOX

38QE9XX300 208/230/1 187 254 20 20

FLA —Full Load Amps

HACR—Heating, Air Conditioning and Refrigeration

MCA —Minimum Circuit Amps

RLA —Rated Load Amps

LRA —Locked Rotor Amps

VOLT/PHASE

VOLT AG £♦

MIN

187 254

187

MAX

254 .5

♦Permissible limits of the voltage range at which the unit will operate

satisfactorily.

♦♦Outdoor Coil Wiring—For 25-ft wire run or less, use minimum 14 AWG

wire size. For longer wire run, use same size wire as supply to compres

sor section.

COMPRESSOR FAN

LRA

35.0

35.0 25.3 50

RLA FLA

20.3 40

.7

MAX FUSE or

HACRTYPE

CIRCUIT BKR

AMPS

MCA

25.9

32.4

230 V operation. The primary connection on control trans

formers must be rewired to the 208 volt wires for line volt

age between 187 emd 218 Volts. Refer to the 38QE Compres

sor Section label wiring diagram for location and wire identi

fication to rewire the two (2) transformers in the main con

trol box. Refer to the 40QE label wiring diagram for loca

tion and wire identification to rewire the transformer in the

accessory heater or cooling-only control package. Cap each

unused transformer wire with a wire nut and tape or, if the

unused lead has a push-on terminal, tape and protect any

exposed metal on the terminal.

Compressor Section

InstaR branch circuit disconnect of adequate size to handle

compressor section. Route line power leads from disconnect

through hole provided in compressor section top rear panel

and into the main control box. Connect ground wire to

ground lug. Connect main power to the terminal block

located within the main control box. The compressor section

wire label illustrates the terminal block location.

Rear panel wiring holes are shown in Fig. 4. See Fig. 12 for

connection schematic.

38QE Compressor

Section Control Box

Outdoor Fan Coil Section

The outdoor fan coil section receives power from the com

pressor section. Provide a separate disconnect switch for

the outdoor fan cofi. section. Fig. 12 illustrates the connec

tions from the compressor section to the disconnect switch

and then to the outdoor fan coil section.

Connect ground wire to ground lug. Route power wires for

the outdoor fan coil section through the 7/8-in. hole provided

in the top rear panel of the compressor section. Splice wires

to pigtails with wire nuts.

Connect the power wires to the outdoor disconnect switch.

From the disconnect switch, extend wires through hole pro

vided in outdoor fan coil section and into line voltage sec

tion of control box. Splice leads to black and yeUow pigtails

with wire nuts. Connect ground wire to ground lug inside

control box.

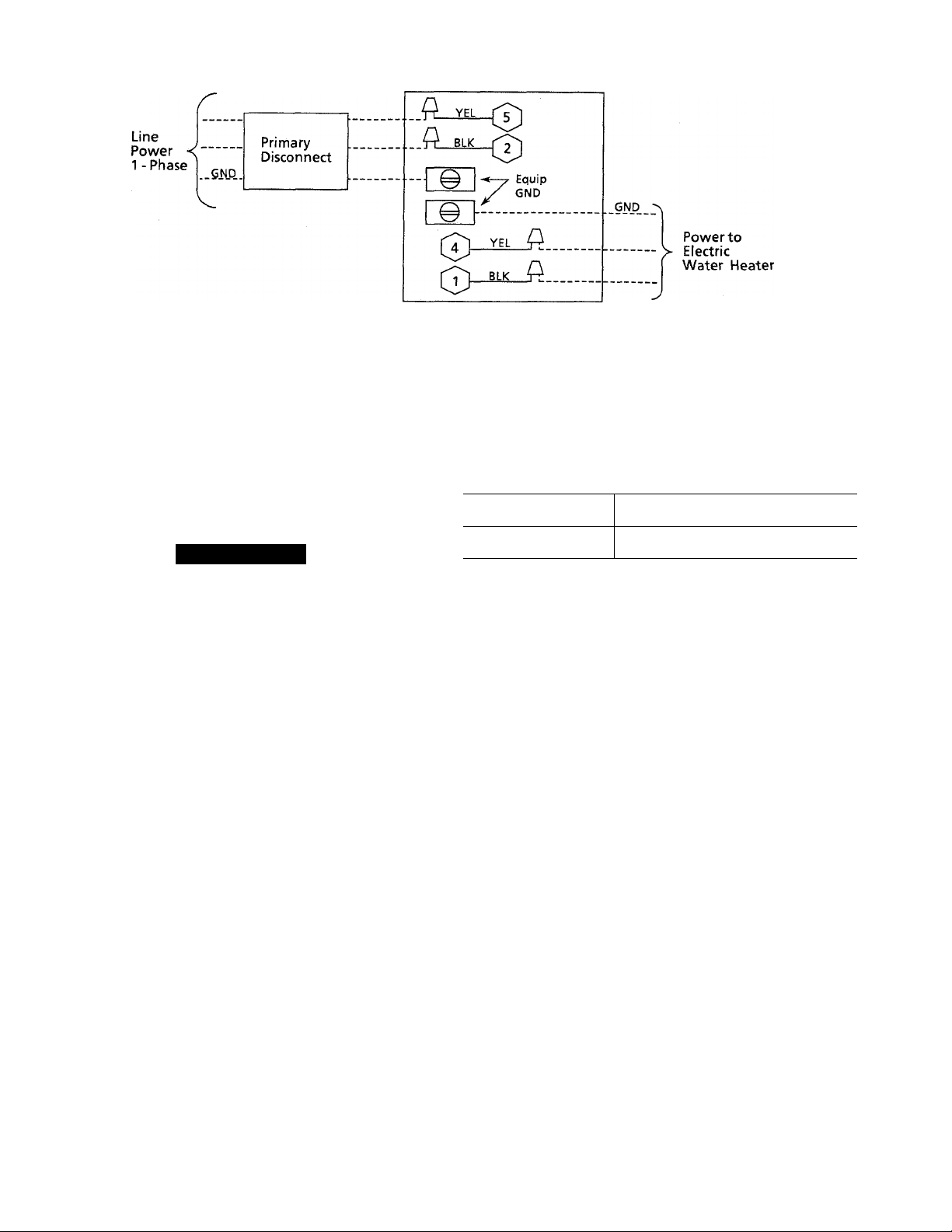

Domestic Water Heater Control Box (Electric Heater Only)

Install branch circuit disconnect of adequate size to handle

domestic water heater. Fig. 13 illustrates the required wir

ing connection between the branch disconnect and the 38QE

Splice Connection

Field Wiring

Factory Wiring

Fig. 12—Compressor Section and Outdoor

Section Power Connections

11

Page 12

38QE Water Heater

Control Box

Splice Connection

Field Wiring

Factory Wiring

Fig. 13—Water Heater Control Box Power Connections

(Electric Water Heater Only)

A89056

water heater control box and the domestic water heater

splice box.

A CAUTION

The water heater control box is designed for a maxi

mum of 20 Amps. Make certain that the water heater

does not exceed this 20 Amp limit. This system is not

designed to be installed with commercial grade electric

water heaters that may have greater than 20 Amp

requirements.

Indoor Fan Coil Section

Install branch circuit disconnect of adequate size to handle

indoor fan coil section. The proper wire sizing and lengths,

circuit breaker or fuse amp requirements are included in the

40QE installation instructions. Indoor power connection

diagrams are also included in the 40QE installation

instructions.

SYSTEM SET-UP ADJUSTMENTS

Step 14—Inspect Indoor Blower Speed Limits

40QE fan coils are supplied with maximum and minimum

speeds preset at the factory. Maximum and minimum

blower speeds are determined by an 11-pin torque selection

connector located on the blower controller. (See indoor imit

installation instructions for component location.)

To Inspect Blower Speed Settings—

1. Remove indoor unit access doors.

2. Refer to indoor unit installation instructions to locate

11-pin speed selection connector on controller.

3. Check for proper factory speed pin settings on control

ler and adjust as shown below, if necessary.

Minimum and maximum settings may require adjustment

later. Refer to the 38QE and 40QE Start-Up and Service

Instructions.

Step 15—Adjust Domestic Water Heating Tank Thermo

stats (Electric Heater Only)

Adjust the lower element thermostat setting to the mini-

INDOOR

UNIT

40QE024

40QE036

Refer to 40QE Installation Instructions for proper Indoor Fan Coll Blower

setup.

NOMINAL SPEED SETTINGS

(MAX.-MIN.)

5-2

7-3

mum value possible. This maximizes the heat pump water

heating capability. If this element is set above 100 F the

heat pump will not provide water heating. When the tem

perature setting of the lower element is above 100 F the

tank will operate as a conventional electric water heater.

(NOTE: If the 38QE has been installed with a conventional

gas water heater the above steps are not required.)

Step 16—Configure Thermostats

In order for the 38QE system to work properly the thermo

stat must be corrrectly configured.

This procedure contains basic instructions for thermostat

operation. For detailed information on adjusting setpoints

or setup, refer to the instructions inside the thermostat

cover and the HydroTech 2000 Start-up and Service

Manual.

If the thermostat appears to malfunction during this proce

dure, refer to the appropriate Parker Thermostat Operation

Manual. HydroTech 2000 Start-up and Service Manual or

the Parker Homezone Troubleshooting Guide.

Make sure thermostat mode switches are set to OFF, and

FAN is set to AUTO.

Turn the indoor unit main disconnect switch ON (Note:

Transformers supplying power to multi-zone dampers and

thermostats may be on separate circuit from indoor unit.).

When the thermostat is powered up, the display will show

cooling and heating set points. If the display is blinking on

and off, it is indicating incorrect wiring connections or that

the thermostat is not receiving adequate power. Check wir

ing connections and supply voltage from the transformer.

The voltage must be 22 volts minimum. Make certain that

the thermostat ribbon cable has been inserted into the con

nector board correctly.

12

Page 13

If the thermostat displays a hardware, software, heat pump,

or fan coil error code (HF,SF,HP or FC followed by a two

digit number), refer to the HydroTech 2000 Start-up and

Service Manual for further instruction on how to isolate and

clear system problems.

At initial start-up, thermostat(s) and bypass controller func

tions must be manually configured. This may be accompHshed per the instructions located under the thermostat

cover with addressing exceptions as Hsted below:

NOTE: Be sure to correctly configure system for a variable

speed system and single- or multiple-zone application as

detailed in the instructions for rotary switch position F8, F9

and F13.

The proper configuration, programming and setup for

single- and multiple-zone installations are described here:

1. Address numbers 1 thru 2 are reserved for the 38QE

controls. No other devices can use address 1 thru 2. Be

sure the 38QE compressor section control module is set

to address 1 and the 40QE fan section control module

is set to address 2.

2. The monitor thermostat used for single-zone applica

tions should use address 3.

3. For multiple-zone apphcations the monitor thermostat

MUST BE addressed to the highest number followed

by the bypass controller (required) and then the slave

thermostats in any order (example: monitor thermostat

is address 6, bypass controller is address 5, zone 2

slave thermostat is address 4, zone 3 slave thermostat

is address 3.)

4. Power to indoor unit must be cycled after any change

to monitor thermostat address.

After all device features have been set or checked, return all

rotary switches to position 0 then, start-up and check the

operation of the 38QE variable speed system. Refer to

HydroTech 2000 Start-up and Service Manual.

To check the configm-ation:

1. Power up the thermostat.

2. Remove the thermostat cover.

3. Turn the rotary switch to the position indicated in

Table 5.

4. Check that the configuration settings are correct.

After the configuration values are correctly set:

1. Turn the rotary switch to position “0”.

2. Replace the thermostat cover.

These configuration items are the minimum required to get

the system running. There are many other options and fea

tures available through the remaining configuration set

tings. Refer to the Parker Reference Manuals for a complete

description and correct use of these additional features.

Step 17—Adjust Refrigerant Charge

38QE refrigerant charge adjustment or recharge must be

made by weighing-in the proper amount of refrigerant. Serv-

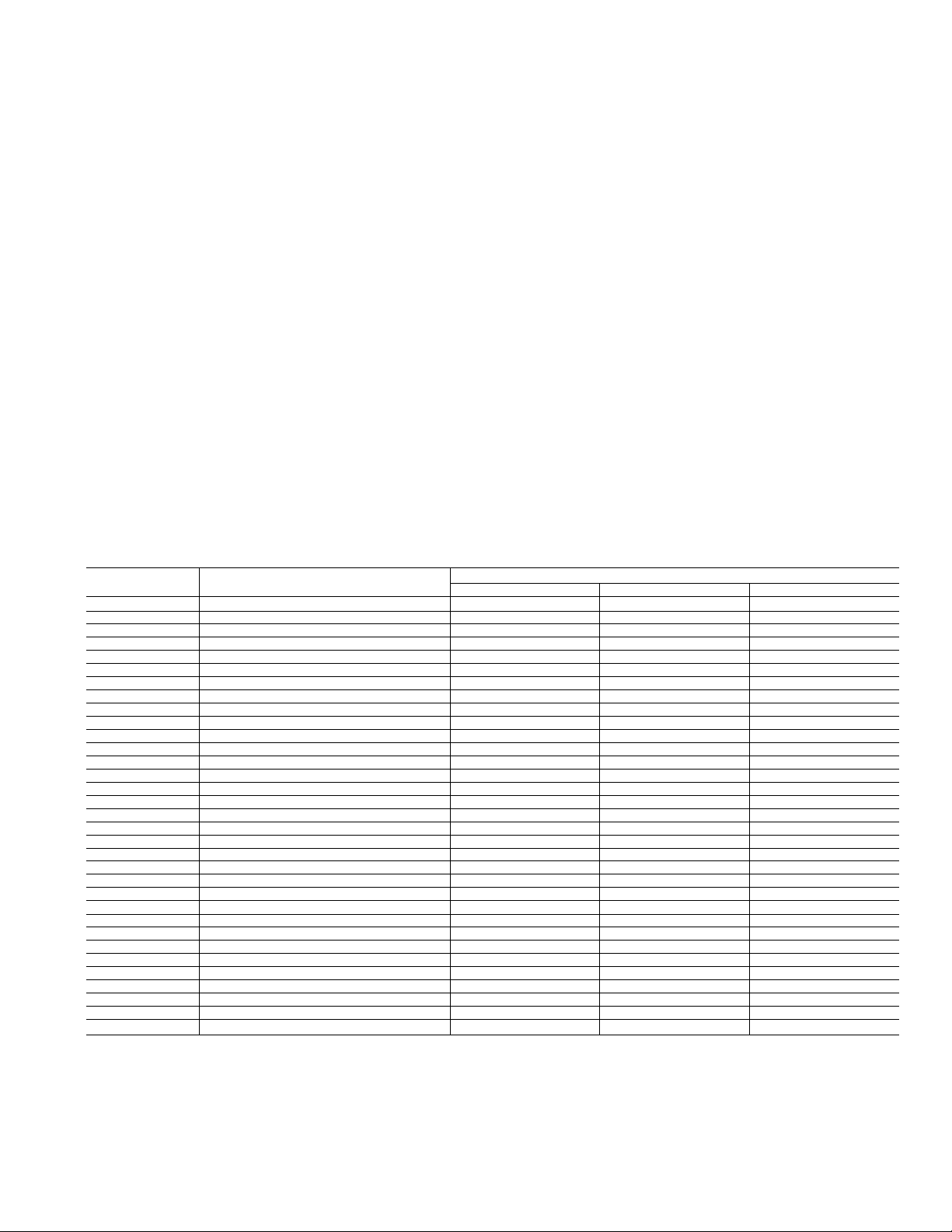

Table 5—Carrier/Parker HT2000 Home-Zone® Thermostat Configuration

ROTARY SWITCH

POSITION ROTARY SWITCH SETTING

0 COMFORT SETPOINTS 74 74 74 74

1

2 SETBACK OVERRIDE TIME LIMIT 60

3

4

4

5 ZONE TEMP. SENSOR CALIBRATION

6 SUPPLY AIR TEMP. SENSOR CALIBRATION

7 COMMUNICATION CHECK

8 PRESSURE SENSOR ERROR CORRECTION

9

A

B

c

D NOT USED

E

F1

F2

F3 ERROR CODE DISPLAY

F4 2400 BAUD RATE

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

FI 7

*VSE PARAMETERS ARE USED TO CONFIGURE OR TROUBLESHOOT THE VARIABLE SPEED SYSTEM. FOR DETAILS, REFER TO THE START-UP

AND SERVICE MANUAL FOR THE COMPRESSOR BEARING SYSTEM.

NOTE: ADDRESS THERMOSTAT FOR MULTIPLE-ZONE OPERATION AS FOLLOWS: SLAVE 2 ADDRESS = m-3

MONITOR ADDRESS = m I

BYPASS CONTROL ADDRESS = m-1 I

SLAVE 1 ADDRESS = m-2 SLAVE x ADDRESS = 3

DEVICE ADDRESS

SETBACK SETPOINTS 85 65 85 65

DAMPER MAXIMUM OPEN POSITION

DAMPER VENTILATION POSITION 05

MAXIMUM PRESSURE SETPOINT 100*

HUMIDITY SETPOINT 50

SYSTEM MODE DEMAND/LARGE DEMAND

VARIABLE SPEED EQUIPMENT CONFIG.

NOT USED

HTG./CLG. TIMEGUARD OVERRIDE

CELSIUS TEMPERATURE DISPLAY

HEAT PUMP SYSTEM ON

LOCAL OUTSIDE AIR TEMP. SENSOR**

DX COIL TEMPERATURE SENSOR OFF

MULTIPLE ZONE SYSTEM OFF

VARIABLE SPEED EQUIPMENT ON

LOCAL HUMIDITY SENSOR OFF

EFFICIENCY OPERATING MODE OFF*

ALTERNATE INFORMATION DISPLAY

HIGH/LOW TEMPERATURE LIMITS OFF

AUTO FAN OFF FOR HEAT

TEMPERATURE TREND STAGING ON

SETBACK LOCKOUT OFF

BYPASS CONTROLLER OFF

FACTORY SET. SINGLE ZONE

3

15

*

*

OFF

*

1

*

BLANK BLANK BLANK

BLANK

OFF

OFF

ON

ON

OFF

OFF

ON

X = NO. OFZONES-1

4 ZONES MAX. (MONITOR -I- SLAVES)

(REFER TO COMPRESSOR UNIT INSTRUCTIONS

FOR OTHER ZONING LIMITATIONS)

DISPLAY

3 m*

60

15

05 05

*

MULTIPLE-ZONE

*

OFF

*

100*

50

1 4

«

BLANK

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

ON

OFF

OFF*

OFF

OFF

ON

OFF

OFF OFF

OFF

74 74

60

85 65

15

*

*

OFF

*

100*

50

1 4

*

BLANK

OFF

OFF

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF*

OFF

OFF

ON

OFF

ON

13

Page 14

ice ports are provided on the liquid and vapor service

valves. Schrader fittings are also provided on the suction

and discharge tubes within the compressor section. Dial-ACharge charging cylinder is an accurate device for recharg

ing systems by weight.

A WARNING

Outdoor section service valve gauge ports are not

equipped with schrader valves. To prevent personal

injury, make sure gauge manifold or port caps are con

nected to the valve gauge ports before moving valves

off fully backseated position. Wear safety glasses and

gloves when handling refrigerant.

A CAUTION

Evacuate and purge BOTH suction and discharge

Schraders of COMPRESSOR SECTION. Purging only

from one or from only the outdoor service valves may

result in refrigerant being isolated in indoor section due

to system refrigerant control valving.

A CAUTION

Compressor damage may occur if system is over

charged. Weigh-in all refrigerant.

Initial system charging

The outdoor units are shipped with the base system refrig

erant charge for correct operation with a total piping length

from indoor section to outdoor section of 25 ft. The remain

ing components of the system should be leak-checkefl and

evacuated or purged before opening the service valves at

the outdoor cod. The procedure described here should be fol

lowed for the initial charge:

1. Pressurize the remaining system with R-22 vapor to

100 psig.

A WARNING

Never use oxygen or other flammable gases in a refrig

eration system for leak checking or any other purpose.

Personal injury or death can result from doing so.

After refrigeration system has been pressurized, with

the appropriate gas, to 100 psig, inspect all compo

nents, solder joints, mechanical connections, etc., for

leakage.

3. If a leak is found, do not attempt to repair until all

pressure has been reheved from the system. After the

pressure has been reheved, make repairs to leaking

component, repressurize system to 100 psig and con

tinue leak checking.

4. After ah components, solder joints, mechaniceJ connec

tions, etc. have been leak-checked, reheve ah system

pressure and evacuate or purge system.

NOTE: If either refrigerant tubing or unit piping is exposed

to atmospheric conditions for longer than 5 minutes, it must

be evacuated to 1000 microns to eliminate contamination

and moisture in the system.

5. Slowly open (turn clockwise) both service valves on the

outdoor fan coil section allowing the bare system

refrigerant cheuge to be released throughout the sys

tem. Service valves should be fuhy opened and back

seated. Port caps mstahed tightly.

6. Unit is shipped with valve stem(s) frontseated, and

caps installed. Replace stem caps after system is

opened to refrigerant flow (backseated). Replace caps

finger tight and tighten additional 1/12 turn (20-ft lbs

torque) using a backup wrench on valve body flats to

prevent distortion of sheet metal.

7. See refrigerant charging instructions or charging label

of outdoor or compressor section for field charge

adjustment for piping lengths used.

Full charge replacement

If refrigerant escapes from the system, leak test and evacu

ate entire system. Fohow precautions hsted in initial system

charging. Weigh-in system base charge plus adjustment for

field piping. Refer to charging label on outdoor or compres

sor section.

System Startup

A WARNING

DO NOT attempt to manually operate the contactor for

any reason. PersoneJ injury can result.

NOTE: The 38QE system compressor section is equipped

with a crankcase heater. It is recommended that the heater

be energized 24 hours prior to starting the unit. To energize

crankcase heater set thermostat mode swritches to “off,”

turn on power to compressor section to the indoor fan coU

and thermostat.

Refer to the HydroTech 2000 Start-up and Service Manual

for further instructions before operating system. Leave the

thermostat mode switches to ‘OFF’ position until the start

up instructions have bjgen>thoroughly and completely read

and proper system op®E&on has been confirmed.

Copyright 1990 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

I

Tab l5al5a

^ PC 101 Catalog No. 563-964 Printed in U.S.A. Form 38QE-3SI Pg 14 , 5-90 Repiaces: 38QE-2Si

Loading...

Loading...