Page 1

Accessory Hot Gas Bypass

Installation Instructions

Part No. 30GT911054

38AKS014-024

30GT015-035

50/60 Hz

GENERAL

These installation instructions cover field installation of the

accessory hot gas bypass valve, pilot valve, and hot gas solenoid. For 30GT units, these instructions are intended for units

with a starting serial number of 2294F--- or higher. The hot gas

bypass package is not required on 30GT015, 50 Hz units or on

30GT020, 60 Hz units, since these 2 units have hot gas bypass

installed as standard from the factory. See table below for a listing of package contents.

NOTE: Since the 30GT015-035 and 38AKS014-024 units are

single-circuit units, only one accessory package is required per

unit.

ACCESSORY PACKAGE CONTENTS

ITEM QUANTITY PART NO.

Pilot Valve 1 EF11BS038

Hot Gas Solenoid

With Clip

Hot Gas Bypass

Val ve

1 EF19XS024

1 EA52DC421

In addition, the following parts will need to be

field-supplied:

1

•

/4-in. refrigerant grade copper tubing (amount will vary

with application)

3

/8-in. refrigerant grade copper tubing (amount will vary

•

with application)

•5/8-in. refrigerant grade copper tubing (amount will vary

with application)

• For 30GT units, one manual shut-off valve for

5

/8-in. line

• One 3-way-tee with an internal branch OR one standard

3-way tee (depending on application - see Pilot Valve

and Hot Gas Solenoid section for more information)

• For 38AKS/indoor coil split system, an auxiliary side

connector may be required.

Examine Package Contents — Examine each item

in the package. If any part is damaged or missing, file a claim

immediately with the shipper. See table above for accessory

package contents.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip-

ment can be hazardous due to system pressures, electrical

components, and equipment location.

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on air-conditioning equipment, observe pre-

cautions in the literature and on tags, stickers, and labels attached to the equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Use care in handling equipment.

Be sure power to equipment is shut off before performing

maintenance or service functions. Electrical shock may

cause personal injury.

INSTALLATION IN 30GT

AIR-COOLED CHILLERS

Step 1 — Install Piping

Shut off all power to the unit and remove refrigerant charge

before continuing with this accessory installation. Failure

to do so may result in personal injury.

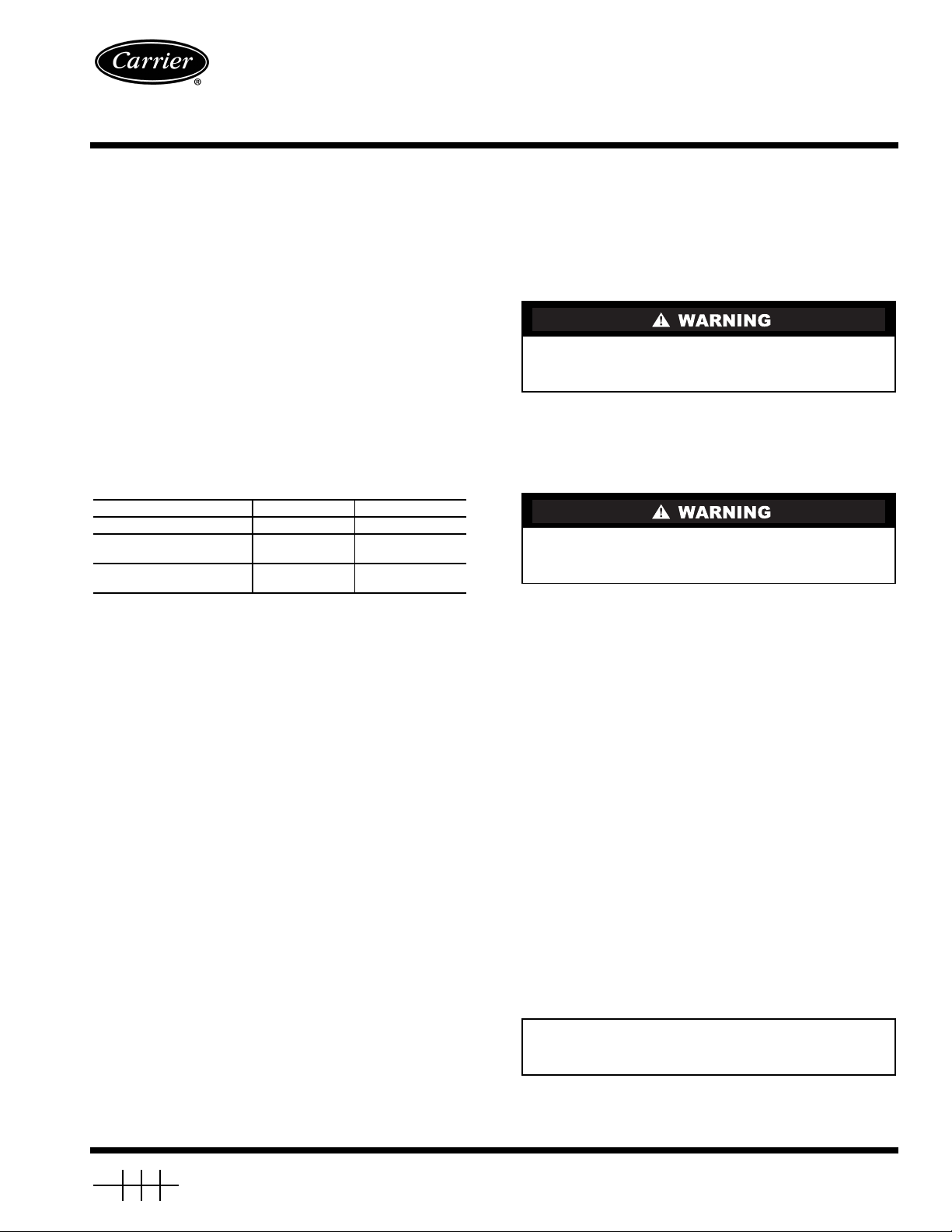

See Fig. 1 for a schematic of the unit piping.

BYPASS LINE — Install the

between the factory-supplied stubs in the discharge line (from

the compressor) and in the liquid line between the expansion

valve and cooler. See Fig. 2.

NOTE: The stubs are sealed as shipped from the factory.

Install the field-supplied shut-off valve in the bypass line as

close to the discharge line as possible. The shut-off valve will

aid in the pumpdown of the low side when closed.

HOT GAS BYPASS VALVE — Install the valve in the bypass

line near the shut-off valve installed in the Bypass Line section

above. The bypass valve has

each), and a

3

/8in. ODM equalizer port (sweat connection). To

ensure proper operation, the valve should be installed in a horizontal section of the bypass line and the pilot valve should be

installed above bypass valve body.

PILOT VALVE AND HOT GAS SOLENOID — Install the

hot gas solenoid onto the pilot valve. The solenoid fits over the

stem of the valve and attaches with the supplied clip on the top

(over the coil).

Install the pilot valve/solenoid assembly in the external

equalizer line of the bypass valve (

The pilot valve has a

3

/8in. ODF inlet and a1/4in. SAE

(Society of Automotive Engineers, U.S.A.) connection to the

TXV (thermostatic expansion valve) equalizer line.

IMPORTANT: Be sure the sweat connection on the hot gas

bypass valve is facing the pilot valve/solenoid assembly in

the equalizer line (See Fig. 1).

5

/8in., field-supplied line

5

/8in. ODF inlet and outlet (one

3

/8in. ODF equalizer port).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book124

Ta b 3 a 5 c 2 a

PC 111 Catalog No. 533-00067 Printed in U.S.A. Form 30GT/38AKS-1SI Pg 1 1-05 Replaces: 30GT-35SI

Page 2

LEGEND

TXV — Thermostatic Expansion Valve

Factory Piping

Field Piping

5

NOTE: The bypass valve in this package has

connections and can be used directly on 30GT015035 units.

/8in.

Fig. 1 — 30GT Piping Schematic

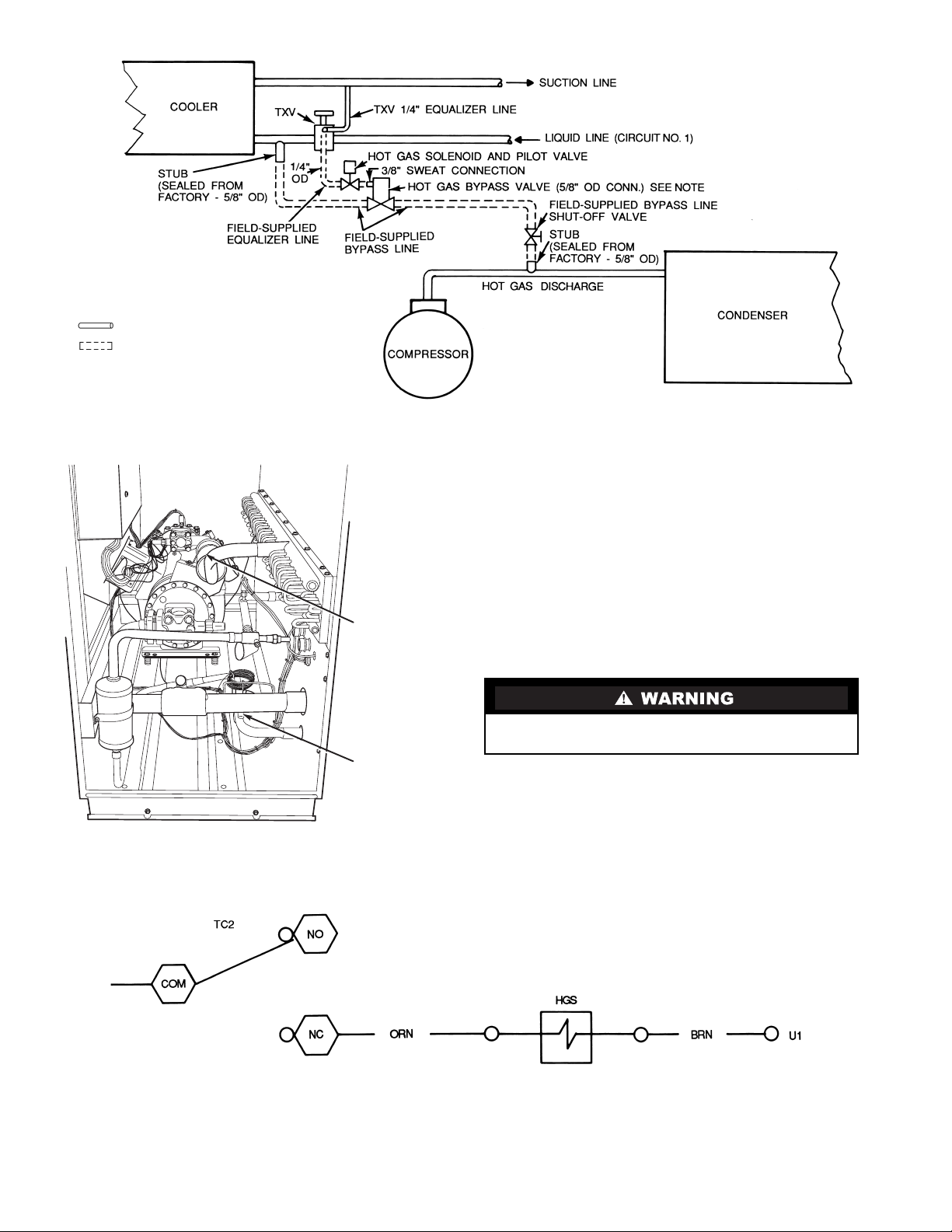

Fig. 2 — 30GT Stub Locations

DISCHARGE

STUB

(HIDDEN)

LIQUID

STUB

Install the field-supplied

1

/4in. OD tubing from the SAE

connection to the TXV equalizer line. If the connection is made

directly to the TXV, use the field-supplied, 3-way tee with an

internal branch (install horizontally in the line with the internal

branch attaching directly to the TXV). If the connection is

made into the equalizer line, use the field-supplied, standard 3way tee.

Step 2 — Dehydrate and Recharge the Circuit —

replace the filter drier cores. Then evacuate, dehydrate, and recharge the circuit, using approved refrigeration practices.

When piping is completed, leak test the assembly and

Step 3 — Install Control Wiring

Be sure all power to the unit is off before proceeding, and

that all disconnects are open and tagged.

Follow all local codes and NEC (National Electrical Code,

U.S.A.) when installing control wiring. All wire must be a minimum of 16 AWG (American Wire Gage, U.S.A.).

Connect control wires as shown in Fig. 3. At hot gas solenoid (HGS), connect to brown and orange wires as shown.

LEGEND

COM — Common NC — Normally Closed TC — Temperature Controller

HGS — Hot Gas Solenoid NO — Normally Open U1 — Unloader 1

Fig. 3 — 30GT Hot Gas Solenoid Wiring

2

Page 3

INSTALLATION IN 38AKS014-024/INDOOR

FAN COIL (CONSTANT VOLUME)

SPLIT SYSTEM COMBINATION

Step 1 — Install Piping (See Fig. 4)

Shut off all power to the unit and remove refrigerant charge

using an approved refrigerant recovery device before proceeding with installation. Failure to do so may result for

personal injury.

IMPORTANT: Do not bury refrigerant piping underground.

1. In applications where the air handler refrigerant distributor is not equipped with a side outlet connection, it is recommended that a Sporlan in-line auxiliary side connector

with standard distributor be used. Refer to the installation

instructions for the indoor fan coil to obtain nozzle size

and distributor connection size. Select the auxiliary side

connector based on this information. The side connector

must be installed on refrigerant circuit no. 1 (first stage of

cooling) of the fan coil being used.

2. Install a field-supplied

1

/4in. NPT to1/4in. flare fitting on

the gage connection port of the compressor suction

service valve.

3. Sweat the pilot solenoid valve supplied in the hot gas ac-

cessory package directly to the hot gas bypass valve on

3

the

/8in. ODF external equalizer port.

4. Install field-supplied

1

/4in. copper tube (flared with a nut

on each end) between the compressor suction valve and

the hot gas pilot solenoid valve.

5

5. Connect a field-supplied

/8in. OD copper tube between

the discharge line process tube (hot gas stub) and a fieldsupplied manual shutoff service valve, avoiding any traps

in piping.

6. Connect another field-supplied

5

/8in. OD copper tube between the manual shutoff valve outlet and the hot gas bypass valve inlet.

5

7. Connect a field-supplied

/8in. OD copper tube between

the leaving sideof the hot gas bypass valve and theSporlan

auxiliary side connector (distributor-side connector).

LEGEND

TXV — Thermostatic Expansion

*Pilot valve connects directly to

bypass valve per sketch A.

Val ve

Fig. 4 — 38AKS Hot Gas Bypass Piping

3

Page 4

Step 2 — Install Control Wiring (See Fig. 5)

1. Install a field-supplied relay with a 24-v coil and normally closed contacts rated for 20 va at 125 vac inductive

load. Mount this relay in the 38AKS control box.

NOTE: This relay is identified in Fig. 5 as HGR (hot gas

relay).

2. For 38AKS014-024:

a. Connect a field-supplied wire between TB2-3 and

the L1 side of the HGR coil.

b. Connect a field-supplied wire between TB2-9 and

the L2 side of the HGR coil.

c. Connect a field-supplied wire between TB2-2 and

HGR-4, one of the normally closed (NC) contacts.

d. Connect one leg of the hot gas pilot solenoid valve

to HGR-6, the other NC contact.

e. Connect the other leg of the hot gas pilot solenoid

valve to C2.

Step 3 — Restore Refrigerant Charge — Charge

unit in accordance with 38AKS Charging Chart found on unit.

Hot Gas

TB2

9

C2

TC2

TB2

TB2

3

BLU

YEL

LLS

HGR

HGR

ACCESSORY OPERATION AND

ADJUSTMENT

Adjustment — The hot gas bypass valve is set to begin

opening when the suction pressure falls to approximately

62 psig (427 kPa). The pressure corresponds to a chilled water

set point of approximately 44 F (6 C). If the chilled water set

point is lower than 44 F (6 C), the bypass setting must be decreased. The opposite is true if the chilled water setting is

above 44 F (6 C).

Condensing temperature also affects the setting of the bypass

valve, and a change may be required. To adjust the setting of the

bypass valve, a

5

/16in. hex wrench is required. Remove the cap

on the valve, and turn the adjustment nut with the hex wrench.

Turning in a clockwise direction increases the setting, and turning in a counterclockwise direction decreases the setting.

Operation — The hot gas bypass accessory operates as fol-

lows: When a call for cooling is received, the compressor start

circuit is energized, along with the hot gas solenoid (HGS) and

all unloaders. Once the HGS circuit is completed, the solenoid

valve opens allowing the hot gas bypass valve (HGBV) to

sense suction pressure and respond accordingly.

If the suction pressure is below the HGBP (hot gas bypass)

valve setting, the valve begins to open. The valve continues to

open until it either reaches an equilibrium or the maximum

open position. Discharge gas is bypassed into the mixed-phase

line between the expansion valve and the cooler. This condition

continues until the suction pressure rises above the HGBP

valve setting, a second stage of temperature control is called

for, or the unit cycles off.

LEGEND

HGR — Hot Gas Relay

LLS — Liquid Line Solenoid

TB — Te r m i n a l B l o ck

TC — Thermostat Cooling

NOTE: Hot Gas Relay (HGR) use Part No. HN61KK324.

Pilot Solenoid Valve

Fig. 5 — 38AKS014-024 Hot Gas Bypass Wiring

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Hot Gas Bypass Valve Fails to Open. 1. Dirt or foreign material in valve.

2. Equalizer passageway clogged.

3. External equalizer not connected or

equalizer line is pinched shut.

Hot Gas Bypass Valve Fails to Close. 1. Dirt or foreign material in valve.

2. Diaphragm failure.

1. Disassemble and clean valve.

2. Disassemble and clean valve.

3. Connect or replace equalizer line.

Check solenoid valve.

1. Disassemble and clean valve.

2. Replace element only.

Copyright 2005 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book124

Ta b 3 a 5 c 2 a

PC 111 Catalog No. 533-00067 Printed in U.S.A. Form 30GT/38AKS-1SI Pg 4 1-05 Replaces: 30GT-35SI

Loading...

Loading...