Page 1

Number One

AirConditbninq

Maker

Installation, Start-Up

Division of

Carrier Corporation

e

Carrier Parkway • Syracuse NY 13221

and Service Instructions

Heat Pump — Outdoor Section

CONTENTS

SAFETY CONSIDERATIONS............................. 1

INSTALLATION

Step 1 —Check Equipmentand Jobsite.. 1

• UNPACK UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER SYSTEM

REQUIREMENTS

Step 2 — Mount Outdoor Heat Pump ... 2

• ON THE GROUND: MOUNT ON A

SOLID, LEVEL CONCRETE PAD

• ON THE ROOF: MOUNT ON A LEVEL

PLATFORM OR FRAME

Step 3 — Make Piping Connections

• REPLACE THE ACCURATER™ RE

FRIGERANT CONTROL PISTON IN

THE INDOOR COIL AS REQUIRED

• CONNECT REFRIGERANT LINES

Step 4 — Make Electrical Connections... 5-6

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER NEC

• ROUTE LINE POWER LEADS

INTO UNIT

• CONNECT GROUND LEAD AND

POWER WIRING

• SEE INDOOR UNIT AND ELECTRIC

HEATER INSTALLATION, START-UP

AND SERVICE INSTRUCTIONS

• CONNECT CONTROL POWER

WIRING (24 v)

START-UP..........................................................6-8

SERVICE

MAINTENANCE

Installation and servicing of air conditioning

equipment can be hazardous due to system pres

sure and electrical components. Only trained and

qualified service personnel should install, repair or

service air conditioning equipment.

Untrained personnel can perform basic mainte

nance functions of cleaning coils and cleaning and

replacing filters. All other operations should be per

formed by trained service personnel. When working

on air conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit

and other safety precautions that may apply.

..........................................................

.................................................

....................

.............................................

SAFETY CONSIDERATIONS

8-16'*

16-19

Page

1-6

2-5

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing opera

tions. Have fire extinguisher available for all brazing

operations.

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACK UNIT — Move to final location. Lift

carton off, taking special care not to damage service

valves or grilles.

INSPECT EQUIPMENT — File claim with ship

ping company if shipment is damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installing the 38QB.

Consult local building codes and National Elec

trical Code (NEC) for special installation

requirements.

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and servicing.

Position so water or ice from roof cannot drop

directly on top of unit.

Make provisions for condensate drainage and

defrost water disposal whether unit is installed on

ground or roof. (Ensure unit basepan drainage holes

are not blocked.) See Step 2 for details. Roof instal

lation method for 38QB depends on building con

struction and special requirements of local codes.

Be sure that roof can support unit weight.

It is recommended that 38 QB units be used with

Carrier approved indoor sections; see Table I.

System Refrigerant Control on 38QB units and

matching Carrier indoor units is a factory-installed

AccuRater device (bypass-type). Bypass-type AccuRater components are discussed in the service sec

tion of this booklet. The AccuRater piston has a

refrigerant metering hole thru it and is field replace

able. Table 1 indicates indoor units for which the

required replacement piston is factory supplied with

specified 38QB outdoor unit. Replace piston as

described under AccuRater Servicing on page 15.

© Carrier Corporation 1983 Form 38QB-7SIM

Page 2

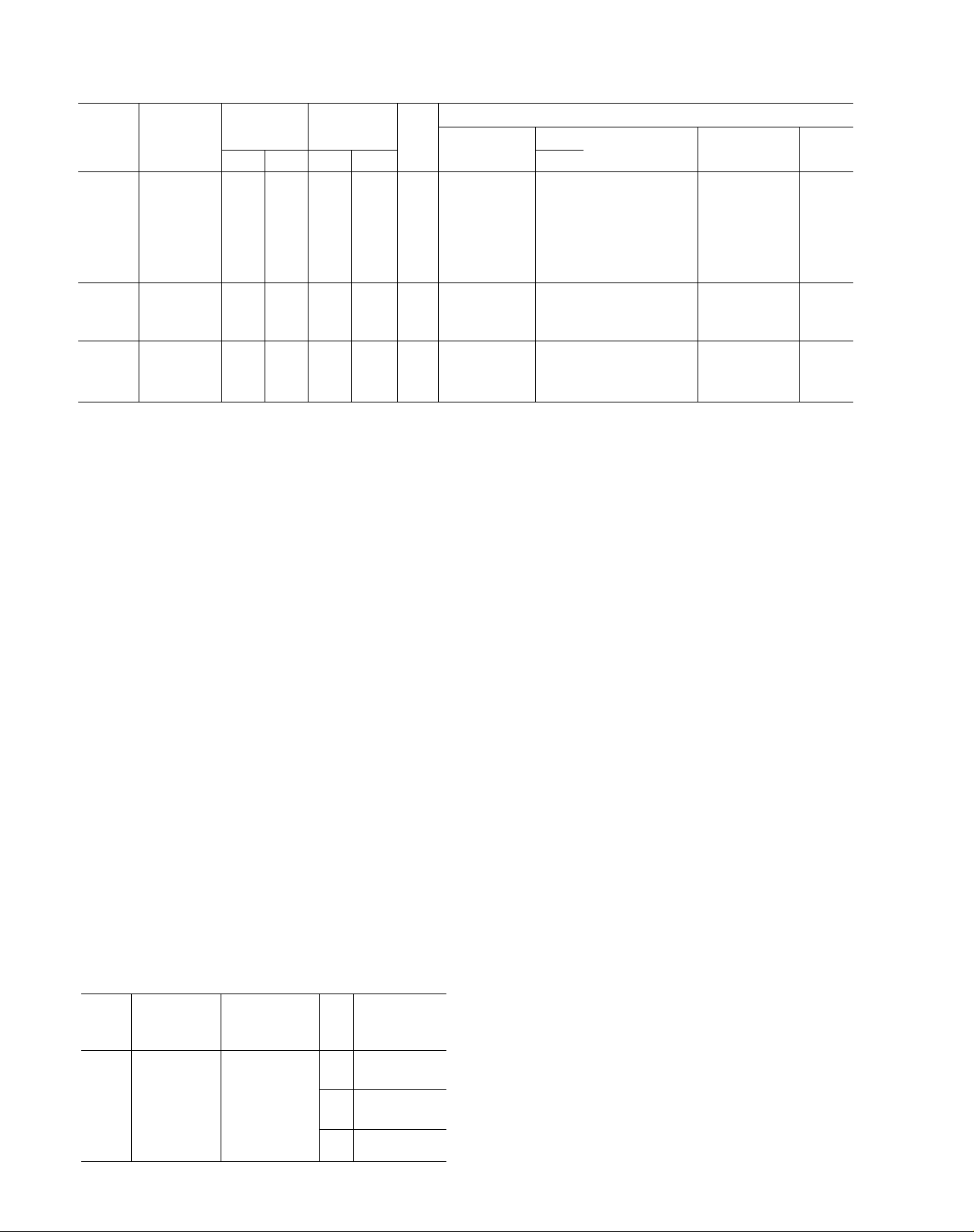

^ Table 1 — Carrier Approve^^6^ Systems

OUTDOOR

UNIT

38QB

015

018

024

030

036

042

048

060

‘Replace factory-installed piston with this piston size

REQUIRED

OUTDOOR

PISTON

SIZE

38

42

46

59

61

63

73

82

INDOOR

UNIT

MODEL 8i

SIZE

28HQ.VQ018

40AQ018

40DQ018

28HQ.VQ024

40AQ024

40DQ024

28HQ.VQ024 55

40AQ024

40DQ024 59

28HQ.VQ030

40AQ030

40DQ030

28HQ.VQ030

40AQ030

40DQ030

28HQ.VQ036

40AQ036

40FS160 1 28HQ.VQ036

28HQ.VQ036

40AQ036

40FS160 1 28HQ.VQ036

28HQ.VQ042

40FS160 1 28HQ.VQ042

40QB.QH042

28HQ.VQ042

40FS160 I 28HQ,VQ042

40QB.QH042

28HQ.VQ048

40FS200 1 28HQ.VQ048

40QB.QH048

40QB.QH060

REQUIRED

INDOOR

PISTON

SIZE

46

46*

52*

55*

61*

63

63*

63

70*

67

76

76

86*

93

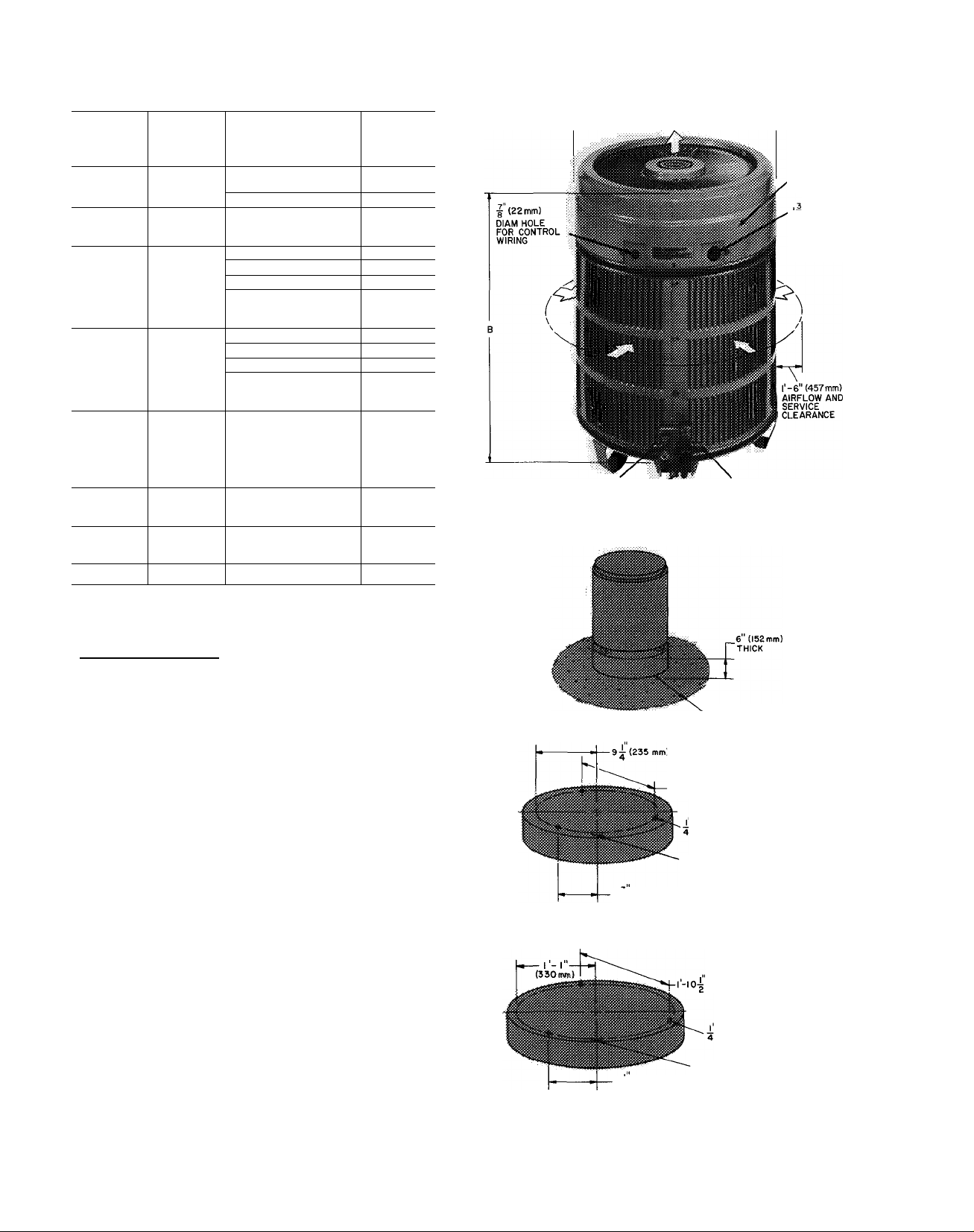

4'-0" (1220 mm) OVERHEAD SPACE REQUIRED

FOR SERVICE AND AIRFLOW

TOP

COVER

DIAM HOLE

FOR POWER

WIRING

LIQUID VALVE SERVICE PORT f VAPOR VALVE SERVICE PORT

[//> AIRFLOW SUCTION SERVICE PORT

I

Top Cover Removal — Top cover can be removed

for wiring or servicing heat pump. Loosen decora

tive strip and slide down off screw heads. Remove

3 screws in connector plate and 2 screws on front of

unit. Loosen remaining 4 serews. Lift top from unit

(see Fig. 1).

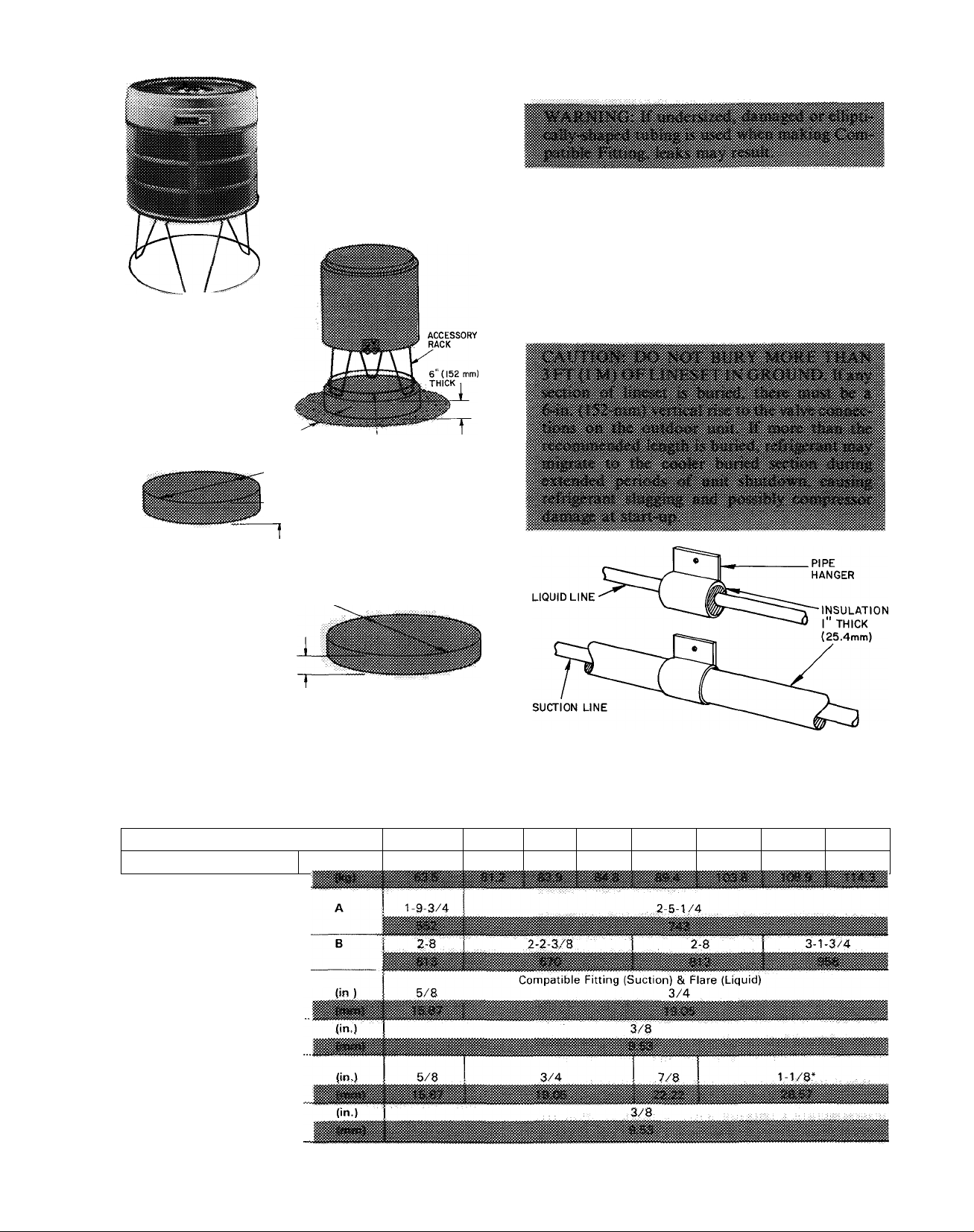

Step 2 — Mount Outdoor Heat Pump

ON THE GROUND: MOUNT ON A SOLID

LEVEL CONCRETE PAD (see Fig. 1). Swing 3

legs down and lock in position, except when using

accessory rack. Use accessory heat pump rack

(Fig. 2) in areas where prolonged subfreezing tem

peratures or heavy snow occur. (Refer to installation

instructions included with rack.) Drainage holes in

unit base must not be obstructed.

ON THE ROOF; MOUNT ON A LEVEL PLAT

FORM OR FRAME. Proper precaution must be

taken for support of unit in roof design. Elevate unit

for proper clearance as described under ground

installation, above. Plan roof design and water

drainage to prevent unit from setting in water. Flash

all roof openings to prevent leaks.

Roof mounted units exposed to winds above

5 mph (8 km/h) may require protective wind baffles

(field fabricated) to achieve adequate defrost.

12 (305mm)

GRAVEL APRON

I-4 (407mm) TYPICAL 3 PLACES

(6.35 mm) TIEDOWN BOLTS

CENTERLINE BETWEEN

VALVES

6^ (172 mm)

Г-н" (585mm) DIAM x 6"(l52mm)THK CONCRETE

MOUNTING PAD FOR 38QB0I5

(572 mm) TYPICAL 3 PLACES

(6.35 mm) TIEDOWN BOLTS

CENTERLINE BETWEEN

9^ (241 mm)

VALVES

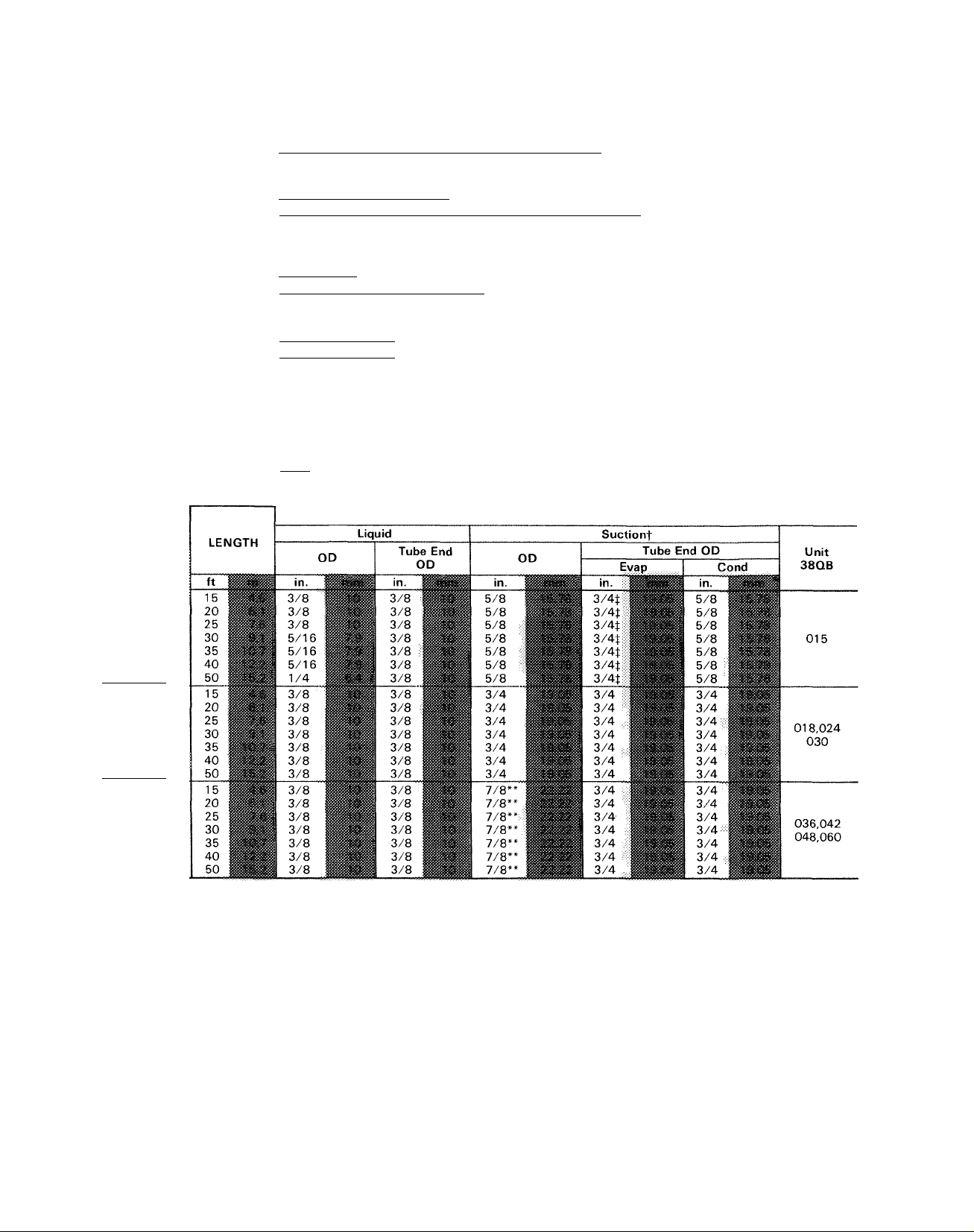

Step 3 — Make Piping Connections — Heat

pumps may be eonneeted to indoor sections using

Carrier aecessory tubing package (Table 3) or fieldsupplied tubing of refrigerant grade, correct size and

2-6" (762 mm) DIAM x 6" (152mm) THK CONCRETE

MOUNTING PAD FOR 38QB0i8-060

Fig. 1 — Dimensions, Connections and

Mounting Pad (Refer to Table 2.)

Page 3

condition (Table 2). For requirements beyond 50 ft,

obtain information from loeal Carrier distributor.

If 1-1/8in. tubing is used (38QB042,048,060),

braze it to the accessory 1-1/8 x 3/4-in. suction

connection adapter (Carrier Part No. 28AU900061)

or to a correctly sized field-supplied adapter, then

make Compatible Fitting connections. Isolate inter

connecting tubing from framing and ductwork or

where tubing runs thru stud spaces, enelosed ceilings

or pipe chases. Use isolation type hangers. Fig. 3,

since rigid fastening transmits pulsations to struc

ture creating objectionable sound.

I'-O" (305 mm)

GRAVEL APRON

Г-И" (584mm) DIAM

б" (152 mm)

THICK

CONCRETE MOUNTING PAD FOR 38QB0I5

2-6" (762mm) DIAM

6" (152 mm)

THICK

CONCRETE MOUNTING PAD FOR 38QB0I8-060

Fig. 2

- Accessory Mounting Rack

‘marker tape

(HIDDEN)

Table 2 — Installation Data (Fig. 1)

UNIT 38QB 015

OPERATING WEIGHT

(l|))

140 179

018

Fig. 3 — Refrigerant Line Hangers

024 030

185 187 , 197

036

042

229

048

240

060

252

DIMENSIONS

Diameter (ft-in.)

(mm)

Height (ft-in.)

(mm)

REFRIGERANT CONNECTIONS

Suction (ODF)

Liquid (ODF)

REFRIGERANT LINES

Suction (ODF)

Liquid (ODF)

‘May use 7/8-in (22 22-mm) accessory tubing package with slight capacity loss See Table 3

3

Page 4

Table 3 — Accessories

PART NO.

99TZ90040106

99TZ90041106

38QB90002106

99TZ90029101

28AU90006112

38R090008106

HN65DE026*

38HQ900002

38CQ900172

38RQ900091

38QB90001106

38QF90000106

38HQ90014106

38QB90003106

HC95DD120* Start Capacitor

HC95DD12V Start Capacitor

HC95DD058* Start Capacitor

HC95DD088* Start Capacitor

HN61HB515* Relay

HN61HB496*

38EB660002*

TUBING

PACKAGE

Low-Voltage Control — Honeywell Thermostat HH07AT171 and

Thermostat Subbase HH93AZ173 — (Automatic Changeover)

Low-Voltage Control — Honeywell Thermostat HH07AT171 and

Thermostat Subbase HH93AZ175 — (Manual Changeover)

Service Sentry (Six HN65CT004)

Honeywell — Manual Changeover. 2-Stage Heating, 1-Stage Cooling

Twelve 3/4- x 1-1/8 in. Connection Adapters

Bi-Flow Heat Pump Filter Drier (Six KH45LD077)

Supplemental Heat Relay-

(Service Parts)

Outdoor Thermostat (Six 38HQ900011)

0ptimizerControlOutdoorThermostat(Six38CO900161 ref HH22AG110)

Optimizer II Control Assembly (Use with HH2AG1 lOoutdoorthermostat.)

Heat Pump Rack (Six)

Heat Pump Rack (Six)

Optimizer III (Six 38HQ900141)

Solid-State Time Guard II (24-volt)

Relay

Wire Bundle for Start Capacitor and Relay

__________

DESCRIPTION

- (Required with 2 Outdoor Thermostats )

TUBING

UNIT 38QB

All

042-060

All

015-018

024-060

All

015

018

024,030

036

015,018

024,030,036

015-036

38LS958151

38LS958201

38LS958251

38LS958301

38LS958351

38LS958401

38LS958501

38LS934151

38LS934201

38LS934251

38LS934301

38LS934351

38LS934401

38LS934501

38LS978151

38LS978201

38LS978251

38LS978301

38LS978351

38LS978401

38LS978501

*Available thru Carrier Service Parts

tSuction line is insulated and has 90° bend

tFor 5/8-in (15 9-mm) evaporator connection, cut off 3/4-in (19 05-mm) belled end

‘‘Capacity reduction may occur when 7/8-in (22 22-mm) accessory tubing is used on 38QB042,048,060

A capacity reduction will result if accessory tub

ing is used in 38QB042 systems. For example, when

a 25-ft (7.6-m) 7/8-in. (22-mm) accessory package is

used, there is a capacity reduction of 1-1/2percent.

When other than 25 ft (7.6 m) of interconnecting

tubing is used, follow special requirements described

in Refrigerant Charging. Do not use less than 10 ft

(3 m) of interconnecting tubing. Do not cut 5/ 16-in.

(7.9-mm) or 1/4-in. (6.4-mm) liquid line due to

swage at ends. Do not cut 7/8-in. (22.22-mm)

suction line. Bend or coil to fit.

Do not use damaged or contaminated tubing.

Always evacuate or purge evaporator coil and

tubing system (use field-supplied refrigerant, not

unit refrigerant).

When making tubing connections, be sure to

provide clearance at unit for electrical connections.

Page 5

REPLACE THE ACCURATER™ REFRIGER

ANT CONTROL PISTON IN THE INDOOR

COIL AS REQUIRED before connecting refriger

ant lines. See Table I. Correct piston is supplied

with 38QB unit. For piston replacement instruc

tions, see AccuRater Servicing on page 15.

CONNECT REFRIGERANT LINES to fittings on

unit suction and liquid service valves (Fig. 1).

Liquid service valve has flare fitting; suction service

valve has Compatible Fitting. Make suction line

connection first. Slide flare nut on liquid line, then

flare and connect liquid line. Use a maximum

torque of 15ft-lb (20N-m) to tighten flare nut. (Do

not disassemble AccuRater.) Unit Compatible

Fitting permits mechanical or sweat connection as

described below.

When a 7/8-in. (22.22-mm) field-supplied suction

line is used on 38QB036,042,048 and 060, a field-

supplied 3/4-in. (19.05-mm) to 7/8-in. (22.22-mm)

suction line adapter must be provided (not required

if 38LS accessory tubing is used).

When a 1-1/8in. (28.57-mm) field-supplied

suction line is used on 38QB042,048 and 060, use

accessory adapter 28AU900061 or other fieldsupplied connection. Sweat connect refrigerant

suction line to 1-1/8 in. (28.57-mm) end of adapter.

Connect 3/4-in. (19.05-mm) end of adapter to unit

suction line Compatible Fitting.

Mechanical Connection to Compatible Fitting

(Mate one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure O-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Insert tube into Compatible Fitting until it

bottoms.

5. Tighten nut until it bottoms on back coupler

flange. Keep tube bottomed in Compatible

Fitting while tightening nut.

Sweat Connection to Compatible Fitting (Use

refrigerant grade tubing.)

1. Remove locking nut, rubber O-ring and Schrader

core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to pre

vent damage by heat. Solder with low tempera

ture (430 F [221 C]) silver alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied

refrigerant.

nameplate. Contact local power company for cor

rection of improper line voltage.

Do not apply units in system where voltage may

fluctuate above or below permissible limits.

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 4 for recommended wire and fuse sizes.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER NEC of adequate size to handle unit starting

current. Provide a separate disconnect for outdoor

unit, indoor unit and for each accessory electric

heater circuit as required. (See Indoor Unit and

Electric Heater Installation, Start-Up and Service

Instructions.) Locate disconnect(s) within sight

from and readily accessible from the unit per section

440-14 of National Electrical Code (NEC).

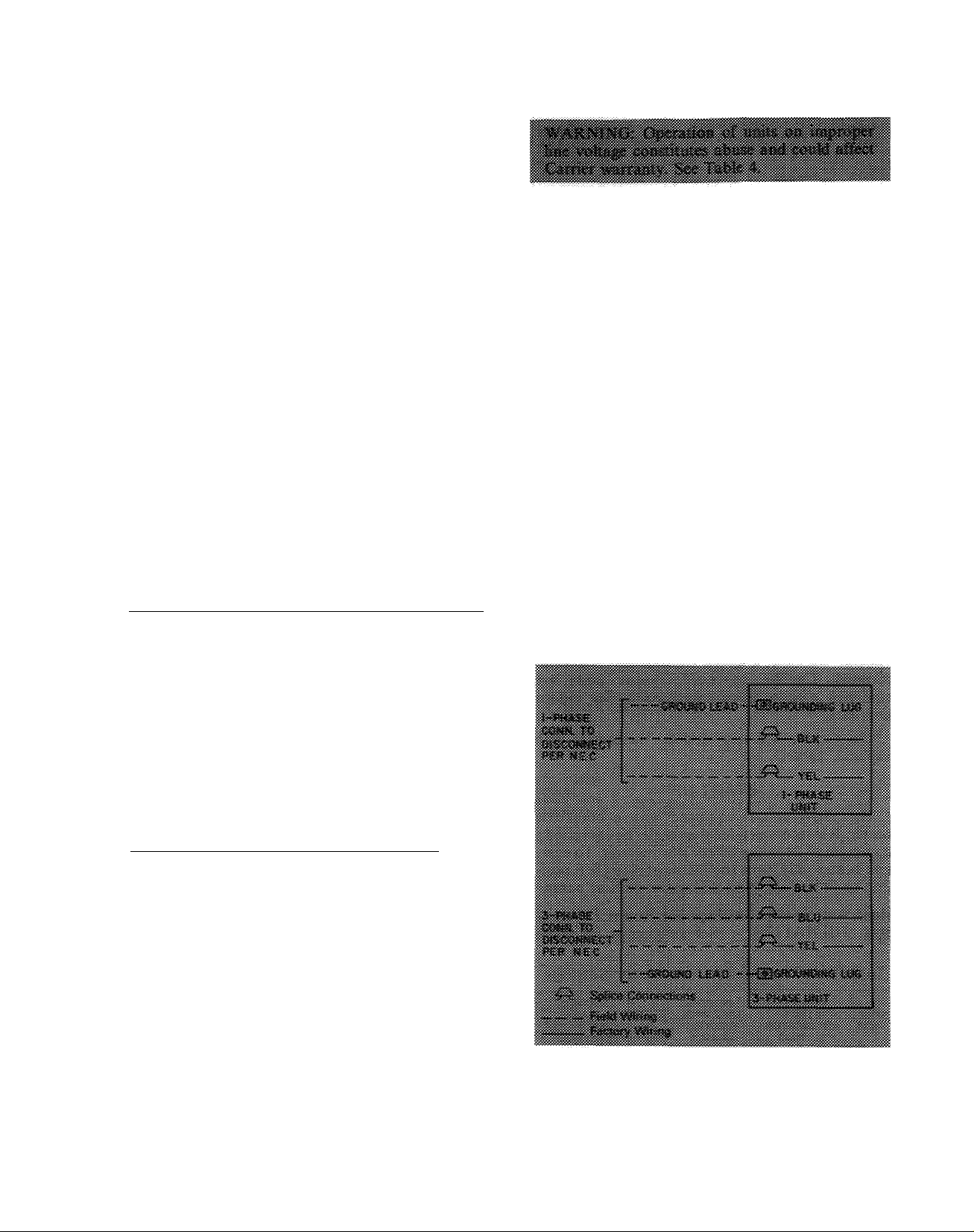

ROUTE LINE POWER LEADS INTO UNIT —

Extend leads from disconnect thru power wiring

hole provided (see Fig. 1) and into unit splice area.

Remove top cover to gain access to unit wiring.

CONNECT GROUND LEAD AND POWER

WIRING — Connect ground lead to a ground lug

in control box for safety. Then connect power

wiring. See Fig. 4. Splice line power leads to yellow

and black pigtails. Use wire nuts and tape at each

connection. Connect unit wiring to copper power

wiring.

Fig. 4 — Line Power Connections

Step 4 — Make Electrical Connections — Field

wiring must comply with local and national fire,

safety and electrical codes. Voltage to unit must be

within permissible limits of voltages indicated on

SEE INDOOR UNIT AND ELECTRIC HEATER

INSTALLATION, START-UP AND SERVICE

INSTRUCTIONS for line power wiring details. All

control wiring is shown in this booklet.

Page 6

Table 4 — Electrical Data (60 Hz)

UNIT

38QB

015

018

024 208-230/1

030

036

042

048

060

036

042

048

060

036

042

048

060

AWG — American Wire Gage

FLA — Full Load Amps

FIACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

RLA — Rated Load Amps

‘Permissible limits of the voltage range at which the unit will

operate satisfactorily

V/PH

208-230/1 254

208-230/1 254

208-230/1 254

208-230/1 254

230/1 254 207

230/1 254 207 105

230/1 254 207

208-230/3

208-230/3 254 197 80 13 3 24 14 29 1

208-230/3

208-230/3

460/3

460/3 506

460/3 506

460/3 506

OPER

VOLTAGE*

Min

Max

197

197 48 124

254 197

197

197 88 20 6

254 197

254 197 80 16 3 24 12

254 197 98

506 414 30 5 1 1 2 14 159 1

414 35 72 1 2 14 120 1

414 40

414 49 104 1 2

COMPR

LRA

RLA

34

66

15 5 24 12 32 ;l 12

82

165

98

199 24

22 4

130 27 8

87

11 7 24 14 32 1

20 9 24

7 7

80

FAN

FLA

1 25

1 25

24

24

24

24

1 2 14 109 1

Min Wire

Size (AWG)t

14

14

12 32 1 12

10

10

8

8

10

14

tCopper wire sizes based on 60C Use copper wire only.

tRequired when using nonmetallic conduit

“Time-delay fuse

NOTE: All units have 24-v control circuit which requires external

power source

Max \

40 1

27 1

39 1

44 1

62 1

51 I

24 1

_3I ■

BRANCH CIRCUIT

'Vire ; 1 Min Gnd

Wire Sizel

M 10

__________

14

u

10

10

10

14

14

12

14

14

14

______

Max Fuse**

or HACR Type

Ckt Bkr Amps

15 109

25

35

35 23 0

45

45

50

60

25

30

35

45

15

15

15

20

MCA

168

21 8

28 2

27 3

30 4

37 2

170

190

22 8

28 5

76

102

11 2

142

CONNECT CONTROL POWER WIRING (24 V)

— Extend wiring thru hole provided (Fig. I) and

into low-voltage section of unit control ring.

Connect leads to control wiring terminal board as

shown in Fig. 5.

Use indoor unit transformer as 24-v supply for

system. At least a 60-va transformer is recom

mended. Carrier approved indoor units are

equipped with a 60-va transformer. See indoor

unit data.

Use Carrier accessory indoor thermostat with

suhbase, Table 3.

START-UP

The 38QB unit is equipped with a crankcase

heater. It is recommended that heater be energized a

minimum of 24 hours before starting unit. To ener

gize heater only, turn the thermostat to OFF posi

tion and close electrical disconnect to heat pump.

Heat Anticipator Settings for Room Thermo

stat (HH0IAT171) — Set anticipator for room

^ Table 5 — Thermostat Anticipator Settings

UNIT

38QB

015

018

024

030

036

042

048

060

FIRSTSTAGE

ANTICIPATOR

SETTING

Fixed

INDOOR

UNIT WITH

ELECTRIC

HEATER

40DQ and

40AQ Fan Coil

with 40AQ Htrs

or 40QB,QH

Fan Coil with

40QB Htrs

HTR

KW

150

20 0

25 0

30 0

34 0

ANTICIPATOR

50

7 5

100

SECOND-

STAGE

SETTINGS

25

50

75

thermostat according to Table 5. These settings may

be changed slightly to provide a greater degree of

comfort for a particular installation.

Accessory Outdoor Thermostat provides adjust

able outdoor control of accessory electric heater.

This thermostat makes contact when a drop in out

door temperature occurs. It energizes a stage of elec

tric heat when the outdoor temperature setting is

reached, provided the room thermostat is on the

second stage of heating. One outdoor thermostat is

recommended for each stage of electric heat after the

first stage. Set the outdoor thermostat(s) pro

gressively lower for each stage. Refer to heat load of

building and unit capacity to determine the correct

outdoor thermostat settings.

The accessory supplemental heat relay is required

when 2 outdoor thermostats are used. It is auto

matically energized by the manually operated

supplemental heat switch in the indoor thermo

stat subbase. The thermostat locks out compressor

and the relay bypasses the outdoor thermostats for

electric heater operation during heat pump shut

down. When one outdoor thermostat is used, a sup

plemental heat relay is not required. The supple

mental heat switch in the indoor thermostat subbase

bypasses outdoor thermostat, locks out compressor

and activates electric heater.

MOUNT OUTDOOR THERMOSTAT on control

ring, to the left of the low-voltage control connec

tion. See Fig. 1.

Attach brackets with short sheet metal screws to

avoid contaet with coil. Leave capillary tube coiled

in control compartment making sure it is clear of all

electrical connections and sharp metal edges.

Page 7

THERMOSTAT

AND

SUBBASE

40AQ OR 40QB FAN COIL

COOLING CONTROL KIT

TERMINAL BOARD

(38QB/40AQ 0R40QB WITHOUT ELECTRIC HEATER)

380B

TERMINAL

BOARD

THERMOSTAT

AND

SUBBASE

(38QB WITH 40AQ, 40QB,QH OR 40FS/28HQ,VQ

EQUIPPED WITH ELECTRIC HEATER;

SUPPLEMENTAL HEAT, ONE OUTDOOR THERMOSTAT)

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

COOLING AND TWO-STAGE HEATING

38QB

TERMINAL

BOARD

THERMOSTAT

AND

SUBBASE

COOLING AND TWO-STAGE HEATING

(38QB WITH 40AQ,40QB,QH OR 40FS/28HQ,VQ

EQUIPPED WITH ELE6tRIC HEATER;

SUPPLEMENTAL HEAT, NO OUTDOOR THEf^MOSTATS)

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

В

THERMOSTAT HH07AT171 40DQ ELEC.HEATER

WITH HH93AZI73(AUTO (ALL MODELS) 38QB

CHANGEOVER) OR HH93AZI75 LOW VOLTAGE TERM. TERMINAL

(MAM CHANGEOVER) SUBBASE SPLICE CONNECTIONS BOARD

38Q8

TERMINAL

BOARD

THERMOSTAT

AND

SUBBASE

COOLING AND TWO-STAGE HEATING

EQUIPPED WITH ELECTRIC HEATER;

SUPPLEMENTAL HEAT, TWO OUTDOOR THERMOSTATS)

40AQ OR 40QB

ELECTRIC HEATER

TERMINAL BOARD

(38QB WITH 40FS/28HQ,VQ

38QB

TERMINAL

BOARD

ODT — Outdoor Thermostat

SHR — Supplemental Heat Relay

------------

------------

Factory Wiring

Field Wiring

SUPPLEMENTAL HEAT, NO OUTDOOR THERMOSTATS)

‘Transformer (60 va) located in cooling control kit or electric heater

fRemove factory-installed jumper (Connection B) when installing outdoor thermostats (ODT)

Fig. 5 — Control Circuit Connections

Page 8

MOUNT SUPPLEMENTAL HEAT RELAY in

convenient location on indoor unit. Attach with

sheet metal screw.

To Start Unit — (Make sure crankcase heater has

been energized for 24 hours.) Adjust the thermostat

as follows:

1. Set selector switch at OFF.

2. Turn on main disconnect switch(es) to indoor

and outdoor units.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Refrigerant

Charging.

(Fig. 8, 10, 12, 14, 16, 18, 20, 22) and follow

Charging Chart Method below. The charging chart

may also be used as an alternate method of recharg

ing system.

To check system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 9, 11, 13, 15, 17, 19,21,23). These charts indi

cate whether a correct relationship exists between

system operating pressures and air temperatures

entering indoor and outdoor units. If pressure and

temperature lines do not intersect on chart, the sys

tem refrigerant charge may not be correct or other

system abnormalities may exist. Do not use Opera

tion Check Charts to adjust refrigerant charge.

Weigh charge into system.

SERVICE

Refrigerant Charging — The 38QB units contain

correct operating charge for complete system when

connected to 28HQ,VQ, 40QB,QH or 40AQ indoor

units with 25 ft (7.6 m) of tubing of recommended

diameter. Charge adjustment is required on other

systems. Adjust system charge for refrigerant line

lengths and diameters that differ from 25 ft (7.6 m)

and 3/8in. (10mm) OD (liquid line), respectively,

using refrigerant weights below. Twenty-five ft

(7.5-m), 3/8-in. (lO-mm)ODtubingcontains 14.4 oz

(.4 kg) of R-22. Add R-22 charge to system if liquid

line is over 25 ft (7.6 m); remove charge if liquid

line is shorter than 25 ft (7.6 m).

When recharging is necessary during heating or

cooling season, weigh in total charge indicated in

Table 6. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in sys

tem before recharging. If system has lost complete

charge, triple-evacuate system to 5000 microns

(29.7 in. [100.5 kPa] vacuum) before recharging.

Service port connections are provided on liquid and

suction line service valves for evacuation and charg

ing. (See Fig. 6 for correct service port location

on cooling and heating cycles.) Dial-a-charge

charging cylinder is an accurate device used to re

charge systems by weight. These cylinders are avail

able at refrigeration supply firms.

To check and/or adjust charging during cooling

season, use correct Cooling Cycle Charging Chart

LIQUID LINE

DIAM (in.)

3/8 .58

5/16 36

1/4 .21

Fig. 6 — 38QB Refrigerant Flow Diagrams

OUNCES OF R-22/FT LENGTH

OF LIQUID LINE

Page 9

Table 6 — Service Data

UNIT 38QB 015

R-22CHG (lb)

40

018 024

6 2

AccuRator-'-' (Bypass iypo)

030 036 042

7 3 7 8 8 5

7 2

048;

8 6

060

8 0

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes be

fore checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

outdoor unit suction service port. (See Fig. 6

for correct service port location on cooling cycle.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature with service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor unit.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within nameplate

limit and compressor does not start, give compres

sor a temporary capacitance boost. See Carrier

Standard Service Techniques Manual, Chapter 2,

for details.

Table 7 — Compressor Data (60 Hz)

UNIT

38QB

015

018

024

030

036

042 PC4616BD

048

060 PC6016BD

036

042

048

060

036 MH3513GE

042

048 PH5016BD 64

060 PH6016BF 64

‘Refer to Service Parts Catalog for replacement compressor

model numbers

STRAINER VAPOR REVERSING

MUFFLER SOLENOID HOT GAS

V/PH

208-230/1

230/1

208-230/3

460/3

LINE VALVE

COIL DISCHARGE LINE

PRODUCTION COMPRESSOR

Model*

REK3-0125-PFV

CRA1-0150-PFV

MD2314GE

MD3214GE

MD3514GE 44 1

PC5016BD

MF3513GE

PY4616AD

PY5016BD

PY6016BF

PH4616AD

ECOIL

Oil Recharge

Ounces

20 1

51 1

44 i

44 j

64

64 1

64 1

44

64

64

64 1

44 i

64 !

COMPRESSOR

ACCUMULATOR

Fig. 7 — Component Location

Follow safety codes. Wear safety glasses and

work gloves. Have quenching cloth available.

Compressor Removal — See Table 7 for com

pressor information and Fig. 7 for component

location. Shut off power to unit. Remove refrigerant

from unit using refrigerant removal methods de

scribed in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants.

Be sure system pressure is 0 psig before

proceeding.

1. Remove top cover as described in Installation,

Step 1.

2. Disconnect high- and low-voltage field wiring

and fan motor leads from capacitor and

contactor.

3. Remove screws holding discharge grille in place.

Lift grille from unit.

4. Disconnect compressor leads (crankcase heater,

low-pressure switch, defrost thermostat and

solenoid coil) from electrical components and

pull them thru the wire access opening into the

Page 10

coil section. Lift fan orifice/control ring after

pinching and pressing down on 3 plastic pins of

tube supports.

5. Remove louvered casing by taking out 16 screws

seeuring it to the cabinet and sliding it away

from the eoil.

6. Using a midget tubing cutter, cut liquid and

discharge lines on the coil and suction and

discharge lines at a convenient place near the

compressor for easy reassembly with copper

slip couplings.

7. After plugging connections, remove condenser

coil by pinching plastic pins of tube supports

that extend into basepan and lift vertically.

Set coil on a clean, flat surface.

8.

Remove compressor holddown bolts and slide

out compressor. Remove crankcase heater.

9. Carefully unbraze suction and discharge line

piping stubs from compressor after noting posi

tion of stubs to assist when reinstalling.

10. Install new eompressor, placing crankcase

heater around compressor. Be sure compressor

holddown bolts are in place.

11. Replace coil; braze suction and discharge lines

to compressor piping stubs (at points where cut.

Step 6); rewire compressor and leak test.

12. Replace fan orifice/control ring; connect com

pressor wires after feeding them thru control

ring; replace fan/grille assembly and rewire;

connect high- and low-voltage power wiring;

and replace louvered casing.

13. Replace top cover by running 4 screws into

orifice loosely (2 on each side of unit) and

tighten when cover is in place. Replace remain

ing screws.

14. Evacuate and recharge system.

CHARGING AND PRESSURE CHECK CHARTS

Fig. 8 — 38QB015 with 28HQ.VQ018,

40AQ018 or 40DQ018 Cooling Cycle

Charging Chart

Fig. 9 — 38QB015 with 28HQ,VQ018,

40AQ018 or 40DQ018 Heating Cycle

Operation Check Chart

10

Page 11

(kPa)

PRESSURE AT SUCTION SERVICE VALVE

Fig. 10 — 38QB018 with 28HQ,VQ024,

40AQ024, or 40DQ024 Cooling Cycle

Charging Chart

Fig. 12 — 38QB024with 28HQ,VQ024,030,

40AQ024,030 or 40DQ030 Cooling Cycle

Charging Chart

Fig. 11 — 38QB018 with 28HQ.VQ024,

40AQ024 or 40DQ024 Heating Cycle

Operation Check Chart

11

(kPa)

SUCTION PRESSURE AT SERVICE PORT

Fig. 13 — 38QB024 with 28HQ,VQ024,030,

40AQ024.030 or 40DQ030 Heating Cycle

Operation Check Chart

Page 12

PSIG

(kPa)

62 64 66 68 70 72 74 76 78 80 82 84

(427) (441) (455)(469)(483)(496)(5I0) (524)(538)(552) (565)(579)

PRESSURE AT SUCTION SERVICE VALVE

PSIG

(kPa)

(455)(469) (483)(496) (510) (524)(538) (552)(565) (579)(595) (609)

PRESSURE AT SUCTION SERVICE VALVE

Fig. 14 — 38QB030with 28HQ,VQ030,036,

40AQ030.036, 40DQ030 or 40FS160 with

28HQ,VQ036 Cooling Cycle Charging Chart

Fig. 16 — 38QB036 with 40AQ036,042,

28HQ,VQ036,042, 40QB,QH042 or

40FS160 with 28HQ,VQ036,042 Cooling

Cycle Charging Chart

Fig. 15 — 38QB030with 28HQ,VQ030,036,

40AQ030,036, 40DQ030 or 40FS160 with

28HQ,VQ036 Heating Cycle Operation

Check Chart

12

(kPa)

SUCTION PRESSURE AT SERVICE PORT

Fig. 17 — 38QB036 with 40AQ036,042.

28HQ.VQ036,042, 40QB,QH042 or

40FS160 with 28HQ.VQ036,042 Heating

Cycle Operation Check Chart

Page 13

PSIG (441) (469) (496) (524) (552) (579)

(kPa) PRESSURE AT SUCTION SERVICE VALVE

64 68 72 76 80 84

Fig. 18 — 38QB042 with 40QB,QH042,

28HQ,VQ042 or 40FS160 with

28HQ.VQ042 Cooling Cycle Charging Chart

Fig. 20 — 38QB048 with 28HQ,VQ048.

40FS200 with 28HQ,VQ048 or

40QB.QH048 Cooling Cycle Charging Chart

(kPa)

SUCTION PRESSURE AT SERVICE PORT

Fig. 19 — 38QB042 with 40QB,QH042.

28HQ.VQ042 or 40FS160 with

28HQ,VQ042 Heating Cycle Operation

Check Chart

Fig. 21 — 38QB048 with 28HQ,VQ048,

40FS200 with 28HQ,VQ048 or

40QB,QH048 Heating Cycle Operation

Check Chart

13

Page 14

360

(2482)

340

(2344)

3 300

> (2069)

01

a

S 280

5 (1931)

!;

I 260

« (1793)

240

(1655)

220

(1517)

PSIG

(kPa)

. ;TT

ÌFH

-r^

:|T|C

T-i ¡J-

i_!_;

LI ■ :

: (li

=•1^1=2

000:

liii-

Pi

iiO

ET-

NT IN

;jj E UNIT

• 1 r i

Mi!

4it

'P';

'Hi- -Hip

JP

:[n

i|4

1 , ; :

! : :t

Fi" ”

PI

r 85 F

Ì:It

ijtr

i (29.4 C)

pH;

44-4

4

ÌÌ4

i-Ì4

#

iitt

tm

ì4H-

ip-

ìSl

2lii

64

(441)

rii^

p| i4

II5F

05 F

O.bC

44-

"7

tr

44

iP

ljp

P 62 F

pi (I6.6C)

ri ;J

4P;

p:[

pii

) /

RT

-i/-

iH-p

Pi-

/. : S

'-'t P

P;l

w

tp.

UT

iPr

pp-ip-

-7;

ii:i-

44:

l'r :

44

: ; 1 .

Ph

itlp

Pl

f

76

(524)

Pi

P H

Ìpi;

f-r:

p4

PII

/i-

-4 f4-

4 ì it

i-PP-

til

■ j f!

1 u t

: 1 ! .

tp

TrPF(46.l(

i-iiL

3ULB

TEMPAIR

DOOF

1Pi|P:i

t-pt

ip

i-y (4

h: :p

l:.i±r

1 i -

96F

350

-PI

TTtt

■PP T

fip

t/ ■

Cil: j

pi

-jfiP

■fljH

ifii

68

(469)72(496)

PRESSURE AT SUCTION SERVICE VALVE

80

(552)

Fig. 22 — 38QB060 with 40QB,QH060

Cooling Cycle Charging Chart

Filter Drier — Install field-supplied filter drier

(Table 3) in system liquid line when refrigerant sys

tem is opened for service as described under Com

pressor Removal. Position drier in liquid line at

convenient location.

Pumpdown Procedure — The system may be

pumped down in order to make repairs on low side

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (35 kPa) (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

Fig. 23 — 38QB060 with 40QB.QH060

Heating Cycle Operation Check Chart

INTERNAL CURRENT AND TEMPERATURE

SENSITIVE OVERLOAD resets automatically

when internal compressor motor temperature drops

to a safe level (overloads may require up to 45

minutes to reset). When an internal overload is

suspected of being open, check by using an ohmmeter or continuity tester. If necessary, refer to

Carrier Standard Service Techniques Manual,

Chapter 2, for complete instructions.

LIQUID LINE LOW-PRESSURE SWITCH

(LLPS) is connected in liquid line to work with

compressor internal thermostat in providing loss-of-

charge protection during the heating cycle. Control

is mounted on liquid line.

With a high-side leak, pressure gradually de

creases until low-pressure control stops the com

pressor. (Low-pressure control settings are shown

in Table 8.)

Table 8 — Pressure Switch Settings

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE is located in

compressor. Relief valve opens at a pressure differ

ential of approximately 500 psig (3448 kPa) between

suction (low side) and discharge (high side) to allow

pressure equalization.

14

UNIT

38QB

015

018

024

030

036

042

048

060

LIQUID LINE

LOW-PRESSURE SWITCH

Cut-in

22 + 5t)sis

Cutout

7 ± 3 psio

Page 15

With a low-side leak there is always some pressure

in the liquid line. However, compressor motor tem

perature increases because of insufficient suction

gas cooling. This causes internal thermostat to

actuate and stop compressor. When compressor

stops, system pressure equalizes and contacts on

pressure control open. The compressor cannot

restart until leak is repaired and system recharged.

CRANKCASE HEATER is connected across line

side of contactor and operates continuously.

The purpose of the heater is to keep the crankcase

warm during the off cycle and thus prevent dilution

of the oil with refrigerant. This assures good lubrica

tion and prevents loss of oil from crankcase during

start-up.

To energize crankcase heater, turn thermostat to

OFF position and energize electrical disconnect to

heat pump.

If the electrical disconnect switch to the outside

unit has been off for an extended period of time, the

crankcase heater should be energized for 24 hours

before starting the compressor.

DEFROST CONTROL, consisting of defrost

control board and defrost thermostat, interrupts

normal system heating operation every 90 minutes

to defrost outdoor coil, if the coil saturated suc

tion temperature indicates freezing temperatures.

Defrost control simultaneously stops outdoor fan,

energizes reversing valve solenoid to return system

to cooling cycle (outdoor unit as condenser, indoor

unit as evaporator), and activates accessory electric

heater.

For the heat pump to defrost, 2 conditions are

necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit must

be cold enough to cause defrost thermostat

contacts to close. Contacts close at 31 ± 4F

(-.5 + 2.2 C).

Every 90 minutes of elapsed running time, the de

frost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally, the frost is removed and

the defrost thermostat contacts open to terminate

defrosting before 10 minutes have elapsed. Defrost

thermostat contacts open at 80 ± 6 F (26.7 ± 3.3 C)

liquid refrigerant temperature. When defrosting is

terminated, the outdoor fan motor is energized and

reversing valve solenoid is de-energized, returning

unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 6 are re

frigerant flow diagrams for heating and cooling

cycles.

AccuRater™ (Bypass-Type) Servicing — See

Fig. 24 for bypass-type AccuRater components. The

piston has a refrigerant metering hole thru it. The

retainer forms a stop for the piston in the refrigerant

Fig. 24 — AccuRater (Bypass-Type)

Components

bypass mode, and a sealing surface for liquid line

flare connection. To check, clean or replace piston:

1. Shut off power to unit.

2. Pump unit down using Pumpdown Procedure

described previously.

3. Remove liquid line flare connection from

AccuRater.

4. Pull retainer out of body, being careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use locking pliers to

remove retainer.

5. Slide piston out by inserting a small soft wire,

with small kinks, thru metering hole. Ensure

metering hole, sealing surface around piston

cones and fluted portion of piston are not

damaged.

6. Clean piston refrigerant metering hole.

7. Replace retainer O-ring before reassembling

bypass-type AccuRater. Carrier O-ring part no.

is 99CC501052.

LIQUID LINE STRAINER (protects AccuRater)

made of wire mesh is located in the liquid line inside

38QB unit behind liquid line service valve. Liquid

line is belled and sweat connected where strainer is

located. If strainer is plugged, unsweat belled liquid

line connection and replace strainer. See Fig. 7.

Compatible Fitting Repair

LEAKING MECHANICAL CONNECTION —

Frontseat outdoor section service valves after reliev

ing refrigerant pressure in system. Back locknut off

Carrier Compatible Fitting onto tube. Cut fitting

between threads and O-ring shown in Fig. 25. Re

move tubing section remaining in threaded portion

of fitting. Discard locknut.

Clean, flux, and insert new tube end into remain

ing portion of Carrier Compatible Fitting. Wrap

valve base in wet rag. Heat and apply lowtemperature solder (430 F [221 C]).

LEAKING SWEAT CONNECTION — Frcntseat

service valves and relieve refrigerant pressure in

tubing. Clean and flux area around leak and apply

low-temperature solder (430 F [221 C]).

15

Page 16

Fig. 25 — Carrier Compatible Fitting

Condenser Fan Motor Removal

1. Shut off power to unit. Failure to do so may

result in electric shock or injury from rotating

fan blade.

2. Remove top cover as described on page 2.

3. Disconnect fan motor leads from controls.

4. Remove 6 screws holding fan motor/discharge

grille in place and lift assembly from unit.

5. Remove Carrier nameplate by straightening tabs.

6. Remove 4 nuts holding fan motor to discharge

grille. Remove motor and leads.

7. Reverse procedure for reassembly. Seal with

Permagum sealer around hub to prevent entry of

water between hub and shaft. Make sure fan is

positioned correctly as shown in Fig. 26.

MAINTENANCE

Lubrication

FAN MOTOR BEARINGS — Oiling holes are

provided at each end of condenser fan motor. Re

move fan motor and lubricate motor with 32 drops

(16 drops per hole) of SAE-10 nondetergent oil at

intervals described below.

a. Annually, when environment is very dirty,

ambient temperature is higher than 105 F (40 C),

and average unit operating time exceeds 15 hours

a day.

b. Every 3 years when environment is reasonably

clean, ambient temperature is less than 105 F

(40 C) and unit operating time averages 8 to

15 hours a day.

c. Every 5 years when environment is clean,

ambient temperature is less than 105 F (40 C) and

unit operating time averages less than 8 hours

a day.

COIL REPAIR — A flare-union coupling is used

for E-coil repair. A kit is available, with instructions,

thru Carrier Service Parts.

COMPRESSOR contains factory oil charge. If oil

requires replenishment, see Table 7 for oil recharge

and Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants, page 1-21, for instructions.

Use Carrier PP33-1, Texaco WF-32 or Suniso

3GS oil.

Coil Cleaning to be done at the beginning of

each cooling season or more often if required.

Fig. 26 — Condenser Fan Position

1. Shut off power to unit.

2. Remove louvered casing by taking out 16 screws

securing it to the cabinet and sliding it away from

the coil.

16

Page 17

3. Clean coil using vacuum cleaner and its crevice

tool (see Fig. 27). Work crevice tool vertically

making sure tool only touches dirt on fins. To

prevent fin removal, do not “scrub” fins with

tool or move tool horizontally.

4. If oil deposits are present, spray coil with house

hold detergent (Fantastic, Lestoil, 409, or any

similar type). Wait 10 minutes then proceed to

step 5.

Using garden hose, spray coil vertically down

5.

ward with a constant stream of water at moderate

pressure (see Fig. 28). Keep nozzle at a 15 to 20

degree angle, about 3in. (76 mm) from coil face

and 18 in. (457 mm) from tube. Spray so debris is

washed out and away from coil.

Reinstall louvered casing being careful not to

6.

damage coil.

Restore power to unit.

7.

Fig. 27 — Crevice Cleaning Tool

Fig. 28 — Positioning Hose to Spray Coil

17

Page 18

TROUBLESHOOTIIMG CHART — COOLING CYCLE

Page 19

VO

TROUBLESHOOTING CHART — HEATING CYCLE

Page 20

For replacement items use Carrier Specified Parts

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab

4

5a 5a

Form 38QB-7SIM Supersedes 38QB-2SIM Printed in U S A 9-83 PC 101

Catalog No 563-807

Loading...

Loading...