Page 1

Owner's Manual & Installation Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS ......................... 2

SYSTEM REQUIREMENTS .......................... 2

Preface ............................................. 3

2 Product Introduction ................................ 4

2.1 Name of Main Parts ............................... 4

2.2 Combinations for outdoor and indoor traits ............ 5

2.3 Rated working condition ........................... 6

2.4 The range of production working temperature ........... 6

3 Preparation before Installation .......................... 7

3.1 Standard parts ................................... 7

3.2 Selecting installation site ........................... 7

3.3 Piping Connection ................................ 8

4 Installation ........................................ 9

4.1 Outline and dimension of the outdoor unit ............. 9

4.2 Installation of the Connection Pipe ................. 10

4.3 Air Purgingand Refrigerant Charge .................. 14

4.4 Electric Wiring .................................. 15

5 Troubleshooting .................................... 17

6 The conditions listed below are not classified into errors ..... 18

NOTE: Read the entire instruction manual before starting the

installation.

7 Troubleshooting .................................... 20

8 Maintenance ...................................... 21

PAGE

NOTE TO EQUIPMENT OWNER:

Please read this Owner's Information Manual carefully before installing and using this appliance

and keep this manual for future reference.

For your convenience, please record the model and serial numbers of your new equipment in the

spaces provided. This information, along with the installation data and dealer contact information,

will be helpful should your system require maintenance or service.

UNIT INFORMATION

Model #

Serial #

INSTALLATION INFORMATION

Date Installed

DEALERSHIP CONTACT INFORMATION

Company Name:

Address:

Phone Number:

Technician Name:

Page 2

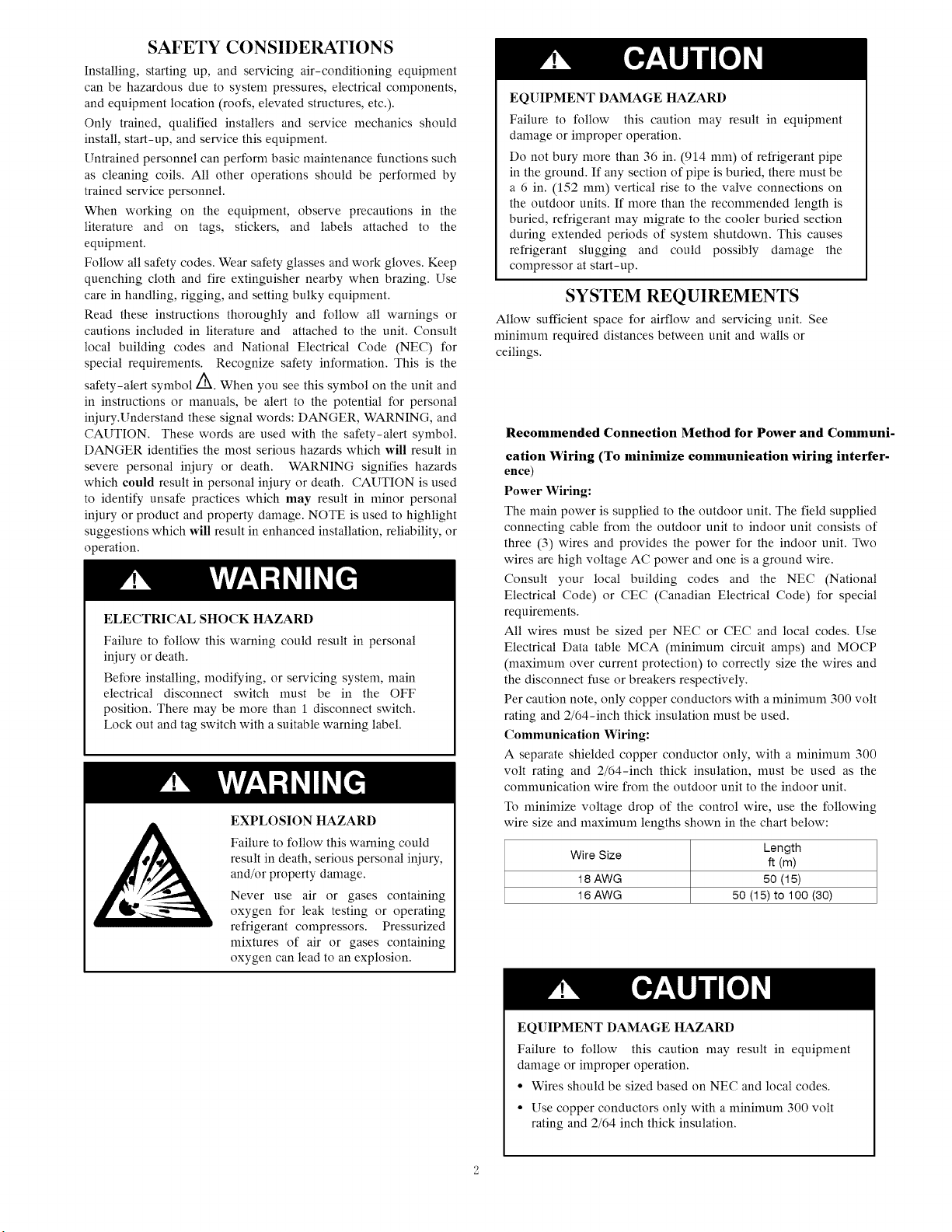

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance flmctions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and National Electrical Code (NEC) for

special requirements. Recognize safety information. This is the

safety-alert symbol/}k When you see this symbol on the unit and

in instructions or manuals, be alert to the potential for personal

injury.Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in nfinor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

nfixtures of air or gases containing

oxygen can lead to an explosion.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 ram) of refrigerant pipe

in the ground. If any section of pipe is buried, there must be

a 6 in. (152 ram) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may nfigrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start-up.

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit. See

minimum required distances between unit and walls or

ceilings,

Recommended Connection Method for Power and Communi-

cation Wiring (To minimize communication wiring interfer-

ence)

Power Wiring:

The main power is supplied to the outdoor unit. The field supplied

connecting cable from the outdoor unit to indoor unit consists of

three (3) wires and provides the power for the indoor unit. Two

wires are high voltage AC power and one is a ground wire.

Consult your local building codes and the NEC (National

Electrical Code) or CEC (Canadian Electrical Code) for special

requirements.

All wires must be sized per NEC or CEC and local codes. Use

Electrical Data table MCA (minimum circuit amps) and MOCP

(maximum over current protection) to correctly size the wires and

the disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300 volt

rating and 2/64-inch thick insulation must be used.

Communication Wiring:

A separate shielded copper conductor only, with a minimum 300

volt rating and 2/64-inch thick insulation, must be used as the

communication wire from the outdoor unit to the indoor unit.

To nfininfize voltage drop of the control wire, use the following

wire size and maximum lengths shown in the chart below:

Wire Size Length

18 AWG 50 (15)

16 AWG 50 (15) to 100 (30)

ft (m)

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

• Wires should be sized based on NEC and local codes.

• Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

Page 3

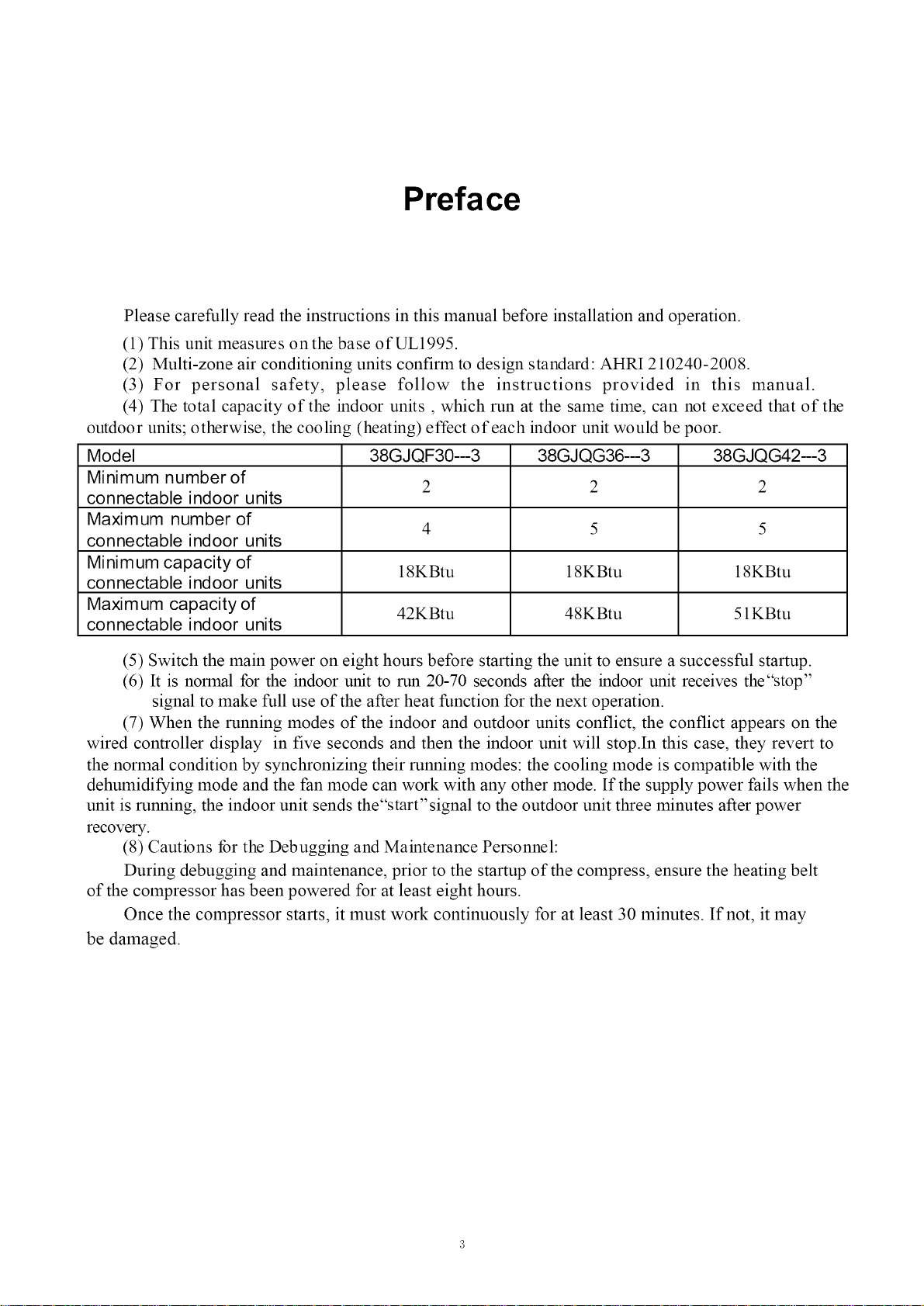

Preface

Please carefully read the instructions in this manual before installation and operation.

(1) This unit measures onthe base of UL1995.

(2) Multi-zone air conditioning units confirm to des ign s tandard: AHRI 210240- 2008.

(3) For personal safety, please follow the instructions provided in this manual.

(4) The total capacity of the indoor units , which run at the same time, can not exceed that of the

outdoor units; otherwise, the cooling (heating) effect of each indoor unit would be poor.

Model 38GJQF30--3 38GJQG36--3 38GJQG42--3

Minimum number of

connectable indoor units

Maximum number of

connectable indoor units

Minimum capacity of

connectable indoor units

Maxim um capacity of 42KBtu 48KBtu 51KBtu

connectable indoor units

2 2 2

4 5 5

18KBtu 18KBtu 18KBtu

(5) Switch the main power on eight hours before starting the unit to ensure a successful startup.

(6) It is normal for the indoor unit to run 20-70 seconds after the indoor unit receives the"stop"

signal to make full use of the after heat function for the next operation.

(7) When the running modes of the indoor and outdoor units conflict, the conflict appears on the

wired controller display in five seconds and then the indoor unit will stop.In this case, they revert to

the normal condition by synchronizing their running modes: the cooling mode is compatible with the

dehumidifying mode and the fan mode can work with any other mode. If the supply power fails when the

unit is running, the indoor unit sends the"start'signal to the outdoor unit three minutes after power

recovery.

(8) Cautions for the Debugging and Maintenance Personnel:

During debugging and maintenance, prior to the startup of the compress, ensure the heating belt

of the compressor has been powered for at least eight hours.

Once the compressor starts, it must work continuously for at least 30 minutes. If not, it may

be damaged.

Page 4

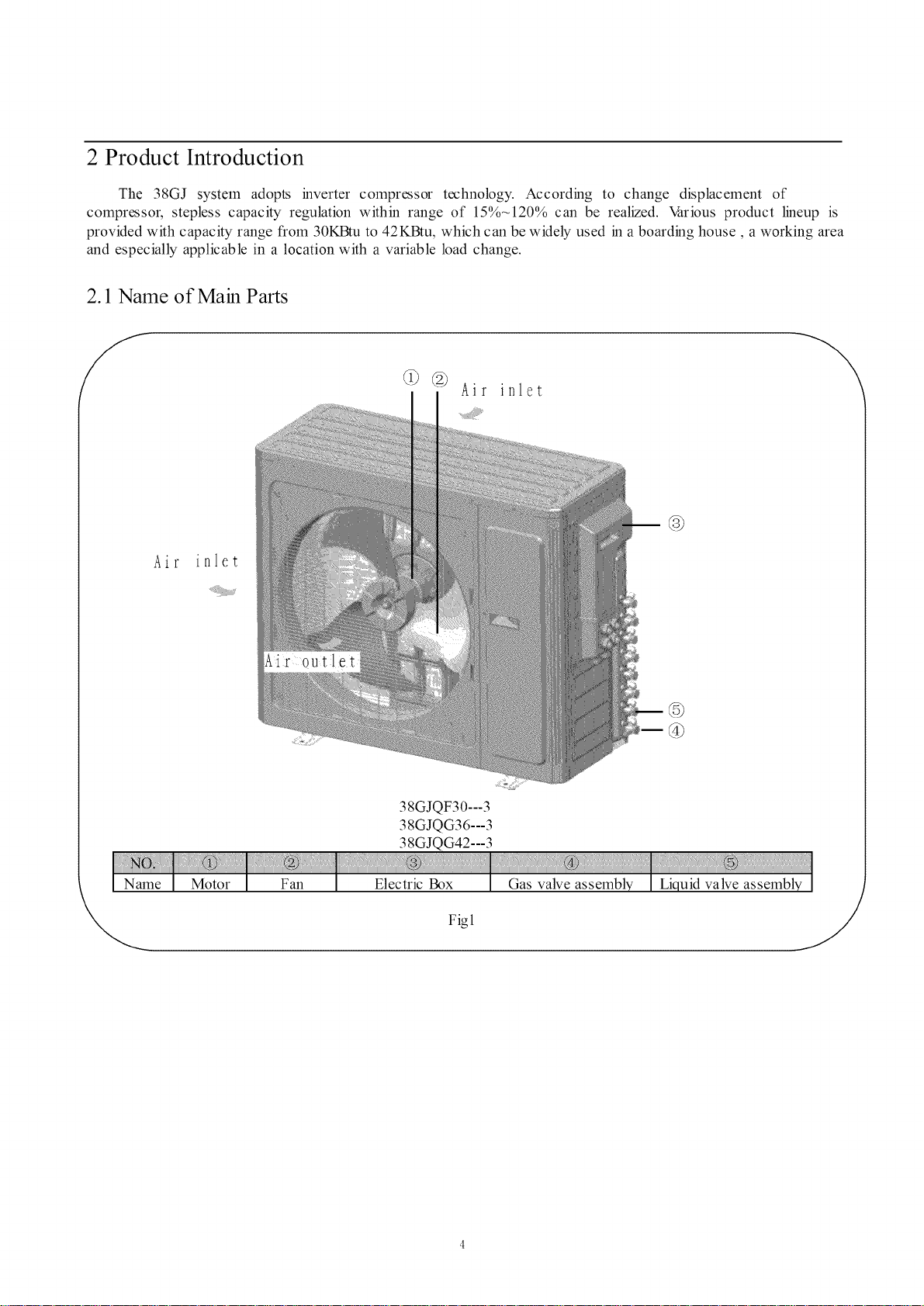

2 Product Introduction

The 38GJ system adopts inverter compressor technology. According to change displacement of

compressor, stepless capacity regulation within range of 15%-120% can be realized. Various product lineup is

provided with capacity range from 30KBtu to 42KBtu, which can be widely used in a boarding house, a working area

and especially applicable in a location with a variable load change.

2.1 Name of Main Parts

@ @ Air inlet

@

Air

\

@

38GJQF30---3

38 GJQ G36 --- 3

38GJQG42---3

Fig1

Page 5

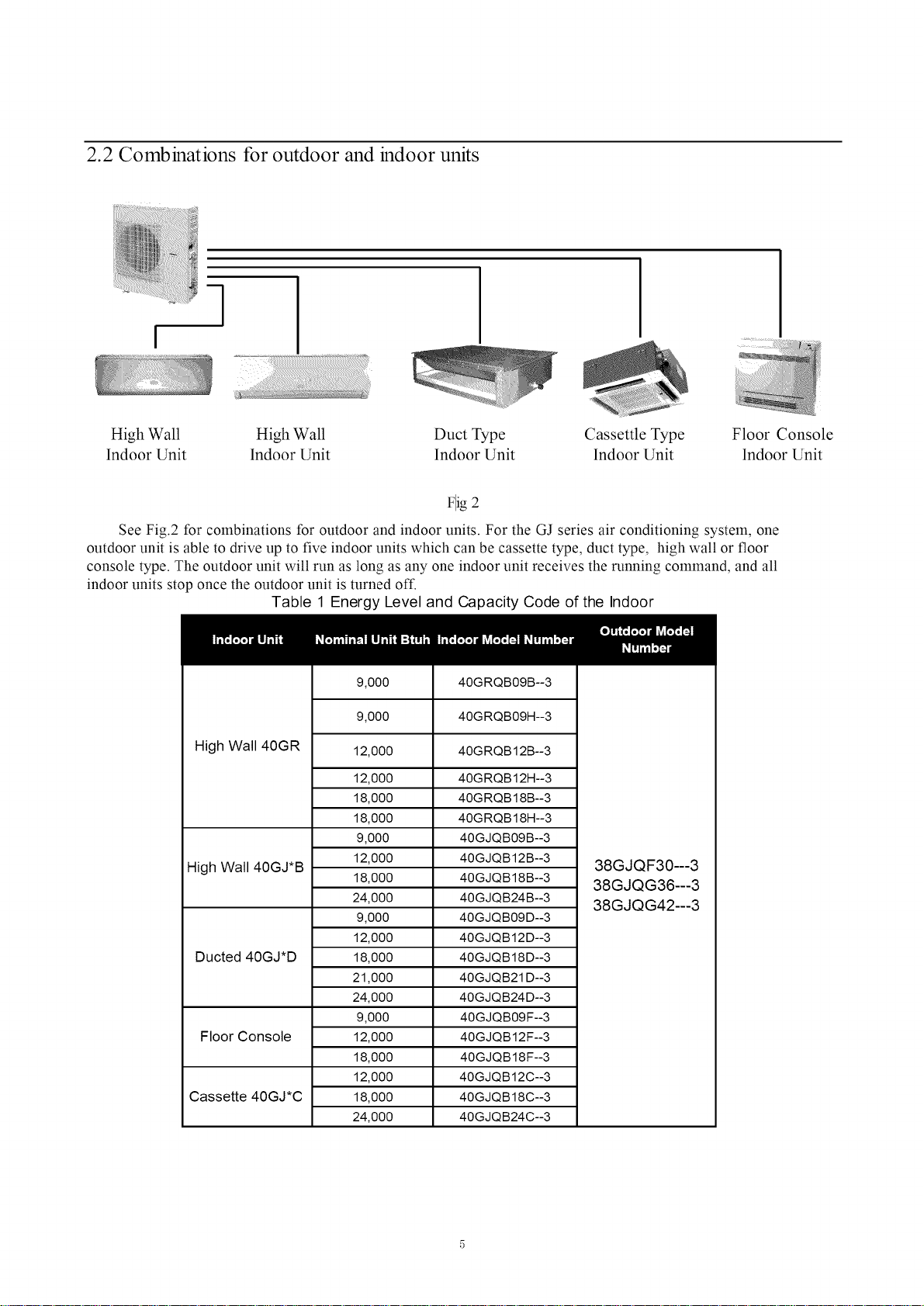

2.2 Combinations for outdoor and indoor units

q

High Wall High Wall Duct Type Cassettle Type Floor Console

lndoor Unit lndoor Unit lndoor Unit lndoor Unit lndoor Unit

Flig 2

See Fig.2 for combinations for outdoor and indoor units. For the GJ series air conditioning system, one

outdoor unit is able to drive up to five indoor units which can be cassette type, duct type, high wall or floor

console type. The outdoor unit will run as long as any one indoor unit receives the running command, and all

indoor units stop once the outdoor unit is turned off.

Table 1 Energy Level and Capacity Code of the Indoor

High Wall 40GR

High Wall 40GJ*B

Ducted 40GJ*D

Floor Console

Cassette 40GJ*C

9,000

9,000

12,000

12,000

18,000

18,000

9,000

12,000

18,000

24,000

9,000

12,000

18,000

21,000

24,000

9,000

12,000

18,000

12,000

18,000

24,000

40GRQB09B--3

40GRQB09H--3

40GRQB12B--3

40GRQB12H--3

40GRQB18B--3

40GRQB18H--3

40GJQB09B--3

40GJQB12B--3

40GJQB18B--3

40GJQB24B--3

40GJQB09D--3

40GJQB12D--3

40GJQB18D--3

40GJQB21 D--3

40GJQB24D--3

40GJQB09F--3

40GJQB12F--3

40GJQB18F--3

40GJQB12C--3

40GJQB18C--3

40GJQB24C--3

38GJQF30---3

38GJQG36---3

38GJQG42---3

Page 6

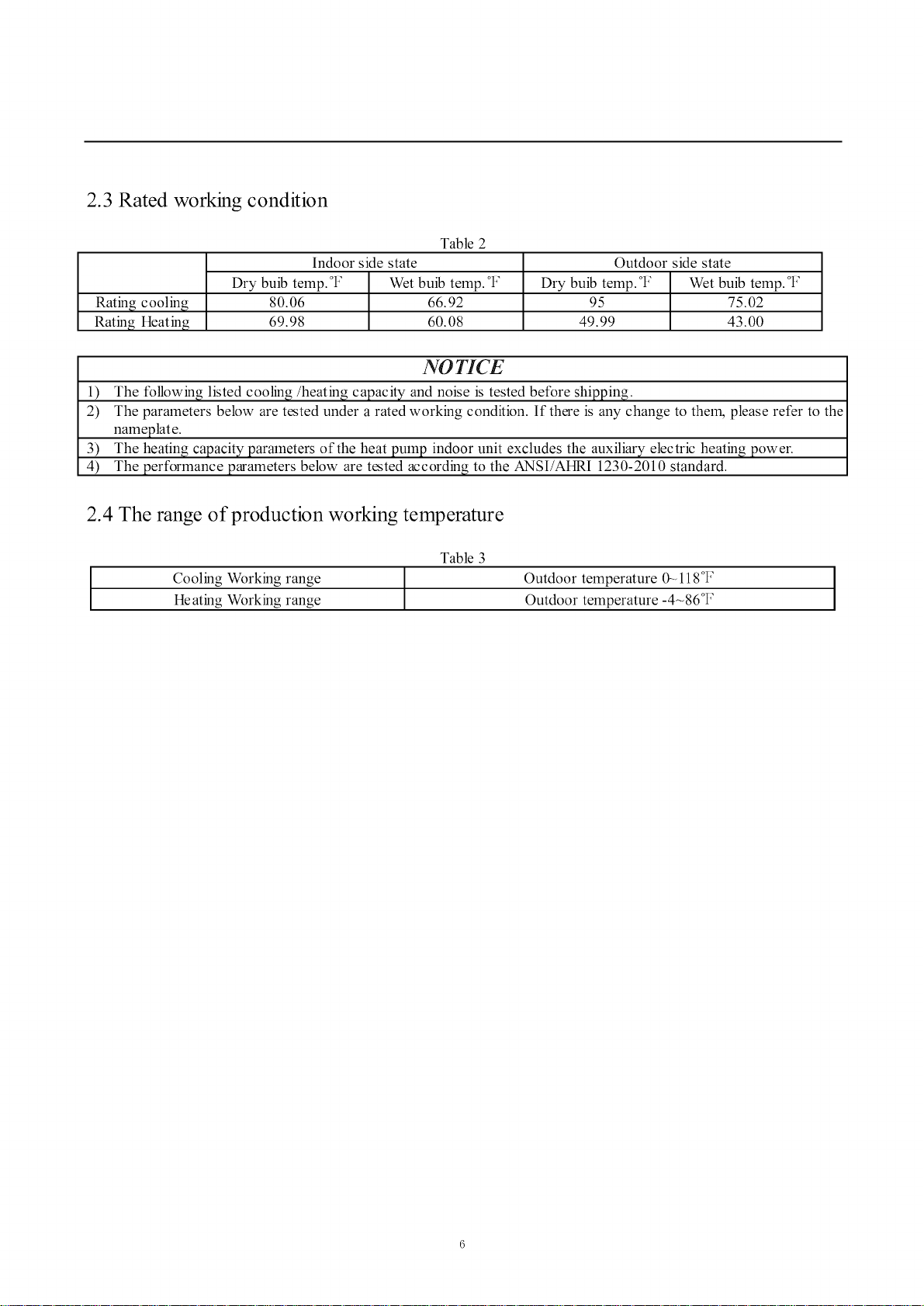

2.3 Rated working condition

Table 2

Rating cooling

Rating Heating

Indoor side state

Dry buib temp. °t: Wet buib temp. °t:

80.06 66.92

69.98 60.08

Dry buib temp. °F Wet buib temp. °F

Outdoor side state

95 75.02

49.99 43.00

NO TICE

1) The following listed cooling/heating capacity and noise is tested before shipping.

2) The parameters below are tested under a rated working condition. If there is any change to thel_ please refer to the

nameplate.

3) The heating capacity parameters of the heat pump indoor unit excludes the auxiliary electric heating power.

4) The performance parameters below are tested according to the ANSI/AHRI 1230-2010 standard.

2.4 The range of production working temperature

Table 3

Cooling Working range Outdoor temperature 0_ 118°F ]

Heating Working range Outdoor temperature -4-86°F

I

Page 7

3 Preparation before Installation

3.1 Standard parts

Please use the following standard parts included with the air conditioning units.

Table 4

Outdoor Unit Parts

Number Name Picture

.......................Z47_::oo:o

Owner's manual

;_.;$, :v:,:::v,a..........................

Tube connector

subassy

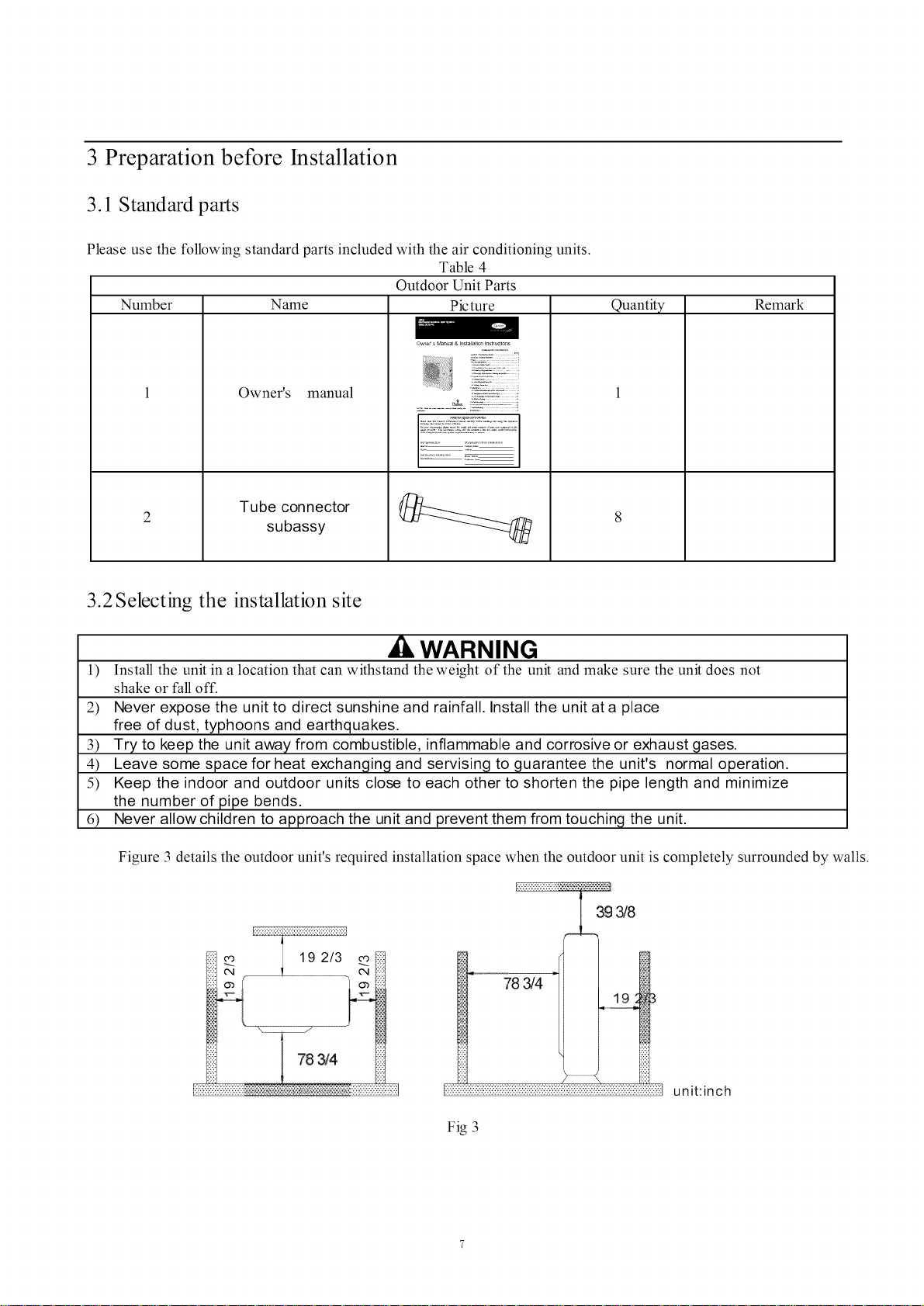

3.2 Selecting the installation site

Quantity

Remark

WARNING

1) Install the unit in a location that can withstand the weight of the unit and make sure the unit does not

shake or fall off.

2) Never expose the unit to direct sunshine and rainfall. Install the unit at a place

free of dust, typhoons and earthquakes.

3) Try to keep the unit away from combustible, inflammable and corrosive or exhaust gases.

4) Leave some space for heat exchanging and servising to guarantee the unit's normal operation.

5) Keep the indoor and outdoor units close to each other to shorten the pipe length and minimize

the number of pipe bends.

6) Never allow children to approach the unit and prevent them from touching the unit.

Figure 3 details the outdoor unit's required installation space when the outdoor unit is completely surrounded by walls.

3g 3/8

78 _4

unit:inch

Fig 3

Page 8

3.3 Piping Connection

The maximum pipe length is shown in the following table. When the distance between units (piping length) is

out of the range listed below, normal operation of the unit can not be guaranteed.

Table 5

Mode 1

38GJQF30---3

38GJQG36---3

3 8GJQG42---3

Connecting Pipe (inch)

Liquid Gas

@1/4 c_3/8

@1/4 @3/8

@1/4 @3/8

Max. Pipe length(ft)

229.6

246.1

246.1

NOTICE

1) Use water-proof insulating pipe.

2) Wall thickness of pipe: 0.019-0.039 inch; bearing pressure: 3.0MPa

3) The longer the connection pipe is, the more the cooling and heating capacity will decrease.

Max. Height Difference between Indoor

Unit and Outdoor Unit (ft)

When the outdoor unit is above,

the maximum height difference between

the indoor and outdoor units is up to 49.21%

When the indoor unit is above,

the maximum height difference between

the indoor and outdoor units is up to 49.2ft.

Page 9

4 Installation

4.1 Outline and dimension of the outdoor unit

38GJQF30---3

Outline dimension and mounting holes

36 2/9

14 4/7

1

38GJQG36---3, 38GJQG42---3

Outline dimension and mounting holes

38 3/7

362/9

17 1/3

Unit:inch

Fig 4

144/7

38 3/7

17113

Unit:inch

Fig 5

Page 10

4.2 Installation of the Connection Pipe

Connecting piping for the indoor unit and outdoor unit are in the manifold mode (see the figure below).

/tlliiti

I

Fig6

4.2.1 Piping between the Indoor and Outdoor Units

(1) If the liquid and gas stop valves, which have the sign A, 13, C, D or E , have not been connected to the

indoor units, turn off the screw cap with the spanner airproof.

(2) Refer to Fig.7 for the appropriate amount of torque to tighten the screws.

(3) Point the flare end of the copper pipe at the screw and tighten the screw by hand.

(4) Next, tighten the screw with the torque wrench until it emits a sound (as shown in Fig.7).

(5) The bending degree of the pipe can not be too small; otherwise it will crack Use a pipe tube

bender to bend the pipe.

(6) Wrap the exposed refrig_ipe and the joints by sponge and then tighten them with the plastic tape.

':?' :¢ "" "75"

Spanner .................//

Pipe Flare Nut Pipe

Torque Wrench

Fid 7

Pipe Thickness of Tightening

diameter copper tube torque

qbl/4 inch >0.0315 inch 11--22 ft.lbf

qb3/8 inch >0.0315 inch 26--29 ft.lbf

qbl/2 inch >0.0315 inch 33--37 ft.lbf

qb5/8 inch >0.0394 inch 44--48 ft.lbf

ACAUTION

1) During the connection of the indoor unit and the refrigerant pipe, never pull the indoor unit joints forcefully,

otherwise the capillary or other pipes may crack, which would result in leakage.

2) The refrigerant pipe should be supported by brackets. Do not allow the unit to support the weight of the refrigerant pipe.

3) If the piping connection size of the outdoor unit does not match the piping connection size of the indoor unit, use the

piping connection dimension of the indoor unit. Use different-diameter joints which is installing on the place of

the piping connection to connect the indoor unit.

4) For the Free Match system, each pipe should be labeled to indicate which system it belongs to avoid mistaken

inaccurate piping.

4.2.2 Allowable pipe length and drop height among indoor and outdoor units

If the total refrigerant pipe length (liquid pipe)

refrigerant will be charged.

Model

Total Liquid Pipe

Length (a+b+c+d+e)

38GJQF30---3

131.2ft

is shorter than that listed in the table below, no additional

Table 6

38GJQG36---3 38GJQG42---3

131.2ft 131.2ft

10

Page 11

Allowable Length and Height for the Refrigerant Pipe

38GJQF30---3

Total length (actual length) of fitting

229.6ft

pipe

Length of farthest fitting pipe (ft)

Table 7

Allowable Value

82ft

38GJQG36---3

38GJQG42---3

246.1 ft

82ft

Fitting P ipe

LI÷L2+-"+I. M(M 45)

Lx (X-I, 2, 3, 4,5)

Height difference

Outdoor unit at

between outdoor upper

unit and indoor unit Outdoor unit at

low er

Height difference between indoor

units (m)

C

o

o

C

C

o

'o

C

C

(1)

_D

..Q

00

O

¢-

"CJ

c_

I

Outdoor unt

L1

49.2ft

49.2ft

24.6ft

49.2ft

49.2ft

24.6ft

Equivalent length of the farthest fitting pipe Lx

L2

L3

L4

b

Indoor unit

c

Fig 8

d

H1

H3

H2

L5

e

11

Page 12

4.2.3 Oil Trap Design Requirements

If theheight differencebetweentheindoor unitandthe outdoorunitexceeds19.7ft(6m), installan oil trapevery19.7ft(6m)from

the lower to the upper section of the vertical gas pipe. The oil trap shall be fabricated into two U-type

elbows or one return-type elbow. The height shall be 3~5 times the piping diameter.

See below for details on the installation and fabrication of the oil trap.

_. The oil trap may be fabricated into a U-type or return-type.

If the outdoor unit is below the indoor unit, it is not needed to install an oil trap on the vertical pipe for gas piping.

@. If the outdoor unit is below the indoor unit, it is not needed to install an oil trap at the highest or lowest

position. If the outdoor unit is above the indoor unit, the oil trap and stop elbow must be installed at the lowest and

the highest position of the vertical pipe. Refer to the schematics below.

_. The fabrication dimensions of the oil trap are shown below.

¢3/4i n (19.05m

@. Refer to the schematics below.

• The outdoor unit is lower than the indoor unit.

Gas pipe

Liquid pipe

Oiltrap

Stopelbow

Indoor

unit

19.7ft (6m)

19.7ft (6m)

19.7ft (6m)

Outdoor

unit

/

19.7ft (6m)

19.7ft (6m)

12

Page 13

• Theoutdoorunitis higherthantheindoorunit.

Stopelbow

/

/

Outdoor

unit

Gas pipe

Liquid

19.7ft (6m)

19.7ft (6m)

19.7ft (6m)

Oiltrap

19.7ft (6m)

19.7ft (6m)

Oil returntrap

Indoor

unit

4.2.4 Installation of the Refrigerant Pipe Protection Layer

The refrigerant refrigerant pipe should be insulated by the insulating material and plastic tape to prevent

condensation and water leakage.

The joints of the indoor unit should be wrapped with the insulating material.Ensure there is no gap on the joint

of the indoor unit, as shown in Fi .9.

The thermal insulating layer is required to be wrapped at this part.

Fig9

13

Page 14

,A CAUTION

Alter the pipe is protected, do not bend it to form a small angle; otherwise it will crack or

break.

(3)Wrap the Pipe with Tape:

a. Bundle the refrigerant pipe and electric wire together with tape, and separate them from the drain pipe to

prevent the condensate water from overflowing.

b. Wrap the pipe from the bottom of the outdoor unit to the top of the pipe where it enters the wall. During the

wrapping, the later circle should cover half of the former one.

c. Fix the wrapped pipe on the wall with clan_s. AUT_ON_"

1) Do not wrap the pipe too tight; otherwise the insulation effect would be weakened.Ensure

drain hose is separated from the pipe.

2) Next, fillthe hole on the wall with sealing material to prevent wind and rain from entering the room.

4.2.5 Support and protection for the pipeline

Support should be made for hanging the connection pipe. The distance between each supportcan not exceed 3.3 fl (hn).

4.3 Air Purging and Refrigerant Charge

4.3.1 Air purging

(1) The refrigerant in the outdoor unit was charged before shipment. Additional refrigerant needs to

be charged into the refrigerant pipe during the field installation.

(2) Ensure the outdoor unit's liquid and gas valves are closed completely.

(3) As shown in the following figure (Fig. 10), expel the gas inside the indoor unit and the refrigerant pipe with the

vacuum pump.

"LO"Knob

liquid valve

\

\,

\

Manometer

[i:::i

\

Connection hose

,::Gas xa!ve

Manometer

/

/

f

_/= :_: Vacuum pump

"Hl"Knob

f

/

/

//

Fig 10

(4) When the compressor is not running, charge the R410A refrigerant into the refrigerant pipe from the liquid

valve of the outdoor unit (do not charge from the gas valve).

4.3.2 Additional refrigerant charging

(1) Refrigerant Charge in the Outdoor Unit before Shipment

NO TICE

1) The outdoor unit has been charged with refrigerant prior to delivery. The refrigerant charge is not included and is

an additional charge for the indoor unit and the refrigerant pipe.

2) The amount of the additional refrigerant charge depends on the diameter and length of the liquid refrigerant

pipe which is determined by the actual yield installation requirement.

3) Record the additional refrigerant charge for future maintenance.

14

Page 15

(2) Calculation of the Additional Refrigerant Charge

Additional Refrigerant Charge-

(EI.ength of' Liquid Pipe_b0.375X54+ELength of Liquid Pipe {b0. 25 X 22) 880

The largest additional refrigerant charge value is 800g.This means if the calculated value exceeds 800g, the

additional refrigerant charge takes 800g, while the calculated value takes less than 800g, the additional refrigerant charge

takes the calculated value.

4.4 Electric Wiring

4.4.1 Wiring precautions

(1) The installation must be done in accordance with the national wiring regulations.

(2) Only a power cord with the rated voltage and exclusive circuit for the air conditioning can be used.

(3) Do not pull the power cord forcefully.

(4) The electric installation should be performed by a technician instructed in the local laws, regulations

and this manual.

(5) The diameter of the power cord should be large enough for the unit. If the cord is damaged, it must be replaced by the

dedicated one.

(6) The ground should be firm and the earth wire should be connected to the dedicated device of the building

by the technician.The air switch coupled with the leakage current protection switch must be equipped and have

enough capacity in both the magnetic and the_Tnaltripping functions in case of the short circuit and overload.

Table 8

Models Power Supply Capacity of the air Switch (A)

38GJQF30---3 208/230V-60Hz 32 3 X 0.0062 sq in

38GJQG36---3 208/230V-60Hz 32 3 X 0.0062 sq in

38GJQG42---3 208/230V_60Hz 32 3 X 0.0062 sq in

Recommended Cord (pieces X

sectional area)

38GJ_QF30---3

0UTD00t{ UNIT

IT IT 1 IT2 IT3 IT4

_ N(1) 2 3 N(1) 2 3 N(1) 2 3

/

In ..... I I , II n..... I

POWEt{ [IND()()t{ UNIT AI [INDO0t{ UNII B I IINDOOR UNIT C I [INDO()t{ UNII DI

Fig 11

PE

15

Page 16

38GJQG36---3,38GJQG42---3

r 1

i OUTDOORUNIT

Ii XT XT1 XT2 XT3 XT4 XT5 I

N(1) 2 3 N(1) 2 3 N(1) 2 3 N(1) 2 3 N(1) 2 3

--_ PE _) PE PE PE PE PE

1

POWER i INDOORUNIT A I INDOORUNIT B i INDOORUNIT C ii INDOORUNIT D I INDOORUNIT EI

Fig 12

4.4.2 Grounding Require ments

(1) The air conditioner is classified as a Class I appliance, so its grounding must be reliable.

(2) The yellow-green line of the air conditioner is the earth line and can not be used for any other purpose, cut off or

fixed by the tapping screw; otherwise it would cause an electric shock.

(3) A reliable ground terminal should be provided and the ground wire can not be connected to any of the following

items:

@Running water pipe @Coal gas pipe @Sewage pipe @Other places where the professional personnel

think unreliable.

4.4.3 Electrical Cable Connection

A CAUTION

1) A mistake connecting the line will result in a malfunction. After the electrical wiring is working, ensure

the wire between the connection place and the fixed place has a certain amount of space.

2) The connection piping and connection line of each indoor unit should connectwell according to the instruction.

3) The electric installation should be carried out by a technician instructed in the local laws, regulations and

this manual.

4) The installation location should be dry, shielded from direct sunlight or strong winds.

5) Install a breaker in the circuit that can shut off the system's main power supply. Also install an air

switch coupled with the leakage current protection switch must be equipped.

4.4.4 Wiring of the Power Cord

(1). Open the side plate.

(2). Connect the power cord to terminals "L1 ", "L2" and the earthing bolt. Next, connect the wiring

terminals "N(1),2,3" of the indoor unit to the corresponding outdoor unit terminals.

(3). Fix the power cordwith wire clips.

(4). Place the power cord through the rubber ring.

,A,CAUTION

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualified person to avoid a hazard.

16

Page 17

5 Troubleshooting

WARNING

1) In the event of abnormal conditions (for example, a foul smell), shut off the main power supply inmlediately and

contact your Service Center.Operating under abnormal conditions would damage the

air conditioning unit and would cause electric shock or a fire hazard.

2) Do not attempt to repair the air conditioning.Contact a professionally skilled technician at the

appointed service center. An incorrect repair would cause electric shock or a fire hazard.

Check before Contacting Service Center.

Table 9

Check Items

Has the unit been secured firmly?

Have you done the gas leakage test?

Does the unit have proper thermal insulatio

Does the unit drain well?

Is the voltage in accordance with the

rated voltage specified on the nameplate?

Is the electric wiring and piping

connection installed correctly and

securely?

Has the unit been earthed securely?

Is the power cord specified?

Has the inlet and outlet been blocked?

It may cause insufficient cooling/heating

capacity.

1? It may cause condensation and drippil

It may cause condensation and dripping.

It may cause a malfunction or damage the part.

It may cause malfunction or damage the part.

It may cause electrical leakage.

It may cause malfunction or damage the part.

It may cause insufficient cooling/heating

capacity.

Conditions Might Happen

The unit may drop, shake or emit noise

NOTICE!

If the air conditioner still runs abnormally after the above checks, please contact a

maintenance serviceman at the local appointed service center and provide a description of the error

as well as the model of the unit.

Check

17

Page 18

6 The conditions listed below are not classified into errors.

Table 10

Conditions

The unit does not run

The unit blows out mist

The unit generates noise

The unit blows out dust.

When restarted ilnlnediately after it

was stopped.

As soon as power is on.

When the cooling operation starts.

The unit "clatters" as soon as it

starts running.

The unit "swishes" during the

cooling operation.

The unit "swishes " when it

starts or stops.

The unit "swishes" when it is on

and after it runs.

The unit "squeaks" when it is on

and after it runs.

When the unit restarts after

The overload protection switch of the unit

delays the startup for three minutes.

The unit remains in stand by mode for

approximately one minute.

The hi-humidity indoor air is cooled quickly.

It is the sound generated during the initialization

of the electronic expansion valve.

It is the sound of the refrigerant gas that runs inside

the unit.

It is the sound of the refrigerant gas as it stops

running.

It is the sound of the draining system

operating.

It is the sound of friction generated by the skin

plate which swells due to the temperature

change.

The dust inside the unit is blown out.

not running for a long time.

The unit emits odors.

When the unit is running.

The odors absorbed by the unit are blown out.

NOTICE!

If problem can not be solved after checking the above items, #ease contact service center and provide

details and model(s).

The following conditions are not malfunctions.

malfunctions Table 11

Malfunction

Unit does not run

Mist comes from the

unit

Noise is emitted

When the unit is started

immediately after it is just

turned off

When power is turned on

Under cooling

Slight cracking sound is heard

when unit is turned on

Overload protection function provides a 3 minute

delay

Standby function delays operation for about 1 minute

Indoor high humidity air is cooled rapidly

It is the sound generated during the initialization of the

electronic expansion valve.

Causes

Re ason

The unit blows out

dust

The unit emits odor

Indoor unit still runs

after turned off

There is sound

when cooling

There is sound when the unit starts

or stops

There is a slight and repetitive

sound when the unit is running o_

after running

A cracking sound is heard when

the unit is operating and after

operating

When the unit runs after

not running for a long time.

Operating

After every indoor unit receive

"stop" signal, fan keeps

The gas refrigerant is flowing in unit

The gas refrigerant has stopped flowing

This is the sound of the drainage system.

The sound is caused by expansion of the panel and other

parts due to temperature change

Dust in the indoor unit is blown out

The room odor absorbed by the unit is blown out

Indoor fan motor keep running 20-70s to make

good use of excess cooling and heating and to prepare for

18

Page 19

running

next operation

Mode conflict

COOL or HEAT mode can not

be operated

When the indoor operating mode conflicts with that of

outdoor unit, the indoor fault indicator flashes and the

conflict appears on the wired controller after 5 minutes.

The indoor unit stops. The outdoor operating mode

switches to the mode of the indoor unit. Next,

the unit returns to normal. The COOL mode does not

conflict with the DRY mode. The FAN mode does not

conflict with any mode.

19

Page 20

7 Troubleshooting

The error code displays on the wired conlroller and the main board of the outdoor unit

Table 12 details the meaning of each error.

Table 12

Malfunction

Compressor runs

Defrost

Anti-freezing protection

IPM protection

AC over-c urrent protec tion

Over-burden protection

Compressor exhaust high temperature protection

Compressor overload protection

Power protection

EEPROM reads and write protection

Low PN voltage protection

Over voltage protection for PN

PFC protection

PFC module temperature protection

Low pressure protection

High pressure protection

Linlit/decline frequency(electric current) Flash 1 times

Frequency limit (exhaust) Flash 2 times

Frequency limit (Over-burden) Flash 3 times

Outdoor ambient sensor malfunction Flash 6 times

Outdoor tube sensor malfunction Flash 5 times

Exhaust sensor malfunction Flash 7 times

Attain the temperature of switch on Flash 8 times

Frequency limit(power) Flash 13 times

Outdoor fan malfunction Flash 14 times

Frequency limit(PFC module temperature) Flash 15 times

PFC module sensor malfunction Flash 16 times

Liquid pipe temperature sensor malfunction of A Flash 17 times

Gas pipe temperature sensor malfunction of A Flash 18 times

Liquid pipe temperature sensor malfunction of B Flash 19 times

Gas pipe temperature sensor malfunction of B Flash 20 times

Liquid pipe temperature sensor malfunction of C Flash 21 times

Gas pipe temperature sensor malfunction of C Flash 22 times

Liquid pipe temperature sensor malfunction of D Flash 23 times

Gas pipe temperature sensor malfunction of D Flash 24 times

Liquid pipe temperature sensor malfunction of E Flash 25 times

Gas pipe temperature sensor malfunction of E Flash 26 times

Exit of the condenser tube sensor malfunction Flash 27 times

Correspondence is normal unit number)

Communication failure between indoor unit and ( indoor unit all

outdoor unit Communication failure )

Yellow light

Flash once

Flash twice

Flash 3 times

Flash 4 times

Flash 5 times

Flash 6 times

Flash 7 times

Flash 8 times

Flash 9 times

Flash 11 times

Flash 12 times

Flash 13 times

Flash 14 times

Flash 15 times

Flash 17 times

Flash 18 times

The indicator display

Red light Green light

Flash n times (n=indoor

Often bright

2O

Page 21

8 Maintenance

A regular inspection, maintenance and care should be performed by professional personnel, which will prolong the unit's

life span.

8.1 Outdoor heat exchanger

The outdoor heat exchanger should be cleaned once every two months. Use a vacuum cleaner with a nylon brush

to clean up dust and small particles on the surface of the heat exchanger. Blow away dust with compressed air, if available.

Never use water to wash the heat exchanger.

8.2 Drain Pipe

Regularly check if the drain pipe is clogged to drain condensate smoothly.

8.3 Notice before Seasonal Use

(1) Check if the inlet/outlet of the indoor/outdoor unit is clogged.

(2) Check if the ground wire is earthed reliably.

(3) Check if the battery of remote wireless controller has been replaced.

(4) Check if the filter screen has been set correctly.

(5) After a long period ofnonuse, open the main power switch 8 hours before re-operating the unit to

preheat the compressor crankc ase.

(6) Check if the outdoor unit is installed securely. If there is anything abnormal, contact the

appointed service center.

8.4 Maintenance after Seasonal Use

(1) Cut off the main power supply to the unit.

(2) Clean the filter screen and the indoor and outdoor units.

(3) Clean the dust and small particles on the indoor and outdoor units.

(4) In the event of rusting, use anti-rust paint to stop t h e spreading of rust.

8.5 Parts Replacement

Purchase parts from an appointed service center or dealer if necessary.

NOTICE!

During the airtight and leakage test, never mix oxygen, ethyne and other dangerous gas into the refrigeration

circuit. In case of hazard, it is better to use nitrogen or refrigerant to perform the test.

21

Page 22

(opyri_ht 2014 (arz'iez"(orporationS 7310W. \[orz'isSt. S Indianapolis, IN 46231 Edition Date:llA4

\!tmufacturerresez'vesthe ri_ht to change, at any time, speeifict_tionsanddesigns wid_out notice and without obli_ations.

Catalog No: 380J 30 42 010M

Replaces;New

1

66129917007

Loading...

Loading...