Page 1

38AK007

HEATING & COOLING

Installation, Start-Up and Service

Instructions

SAFETY COIMSIDERATIONS

Installing and servicing air-conditioning equipment can

be hazardous due to system pressure and electrical compo

nents. Only trained and qualified service personnel should

install or service air-conditioning equipment.

When working on air-conditioning equipment, observe

precautions in literature and on tags and labels attached to

unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available. Read these instructions thor

oughly. Consult local building codes and National Electri

cal Code (NEC) for special installation requirements.

A WARNING

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Electrical shock can cause personal

injury.

Air-Cooled Condensing Unit

INSTALLATION

Step 1 — Complete Pre-Installation Checks

UNCRATE UNIT — Remove unit packaging except for

the top skid assembly and wood bumpers, which should be

left in place until after unit is rigged into place.

INSPECT SHIPMENT — File claim with shipping com

pany if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and NEC for special instal

lation requirements.

• Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Eig. 1 and

Table 1.

• Locate unit so that condenser airflow is unrestricted on

all sides and above. Refer to Fig. 1.

• Unit may be mounted on a level pad directly on base

rails or mounted on raised pads at support points. See

Table 2 for weight distribution based on recommended

support points.

NOTE: If vibration isolators are required for a particular in

stallation, use data in Table 2 to make proper selection.

Table 1 — Physical Data

UNIT 38AK

OPER WEIGHT (lb)

REFRIGERANT*

COMPRESSOR

on (oz) 65

CONDENSER AIR FAN

Number...Rpm 60 Hz

Diameter (in.)

Motor Hp (NEMA)

Nominal Cfm Total

CONDENSER COIL

Face Area (sq ft)

Storage Capacity (lb)t

CONNECTIONS (sweat)

Suction (in.)

Liquid (In.)

CONTROLS

Pressurestat Settings

High Cutout

Low Cutout

FUSIBLE PLUG 200 F

‘Unit is factory supplied with holding charge only.

fStorage capacity of condenser coil with coil 80% full of liquid R-22

at 124 F

50 Hz

Cut-in

Cut-in

Propeller; Direct Drive

007

340

22

1.. .850

1.. 708

26

Vs

3800

12 24

11.264

1V8

V2

426 ± 7 psig

320 ± 20 psig

7 ± 3 psig

22 ± 5 psig

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC 111 Catalog No 633-809 Printed in U.S A Form 38AK-2SI Pg 1 6-92 Replaces: New

Tab 3a 2a

Page 2

Table 2 — Weight Distribution

STD. UNIT

UNIT

38AK007

UNIT

38AK007 77

WEIGHT

lbs.

340

CORNER WEIGHT

lbs.

CORNER WEIGHT

lbs.

kg.

154

(C)

86

kg.

35

(A)

CORNER WEIGHT

kg. lbs.

39 53

CORNER WEIGHT

(D)

lbs. kg.

124 56

(B)

kg.

24

REFRIGERANT PIPING SIZES

EQUIVALENT LENGTH OF PIPING - FT

IVe V2

76-100

s

IVs

COND

UNIT

38AK007

L — Liquid Line S — Suction Line

NOTES:

1. Pipe sizes are based on a 2° F loss for liquid and suction lines

2. Pipe sizes are based on an equivalent length equal to the max

imum length of interconnecting piping plus 50 percent for fittings.

3. Charge units with R-22 in accordance with unit installation

instructions.

0-25 26-50 51-75

Line Size (in. OD)

L

V2 IVs

L s L s L

s

IVa

V2

Va

SIZE REFRIGERANT LINES - Consider length of pip

ing required between condensing unit and evaporator, amount

of liquid lift, and compressor oil return. See Table 3 and

also refer to Part 3 of Carrier System Design Manual for

design details and line sizing. Refer to evaporator installa

tion instructions for additional information.

INSTALL FILTER DRIER AND MOISTURE INDICA

TOR — The filter drier is factory supplied and field in

stalled. Moisture indicator is a field-installed option and should

be installed just after liquid line shutoff valve. Do not use a

receiver; there is none provided with unit and one should

not be used.

NOTE: Unit is shipped with R-22 holding charge. System

pressure must be relieved before removing caps.

Pass nitrogen or other inert gas through piping while braz

ing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve to evap

orator section. It is recommended that a field supplied liq

uid line solenoid be positioned in the main liquid line close

to the evaporator coil, and wired to close when compressor

stops to minimize refrigerant migration during the “OFF”

cycle.

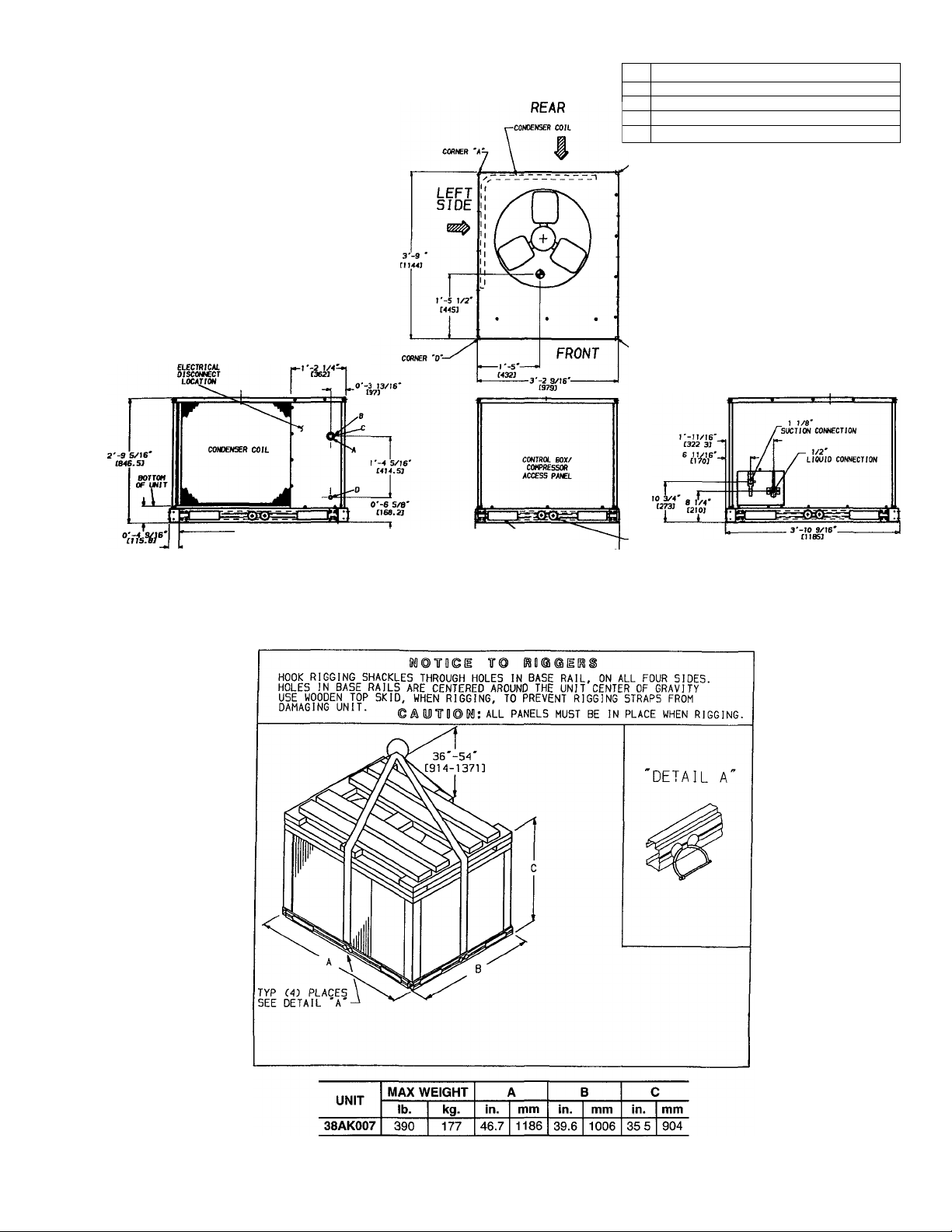

Step 2 - Rig and Mount the Unit

ik CAUtlON

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rig

ging. Refer to rigging label for preferred rigging method.

Spreader bars are not required if top crating is left on unit.

All panels must be in place when rigging. (See Fig. 2) As

further protection for coil faces, plywood sheets may be

placed against sides of unit, behind cables. Run cables to a

central suspension point so that angle from the horizontal is

not less than 45 degrees. Raise and set unit down carefully.

If it is necessary to roll unit into position, mount unit on

rails, using a minimum of 3 rollers. Apply force to rails,

not unit. If unit is to be skidded into position, place it on a

large pad and drag it by the pad. Do not apply any force to

unit.

Raise from above to lift unit from rails or pad when unit

is in final position.

After unit is in position, remove all shipping wrapping

and top crating.

Step 3 — Complete Refrigerant Piping Connec

tions — Suction connection is 1-1/8-in. sweat with plas

tic cap; liquid connection is 1/2-in. sweat with plastic cap.

Follow standard piping practices.

Table 3 — Liquid Line Data

MAX

UNIT 38AK007

60 Hz

50 Hz

NOTE: Values shown are for units operating at 45 F saturated suc

tion and 95 F entering air

ALLOWABLE

LIQUID

LIFT (ft)

86 7

72

Max Allowable

Pressure Drop

LIQUID LINE

(psi)

7

Max Allowable

Temp Loss

(F)

2

2

Step 4 — Make Electrical Connections

A WARNING

Unit cabinet must have an uninterrupted, unbroken elec

trical ground to minimize the possibility of personal in

jury if an electrical fault should occur. This ground may

consist of electrical wire connected to unit ground lug

in control compartment, or conduit approved for elec

trical ground when installed in accordance with NEC

ANSI (American National Standards Institute)/NFPA

(National Fire Protection Association) 70-1987 and lo

cal electrical codes. Failure to follow this warning could

result in the installer being liable for personal injury of

others.

Page 3

NOTES:

1. Dimensions in are in miiiimeters.

Center of gravity.

3

4 Minimum ciearance (locai codes or jurisdiction may

5. With the exception of the clearance for the condenser

6 Units may be installed on combustible floors made from

Direction of air fiow.

prevaii):

a Bottom to combustibie surfaces 0 in.

b Condenser coil, for proper air flow, 36 in. one side,

12 in the other The side getting the greater ciear

ance is optionai

c Overhead, 60 in to assure proper condenser fan op

eration.

d Between units, controi box side, 42 in per NEC.

e Between unit and ungrounded surfaces, control box

side, 36 in per NEC

f Between unit and block or concrete walls and other

grounded surfaces, control box side, 42 in per NEC

coil as stated in notes 5a, b, and c, a removable fence

or barricade requires no clearance

wood or class A, B, or C roof covering material

A 1%” DIA. [35] FIELD POWER SUPPLY HOLE

CONNECTION SIZES

B 2” DIA. [51] POWER SUPPLY KNOCK-OUT

c 2V2'’ dia [64] POWER SUPPLY KNOCK-OUT

Ve" DIA [22] FIELD CONTROL WIRING HOLE

D

rxp ÍKMSr

► -0'-2 9/16

LEFT SIDE

-3’-S 3/IS"

Fig. 1 -

FORIC TRUX SLOTS

<3 SlOeS ÚM.W

u 3'-3 1/2'

0003}

-------------------

FRONT

Dimensions (ft-in.)

0*-2 Ì/4'DJA Í57J

(TYP 0 PLACES)

RIGHT SIDE

Fig. 2 - Rigging Label

Page 4

FIELD POWER SUPPLY - All units except 208/230-v

units are factory wired for the voltage shown on the name

plate. If the 208/230-v unit is to be connected to a 208-v

power supply, the transformer must be rewired by moving

the black wire from the 230-v orange wire on the trans

former and connecting it to the 200-v red wire from the

transformer. The end of the orange wire must then be

insulated.

Refer to unit label diagram for additional information.

Pigtails are provided for field wire connections. Use

factory-supplied splices or UL (Underwriters’ Laborato

ries) approved copper/aluminum connector.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local

requirements.

Install field wiring as follows;

1. Install conduit through side panel openings.

2. Install power lines to connections as shown in Fig. 3.

Wrap connections with electrical tape.

Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Table 4). On 3-phase units, voltages between phases

must be balanced within 2% and the current within 10%.

Use the formula shown in Table 4, Note 2, to determine the

% voltage imbalance. Operation on improper line voltage

or excessive phase imbalance constitutes abuse and may cause

damage to electrical components. Such operation would in

validate any applicable Carrier warranty.

LEGEND

C — Contactor

NEC — National Electrical Code

----------

Field Wiring

Factory Wiring

Splice Connection

(Factory Supplied)

Fig. 3 — Power Wiring Connections

Table 4 — Electrical Data

UNIT

NOMINAL VOLTAGE

(V-Ph-Hz)

208/230-3-60

460-3-60

38AK007 575-3-60

220-3-50

400-3-50

LEGEND

CSA

FLA

HACR

LRA

MCA

MOCP

NEC

OFM

RLA

NOTES:

1 In compliance with NEC requirements for multimotor and combi

nation load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR

breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt

age is greater than 2%. Use the following formula to determine

the % voltage imbalance.

= 100 X

Canadian Standards Association

Full Load Amps

Heating, Air Conditioning and Refrigeration

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Outdoor (Condenser) Fan Motor

Rated Load Amps

max voltage deviation from average voltage

---------------------------------------------------------

average voltage

-----------------------------------

VOLTAGE RANGE COMPR OFM

MIN MAX

187 254 19.0 142 1.9 25 6 351

414 508

518

198 242

360 440

RLA LRA FLA MCA MOCP

9.5 72

632 76 58 1.9

19.0 142

9.5 72

Example: Supply voltage is 460-3-60.

AB = 452 V

BC = 464 V

AC = 455 V

Average Voltage =

NOTE: The 575-v units are CSA only.

(AB) 457 - 452 = 5 V

(BC) 464 - 457 = 7 V

(AC) 457 - 455 = 2 V

Maximum deviation is 7 v.

Determine % voltage imbalance

% Voltage Imbalance = 100 x — = 1 53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

1 0 12.9

1.9

1.0 129

POWER SUPPLY

11.4 15.2

25.6 35.1

452 -H 464 -H 455

1371

7

457

17.6

17.6

3

^ 457

IMPORTANT: If the supply voltage phase imbalance is more

than 2%, contact your local electric utility company immedi

ately.

Page 5

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation in

structions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense

average temperature in accordance with thermostat instal

lation instructions.

Route thermostat cable or equivalent single leads of col

ored wire from subbase terminals to low-voltage connec

tions on unit (shown in Fig. 4) as described in Steps 1 through

3 below.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (Amer

ican Wire Gage) insulated wire (35 C minimum). For 50 to

75 ft, use no. 16 AWG insulated wire (35 C minimum).

For over 75 ft, use no. 14 AWG insulated wire (35 C min

imum). All wire larger than no. 18 AWG cannot be directly

connected to the thermostat and will require a junction box

and splice at the thermostat.

1. Connect thermostat wires to screw terminals of lowvoltage connection board.

2. Pass the control wires through the hole provided in the

comer post.

3. Feed wire through the raceway built into the comer post

to the 24-v barrier located on the left side of the control

box. See Fig. 5. The raceway provides the UL required

clearance

between the high- and low-voltage

wiring.

THERMOSTAT CONNECTIONS

THERMOSTAT

WIRING CONNECTIONS

FOR STANDARD UNIT

UNIT CONNECTION

BOARD

Fig. 4 — Control Wiring Connections

START-UP

Preliminary Checks

1. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

2. Field electrical power source must agree with unit name

plate rating.

3. All service valves must be open.

Leak Test — Test entire refrigerant system by using soap

bubbles and/or an electronic leak detector.

Evacuate and Dehydrate — Evacuate and dehy

drate entire refrigerant system by use of the methods de

scribed in GTAC II, Module 4, System Dehydration.

Refrigerant Charge — Refer to GTAC II, Module 5,

Charging Recovery, Recycling and Reclamation.

Unit panels must be in place when unit is operating dur

ing charging procedure.

Unit is shipped with holding charge only. Weigh in 7 lbs

R-22 to start unit.

NO CHARGE — Use standard evacuating techniques. Af

ter evacuating system, weigh in the specified amount of re

frigerant. (Refer to Table 1.)

LOW CHARGE COOLING - Use Cooling Charging Chart,

Fig. 6. Vary refrigerant until the conditions of the chart are

met. Note the charging chart is different from type nor

mally used. Chart is based on charging the units to the cor

rect subcooling for the various operating conditions. Accu

rate pressure gage and temperature sensing device are required.

Connect the pressure gage to the service port on the liquid

line service valve. Mount the temperature sensing device

on the liquid line, close to the liquid line service valve and

insulate it so that outdoor ambient temperature does not af

fect the reading. Indoor-air cfm must be within the normal

operating range of the unit.

Operate unit and adjust charge to conform with charging

chart, using liquid pressure and temperature to read chart.

TO USE COOLING CHARGING CHART - Initially charge

with 7 lbs. R-22. Place pressure gage at liquid line service

valve. Install thermocouple to liquid line near the liquid line

service valve. Operate unit. Plot liquid pressure and tem

perature on chart and add or reduce charge to meet curve.

HOLE IN

END PANEL

(HIDDEN)

Fig. 5 - Field Control Wiring Raceway

CHARGING CHART - 38AK007

OUTDOOR FAN MUST BE OPERATIN0

Q.

g

uj

>

/

Q

1

<

p

< 90-

tt

UJ

1

2

5

o

AC

Ì » 1 F AG5^

/

:

UR№

7

/

i

2

2

/

/

« XX£

:h

UMe IF« .iU

a

Ì

UOUiO

0 2

PRESSURE

h 0 r

s

LIQUID

0 25

0 31

VALVE (PS

0 3!

IG)

0 400

Fig. 6 — Cooling Charging Chart — 38AK007

ve

i

Page 6

Unit Preparation — Make sure that unit has been in

stalled in accordance with installation instructions and ap

plicable codes.

Compressor Mounting — Compressors are inter

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required.

Time Guard II® Device — Time Guard II Circuit pro

vides for a delay of approximately 5 minutes before restart

ing compressor after shutdown from safety device action.

On start-up, the Time Guard timer causes a delay of ap

proximately 15 seconds after thermostat closes.

Refrigerant Service Ports — Each unit system may

have Schrader type service ports: one on the suction line,

one on the liquid line, and one on the compressor discharge

line. Be sure that caps on the ports are tight.

Cooling — Set space thermostat to OFF position. Set sys

tem selector switch at COOL position and fan switch at AUTO,

position. Adjust thermostat to a setting below room tem

perature. Compressor starts on closure of contactor.

Check cooling effects at a setting below room tempera

ture. Check unit charge. Refer to Refrigerant Charge sec

tion on page 5.

Reset thermostat at a position above room temperature.

Compressor will shut off.

SERVICE

A CAUTION

When servicing unit, shut off all electrical power to

unit to avoid shock hazard or injury from rotating parts.

Cleaning — Inspect unit interior at the beginning of each

cooling season and as operating conditions require.

CONDENSER COIL — Inspect coil monthly. Clean con

denser coil annually and as required by location or outdoorair conditions.

Clean coil as follows:

1. Turn off unit power.

2. Remove top panel screws on condensing unit.

3. Remove condenser coil comer post. See Fig. 7. To hold

top panel open, place coil comer post between top panel

and side panel. See Fig. 8.

CONTROL BOX

CORNER POST

TO SHUT OFF UNIT - Set system selector switch at OFF

position. Resetting thermostat at a position above room tem

perature shuts unit off temporarily until space temperature

exceeds thermostat setting. Units are equipped with CycleLOC™ protection device. Unit shuts down on any safety

trip and remains off; an indicator light on thermostat comes

on. Check reason for safety trip.

Compressor restart is accomplished by manual reset at

the thermostat by turning the selector switch to OFF posi

tion and then to ON position.

Sequence of Operation — At start-up, the thermo

stat calls for cooling, and with all safety devices satisfied,

the compressor contactor and fan contactor will energize,

causing the compressor and outdoor-fan motor to operate.

Contacts on TBl terminals 1 and 2 are also energized, al

lowing the field supplied and installed indoor-fan contactor

to function. A field supplied and installed liquid line valve

(connect to TB1 terminals 3 and 4) will also open, allowing

the system to function in cooling. As cooling demand is

satisfied, the thermostat contacts break, deenergizing the

contactor causing the system to shut off. The liquid line

shutoff valve closes minimizing the potential for refrigerant

migration at this time. The compressor does not restart un

til the thermostat again calls for cooling. If a demand for

cooling occurs within 5 minutes after the thermostat is sat

isfied, the system will not restart due to the feature of Time

Guard®II. After the 5 minute time period, the system will

restart as normal upon thermostat demand. The system is

protected with Cycle-Loc device so that the compressor will

not start if a high-pressure or low-pressure fault occurs. Merely

turn down the thermostat to eliminate the cooling demand

to reset the Cycle-Loc device. This should be done only

once, and if system shuts down due to the same fault, de

termine the problem before attempting to reset the CycleLoc device. The 38AK007 unit does not require a crank

case heater.

Fig. 7 — Cleaning Condenser Coil

Page 7

TOP VIEW

4. Remove device holding coil sections together at return

end of condenser coil. Carefully separate the outer coil

section 3 to 4 in. from the inner coil section. See

Fig. 9.

5. Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and de

bris. Clean the outer surfaces with a stiff brush in the

normal manner.

6. Reposition the outer coil section, and remove the coil

comer post from between the top panel and side panel.

Secure the sections together. Install the coil comer post

and replace all screws.

Condenser-Fan Adjustment (Fig. lO)

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor

cover, and fan).

3. Loosen fan hub setscrews.

4. Adjust fan height as shown in Fig. 10.

5. Tighten setscrews.

6. Replace condenser-fan assembly.

MOTOR COVER OUTLET GRILLE

Fig. 10 — Condenser-Fan Adjustment

Lubrication

COMPRESSORS — Each compressor is charged with cor

rect amount of oil at the factory.

FAN MOTOR BEARINGS — Fan motor bearings are of

the permanently lubricated type. No further lubrication is

required.

Page 8

TROUBLESHOOTING GUIDE

COMPRESSOR DOES NOT RUN

Contactor Open

Power off — restore power.

Fuses blown — replace with correct fuses after finding cause

and correcting.

Transformer dead — replace transformer if primary wind

ings are receiving power.

Thermostat circuit open — check thermostat setting.

Low-pressure switch open — check for refrigerant under

charge or obstruction of indoor airflow.

High-pressure switch open — check for refrigerant over

charge or obstruction of outdoor airflow.

Connections loose — tighten all connections.

Compressor motor thermostat open — check for excessive

motor temperature.

Contactor Closed

Compressor leads loose — check connections.

Single phasing — replace blown fuse.

COMPRESSOR CYCLES ON

HIGH-PRESSURE SWITCH

Condenser Fan On

High-pressure switch faulty — replace switch.

Airflow restricted — remove obstruction.

Air recirculating — clear airflow area.

Noncondensables in system — purge and recharge as re

quired.

Refrigerant overcharge — purge as required.

Refrigerant system restrictions — check or replace filter

drier, expansion valve, etc.

Condenser Fan Off

Fan slips on shaft — tighten fan hub setscrews.

Motor not running — check power and capacitor.

Motor bearings stuck — replace bearings.

Motor overload open — check overload rating. Check for

fan blade obstruction.

Motor burned out — replace motor.

COMPRESSOR CYCLES ON

LOW-PRESSURE SWITCH

Evaporator Air Fan Running

Filter drier plugged — replace filter drier.

Expansion valve power head defective — replace power

head.

Low refrigerant charge — add charge. Check low-pressure

switch setting.

Airflow Restricted

Evaporator coil iced up — check refrigerant charge.

Evaporator coil dirty — clean coil fins.

Indoor air filter dirty — clean or replace filters.

Indoor air dampers closed — check damper operation and

position.

Evaporator Air Fan Stopped

Electrical connections loose — tighten all connections.

Fan relay defective — replace relay.

Motor overload open — check power supply.

Motor defective — replace motor.

Fan belt broken or slipping — replace or tighten belt.

COMPRESSOR RUNS BUT

COOLING INSUFFICIENT

Suction Pressure Low

Refrigerant charge low — check charge.

Head pressure low — check refrigerant charge.

Indoor-air filters dirty — clean or replace filters.

Expansion valve power head defective — replace power

head.

Evaporator coil partially iced — check low-pressure

setting.

Evaporator airflow restricted — remove obstruction.

Suction Pressure High

Heat load excessive — check for open doors or windows.

Copyright 1992 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |4 PC 111 Catalog No 533-809 Printed in U S A Form 38AK-2SI Pg 8 6-92 Replaces: New

Tab 3a 2a

Loading...

Loading...