Page 1

38AK,38AKS,38AQS008-012

48/50H J,48/50TJ,50LJQ008-014

Accessory Low Ambient Operation

Motormaster® III Control Package

Installation Instructions

Part Numbers: CAMOTOR3001AOO, CAMOTOR3002A00

50/60 Hz

CONTENTS

Page

SAFETY CONSIDERATIONS

GENERAL

..............................................................

...................................

1

1,2

INSTALLATION......................................................2-16

Step 1 — Install Motor .............................................2

Step 2 — Install Motormaster III

Controller

..............................................................

3

Step 3 — Install Sensor ...........................................3

Step 4 — Make Electrical Connections

.................

6

Step 5 — Install Field-Fabricated

Wind Baffies and Brackets

..................................

6

Step 6 — Restore Power to Unit..............................6

TROUBLESHOOTING

..........................................

17

SAFETY CONSIDERATIONS

Installation, start-up, and servicing of this equipment

can be hazardous due to system pressures, electrical com

ponents, and equipment location (roofs, elevated struc

tures, etc.)-

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature and on tags, stickers, and labels attached to

the equipment and any other safety precautions that may

apply.

A WARNING

Open all remote disconnects before servicing this equip

ment. Electrical shock could result in personal injury.

GENERAL

This book contains instructions for the installation,

start-up, and service of the Motormaster III control on

38AKS008-012, 38AQS008, 38AK008-012, 48/50TJ008-

014, 48/50HJ008-014, and 50LJQ008,012 units. The

Motormaster III control is not used on 50-Hz versions of

the 50HJ008-014 and 50LJQ008,012 units.

NOTE: The Motormaster III control is not used on 48/50HJ

and 48/50TJ units with 2 condenser fans. The control is

used on single condensing fan units only.

The Motormaster III accessory is UL (Underwriters’ Lab

oratories) and CSA (Canadian Standards Association)

approved on all split system and small rooftop electric cool

ing and gas heating/electric cooling units.

The Motormaster III device is a motor speed control de

vice which adjusts condenser fan motor speed in response

to declining liquid temperatures. A properly applied Motormaster III control extends the operating range of air condi

tioning systems and permits operation at lower outdoor am

bient temperatures.

Table 1 shows the ambient temperature in cooling at which

each unit will operate without modification.

Table 1 — Unit Ambient Temperature Operation

UNIT

Small Rooftop Units

All 100%

Split System Units

38AQS008 (60 Hz) 100%

38AK/AKS008

(50/60 Hz)

38AKS009 (60 Hz) 100%

38AKS009 (50 Hz) 100% 90 (32) 57 (14)

38AKS012*

(50/60 Hz)

38AK012

(50/60 Hz)

* Unit has one step of unloading.

COMPRESSOR

CAPACITY

100%

100%

67%

100%

CONDENSER

TEMP

F(C)

90 (32)

90 (32)

90 (32)

90 (32) 53 (12)

90 (32)

80 (27)

90 (32)

MINIMUM

OUTDOOR

TEMP

F(C)

25 (--1)

55 (13)

60 (15)

48 (9)

52 (11)

52 (11)

To operate the units below the ambient temperatures in

Table 1, wind baffles and the Motormaster III control pack

age must be added. The Motormaster III control permits

operation of the unit to an ambient temperature of -20 F

(-29 C) for small rooftop units, and 0 F (-18 C) for split

system units.

The Motormaster III regulates the speed of 3-phase fan

motors which are compatible with the control. These

motors are included in the package. See Tables 2 and 3 for

the contents of the Motormaster III accessory packages.

The CAMOTOR3001A00 package contains a motor for

208/230 volt, 60 Hz and 220 volt, 50 Hz applications. The

CAMOTOR3002A00 package contains a motor for 460

and 575 volt, 60 Hz and 400 volt, 50 Hz applications. See

Fig. 1.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |1 |1 |1 |4 |4 |4 |4 PC 111 Catalog No 533-803 Printed in U S A. Form 38/48/50-4SI Pg 1 1-95 Replaces: New

Tab la 1b 3a 5a 2a 5a 6a 6b

Page 2

Table 2 - Motormaster® III Control Package

CAMOTOR3001A00, 208/230 v, 60 Hz and 220 v,

50 Hz Applications

INSTALLATION

Step 1 — Install Motor

QUANTITY

1 Motormaster III Control HR46GN001

1

1

8 Screw (5/16-In.)

1 Relay

2

1 Bracket 50DK507132

1 Socket HY07RB030

Sensor 30GT412176

Motor

Screw (no. 6 — 20 X 3/4-ln )

ITEM

PART NO.

HD52GK208

AL81AS216

HN61KZ024

AL56AU128

Table 3 — Motormaster III Control Package

CAMOTOR3002A00, 460 and 575 v, 60 Hz and

400 V, 50 Hz Applications

QUANTITY ITEM

1

1 Sensor

1

8

1 Relay

2 Screw (no. 6 — 20 X 3/4-in.)

1

1 Socket

Motormaster III Control

Motor HD52GK460

Screw (5/16-in )

Bracket

PART NO.

HR46GN001

30GT412176

AL81AS216

HN61KZ024

AL56AU128

50DK507132

HY07RB030

Before Installing — inspect the contents of the acces

sory package before installing. File a claim with the ship

per if shipping damage is found. Contact the Carrier dis

tributor if a part is missing.

3 1/4 IN.

(83 mm)

A WARNING

To avoid the possibility of electrical shock, open all

disconnects before installing or servicing this

accessory.

1. Shut off unit power supply.

2. Remove unit access panel and control box cover.

3. Disconnect fan motor connection in control box and

remove motor leads from control box.

4. Remove condenser fan assembly (grille, motor, motor

cover, and fan) by removing the 6 grille holddown screws.

5. Loosen fan hub set screws and remove condenser fan

from motor shaft.

6. Carefully lift off motor cover.

7. Remove the 4 holddown nuts that attach the motor to

the grille. Pull the motor wires through the grille

conduit.

8. Cut back the steel conduit on the grille (one grille wire

width) to allow adequate space for new fan motor.

9. Feed the Motormaster III motor wires through the con

duit and install motor from accessory kit onto grille us

ing nuts from Step 7.

10. Replace the motor cover on the grille using the square

cutouts.

11. Replace condenser fan on motor shaft.

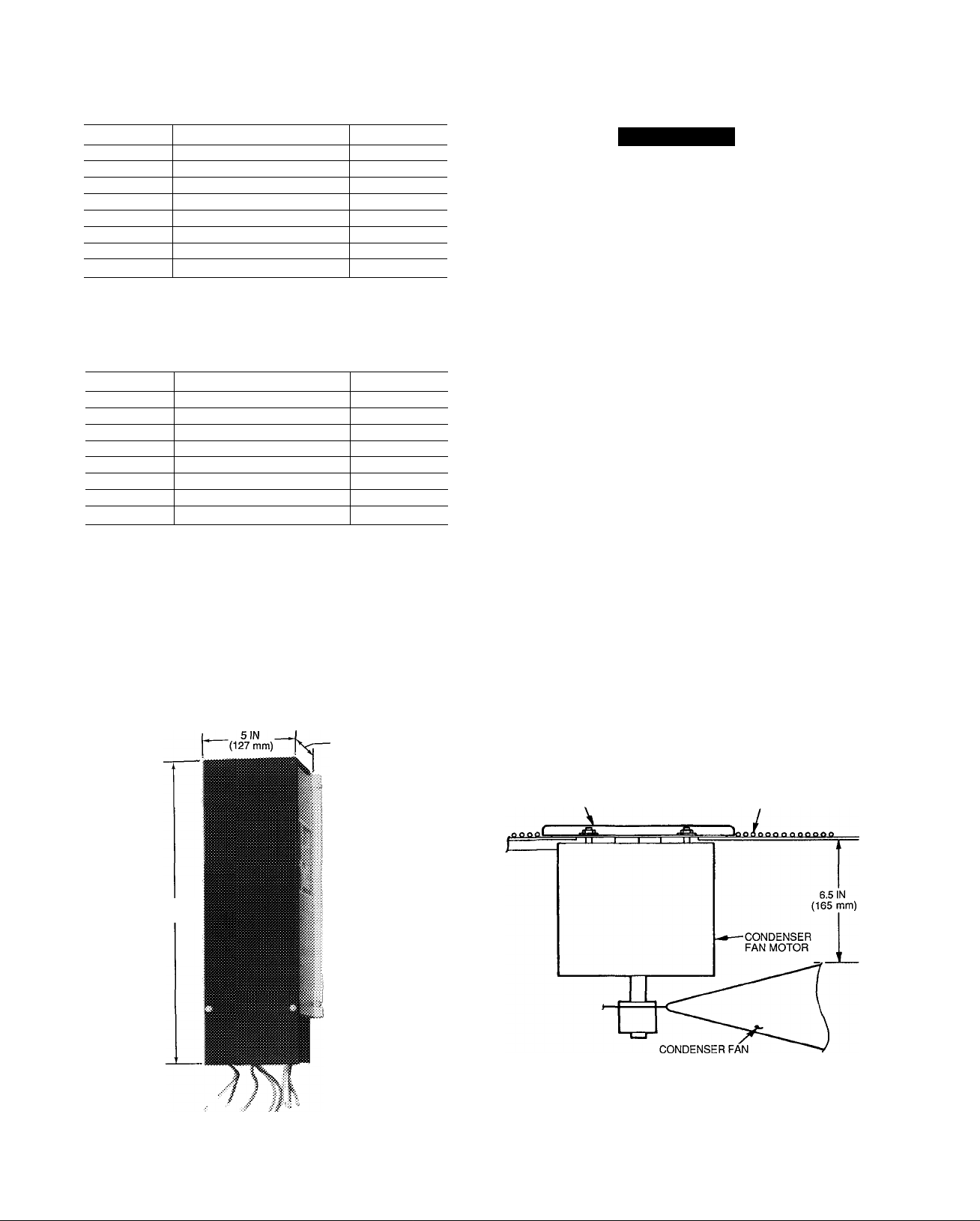

12. Adjust fan height as shown in Fig. 2.

13. Tighten set screws on fan hub to 7 ft-lbs (9.52 N-m

[newton-meters]) ± 1 ft-lb (1.5 N-m).

NOTE: On 48HJ009 and 48HJ/TJ014 units, perform Step 2

— Install the Motormaster III Controller through Step 4 —

Make Electrical Connections, before reinstalling the con

denser fan. Motormaster III installation is done through the

condenser fan opening with the fan and motor removed.

14. Reinstall condenser fan assembly onto unit using screws

from Step 4. Torque to 20 in.-lbs (2260 mN-m)

± 2 in.-lbs (226 mN-m).

15. Pull motor wires completely through conduit.

16 IN

(406 mm)

MOUNTING

BASE

/

Fig. 1 — Motormaster III Control

MOTOR COVER OUTLET GRILLE

Fig. 2 — Condenser Fan Height Adjustment

Page 3

Step 2 — Install Motormaster® III Controller

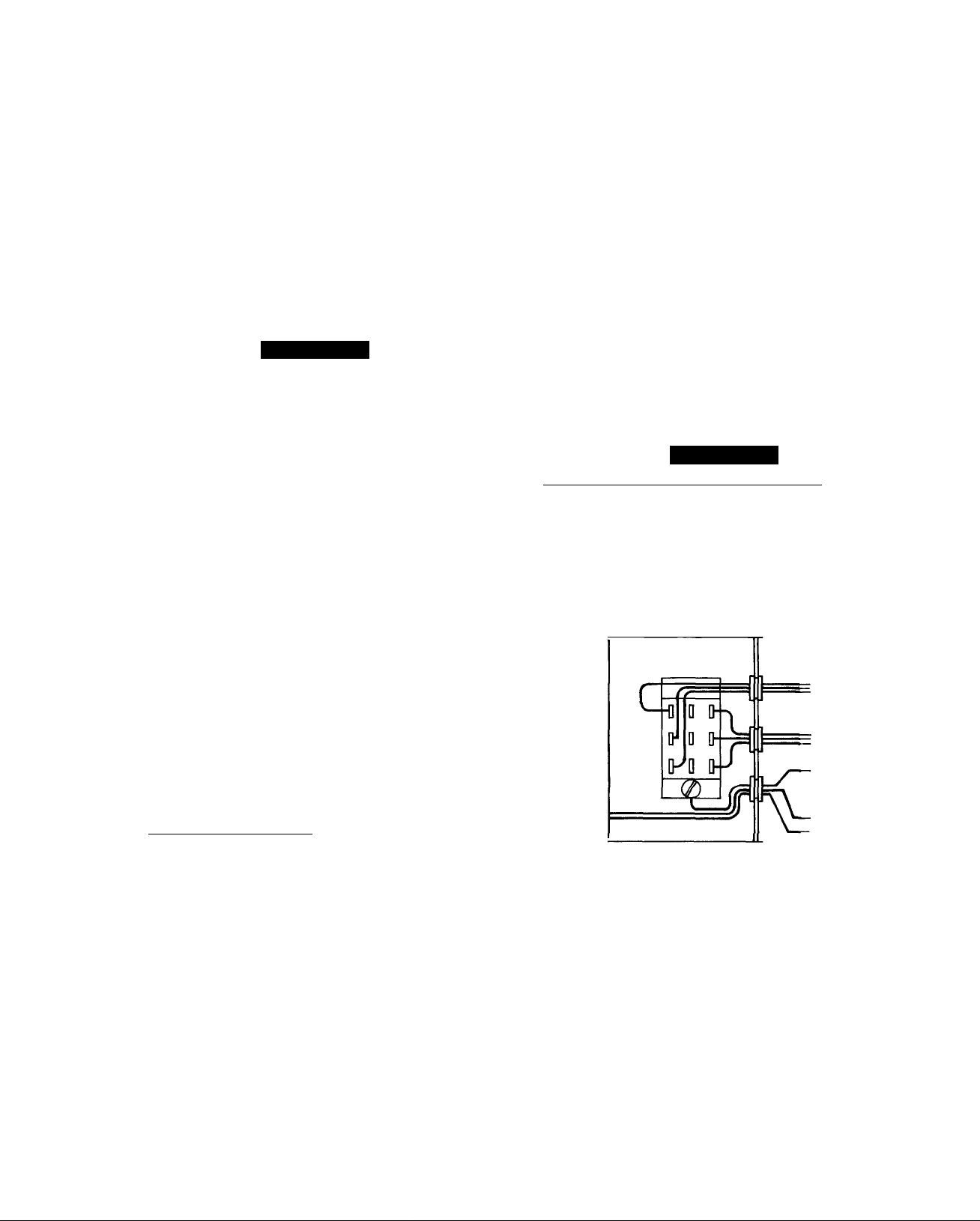

1. Configure the control signal selection switch. Remove

the cover of the Motormaster III control. Set the switch

on the Motormaster III control board (underneath cover)

to accept the thermistor (sensor) input signal. Set the

frequency switch to match the unit power supply (50 Hz

or 60 Hz). See Fig. 3 for switch locations and proper

position. Replace the cover.

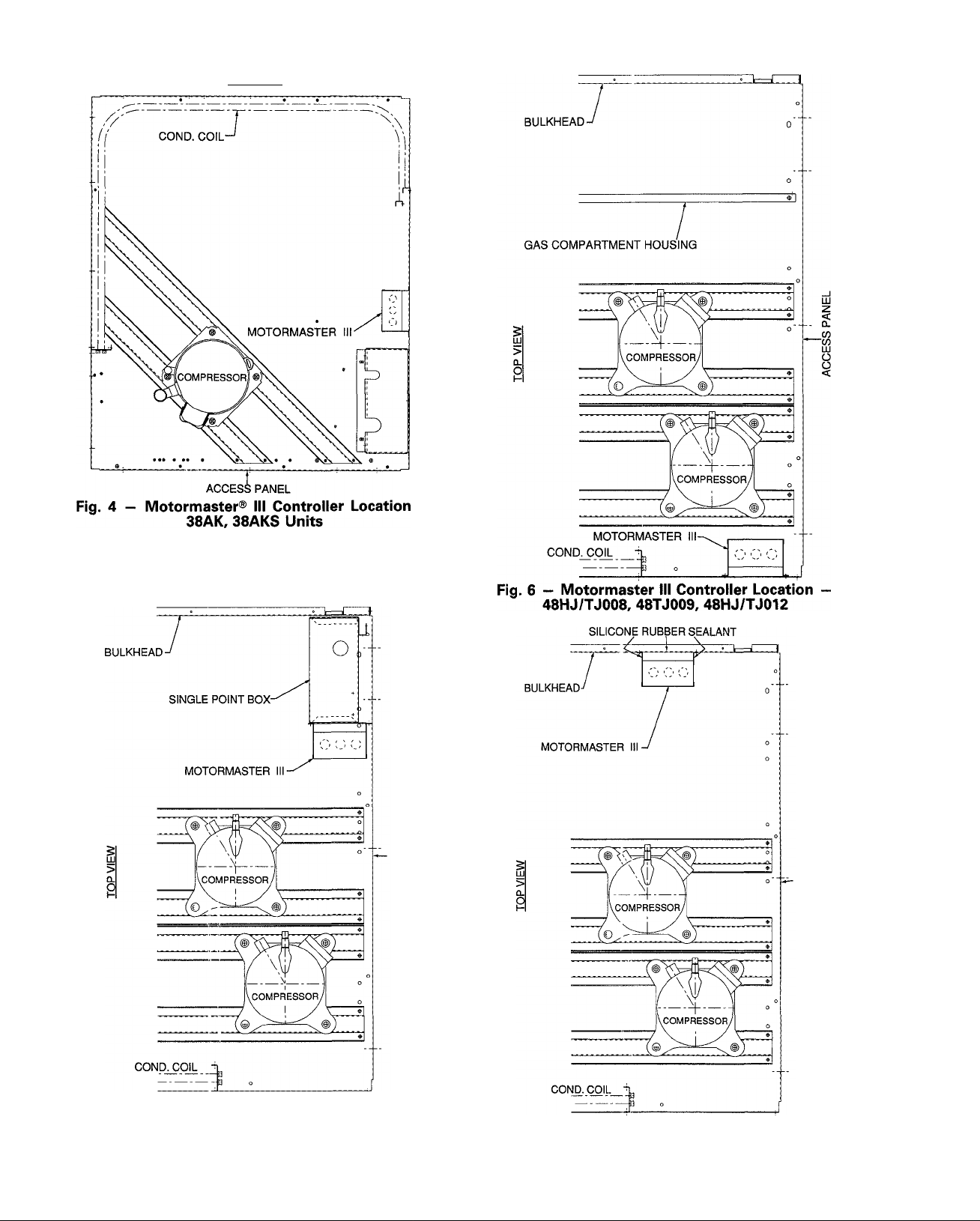

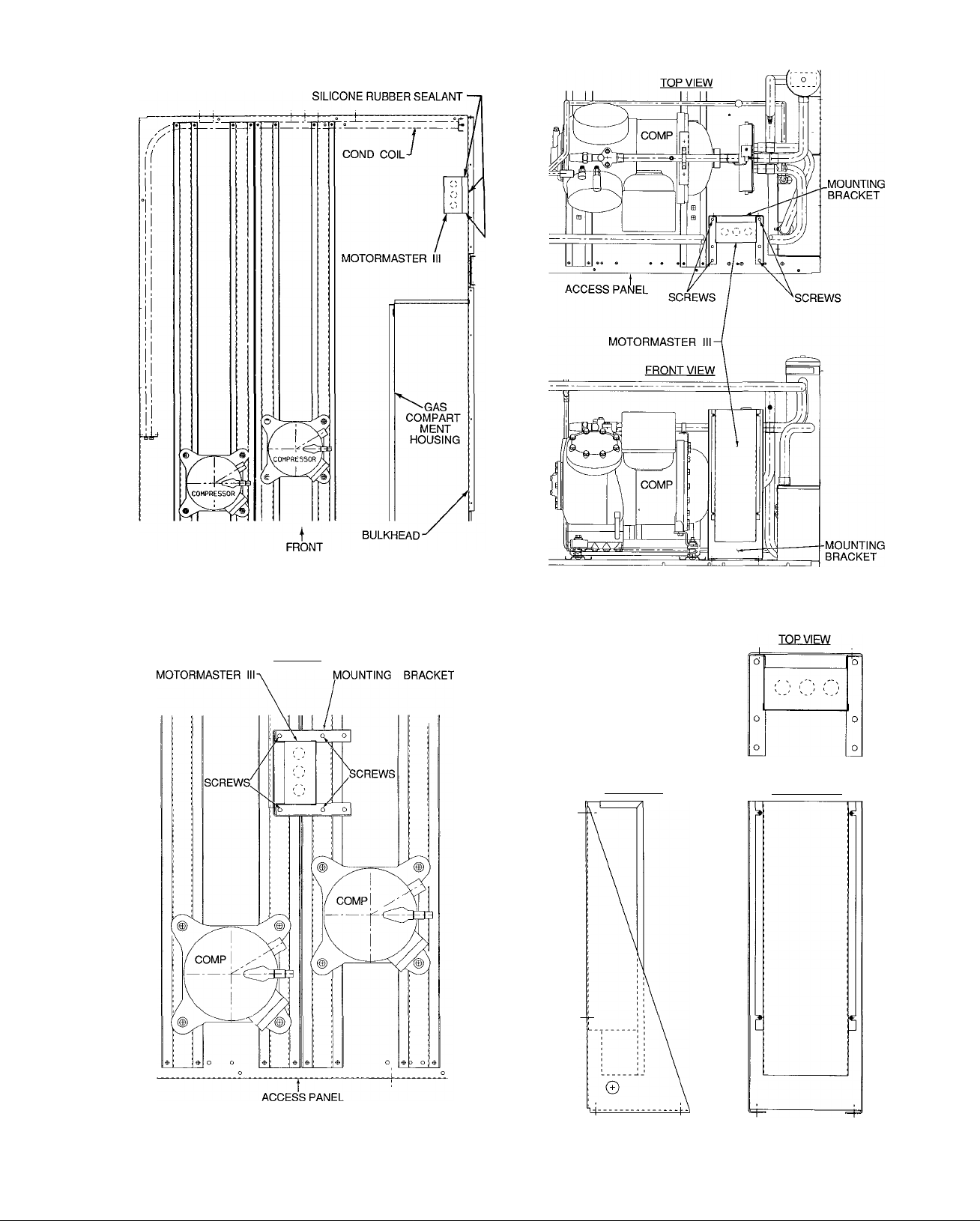

2. 38AK008.012; 38AKS008-012; 48HJ008,012; 48TJ008012; 50HJ/TJ008-014; AND 50UQ008,012; UNITS WITH

SINGLE POINT BOX: Mount the Motormaster III con

troller on the unit in the location specified in Fig. 4-6.

The controller must be mounted vertically with the leads

at the bottom. Using the template provided on the last

page of the book, mark the 4 mounting hole locations.

Mount the controller using the Yie-in. self-drilling screws

provided.

A CAUTION

To avoid damaging components and wiring, use ex

treme care when drilling screw holes and screwing

in fasteners.

50HJ/TJ008-014 AND 50LJQ008,012 UNITS WITH

OUT SINGLE POINT BOX; 48HJ009 (208/230

AND 460 V); AND 48HJ/TJ014 UNITS: Mount the

Motormaster III controller on the unit in the location spec

ified in Pig. 7 and 8. The controller must be mounted

vertically with the leads at the bottom. Using the tem

plate supplied on the last page of the manual, mark the

4 mounting locations. Mount the controller using the

yi6-in. self-drilling screws provided. To prevent any

water leakage though the bulkhead (the partition sepa

rating the indoor and outdoor sections), an electric

component compatible, general purpose silicon rubber

sealant must be used along the 4 edges of the controller

and at the 4 mounting-screw locations.

38AQS008 AND 48HJ009 (575 V) UNITS: The

Motormaster III controller must be mounted on a sheet

metal bracket provided. Mount the bracket on the unit

in the location specified in Fig. 9 and 10 using four

yi6-in. self-drilling screws provided. If needed, a bracket

mounting template is provided on page 21. The control

ler must be mounted vertically, with the leads at the

bottom. Mount the controller on the bracket using the

remaining four 5/16-in. self-drilling screws. See Fig. 11

for controller mounting details.

Step 3 — Install Sensor

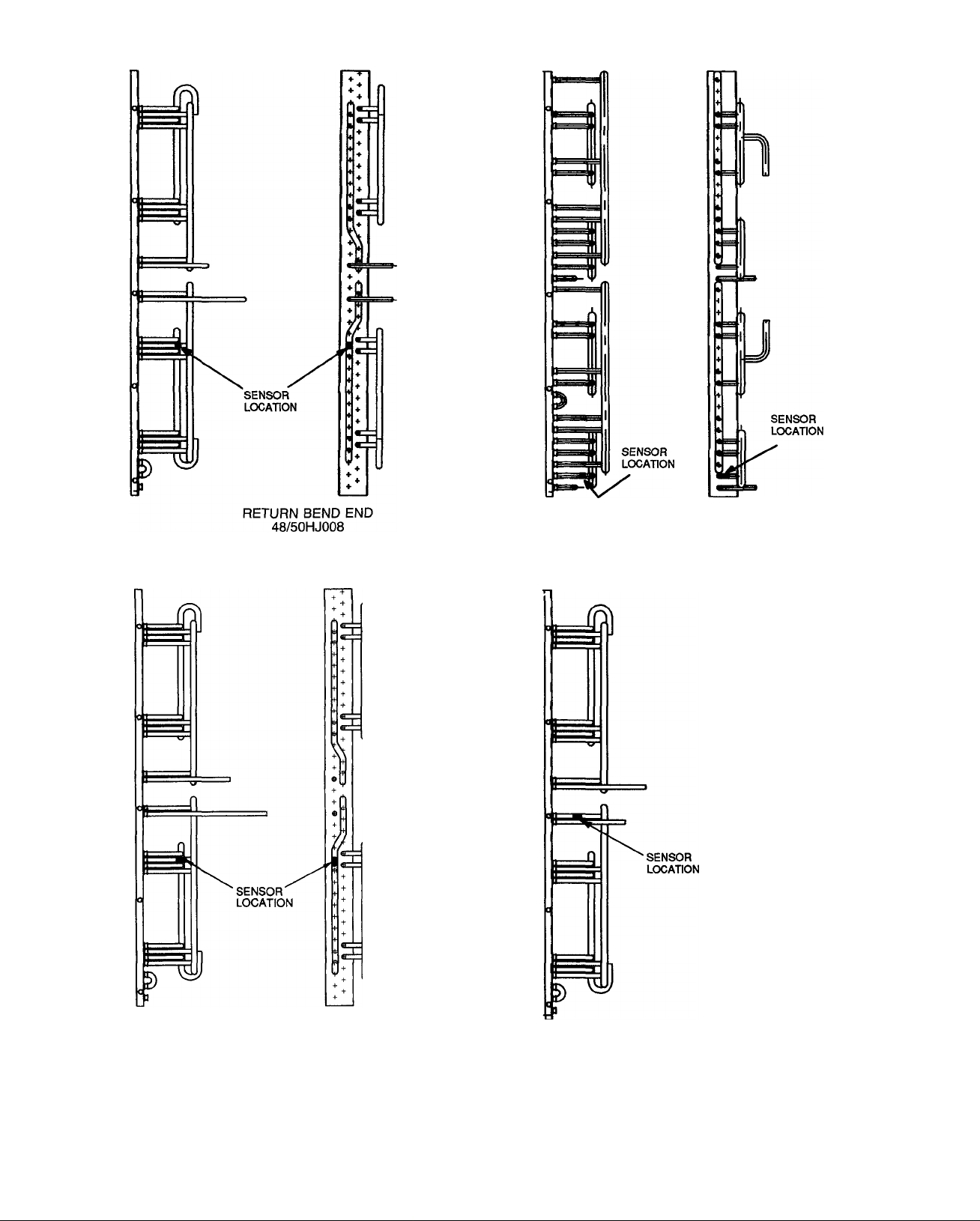

38AK008,012; 38AKS008-012 AND 48/50HJ,TJ008-014

UNITS — Install the sensor for thermistor input control on

the header tube designated in Fig. 12. Connect the sensor

leads to the violet and gray control signal leads on the

Motormaster III controller. Wrap and tie excess sensor wir

ing. Refer to Step 4 — Make Electrical Connections and

the unit wiring diagram for more information on wiring the

sensor.

A CAUTION

I Sensor assembly is delicate. Handle with care. |

38AQS008 AND 50LJQ008,012 UNITS - Wiring is fieldsupplied. Wiring must be 16 AWG (American Wire Gage)

(1.5 mm^), appliance wiring material, rated 75 C or its equiv

alent, with %4-in. (.8 mm) minimum insulation thickness.

All wiring must comply with NEC (National Electrical Code)

and applicable local codes.

50 HZ

,(o^

60 HZ

CONTROL INPUT

___

(SENSOR) THERMISTOR* 4 - 20 mA

GND — Ground

*For thermistor (sensor) signal, move switch to the left.

NOTE: Thermistor is designated in text as “sensor.”

PHASE SEQUENCE

INDICATOR

ADJUST SWITCH

TO MATCH LINE

FREQUENCY

ADJUST SWITCH TO

\ MATCH INPUT

k CONTROL SIGNAL

CE]

__________

LEGEND

Fig. 3 — Motormaster III Control Signal Selection Switch

□

LH izzi

□

LEADS TO POWER

SOURCE

LEADS TO

MOTOR

3 HOLES 0 88 DIA (FOR 1/2 IN CONDUIT)-

BLACK LI

BLUEL3 YELL2

GRN (GND)

CONTROL

SIGNAL

LEADS

+VIO

-GRAY

Page 4

TOP VIEW

Fig. 5 — Motormaster III Controller Location

50HJ,50LJQ,50TJ008-014

(With Single Point Box)

-CO

UJ

z

<

a.

CO

LU

o

o

<

-CO

Lil

Z

<

0.

CO

iii

o

o

<

K

Fig. 7 - Motormaster III Controller Location -

50HJ, 50LJQ, 50TJ008-014 (Without Single Point Box)

Page 5

TOP VIEW

Fig. 8 — Motormaster® III Controller Location —

48HJJJ014, All Voltages; 48HJ009, 208/230,

460-3-60 Only

TOP VIEW

Fig. 10 — Motormaster III Controller Location —

38AQS008

SIDE VIEW

FRONT VIEW

Fig. 9 — Motormaster III Controller Location

48HJ009 (575 V)

Fig. 11 — Motormaster Hi Controller Mounting

Page 6

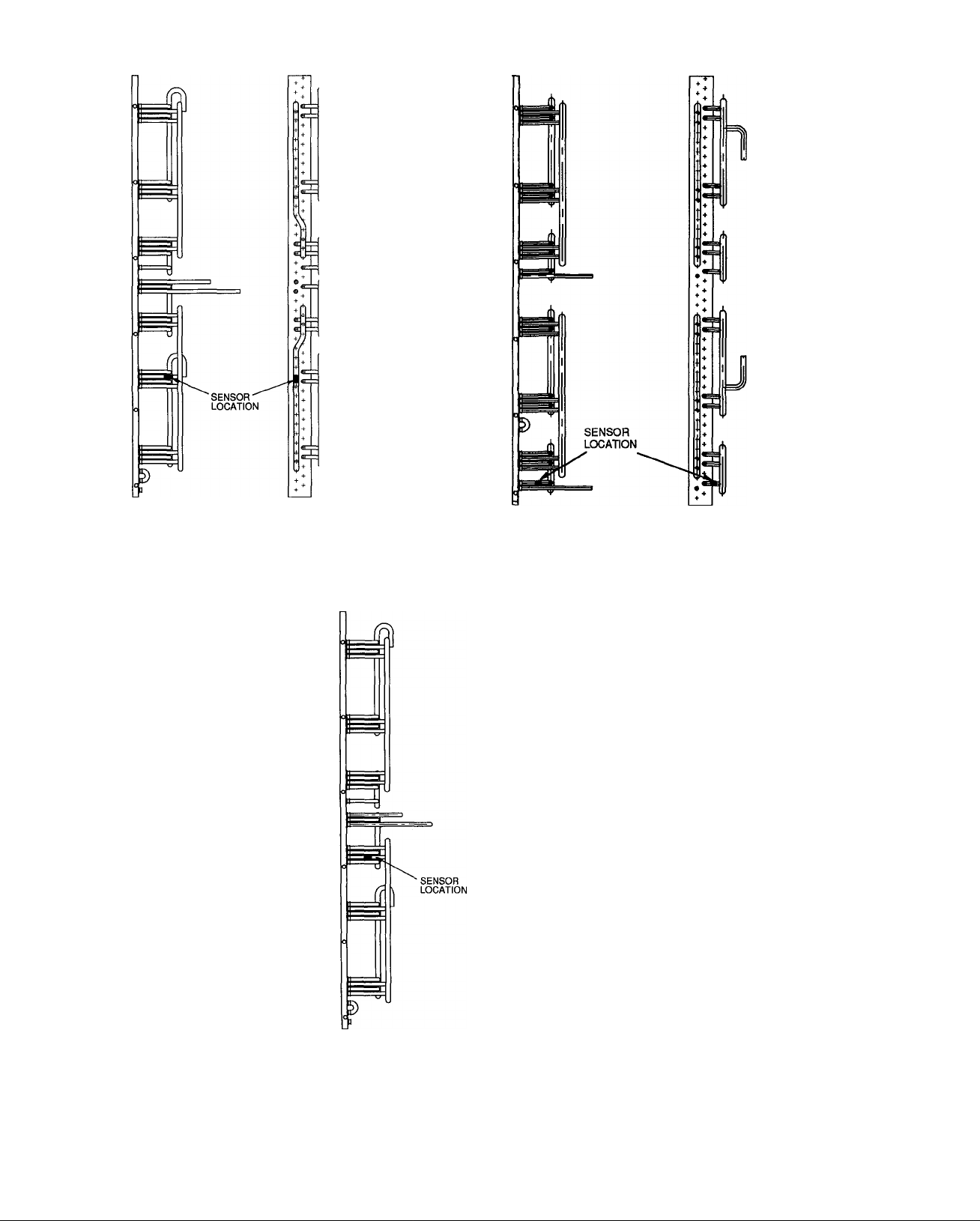

Install the sensor for thermistor input control on the header

tube designated in Fig. 13 and 14. Insert relay into socket.

Install the Motormaster® III relay in the unit control box,

in the location specified in Fig. 15 and 16. Use the two

no. 6-20 X 3/4-in. screws provided.

Connect one sensor lead to the violet control signal lead

on the Motormaster III controller and to a field-supplied

16 AWG wire with a wirenut. Connect the remaining

sensor lead to the gray control sensor lead on the

Motormaster III controller and to another field-supplied

16 AWG wire with a wirenut.

Route both field-supplied wires through a factorypunched access hole under the control box. Attach the wires

to screw terminals 1 and 9 on the Motormaster III relay in

the control box. Wrap and tie excess sensor wiring. Wrap

wirenuts with waterproof tape to prevent them from loos

ening and to ensure watertightness. Refer to Step 4 - Make

Electrical Connections and the unit wiring diagram for more

information on wiring the sensor.

A CAUTION

Sensor assembly is delicate. Handle with care.

Step 4 — Make Electrical Connections

A WARNING

To avoid possibility of electrical shock and personal

injury, turn off all power to unit before making elec

trical connections. Tag all disconnects to alert others

not to turn on power until work is completed.

The wires necessary for wiring the Motormaster III con

trol to the unit must be field-supplied. Use 16 AWG (Amer

ican Wire Gage) (1.5 mm^) appliance material wire, with

2/64-in. (.8 mm) minimum insulation thickness. Use 75 C

type or equivalent. All wiring must comply with NEC

(National Electrical Code) and applicable local codes.

38AK008,012 AND 38AKS008-012 UNITS - Power wir

ing must comply with all local and national electrical code

(NEC) requirements. Refer to Eig. 17-19 for power wiring

connections. Utilize field-supplied wirenuts and 'A in.

insulated female quick-connects for making power wiring

connections. Wrap wirenuts with waterproof tape to pre

vent them from loosening and ensure watertightness.

NOTES;

1. On 50 Hz units, disconnect the yellow wire connected

to terminal 22 of the compressor contactor (C).

2. See wiring diagram on unit for more details.

48/50HJ008-014 AND 48/50TJ008-014 UNITS - Power

wiring must comply with all local and National Electrical

Code (NEC) requirements. Refer to Fig. 20-25 for power

wiring connections. Utilize field-supplied wirenuts and

V4-in. insulated female quick-connects for making power

wiring connections. Wrap wirenuts with waterproof tape to

prevent them from loosening and ensure watertightness.

NOTES;

On 220 V, 50 Hz units, disconnect the black wire con

1

nected to capacitor 1. On 400 v, 50 Hz units, disconnect

blue wire connected to capacitor 1. Cap wire with a wire

nut (50TJ008-014 only).

2. See wiring diagram on unit for more details.

38AQS008 AND 50LJQ008,012 UNITS - Power wiring

must comply with all local and National Electrical Code

(NEC) requirements. Refer to Fig. 26-28 for power wiring

connections. Utilize field-supplied wirenuts and 'A-in. in

sulated female quick-connects for making power wiring con

nections. Wrap wirenuts with waterproof tape to prevent

them from loosening and ensure watertightness. See wiring

diagram on unit for more details.

Step 5 — Install Field-Fabricated Wind Baffles

and Brackets

A WARNING

To avoid the possibility of electrical shock, open

all disconnects before installing or servicing this

accessory.

Wind baffles must be field-fabricated for all units to en

sure proper cooling cycle operation at low-ambient temper

atures with Motormaster III controls. See Fig. 29 and 30

for number and sizes of baffles required and for baffle de

tails. Use 20-gage (1 mm) galvanized sheet metal or similar

corrosion-resistant material for the baffles. Use fieldsupplied screws to attach baffles to unit. Screws should be

'A-in. (6.3 mm) diameter or larger. Drill required screws

holes for mounting the baffles.

A CAUTION

To avoid damage to refrigerant coils and electrical com

ponents, use extreme care when drilling screw holes

and screwing in fasteners.

Step 6 — Restore Power To Unit - When all elec

trical connections have been made, ensure they are tight

and correct.

1. Restore power to the unit.

2. Check the phase sequence indicator on the Motormaster

III control. It should not be lit. If lit, turn off power and

reverse LI (black) and L2 (yellow) power leads. See

Fig. 3.

3. With phasing on Motormaster III control correct,

make sure that the fan motors are rotating in the

proper direction. If fan rotation is backwards, shut off

power. Reverse the supply power leads between the

Motormaster III control and the condenser fan motor to

correct rotation.

4. Reinstall control box cover.

5. Reinstall unit access panel.

Page 7

oo

$

qO

\

Oj

RETURN BEND END

48/50TJ008

OD

qO

e

i

V

RETURN BEND END _.,r.

38AK008.012, 38AKS008,009,012; 48/50HJ009 48/50TJ009

Fig. 12 — Motormaster® III Sensor Locations — 38AK, AKS; 48/50HJ,TJ Units

i

qO

qO

Page 8

RETURN BEND END

48/50HJ012

RETURN BEND END

48/50TJ012

+

RETURN BEND END

48/50HJJJ014

Fig. 12 - Motormaster® III Sensor Locations — 38AK, AKS and 48/50HJ,TJ UNITS (cont)

Page 9

RETURN BEND END

Fig. 13 — Motormaster® III Sensor Locations — 38AQS Units

yT-

-SENSOR

LOCATION

7^

ir

5s,

!

SENSOR

LOCATION

m

№

RETURN BEND END

50LJQ008

Fig. 14 — Motormaster III Sensor Locations — 50LJQ Units

V

RETURN BEND END

50LJQ012

Page 10

<n> © O

C0.

+® (3) +

CD (D

IF&

cx

<a> © ®

MOTORMASTER III RELAY

EES ®

Fig. 15 — Motormaster® III Relay Location

38AQS008

LEGEND

C — Compressor Contactor

MMSN — Motormaster Sensor

OFC — Outdoor-Fan Contactor

OFM — Outdoor-Fan Motor

NOTES;

1. On 50 Hz units, disconnect yeliow wire connected to Terminai 6

of the outdoor fan contactor (OFC). Tape wire and secure in

side control box

2. See wiring label on unit for more details.

Fig. 17 - Fan Power Wiring - 38AKS009,012 - 208/230 V, 460 V; 60 Hz and 220 V, 400 V; 50 Hz

MOTORMASTER

m

CONTROLLER

MOTORMASTER III RELAY

Fig. 16 - Motormaster ill Relay Location

GRA—•-

VIO •

50LJQ008,012

MMSN

OFM

(

GRN-YEL-

-9

BLK

• YEL

13

23^

BLU

□

C — Compressor Contactor

MMSN — Motormaster Sensor

OFM — Outdoor-Fan Motor

NOTES:

1. On 50 Hz units, disconnect yellow wire connected to Termi

nal 22 of the compressor contactor (C). Tape wire and se

cure inside control box.

2. See wiring label on unit for more details

LEGEND

Fig. 18 - Fan Power Wiring - 38AK008,012; 38AKS008 -208/230 V, 460 V; 60 Hz and 220 V, 400 V; 50 Hz

10

Page 11

LEGEND

MMSN — Motormaster® Sensor

OFC — Outdoor-Fan Contactor

OFM — Outdoor-Fan Motor

TB2 — Terminal Block 2

NOTE: See wiring labei on unit for more detaiis

Fig. 19 - Fan Power Wiring - 38AK008,012; 38AKS008,009,012 - 575 V; 60 Hz

r

MOTORMASTER

JET

CONTROLLER

GRA ■

VIO ■

MMSN

' RED

ORN

BRN

MMSN — Motormaster Sensor

OFC — Outdoor-Fan Contactor

OFM — Outdoor-Fan Motor

NOTE: See wiring label on unit for more detaiis

Fig. 20 - Fan Power Wiring - 50HJ008-012 - 208/230 V; 60 Hz, 50HJ008-014 - 460 V; 60 Hz,

and 50TJ014 - 460 V; 60 Hz

MMSN — Motormaster Sensor

OFM — Outdoor-Fan Motor

NOTE: See wiring label on unit for more details.

Fig. 21 - Fan Power Wiring - 48/50TJ008-012 - 208/230 V and 460 V; 60 Hz

11

Page 12

C2

NOTE. See wiring label on unit for more details.

Fig. 22 - Fan Power Wiring - 50HJ014; 50TJ014 - 208/230 V; 60 Hz

OFM — Outdoor-Fan Motor

NOTE: See wiring label on unit for more details

Fig. 23 - Fan Power Wiring 48HJ008-014; 48TJ014 - 208/230 V and 460 V; 60 Hz

YEL

TB3 — Terminal Block No. 3

NOTE: See wiring label on unit for more details

Fig. 24 — Fan Power Wiring — 48/50HJ,TJ008-014 — 575 V; 60 Hz

12

Page 13

BLK—S

BLK—•

' BLK—S

--------

BLK-

BLU-

MOTORMASTER

Hl

CONTROLLER

LEGEND

Cl — Compressor Contactor No. 1

MMSN — Motormaster® Sensor

OFM — Outdoor-Fan Motor

NOTES:

1. Disconnect black wire on 220-v units and blue wire on 400-v

units connected to capacitor no. 1. Cap with wirenut.

2. See wiring label on unit for more details.

Fig. 25 - Fan Power Wiring — 50TJ008-014 - 220 V and 400 V; 50 Hz

GRA —

VIO ■

MMSN

BRN

RED

ORN

MMR

13

Page 14

CONTROL WIRING

Fig. 27 - Fan Control/Power Wiring - 50LJQ008-012 - 208/230 V and 460 V; 60 Hz

MMR

Fig. 28 — Fan Control/Power Wiring — 50LJQ008-012 — 575 V; 60 Hz

14

Page 15

REAR

UNIT

38

AK008;

AKS008-012;

AQS008

AK012

UNIT

38

AK008;

AKS008-012;

AQS008

AK012 36y2

DIMENSIONS (in.)

LEFT BAFFLE

B C

A

29ys 30V2 35

28%

28% 29% 30V2

REAR BAFFLE

B

A

36V2

37% 38V4

37%

c

38V4 35 2 10 18 26 34 AK012

D E F G H

2

35 2 10 18

D E F G H

35 2

10

10

18

18

, UNIT

' 38

34

26

34 AK012

26

, UNIT

' 38

34

26

AK008;

AKS008-012;

AQS008

AK008;

AKS008-012;

AQS008

LEFT

A B

730

730

A B C

927

927

DIMENSIONS (mm)

LEFT BAFFLE

C D

752 775

752 775

REAR BAFFLE

972

949

972

949

E

889 51 254 457

889 51

E

D

889 51 254 457

51

889

RIGHT

F G H

660

254 457

660

F G H 1

660

457

254

660

1

864

864

864

864

UNIT

38

AK008;

AKS008-012;

A

9'%6

AQS008

AK012 19 7/8 20%

RIGHT BAFFLE RIGHT BAFFLE

B

101%6 11 1 V16 35 2 10 18 26

21%

c

D E F G

35 2

10

18

, UNIT

H

' 38

34 AKS008-012;

26 34 AK012 505

AK008;

AQS008

A

252 275

B C D E F

297

889 51 254 457

527 549

889 51 254

Fig. 29 — Wind Baffie Mounting Detaiis, 38AK,AKS,AQS Units

15

G

457

H 1

660

660

864

864

Page 16

NOTE: Dimensions in ( ) are millimeters

UNIT A

48/50HJ,TJ008,009;

50LJQ008

48/50HJ,TJ012,014;

50LJQ012

43ye

43Vs

SIDE BAFFLE

DIMENSIONS (in.)

B C D E

43^8 44% 35V4 5%

43%

44%

43V4 5%

SIDE OF UNIT

F G

14% 22V4

14%

22V4 30V2 38Vs

H

30V2

J

- -

K

-

UNIT A

48/50HJ,TJ008,009;

50LJQ008

48/50HJ,TJ012,014;

50LJQ012

1096 0

1096.0

UNIT A

48/50HJ008

48/50HJ009; 48/50TJ008;

50LJQ008

48/50TJ009

48/50TJ012

48/50HJ012,014; 48/50TJ014;

50LJQ012

UNIT

48/50HJ008

48/50HJ009; 48/50TJ008;

50LJQ008

48/50TJ009

48/50TJ012

48/50HJ012,014; 48/50TJ014;

50LJQ012

DIMENSIONS (mm)

B C D E

1115.0

1115.0

1134.0

1134.0

1098.0 150.0

FRONT BAFFLE

DIMENSIONS (in)

B C D E

31%

41%

16%

26%

41%

A

805.0

1058.0

423.0

677.0

1058 0

32V2 33V4

42% 43ye 35 1 / 4 11/ 4

17% leys 351/ 4 11/4

27%

42% 43ye

28ya

DIMENSIONS (mm)

B C D

824.0

1077.0

442.0

696.0

1077.0

843 0

1096.0 894.0

461.0

715 0

1096.0

894.0

351/ 4

431/4

431/4

894 0

894.0 32 0

1098.0 32 0

1098.0 32.0

F

150.0 377.0

377 0 566.0

F

11 / 4

11 / 4

11 / 4

91/ 4 171/4 25 1/4 331/4

91/ 4 171/4

91/ 4 171/4

91/ 4 171/4 25 1/4 331/4 41 1/4

91/ 4 171/4 25 1/4 331/4 41 1/4

E F

32.0

32.0

235 2 438.4 641.6 844.8

235 2 438.4

235.2 438.4 641.6 844 8

235.2

235 2 438.4 641 6

G

566 0 774 0

G

G

438 4 641.6

H

774.0 967.6

H

251/4

251/4 33 1 /4

H

641 6

J

-

J

331/ 4

J

844.8

844 8 1048 0

844.8 1048.0

K

K

-

-

-

K

-

-

-

-

-

Fig. 30 — Wind Baffle Mounting Details, 48/50HJ,TJ008-014; 50LJQ008,012

16

Page 17

TROUBLESHOOTING

1. The Motormaster® III control must be securely grounded

to the cabinet of the unit to function properly.

2. The power frequency switch must be in the correct

position for the power supply being used. The control

switch must be set at the thermistor setting.

3. Motormaster III controls may be applied only to spe

cially qualified fan motors. Ensure that the proper fan

motor has been installed with the Motormaster III con

trol. See Tables 2 and 3.

4. A true RMS (Root Mean Square) meter is required to

accurately read the output from the Motormaster III

control because of the electronically controlled output

voltage.

5. Thermistor sensor lead connections should be carefully

rechecked if there is an operational problem. See the

thermistor characteristic for sensor 30GT412176 shown

in Fig. 31. The controller operates between 1600 ohms

and 5800 ohms. At 1600 ohms the controller is at full

voltage. At 5800 ohms the output is at a minimum (10%

of motor speed).

15

LEGEND

¡Tolerance band for allowable Motormaster III resistance values.

20

25 30 35

TEMPERATURE (C)

Fig. 31 - Thermistor Resistance vs Temperature

40

45

50

17

Page 18

Copyright 1995 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Bookll II

| 1 | 1

Tab la 1b 3a 5a 2a 5a 6a 6b

|4 |4 |4 |4 PC 111 Catalog No 533-803 Printed in U S.A. Form 38/48/50-4SI Pg 18 1-95 Replaces: New

Page 19

с

19

Page 20

T TEMPLATE

0.130" (3.3mm)

DIA

0.134 (3.4mm)

(6 PLACES TYPICAL)

Page 21

Page 22

DIA (4 PLACES TYPICAL)

-16.05 —

C407.7mm)

MOTORMASTER CONTROLLER TEMPLATE

12.00-

(305.0mm)

20

Page 23

о

1=

о

ш

Page 24

ef^

Copyright 1995 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|1 |1 |1 |1 |4 |4 |4 |4 PC 111 Cataiog No. 533-803 Printed in U S A Form 38/48/50-4SI Pg 22 1-95 Repiaces: New

Tab la 1b 3a 5a 2a 5a 6a 6b

Loading...

Loading...