Page 1

38AK024-044

HEATING A COOLING

Air-Cooled Condensing Units

Installation, Start-Up and Service Instructions

50- and 60-Hertz Air-Cooled Packages

CONTENTS

Page

SAFETY CONSIDERATIONS

BEFORE INSTALLATION

Rigging ...........................................................................l

Placing Unit .................................................................. 3

Mounting Unit

Compressor Mounting

INSTALLATION

Refrigerant Piping Connections ..................................3

Single Pumpout Control

Filter Drier and Moisture Indicator...............................3

Receiver .........................................................................3

Piping Procedure ...........................................................3

Power Supply .................................................................5

Power Wiring..................................................................5

START-UP ................................................................11-16

Initial Check...................................................................11

Leak Test and Dehydration

Preliminary Charge

Start Unit .......................................................................11

...............................................................

..........................................................

......................................................

.........................................

.............................................

.................................................

...............................................

.........................................

1-3

3

3-10

3

11

11

1

3

Charge System .........................................................11

Operation ..................................................................11

Timer Functions ........................................................16

Sequence of Operation.............................................16

Complete Unit Stoppage

SERVICE

Access for Servicing ................................................17

Fan Adjustment ........................................................18

Oil Charge

Liquid Shutoff/Charging Valve

Capacity Control .......................................................18

Oil Pressure Safety Switch (OPS)

Compressor Protection

High-Pressure Switch ..............................................19

Low-Pressure Switch ...............................................19

Winter Start Control

Head Pressure Control

TROUBLESHOOTING .20

..............................................................

.................................................................

.........................................

...............................

............................................

.................................................

............................................

17-19

..........................

Page

16

18

18

19

19

19

19

SAFETY CONSIDERATIONS

Installing, starting up and servicing air conditioning

equipment can be hazardous due to system pressures,

electrical components and equipment location (roofs, ele

vated structures, etc.)

Only trained, qualified installers and service mechanics

should install, start-up and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance

functions such as cleaning coils. All other operations should

be performed by trained service personnel.

When working on the equipment, observe precautions in

the literature and on tags, stickers and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Keep quenching cloth and fire extinguisher nearby when

brazing.

• Use care in handling, rigging and setting bulky equipment.

• See Table 1 for Physical Data.

ELECTRIC SHOCK HAZARD

Cm

tr

Open all remote disconnects before

servicing this equipment.

BEFORE INSTALLATION

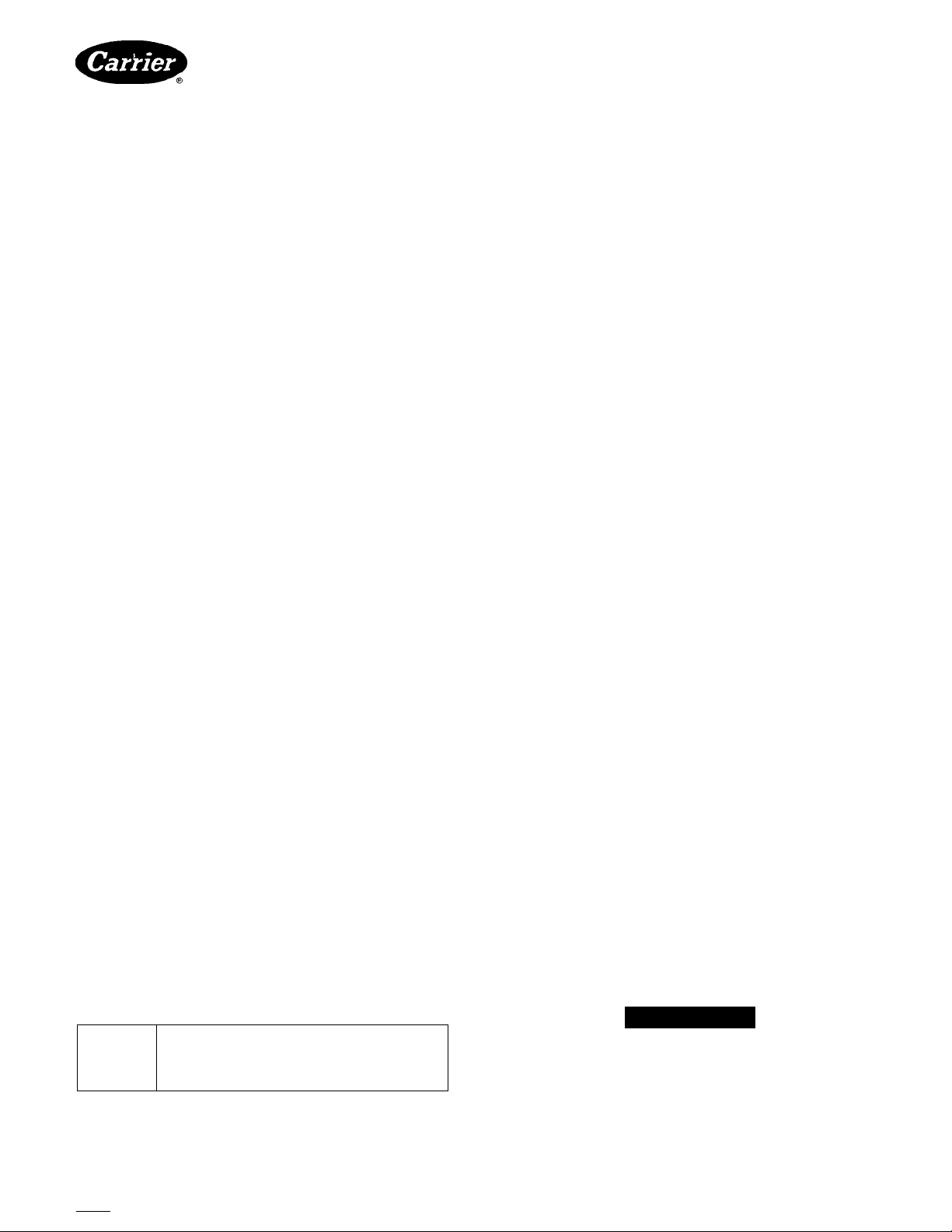

Rigging — Preferred method is with spreader bars

from above the unit. Use 2-in. (50 mm) OD pipe or

hooks in lifting holes. Rig with 4 cables and spreader

bars. All panels must be in place when rigging. See

rigging label on unit for details concerning shipping

weights, distance between lifting holes, center of

gravity and spreader bar dimensions. See Fig. 2.

If overhead rigging is not possible, place chiller on

skid or pad for rolling or dragging. When rolling, use

minimum 3 rollers. When dragging, pull the pad. Do

not apply force to the unit When in final position, raise

from above to lift unit off pad.

A CAUTION

All panels must be in place when rigging. Do not fork

units if no skid is supplied. If unit has skid, truck from

sides only.

Book 1

Tab I 3a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

PC111

Catalog No 563-915

Printed in U S A Form 38AK-1SIM

Pgi

11-89

Replaces: New

Page 2

3/4-IN (19mm) NOTCHES

IN END OR SPREADERS

Fig. 1 - Model 38AK (024 shown)

Fig. 2 — Rigging with Spreader Bars (Field Supplied)

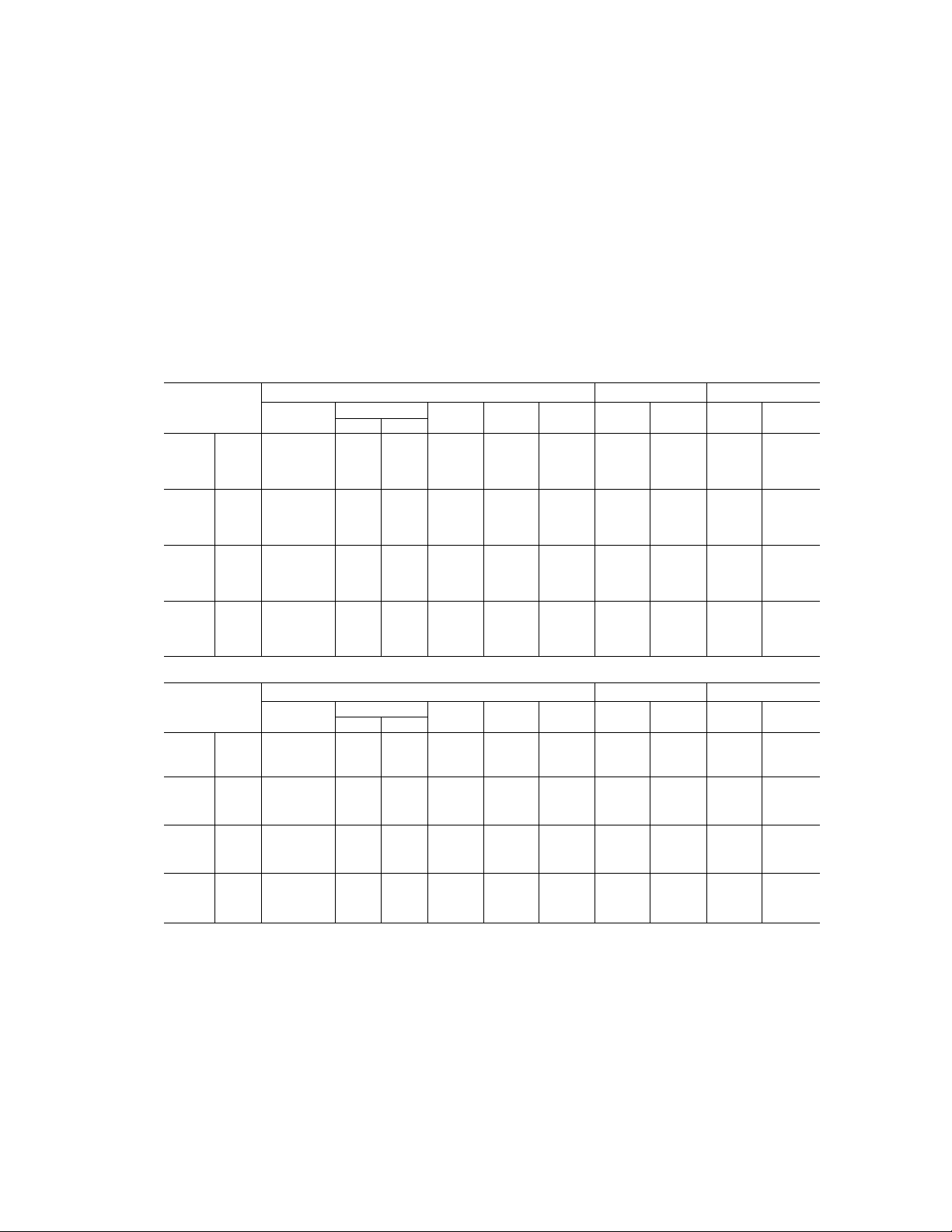

Table 1A — Physical Data — 60 Hertz

UNIT 38AK

COMPRESSOR Reciprocating Semi-Hermetic

No. ...Type 1 06E4250 1 06E9265

No. Cyls (ea) ...Speed, Rpm (r/s) 4 1750(29)

Capacity Steps

Oil Charge*, Pt (L) 14(66)

Oil Pressure Switch Setting (psid)

Crankcase Heater (watts)

Protection See Note

Capacity Control

No. 1

Load

Unload

No. 2

Load

Unload

REFRIGERANT CHG, R-22

Approximate lb (kg)

CONDENSER FANS, Type Propeller Type, Direct Driven

No. ...Diameter, in. (mm)

Total Airflow, Cfm (L/s) 10,600 (5,000) 15,700 (7,400) 23,700(11,200)

Speed, Rpm (r/s) 1140(19)

CONDENSER COIL, Type Horizontal, Plate Fin

Rows...Fins/in. (Fin Spacing mm)

Total Face Area, sq ft (m‘)

024 028 034

1 06E9275

2

6 1750(29)

3

19(9)

180

Suction Pressure Unloader(s)

Unloader Settings (psig)

76

58

—

—

28 (12 7) 305(138)

3 ... 17 (1 49) 2 19(134)

235(218) 39 2(364) 584(543)

76

58

Unloader Settings (psig)

78

60

2 30(762)

76 76

58 58

78 78

60

435(19.7) 65(295)

3 ...30 (762)

3 17(149)

Table IB — Physical Data — 50 Hertz

UNIT 38AK 024

COMPRESSOR

No.... Type 1 06E4250

No. Cyls (ea)... Speed, Rpm (r/s)

Capacity Steps

Oil Charge*, Pt (L)

Oil Pressure Switch Setting (psid)

Crankcase Heater (watts)

Protection

Capacity Control

No. 1

Load

Unload

No. 2

Load

Unload

REFRIGERANT CHG., R-22

Approximate lb (kg)

CONDENSER FANS, Type Propeller Type, Direct Driven

No.... Diameter, in. (mm)

Total Airflow, dm (L/s)

Speed, Rpm (r/s)

CONDENSER COIL, Type Horizontal, Plate Fin

Rows ... Fins/in. (Fin Spacing mm)

Total Face Area, sq ft (m‘)

*See Service, Oil Charge, for Carrier-approved oil

Paid - pounds per sq in differential

4 1450(24 2)

2

14(66)

76

58

—

—

28(12 7)

10,600 (5,000)

3... 17 (149)

235(218) 39.2(364)

NOTE: Circuit breaker in main power circuit and discharge gas thermostat in control circuit

028 034 044

Reciprocating, Semi-Hermetic

1 06E9265 1 06E9275 1 06E9299

Suction Pressure Unloader(s)

Unloader Settings (psig)

76

58

Unloader Settings (psig)

78

60

305(13.8)

2 30 (762) 3... 30 (762)

15,700 (7,400) 23,700 (11,200)

950 (15 8)

2 19(134)

c

180

See Note

6 1450(24 2)

3

19(9)

76 76

58 58

78

60

435(197) 65(295)

3. 17(149)

2

044

1 06E9299

60

78

60

584(543)

Page 3

Placing Unit — There must be 4 ft (1220 mm) for service

and for unrestricted airflow on all sides of unit, and a

minimum of 8 ft (2440 mm) clear air space above unit. For

multiple units, allow 8 ft separation between units for

airflow and service.

Mounting Unit — When unit is in proper location, use of

mounting holes in base rails is recommended for securing

unit to supporting structure, or for mounting unit on

vibration isolators if required. Fasteners for mounting unit

are field supplied. Be sure to mount unit level to ensure

proper oil return to compressors.

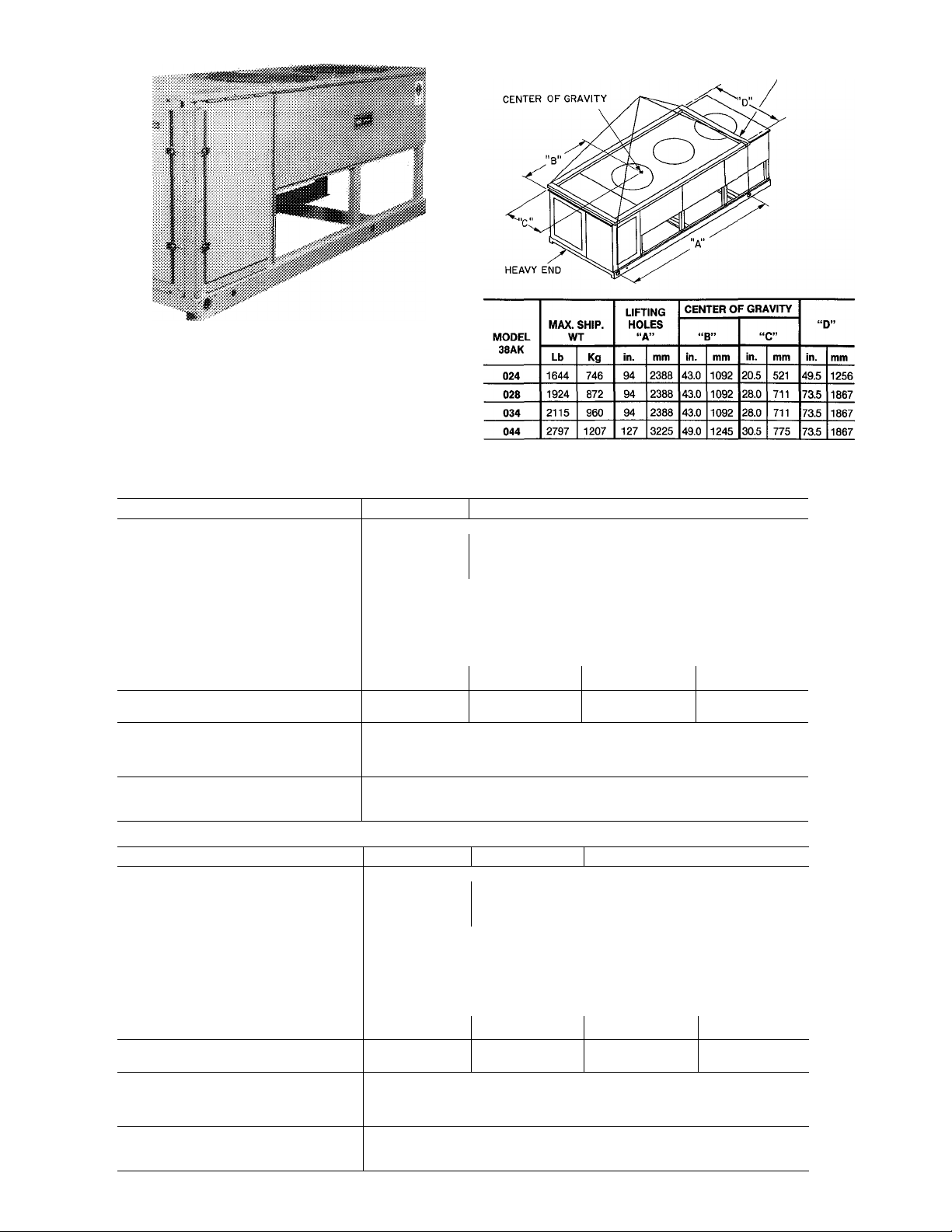

Compressor Mounting — As shipped, compressor is

held down by 4 bolts. After unit is installed loosen each bolt

until the snubber washer can be moved with finger pressure.

See Fig. 3.

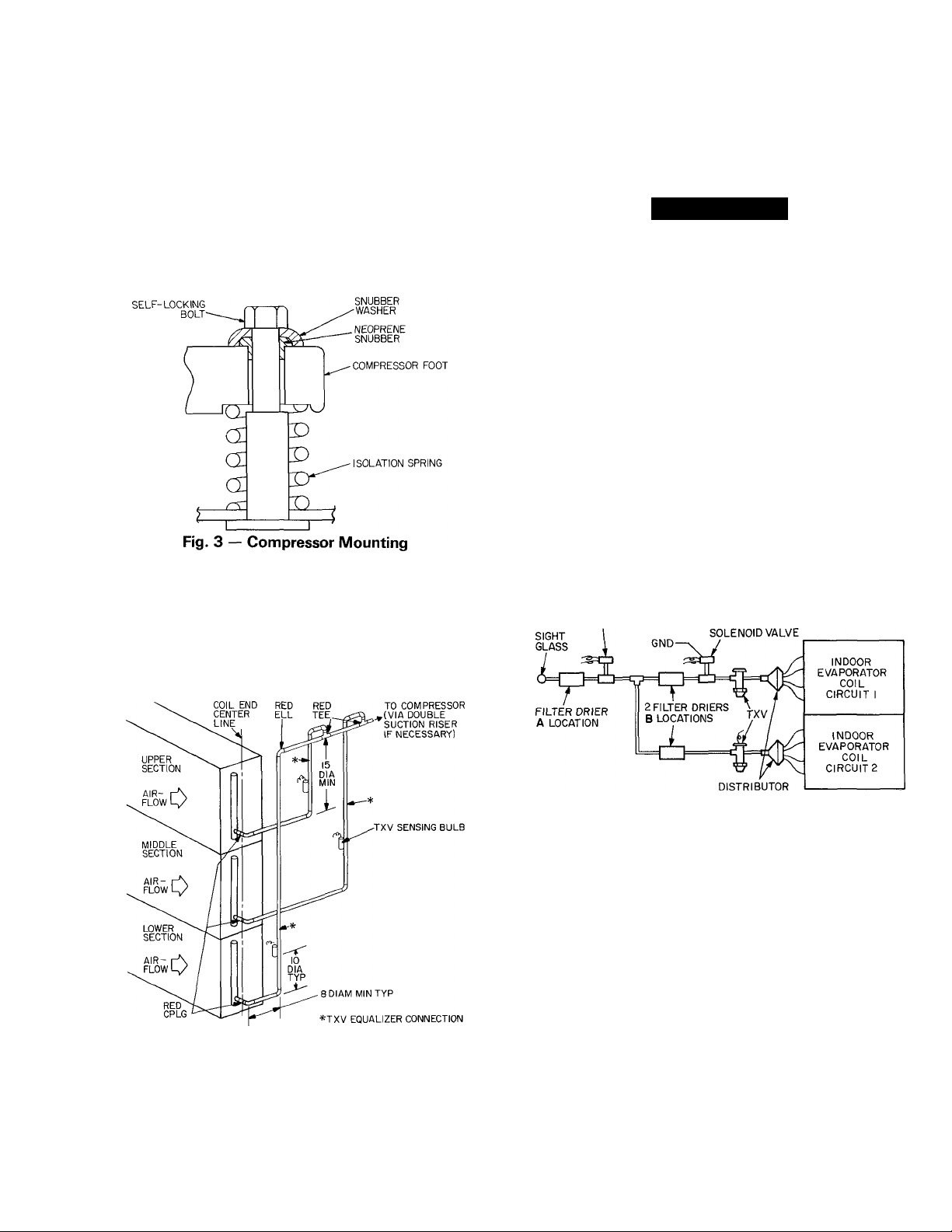

Single Pumpout Control — All units are factory wired

to operate on single pumpout control. A factory-supplied

liquid line solenoid valve must be installed in the liquid line

ahead of the indoor coil. See Fig. 5. Wires from solenoid

valve must be in conduit, and a ground wire must be

provided to comply with codes.

A WARNING

Failure to properly install liquid line solenoid at the

indoor unit as described, without Carrier author

ization, may VOID warranty.

If unit is used with a chiller, wiring modifications may be

required.

Filter Drier And Moisture Indicator — Every unit

should have a filter drier and a sight glass (moisture

indicator) field installed. Select the filter drier for maximum

unit Capacity and minimum pressure drop. Figure 5 shows

recommended locations of filter drier(s) and sight glass.

Complete the refrigerant piping from the evaporator to the

condenser before opening the liquid and suction lines at the

condensing unit. One filter drier may be installed at location

A in Fig. 5, or 2 filter driers may be installed at locations B.

INSTALLATION

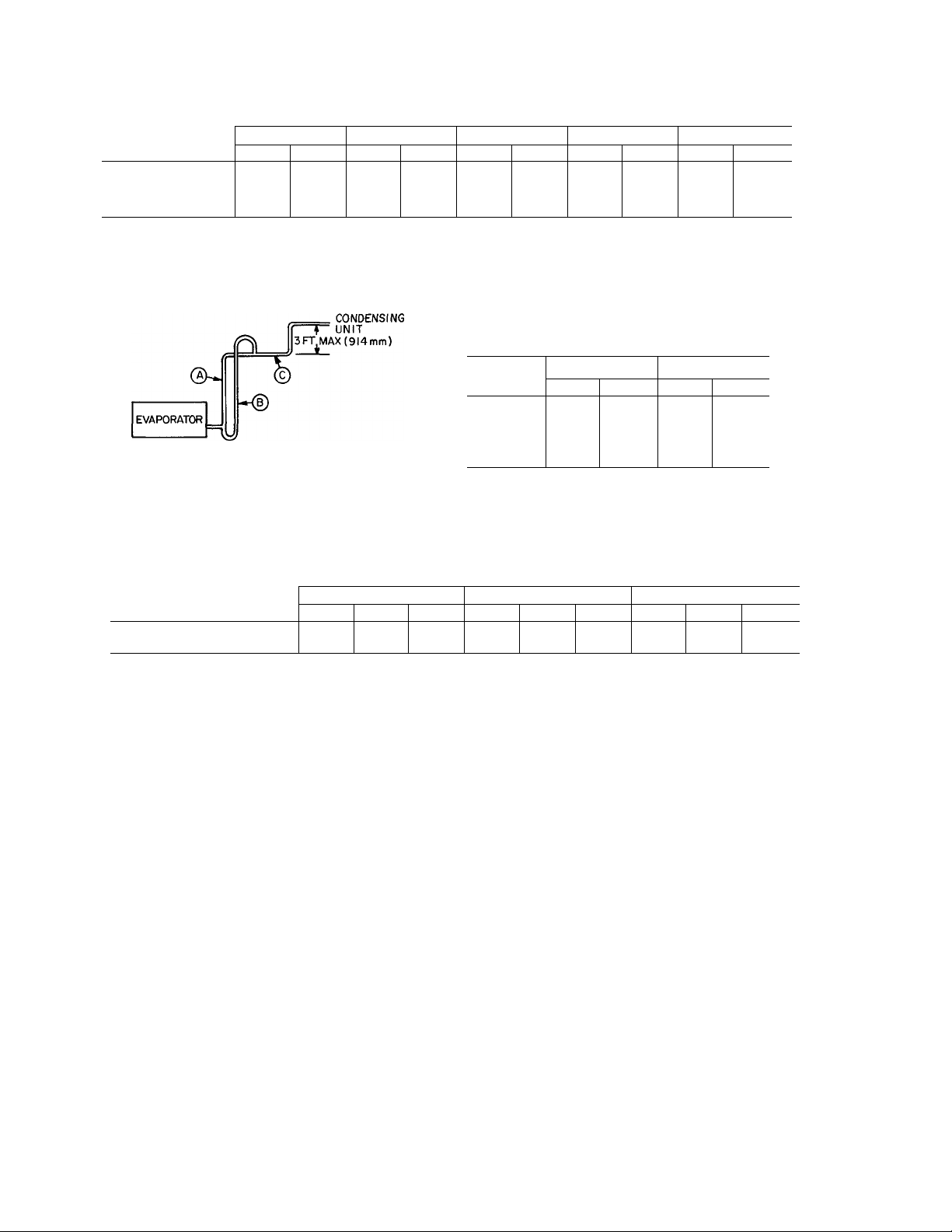

Refrigerant Piping Connections — Line sizes depend

on length of piping required between condensing unit and

evaporator. See Table 2. It is important to consider liquid

lift and compressor oil return. Refer to Part 3 of Carrier

System Design Manual for line sizing information, and

Fig. 4 for recommended piping details.

NOTES:

1 Suction line is connected to coil on same side as the entering air.

2 For coils having only one section, use upper section piping; for coiis

having 2 sections, use upper and middle section piping

3 Lower section is first on and last off.

4 For more complete piping information, refer to Carrier System

Design Manual, Part 3

Fig. 4 — Suction Line Piping to Unit

with 3 Section Coil Split

FACTORY SUPPLIED

SOLENOID VALVE

FIELD SUPPLIED

CAPACITY CONTROL

Fig. 5 — Liquid Line Solenoid Valve,

Filter Drier(s) and Sight Glass Locations

Receiver — No receiver is provided with the unit; it is

recommended that one not be used.

Piping Procedure — Do not remove run-around pipe

from suction and liquid line stubs until piping connections are

ready to be made. Pass nitrogen or other inert gas through

piping while brazing, to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve in

liquid line ahead of each evaporator section. For 2-step

cooling, the fleld-supplkd solenoid used must be wired to be

opened by control from a 2-step thermostat

For example: 2 solenoids may be used with 3 TXVs —one

of the solenoids serving a liquid line feeding 2 of the TXVs.

Page 4

Table 2 — Refrigerant Piping Sizes

SINGLE SUCTION RISERS

MODEL

38AK

024 5/8 1-5/8

028 7/8 1-5/8

034

044

L-Liquid Line S-Suction Line

* IMPORTANT — Requires a double suction riser, see below:

NOTE: Liquid and suction iine sizes are OD (in)

(a) - SUCTION RISER WITHOUT TRAP

(b) - SUCTION RISER WITH TRAP

(^- SUCTION LINE TO CONDENSING UNIT

7/8

7/8

16-25

L

S L S

2-1 /8

2-1/8 7/8 2-1/8

LENGTH OF INTERCONNECTING PIPING (FT)

26-50

7/8 1-5/8

7/8

7/8

2-1 /8 7/8

2-1/8 7/8

DOUBLE SUCTION RISERS

51-75

L

7/8

1-1/8

UNIT 38AK

024 86

028

034 67

044 76

76-100

S

2-1/8 7/8

2-1/8 7/8

2-1/8

*

L

1-1 /8

1-1/8

2-1/8

2-1/8

MAXIMUM LIQUID LIFT

60 Hz 50 Hz

Ft

M

26 72

76

23

20

23

S

*

*

101-200

L S

7/8 2-1/8

7/8 2-1/8

1-1/8

1-1/8

Ft

21

66 20

60

18

66 20

*

*

M

MODEL

38AK

034

044

NOTE: A, B, C dimensions relate to reference diagram

2-1/8

51-75 76-100

A

B C

1-5/8

SUCTION PIPING AT EVAPORATOR AND TXV BULB LOCATION (See Fig. 5)

The purpose of these recommendations is to achieve good

mixing of the refrigerant leaving the evaporator suction

header for proper sensing by the TXV bulb.

1. A minimum of two 90° elbows must be installed

upstream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is neces

sary, secure the bulb at approximately the 4 o’clock

position.

3. Size the suction line from the evaporator through the

riser for high velocity. Enter the suction pipe sizing charts

in the Carrier System Design Manual at design tons and

equivalent length (for 2 degree F loss). If reading falls

between 2 sizes on chart, choose the smaller pipe size.

LENGTH OF INTERCONNECTING PIPING (FT)

A B C A

2-5/8

1-5/8

1-5/8

2-1/8

2-1/8

2-5/8

2-5/8

1-5/8

1-5/8

Suction piping for the high velocity section should be

selected for about 0.5 degree F friction loss. If a 2 degree

F loss is allowed for the entire suction line, 1.5 degree F

is left for the balance of the suction line and it should be

sized on that basis. Check that the high-velocity sizing is

adequate for oil return up the riser.

If an oil return connection at the bottom of this

suction header is supplied with an evaporator, this

connection must be teed-in ahead of first mixing elbow.

When the compressor is below the evaporator, the riser

at the evaporator does not have to extend as high as the

top level. After a 15-diameter riser has been provided,

the suction line may elbow down immediately.

SAFETY RELIEF — A fusible plug is located on unit

liquid line before the liquid valve.

101-200

B

2-1/8

2-1/8

C

2-5/8

2-5/8

Page 5

Power Supply — Electrical characteristics of available

power supply must agree with unit nameplate rating. Supply

voltage must be within limits shown in Table 3.

IMPORTANT: Operating unit on improper supply

voltage, or with excessive phase imbalance, constitutes

abuse and may affect Carrier warranty. See Unbal

anced 3-Phase Supply Voltage, page 6.

Power Wiring — All power wiring must comply with

applicable local and national codes. Install field-supplied

branch circuit fused disconnect(s) per NEC (National Electri

cal Code) of a type that can be locked OFF or OPEN.

Disconnect(s) must be within sight from and readily acces

sible from unit in compliance with NEC Article 440-14.

Table 3 — Electrical Data

60 HERTZ

MODEL

OfiAtr

024

028

034

044

500

200

600

100

500

200

600

100

500

200

600

100

500

200

600

100

Volts

3 Ph, 60 Hz

208/230

380 342 418 51 1 80 194.9 346 191 3.9

460 414 508

575

208/230

380

460

575 518 632

208/230

380

460

575 518

230

380

460

575

SuDolied*

Min. Max. (Fuse)

187

518 632

187 254

342

414

187

342

414

187 254

342

414

518

UNIT COMPRESSOR

MCA

254 92.1 150 348.6

46.9

42.9 70

124.6 200

418 64.7 110

508 60 7 100 226.1

52.5 80

254

145 5 250

418 72.5 125

508 687 110

632

418

508 91 0 150

632 81.5 125 282.8

54.9 90

2030 350

111 1

50 HERTZ

MODEL

38AK

024

034

044 300

800 230

300 346

900

800

028 300 346

900 400

800 230

300

900

800 230

900

Volts

3 Ph, 50 Hz

400

230

346

400

346

400

Supplied*

Min. Max.

198 254

311

342

198 254 109 175 348.4 76.9 342

311

342

198 254 1202

311

342

198 254

311

342

UNIT

MCA

380 50.5 80

400 49.3 80 1740 347 173 1.0

380 64.9 100

400 605 100 226.0 436 223 30

88.1 125

380 76.1 125

400 68.5

1506 250

380 112.6 175

400 90.8 150 351 0

GENERAL WIRING NOTES

1. A crankcase heater is wired in the control circuit so it is

always operable as long as power supply disconnect is

on, even if any safety device is open or unit stop-start

switch is off. It is protected by a 5-amp circuit breaker in

control power.

2. The power circuit field supply disconnect should never be

open except when unit is being serviced or is to be down for a

prolonged period When operation is resumed crankcase

heater should be energtedfor 24 hours before start-up. If unit

is to be shut down for a prolonged period it is recommended

that the suction arid discharge valves be closed to prevent an

excessive accumulation of refrigerant in the compressor oil

3. Power entry is at one end only.

MOCP

ICF RLA LRA FLA (ea)

68

80 1748

175

MOCP

(Fuse)

123.4

452.2 89.8 446 6.2

250.9 45.5 247 3.9

167.4 36.5 164 3.4

512.2 106.5 506 6.2

283.9 52.6 280

256.1 50 253 3.1

179.4 38.5 176 3.4

702.4

3898 79.5 382 39

351 2 65.4 345 3.1

ICF RLA LRA FLA (ea)

256.4 60.3

2044

34 7

28.9 120 3.4

43.6 223 31

147 5 690

57.1 276 3.4 3

COMPRESSOR

333 200

263.4 44.9

200

110

372.4

2984

2560 50.0 253 3.0

5578 105.1

408.8 79.5

859 366

539 294

65.4

FAN MOTORS!

345

3.6

173 1 8

3.9

62 3

FAN MOTORS!

250

259

545

400

345 30

6.4 2

44 2

64 2

4.4 2

6.4

4.4 2

6.4 3

4.4

Qty

2

2

2

2

2

2

2

2

2

2

2

2

3

3

Qty

2

2

2

2

3

3

FLA — Full Load Amps

ICF — Maximum Instantaneous Current Flow during starting (the

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (complies with National Electrical

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

* Units are suitable for use on electrical systems where voltage

supplied to unit terminals is not below or above listed minimum and

maximum limits

t All fans are protected by a single circuit breaker.

point in the starting sequence where the sum of the LRAfor

the starting compressor, plus the total RLA for all running

compressors, plus the total FLA for all running fan motors

is maximum).

Code [NEC], Section 430-24)

Page 6

4. Maximum field wire sizes allowed by lugs on terminal

block are:

350 MCM for models 38AK028 (208/230-3-60),

38AK034 (208/230-3-60, 230-3-50), and

38AK044 (208/230-3-60, 230-3-50)

2/0 AWG for all other models.

5. Terminals for field power supply are suitable for

copper, copper-clad aluminum or aluminum conduc

tors. Insulation must be rated 167 F (75 C) minimum.

UNBALANCED 3-PHASE SUPPLY VOLTAGE —

Never operate a motor where a phase imbalance in supply

voltage is greater than 2%. Use the following formula to

determine the % voltage imbalance:

% Voltage Imbalance

= 100 X

max voltage deviation from average voltage

average voltage

I ^

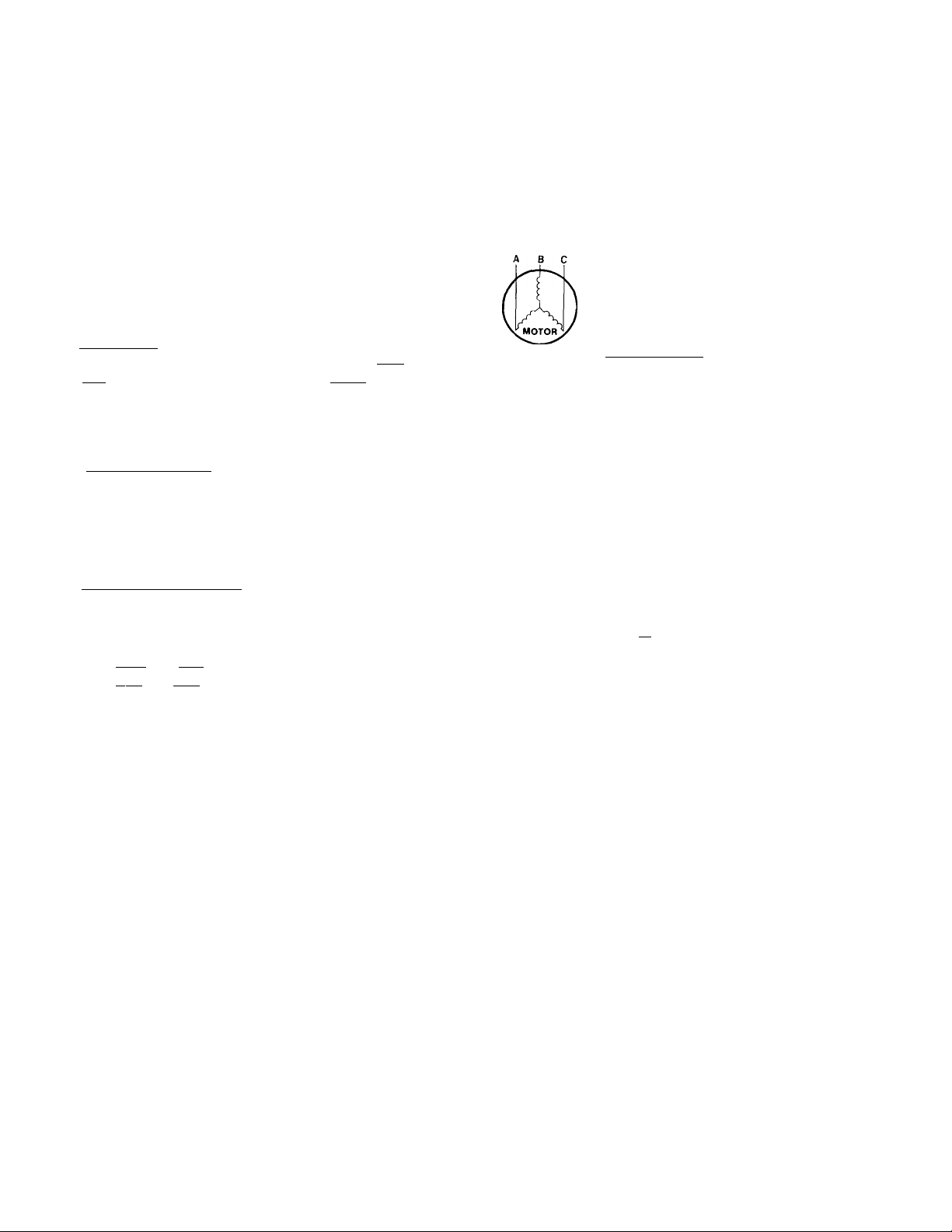

CONDENSER FANS — The fans must rotate counter

clockwise when viewed from above. If necessary, correct

direction of fan rotation by interchanging any 2 power

input wires at disconnect switch. Affix crankcase heater

decal (located in installer’s packet) to unit disconnect switch.

FIELD CONNECTIONS

1. Main Power — Bring wires from the fused disconnect

switch through hole in bottom rail of unit to control

box (Fig. 6, 7, 8) and connect terminals 1111, [12

on line side of terminal block TBl (see Fig. 9).

13

To comply with NEC Article 440-14, the disconnect

must be located within sight from and readily acces

sible from unit.

■ 2. 24-v Control Power — Units have single point power

connections. Control circuit is directly connected inter

nally to unit. Maximum 24-v control circuit is 3 amps.

NOTE: For wire runs up to 50 ft. use no. 18 AWG

insulated wire (35 C min.). For 50 to 75 ft., use no. 16

AWG insulated wire (35 C min.). For over 75 ft. use 14

AWG insulated wire (35 C min.).

3. Control Circuit Interlock — An airflow switch may be

installed in the indoor air handler to prevent unit from

running when indoor air is not flowing. This switch (no.

HR81JE001) is available from Service Parts Center, or

equivalent can be field supplied. This should be electri

cally interlocked in the control circuit, between term

inals I 1 I and I 6 I (for flow switch) on TB2. See Fig.

9 for field wiring. This is in the 115-v circuit. Wires must

be run in conduit with ground wire.

4. Transformer Connections — See unit wiring label dia

gram, notes 1 and 2, located behind compressor com

partment end access door.

Example: Supply voltage is 240-3-60.

AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage =

Determine maximum deviation from average voltage:

(AB) 243 - 239 = 4 volts

(BC) 239 - 236 = 3 volts

(AC) 239 - 238 = 1 volt

Maximum deviation is 4 volts. Determine % voltage

imbalance:

% Voltage Imbalance = 100 x —^ = 1.7%

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

IMPORTANT: Contact your local electric utility

company immediately if the supply voltage phase

imbalance is more than 2%.

243 + 236 + 238 = 239 volts

239

IMPORTANT: Ensure power to the crankcase

heater is always on (except when servicing the unit).

If circuit breakers inside unit shut down the com

pressor and condenser fans, crankcase heater

remains on.

Page 7

NOTES:

1

THERE MUST BE [1220 mm] 4 ft FOR SERVICE AND

FOR UNRESTRICTED AIRFLOW ON ALL SIDES OF UNIT.

THERE MUST BE MINIMUM C2440 mml 8 ft CLEAR

AIR SPACE ABOVE UNIT.

THE APPROXIMATE OPERATING WEIGHT OF THE UNIT IS:

3.

60 HZ

UNIT WT LBS

38AK024

1456 661

38AK024C 1580

NOTE: "C" INDICATES COPPER COIL.

2 4

WT KG

717

50 HZ

UNIT WT LBSWT KG

38AK024

38AK024C 1580

60 Hz

024

024C

50 Hz

024

024c

1456 661

717

APPROX. OPER. WT. (LB.)

AT SUPPORT POINTS

1 2

411

501

448 533

587

433

626

462

245

273 326

486 358

518

HINGED ACCESS DOOR•

CONTROL BOX

3 4

299

382

TOT.

1456

1580

1864

1988

[63.5-92.1] 2 1/2'-:

FIELD MAIN POWER SU

- A

' II

HINGED ACCES

[1315]

4'-3 3/4'

[61]

2 7/16

[19.1]

3/4' dia;

MOUNTING HOLES

(TYP 4 PLACES)

[63.5-92.1]

2 1/2'-3 5/8'DIA.

FIELD POWER

ENTRY 8 LIFTING

[22.2]

7/8' DIA.

FIELD CONTROL

POWER ENTRY

Fig. 6 — Dimensioi

Page 8

ECimON

PAM No. 2

5/8' DIA.

LY

[22.2] 7/8' DIA.

FIELD CONTROL CIRCUIT WIRING

TOP VIEW

1 Drawing, 38AK024

10'-7 13/16'

SIDE VIEW

Page 9

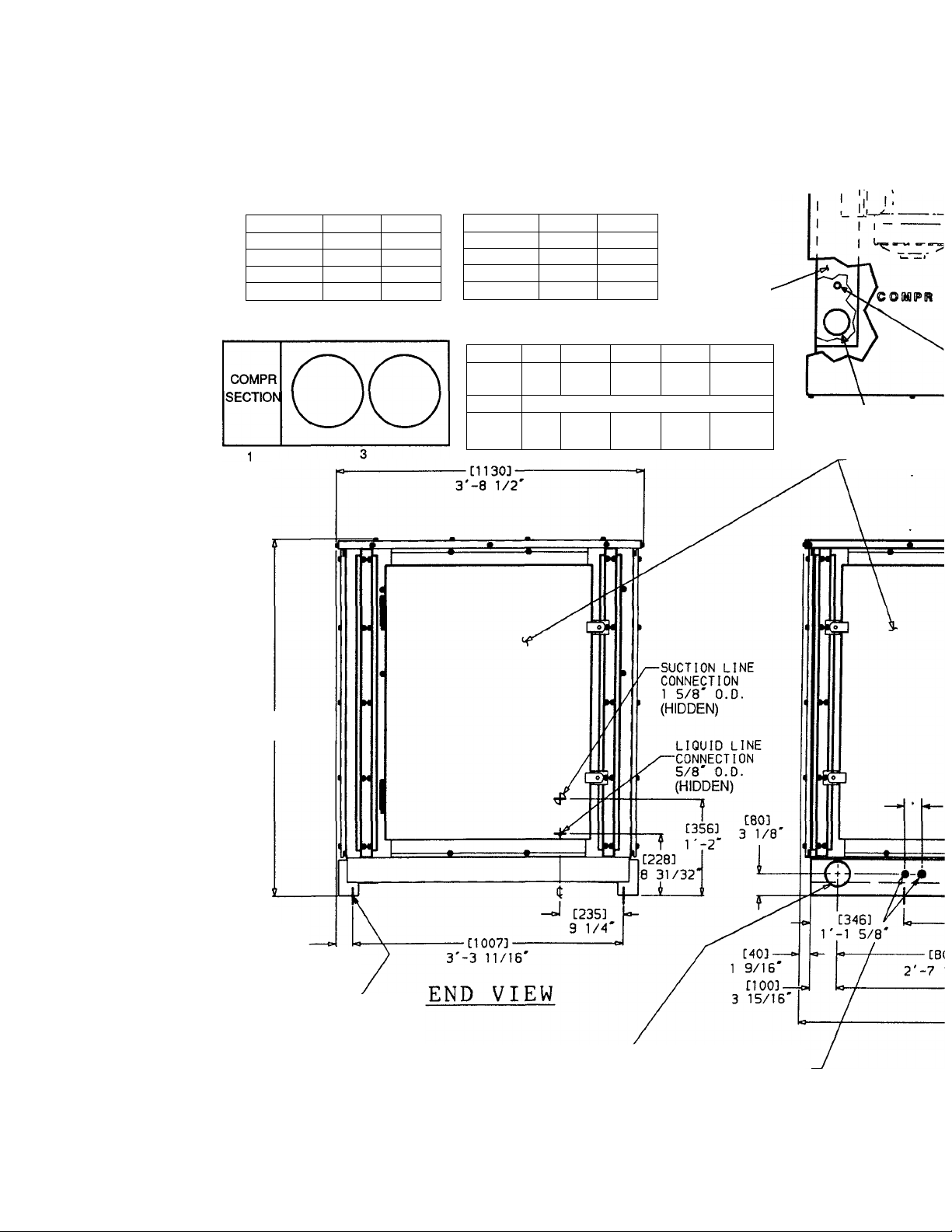

NOTES:

1. THERE MUST BE [1220 mm] 4 Ft FOR SERVICE AND

FOR UNRESTRICTED AIRFLOW ON ALL SIDES OF UNIT.

2. THERE MUST BE MINIMUM [2440 mm] B ft CLEAR

AIR SPACE ABOVE UNIT.

3. THE APPROXIMATE OPERATING WEIGHT OF THE UNIT IS:

60 HZ

UNIT

38AK028

WT LBS

1650

WT KG

748

38AK028C 1804 818

38AK034

1803 818

38AK034C 2009 911

NOTE: “C" INDICATES COPPER COIL.

UNIT WT LBSWT KG

38AK028 1650 748

38AK028C

38AK034 1803

38AK034C

50 HZ

1804

2009

APPROX. OPER. WT. (LB.)

AT SUPPORT POINTS

1

60 Hz

028

028C

034

034C

50 Hz

025

025C

030

030C

2

418

626

462

666

459

673

518

719

590

507

632

542

628

538

683 586

818

818

911

3

242

276

272

323

590

632

628

683

4

364

400

399

449

506

541

538

586

HINGED A(

[22.2] 7/8

FIELD CONTROL CII

[63.5-92.1] 2 1/2'-3

FIELD MAIN POWER I

CONTRC

TOT.

1650

1804

1803

2009

2193

2347

2332

2538

Fig. 7 — Dir

Page 10

ESS DOOR

DIA.

UIT WIRING

8' OIA.

^PLY.

BOX

coMip« secirioN

(FAN No. 1

TOP VIEW

No. 2

FIELD CONTROL

POWER ENTRY

insional Drawing, 38AK028,034

SIDE VIEW

Page 11

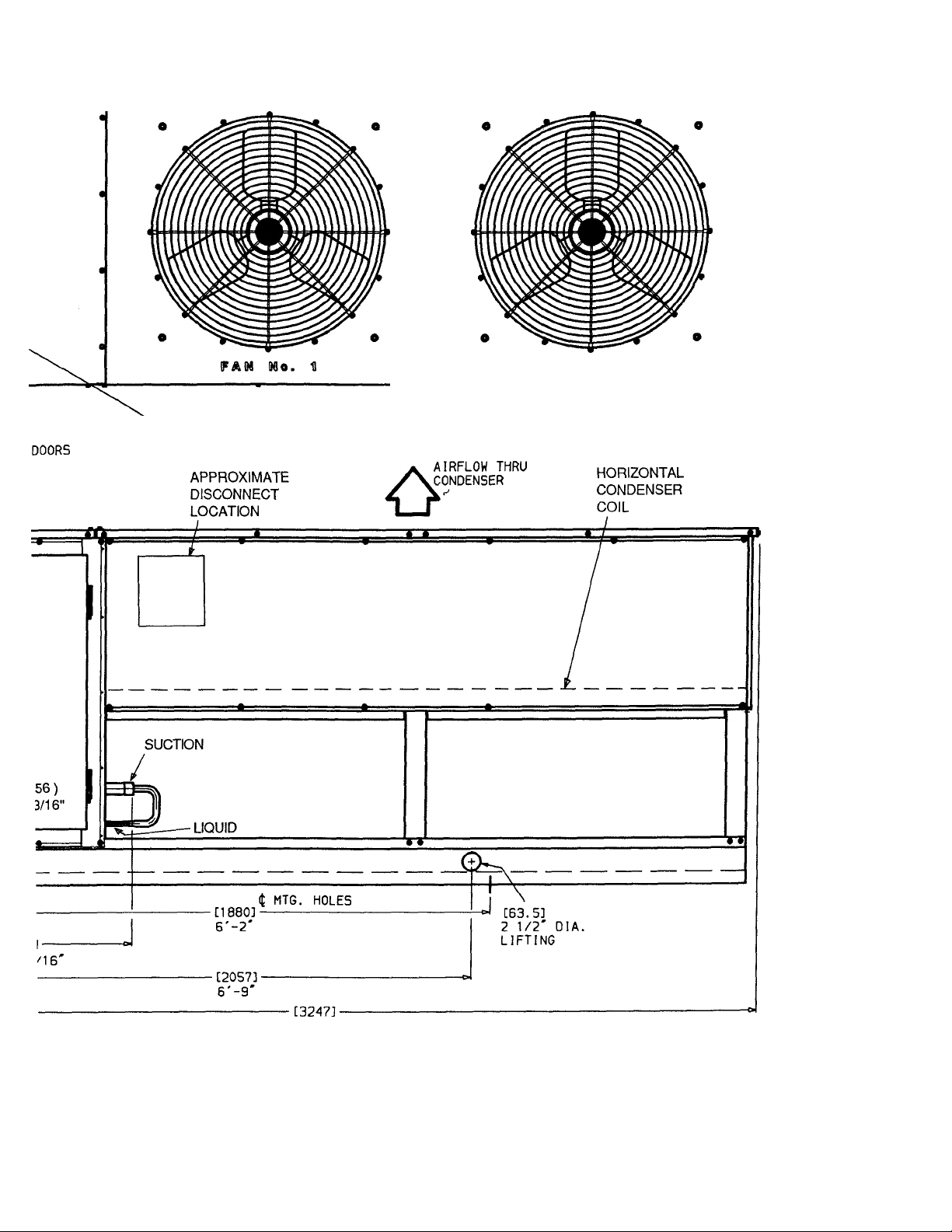

NOTES:

HINGED ACCESS DOOR

1. THERE MUST BE £1220 ram] 4 Ft FOR SERVICE AND

FOR UNRESTRICTED AIRFLOW ON ALL SIDES OF UNIT.

2. THERE MUST BE MINIMUM £2440 mm] 8 ft CLEAR

AIR SPACE ABOVE UNIT.

3. THE APPROXIMATE OPERATING WEIGHT OF THE UNIT IS:

50 HZ 8 60 HZ

UNIT

38AK044

WT LBS

2437

38AK044C 2745

WT KG

1106

1246

CONTROL BOX-

NOTE: “C" INDICATES COPPER COIL.

2 4

APPROX. OPER. WT. (LB.)

AT SUPPORT POINTS

60 Hz

044

044C

1

722

808

2

924

995

3 4

347

422

444

520

TOT.

2437

2745

£1742]

£1315]

4'-3 3/4

FIELD CONTROL CIRCUIT WIRING

£22.2] 7/8' DIA:

£63.5-92.1] 2 1/2'-3 5/8' DIA:

FIELD MAIN POWER SUPPLY

HINGED ACCESS DOOR

SUCTION LINE

CONNECTION

2 1/8' O.D.

(HIDDEN)

LIQUID LINE

CONNECTION

7/8' O.D.

(HIDDEN)

£452]

r-1 9/16'

COOWPR SeCTDOM

£61]-

2 7/16'

£19.1]

3/4' DIA

MOUNTING HOLES

CTYP 4 PLACES)

S'-3 3/4

END VIEW

£63.5--92.1]

■-3 5/8' DIA.

2 1/2

FIELDPOWER

ENTRYa LIFTING

—

£346]

I

r-1 5/8'

•£806] —

2'-7 3/4'

£22.

7/8'

FIEL

POWE

Fig. 8 — Dimensional Dre

Page 12

FAN No. 1

FAN No. 2

TOP VIEW

FAN No. 3

)1A.

CONTROL

ENTRY

ing. 38AK044

SIDE VIEW

Page 13

OR DIA HOLE

[92 I] 3 5/8"

NOTES:

1 Factory wiring in accordance with National Electricai Code (NEC) Any fieid modifications or additions must be in

compliance with aii appiicabie codes

2 AM field interlock contacts in the 115-y control circuit must have minimum rating of 180 va pilot duty pi us capacity required

for field-installed equipment All field interlock contacts in the 24-v control circuit must have minimum ratingof TOvapilot

duty plus capacity required for field-installed equipment Remove wire between terminals TB2-1 and 6 when airflow

switch is field installed

3 For internal unit wiring, reference wiring book TB2 is 115-1-60, TB3 is 24-1-60

LEGEND

AFS — Airflow Switch

GND — Ground

LLSV1 — Liquid Line Solenoid Valve for Pumpout

LLSV2 — Liquid Line Solenoid Valve for Capacity Control

TB — Terminal Block

_——— Field Power Wiring

________

________

Field Control Wiring

Factory Installed Wiring

Fig. 9 — Typical Wiring Schematic

10

Page 14

START-UP

Initial Check

A CAUTION

Do not attempt to start the condensing unit, even mo

mentarily, until the following steps have been com

pleted. Compressor damage may result.

1. Check all auxiliary components such as air handling

equipment, and other equipment. Consult the manu

facturer’s instructions regarding any other equipment

connected to the condensing unit. If used, air flow

switch must be properly installed. See Fig. 9.

2. Backseat (open) compressor suction and discharge

valves. Close valves one turn to allow pressure to reach

test gages.

3. Open liquid line service valve.

4. Set thermostat.

5. Check tightness of all electrical connections.

6. Compressor oil level should be visible in sightglass. See

Service, Oil Charge.

7. Be sure unit is properly leak checked, dehydrated and

charged. See below.

8. Electrical power source must agree with nameplate

rating.

9. Crankcase heater must be firmly locked into compres

sor crankcase. Be sure crankcase is warm (heater should

be on for 24 hours before starting compressor).

10. Be sure compressor floats freely on the mounting

springs. See Compressor Mounting and Fig. 3 for

loosening compressor bolts.

Leak Test and Dehydration — Leak test the entire

refrigerant system by the pressure method described in the

Carrier Service Techniques Manual, Chapter 1, Section 1-6.

Use R-22 at approximately 25 psig backed up with an inert

gas to a total pressure not to exceed 200 psig.

Preliminary Charge — Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-8 for

charging methods and procedures. Charge system with

approximately 25 lbs of R-22 by the liquid charging method

and charging by weight procedure.

Start Unit — Close field disconnect, fan circuit breaker

and set thermostat above ambient temperature so that there

is no demand for cooling. Now, only the crankcase heater is

energized. After the heater has been on for 24 hours, the unit

can be started. If no time has elapsed since the preliminary

charge step has been completed, it is unnecessary to wait the

24-hour period.

Close the compressor circuit breaker, then reset the

indoor thermostat below ambient temperature, so that a call

for cooling is ensured.

NOTE: Do not use the compressor circuit breaker to start

and stop compressor, except in an emergency.

Depending on the position of the Time Guard timer,

start-up of the compressor occurs within 12 seconds and 8

minutes from the time the control circuit is energized.

Charge System — Actual start-up should be done only

under supervision of a qualified refrigeration mechanic.

Refer to charging charts.

See Fig. 10 through 13 for the particular unit being

charged. Measure pressure at the liquid line service valve,

being sure a Schrader depressure is used if required. Also,

measure liquid line temperature as close to the liquid service

valve as possible. Add charge until the pressure and

temperature conditions of the charging chart curve are met.

If liquid pressure and temperature point fall below curve,

add charge. If liquid pressure and temperature point fall

below curve, reduce the charge until the conditions match

the curve.

A CAUTION

Never charge liquid into the low-pressure side of

system. Do not overcharge. During charging or

removal of refrigerant, be sure indoor fan system is

operating.

Operation — Refer to control circuit diagram on the unit,

or in the unit wiring book.

11

Page 15

LiJ

a

Z3

o

UJ

(C

z>

tE

UJ

Q.

s

UJ

19

BOTH OUTDOOR FANS MUST BE OPERATING

o

LIQUID PRESSURE (PSIG) AT LIQUID VALVE

Fig. 10 — 38AK024 Charging Chart, 50/60 Hz

Page 16

UJ

o

LlJ

OC

Z)

l<

cc

UJ

Q.

UJ

z>

o

BOTH OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE (PSIG) AT LIQUID VALVE

Fig. 11 — 38AK028 Charging Chart, 50/60 Hz

Page 17

ijj

%

3

o

<

uT

UJ

cc

3

t-

<

CE

liJ

Q.

LU

t9

3

g

=j

BOTH OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE (PSIG) AT LIQUID VALVE

Fig. 12 — 38AK034 Charging Chart. 50/60 Hz

Page 18

UJ

%

a

3

o

UJ

tr

QC

UJ

Q.

s

UJ

3

o

ALL OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE (PSIG) AT LIQUID VALVE

Fig. 13 — 38AK044 Charging Chart, 50/60 Hz

Page 19

Timer Functions — (See Fig. 14)

Switch A (contacts A-Al and A-A2) provides Time

1.

Guard® Control Circuit function. Start of compressor

is delayed approximately 5.5 minutes after shut-off.

The minimum time between starts of compressor is 8

minutes.

Switch B (contacts B-Bl and B-B2) starts compressor.

Switch D (contacts D-Dl) bypasses the low-pressure

switch (LPS) for 2.5 minutes at start-up for winter start

control.

(BLACK DENOTES CLOSED CONTACTS) TIMER POSITION DURING

OMIN OR

J.P

_ A-AI

A-AZ*^

® -¡-M f-

— E-El

— D-DI

D-D2

----------------

--------h-—COMPRESSOR STARTS

U— 12 SEC +2 1

-----------------

--

-------

-----

'-H I-

----

5 SEC ±2 1

40 SEC i5

-2-6SEC

150 SEC ±5

1 SEC io.5 1

---------

150 SEC ±5

UNIT OPERATION^

----------------------

M 1

2-6 SEC

-5.5 MIN^A--

Fig. 14 — Timer Cycle

Sequence of Operation — At start-up, the thermostat

calling for cooling and all safety devices satisfied, the control

circuit relay (CRl) closes. The indoor fan motor starts imme

diately. With minimal demand for cooling, only TCI of the

thermostat is made. The timer motor starts and condenser fan

no. 1 starts. Fan no. 2 starts if high side pressure is higher than

260 psig (1793 kPa). Fan no. 3 (38AK044 only) starts if

outdoor ambient rises above 80 F. After a delay by Time

Guard® circuit of 12 seconds to approximately 8 minutes

depending on the timer position, the compressor starts and the

primary liquid line solenoid valve opens.

With only TCI calling for cooling, the capacity control

liquid line solenoid is not energized, therefore the suction

pressure is such that the compressor unloads on suction

pressure shortly after compressor start-up. The compressor

operates at either 1 or 2 steps of unloading depending on the

suction pressure which is, in turn, dependent on the

evaporator load conditions. As cooling demand increases,

TC2 of the 2-stage thermostat energizes the capacity control

liquid line solenoid causing full surface of the evaporator to

be active, tending to raise the suction pressure so that the

compressor loads.

A pump-out relay (FOR) in the control circuit is

energized when thermostat contacts make. A set of normally

open FOR contacts close, completing a compressor control

circuit which bypasses the CRl contacts. As cooling

demand is satisfied, the thermostat contacts break, de

energizing CRl. The LLS valve eloses, stopping the flo\v of

liquid refrigerant to the evaporator and subsequent suction

gas to the compressor. The compressor continues to operate

because of the CRl bypass with relay TRl. With no

refrigerant returning to the compressor, low side pumpout

takes place and the compressor shuts down on lowrpressure

control. The compressor does not restart until the thermo

stat again calls for cooling.

Complete Unit Stoppage

CAUSES — Interruption of supplied power, open discharge

gas thermostat (DGT), compressor overtemperature pro

tection, or open high-pressure safety switeh eauses com

pressor stoppage.

RESTART — The unit recycles and restarts automatically

under the Time Guard® device when power is restored.

Stoppage by DGT, HFS, or compressor circuit breaker

requires manual resetting of the control circuit. To restart

the Time Guard timer when DGT or HFS are tripped,

merely open and then close the thermostat contacts. It is

necessary to manually reset the compressor circuit breaker

at the unit.

If LFS is not closed within 2.5 minutes after compressor

starts, the compressor locks out and the outdoor fans

continue to run. It stays locked out for 5.5 minutes until the

timer motor comes back to 0 time (see Fig. 14). At 0 time, the

LFS is jumpered (winter start control). It remains jumpered

for 2.5 minutes. Because the LFS is jumpered, the com

pressor restarts and runs for the 2.5-minute time period. At

the end of this 2.5 minutes, if the LFS has still not closed, the

compressor is again locked out. The timer motor is de

energized and cannot restart until the LFS closes. The

outdoor fans continue to run as long as there is a call for

cooling. Automatic reset of the LFS causes the timer to

recycle so that the compressor can start.

If sufficient compressor oil pressure has not been built

within 2.5 minutes after the compressor starts, the unit is

completely de-energized until the OFS is manually reset at

the unit.

A CAUTION

If unit or circuit stoppage occurs more than once due

to any safety device, the trouble should be corrected

before any attempt to restart.

16

Page 20

SERVICE

A CAUTION

Turn off all power to unit before proceeding.

OIL PRESSURE SAFETY SWITCH is reset by opening

the side access door on the left side of the unit (as viewed

from the compressor end). The liquid line service valve can

be found behind the side access door on the right-hand side

of the unit (as viewed from the compressor end).

Access for Servicing (See Fig. 15)

COMPRESSOR SECTION — The compressor compart

ment has 2 side doors and one front door for servicing,

providing access to compressor, all components of the

refrigeration system, electrical controls and control box.

After opening front door an inner cover must be removed

for access to control box.

CONDENSER SECTION — Condenser fan motors and

fans can be serviced by removal of outlet grilles or side

panels. If a fan motor is serviced, be sure the wire fan guard

is in place over each fan before starting unit. See Fig. 16 for

proper fan adjustment. Tighten fan hub securely on motor

shaft with setscrew which bears against the key. Be sure to

replace Permagum and rubber cap over end of motor shaft

to protect against moisture causing fan to rust on shaft.

COMPRESSOR END AND RIGHT-SIDE VIEW

OIL

PRESSURE—

SWITCH

COMPRESSOR END, LEFT-SIDE ACCESS DOOR

Fig. 15 — 38AK Unit with Access Panels Removed

COMPRESSOR END, CONTROLS PANEL REMOVED

COMPRESSOR END, RIGHT-SIDE ACCESS DOOR

(38AK024 Shown)

Page 21

Fan Adjustment (See Fig. 16)

TOP OF FAN ORIFICE

ORIFICE

FAN SHAFT

PROP LOCATION

60 Hz

36AK024

38AK028-034

38AK044

50 Hz

38AK024

38AK028,034,044

3.12(79.2)

3.62(91.9) 3.88 (98.6)

3.62(91.9)

3.12(79.2)

FILL HOLE IN FAN HUB

WITH PERMAGUM

“A” in (mm)

Min. Max.

Fig. 16 — Location of Prop on Motor Shaft

from Outside of Orifice Ring

FAN BLADE

HUB PLATE

3.38 (85.9)

3.88 (98.6)

338(85.9)

Liquid Shutoff/Charging Valve is located inside the

compressor compartment and is provided with 1/4-in. flare

connection for field charging.

Capacity Control is by either one or 2 suction pressure

actuated unloaders. Each controls 2 cylinders. Unloaders

are factory set (see Table 1) but may be field adjusted.

Number 1 unloader is on cylinder bank on same side of

compressor as terminal box.

CONTROL SET POINT — The control set point (cylinder

load point) is adjustable from 0 to 85 psig. To adjust, turn

control set point adjustment nut (Fig. 17) clockwise to its

bottom stop. In this position, set point is 85 psig. Then, turn

adjustment counterclockwise to desired control set point.

Every full turn counterclockwise decreases set point by 7.5

psig.

CONTROL

SET POINT

ADJUSTMENT

NUT

Oil Charge — Compressors are factory charged with oil

as follows:

COMPRESSOR

06E4250

06E9265

06E9275

06E9299

AMOUNT

pints (liters)

14(6.6)

19(9.0)

19(9.0)

19(9.0)

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil:

Witco Chemical Corp

.......................................

Suniso 3GS

Texaco, Inc................................................... Capella WF-32

Shrieve Chemical Co

..........................

Zerol 150 (Synthetic)

IMPORTANT: Do not use drained oil or use oil that

has been exposed to atmosphere. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants, for procedures to add or remove oil.

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

BYPASS PISTON

DIFFERENTIAL SCREW SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

POWER HEAD

VALVE BODY

Fig. 17 — Capacity Control Valve

PRESSURE DIFFERENTIAL—The pressure differenti^

(difference between cylinder load and unload points) is

adjustable from 6 to 22 psig. To adjust, turn pressure

differential adjustment screw (Fig. 17) counterclockwise to

its backstop position. In this position, differential is 6 psig.

Then, turn adjustment clockwise to desired pressure differ

ential. Every full turn clockwise increases differential by 1.5

psig.

18

Page 22

Oil Pressure Safety Switch (OPS) in the control

circuit stops the compressor, and unit, if proper oil pressuré

differential is not established at start-up or maintained

during operation. If OPS stops the unit, determine the cause

and correct before restarting unit. Failure to do so will

constitute abuse. Equipment failure due to abuse may void the

Warranty.

Low-Pressure Switch has fixed, nonadjustable settings.

Switch is mounted on the compressor.

TO CHECK — Slowly close liquid shutoff valve and allow

compressor to pump down. Do not allow compressor to

pump down below 2 psig (13.8 kPa). Compressor should i

shut down when suction pressure drops to cutout pressure in'

Table 4, and should restart when pressure builds up to cut-in

pressure shown.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual reset,

ambient compensated, magnetic breaker protects against

motor overload and locked rotor conditions.

DISCHARGE THERMOSTAT — A sensor in the dis

charge gas of 06E compressor reacts to excessively high

discharge gas temperature and shuts off the compressor.

TIME GUARD® control protects compressor against short

cycling. See Sequence of Operation (page 16).

CRANKCASE HEATER minimizes absorption of liquid

refrigerant by oil in crankcase during brief or extended

shutdown periods. Control circuit is maintained if com

pressor fan motor circuit breakers are turned off. Main

disconnect must be on to energize crankcase heater.

IMPORTANT: Never open any switch or disconnect

that de-energizes the crankcase heater unless unit is

being serviced or is to be shut down for a prolonged

period. After a prolonged shutdown on a service job,

energize the crankcase heater for 24 hours before

starting the compressor.

High-Pressure Switch has fixed, nonadjustable set

tings. Switch is mounted on the compressor.

TO CHECK — Open the condenser fan circuit breaker.

Head pressure builds up until compressor shuts down. This

should be at the cutout pressure in Table 4. Close condenser

fan circuit breaker. After pressure drops to cut-in setting,

reset control circuit by opening, then closing the control

circuit switch. After control circuit is reset, the Time Guard

timer cycles and in approximately 5.5 minutes the com

pressor restarts.

Table 4 — Pressure Switch Settings, psig (kPa)

HIGH PRESSURE

Cutout

426 ±7 320 ± 20 27 + 3

(2937 ± 48) (2206 + 138) (186 + 21) (303 + 34)

Cut-in

LOW PRESSURE

Cutout Cut-in

44 + 5

Winter Start Control — Switch D in the 4-function

timer bypasses low-pressure switch for 2(4 minutes on unit

start-up.

Head Pressure Control reduces condensing capacity

under low ambient temperature conditions.

FAN CYCLING — These 38AK units have standard

provision for fully automatic intermediate-season head

pressure control through condenser fan cycling. Fan no. 2 is

cycled by a fan cycling pressure switch (FCPS) which

responds to variation in discharge pressure. The pressure

sensor is located in the liquid line of the refrigerant circuit.

Fan no. 3 cycling is controlled by outdoor air temperature

through an air temperature switch (ATS) (38AK044 units

only).

The ATS is located in the lower divider panel between the ,

compressor compartment and condenser section. Through i

a hole in the panel, the sensing element is exposed to air

entering the no. 1 fan compartment. Fan no. 1 is non

cycling. Table 5 shows the operating settings of the fan

cycling pressure switch and the air temperature switch.

Table 5 — Fan Cycling Controls

CONTROL BY SWITCH OPENS

Temp, F (C)

Pressure,

psig (kPa)

NOTE: See Fig. 6, 7, 8 for fan arrangement

70 + 3(21 +1.7) 80 + 3 (27 + 1.7)

160 + 10(1103 + 69)

SWITCH CLOSES

260+ 15(1793 + 103)

19

Page 23

TROUBLESHOOTING

SYMPTOM AND PROBABLE CAUSE

COMPRESSOR DOES NOT RUN

1. Power line open

2. Oil pressure switch tripped

3. Safety device tripped

4. Contactor stuck open

5. Loose terminal connection

6. Improperly wired controls

7. Seized compressor

8. Low line voltage

9. Compressor motor defective

COMPRESSOR STOPS ON LOW-PRESSURE

CONTROL

1. Compressor suction shutoff valve partially closed

2. Low refrigerant charge

3. Liquid line solenoid valve(s) fails to open

COMPRESSOR STOPS ON HIGH-PRESSURE

CONTROL

1. Compressor discharge valve partially closed

2. Air in system

3. Condenser fan(s) not operating

UNIT OPERATES TOO LONG OR CONTINUOUSLY

1. Low refrigerant charge

2. Control contacts fused

3. Air in system

4. Partially plugged expansion valve or filter drier

PROBABLE REMEDY

1. Reset circuit breaker

2. Reset oil pressure switch at unit

3. Reset control circuit with thermostat

4. Replace contactor

5. Check connections

6. Check and rewire

7. Check motor winding for open or short. Replace

compressor, if necessary

8. Check line voltage — determine location of

voltage drop and remedy deficiency

9. Check motor winding for open or short. Replace

compressor, if necessary

1. Open valve

2. Add refrigerant

3. Check liquid line solenoid valve for proper operation.

Replace if necessary

1. Open valve or replace if defective

2. Purge and evacuate system

3. Check motor wiring and repair or replace if defective

1. Add refrigerant

2. Replace control

3. Purge and evacuate system

4. Clean or replace

SYSTEM IS NOISY

1. Piping vibration

2. Compressor noisy

COMPRESSOR LOSES OIL

1. Leak in system

2. Crankcrase heaters not energized during shutdown

3. Inadequate piping

FROSTED SUCTION LINE

1. Expansion valve admitting excess refrigerant

HOT LIQUID LINE

1. Shortage of refrigerant due to leak

2. Expansion valve opens too wide

FROSTED LIQUID LINE

1. Restricted filter drier

COMPRESSOR WILL NOT UNLOAD

1. Defective unloader

2. Defective capacity control solenoid valve

3. Miswired liquid line solenoid

4. Weak, broken or wrong valve body spring

COMPRESSOR WILL NOT LOAD

1. Miswired capacity control liquid solenoid

2. Defective capacity control solenoid valve

3. Plugged strainer (high side)

4. Stuck or damaged unloader piston or piston ring(s)

1. Support piping as required

2. Check valve plates for valve noise. Replace

compressor if bearings are worn

1. Repair leak

2. Check wiring and relays. Check heater and replace

if defective

3. Check piping for oil return. Replace if necessary

1. Adjust expansion valve

1. Repair leak and recharge

2. Adjust expansion valve

1. Remove restriction or replace

1. Replace

2. Replace valve

3. Rewire correctly

4. Replace spring

1. Rewire correctly

2. Replace valve

3. Clean or replace strainer

4. Clean or replace the necessary parts

20

Page 24

Book 1

Tab

1

3a

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC111

Catalog No 563-915 Printed in U S A Form 38AK-1SIM Pg21 11-89

Replaces: New

V.

Loading...

Loading...