Page 1

HEATING & COOUNG

38GNA

Air Conditioning Unit

instaliation and Start-up instructions

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock or other condi

tions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions pack

aged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special require

ments.

It is important to recognize safety information. This is the safetyalert symbol /îy . When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

Understand the signal word DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage.

The 024 size is equipped with a time-delay device which prevents

restart within 5 minutes of power interruption.

Compressor motor is equipped with an internal protector. Exces

sive current or temperature causes protector to open which gives

indication of an open circuit in motor winding. Sufficient time

should be allowed for overload to reset before assuming compres

sor has an open winding.

Compressor motor is designed to start under low-load conditions

only. Make sure system pressures have equalized before attempt

ing to start unit. Equalization takes approximately 3 minutes.

Owner should be informed not to short-cycle unit with thermostat

as this causes compressor to trip out on overload.

Each unit is shipped with refrigerant charge adequate for use with

matching coils and refrigerant tubing kits. Charge is adequate for

systems using 25 ft of interconnecting tubing. See unit rating plate

for charge quantity. See Refrigerant Charging section and Table 2

for adjustment requirements.

A WARNING

Relieve all pressure before refrigerant system repair or final

unit disposal to avoid personal injury or death. Use all service

ports and open all flow control devices, including solenoid

valves.

A CAUTION

Do not vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

A WARNING

Before installing or servicing system, always turn off main

power to system. There may be more than 1 disconnect

switch. Turn off accessory heater power if applicable. Elec

trical shock can cause personal injury or death.

Intake and discharge are on front of the unit. A minimum service

access distance of 30 in. behind unit must be provided.

NOTE: Refer to unit rating plate for ratings. '

This condensing unit is designed for use with evaporator coils or

fan coils equipped with capillary tube or piston-type refrigerant

control device. It may also be used with evaporators which have

expansion valves that equalize pressure during the off cycle or

hard shut-off expansion valves. The 018 size with hard shut-off

expansion valve requires a hard start kit.

BEFORE INSTALLATION

Check power supply: voltage, frequency and phase must corre

spond with data on unit rating plate. Power supply must be able to

handle the additional load imposed by this equipment.

The 38GNA does not have a transformer. Therefore, the furnace

transformer (or another source) must be used as a low-voltage

supply. Transformer must have an additional capacity of 15 va

above the requirement of furnace or air handler.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book] 1 I 4 PC 101 Catalog No. 563-712 Printed in U.S.A. Form 38GNA-2SI Pg 1 11-92 Replaces: 38GNA-1 SI

Tab |3a|2a

GENERAL

NOTE: Check indoor coil piston to see if it matches the required

piston shown on unit rating plate. If it does not match, replace

indoor coil piston with piston shipped with this unit. The piston

shipped with outdoor unit is correct for any approved indoor coil

combination.

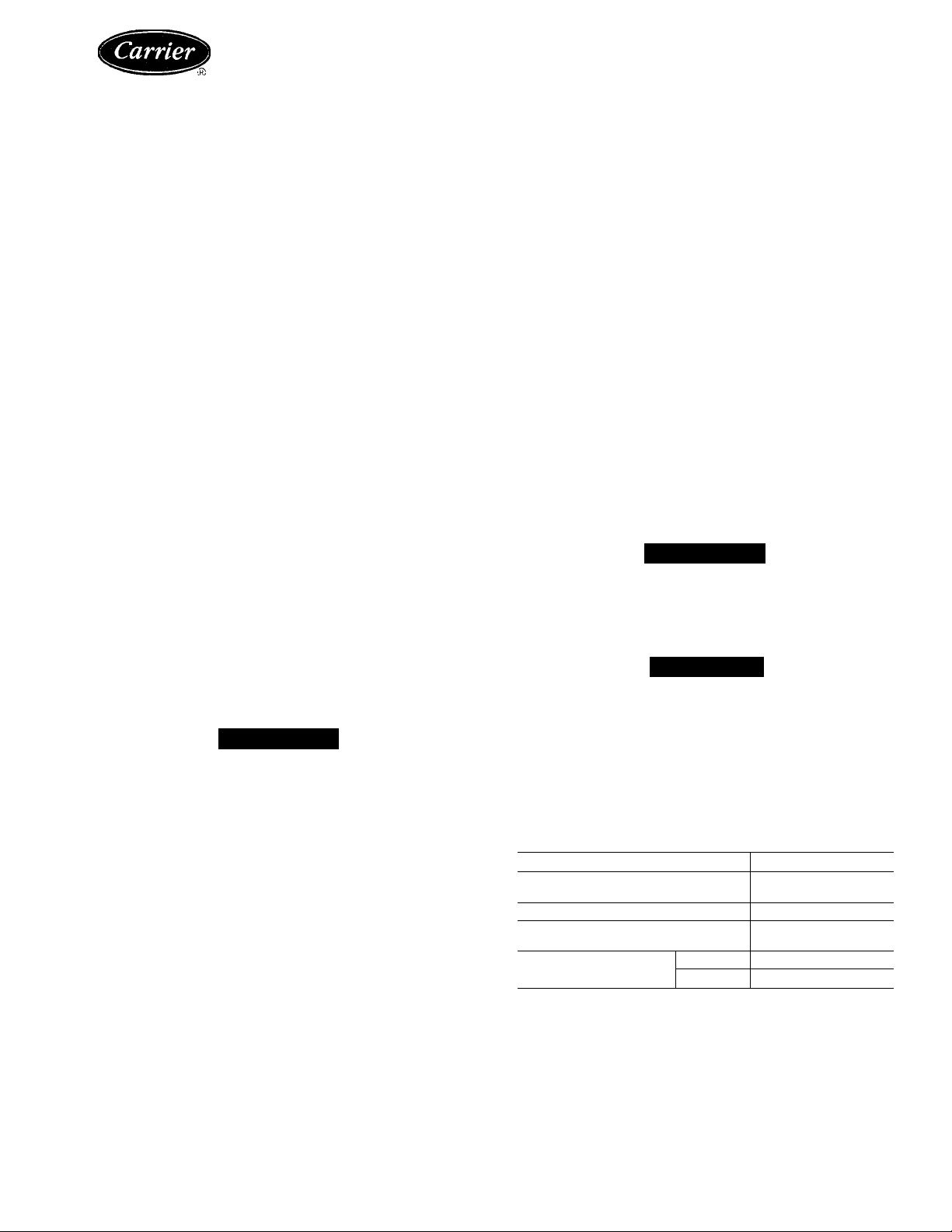

Table 1—Installation Data (In.)

38GNA

Through-the-Wall

Clearance Dim.

Air Clearance

Concrete Mounting

Pad Dim.

Service Clearance*

’Unit is serviced through rear access panel. Therefore, unit can be installed

with 0-in. end clearance.

Sides

Back

018 024

26-1/2 X 29

36

27 X 17 X 5

0

30

INSTALLATION

Install condensing unit either through-the-wall, outdoors on a slab

or on the roof. When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and servicing. Consult local

building codes and National Electrical Code (NEC) for special

installation requirements. See Fig. 1, 2 and 3 and Table 1 for

detailed installation data.

Page 2

AIR OUT

Fig. 1—Dimensions and Connections

7/8 DIA HOLE & 1-3/32 DIA K.O.

POWER INLET

A75135

Fig. 2—Roughing-ln Supporting Frame

Step 1—Make Opening in Wall

Make an opening approximately 26-1/2 x 29 in. in a wall as close

to the cooling unit as possible. Build a frame to support the

condensing unit. (See Fig. 2.)

1. Insert condensing unit with frame into the wall opening.

2. Extend unit approximately 1 in. beyond outside (finished) wall

and tilt to the outside to allow rainwater to drain off. (See Fig.

3.)

3. Fasten unit to frame with metal straps.

4. Use flashing under unit and caulk all edges to provide

weathertight seal. (See Fig. 3.)

(M>

Step 2—Make Piping Connections

SELECT CORRECT LIQUID AND SUCTION LINE

LENGTHS/DIAMETERS - Refer to Table 2.

INSTALL REFRIGERANT LINES — The condensing unit is

fully charged at the factory. Be sure both service valves are front

seated (turned clockwise) to avoid loss of charge. Do not remove

refrigerant line connection seals from condensing unit, matching

coil, or refrigerant tubing until ready to make actual connection at

point of seal.

Page 3

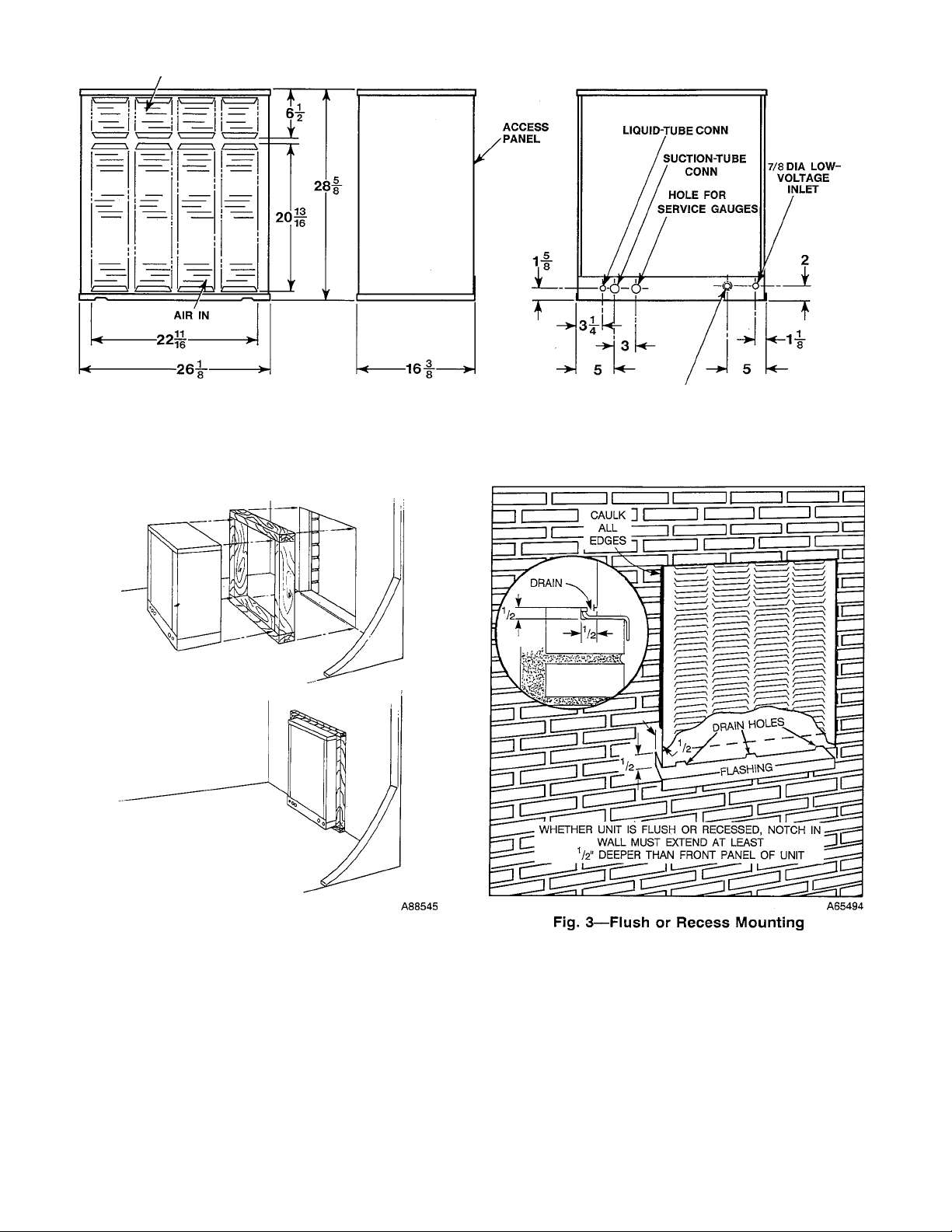

Table 2—Tubing Data

REFRIGERANT LINE LENGTH

UNIT SIZE

018, 024

1. Maximum vertical separation for evaporator over condensing unit is 50 ft.

2. Over 50 ft of vertical separation, the condensing unit must be located above

the evaporator. For requirements beyond 50 ft, obtain information from

distributor or consult Long-Line Application Guideline.

3. Charge adjustment is required when using more than 25 ft of tubing. See

Refrigerant Charging information on unit rating plate.

4. Do not use larger than 3/4-in. suction line.

10 to 50 ft

Suction

5/8 3/8

Diameter (In.)

Liquid Suction

If accessory tubing package or evaporator coil has been open for

more than 5 minutes, evacuate evaporator coil and tubing system.

Always evacuate if field-supplied tubing is used. See Evacuation

section.

Ensure field-supplied tubing is of refrigerant grade. Insulate the

suction line with insulation that has an adequate vapor barrier.

Evacuate tubing.

1. Run refrigerant lines as directly as possible, avoiding any

unnecessary turns and bends.

2. Tape the liquid line to the top of the insulated suction line for

support.

3. Suspend the refrigerant lines so they do not damage the

insulation on the suction line and do not transmit vibration to

the structure.

4. If the refrigerant lines are too long, the excess may be cut off.

5. Connect tubing to the condensing unit. The refrigerant tubing

and evaporator coil should be leak tested upon completion.

When making piping connections, be sure to provide clearance at

unit for electrical connection.

Connect suction and liquid refrigerant lines to condensing unit.

(See Fig. 1.) Make suction line connection first.

Two grommets are provided to seal the gap between refrigerant

lines and unit casing. Cut small grommet, slip it over liquid line

and push it into casing opening. Gap around suction line is sealed

in same manner except that suction line insulation must be cut and

pushed back before grommet can be slipped into place. (See Fig.

4.)

FIELD TUBING CONNECTIONS - All models are equipped

with 3/8-in. liquid and 5/8-in. suction back seated service valves

with mechanical flare field connections. Factory-supplied 3/8-in.

to 3/8- in. and 5/8-in. to 5/8-in. flare-to-sweat adaptor tubes are

provided. Field-supplied couplings are required for tubing pack

ages exceeding 50-ft long-line applications.

51 to 100 ft

3/4

Liquid

3/8

Step 3—^Test Unit

LEAK TESTING — No installation is complete until all field and

factory joints have been checked for leaks.

1. Remove valve stem caps from both service valves and check

to be sure valves are front seated (turned clockwise). Remove

service port caps.

2. Attach gage manifold to service ports of service valves and

purge hoses.

3. Pressurize evaporator coil and interconnecting refrigerant

tubing with vapor from an external refrigerant cylinder of

R-22 until the system and cylinder pressure are equalized.

NOTE: NEVER USE A UNIT CHARGE FOR LEAK TEST

ING.

4. Leak test with an electronic detector, a halide torch, or a liquid

soap solution.

5. Recover refrigerant and repair any leaks.

6. If system is free of leaks, prepare unit for operation.

EVACUATION

1. Connect evacuation equipment to system gage manifold.

2. Evacuate system following appropriate steps for type of

evacuation equipment used.

3. Pressurize system with refrigerant to 10 psig and open (turn

counter-clockwise) both service valves.

4. Remove gage manifold. Replace valve stem and service port

caps on both service valves.

Step 4—Make Electrical Connection

Field wiring must comply with local and national fire, safety and

electrical codes. Voltage to unit must be within range of 253v to

187v. Refer to nameplate for other electrical data. Contact local

power company for correction of improper line voltage.

A WARNING

According to NEC, ANSI/NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken ground, to

minimize personal injury if an electrical fault should occur.

The ground may consist of electrical wire or metal conduit

when installed in accordance with existing electrical codes.

Failure to follow this warning could result in an electric

shock, fire, or death.

See unit’s rating plate for recommended fuse size. When making

electrical connections, provide clearance at unit for refrigerant

piping connections.

BRANCH CIRCUIT DISCONNECT - Install a branch circuit

disconnect per NEC of adequate size to handle unit starting

current. Locate disconnect within sight from and readily accessible

from unit, per Section 440-14 of the NEC.

LINE POWER LEADS

Extend leads from disconnect per NEC into unit through hole

provided in service panel. (See Fig. 1.) Connect ground lead to

ground lug in control box for safety. Connect line power leads to

contactor screw terminals LI and L2. (See Fig. 5 or 6.) Contactor

terminals are approved for use with copper field wiring.

CONTROL POWER (24V) — Use furnace or fan coil trans

former as 24v supply for system. Transformer must have a

minimum capacity of 30 va. Bring control wiring through hole in

unit service panel and connect to pigtails from unit contactor.

Contactor pigtails are labeled Y and C. Refer to Fig. 5 or 6 for

system control circuit connections.

Page 4

CONT CONTACTOR

IFR INDOOR FAN RELAY

CC COOLING COMPENSATOR

TC THERMOSTAT COOLING

----------

FACTORY CONTROL WIRING

----------

FIELD POWER WIRING

----------

FIELD CONTROL WIRING

O COMPONENT CONNECTION

FIELD SPLICE

Fig. 5—Control Circuit Connection (018)

A92407

CTD - COMPRESSOR TIME DELAY

IFR - INDOOR FAN RELAY

DTS - DOME THERMOSTAT

CONT - CONTACTOR

Fig. 6—Control Circuit Connection (024)

FACTORY WIRING

FIELD WIRED

POWER WIRING

SPLICE CONNECTION

A88547

START-UP

Step 1—Start-up Procedure

1. Back seat (open) liquid and suction line service valves.

2. Set thermostat selector switch at OFF.

3. Set room thermostat to desired temperature.

4. Close electrical disconnects, energizing entire system.

5. Set room thermostat at COOL and fan switch as desired, FAN

or AUTO. Operate unit for 15 minutes, then check system

refrigerant charge. See Refrigerant Charging section.

Motors and controls operate satisfactory in the 253-v/187-v range.

Do not connect charging hoses during initial start-up procedure.

(Loss of charge from this procedure may result in capacity

reduction.) If necessary to add manifold gages for servicing, refer

to the service manual for bypass method of returning charge to

system.

Step 2—Sequence of Operation

When thermostat "calls for cooling," thermostat contacts close,

energizing contactor holding coil from 24-v external power source.

Contacts close, energizing compressor motor and condenser fan

motor with supply voltage.

When thermostat is satisfied, contacts open, de-energizing contac

tor holding coil and, in turn, breaking supply voltage circuit. All

motors should stop. In 024 size applications the lock-out relay

prevents restart for up to 5 minutes. Refer to presale literature.

Step 3—Refrigerant Charging

Refer to information on unit rating plate.

A CAUTION

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system. This

can cause compressor flooding.

SERVICE

Access to all controls and unit components is through rear access

panel.

A WARNING

Because of possible damage to equipment or personal injury,

maintenance should be performed by a trained technician.

Consumer service is recommended only for filter cleaning/replacement.

Minimum maintenance to be performed:

1. Check condenser coil for cleanliness each month during

cooling season. Clean as necessary but at least once at

beginning of each season.

2. Check blower motor and wheel for cleanliness and proper

lubrication each cooling season. Clean as needed.

3. Check electrical connections for tightness and controls for

proper operation each cooling season. Service as necessary.

A WARNING

As with any mechanical equipment, personal injury can result

from sharp metal edges, etc., therefore, be careful when

removing parts.

NOTE: Never operate unit more than 2 minutes with rear door

removed as unit damage may result.

Page 5

For continued high performance and to minimize possible equip

ment failure, periodic maintenance is essential. Consult dealer for

proper maintenance frequency and availability of a maintenance

contract.

Air for unit is drawn into front of unit at the bottom, and

discharged out same side at the top. Keep air inlet and outlet

louvers unplugged and clear of any obstructions at all times. Never

cover unit or lean anything against it which might restrict airflow

or cause hot air from upper louvers to recirculate into lower

louvers. Keep trash and debris away from unit. Never stand on unit

or use it as a support for ladders, etc.

Refrigerant tubing is easily crushed or crimped, therefore, do not

hang or stand anything on it. Do not move unit after it has been

installed, as this may crimp tubing and cause unit to malfunction.

The ability to properly perform maintenance on this equipment

requires certain mechanical skills and tools. If you do not possess

these, contact dealer for maintenance.

A WARNING

System contains oil and refrigerant under pressure. Do not use

a torch when disconnecting refrigerant components. Wear

safety goggles.

To disconnect refrigerant components;

1. Turn off electrical power to unit.

2. Recover refrigerant from unit.

3. Cut component connecting tubing with tubing cutter and

remove component from unit.

4. Carefully unsweat tubing stubs from component. Oil may

ignite when exposed to torch flame.

Step 1—Blower Wheel and Motor Removal

The blower assembly may easily be removed through the rear

access panel in the following manner:

1. Shut off all power to the unit.

2. Loosen and remove 3 screws holding the rear access panel in

place and remove rear access panel from unit. (See Fig. 7.)

3. Disconnect the 2 electrical leads from the blower motor to the

compressor contactor.

4. Remove screws at top right and top left of blower retaining

panel.

5. Remove entire blower assembly by lowering rear of assembly

and lifting it toward you, so as to disengage it from slots in

angles attached to sides of casing. Entire assembly can be

removed through rear of unit.

NOTE: Assembly must be supported when screws are removed.

6. To change motor or wheel, loosen wheel setscrews with

wrench. Remove 2 screws from blower housings. Remove 2

motor clamps and free assembly from panel.

7. Slide wheel and scroll from motor shaft.

8. Remove wheel from blower housing by removing 2 screws at

top of scroll outlet and pushing wheel through outlet.

9. Reassemble in reverse procedure. Be sure blower wheel is

centered in housings before entire blower panel assembly is

placed back in the unit.

10. Connect the 2 electrical leads from the blower to the com

pressor contactor.

11. Replace the rear access panel and tighten the 3 screws.

12. Turn on power to unit.

A88548

Fig. 7—Rear Access Panel Removed

Step 2—Electrical Controls and Wiring

Disconnect power to unit. Check all electrical connections for

tightness. Tighten all screws on electrical connections. If any

smoky or burned connections are observed, disassemble the

connection(s), clean all parts, strip wire, reassemble properly (use

new connector if old one is burned or corroded), and secure tightly.

Electrical controls are difficult to check without proper instru

ments. Therefore, reconnect electrical power to unit and observe it

through a complete operating cycle. If there are any performance

problems in operating cycle, correct them.

Step 3—Refrigerant Circuit

This circuit is difficult to check for leaks without proper equip

ment. Therefore, if low cooling performance is suspected, dealer

service is required.

Step 4—Compressor Protection

The 018 size unit is equipped with a reciprocating compressor,

while the 024 size has a scroll compressor. In both applications

the compressor motor is protected by an internal current and

temperature-sensitive overload. Excessive current or temperature

causes internal overload to open, giving the indication of an open

circuit in the motor windings. The overload resets automatically

when internal motor temperatures drop to a safe level (overloads

may require up to 30 minutes to reset). When an internal overload

is suspected of being open, check by using an ohmmeter or

continuity tester.

The scroll compressor is equipped with a low-voltage dome

thermostat that will interrupt low-voltage power to the contactor.

The 024 size has time-delay relay (TDR) as standard equipment to

ensure against short cycling which can cause reverse rotation on

shutdown.

Step 5—Compressor Removal

Follow safety codes, and wear safety glasses and work gloves.

Have quenching cloth available for Step 7 below.

1. Shut off power to unit. Remove rear access panel.

Page 6

2. Remove refrigerant from system.

A CAUTION

Do not vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

3. Disconnect compressor wiring at compressor terminal box.

4. Using a tubing cutter, cut suction and discharge (hot gas) lines

at convenient place near compressor for easy reassembly to

new compressor.

5. Remove compressor hold-down bolts and lift compressor out.

6. Remove mounting grommets from old compressor and install

on new compressor.

7. Carefully unbraze suction and discharge line piping stubs from

old compressor. If oil vapor in piping stubs ignites, use

quenching cloth. Braze piping stubs onto new compressor.

8. Install new compressor in unit. Braze suction and discharge

lines to compressor piping stubs at points where cut (Step 4),

using field-supplied copper slip couplings. Ensure that com

pressor hold-down bolts are in place. Connect wiring.

9. Clean system. Add new liquid line filter drier.

10. Evacuate and recharge unit.

Step 6—Cleaning Condenser Coil

Disconnect electrical power before removing access panel. Re

move rear access panel. Since air is drawn into front of unit at

bottom and discharged out the same side at the top, dirt collects on

front of coil and unit. To clean coil, flush out from inside of unit

with a high velocity stream of water. Be careful not to damage fins.

If coil is coated with oil or grease, clean it with a mild detergent

or an approved coil-cleaning agent, then rinse with clear water. Do

not allow water to get into compressor and unit control box.

Cabinet is equipped with drain holes at bottom of front edge. Be

sure holes are unclogged and free to drain.

Page 7

SYMPTOM

Compressor and condenser fan do

not start

Compressor does not start, but con

denser fan runs

Compressor cycles (other than nor

mally satisfying thermostat)

Compressor operates continuously

Excessive head pressure

Head pressure too low

Excessive suction pressure

Suction pressure too low

Trouble Analysis Chart

CAUSE

Power failure

Fuse blown or circuit breaker tripped

Defective thermostat contactor or con

trol relay

Low-line voltage

Incorrect or faulty wiring

Thermostat setting too high

Faulty wiring or loose connections in

compressor circuit

Compressor motor burned out, seized,

or internal overload open

Defective run capacitor

Refrigerant overcharged or under

charged

Defective compressor Determine cause and replace

Low-line voltage

Blocked condenser

Defective run capacitor

Defective thermostat Replace thermostat

Faulty condenser fan motor or capacitor

Restriction in refrigerant system

Unit undersized for load

Thermostat setting too low

Low refrigerant charge

Leaking valves in compressor

Air in system

Condenser coil dirty or restricted Clean coil or remove restriction

Dirty condenser coil

Refrigerant overcharged

Air in system

Condenser air restricted or air short cy

cling

Low refrigerant charge

Compressor valves leaking Replace compressor

Restriction in liquid tube

High-heat load

Compressor valves leaking

Refrigerant overcharged

Low refrigerant charge

Metering device or low side restricted Remove source or restriction

Low evaporator air

Temperature too low in conditioned

area

Call power company

Replace fuse or reset circuit breaker

Replace component

Determine cause and correct

Check wiring diagram and rewire cor

rectly

Lower thermostat setting below room

temperature

Check wiring; repair or replace

Replace compressor and determine

cause

Determine cause and replace

Remove refrigerant, evacuate system,

and recharge

Determine cause and correct

Determine cause and correct

Determine cause and replace

Replace

Locate restriction and remove

Decrease load or increase unit size

Raise thermostat setting above room

temperature

Locate leak; repair and recharge

Replace compressor

Remove refrigerant, evacuate system,

recharge

Clean coil

Remove excess refrigerant

Remove refrigerant, evacuate system,

and recharge

Eliminate cause

Locate leak; repair and recharge

Remove restriction

Check for source and eliminate

Replace compressor

Remove excess refrigerant

Locate leak; repair and recharge

Increase air

Reset thermostat

REMEDY

Page 8

Copyright 1992 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book] 1 I 4 PC 101 Catalog No. 563-712 Printed in U.S.A. Form 38GNA-2SI Pg 8 11-92 Replaces: 38GNA-1 SI

Tab |3al2a

13089

Loading...

Loading...