Page 1

38EV,QV

HEATING A COOLING

Operation, Service and Troubleshooting

For Models 38EV024320, 38EV036320, 38QV024320, 38QV036320

CONTENTS

INTRODUCTION

Step 1 —General System Description

Step 2—Component Functional Description

• Outdoor Unit Components

• Indoor Unit Components

Step 3—Sequence Of Operation........................................ 7

Step 4—VVT-II Thermostat Operation Troubleshooting. 13

Step 5—System Troubleshooting

• Self-Diagnostics—Error Codes

• System Malfunctions—No Error Code

Step 6—Service and Maintenance....................................40

NOTE: Malfunction of certain electronic control compo

nents can cause lack of Automatic Emergency Heat initia

tion. See Service and Maintenance section for corrective

servicing procedures.

INTRODUCTION

This publication is designed to provide the information nec

essary to understand and troubleshoot Carrier’s 38EV and

s 38QV Variable Speed Split System Heat Pump and Air

' Conditioning Systems. The text covers variable speed 38EV

condensing and 38QV heat pump outdoor units, coupled

with 40QV Fan Coil or 28RD/RN Coil and 58SS Furnace

with blower accessory package. AU system combinations

are controUed in a similar manner utilizing the same elec

tronic components for both heat pump and cooling only sys

tems. System Diagrams are shown in Figs. 2 and 3.

This guide covers single zone applications only. For multi

ple zone instaUation, see proper supplemental manual.

STEP 1—Gênerai System Description

Outdoor Units:

The 38EV condensing and 38QV heat pump units are

derived from standard Carrier single-speed units. The con

trol box is slightly larger to aUow room for the induction

inverter and system microprocessor control board.

Although the unit is 208/230 VAC single phase, the inverter

supplies three-phase power at a wide r^ge of frequencies to

control the speed of the three-phase compressor. By varying

compressor speed, the system is able to control its output

within a range of about one-half to fuU rated capacity. The

outdoor fan motor is of standard single-phase, single-speed

design.

Indoor Units:

The 40QV Fan Coü provides variable indoor airflow control

for the system. This feature gives the system the capability

not only to vary its output capacity, but to control humid

ity levels throughout this capacity range.

The 58SSB Blower Accessory provides these same,features

when coupled with a 58SSB Furnace and 28RD/RN Furnace

Coil.

..............................

....................

.......................................

1

1

15

Variable Speed Systems

Thermostat:

The 38EV/QV system must be installed with a VVT-II ther

mostat Model MST-04 or MST-16 with software revision 6.7

or higher, available through your Carrier distributor.

General Operation:

The abflity of the system to control compressor and blower

speeds as described above allows it to adjust its output

capacity to match the varying load requirements of an

installation.

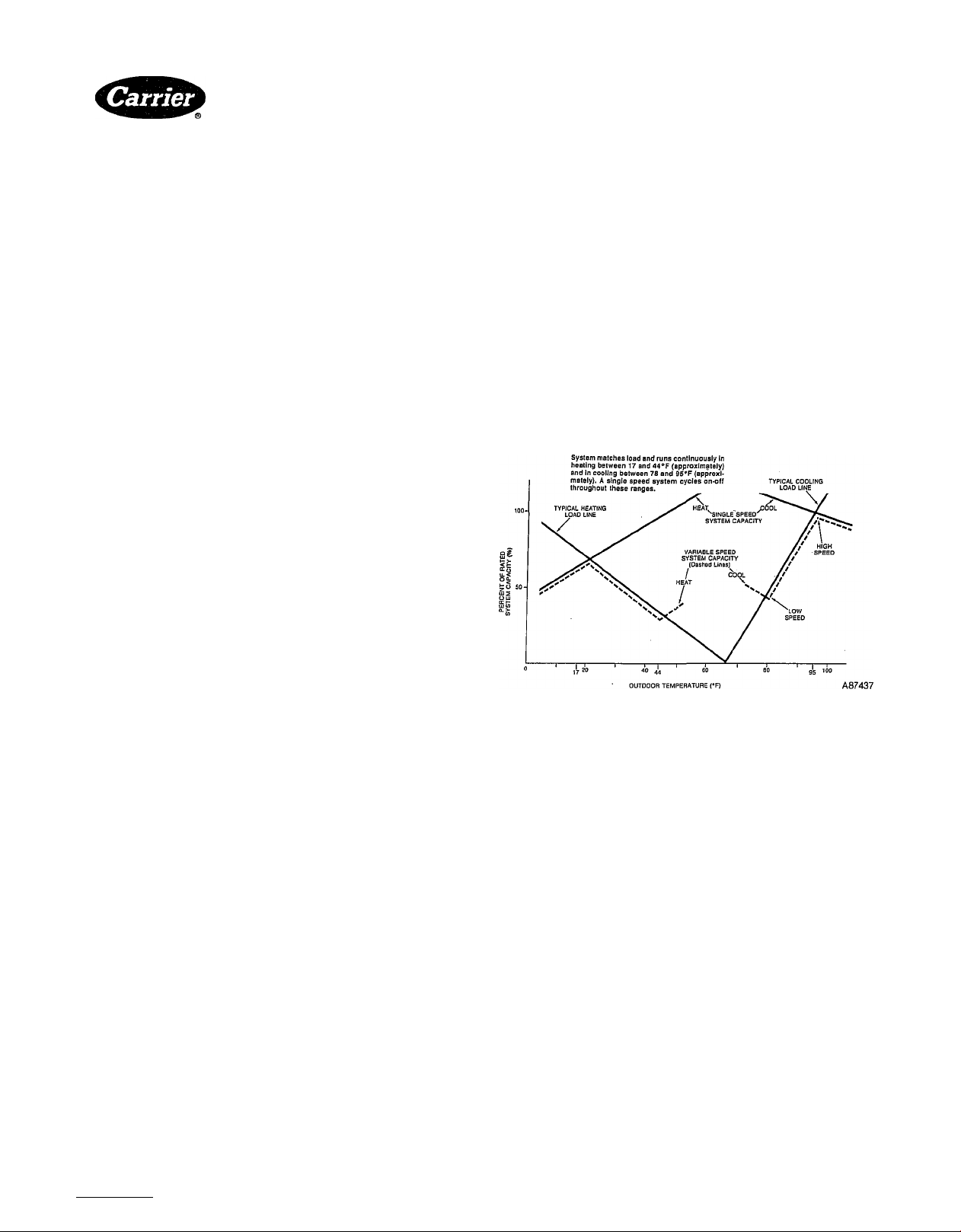

This type of operation results in less on-off cycling (ref. Fig.

1), quieter operation and improved temperature control at

modera:te and low load conditions.

Fig. 1—Variable Speed System Matches Load

STEP 2—Component Functional Description

CONTENTS

Page

38EV, QV Outdoor Units

Main Control Board...............................................................4

Compressor Inverter..............................................................4

Compressors

Outdoor Coil, Suction Thermistor (Tl, T2)

Outdoor Fan Motor/Capacitor

Outdoor Solenoid Expansion Valve (SEV)

High Pressure Switch (HPS)

Low Pressure Switch (EPS)....................................................7

Emergency Stop Switch (ESS)

Crankcase Heater and Switch (CH, CHS)...........................7

40QV Fan Coil, 58SSB Furnace Blower Accessory

Interface Board ....

Blower Controller...................................................................7

Blower Motor

Indoor Solenoid Valve (SEV) . .............................................

Indoor Coil Thermistor (T3)..................................................7

Figs. 2 and 3 shows layout of components in the variable

speed control system. This section will describe each compo

nent and discuss its function in attaining proper system

operation.

..........................................................................6

..........................................................................

..........................................................

..........................

..............................................

..........................

..............................

.......................

...............................................................7

...................

.......................7

................

6

7

7

7

7

4

6

6

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book| 1 I 1 I 4 I 4 PC 101 Cataiog No. 533-895 Printed in U.S.A. FormSSEV, QV-1SM Pg 1 12-87 Replaces: New

Tab I3al5al2al5a

Page 2

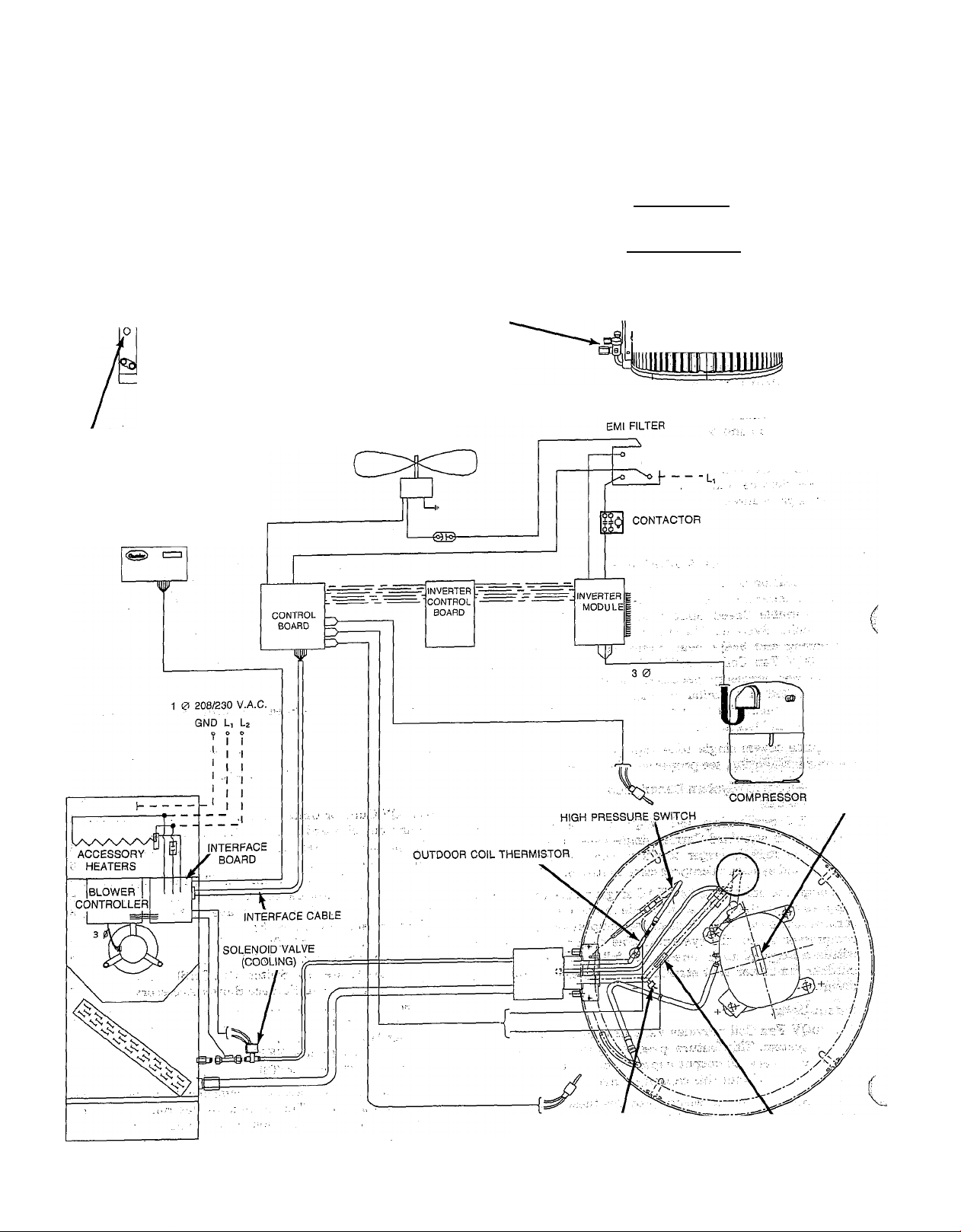

38EV Variable Speed Air Conditioning System

SERVICE VALVES

THERMOSTAT

FAN COIL

40QV024

40QV036

SERVICE VALVES,

SERVICE PORT

OUTDOOR FAN

OUTDOOR UNIT

38EV024

38EV036

&

inrininTlTnili

iMTrifrilTTnW

felinui

™eidemh

N>1

----

°

-----

U

GND , 1 0 208/230 V.A.C.

LOW PRESSURE SWITCH

Fig. 2—Simplified System Schematic

(shown with 40QV Fan Coil)

ESS SWITCH

(036 ONLY)

SUCTION THERMISTOR

A87260

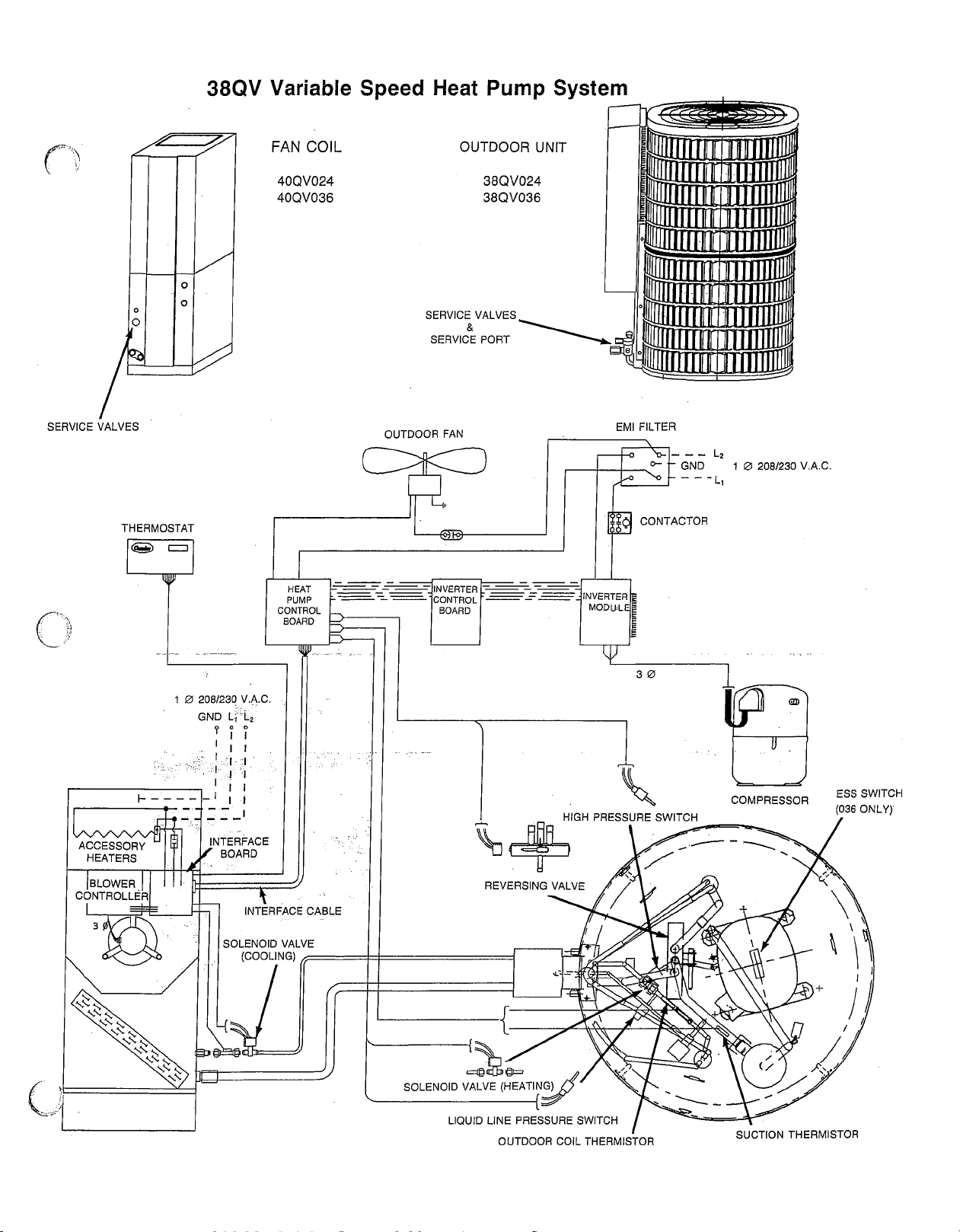

Page 3

Fig. 3—Simplified System Schematic

(shown with 40QV Fan Coil)

A87215

Page 4

38EV, 38QV Outdoor Unît

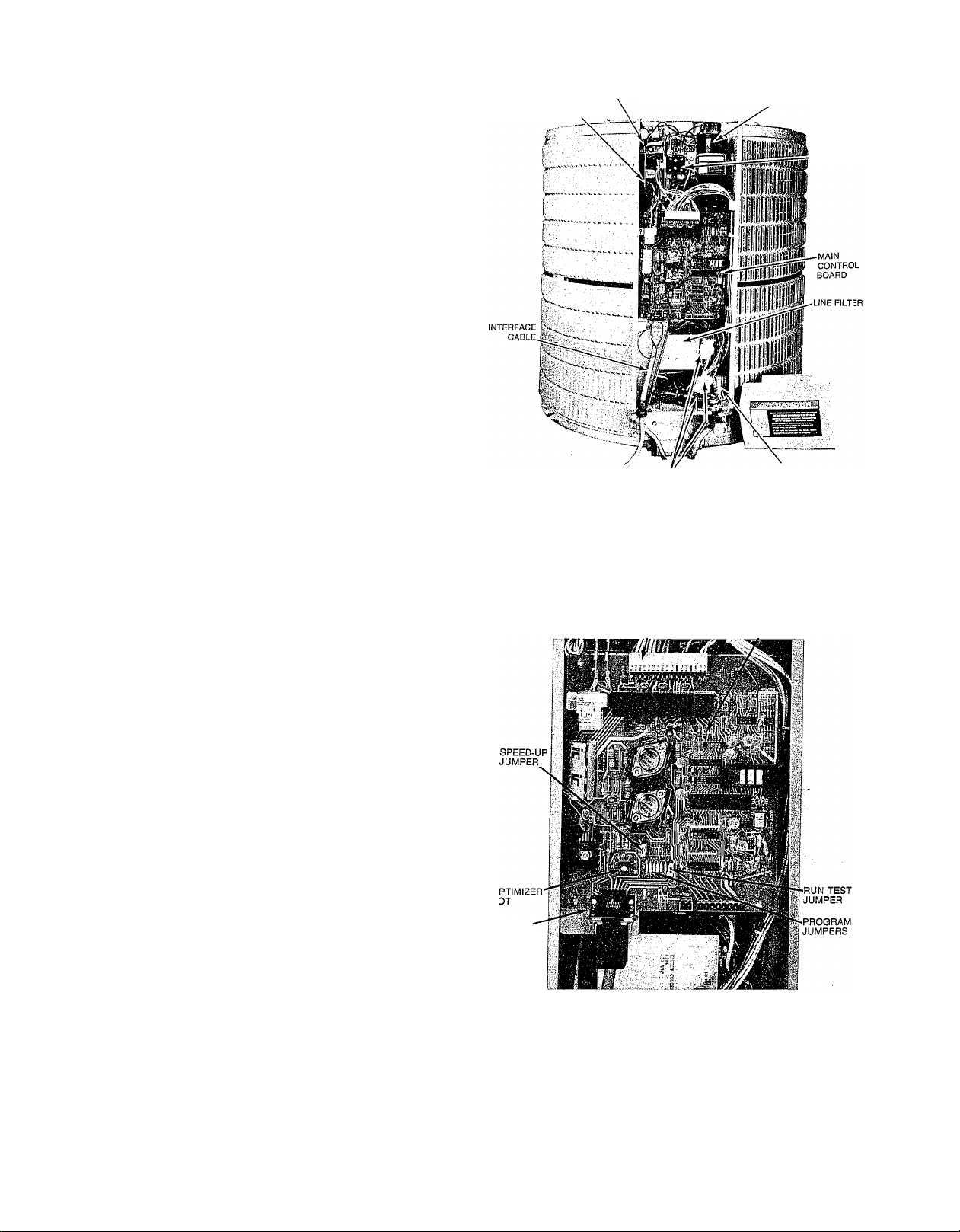

Main Control Board:

The main control board is located in the front of the 38E V/

QV control box. It is fully visible and serviceable by simply

removing the control box cover, as shovm in Fig. 4. All wir

ing connections for components internal to the unit are at

the top of the board as shown in Fig. 5. Low voltage connec

tions are at thè white 17 pin connector, high voltage (O.D.

fan relay) at the two push on terminals in the upper left. All

connections to the indoor unit aré made through the 15 con

ductor Interface Cable connector located in lower left of the

board.

Thè main "control boárd receives information on system sta

tus from 5 devices (including WT-II thermostat) and uses

it to determine proper control for its 10 outputs. These I/O’s

are listed below: •

Inputs:

1) Thermistor (T2), Suction Line.

2) Thermistor (Tl), O.D. coil (between expansion device

and coil).

3) Thermistor (T3), I.D. coil (between expansion device

and coil).

4) Compressor Inverter (over-current alarm).

5) Thermostat (cool/heat, capacity demand, etc.)

Outputs:

1) Inverter (compressor) speed signal.

2) I.D. Blower Speed Signal (via interface board).

3) O.D. Solenoid Expansion Valve* (refrig, expansion con

trol, heat mode).

4) I.D. Solenoid Expansion Valve (refrig, expansion con

trol, cool model).

5) Main Contactor (inverter/compressor on-off control).

6) O.D. Fan (on-ofif control).

7) Reversing Valve* (on-off control).

8) Aux. Heat (electric or furnace heat on-ofif).

9) On-Board LED (on-off for diagnostics codes, etc.)

10) Thermostat (display of diagnostics codes, etc.)

*38QV Heat Pump Units Only

Compressor Inverter:

NOTE: The following text describes disassembly of the con

trol box for purposes of explaining inverter, coniponent func

tion only. Inverter components are not serviceable, and

shoüld not be removed from the control box.

Serviceable items include only the main control board, con

tactor and fan capacitor.

Failure of any other component requires replacement of the

entire control box. See instructions included with replace

ment control box for this procedure.

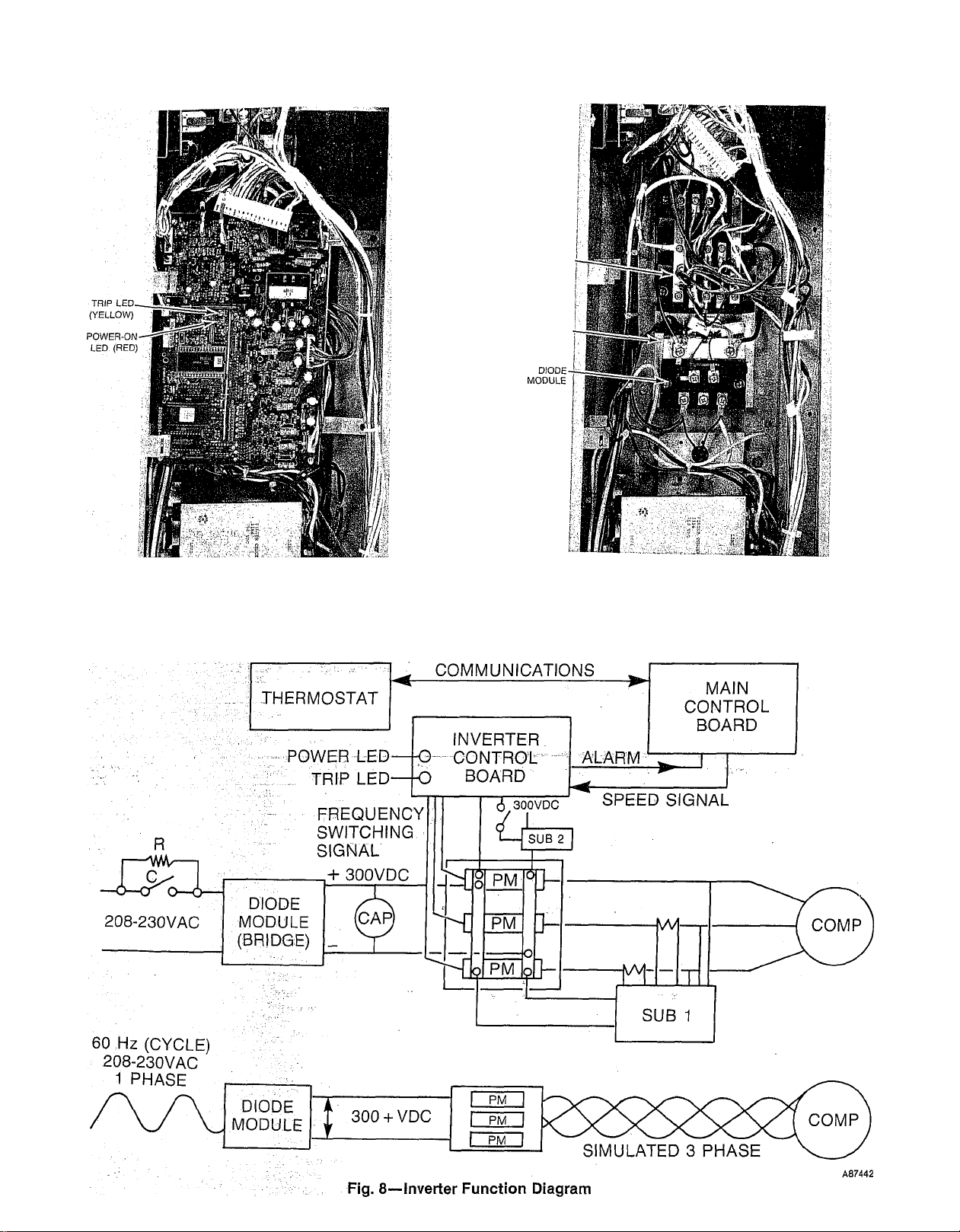

The inverter is made up of 6 components, all mounted in the

38EV/QV control box. , ~

With the main system control board and backpanel

removed (3-screws) the inverter board is clearly visible (See

Fig. 6). _ w,, /;

Removal of the inverter board allows a view of the rest of

the inverter components, which are pointed out in Fig. 7.

(Refer to Fig. 8) The inverter operates with 208-230VAC,

single-phase input power provided to the Diode Module (or

diode bridge). Here the AG power is converted to high volt

age DC (325V approx.).

The large (black) Smoothing Capacitor in upper right of the

control box is required to Smooth the DC voltage and is at

this 325 VDC potential.

SUB-BOARD it2

SUB-BOARD tn

SMOOTHING CAPACITOR

CONTACTOR

CONTROL BOX-TO-UNIT

CONNECTORS

FAN CAPACITOR

Fig. 4—Control Box, Cover Off

17 PIN DIAGNOSTIC

CONNECTOR LED

INTERFACE

CABLE

CONNECTOR &

RETAINER

LATCH

Fig. 5—Control Board

The DC power is then provided to the Power Modules (3) or

Power Transistors via a buss mounted across all 3 modules.

The power modules drive the 3-phase compressor when the

Inverter Board receives a signal from the main control

board requesting a certain compressor speed. The inverter

board switches each power module on-ofif into a signal simu

lating a single-phase signal. (See Fig. 9A). Each power mod

ule is switched in the same pattern, but 120-deg. out-of

phase from the other two modules, so the total output is in

3-phase form. (See Fig. 9C).

A87438

A87216

Page 5

POWER

MODULES (3)

HEAT SINK

A87440

Fig. 6—Control Board Removed Fig. 7—Inverter Board Removed

38EV/QV COMPRESSOR INVERTER OPERATION

. - .

.... SERIAL ........................................................

........

- -

A87441

..........

Page 6

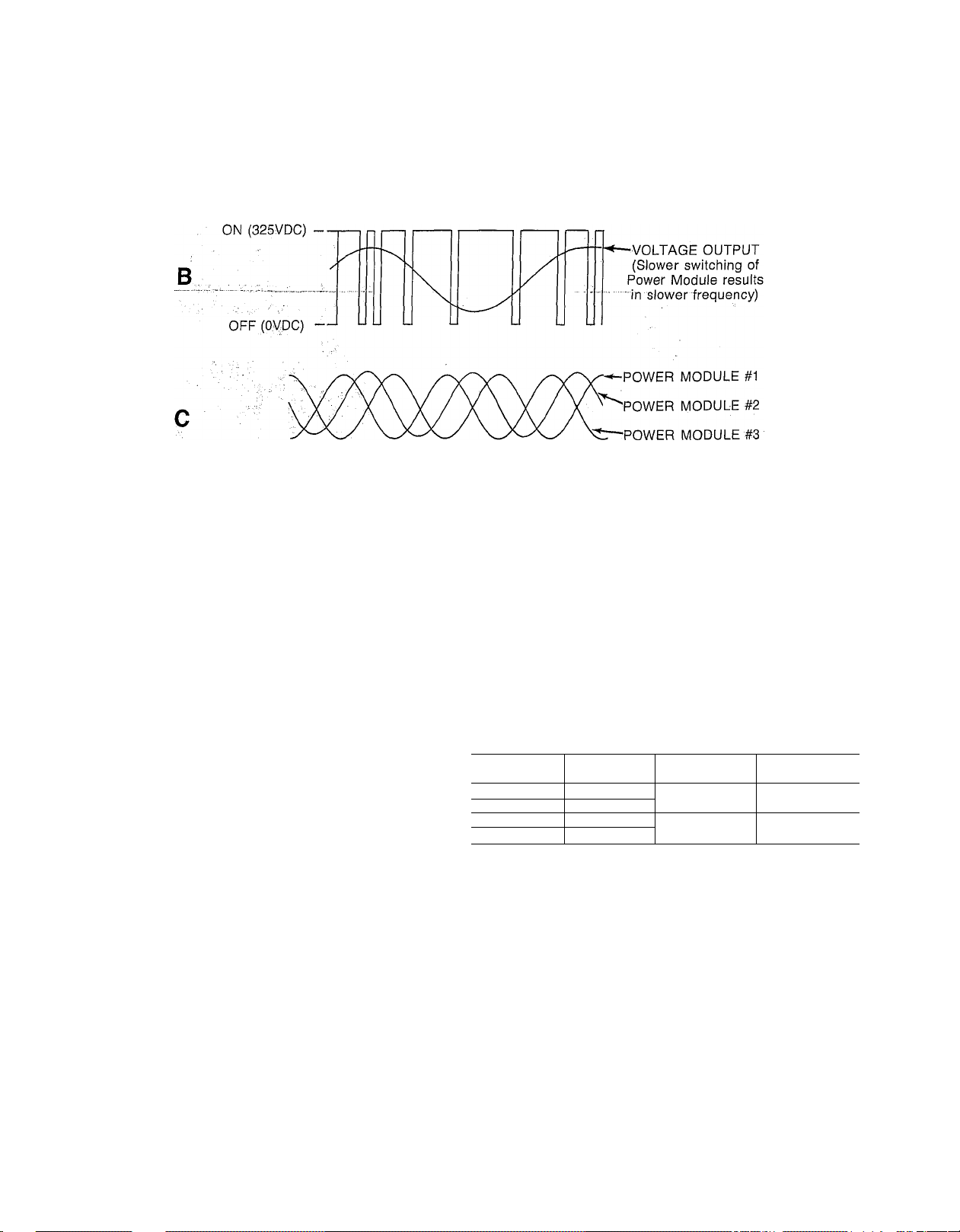

ON (325VDC) —

OFF (OVDC) —

/

\

Fig. 9—Inverter Power Module Switching

VOLTAGE OUTPUT

(Average of ON-OFF

■ voltage)

o

A87443

A change in the speed signal from the main control board

causes thé inverter board to switch the power modules at a

different rate, thus changing the 3-phase output frequency,

and compressor speed. (Ref. Fig..9B),

In summary, the inverter takes a 230V, single-phase, 60 Hz.

frequency input and converts it'to high voltage DC. It then

converts it to 3-phase AC power at frequencies of 30-90 Hz.

to drive the 3-phase compressor at speeds of 1800 to 5400

RPM.

Although other inverter components (shown in Fig. 4) were

not needed in the above'functional description, they are still

necessary to maintain inverter integrity and reliability.

Sub-board #1 is used to suppress electrical noise caused by

power module switching to prevent interference with the

inverter microprocessor. It also contains 2'current loops so

the inverter can monitor its own current output. Sub-board

#2 is an under-voltage protector for the inverter bbardr

Compressors—are of a spedial design to operate reliably

over the 180Ô-540Ô RPM (30-90 Hz. frequency) speed range.

They are driven by a standard design 3-phase motor. ,

—38EV024, 38Qy024 Models—have a reciprocating 'com

pressor with internal PTC heater and internal overload

feature. It has specially hardened valves for high speed

operation, and special oil pump to retedn proper lubrica

tion at low speeds.

Its internal current and temperature sensitive overload

resets automaticaUy when internal compressor motor

temperature drops to a safe level (overloads may require

. .. up to 30 minutes to reset). When an internal overload is

suspected of being open, check by using an ohm-meter

or continuity tester. - -

..:...

■

The internal high Pressure Relief Valve opens at a pres

sure differential of approximately 450-f-50 psig

between suction (low side) and discharge (high side) to

. allow pressure equalization..

See Table 1 for proper oil charge.

—38EV036, 38QV036 Models—have a scroll compressor.

This type of compressor contains no valves, similar to a

rotary type. The “movable” vane osciQates in a cam fash-

ion to force refrigerant around from outer edge to the cen

ter discharge, while compressing it.

The scroll compressor contains no internal overload

devices. Instead, an emergency stop switch (ESS) is

mounted to the top of the compressor (see description

below).

It also requires no high' pressure relief valve. At exces

sive pressure the scroll vane is hfted from its seahng

surface, allowing high tolow'side bypass.

Table 1—Refrigerant and Oil Charge

Unit

Model

38EV024

38QV024 ;

38EV036 : 8.1

38QV036

Charge

R-22(lb)

, 8;5 Sontex2000

9.5

Oil

Type

Calumet RD-15 or

Sunisco 4GS 41/39

Oil Charge (oz)

New/Recharge

( , : 55/51

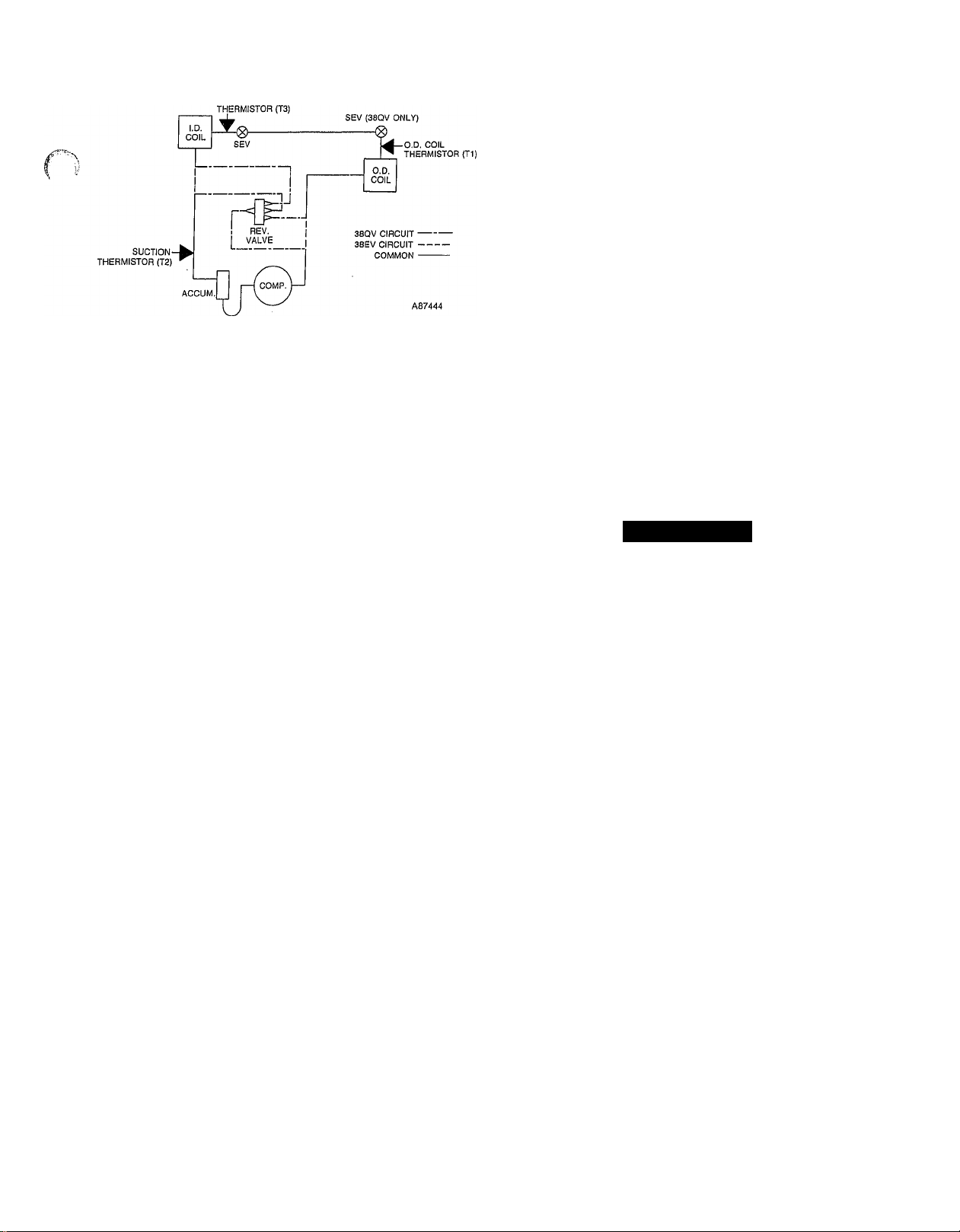

Thermistors:

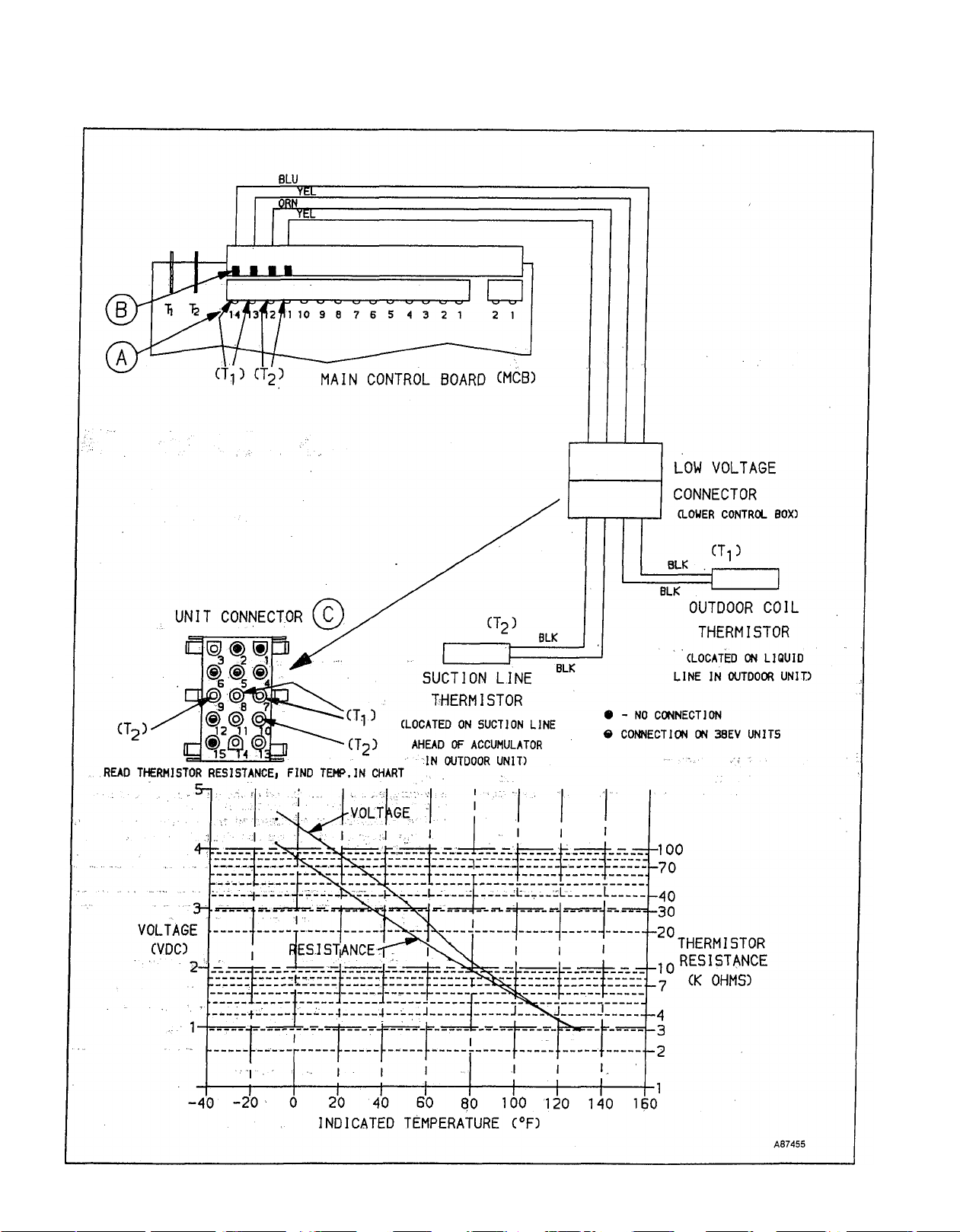

Three thermistors are utilized by the main control board to

monitor refrigerant temperatures at locations shown in

Figs. 2, 3 and 10. The same model thermistor is used at all

three locations. Each is mounted in a %6” O.D. tube secured

to the refrigerant hne for improved accuracy and protection

of the device, and then heavily insulated (armaflex tube).

O.D. Fan Motor/Capacitor:

The totally enclosed fan motor is of standard 208-230

single-phase design for single-speed operation. Its related

capacitor, located in lower right of the control box, is also of

standard design.

Outdoor Solenoid Expansion Valve (SEV)—38QV Heat

Pumps Only.

This device is identical to that used at the indoor unit,

except for accurator piston size. Refer to Indoor Solenoid

Expansion Valve Description.

Page 7

Fig. 10—Thermistor Locations

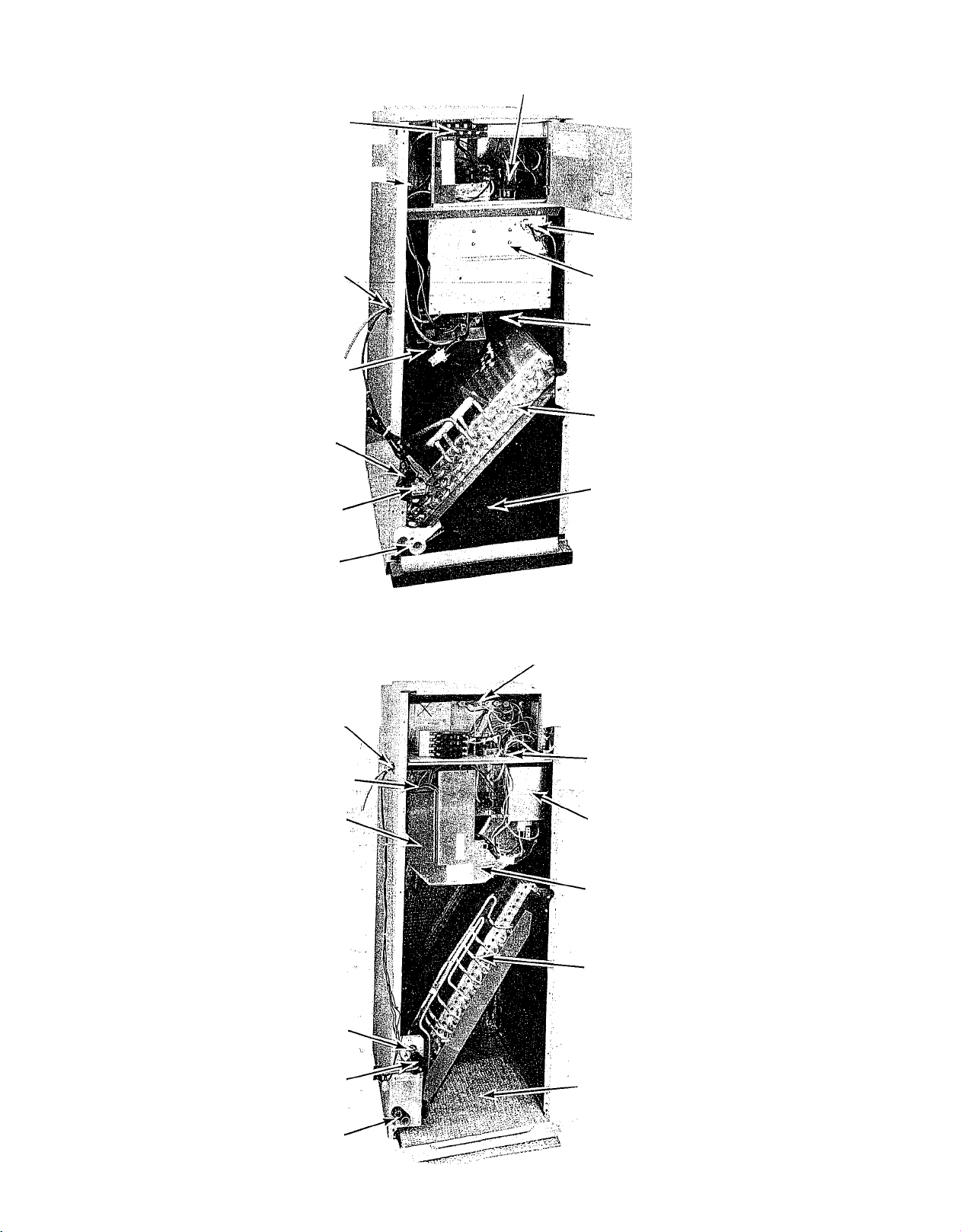

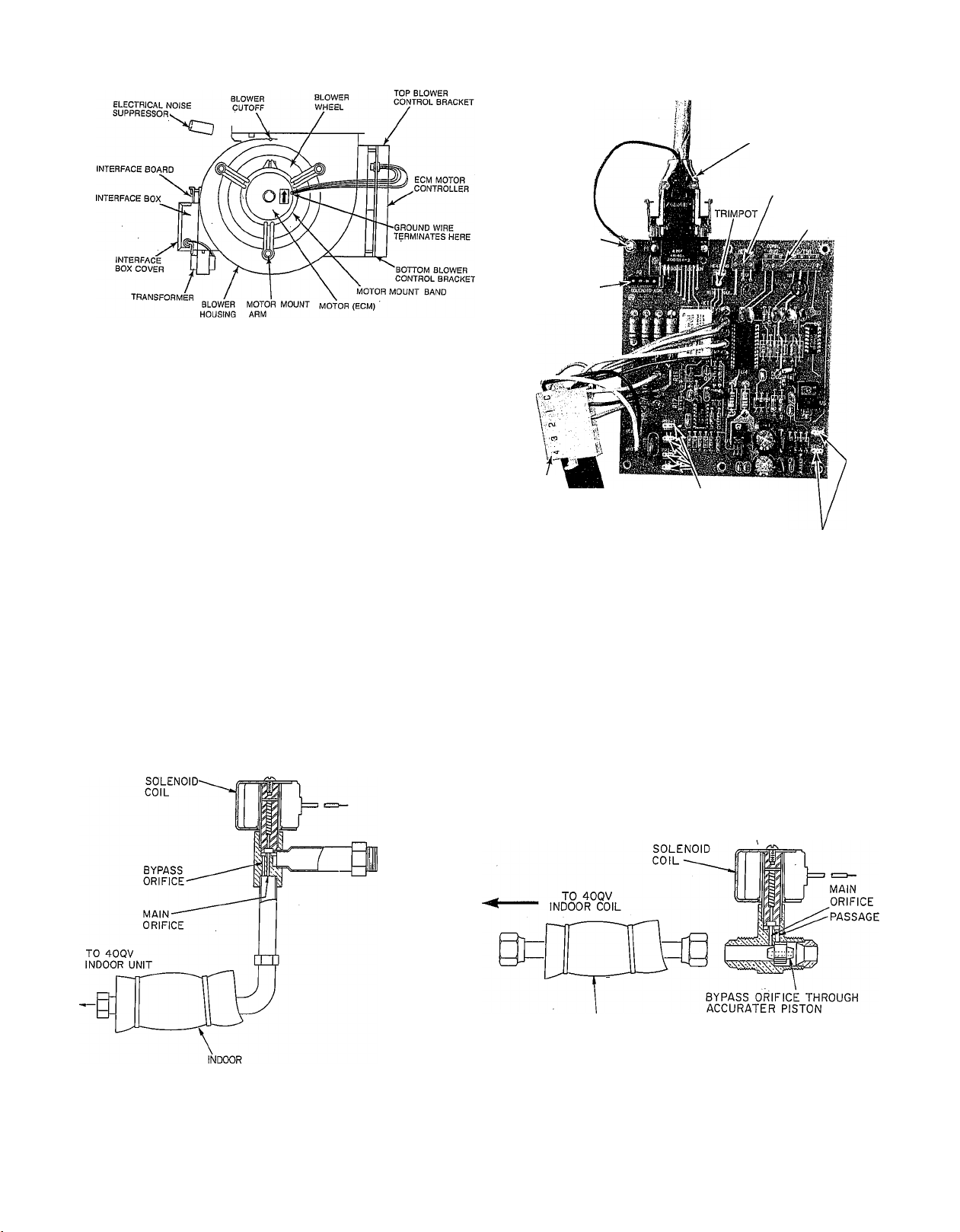

58SSB Furnace Blower Accessory—Includes the same

motor as the 40QV fan coil. Its controller and interface

board are 115 VAC versions of the fan coil components,

mounted as shown in Fig. 13.

Interface Board—serves three major functions in the

system.

Whenever gas or electric heat is energized, the interface

board takes over control of the blower from the outdoor

unit. It then forces the blower to high heating speed, which

is adjusted at the blower speed trimpot (ref. Fig. 14).

The board also contains the VVTTI thermostat power

supply.

Last of all, it acts as a connection point for input power, and

the control circuit between outdoor unit and indoor compo

nents (i.e., indoor SEV, thermistor, transformer, and blower

motor).

Blower Controller—serves a function similar to the outdoor

unit compressor inverter. It converts single-phase, 60 Hz.

power into a variable frequency output to control blower

motor speed. High and low motor speed settings are adjust

able at a 10-pin connector on the controller.

Blower Motor—is of unique design, containing a permanent

magnet rotor for superior eflBciency.

High Pressure Switch (HPS)—is provided for high pressure

protection of the system. It is located on the hquid line in

38EV units, and the discharge hne in 38QV units, (ref. Figs.

2 and 3). Its setting is 425 (+ -10) psig.

Low Pressure Switch (LPS)—is included to provide loss-ofcharge protection.

(

In 38QV heat pumps the LPS is located in the hquid line

between the outdoor coil and outdoor SEV (ref. Fig. 3). Its

setting is 5 + (+ -3) psig and provides protection in the heat

ing mode.

In 38EV coohng units, the LPS is located in the suction line

between suction service valve and accumulator (ref. Fig. 2).

Its setting is 27 (4--5) psig.

Emergency Stop Switch /EiSSj—Is used only on 38ÉV036

and 38QV036 model units. It is mounted to the top of the

scroU compressor to provide over-temperature protection,

as the scroll has no internal overload. It is located in the

safety electrical circuit in series with LPS and HPS

switches. The ESS is set to open on temperature rise at

265 + -10 deg.F and reclose at 210 + -20 deg.F.

Crankcase Heater and Switch (CH,CHS)—is connected

across the input side of the line filter and operates continu

ously except above the setting of the crankcase heater

switch (70-deg.F) which is located on the liquid hne.

The purpose of the heater is to keep the crankcase warm

during the off cycle and thus prevent dilution of the oil with

refrigerant. This assures good lubrication and prevents loss

of oil from the crankcase during startup. To energize crank

case heater, turn the indoor thermostat to OFF position and

energize electrical disconnect to the outdoor unit. If the elec

trical disconnect switch to the outside unit has been off for

an extended period of time, the crankcase heater should

be always energized for 24 hours before starting the

compressor.

INDOOR UNIT COMPONENT DESCRIPTION

40QV Fan Coils—Are essentially standard Carrier indoor

units with motor replaced by the variable speed motor and

208-230 VAC controller and interface board (ref. Figs. 11

and 12.)

A CAUTION

An extremely hard or sharp blow to the casing or drop

ping the motor may affect motor operation due to mag

net damage.

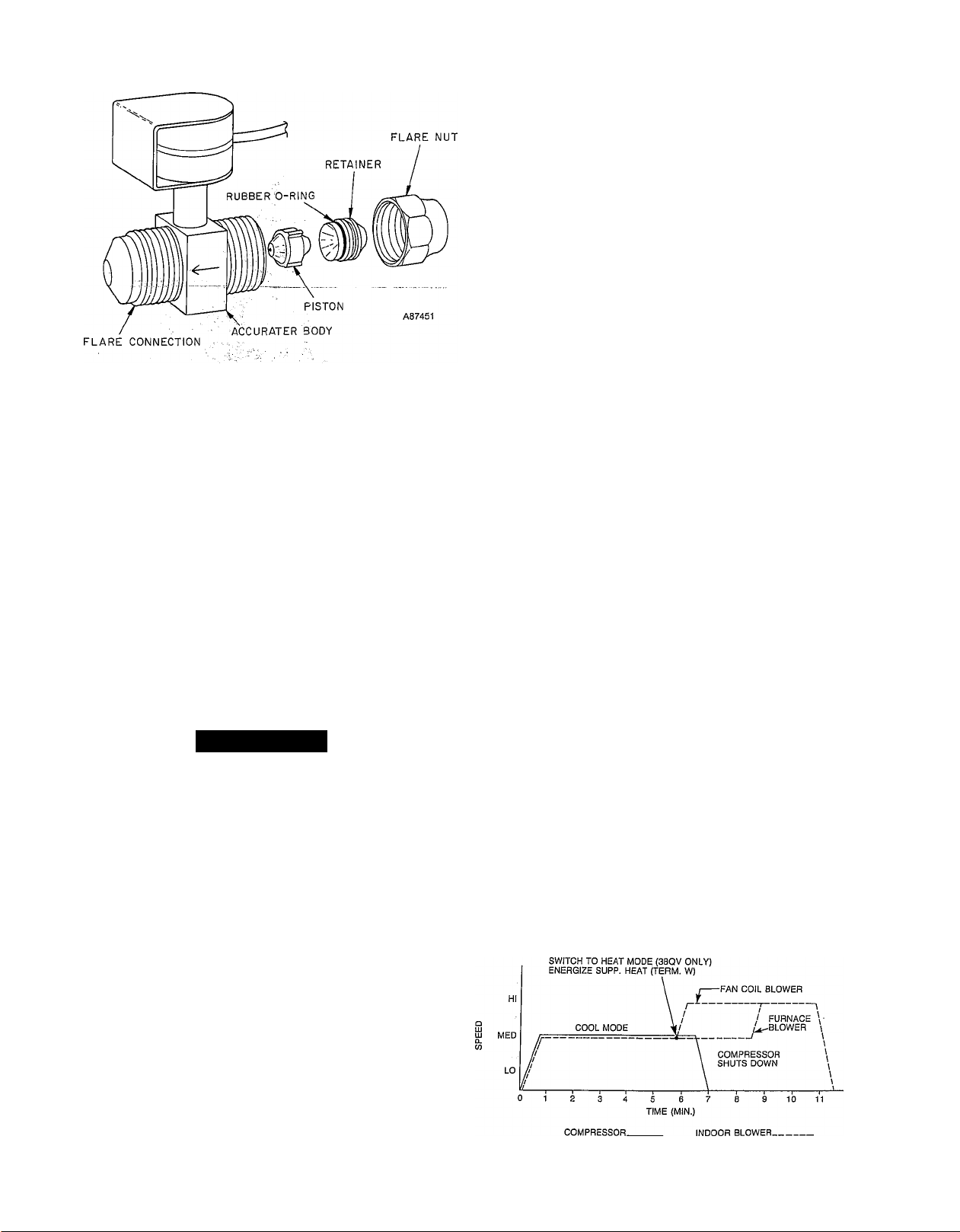

Indoor SEV Assembly—Is provided with the 38EV or 38QV

outdoor unit. It must be mounted to indoor unit liquid con

nection during installation. The 38EV SEV assembly pro

vides two expansion orifices in parallel; a main orifice, which

is controlled by the solenoid, and a b3q)ass orifice (See

Fig. 15).

The b5qiass orifice is sized to meter refrigerant properly at

low compressor speeds with valve de-energized. At high

Compressor speed, the solenoid is energized, allowing paral

lel flow through a second, main orifice, sized properly for the

additional refrigerant flow needed. At intermediate com

pressor speeds, the solenoid is cycled on-off to control mid

range flow rates.

The 38QV heat pump valve functions in much the same

manner, except the fixed bypass orifice is replaced by a

standard accurator piston. This allows the capability for

non-expanded flow in the reverse direction needed in heat

pumps. This valve, with cutaway, is shown in Figs. 16

and 17. See Table 3 for piston sizes.

The SEV solenoids are energized by a 24 VDC coil, driven

directly by the main control board.

Indoor Coil Thermistor (T3)—Mounted to the SEV assem

bly, it is identical to the outdoor unit thermistors.

STEP 3—Sequence Of Operation

Startup—Once the system is properly installed or serviced,

there are two methods available to start the system and

check operation.

The first method is the “Run Test” function, which is

highly recommended for operational checkout after initial

installation or servicing. The Run Test automatically oper

ates the system in both the heat (including aux. heat) and

cool modes, thus eliminating the need to adjust the thermo

stat a number of times to force system into the desired oper

ating conditions. “Run test” operation is detailed below.

Page 8

LOW-VOLTAGE

TERMINAL AREA i|

FAN DECK WIRING-^^

PASSAGE HOLE

(HIDDEN)

ACC ELECTRIC HEATER

AND CONTROLS

MOTOR LEADS

OUTDOOR CABLE

ENTRY HOLE

INTERFACE BOX

REFRIGERANT LINE

CONNECTIONS

SEV ASSEMBLY'

CONDENSATE

DRAINS

OUTDOOR CABLE

ENTRY HOLE

ECM MOTOR

CONTROLLER

BLOWER ASSEMBLY

INDOOR COIL

FILTER SECTION

A87445

Fig. 11—40QV024 Fan Coil

ACC. ELECTRIC

HEATER AND CONTROLS

jr LOW-VOLTAGE

TERMINAL AREA

1^'

MOTOR LEADS

ECM MOTOR

CONTROLLER

REFRIGERANT

LINE CONNECTIONS

SEV ASSEMBLY

CONDENSATE

DRAINS

FAN DECK WIRING

PASSAGE HOLE

INTERFACE BOX

BLOWER

ASSEMBLY

INDOOR COIL

FILTER SECTION

A87446

Fig. 12—40QV036 Fan Coil

R

Page 9

ISOLATOR GROMMET

Fig. 13—58SSB Furnace Blower Assembly

A87447

INTERFACE CABLE

GROUND WIRE

SEV/THERMISTOR

CONNECTOR

INTERFACE CABLE

LOW VOLTAGE TERMINAL

BLOCK (TO ACCESSORT

HEATERS OR FURNACE)

THERMOSTAT

TERMINAL BLOCK

TO OUTDOOR

UNIT

LIQUID LINE

CONNECTOR FOR HEATER BOX TRANSFORMER

ACCESSORY OR FURNACE

BLOWER LEADS

„ PR1-2 POWER TO INTERFACE

LI, L2 POWER INPUT PRM,

Fig. 14—Interface Board

CONTROL POWER FROM

INTERFACE BOX

TRANSFORMER

A87448

THERMISTOR

Fig. 15—38EV SEV Cutaway

A87449

INDOOR

THERMISTOR

Fig. 16—38QV SEV Cutaway

A87450

Page 10

Fig. 17—38QV SEV Parts

The second method involves setting the thermostat setpoint

for a high demand (4-deg.F or more from room temperature)

in the heat or cool mode. To accomplish this, refer to ther

mostat setup instructions, Step 4. This will allow the sys

tem to start and operate normally.

A “Speed-Up” function is available to aid in operational

checkout if the normal startup method is used. The “Speed-

Up” function shortens the delays and timing sequences of

the normal startup routine, and is described in this section.

The system Self-Diagnostic feature (Eef. Troubleshooting,

Step 5) is incorporated in both the Run Test and normal

startup operation.

Run Test-

Initiation—Remove the outdoor unit control box cover, then

apply power to indoor and outdoor units.

A WARNING

High Voltage power is supplied to control box compo

nents immediately upon closure of external main dis

connect. The main contactor is bypassed fqr initi^

charge-up of inverter capacitor (ref. Fig, 8). Electrical

shock or death may result,, ,,

one of the following responses:

a) The unit may not start (Error Codes 3-5,8).

b) The unit may shut down prematurely (Error Codes 9,

10). Compressor and/or indoor fan speed may fluctuate

before shutdown as the system attempts to verify or

clear the problem (Error Codes 11, 14).

c) The unit may complete the Run Test properly, but

flash an Error Code during operation. Some diagnos

tics, such as low cheu-ge indication (Error Code 15), are

designed to warn the serviceman of potential problems

but may not affect system operation.

Manual Checkout During Run Test:

Although the system is equipped with self-diagnostic capa

bilities, it should stül be visually and audibly inspected for

proper installation and operation during the Run Test.

A check list of system operational functions is included

below. Refer to Fig. 18 for the sequence of these functions

and check each item. To complete the list, the Run Test can

be initiated more than once.

a) Verify that compressor and outdoor fan operate with

out excessive vibration of the outdoor unit in its

mounted position.

b) Verify indoor blower operates in both the Cool and

Heat Mode.

c) Verify indoor solenoid expansion valve operates prop

erly by listening closely for valve clicking off-on at

about 3-second intervals.

d) Reversing valve switches off (detected by “woosh”

sound) when unit changes to Heat Mode. This sound

also ensures valve was properly energized for cooling

operation (38QV only). /

e) Verify that indoor blower speed override for gas or elec

tric heat operates properly (blower jumps from medium

to high speed). This function is necessary to guarantee

full blower speed operation when electric heat or fur

nace is on. (Blower control is different for gas vs. elec

tric heat as shown in Fig. 18).

f) Verify that electric heaters or furnace burners operate.

Once the “Run Test” has completed and the unit, including

auxiliary heat is off, the main control board LED will illumi

nate. When it extinguishes, system can be started normally

by adjusting thermostat.

The Red LED on Main Control Board will illuminate for

approximately 30 seconds, and then extinguish.

To initiate “Run Test” function, remove yellow jumper

(board is labeled “Run Test” as ishowri in Fig. 5). Unit will

start soon after jumper is reinstalled in its proper position

on the board. _ v

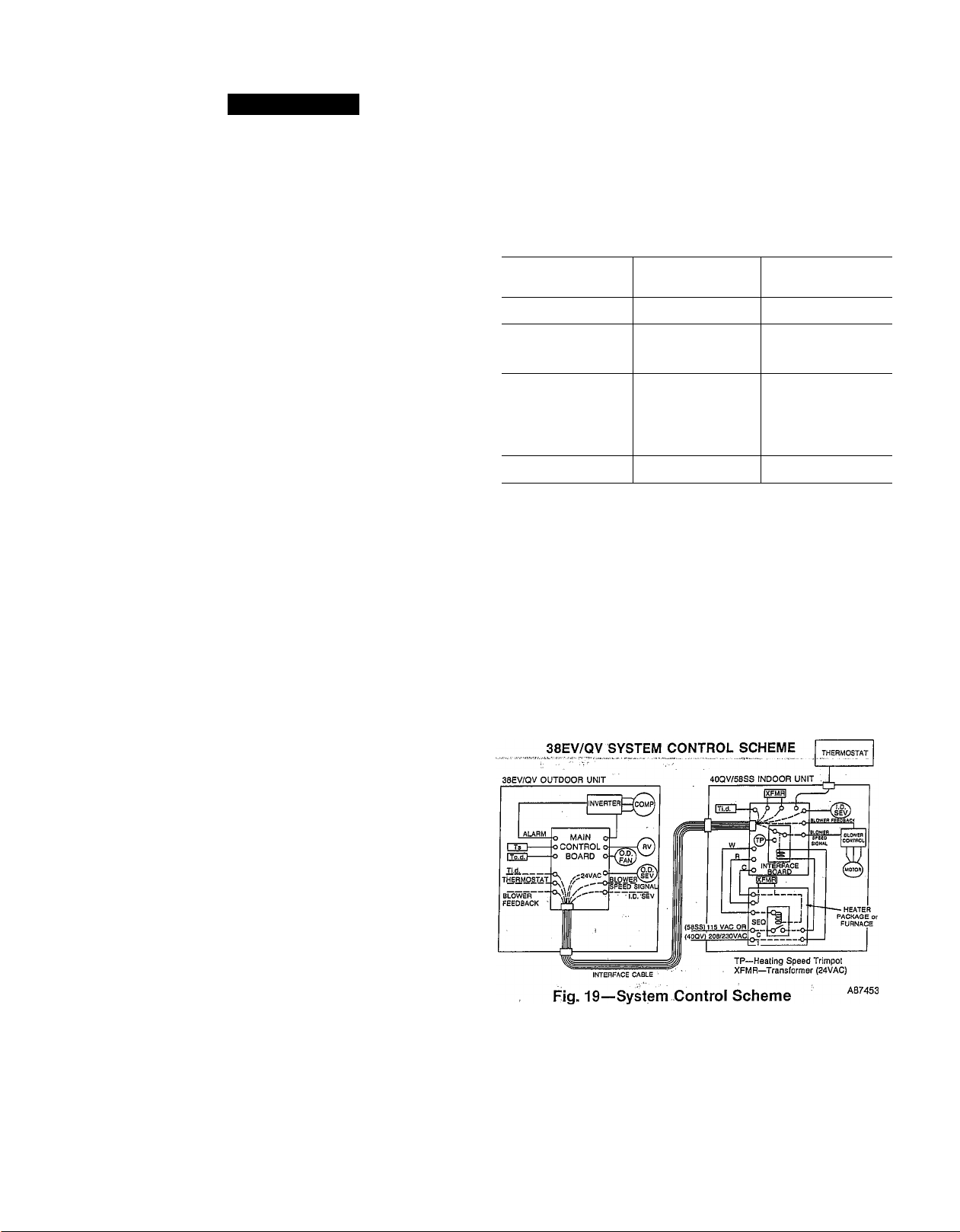

Operating Sequence;

In the absence of any diagnosed problems, the system will

operate in the Cool Mode for 7 minutes. It will then switch

to Heat with auxiliary heat on (gas or electric) and immedi

ately ramp the compressor down and off. Auxiliary heat

remains energized for about 3 minutes. See Fig. 18 for a pic

torial of Run Test sequence.

Influence of Diagnostics:

If a problem is diagnosed by the main control board, the

Red LED will flash an error code. Refer to Section 5, “Trou

bleshooting” for interpretation of the flashing code.

The system may, however, react in different ways, depend

ing upon the problem diagnosed. Certain errors wiU cause

A87452

Fig. 18—Run Test Sequence

Page 11

(J

A WARNING

Unit is capable of restarting on normal thermostat

demand soon after Run Test is completed. Personal

injury can result.

Normal System Startup Sequence

Apply power to indoor units via main disconnect switches.

If outdoor unit control box cover is removed, main control

board LED wiU light and extinguish after 30 seconds.

Thermostat will display HPOO (for 38QV units) or ACOO (for

38EV units).

Set up thermostat in heat, cool or automatic mode for room

temperature desired (Ref. Thermostat Operation, Trouble

shooting Section 4).

Thermostat setpoint must be 2-deg.F or more away from

room temperature for the system to initiate a startup.

(Room temperature can be displayed on thermostat by

pressing both heat setpoint adjustment buttons to right of

display simultaneously).

Startup Sequence

NOTE: Startup delays and sequence times can be shortened

for system checkout by initiating “Speed-Up” jumper,

described below.

a) Time Guard-

Normal Ambient Startup—Mter applying power and/

or adjusting thermostat setpoint, the system will

undergo a 5-minute delay before starting. This will also

occur any time the system cycles off normally, to pre

vent unnecessary on-off cycling.

Low Ambient, Initial Startup—When outdoor tempera

tures are near or below 20-deg.F, the system will

undergo a 26-minute delay bn initial power-up only.

This allows the crankcase heater to at least partially

warm up compressor before startup.

Siartop—Compressor wffl start and ramp up to low

speed, outdoor fan wffl come on. Indoor blower will

start in a similar manner to compressor, 30 seconds

later.

b) Low Speed LocA-Iti—After starting, the' unit will lock

in at low speed for a period of 8 minutes. This is done

for the following reasons:

1. System self-diagnostics wffl monitor system condi-

tionis during this period to verify proper system

operation.

2. Allows indoor blower time to circulate and slowly

mix possibly cold ductwork air with room air, thus

avoiding erratic speed fluctuations due to unstable

thermostat readings.

c) Transition to Normal Control—li the thermostat is sat

isfied during the Srminute period at low speed, the sys

tem wffl remain at low speed for 4 more minutes and

then shut down. If not, it wffl speed up depending upon

thermostat demand. The startup sequence is complete.

“Speed-Up” Function

The “Speed-Up" jumper is a yellow jumper, similar to the

“Run Test” jumper. It’s located on the outdoor unit main

control board next to the label “Speed-Up” (ref. Fig. 5). The

function is initiated by removing and reinstalling the

jumper during the sequence period you want to eliminate.

For instance, if you want to ehminate the time guard period

before startup, wait for the LED to extinguish after powerup. Then pull and reinstall the “Speed-Up” jumper. This

wffl shorten the respective period, (i.e., 5 minutes down to 2

minutes for the normal time guard, or 20 minutes down to 4

minutes for low ambient initial startup).

If the jumper is pulled and reinstalled during a sequence

period listed in Table 2, it wffl shorten that period as indi

cated. The speed-up function will then cancel automatically

when the next event listed in the table occurs. To shorten

subsequent sequence periods, the jumper must be initiated

again.

Table 2—Speed-Up Function

Initiate The

Jumper During

This Period

—Prestart

Time Guard

—Low Speed

Lock in At

Startup

— Between Defrost

Periods (Beiow

32-Deg.F

Ambient)

—During Defrost 4-10 Min.-

*Low Ambient Initial Startup

Period Wiil

Shorten From

Normal- to Speed-Up

5 Min.—2 min.

OR* 20 Min.—4 Min.

8 Min.—

40-50 Seconds

45 Min.—4-5 Min.

(1st Defrost)

30 Min.-4 Mrs.3-24 Min.

(Subsequent

Defrosts)

24 Sec-1 Min.

Speed-Up Function

Will Cancel

When

Compressor Starts

Compressor Begins

Ramping Above

Low Speed, Or

Shuts Down

Unit Initiates

A Defrost

Defrost Termination

Cooling Operation

Compressor—

During normal operation, the compressor speed will vary,

based on thermostat demand, from 2200 RPM at low speed

to 5000 RPM at high speed.

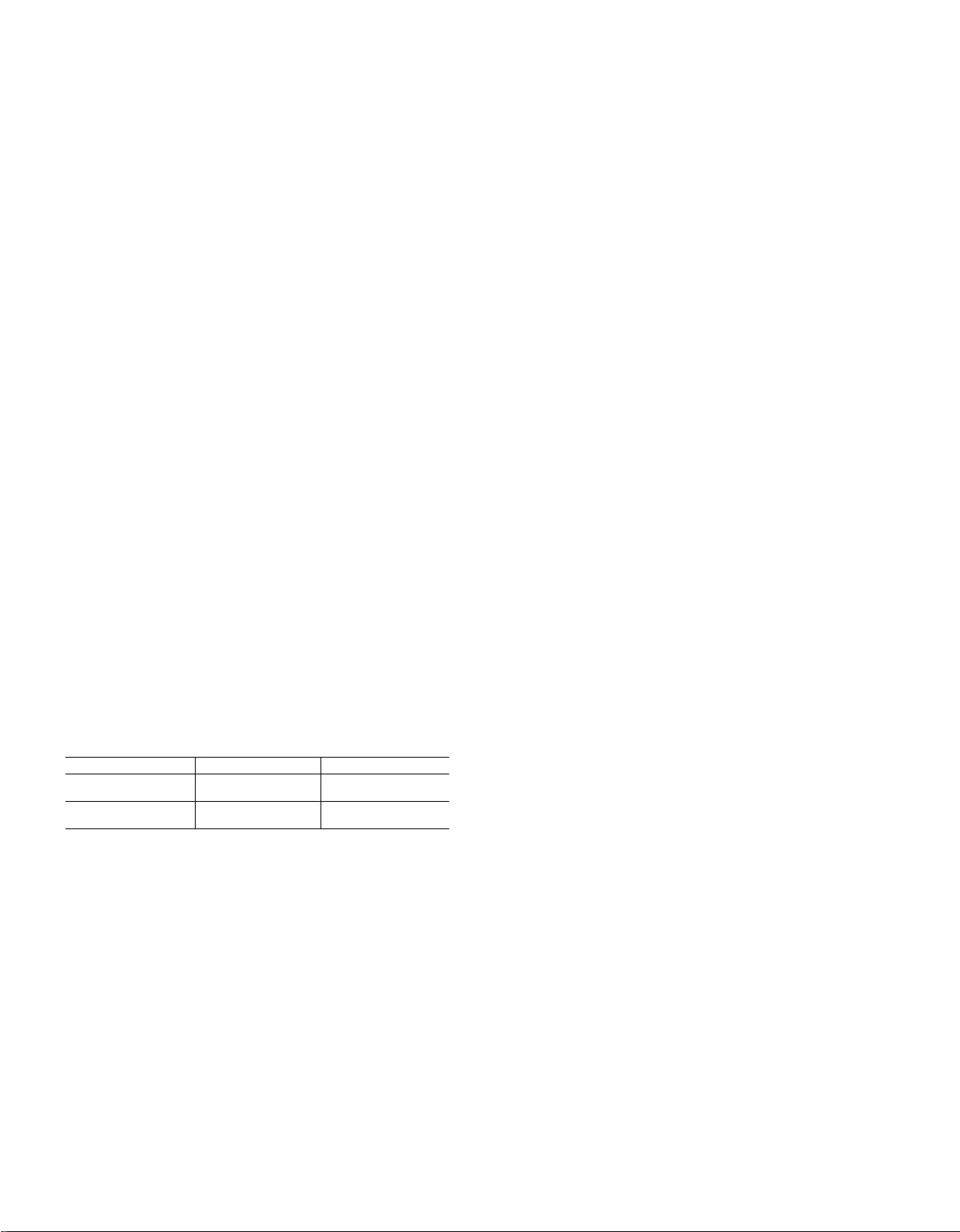

Indoor Blower-

Blower speed (or airflow) wffl “track” or follow compressor

speed; i.e., when the compressor is at low speed, so is the

blower. If the compressor ramps^oTiigh.speed, the blower

ramps to high speed simultaneously. This speed signal is

sent from the outdoor unit main control board, through the

indoor unit interface board to the blower controller. (See

Fig. 19).

Outdoor Fan—

The outdoor fan cycles on-off with the compressor.

Solenoid Expansion Valves (SEV)—

In the cooling mode only, the SEV at the indoor unit is oper

ated. SEV operation “tracks” or follows compressor speed

directly. At low compressor speed operation, the solenoid

remains off and aU refrigerant flow is directed through a

bypass orifice in the valve body (38EV systems). In 38QV

systems, the bypass orifice is located in the accurator piston

(Ref. Component Description, Section 3). At high compres-

Page 12

sor speed, the solenoid is energized on continuously, allow

ing the extra refrigerant flow required through a second oriflce in parallel to the bypass orifice. At intermediate com

pressor speeds, the SEV is cycled on-off at different rates,

depending upon compressor speed. This rate is based on a

5-secpnd on-off period, with the on-time increasing (with

compressor speed) from zero (at low speed) to the full five

seconds on (i.e., continuous on) at high speed. For instance,

at lower speeds, the SEV is on 1 second, off 4 seconds; at

medium speed, on 2.5 seconds, off 2.5 seconds, and so on.

Proper vsllve operation can be checked by listening closely

for the “clicking’’ at the indoor SEV during intermediate

speed operation. - --—

The system will cycle on-off at low speeds at moderate^ (75-

deg.F) outdoor temperatures. It will operate continuously at

increasingly higher speeds as outdoor temperatures

increase.

Heating Operation—38QV Systems Heat Pump

Heat pump operation is executed in the same manner as in

the coohng mode. Indoor blower speed and SEV control

“track” or follow compressor speed directly. However, in

the heat mode, only the outdoor unit SEV is operated. It is

cycled in the same pattern as cool mode control, except

cycling on-time is shortened at colder ambients, (i.e. At low

ambients, the SEV may also be cycling on-off rather than

remaining full on when the unit is at high speed).

The system will cycle on-off at low speeds during normal

operation at moderate (50-deg.F) outdoor temperatures. It

will operate continuously at increasingly higher speeds as

outdoor temperatures drop.

When outdoor temperatures drop to a point where supple

mentary heat is required, dr the optimizer function is ena

bled, electric or gas heat is initiated. Electric heat and

furnace operation are described in the following sections.

Table 3—38QV Piston Sizes

UNIT

38QV024

, - -•

38QV036 ,

Electric Heat Control—(38EV and 38QV ¡Systems)

Electric heat is initiated and controlled by energizing “W”

in the same manner as in standard systems. However, since

the variable speed blower heeds a speed input signal to oper

ate, blower control is considerably different.

Blower Control—In.=a standard 'heat package, energising

‘‘W)’’ energizes the heater sequencer(s). When this is done,

the ian relay is b3^assed-by 230V power to drive the blower

directly. Therefore, if the fan relay is faulty, the blower still

operates for safe electric heat operation.

40QV Fan Coil Units operate in a similar manner (Ref. Wir

ing Diagrams). However, instead of operating the blower

directly, this ■'230VAC power is apphed to the interface

board at terminals C and 1 (see Figs. 14 and 19). When these

terhiinals are energized by the electric heat sequencer, the

interface board relay breaks the speed signal connection

from the outdoor unit and allows the interface board to

drive the board at a speed set by the adjustable pot on the

board. ; '

LOCATION

Outdoor

. . '„ Outdoor ,,

Indoor

. Indoor

...............

. 52

-----

■ PISTON#

42

49

63

When the electric heat (“W”) is cycled off, normal sequencer

operation retains blower control from the interface board

until the heaters cool down. When terminals C and 1 are de

energized by heater package, blower control reverts back to

the outdoor main control board.

Supplemental (2nd Stage) Heat—(38QV Heat Pump/40QV

Fan Coil Systems Only)

Supplemental heat is required when the outdoor tempera

ture drops too low for the heat pump to handle the load

alone. At this point, the system begins cycling electric heat,

in addition to continuing full speed heat pump operation.

This is done by energizing heater package terminal “W.”

The heaters and blowers are controlled as described above.

A change in blower speed when the interface board takes

over control may not be noticeable, since the outdoor unit is

already operating it at high speed.

It may be noticeable if the blower heating speed trimpot is

adjusted below its maximum setting.

Heating Operation—(38EV Cooling Systems) and

Emergency Heat—(38QV Heat Pump Systems)

Electric or gas heat is operated directly on thermostat

demand on 38EV systems or whenever the 38QV outdoor

unit operation is locked out due to a diagnostic problem.

The blower is controlled by the interface board as described

above. However, since the blower is not being operated by

the outdoor unit during electric heat off cycles, the blower

will cycle fuU-on-off similar to standard systems.

NOTE: Malfunction of certain electronic control compo

nents can cause lack of Automatic Emergency Heat initia

tion. See Service & Maintenance section for corrective

servicing procedures.

The 58SSB furnace will operate as described in the litera

ture provided with it. The only difference is control of the

variable speed blower. The standard 58SSB furnace

bypasses its fan relay to lock-in blower operation when the

burner is on, just like an electric heat package.

The variable speed blower package switches blower control

to its interface board when “W” is energized, in the same

manner as described above for “Electric Heat Control.”

(The furnace interface board design is identical to that for

the 40QV fan coil, except it is a il5VAC yersioh)/

The blower will remain off for 2r3 minutes while the burner

ignites and warms the heat exchanger. The blower wUl then

start, and ramp to low speed for a short period before going

to full speed. 'When “W” is de-energized, the blower will

stay on for a short period to use the remaining heat from

theexchanger.

Supplemental (2nd Stage) and Optimizer Control—(38QV

Heat Pump/58SSB Furnace Systems)

Unlike fan coil operation, the furnace wiU not operate simul

taneously with the heat pump. Therefore, whenever the out

door temperature drops to where the heat pump cem no

longer match the load, or the optimizer setpoint is reached,

the heat pump wfll shut down when. furnace startup is

requested (“W” is energized). At this point, the heat pump

wfll also shut down the indoor blower (except if ,the thermo

stat is in the fan-on position). The normal furnace delay of

2-3 minutes wfll then pass before the blower is cycled back

on, to allow the heat exchanger to heat up. Once the thermo

stat is satisfied by the furnace, it will cycle off. Operation

wfll alternate between furnace and heat pump, until either

the heat pump can handle the entire load, or the optimizer

setpoint is reached. If the optimizer setpoint is reached, the

heat pump wfll be locked out (a minimum of two hours) and

the furnace will cycle directly on thermostat demand.

I

Page 13

Adaptive Defrost—

38QV Heat Pump Systems utilize an adaptive defrost con

trol which clears the coil of frost only when necessary.

•r ■■

Based on coil conditions and outdoor temperature, the time

between defrosts is adjusted between 30 minutes and four

hours, as described below.

Between Defrost Period Calculation-

Defrost monitoring is begun when the O.D. coil thermistor

temperature drops below 32 degrees F. The first defrost will

occur 45 minutes later.

When the unit is ready to defrost, the pre-defrost O.D. coil

thermistor temperature (frosted coU) is memorized, and thè

unit then switches to defrost. A short time after defrost is

completed, a post-defrost thermistor temperature (clear coU)

is memorized.

The after-defrost (clear cod) temperature is used to estimate

outdoor temperature and the optimum pre-to-post defrost

coil temperature change (i.e. frosted coil vs. clear coU

temperature).

The time period to the next defrost is then determined by:

a) If defrost time was less than 5 minutes, add 30 minutes

to previous period.

b) If defrost time was maximum (10 minutes), and O.D.

con temperature at termination was:

—more than 45 degrees F, divide previous period in

half.

—less than 45 degrees F, next period will be 30 min

utes.

c) If defrost time was greater than five and less than 10

minutes, the new time is calculated by:

. . , optimum temperature change *

previous peno x actual post-defr. temp..minus pre-defrost temp.

*The new period calculated by this method cannot be less

than half, or more than double the previous period.

Other Limitations:

Maximum period between defrosts is 4 hours.

Minimum period between defrosts is 30 minutes, except:

The initial defirost after coming out of optimizer mode will

occur 15 minutes after startup.

Defrost Sequence—

When a defrost is initiated, compressor speed is dropped to

medium speed. This is done to mininiize shock to the com

pressor. The reversing valve and heat (terminal “W”) relays

are energized, the outdoor fan relay de-energized, and com

pressor then ramped to full speed for a rapid defrost.

Defrost is terminated on any of the following occurrences:

a) O.D. coil thermistor rises to 80 degrees F (when out

door temperature is above 10 degrees F).

b) O.D. coil thermistor rises to 60 degrees F (when out

door temperature is below 10 degrees F).

c) 10-Miuute maximum defrost period.

The system then ramps down to medium speed, returns to

heat mode, and returns to the pre-defrost speed.

Heat/Cool/Auto Control-

This thermostat function controls as in standard systems.

Heat or cool operation may be requested separately. The

“Auto” position allows the' system to switch between these

two modes automatically as required to satisfy thermostat

setpoint demand.

Fan-On/Auto-

With the fan-auto mode selected, the indoor blower will

•HP’OBQV)

\ / \ / \ /

•AC’(38EV).

■HP

00

z' \

NORMAL POWER-UP IMPROPER

Fig. 20-VVT-ll MST Thermostat

--------------------------------------

It

—1

65 HP

56 ;; 56

CONFIGURATION

/

---------------

1 lO'O oii—

^OWER HEAT

SETPOINT

COOL

N

ON I OFF I

68 69 70 71 72 76 77 78 79

4 ’HP' or 'AC:.

\

•66 HP

-HEAT

' \

SETPOINT

ROOM TEMPERATURE

05

SYSTEM

DIAGNOSTIC

ERROR CODE

A87454

cycle on-ofil with the outdoor unit and/or the electric/gas

indoor unit.

The fan-on mode will keep the indoor blower operating at all

times. The blower will operate at low speed during systemoff intervals.

STEP 4 VVT-II Thermostat Startup/Troubleshooting

The MST-04 or MST-16 thermostat consists of a printed cir

cuit board, a connector board, and a wall mounted case.

A thermostat software revision of 6.7 or higher is required.

AU wiring connections to the thermostat are made to the

connector board. .

Mount the thermostat as described in 38EV or 38QV out

door unit installation instructions, or follow the Installation

Instructions included with each control. Thermostat must

be wired as shown in Figs.. 36 and 37.

Fig. 20 shows front view of the VVT-II MST thermostat.

Start-Up Procedure:

Close indoor main disconnect.

Normal Display—The thermostat will. display HPOO (for

38QV systems), ACOO (for 38EV systems), or 4 zeros, then

switch to the normal heating/cooiing setpoint as shown.

Blinking Display—If the thermostat display blinks on .and

off or is erratic, it is an indication that a wiring connection

is not correct, or that the thermostat is not receiving ade

quate power. Check the wiring connections and the supply

voltage (22VAC rninimum) at terminals SEC-1 and SEC-2

on the interface board. Make certain the thermostat ribbon

cable has been inserted into the connector board correctly.

Display Four Zeros—If the display shows four zeros upon

power-up, and then displays “HF-11,” it indicates that the

thermostat is currently configured for a multiple-zone sys

tem. It must be reset for single-zone control.

Setting Thermostat For Single-Zone Control—

To correct the configuration, set the rotary switch to posi

tion #1 (ref. Fig. 20). A number and “ON” or “OFF” will

V /

N

Page 14

appear on the display. Press either of the right (“Heat”)

setpoint buttons to change the display to “OFF.” This is

the indication that the thermostat is now correctly set for

single-zone control. Now adjust the displayed number to

“2” by pressing the cool setpoint buttons; the lower one to

decrease the number, upper one to increase. Return the

rotary switch to position #0 and press any setpoint button

to display the normal setpoints.

Adjust Heating/Cooling Setpoints—The setpoints for both

heating and coohng can be easily adjusted by pressing the

setpoint buttons as shown.

Installer Adjustable_Fe Clock Option—Each

thermostat is equipped with a buüt-in instruction manual

which explains the various installer adjustable features and

how to set the time clock.

FoUow each page of the manual to configure the thermostat

based on the application. Always set the “Local Set-back

Control” to ON.

For single-zone control applications, the following features

wül have no effect on the thermostat operation and can be

disregarded at the time of installation:

#6—Duct Temperature Sensor Calibration

#7—Max Damper Position/Min Ventilation Position

#C—System Demand

#D—Communication Test #E—Supplemental Heat

Error Codes—3ie displayed as HF, SF, HP or AC followed

by a two digit number (ref. Fig. 20.) An HF or SF code

indicates a thermostat malfunction (see Thermostat Trou

bleshooting, below). A HP or AC code indicates a system

diagnostic malfunction (see System Troubleshooting,

Section 5).

Set-Back Feature—li the homeowner desires to use the set

back feature, remove the “set-back override jumper” from

the connector board at the back of the thermostat.

Operation—When an “OFF” time occurs, the thermostat

displays the word “SETBACK” and the highest cooRng and

lowest heating setpoints. When an “ON” time occurs the

thermostat returns to the last setpoints that were displayed

before set-back.

Overriding Set-Back—During set-back the heating'or cool

ing set-back Setpoint can be manually 'overridden by adjust

ing the setpoint through the use of the setpoint buttons.

The setpoint selected becomes the new comfort setpoint

that the thermostat uses when the next “OÑ” time occurs.

When the set-back setpdiiit is overridden the comfort

setpoint chosen remains displayed until the next “OFF”

time occurs; unless the' user manually adjusts the setpoint

back to the set-back setpoint; ;

Programming Set-Back—Follow the built-in thermostat

instruction mandai (behind front cover) to program the ON/

OFF times for set-back operation (and for programming the

electronic time clock). ■ , - .

Set-Back Programming Tips—If it is desirable for a particu

lar period to be in set back coiitinuóuály do not enter any

ON/OFF times for that period;

If it is desirable, for a particular period to be in the comfort

rnode continuoúsíy enter an ON time that is the same as an

OFF time.

Heating/Cooling Cycles—The thermostat should be set to

energize a heating cycle and a cooling cycle. Check to make

certain the 38EV or 38QV system operates properly.

“HEAT,” “COOL,” or “FAN” may be shown in the lower

left corner of the thermostat display depending on the sta

tus of the system. The 38EV or 38QV system controls to

1.5-deg.F from setpoint in both heat and cool modes. It will

start-up at 1.5 deg.F from setpoint (minimum run time is 12

minutes), and cycle off based on rate of room temperature

change (ref. Fig. 20).

VVI-ll Thermostat Troubleshooting

Hardware Failures—HF-11 or HF-12. The thermostat is not

properly configured for single-zone control application.

Make certain that “OFF” is displayed when the rotary

switcMs set to position #1.

HF-14, HF-15, or HF-16. There is a failure in the electronic

circuitry on the thermostat. Replace the thermostat circuit

board.

HF-13. The thermostat room temperature sensor is reading

out of its normal range ... 30 to 180 F. (Ref. thermostat

instructions).

Check the room temperature sensor to make sure that it is

physically intact.

Attempt to calibrate the room temperature sensor by fol

lowing the built-in instruction manual. If cahbration is not

possible, replace the thermostat circuit board.

Storage Failures—The thermostat continuously checks its

memory to make certain that stored information is valid. If

information is ever determined to be invalid an error code of

“SF” followed by a number is displayed.

When an “SF” error is displayed, the thermostat will also

use a safe, substitute value appropriate to the particular

code. (See instructions included with thermostat.)

To Clear An “SF” Error—FoUow the buUt-in thermostat

manual to find the correct rotary switch position and reset

the desired setting. Then return the rotary switch back to

position #0.

Time Clock—The time clock should be accurate to within 10

minutes per year. During a power faUure, the time wiU be

maintained for a minimum of 8 hours, after which it may be

necessary to reset the clock, (Ref. thermostat instructions).

If the clock is not keeping accurate time, m^e certain the

power has not been off for over 8 hours. If it has not, then

replace the thermostat.

Set-Back—If the thermostat never goes into set-back make

certain: '

The set-back override jumper has been removed from the

connector board. ,

The thermostat hasn’t been programmed to be continuously

in the comfort mode.

The thermostat is set for the proper time of day.

If the thermostat never comes out of set-back make certain:

A set-back On/Off program has been entered.

The thermostat is set for the proper time of day.

STEPS System Troubleshooting

TABLE OF CONTENTS

Self-Diagnostics—Description

Diagnostic Error Codes Page

Error Codes 3, 4—Outdoor Coil, Suction

Thermistor Failure

Error Code 5—Indoor Coil Thermistor FaUure

Error Code 8—Locked Compressor Rotor

Error Code 9—Overcurrent Trip

Error Code 10—Contactor Control FaUure.................

.......................................................

..........

...................

............................ .22-23

.16-17

18-19

20-21

24-25

Page 15

Error Code 11—Reversing Valve Failure

Error Code 14—Indoor Coil Freeze

Error Code 15—Low Refrigerant Charge

...................

................................

..................

29-31

26-27

28

System Malfunctions with No Error Code

No LED on power-up.....................................................32-33

No Indoor Blower Operation........................................34-35

Electric/Gas Heat Failure..............................................36-37

Miscellaneous Malfunctions

..............................................

39

BEFORE TROUBLESHOOTING THE SYSTEM

This troubleshooting guide covers all components of the

38EV/QV variable speed system, including outdoor and

indoor units.

See previous section for thermostat troubleshooting. (Ther

mostat Error Codes HF and SF).

A WARNING

High voltage (300VDC) circuit remains energized after

main disconnect is opened. Normal capacitive discharge

time is ten (10) minutes, but this period may be

extended indefinitely by component failure. Before

servicing, always check with D.C. voltmeter between

contactor terminal #23 (violet wire) and ground. Always

reinstall safety shield in top of control box after servic

ing. Electrical shock can cause personal injury or death.

Before replacing components to correct a system malfunc

tion, always inspect circuit for damaged or oorroded wiring.

Connectors should be inspected for improper mating. They

should then be unplugged and examined for corrosion, dam

age or incomplete terrhinal insertion. This procedure is espe

cially required when a system malfunction is intermittent

(does not occur consistently).

Clean and/or repair wiring as required. A special accessory

terminal kit (Carrier Service Part No. 38QV660001) includ

ing terminal extraction tools is available through your local,

distributor.

Use high quality multimeter for troubleshooting electronic

devices in this system.

Self-Diagnostic Error Codes—

Error codes are indicated at an LED located on the outdoor

unit main control board (Ref. Fig. 5), and on the indoor ther

mostat display (Ref. Fig. 20).

Control board LED error codes are shown as a series of %

second on, % second off flashes, followed by a 10-second

pause before repeating.

Thermostat display error codes are shown as a two-digit

number, preceded by “HP” on 38QV heat pump systems or

“AC” on 38EV coohng-only systems.

As an example, when an error Code #5 is diagnosed,

“HP05” or “AC05” will be displayed at the thermostat

when 5 flashes are indicated at the control board LED.

Automatic System Restarts on Diagnostic Shutdown—

AU diagnostic shutdowns described in this text wfll cause as

many as five restarts before final shutdown and compressor

lockout. The system wfll remain off for at least five minutes

(time guard function) before attempting each restart.

Note that the control board LED wfll display the error code

after each shutdown. The thermostat display will indicate

an error code only after final compressor lockout.

A CAUTION

Whenever troubleshooting system with power on and

control board LED flashing error code, check ther

mostat display. If error code is not indicated at thermo

stat, automatic restart is pending. Servicing of equip

ment at time of automatic restart may cause personal

injury.

How to “Clear"Error Codes—

Indoor unit power (i.e., controLpower) must be broken and

reset in order to cancel system lockout on a diagnostic.

. The-Self-Diagnostics, feature is designed .to monitor inputs

(thermistors and inverter alarm) and take over control of the

system if these inputs go out of normal range.

Table 4 lists each of the Self-Diagnostic error codes, the con

ditions, that cause the code, and how the system reacts to

each condition.

Troubleshooting System withRower On—

Always bredk power to both indoor and outdoor units when

servicing, except as indicated in the following procedures.

Table 4—Self Diagnostic Error Codes

ERROR

CODE DESCRIP TION

3

4

5

8 Locked C ompressor Rotor Inverter alarm—on within 2 minutes after contactor

9

10 Contactor Control. Failure No change in thermistor readings (See Note 2)-

11

14

15

NOTES:

* System attempts 5 restarts (each followed by 5 minute timeguard) before lockout and error code display on thermostat.

1. Inverter alarm comes on at 100% of rated inverter output-current. Control board ramps compressor speed down until alarm goes off at 85% of rated

current. If control board drops compressor speed to minimum and alarm remains on, it knows inverter has tripped, and shuts system down. (Inverter

trip requires reset of inverter power through contactor to shut off alarm).

2. Control board compares thermistor readings after 5 minutes of run time to readings taken at startup (contactor energization).

O.D. Coil Thermistor Failure

Suction Thermistor Failure

i.D, Coil Thermistor Failure

Overcurrent Trip -

Reversing Value Failure

indoor Coil Freeze

Low Refrigerant Charge

Thermistor reads greaterthan 160'’F or less than -dO^F '

Same as above

Same as above

energization

Inverter alarm—on after 2 m inutes of run time (See Note 1) Compressor slows down to cancel alarm. If alarm stays on system shuts down.

O.D., IrD. Coii Thermistor readings change in wrong

directions (See Note 2).

Suction Thermistor reads less than 32°F in Cool Mode. Blower speeds up to raise suction temperature above 35°F. If so, blower continues

Suction thermistor reads much higher than I.D.

coil (cool), or O.D. coil (heat) thermistor.

CAUSE ^ SYSTEM REACTION

: Immediate Shutdown or no startup*

Same as above*' - - ■

Same as above*

Sameasabove* -

Immediate Shutdown or no startup*

Com pressor speeds up to shift valve. If thermistor readings don't switch direction,

system shuts down.* - - ■

operation at higher speed. If not, .system shuts down.*'

No effect on system operation. Error code on control board LED only.

Page 16

'I

Fig. 21 — Error Codes 3 and 4

16

Page 17

ERROR CODE #3 - OUTDOOR THERMISTOR FAILURE

ERROR CODE #4 - SUCTION THERMISTOR FAILURE

REASON: CONTROL BOARD READS THERMISTOR TEMPERATURE ABOVE 160T OR BELOW -40T.

POSSIBLE CAUSES:

1) Thermistor failed or out of calibration (see Note 1).

2) Loose or corroded connection.

3) Faulty control board.

Reference Figure 21

Notes:

1) If thermistor is out of caiibra:tion, it may read accurately when system Is off, but may drift from actual

temperatures during operation.

2) COOL MODE: Monitor temperature at unit service valves.

HEAT MODE: Monitor temperature inside unit at thermistor location.

3) Adjust thermostat 4°F or more above or beiow room temperature, depending on mode, to force system

to high speed.

4) if unit has been off a short time, allow refrig, temperatures to stabilize.

A87475

Page 18

Page 19

ERROR CODE #5 - INDOOR THERMISTOR FAILURE

REASON: CONTROL BOARD READS TEMPERATURE ABOVE ISCTF OR BELOW -SCTF.

POSSIBLE CAUSES: 1) Thermistor failed or out of calibration (see Note 1).

2) Loose or corroded connection.

3) Faulty control board, Interface board or cable.

Reference Figure 22

Notes:

1) If thermistor Is out of calibration, it may read accurateiy with system off, but may drift from actual

temperatures during operation.

2) For furnace appiications - Remove furnace access panei and tape kili switch so that panel can later be

removed for blower inspection without breaking power.

Reinstall access panel.

3) Adjust thermostat 4°F or more above or below room temperature, depending on mode, to force system

to fuli speed.

A87477

Page 20

fi

J

20

Page 21

ERROR CODE #8 - LOCKED COMPRESSOR ROTOR Reference Figure 23

REASON; OVERCURRENT OR UNDERCURRENT SITUATION OCCURS DURING FIRST 2 MINUTES OF COMPRESSOR

OPERATION.

POSSIBLE CAUSES; 1. Loose high voltage lead

2. -036 Models; scroll compressor running backwards

3. Failed compressor

4. Failed inverter

I 1

V.

Notes;

1) Inverter alarm may be monitored using DC voltmeter at@, in Figure. Alarm-on is 1VDC. Alarm may energize before

inverter trips.

Inverter trip LED (yellow) may be viewed by removing safety sheild from upper control box. View downward into box,

beyond contactor and under main control board at inverter board. See Figure 7 for LED location.

Power (red) LED should light whenever contactor closes.

Power and Trip LED’s will go off when contactor de-energizes.

2) When contactor energizes, inverter output voltage will increase gradually for about 30 seconds before leveling off.

Inverter may trip on low current at about 10 seconds. as7478

Page 22

YEL

HIGH VOLTAGE

CONNECTOR

(LOWER CJONTROL BOX:

Fig, 24—Error Code 9

Q

A87458

Page 23

n

ERROR CODE #9 - OVERCURRENT TRIP

REASON; OVERCURRENT SITUATION AFTER FIRST 2 MINUTES OF RUN TIME.

POSSIBLE CAUSES: 1) Defective compressor or inverter.

2) Failed control board.

3) loose or corroded high voltage or inverter alarm connection.

4) Excessive loading due to:

Cool Mode - improper fan operation, dirty outdoor coil, overcharge.

Heat Mode - improper blower operation, dirty air fiiter, blocked duct, overcharge.

Reference Figure 24

Notes:

Inverter alarm may be monitored using DC voltmeter at(A)(see Fig). Aiarm-on is 1 VDC. Alarm may ener

1)

gize before inverter trips.

Inverter trip LED (yellow) may be monitored by removing safety sheild from upper control box. View

downward into box, beyond contactor and under main control board at inverter board. See Figure 7 for

LED iocation.

Power (red) LED should light whenever contactor closes.

Power, Trip LED’s will go off when contactor de-energizes.

Adjust thermostat 4°F or more above or beiow room temperature, depending on mode, to force system to

2)

fuil speed. kmm

Page 24

• - NO CONNECTION

« - CONNECTION ON 38QV ONLY

(WIRE NUT CONNECTIONS - 036 ONLY -

INSIDE COMPRESSOR CONTROL BOX)

SUCTION LINE)

3BQV - (LOCATED ON

SERVICE VALVE

LIQUID LINE)

Fig. 25—Error Code 10

LIQUID LINE)

38QV - (LOCATED ON

COMPRESSOR

DISCHAROE LINE)

A87473

Page 25

ERROR CODE #10 - CONTACTOR CONTROL FAILURE

REASON: THERMISTOR TEMPERATURES DID NOT CHANGE AFTER 5 MINUTES OF RUN TIME,

(i.e. REFRIGERANT NOT CIRCULATING IN SYSTEM) see Note 4.

POSSIBLE CAUSES: 1) Failed contactor, or control board output.

2) High, low pressure, or ESS (-036 only) switch.

3) Very low charge.

4) Stuck reversing valve.

Reference Figure 25

U

1) inverter POWER (red) LED can be viewed from above the control box. CAREFULLY remove white safety shield.

Look downward into box beyond contactor and behind main controi board at inverter board. See Figure 7

for LED location. Red LED shouid be on whenever contactor is energized, and outdoor unit power is on.

2) ESS - to - LPS spiice is iocated in compressor terminai box.

3) -036 Modeis Oniy

If compressor has been serviced or repiaced, check for proper 3-phase wiring connections.

If leads are miswired, compressor will not pump in reverse direction.

4) Error code may not appear untii up to 5 minutes after startup (outdoor fan energizes).

A87474

Page 26

1

REV n/10/87

® - NO -CONNECTION ..

e - CONNECTION ON 38QV ONLY

UNIT CONNECTOR

Fig. 26—Error Code 11

OR

REVERSING VALVE

SOLENOID CRVS)

(LOCATED ON 4-WAY

VALVE) C38QV UNITS)

A87459

Page 27

ERROR CODE #11 - REVERSING VALVE FAILURE (38QV HEAT PUMPS ONLY)

REASON: INDOOR THERMISTOR DOES NOT DROP IN TEMPERATURE AFTER SYSTEM STARTUP (COOL

MODE ONLY) see Note 1.

POSSIBLE CAUSES: 1) Reversing valve stuck.

2) Reversing valve coil not energizing.

3) Indoor thermistor not installed property.

:f I

Notes:

1) Error code may not appear until up to 5 minutes after startup.

A87466

Page 28

ERROR CODE # 14 - INDOOR COIL FREEZE

REASON: SUCTION THERMISTOR READS BELOW 32° F.

POSSIBLE CAUSES; 1) Blocked return or supply duct.

2) Dirty air filter.

3) Suction thermistor out of calibration (see Note 1).

Notes: kzim

1) If thermistor is out of calibration it may read accurately with system off, but may drift from actual during operation.

Page 29

ERROR CODE #15 - LOW REFRIGERANT CHARGE (see Note 1).

REASON: LARGE REFRIGERANT TEMPERATURE RISE THROUGH INDOOR COIL (COOL MODE),OR OUTDOOR COIL

(HEAT MODE).

POSSIBLE CAUSES: 1) Low refrigerant charge.

2) Plugged or failed solenoid expansion valve (SEV).

Notes:

1) Error code will not affect system operation, and will only be displayed at control board LED.

2) Superheat Tables provided in outdoor unit installation instructions.

3) In outdoor ambients below 75-80°F in Cool, above 45°F in Heat, system will not go to full speed, and SEV should be

cycling on-off.

4) Refer to Figures 15 and 16 to see location of valve orifices. Valve main orifice may be cleaned by blowing air, etc. into

outlet of valve. If this is unsuccessful, replace valve.

------------

A87471

Page 30

PUSH A SHARP OBJECT

INTO WIRE TERMINAL

HERE TO UNLOCK AND

■ f

REV 11/10/87

CLOCATED ON SERVICE

VALVE LIQUID LINE)

C38QV UNITS ONLY)

»

A87460

Fig. 27—Outdoor Unit Soienoid Expansion Vaive (SEV)

Page 31

(if

(ERROR CODE #15 CONTINUED)

38QV UNITS ONLY

Reference Figure 27

Note:

5) Superheat should be less than 5°F, but may be up to 10°F in above 40°F outdoor temperatures.

A87470

Page 32

22-30 VAC CIRCUIT

(TERMINALS #1,2)

1 \2 3 4 5 S 7 8

rrniITT

CONTROL BOARD

PLUG

(A)

OUTDOOR UNIT

MAIN

CONTROL BOARD

8 7 8 5 4 3 2 1

1 111 ITr T

)

22-30 VAC

(TERMINALS #1,2)

©

ut

___________

NTERFACE BOARD

RECEPTACLE

1

)

■ 208/230 VAC

....

INPUT

TRANSFORMER

Q)

A87461

Fig. 28—Control Board LED Does Not Light

Page 33

Notes:

1) For 208VAC applications •* Check (2) transformers at indoor unit to make sure red (230VAC) transformer lead connections

are replaced by blue (208VAC) transformer leads.

2) For furnace applications - Remove furnace access panel and temporarily tape kill switch so control power can be sup

plied to outdoor unit. A87467

Page 34

SPEED ON-OFF

O DODO O'O 0,

p 2 3 4 5 6 7 a/

\o O O O O o o_7

V 9 10 11 12 13 14 Iff

CABLE CONNECTOR

ON-OFF SPEED

1-14 VDC .1-14 VDC

TTiiYiii-

■

/ )L Jl /

INTERFACE BOARD

INTERFACE

BOARD

INTERFACE BOARD

TEST POINTS

SPEED

1-14 VDC

ON-OFF

-.1-14 VDC

INTERFACE BOARD

CONNECTOR

iCj

BLOWER

SPEED ON-OFF

r

CONTROL BOARD

CONTROLLER

OUTDOOR UNIT

MAIN

CONTROL BOARD

PINS

MOTOR

RESISTANCE

©

COHMS)

1-2

1-3 OPEN

1-4 OPEN

2-3

2-4

CONTROL BOARD

J

TEST POINTS

3-4

5-6

OPEN

9-14

9-14

9-14

0

j

H? (d

-,5 -2

5 3

MOTOR

CONNECTOR

1 1

Fig. 29—Indoor Blower Failure

A87462

Page 35

INDOOR BLOWER FAILURE

f V Reference Figure 29

Notes;

On some models, removal of blower housing is required to determine if wheel is rubbing.

1)

Refer to indoor unit installation instructions for service and repiacement procedures:

2)

For fan coiis without eiectric heat, piace (2) jumpers at Interface board from L1 to C, and L2 to 1 (or 2).

3)

If Neither Speed or On-Off signals are present, wait longer and recheck, as it could take 2-3 minutes for blower to start in

4)

some cases, ■

if biower starts, break power, remove jumper and place between R and W2(or W). Reset power and check to see that

5)

electric or gas heat operate. If not, refer to “Electric/Gas Heat Failure.”

Voltage at C and 1 (or2) may also be read by removing interface box cover and reading at solder joint connections on

6)

board. A87469

Page 36

CONTROL BOARD

S.TS15 R.DUELL 11/10/07

Fig. 30—Electric/Gas Heat Failure

A87463

Page 37

ELECTRIC / GAS HEAT FAILURE

Reference Figure 30

Notes:

1) For furnace applications - Tape the kill switch under access cover so unit can be started and inspected during opera

tion.

2) For furnace applications - Blower will go to high speed 2-3 minutes after burner ignites.

Page 38

/-• V:

u

Fig. 31—Outdoor Fan Circuit

Page 39

©

MISCELLANEOUS MALFUNCTIONS

1) LED stays on after power up.

Reason; Malfunction of communications between thermostat and outdoor unit main control board.

Check For:

A. Improper wiring of thermostat.

B. Loose/corroded connection at:

• thermostat

• indoor unit interface board

• Interface cable at indoor or outdoor unit

C. Defective controi board or thermostat (see Thermostat Section).

2) Compressor does not operate.

• See Error Code #10.

3) Outdoor fan does not operate.

• Fan motor is standard single phase component. Check for failed motor, capacitor, or control board using

Figure 31.

4) Compressor and outdoor fan do not operate.

• Initiate “Run Test” jumper. If either component operates, follow checkout procedure for the failed component

in this section. If neither operates replace control board. If both operate, and control'board LED goes off, unit

is not receiving capacity demand from thermostat. Make sure proper Heat or Cool switch is in “Auto” at

thermostat, and setpoint is at least 2°F away from setpoint. Pull “Speed-Up” jumper to bypass 5 minute

timeguard. If unit does not start within 5 minutes, Follow same procedure for #1 above, “LED stays on after

power up.”

5) Compressor cycles on-off, outdoor fan stays on.

• Compressor is cycling on safety device. See Error code #10 and Figure #25 to investigate excessively high

or low pressures. Check for proper charge, failed fan, blower or failed/plugged solenoid expansion valve.

6) Thermostat display malfunction.

• See thermostat troubleshooting section and instructions included with thermostat.

7) Rev/efsirig válvé does hot operate.

• See Error Code #11.

8) Indoor coil freezing.

• See Error Code # 14.

9) System running abnormally low suction pressures.

• See Error Code #15.

'4. ^

A87465

Page 40

STEP 6—Service And Maintenance

TABLE OF CONTENTS

38EV, 38QV Outdoor Unit Service and Maintenance Page

—Replacement of:

Service Valves......................................................................40

Refrigeration Cod

Control Box..........................................................................40

Outdoor Pan........................................................................41

Compressor

Reversing Valve

Main Control Board...........................................................41

Thermistors............ ...........................................................41

Contactor.............................................................................42

Emergency Stop Switch (ESS)...........................................42

Solenoid Expansion Valve (SEV)

Outdoor Unit

Indoor Unit

Interface Cable....................................................................42

Low, High Pressure Switches

Crankcase Heater, Switch and Fan Motor

Electrical Terminals, Connectors......................................43

—Elimination of Television, Radio Interference

—Maintenance:

Fan Motor Lubrication 43

Compressor Oil. .. ...........

Coil and Heat Sink Cleaning............................................. 43

40 QV Fan Cod, 58SSB blower Accessory Service

and Maintenance.....................................................................44

38EV, 38QV Outdoor Unit Service and Maintenance

NOTE: Malfunction of certain electronic control compo

nents can cause lack of Automatic Emergency Heat initia

tion. See below for corrective servicing procedures.

Component replacement and maintenance procedures are

covered in this text. Refer to 38EV or 38QV Instadation

Instruction for the foUowing procedures:

—System Startup Checkout

—System Charging

—Optimizer, Electric Heat Lockout Setup

—Blower Speed Checkout, Adjustment

Manual Emergency Heat Activation—

38EV and 38QV systems are designed to automaticaUy pro

vide emergency gas or electric heat in the event of compres

sor lockout on a system malfunction.

However, certain system control malfunctions may cause

lack of emergency heat initiation.

In the event that replacement parts are not readdy avadable

in the heating season, malfunction of the main control board

or interface cable can be manuaUy bypassed as described

below to restore gas or electric heat operation.

Note, however, that a malfunction of the interface board

causing inability to control blower speed, or fadure of

blower motor or controUer cannot be bypassed and must be

repaired.

Install a standard thermostat in the heated space for tempo

rary control untd the system can be repaired. Connect ther

mostat leads to the indoor unit terminal board across R and

W, as connected in conventional systems. The interface

board wdl control gas or electric heat to setpoint of the tem

porary thermostat.

COMPONENT REPLACEMENT

Before replacing any component in the entire system, turn

off main power to system. There may be more than one dis

connect switch. Turn off accessory heater power, if

...............................................................

.........................................................................

..................................................................

......................................

...................................................................

......................................................................

............................................

......................

.............

...........................................................................

40

41

41

42

42

42

43

43

applicable.

A WARNING

High voltage circuit remains energized after main dis

connect is opened. Normal capacitive discharge time is

ten (10) minutes, but this period may be extended indef

initely by component fadure. Before servicing, always

check with D.C. Voltmeter between contactor terminal

#23 (violet wire) and ground. Do not service until read

ing is lOVDC or less. Electrical shock can cause per

sonal injury or death. Always re-install safety shield in

top of control box after servicing.

A CAUTION

Aluminum tubing is used in unit cods. Do not overheat

or place excessive strain on tubing or damage may

result.

NOTE: To remove reversing valve, accumulator or compres

sor, control box and coil must be removed first. Coil

removes quickly and easdy. The minimal time required for

cod removal facilitates service and component removal. See

instructions below.

SERVICE VALVE REMOVAL-Cod must be removed to

remove screws holding service valves.

COIL REMOVAL

1. Shut off power to indoor and outdoor units.

2. Remove refrigerant from unit, using refrigerant

removal methods described in Carrier Standard Service

Techniques Manual, Chapter 1, Refrigerants. Be sure

system is 0 psig before proceeding.

3. FoUow steps 4 through 12 below.

CONTROL BOX REMOVAL

Make sure power is off to indoor and outdoor units.

4. Remove control box cover (3 screws).

5. Disconnect (3) in-hne electrical connectors in lower con

trol box.

6. Disconnect power leads and interface cable if control

box cannot be removed and set aside with them

attached.

7. Remove (8) screws securing control box to louvered cas

ing and (2) securing support legs to base pan.

43

A WARNING

High voltage circuit remains energized after main dis

connect is opened. Normal capacitive discharge time is

ten (10) minutes, but this period may be extended indef

initely by component failure. Before servicing, always

check with D.C. Voltmeter between contactor terminal

#23 (violet wire) and ground. Do not service until read

ing is lOVDC or less. Always re-instaU safety shield in

top of control box after servicing.

8. Supporting control box with one hand, remove safety

shield and (2) top screws securing box to fan orifice

ring. Remove control box by sliding horizontally away

from unit.