Carrier 38GK User Manual

Number One

Air(3onditoning

Maker

e

Division of Carrier Corporation

Carrier Parkway • Syracuse NY 13201

Air-Cooled Condensing Units

Table 1 — Physical Data

INTRODUCTION

The 38GK condensing units are designed for

use with Carrier approved evaporator coils or fan

coils which have capillary tube or AccuRater

refrigerant control. They may also be used with

evaporators which have expansion valves that

equalize pressure during the off cycle. If an

expansion valve without pressure equalization fea

ture is used, add an accessory start capacitor kit to

condensing unit.

Install these condensing units either thru-thewall, outdoors on a slab or on the roof. When

installing units, allow sufficient space for air-flow

clearance, wiring, refrigerant piping and servicing

units. Consult local building codes and National

Electrical Code (NEC) for special installation re

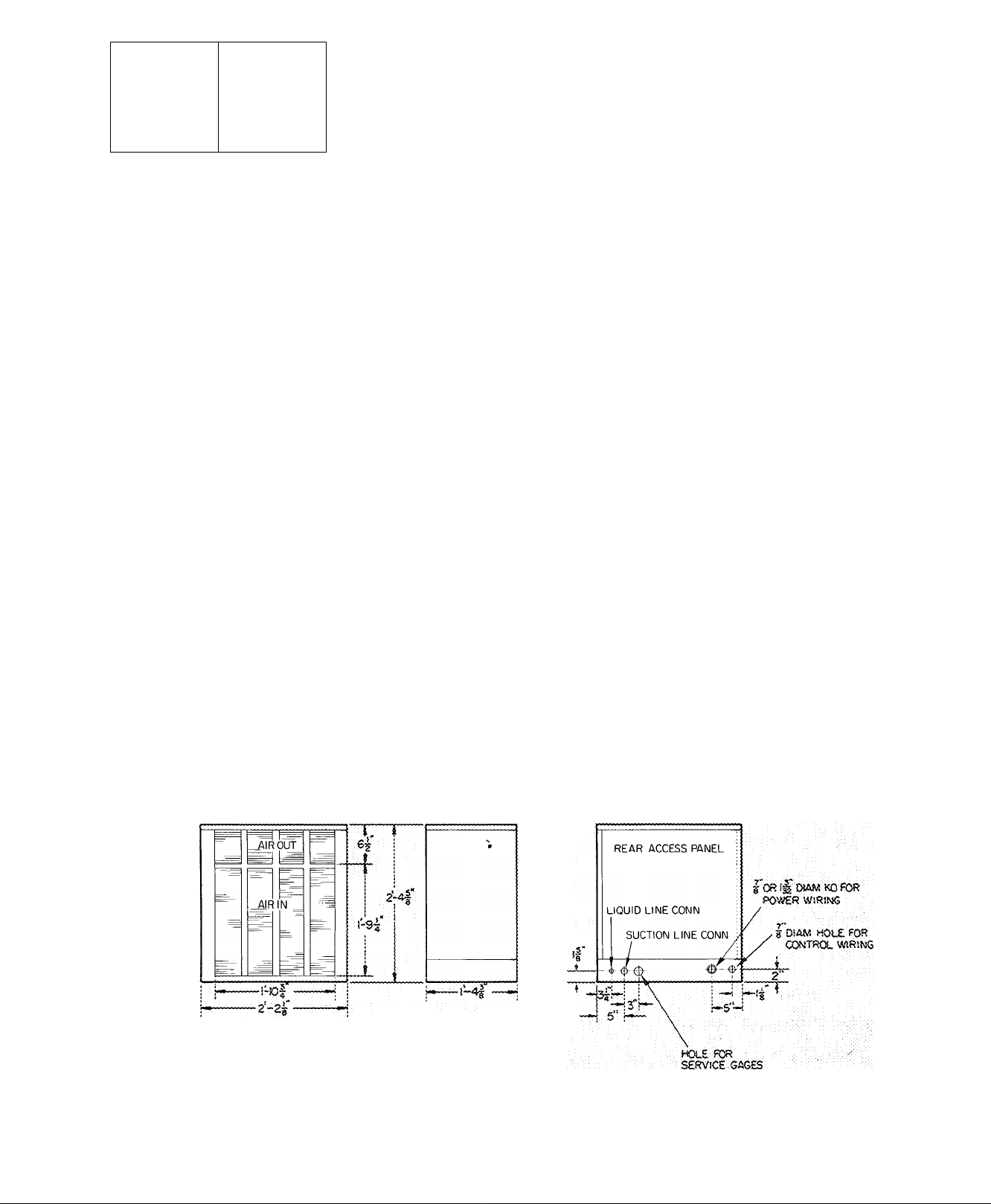

quirements. See Fig. 1 and Tables 1 and 2 for

detailed unit installation data.

COND UNIT

OPER WT (lb)

R-22 CHG (Ib-oz)

COND FAN

D i scharge

Motor Hp

Rpm

Diom + Width (in.)

DIM. (ft-in.)

Length

Width

Height _

CONN.* (in.)

Suction (ODF)

Liquid (ODF)

*Units are equipped with Carrier Compatible Fittings for refrig

erant connections

SS^GKOOl 38GK002 38GK003

144 __ 162

____

186

2j3 _ .3^5 ~ 4Ì3

Twin Centrifugal Biowers —

Direct Drive

Hori zontal

V4

1550

6^6+514

2-2Va

1- 4%

2- 4%

%

Table 2 — Installation Data (ft-in.)

COND UNIT ! 38GK001 | 38GK002 ] 38GK003

THRU-THE-WALL

CLEARANCE DIM.

AIR CLEARANCE

CONCRETE MOUNTING

PAD DIMENSIONS

SERVICE

CLEARANCE

"Units are serviced from rear access panel Therefore, units can be

installed with 0-in end clearance

1/ A I I

Ends

Bock

2-2% X 2-5

3-0

2-3 X 1-5 X 0-5

0*

1-6*

%

%

Certified aimensionarawlngs available oh request ..................................

..............................................

..

Fig. 1 — Dimensions and Connections

© Carrier Corporation 1976 Foim 38GK-4SI

INSTALLATION

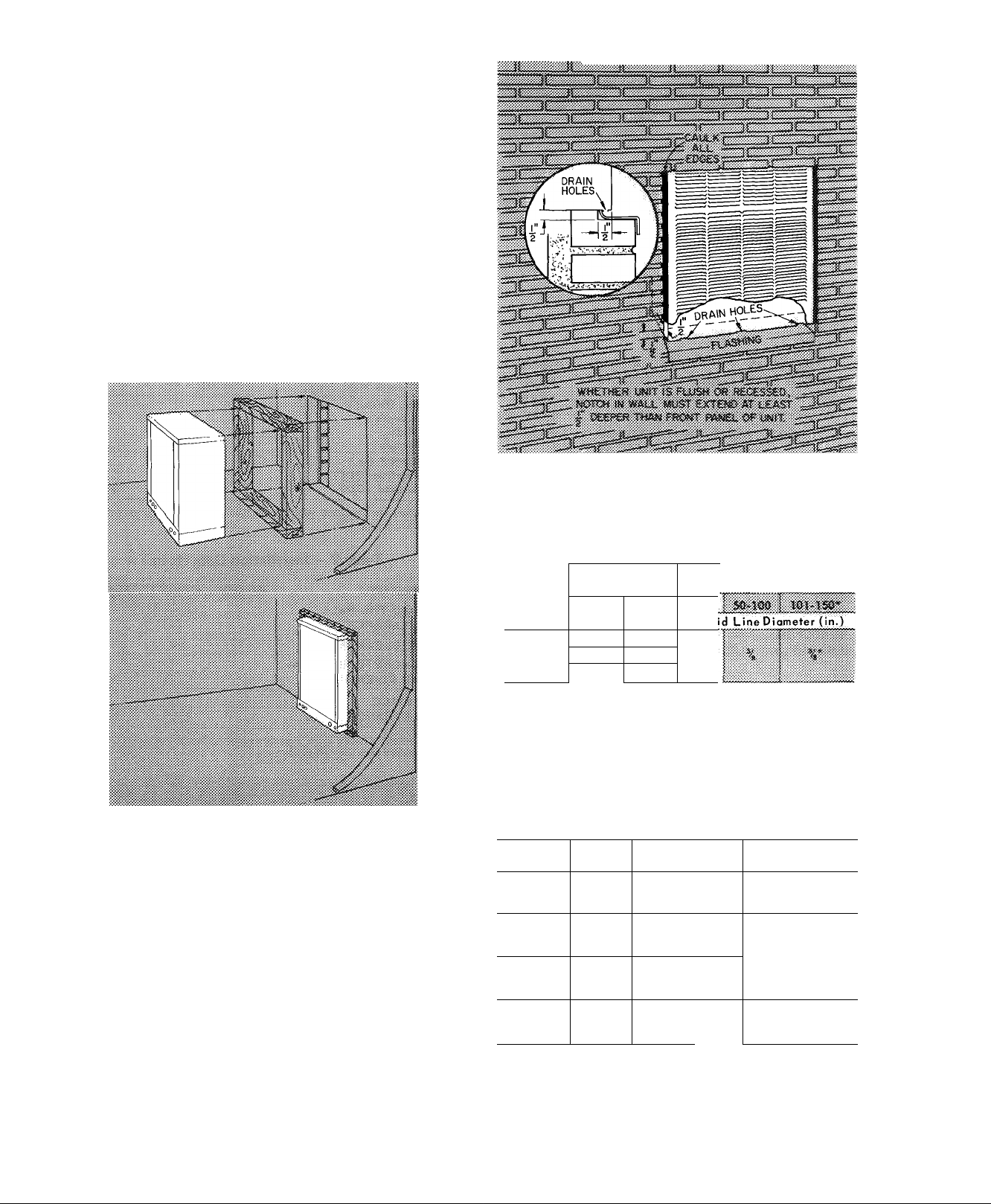

Mounting Thru-The-Wall

An opening approximately 26-1/2 x 29 in. shall

be made in a wall as close to a nearby cooling coil

as possible. Refer to Fig. 2 to build a frame in a

manner to support the condensing unit.

1. Locate unit with frame into the opening until

the unit extends approximately 1 in. beyond

the outside (finished) wall.

2.

Tilt to the front to allow the water to drain off.

See Fig. 3.

3.

Fasten the unit to the frame with metal straps.

4.

Use flashing under the unit and caulk all edges

to provide a weathertight seal (Fig. 3).

Fig. 3 — Flush or Recess Mounting

Fig. 2 — Roughing-ln Supporting Frame

REFRIGERANT LINE SIZING

Selection of Correct Liquid Line — See Table 3 for

maximum allowable vertical and horizontal dis

tance between condensing unit and evaporator

using recommended 3/8-in. liquid line.

Selection of the Correct Suction Line Diameter —

To keep line losses at a minimum, refer to Table 4

to select the correct suction line diameters.

Table 3 — Recommended Liquid Line Sizes

MAX COND*

COND

UNIT

38GK001 40

38GK002 40

38GK003

*Decrease maximum allowable vertical separation by 20% for

every 10 ft of refrigerant line length over 100 feet At 150 ft of

line length, 0 ft vertical separation is allowed

UNIT HT (ft)

40

Below

Evap

50

70

60

Above

Evap

Crankcase heater required

REFF

0-49

Liqu

%

Table 4 — Recommended Suction Line Diameters

UNIT

38GK001 (All)

38GK002 (All)

38GK003 201

38GK003

*Field-supplied 7/8-in to 3/4-in adapter is required

NOTE

The above table is based on a line loss of 2 F Longer lengths can

be used in each diameter listed, but the result will be larger line

losses Refer to Carrier, Syracuse Engineering Office for specific

details

MODEL

301

SUCTION LINE

LENGTH (ft)

0

46

47 - 120

150

121 -

0 - 28

29 - 72

150

73 -

19

0 -

52

20 -

116

53 -

0 - 18

48

19 -

107

49 -

SUCTION LINE

DIAMETER (in.)

=/b

%

Vb*

%

Vb

Vb*

V

/4

V

'A

7/*

%

%

Vb*

INSTALLING REFRIGERANT LINES

General — The condensing unit is fully charged at

the factory. Be sure both service valves are frontseated (turned clockwise) to avoid loss of the

charge. Do not remove refrigerant line connection

seals from the condensing unit, the matching coil,

nor the refrigerant tubing, until ready to make the

actual connection at the point of seal.

If accessory tubing package or evaporator coil

has been open for more than 15 seconds per

connection, evacuate or purge evaporator coil and

tubing system (use field-supplied refrigerant, not

unit refrigerant). Always evacuate or purge if

field-supplied tubing is used. See Purging.

Ensure field-supplied tubing is of refrigerant

grade. Insulate the suction line with insulation that

has an adequate vapor barrier (Armaflex or

Ensolex). Evacuate tubing.

When a complete Carrier system is used, a

filter-drier is not required. However, if other than

Carrier accessory tubing package or evaporator is

used, or if refrigerant tubing or coil is exposed to

atmospheric conditions for longer than 10 minutes,

install a filter-drier in the system near evaporator

coil. Additional refrigerant must be added to the

system to compensate for the additional volume of

the filter-drier.

Installation

1. Run refrigerant lines as directly as possible,

avoiding all unnecessary turns and bends.

2. Tape the liquid line to the top of the insulated

suction line for support.

3. Suspend the refrigerant lines so that they do

not damage the insulation on the suction line

and do not transmit vibration to the structure.

4. If the refrigerant lines are too long, the lines

should be rolled into a loop and placed in a

horizontal plane, or the excess may be cut off.

5. Check to be sure both service valves are

frontseated (turned clockwise). It is necessary

to remove the valve stem caps to check.

6. Connect tubing to the condensing unit. The

refrigerant tubing and evaporator coil should be

leak tested upon completion.

Connection Procedure — When making piping

connections, be sure to provide clearance at unit

for electrical connections.

Connect refrigerant liquid and suction lines to

condensing unit. Fig. 1 (page 1). Unit Compatible

Fittings permit 2 methods of refrigerant line

connection: mechanical (quick connect) or sweat

connection. Make suction line connection first.

MECHANICAL CONNECTION (Mate one set of

connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Insert tube into Compatible Fitting until it

bottoms. Be sure tube is bottomed while nut is

being tightened.

5. Tighten nut until it bottoms on back coupling

flange.

SWEAT CONNECTION (Use refrigerant grade

tubing.)

1. Remove locking nut, rubber 0-ring and

Schrader core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to

prevent damage by heat. Solder with lowtemperature (450 F) silver alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied

refrigerant.

Leak Testing

No installation is complete until all field and

factory joints have been checked for leaks.

1. Remove the valve stem caps from both service

valves and check to be sure the valves are

frontseated (turned clockwise). Remove the

service port caps.

2. Attach a gage manifold to service ports of the

service valves and purge the hoses.

3. Pressurize the evaporator coil and the inter

connecting refrigerant tubing with vapor from

an external refrigerant cylinder of R-22 until

the system and cylinder pressures are equalized.

NOTE: NEVER USE A UNIT CHARGE FOR

LEAK TESTING.

4. Leak test with an electronic detector, a halide

torch, or a liquid soap solution.

5. Release the pressure and repair any leaks found.

6. If the system is to be purged or evacuated, leave

the service valves in the frontseated position.

7. If the system is free of leaks, you may then

prepare the unit for operation by:

a. Backseating (turn counterclockwise) both

service valves.

b. Removing the gage manifold.

c. Replacing the caps on the service port and

valve stem.

Purging — To purge unit, do not use the unit

charge Proceed as follows:

1. Remove the valve stem caps from both service

valves and check the valve stems to be sure they

are frontseated (clockwise).

2. Remove the service port caps from both service

valves and connect a refrigerant cylinder of

R-22 to the service port of the liquid line

service valve.

3. Open the refrigerant cylinder valve and allow

approximately 1/2 to 1 pound of refrigerant to

flow thru the system and out the service port

on the suction line service valve.

Loading...

Loading...