Page 1

Carrier

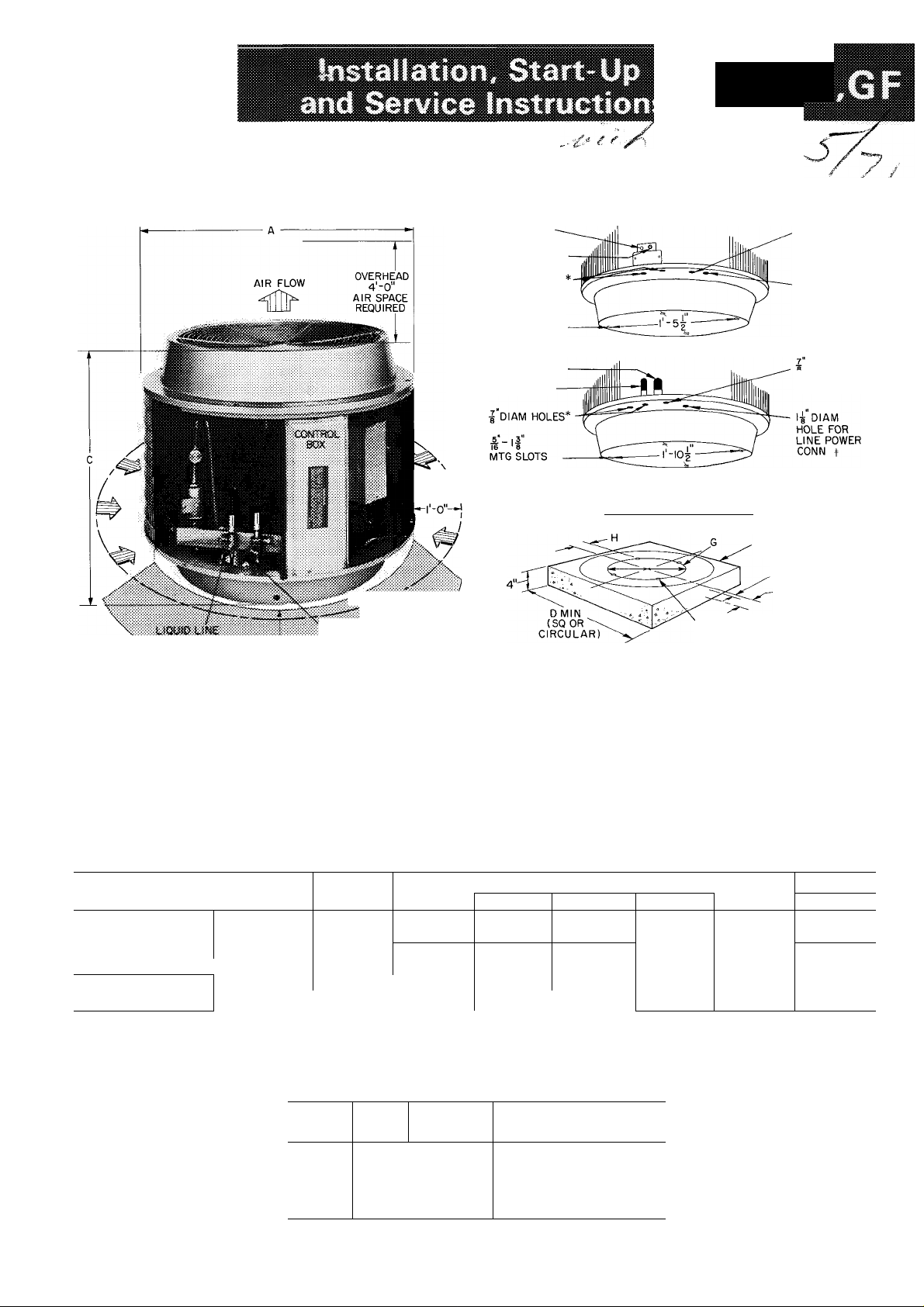

38GC

Æ

c? -1

Air-Cooled Condensing Units

LIQUID LINE

SUCTION LINE

J'dIAM HOLES

MTG SLOTS

\

AIR FLOW

CLEARANCE

(USE ANY TWO)

SUCTION LINE

LIQUID LINE

(USE ANY TWO)

BOTTOM VIEW 38GC10I; 38GC,GFI02,103

BOTTOM VIEW 38GC.GFI04,145,105; 38GFI06

CONCRETE MOUNTING PAD

I DIAM HOLE

FOR CONTROL

POWER CONN t

1-^" DIAM

HOLE FOR

LINE POWER

CONN

DIAM HOLE

FOR CONTROL

POWER CONN t

CONCRETE PAD **

(SQ OR CIRCULAR)

E SUCTION LINE

F LIQUID LINE

rjfiN

SJCT^UM

S'-cr

t

*Two plugged holes to accommodate charging lines Replace plugs when finished

tl nsert rubber grommet (shipped in low voltage splice box) in hole to protect wires if conduit is not used

J1-3/8 in diam on 38GF106 single-phase units

**Concrete pad should weigh 1 -1 /2 to 2 times weight of unit

Fig. 1 — Dimensions, Connections and Mounting Pad (Unit Access Panel Removed)

Table 1 — Installation Data

CO ND E NS IN G U N IT

OP ER A TI NG

WT (l b)

DIM E NS IO N S

(ft-i n. )

RE FR IG E RA N T

CO NN , (in .)

_______

j 38GF units only, field-supplied tubing sizes for oil return and refrigerant charge

*38GF006 supplied with 3/4 to 1 -1 /8 in suction valve connection adapter (field-installed)

38G C

38G F

Dia m A

Hei gh t C

Sue t OD F V,

Liq O DF

38G C

101

111 13 2

- 136

2-0% 2-0 ^4 2-0%

2-1 Vi 6

%

102 103

2-3 Vi 6

=/s

'/b

illl SPACE REQUIRED FOR SERVICE

149 16 5

154 16 9

2-3%,

% ^/4

% %

CONDENSER AIR FLOW

38G C .G F

104

2-5% 2-5%

2-1 Vi 6

TIE DOWN B0LTS(i-20x lin )

(USE ANY TWO LOCATIONS,

180“ APART)

145

207

211

2-5%,

'%

38G F

105 106 *

220

224 250

2-5 ^4

2-5 V, 6

V4

Vb

2-5%

_

2-7%,

IV3

%

© Carrier Corporation 1971

Table 2 — Pad Dimensions (ft—in.)

DIM .

D

E

F

G

H

38G C

101

i6ï, ^T 03 ~~ “

-3

0-2%

0-3V, 0- 7%

-5%

0-1 %

GC ,G F 1 3 8 GF

38

" 10 4 , 1 45 , 1 0 5 " j 1 0 6

2-1 0

0- 4 %

1-1 0%

0- 2

Form 38GC-15SI

Page 2

Table 3 — Accessories

PART

NUMBER

Auxiliary Start’ Capacitor and Relay Package

38GC900001

38GF900132

38GC9000132

38GC9000371

32LM001301

HH0UD038

HH01AZ039

58BV90008Í

58BV900101

38GB9000Í21

38GF900072

'38^GC900152

38GC900031

38GC900041

38GC900051

38GC900061

38GC900191

38GC900181 50

38GC900071

38GC900081

38GC900091

38GC900101

38GC900in

^Standard equipment on all current single-phase units except 38GC101,

102, 103 and 38GF102

fMotor used with units equipped with 06R compressor For all other

units, use fan motor HC38VQ700.

$For 5/8-in evap connection, cut off 3/4-in. end

NOTE All suction lines have a 90-degree bend at one end

(single-phase units)

38GC101

38GC102, 103; 38GF102 (six 38GF900121)

Low Voltage (24 v) Control Transformer

(standard on 38GF units)

38GC101, 102, 145, 105 (six 38GC9000121; 20 va)

38GC103, 104 (six 38GC9000361; 40 va).

Solid State Head Pressure Control. Special fieldinstalled fan motor required on 102 thru 145 units.

UNIT

MOTOR

Low Voltage Control (heat—cool)

Thermostat

Cooling Switch Base

Low Voltage Control (heat—cool) — Grayson

Thermostat (six HH01YA092)

Cooling Switch Base (six HH93YZ094)

Expansion Valve Package (six EA16DC100

38GF102, 103, 104)

Expansion Valve Package (six EA12XC400 —

38GF145, 105, 106)

Indoor Fan Relay (six 38BA400693)

Precharged Tubing (not available for 38GF106

Units)

Lgth

(ft)

35

38GF102 38GF103t 38GF104t

NO. 500011

10

18

25

50

10

18

25

35

50

38GF 38GF

UQ

UID

OD

(in.)

Vs

Vs

Vis

Vis

Vs

Vs

Vs

3/

3/

Vs

Vs

DESCRIPTION

Fan Motor Carrier Part No.

50001 It VE230t VL700

SUCTION

Tube End

Tube End

OD (in.)

4

Vs

Vs

4

V

4

V

4

V

V

3/

4

Vs

Vs

(in.)

Vs

%

%

Vs

V

4

V

4

V

V

4

V

4

4

OD (in.)

Evap

Vst

Vst

Vt

Vst

Vt Vs

Vst

V V

Vs

V

V

4 V

4

HC38

___

Con8

Vs

Vs

V

V

Vs

V

V

4

4

4

38GF145

HC40

Honeywel I

__ _ __

UNITOD

3800101,102,

103, 38GF102

38GC101,102,

38GF102

38GC103

38GC104,145,

105, 38GF103,

104,145,105

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete.

SKID REMOVAL

Move condensing unit to final location. Remove top

grille. Reach between fan blades and remove 1/4-in.

hex head screws holding unit to skid. On the 145, 105,

106 units, remove the two compressor shipping brackets

attached to top of compressor and sides of unit.

PRELIMINARY SURVEY

Consult local building codes for special installa

tion requirements.

When installing unit, allow sufficient space for

air-flow clearance, wiring, refrigerant piping and

servicing unit. NEC minimum requirement is 3 ft

(see Fig. 1). Position unit so water from roof or

eaves will not pour directly on top of unit.

Install unit on a solid, level mounting pad.

Position tie-down bolts in pad. Any two holes in

unit base may be used to fasten unit to pad.

38GC,GF Condensing Units are designed for appli

cation with any Carrier or other evaporator of

proper capacity. Install each unit in accordance

with Refrigerant Piping Data, (Table 4) and the

following special requirements.

Where refrigerant line lengths exceed 25 ft, it is

recommended that a liquid line filter-drier, crank

case heater and accessory start capacitor with relay

be added to condensing unit.

Liquid line filter-drier and crankcase heater are

factory installed on 38GF units. Start capacitor

with relay is available as an accessory for

38GC101, 102, 103 and 38GF102; factory in

stalled on remaining sizes.

When evaporator is below condensing unit,

reduce liquid line size one diameter (min 114-in.

OD).

PIPING CONNECTIONS

38GC,GF Condensing Units can be connected to

evaporator sections using Carrier accessory pre

charged tubing or field-supplied tubing of refrig

erant grade. (Accessory tubing not available for

38GF106.) See Table 3 for accessory tubing sizes

and Table 4 for recommended field-supplied tubing

sizes. When over 25 ft of interconnecting tubing is

used, follow special requirements described above

in Preliminary Survey. Do not use damaged or

contaminated tubing. Do not cut 3/8-in. OD liquid

line to a length shorter than 10 ft. Bend or coil to

fit. When precharged tubing or evaporator section

has been open for more than 15 seconds per

connection, evacuate or purge evaporator coil and

tubing system (use field-supplied refrigerant, not

unit refrigerant). If necessary, refer to Carrier

System Design Manual, Part 3, for standard piping

techniques.

38GC,GF Connection Procedure — When making

piping connections, be sure to provide clearance at

unit for electrical connections.

Connect refrigerant liquid and suction lines to

condensing unit (Fig. 1). Unit Compatible Fitting

permits two methods of refrigerant line connec

tion. mechanical (quick-connect) or sweat

connection.

38GF106 UNITS — Remove suction line adapter

taped to compressor shipping bracket and connect

to suction line Compatible Fitting. Sweat connect

refrigerant suction line to adapter. Connect liquid

refrigerant line to unit.

2

Page 3

(Mate one set ofMECHANICAL CONNECTION

connections at a time).

1. Loosen nut on Compatible Fitting one turn. Do

not remove. Loosen tube clamp.

2. Remove rubber plug and be sure 0-ring is in the

groove inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Use gage on tag attached to service valve to

mark tube end for correct insertion depth.

Insert tube into Compatible Fitting until it

bottoms. (Tube should be inserted at least as

far as mark on tubing.)

5. Tighten nut until it bottoms on back coupling

flange. Tighten tube clamp.

SWEAT CONNECTION (use refrigerant grade

tubing).

1. Remove locking nut and rubber 0-iing from

inside of fitting. Loosen tube clamp entering

condensing unit base.

2.

Cut tubing to correct length.

3.

Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to

prevent damage by heat. Solder with low

temperature (450 F) silver alloy solder. Tighten

tube clamp.

4.

Evacuate or purge system with field-supplied

refrigerant.

ELECTRICAL DATA AND WIRING

Wiring — Field wiring must comply with local and

national codes. Install a branch circuit fused

disconnect of adequate size to handle starting

current. When making electrical connections, pro

vide clearance at unit for refrigerant piping

connections.

LINE POWER is brought thru unit base pan flange

and thru hole provided in control box (Fig. 1). On

38GC101, 38GF106 (230-v, 1-ph) and 38GF103,

104 (208- and 230-v, 3-ph) units, line power

connections are made to pigtails supplied with

unit. Use approved splice connector. Do not use

aluminum field wire for splice connections unless

copper to aluminum adapters is used, and correct

wiring techniques are followed.

On all other models connect line power to

contactor screw power terminals as indicated on

unit label diagram, i.e., connect power leads to

contactor terminals 21 and 23 on single-phase

units, or 21, 22, and 23 on 3-phase units.

On all 3-phase units, do not connect a grounded

high voltage leg to control circuit pigtail or

terminal; connect leg to compressor pigtail or

terminal. See label diagram.

CONTROL POWER is brought thru unit base pan

(Fig. 1), and thru 7/8-in. hole into low voltage

section of control box. All connections are made

to pigtails supplied with unit (Fig. 2). Where

supply voltage exceeds 150 volts to ground, or

local codes require it, ground 24-volt control

circuit at field splice C.

Table 4 — Refrigerant Piping Data

Crankcase heater (standard on GF), liquid line filter-drier (standard on GF)

and start capacitor with relay (accessory on GC101, 102, 103 and GF102)

required Reduce liquid line size one diameter (mini /4-in OD) when evaporator

is below condensing unit

TXV — Thermal Expansion Valve

Cap. Tube — Capillary Tube

*3/4-in on 38GF.

Page 4

THERMOSTAT SUBBASE TERMINALS

(HH93AZ039 OR HH93YZ094)*

Arrangement A — Transformer External to

Condensing Unit (38GC Only)

THERMOSTAT SUBBASE TERMINALS

(HH93AZ039 OR HH93YZ094)*

Arrangement B — Transformer in Condensing Unit

THERMOSTAT SUBBASE TERMINALS

(HH93AZ039 OR HH93YZ094)*

LEGEND

C — Contactor IFM — Indoor Fan Motor

CR — Control Relay IFR — Indoor Fan Relay

FS — Fan Switch LPS — Low-Pressure Switch (see Note 2)

HC — Heating Control Tran - Transformer

A Field Splice

_______

Field Wiring

_______

Factory Wiring

*Accessory (transformer standard on 38GF units)

fl nstall jumper between j^and when one 24-volt transformer is

used (Jumper supplied on HH93YZ094 )

ijiConnect to low speed indoor fan terminal when 2-speed fan is used

NOTES

1 If external transformer is used for condensing unit, it must have

a minimum of 10 va (38GC101), 17 va (38GC102), 27 5 va

(38GC103, 104), or 15 va (38GC145, 105)

2 Low pressurestat supplied on all 38GC units prior to Serial no

9000001 All 38GF units contain low pressurestat

Table 5 — Electrical Data

COMPR

MODEL

38GC

101 —

102-102310 70 14.8

103—

103310

103320

104—

104310 93 22 0

145—

105— 118 26 6

38GF

102—

102310

103—

103310

103320

104—

104310

145—

105—

106—

103—

104—

145—

105—

106— 110.0

103—

104—

145—

105—

106—

104—

145—

105—

106—

VOLTS/

PH

LRA FLA

51

12 8 1.1

57 14 8 1 1 1 ■ 6'.

78 19 0

21 0 1 2

ZoU/ 1

Zo\j/ 1

208/3 90 0 18 6 1 5

230/3 78.0

460/ o

86

104

21.0

85 21 9

118 26 6

57 14 8 1.2

14 8

70

19 0 1 2

78

86 21 0 1 2

104

21 0 1.2

85 21 9

93 22 0 1 2

26 6

118

26.6 2 2 P 0 44:68

118

150 36 0 2 2

61 5 13 0 1 2

14 0 1 5

69 0

90 0

18 6

23 0 2.2

53 5

11 5 1 2 1 oliiiTsIM

60 0 126 1.5

16 1 1 5

16 1

78 5

20.5 2.2

100

30 0

39 3 8 3 1 5

39 3

50 0 10 3

6 5 1 5

8 3

BRANCH CIRCUIT

FAN

Wire Max

Sizet Ft

FLA

(AWG) Wirel

1?11 37ÌÌÌ 20

1 1

1 1 30

1.2 1% 0 3; 5?

1 5

1 2 1 ' . vl

1 5 8 liÉi; 45i^:

1 5 8; 6 4c &0

1 2

1 5

1 5

2 2 11 - ' s'

2 2

2 2

2 2

12 10 3; 50

lOilfi 36i:li 30

10,34,,.«4 35

12iii; 3>i:;ii: 25

li “ 30

10 § 3p 57 30

li "

11 4

li

1 25

iz 10 30

1: 10 16 0?

Ì . -z » «

1

12^107;^

Fuse*

1 ~w irm,

, ' - z /

•Z, , i

11 * i.

Amps

25

25

10

15

45

45

25

10

35

35

45

45

60

20

25

35

35

40

20

30

35

15

15

15

20

Arrangement C — Two Transformers

Fig. 2 — Control Circuit Wiring

FLA — Full Load Amps

LRA — Locked Rotor Amps

*Maximum dual element fuse size.

•fWire sizes and lengths based on copper wire

— Electrical data shown applicable to all models

NOTE:

Motors and controls will operate satisfactorily 10% above and 10%

below unit voltage. On 3-phase units, phases must be balanced

within 2%. Control circuit voltage is 24 volts on all units.

Page 5

START-UP INSTRUCTIONS

38GF Units — Crankcase heater should be ener

gized a minimum of 4 hours before starting unit.

Start Procedure (38GC and 38GF)

1. Backseat (open) liquid and suction line service

valves.

CAUTiON: Seme? v's.tves have Teflon

wassher. Do not ovefíígJtteo (fhiget

seal)» Dei not exceed 10 fi4b torque

when íjghíenMg,

2. Close electrical disconnects energizing entire

system.

3. Set room thermostat to desired temperature.

4. Set room thermostat to “Cool” and fan switch

as desired (“Fan”) (“Auto”).

Motors and controls will operate satisfactorily

10% above and 10% below unit voltage (Table 5).

Do not connect charging hoses to capillary

controlled system during initial start procedure.

(Loss of charge from this procedure may result in

capacity reduction.) If necessary to add manifold

gages for servicing, refer to Carrier Standard

Service Techniques Manual, Chapter 1, pages 1-5,

Fig. 8, for bypass method of returning charge to

system.

COMPRESSOR

38GC101 and 38GC,GF102,103 Unit Single-Phase

Compressors of the split capacitor (PSC) type

require an equalized system pressure to start. (See

Physical Data table for compressor type.)

When supply voltage is within 10% limit and

compressor does not start, give compressor a

temporary capacitance boost. See Carrier Standard

Service Techniques Manual, Chapter 2, for details.

Use a 130 mfd start capacitor. Run compressor for

10 minutes then shut off and allow system pressure

to equalize. Try restarting without boost capacitor.

If after two attempts (without boost capacitor) the

compressor does not start, add an accessory start

capacitor relay package.

Compressor Protection

38GF UNITS have a high pressurestat located on

liquid line and a low pressurestat located on

suction Hue. High pressurestat has black leads and

low pressurestat has blue leads. High pressurestat

settings are" cutout, 428 ± 5 psig; cut-in, 320 ± 20

psig. Low pressurestat settings are: cutout, 27+ 4

psig; cut-in, 60 -t- 15 psig, -0 psig.

38GC UNITS have a high-pressure relief valve

located in compressor. Relief valve opens at a

pressure differential of approximately 600 psi

between suction and discharge. 38GC units prior to

serial number A-900001 were equipped with low

pressurestat located on suction service valve. Low

pressurestat settings are: cutout, 31 ±4 psig;

cut-in, 60-1-15 psig, -0 psig. All units between

serial no. A-900001 and C-962493 not equipped

with low-pressure switch. 38GC units (using 06R

compressors) from serial no. C-962493 are equipped

with liquid line low pressurestat. Settings are:

cutout, 27 ± 4 psig; cut-in, 60 -t- 15 psig, -0 psig.

Table 6 — Service Data

GC

38GC

101

2-7

-

3-10

400214

_ _

__

__

16

-

38GC

1050

2400

38GC

1650 1650

2300

102 103

3-2

•y* >

38 GC

.1

_

_

16

18

. 2-100

C3526CB

F3522CW

G3522CW

1-OSQ j 1050 í. ■

COND UNIT

R-22 CHG* (Ib-oz)

COMPRESSOR

1-Phase 400224

3-Phase 230 V

Type Start (1-Ph) PSC PSC CSRt

Oil Recharge (oz) 21 40

COND FAN

Rpm GC

Rpm GF

Diam (in.)

Diam (in.) GF

Cim

3860102310,103310,104310; 38GF102310,103310,104310

38GC,GF103320

CSR — Capacitor Start

PSC — Permanent Split Capacitor

GC

GF

208 V

460 V

38GC,GF

104

4-6

4-14 5-2 c-3

06 R 06RC OBGC

' ' '

36

1050

18 is

18

2200 ¡4^

' L..^

...................

Propel ler Tvoe

- ' ta

39 26 CE -105 564 C5425CV

H3922CV. H5422CVV

— Di rect Drive

*Factory refrigerant charge adequate when condensing

units are connected to Carrier approved evaporators

with up to 25 ft of tubing See Refrigerant charging

for details

t38GC103 unitsare permanent split-capacitor type

4-7 4-13

F3922CW i - F5422CW F5422CW F7022CW

G3922CV.. ••

CSR ...........CSS

36 46

1050 'ssr

1050 1050

20 CO

20 . 20

2900

38GF

145 105

5-6

6-9

06 R

G5422CV; G5422CV; G7022CW

CSR CSR

72 72

1050

1050 825

20

20

2900

' - ' "1

6-6

7-8

06 R

C5425CV

H5422CV-;

825

22

22

3900 3900

106

—

8-3

06 R

C7022CV

H7022CW

CSR

72

-

825

-

.

Page 6

SINGLE-PHASE compressor motors in 38GC101,

38GC,GF102, 103, 104 units are protected by an

internal current and temperature sensitive

overload.

Single-phase 38GC,GF145, 105 and 38GF106

unit compressors are protected by an internal

thermostat and external current overloads.

THREE-PHASE unit compressors are protected by

an internal thermostat and external current

overloads.

Internal temperature-sensitive overloads reset

automatically when internal motor temperatures

drop to a safe level (overloads may require up to

30 minutes to reset).

When an internal overload is suspected of being

open, check by using an ohmmeter or continuity

tester. See Carrier Standard Service Techniques

Manual, Chapter 2, for complete instructions.

TIME GUARD CIRCUIT (38GC145, 105 and all

38GF units) provides for a 5-minute delay before

restarting compressor after shutdown for any

reason. On starting, the time guard timer causes a

delay of 15 seconds after thermostat closes before

compressor will start. On compressor shutdown,

the timer delays compressor restarting for 4

minutes 45 seconds.

Compressor Removal

1. Shut off power to unit. Vent refrigerant to

atmosphere or use refrigerant removal methods

shown in Carrier Standard Service Techniques

Manual, Chapter 1.

2. Remove top grille and rear access panel.

3. Remove condenser fan motor orifice assembly.

Fan motor wires do not have to be dis

connected.

4. Remove compressor sound shield (if supplied).

5. Remove power leads from compressor terminal

box, and pressure relief plug from suction line.

Unsweat suction and hot gas lines.

6. Remove compressor hold-down bolts. Lift com

pressor out thru top of unit.

PUMPDOWN PROCEDURE

The 38GC and GF units may be pumped down

in order to make repairs on low side of system

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Jumper low-pressure switch.

4. Start unit and run until suction pressure reaches

5 psig (see Caution).

5. Shut unit off and frontseat suction valve.

6. Vent remaining pressure to atmosphere.

CAUTION- The 38GC and CF conckascr»

Will hold only faciory-supplicd smount of

refrigerant. Additionai refrigerant may eauv

38GF unsts cycle os high prc-ssurcMal

and units to reiie^-c pfes*ure thru

mtemai pressure ix-hef vaive (indicated by a

sudden rii>e of suction pressure t before

satetion pressure reache> 5 psig, if this

oceurs, shut ut&i off immediately, frontseat

suction vaive and vent renaaining pressure to

PRESSURE RELIEF PLUG

This plug is a protective device which melts at

210 F relieving excessive system pressure. Remove

plug when soldering on suction tube. For plug

replacement, order Carrier part no. EK02JA203.

REFRIGERANT CHARGING

38GC Units contain correct operating charge for

complete system when connected to Carrier

approved evaporators (capillary tube or thermal

expansion valve controlled) with up to 25 ft of

tubing. When over 25 ft of tubing is used,

additional charge may be required. Use Charging

Chart Method (when available) to check refrigerant

charge or add charge to Carrier approved systems.

To recharge these systems, use Weight Method

when 25 ft or under of interconnecting tubing is

used; Charging Chart Method when over 25 ft of

tubing is used. When charging charts are not

available or when 38GC condensing unit is con

nected to other than a Carrier evaporator, use

Weight Method of recharging.

Do not connect charging hoses to capillary

controlled systems during initial start procedure. If

necessary, to add manifold gages for servicing, refer

to Carrier Standard Service Techniques Manual,

Chapter 1, pages 1-5, Fig. 8, for bypass method of

returning charge to system.

CAimON: Do mt iheise systems, A

small pverebafj-go may rsistiit m compressor

due fo mfri^ranf flooding,

38GC CHARGING METHODS - When required,

evacuate 38GC systems to 5000 microns (29.7-in.

vacuum) before recharging. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

for system evacuation-dehydration instructions and

details of charging instructions listed below.

Charging Chart Method

TXV Systems — Use correct charging chart (Fig. 3

thru 8). See Carrier Standard Service Techniques

Manual, Chapter 1, for procedure.

Capillary Tube Systems — Use correct charging

chart (Fig. 9 thru 24). 38GC capillary tube systems

are charged correctly when intersection of system

A

V

Page 7

suction and discharge pressure lines on charging

chart falls on intersection of indoor air wet bulb

(ewb) and outdoor dry bulb temperature lines.

Weight Method ~ Refer to Table 6 or unit

nameplate for correct system refrigerant charge.

Blow any refrigerant remaining in system before

recharging.

When system is not evacuated, subtract the

following amount from total charge (Table 6).

38GC101,38GC102 - .10 lb (1.6 oz)

38GC103, 104, 145, 105 - .20 lb (3.2 oz)

Keep refrigerant recharge within one oz of

specified charge on 38GC101, 102 systems, and

within 2 oz on 38GC103, 104, 145, 105 systems.

Dial-a-Charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders available at refrigeration supply firms.

38GF Units contain correct operating charge for

complete system when connected to Carrier

approved evaporators (capillary tube or thermal

expansion valve controlled) with up to 25 ft of

tubing. When over 25 ft of tubing is used,

additional charge may be required. Use Charging

Chart Method (when available) to check refrigerant

charge or add charge to Carrier approved systems.

To recharge these systems, use Weight Method

when 25 ft or under of interconnecting tubing is

used; Charging Chart Method when over 25 ft of

tubing is used. When charging charts are not

available or when 38GF condensing unit is con

nected to other than a Carrier evaporator, use

Weight Method of recharging.

A satisfactory operating charge can be obtained

on 38GF thermal expansion valve systems by using

Sight Glass Method. This method may not provide

optimum charge.

38GF CHARGING METHODS - When required,

evacuate 38GF systems to 5000 microns (29.7-in.

vacuum) before recharging. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

for system evacuation-dehydration instructions and

details of charging instruction listed below.

Charging Chart Method

TXV Systems — Use correct charging chart (Fig. 3

thru 8). See Carrier Standard Service Techniques

Manual, Chapter 1, for procedure.

Capillary Tube Systems — Use correct charging

chart (Fig. 9 thru 24). 38GF capillary tube systems

are charged correctly when intersection of system

suction and discharge pressure lines on charging

chart falls on intersection of indoor air wet bulb

(ewb) and outdoor dry bulb temperature lines.

Weight Method — Refer to Table 6 or unit

nameplate for correct system refrigerant charge.

Blow any refrigerant remaining in system before

recharging.

When system is not evacuated, subtract the

following amount from total charge (Table 6).

38GF101, 102 - .10 lb (1.6 oz)

38GF103, 104, 145, 105, 106 - .20 lb (3.2 oz)

Keep refrigerant recharge within one oz of

specified charge on 38GF101, 102 systems and

within 2 oz on 38GF103, 104, 145, 105 and 106

systems.

Dial-a-Charge charging cylinder is an accurate

device used to recharge systems by weight. These

cylinders available at refrigeration supply firms.

Sight Glass Method — A satisfactory operating

charge can be obtained on 38GF TXV systems by

charging to a clear sight glass. For optimum charge,

use Charging Chart Method.

Elevate high-side pressure to 380 ± 10 psig by

blocking condenser fan discharge or condenser

entering air. Service access panel may be adjusted

to bypass entering air. (Do not operate without

panel in place except during charging procedure.)

Charge to a clear sight glass while holding high-side

pressure constant.

38GF106 TXV Systems — Add 11 oz of refrigerant

after clear sight glass is obtained for correct charge.

THERMAL EXPANSION VALVE SYSTEMS

Fig. 3 — 38GC,GF102 Charging Chart

Page 8

THERMAL EXPANSION VALVE SYSTEMS(cont)

Fig. 5 - 38GC,GF104 Charging Chart

CAPILLARY SYSTEMS

Fig. 9-38GC101/28GC,

40GC or 40CL001 Charging Chart

Fig. 6 — 38GC,GF145 Charging Chart

Fig. 7 — 38GC,GF105 Charging Chart

Fig. 10 - 38GC101/28SE001 Charging Chart

Fig. 8 — 38GF106 Charging Chart

Fig. 11 - 38GC,GF102/28SE002 Charging Chart

Page 9

Fig. 12-38GC101/28GC.

40GC or 40CL002 Charging Chart

Fig. 15 — 38GF103/28SE003 Charging Chart

Fig. 13 - 38GC,GF102/28GC,

40GC or 40CL002 Charging Chart

Fig. 14 — 38GC103/28SE003 Charging Chart

Fig. 16 - 38GC.GF102/28GC,

40GC or 40CL003 Charging Chart

Fig. 17 - 38GC,GF103/28GC, 40GC or

40CL003 Charging Chart*

Page 10

CAPILLARY SYSTEMS (cont)

Fig. 18 - 38GC103310, 320; 38GF103310,

320/28GC or 40GC003 Charging Chart

Fig. 19 - 38GC,GF103/28GC,

40GC or 40CL004 Charging Chart^

Fig. 21 - 38GC,GF104/28GC,

40GC or 40CL004 Charging Chart

Fig. 22-38GC,GF104/

28GC or 40GC005 Charging Chart

Fig. 20 - 38GC103310, 320; 38GF103310,

320/28GC or 40GC004 Charging Chart

*Use Charging Charts, Fig. 18 or 20

38GF103310,320/28GC, 40GC systems.

for 38GC103310,320,

Fig. 23-38GC,GF145/

28GC or 40GC005 Charging Chart

Page 11

CAPILLARY SYSTEMS (cont)

Fig. 26 — Condenser Fan Position

Table 7 — Fan Positions

COMPATIBLE FITTING REPAIR

Leaking Mechanical Connection — Frontseat con

densing unit service valves and relieve refrigerant

pressure in tubing Back locknut off Compatible

Fitting onto tube. Cut fitting between threads and

seal ring head as shown in Fig. 25. Remove tubing

section remaining in threaded portion of fitting.

Discard locknut.

UNIT 38

GCÏ01, 102, 103 IH

GC104, 145

GC105

GF102, 103

GF104, 145

GF105, 106

Fan Motor Removal

1.

Shut off power to unit.

2.

Remove unit top cover (grille), rear access panel

DIMENSION “A” (in.)

1^/2 (Lau)

1 (Brookside)

^ 1%

1% (Lau)

1 (Brookside)

IV,

1%

and control box cover.

3. Disconnect fan motor wires from fan capacitor

and control relay or contactor. Pull wires thru

rear of control box.

4. Loosen setscrews holding fan to motor shaft

and remove fan.

5. Remove bolts holding fan motor to motor

mounting bracket. Remove motor thru top of

unit.

Clean, flux, and insert new tube end into

remaining portion of Compatible Fitting. Wrap

valve base in wet rag. Heat and apply low

temperature (450 F) solder.

Leaking Sweat Connection — Frontseat service

valves and relieve refrigerant pressure in tubing.

Clean and flux area around leak and apply low

temperature (450 F) solder.

Evacuate or purge evaporator coil and tubing

system. Add refrigerant charge (see charging

instructions).

CONDENSER

Coil Cleaning — Clean by washing with dry

refrigerant, low-pressure water, or steam.

Fan Position — Required fan position is shown in

Fig. 26. Adjust fan by loosening setscrews and

moving blades up or down.

LUBRICATION

Fan Motor Bearings are prelubricated for three

years heavy duty or five years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

Compressor contains factory oil charge. When oil is

lost, see Table 6 for oil charge and Carrier Standard

Service Techniques Manual, Chapter 1, page 1-21,

for instructions. Use Carrier PP33-1, Texaco

Capella B or Suniso 3 G oil.

11

Page 12

Condenser Fan On

Condenser Air Restricted

Condenser Air Recirculating

Noncondensables in System

Refrigerant Overcharge

Improper Line Voltage

Refrigerant System Restriction

Loose Electric Connections

Faulty Run Capacitor

Condenser Fan Off

Fan Slipping on Shaft

Loose Electric Connections

Fan Motor Overload Open

Fan Motor Bearings Stuck

Fan Motor Defective

Low Suction Pressure

Low Refrig Charge

Defective Low-Pressure Switch

Low-Pressure Switch Setting

High Suction Pressure

Low Head Pressure

Defective Compressor Valves

Slightly Low Suction Pressure

Dirty Filters

Partially Restricted Air Flow

Coil Partially Iced

Slightly Low on Refrigerant

Duct Restricted

Dampers Partially Closed

TROUBLESHOOTING CHART

No Power at Open Contactor

Blown Fuses

Power Failure

Power at Open Contactor

Faulty Control Relay

Holding Coi 1 Open

Internal Compr Overload Open

Low-Pressure Cutout Open

Overloads Cycled

Compressor Stuck

Faulty Run Capacitor

High Head Pressure

Evaporative Fan Running

Low Refrig Charge

Restricted Refrig Flow

Restricted Capillary

Defective TXV

Restricted Evaporator Air

iced Coil

Plugged Filter

Dampers Closed

Restricted Ductwork

Evaporator Fan Stopped

Defective Fan Relay

Loose Leads

Overload Open

Burned Out Motor

Broken Belt

Contactor Open

Dead Tronsformer

Thermostat Circuit Open

Faulty Control Relay

Overload Open

Low-Pressure Switch Open

Contactor Coil Open

Loose Connection

Contactor Closed

Loose Leads at Compressor

Loose Leads at Contactor

Motor Windings Open

Internal Compr Overload Open

Contactor Closed Then Opens

Overload Opens

Compressor Stuck

____________

For replacement items use Carrier specified parts.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 4

Form 38GC-15SI New

Printed in U.S.A. 2-71 Codes D and MS Catalog No. 533-802

Loading...

Loading...