Page 1

HEATING & COOLING

38AH024-034

Air-Cocled Condensing Units

50/60 Hz

Installation, Start-up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS .. .

BEFORE INSTALLATION

Rigging .............................................................. 1

Placing Unit ....................................................... 1

Mounting Unit

Compressor Mounting

INSTALLATION

Refrigerant Piping Connections

Solenoid Drop Refrigerant Control

Filter Drier and Moisture Indicator

Receiver

Piping Procedure ............................................... 5

Power Supply

Power Wiring ..................................................... 7

PRE-START-UP ................................................ 14

System Check

Leak Test and Dehydration............................... 14

Preliminary Charge

START-UP....................................................... 14-16

Preliminary Checks

Preliminary Oil Charge

Start Unit

Adjust Refrigerant Charge

Check Compressor Oil Level

Final Checks..................................................... 15

SEQUENCE OF OPERATION

Single Air Handler —

2-Stage Cool Thermostat ............................... 17

Two Air Handlers —

Two 2-Stage Cool Thermostats

(One Per Air Handler)

Restart

Causes of Complete Unit Shutdown

SERVICE ....................................................... 18-20

Access for Servicing .......................................... 18

Fan Adjustment

Oil Charge

Liquid Shutoff/Charging Valve

Capacity Control, Suction Pressure-

Capacity Control, Electrically Operated

Oil Pressure Safety Switch (OPS)

Compressor Protection

High-Pressure Switches

Low-Pressure Switches

Winter Start Control ........................................... 20

Head Pressure Control

TROUBLESHOOTING.....................................21-23

START-UP CHECKLIST

..............................................................

Actuated Unloaders

Unloaders (Variable Air Volume

Factory-Installed Option Units)

....................................................

.......................................

..............................................

............................................................

....................................................

...................................................

...........................................

...........................................

......................................

...........................................................

....................................

.................................................

.........................................................

.......................................

.....................................

...................................

....................................

.....................................

.....................

.............................

................................

.........................

.....................

......................

................................

............................

.........................

.................

..........................

......................

....................

CL-1, CL-2

1

1-5

5

5

5-13

5

5

5

5

7

14

14

14

14

14

15

15

17

17

17

17

18

18

18

18

18

18

18

18

18

20

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip

ment can be hazardous due to system pressures, electrical

components, and equipment location (roofs, elevated struc

tures, etc.)

Only trained, qualified installers and service mechanics

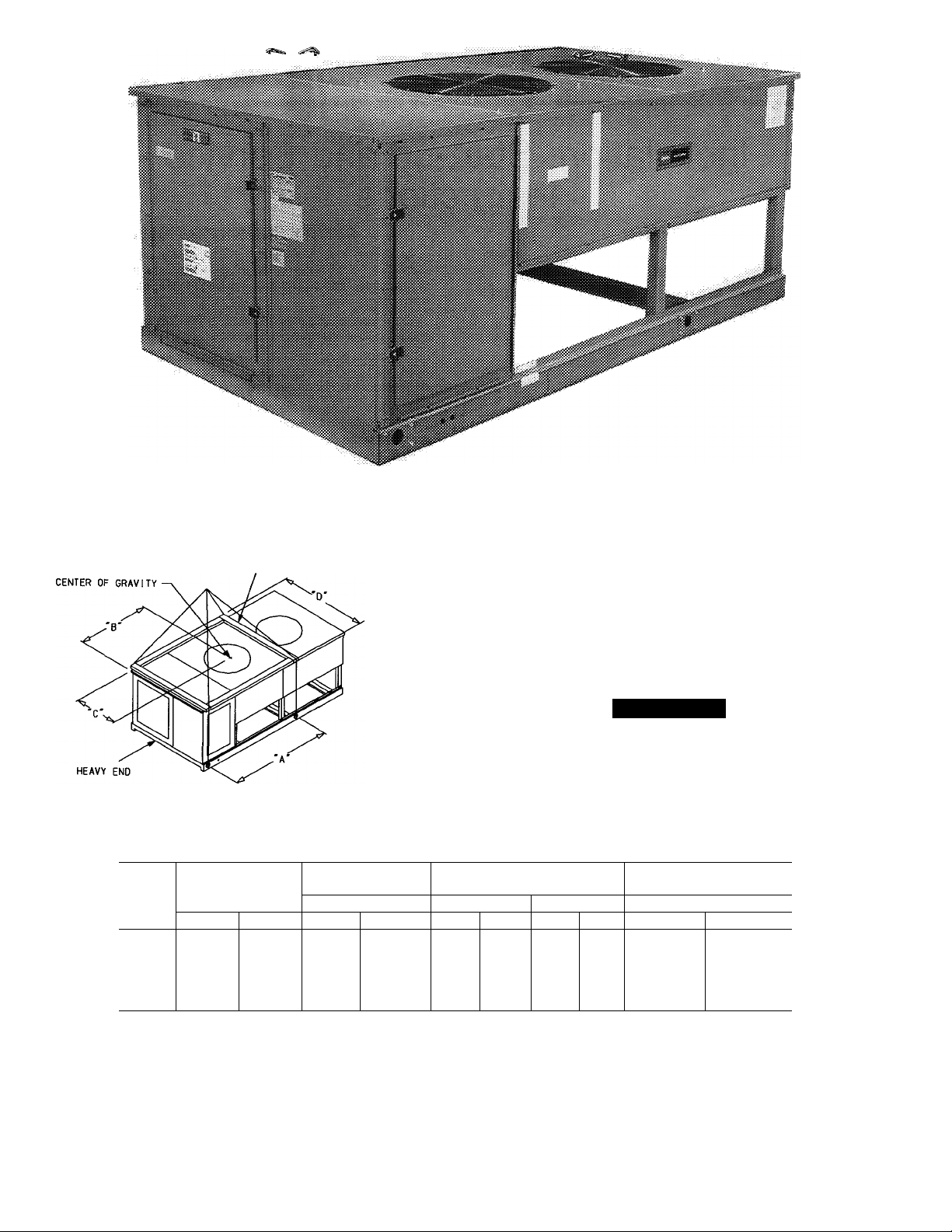

should install, start up, and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance func

tions such as cleaning coils. All other operations should be

performed by trained service personnel.

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to

the equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Keep quenching cloth and fire extinguisher nearby when

brazing.

• Use care in handling, rigging, and setting bulky

equipment.

• See Table lA or IB for Physical Data.

S ilii

¿5

ELECTRIC SHOCK HAZARD

Open all remote disconnects before ser

vicing this equipment.

BEFORE INSTALLATION

Rigging — Preferred method is with spreader bars from

above the unit. Use 2-in. (50 mm) OD pipe or hooks in lift

ing holes. Rig with 4 cables and spreader bars. All panels

must be in place when rigging. See rigging label on unit for

details concerning shipping weights, distance between lift

ing holes, center of gravity, and spreader bar dimensions.

See Fig. 2.

If overhead rigging is not possible, place condensing unit

on skid or pad for rolling or dragging. When rolling, use

minimum 3 rollers. When dragging, pull the pad. Do not

apply force to the unit. When in final position, raise from

above to lift unit off pad.

A CAUTION

All panels must be in place when rigging. Do not fork

units if no skid is supplied. If unit has skid, truck from

sides only.

Placing Unit — There must be 4 ft (1200 mm) for ser

vice and for unrestricted airflow on all sides of unit, and a

minimum of 8 ft (2440 mm) clear air space above unit. For

multiple units, allow 8 ft (2440 mm) separation between

units for airflow and service.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 PC 111 Catalog No 563-739 Printed in U.S A Form 38AH-7SI Pg 1 4-93 Replaces: New

Tab 3a

Page 2

UNIT

38AH

024

024C

028

028C

034

034C

3/4 IN. Cl9 MM) NOTCHES

IN END OF SPREADERS

MAX SHIPPING

WEIGHT

lbs

2240

2403

2300

2463

2360

2577

kgs in.

1018

1092

1045

1120

1073

1171

Fig. 1 - Model 38AH (Size 024 Shown)

NOTES:

1. Use 2 in OD {50 mm) pipe or hooks in lifting holes

2. Rig with 4 cables and spread with two ‘D’ long and two ‘A’ long 2

X 4 in. (50 X 100 mm) or equal.

3. Run the rigging cables to a central suspension point so that the

angle from the horizontal is not less than 45 degrees

4 Shipping weights include skid

All panels must be in place with rigging.

NOTICE TO RIGGERS

LIFTING HOLES

‘A’

mm in.

81

2057

CENTER OF GRAVITY

‘B’ ‘C’ ‘D’

40 0

43.0

39 3

42.3

41 0

44 0

mm

1016

1092

997

1073

1041

1118

in.

32.8

A CAUTION

DISTANCE BETWEEN

RIGGING CABLES

mm in. mm

832

73 5

1867

Fig. 2 — Rigging Label

Page 3

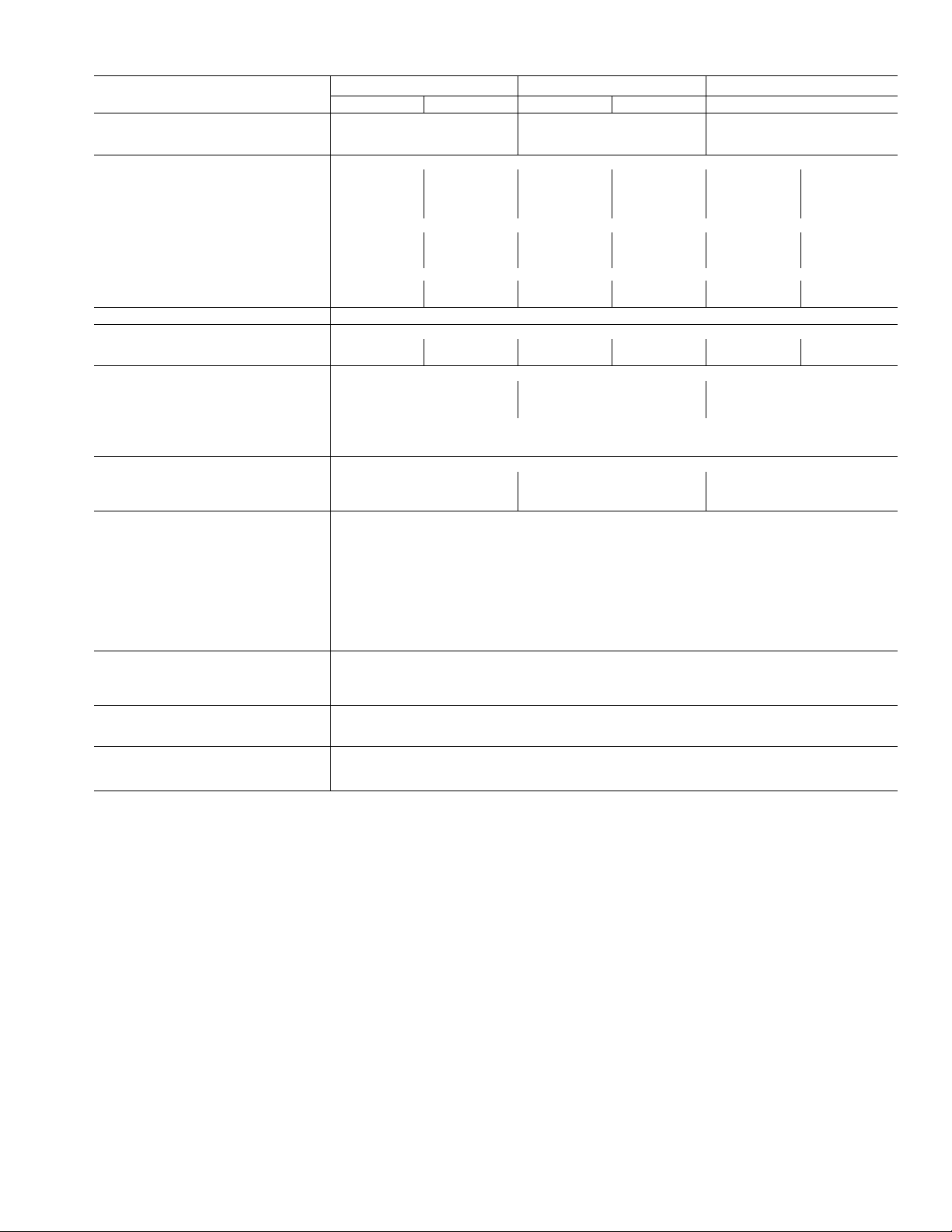

Table 1A — Physical Data — English

6

66*

33t

76

58

024

6

1750 1750

1450 1450

__

—

—

—

UNIT 38AH

OPERATING WEIGHT (lb)

With Alurninum-FIn Coil 1760 1820

With Copper-Fin Coil 1923

COMPRESSOR

Type

Quantity Cylinders (ea)

Speed (rpm) — 60 Hz

Capacity Steps

(FIOP or Асу) - %

Unloader Setting (psig)

— Load

— Unload

- 50 Hz

- %

- %

Circuit 1 Circuit 2 Circuit 1

06DH824 06DA824 06DH328 06DA328

1750

1450

100 100 100 100

OIL CHARGE PER CIRCUIT (Pt)

REFRIGERANT, TYPE**

Shipping Charge (lb)

Operating Charge, Typical (lb)

CONDENSER FANS

Quantity...Dia (in.)

Nominal Hp

Nominal Airflow (cfm) 16,700

Speed (rpm) — 60 Hz

Watts (ea) - 50/60 Hz

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

- 50 Hz

Storage Cap. (Ib)tt

CONTROLS

Pressurestat (psig)

High Pressure

Cutout

Cut-in

Low Pressure

Cutout

Cut-in

Oil Pressure

Cutout (Diff)

Cut-in (Diff)

FAN CYCLING CONTROLS

No. 2 Fan:

Temp Close (F)

Temp Open (F)

PRESSURE RELIEF

Location

Temp (F)

CONNECTIONS (Sweat) (ea ckt)

Suction — in. OD

3 3 3

20 20 20 20

2..

30

1 0

2.. 19

39 20 39 20 39.20

37 7

Liquid — in. OD

LEGEND

Diff — Differential

FlOP — Factory-Installed Option

VAV — Variable Air Volume

'Standard unit — single suction pressure-actuated unioader on compressor no 1

tVAV FiOP — doubie eiectrically actuated unloaders on compressor no 1

"With 25 ft of interconnecting piping

ttCondenser 80% full of liquid R-22 at 120 F

028

Circuit 2 Circuit 1 Circuit 2

1982

Reciprocating Semi-Hermetic

6 6

66*

33t

Factory

76

58

1750

1450

—

—

Installed

—

— 58

10

R-22

Propeller Type — Direct Driven

Enhanced Copper Tubes, Aluminum Lanced Fin

2 30 2. .30

1 0 1.0

16,700 15,700

1140

950

1550

2

3 3 3

19

37.7 56.6

± 7

426

320 ± 20

27

± 3

44 ± 5

Manual Reset

60

8.8

70 ± 3

60 ± 3

Liquid Line, Suction Line, Compressor

Fusible Plug

210

1%

%

034

1880

2097

06DH328 06DA537

6 6

1750 1750

1450

100 100

66*

33t

76

1450

—

—

—

—

25 25

3.. 17

Page 4

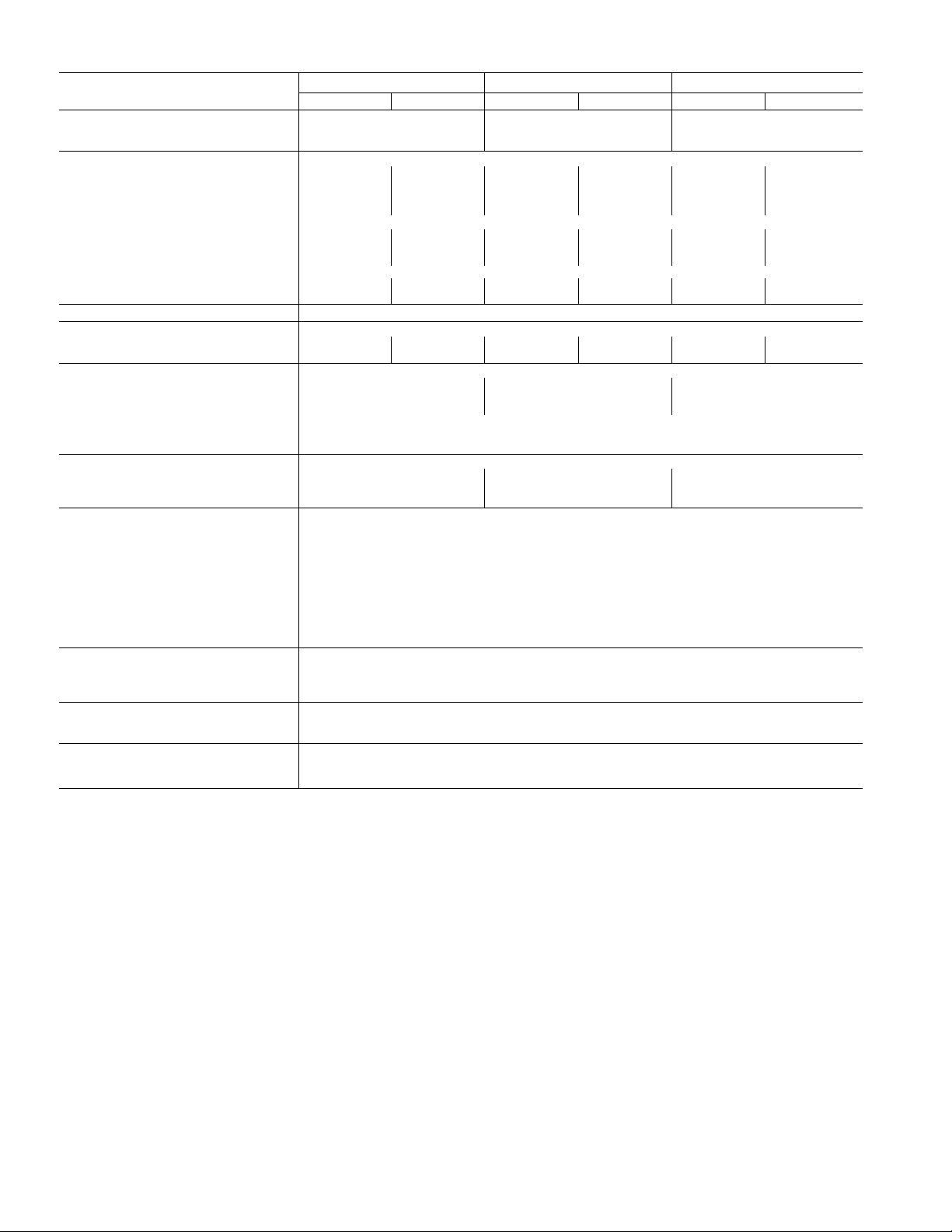

Table IB — Physical Data — SI

UNIT 38AH

OPERATING WEIGHT (kg)

With Aluminum-Fin Coii

With Copper-Fin Coii

COMPRESSOR

Type

Quantity Cyiinders (ea)

Speed (r/s) — 60 Hz

Capacity Steps

(FlOP or Асу) - %

Unloader Setting (kPa)

— Load

— Unioad

- 50 Hz

- %

- %

Circuit 1

06DH824

29.2

24.3 24 3 24 3 24.3

100 100 100 100

024 028

Circuit 2 Circuit 1 Circuit 2

798 3

872 3

06DA824 06DH328

6 6

66*

33t

524

400

29.2 29.2

—

—

—

— 400

OiL CHARGE PER CIRCUIT (L)

REFRIGERANT, TYPE**

Shipping Charge (kg)

Operating Charge, Typicai (kg)

CONDENSER FANS

Quantity...Dia (mm)

Nominal Hp

Nominal Airflow (L/s)

Speed (r/s) — 60 Hz

Watts (ea) — 50/60 Hz

CONDENSER COIL

Rows...Fins/m

- 50 Hz

Total Face Area (sq m)

Storage Cap. (kg)tt

CONTROLS

Pressurestat (kPa)

High Pressure

Cutout

Cut-in

Low Pressure

Cutout

Cut-in

Oil Pressure

Cutout (Diff)

Cut-in (Diff)

FAN CYCLING CONTROLS

No. 2 Fan;

Temp Close (C)

Temp Open (C)

PRESSURE RELIEF

Location

Temp (C)

CONNECTIONS (Sweat) (ea ckt)

Suction — in. OD

Liquid — in. OD

1 36

9.1 9.1

2 ..762

7870

2 ..748

174

1 36 1.36 1.36

1.0

Enhanced Copper Tubes, Aluminum Lanced Fin

3.64 3 64

LEGEND

Diff — Differential

Flop — Factory-Installed Option

VAV — Variable Air Volume

‘Standard unit — single suction pressure-actuated unloader on compressor no. 1

tVAV FlOP — double electrically actuated unloaders on compressor no 1

“With 7.6 m of interconnecting piping

ttCondenser 80% full of liquid R-22 at 48.8 C.

825 6

899.0

Reciprocating Semi-Hermetic

6

66*

33t

Factory

524

06DA328

Installed

6

29 2

_

—

—

4.73

R-22

9 1 9.1

Propelier Type — Direct Driven

2 762

1.0

7870

19

16

1550

2

748

174

2937 ± 48

2206 ± 138

± 21

186

± 34

303

Manuai Reset

41.4

60.7

21 1 ± 1.6

± 1.6

156

Liquid Line, Suction Line, Compressor

Fusible Plug

99

1%

%

Circuit 1

06DH328

6

29.2

24.3

100

66*

33t

524

400

1 36

11.4

034

853 0

951.2

2...762

1.0

7400

3 670

3.64

26.0

Circuit 2

06DA537

6

29 2

24.3

100

—

—

—

—

1.36

11.4

Page 5

Mounting Unit — When unit is in proper location, use

of mounting holes in base rails is recommended for secur

ing unit to supporting structure, or for mounting unit on

vibration isolators if required. Fasteners for mounting unit

are field supplied. Be sure to mount unit level to ensure

proper oil return to compressors.

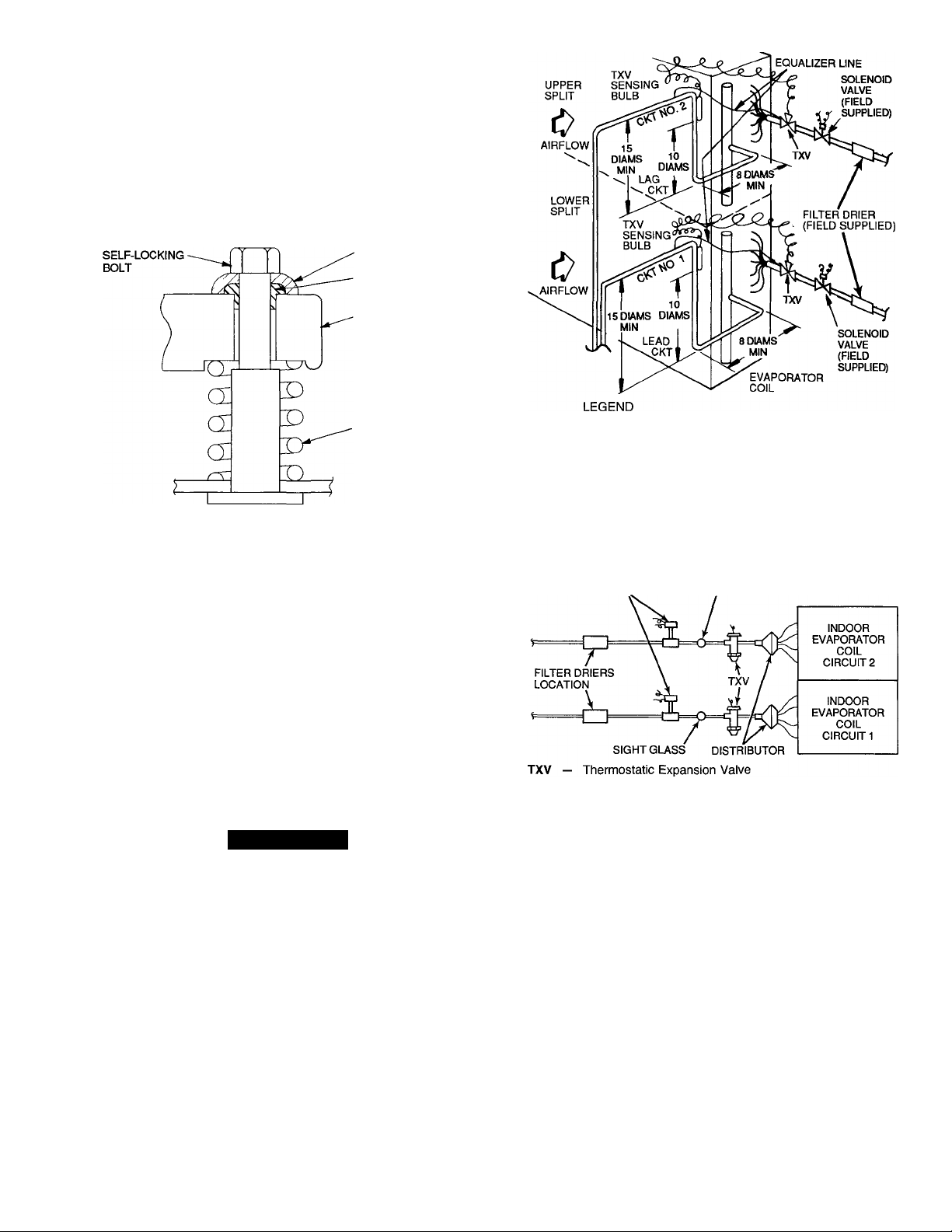

Compressor Mounting — As shipped, compressor

is held down by 4 bolts. After unit is installed, loosen each

bolt until the snubber washer can be moved with finger pres

sure. See Fig. 3.

SNUBBER FLANGED

WASHER

NEOPRENE

SNUBBER

COMPRESSOR FOOT

ISOLATION SPRING

Fig. 3 — Compressor Mounting

INSTALLATION

Refrigerant Piping Connections — Line sizes de

pend on length of piping required between condensing unit

and evaporator. See Table 2A or 2B. It is important to con

sider liquid lift and compressor oil return. Refer to Part 3 of

Carrier System Design Manual for line sizing information,

and Fig. 4 for recommended piping details.

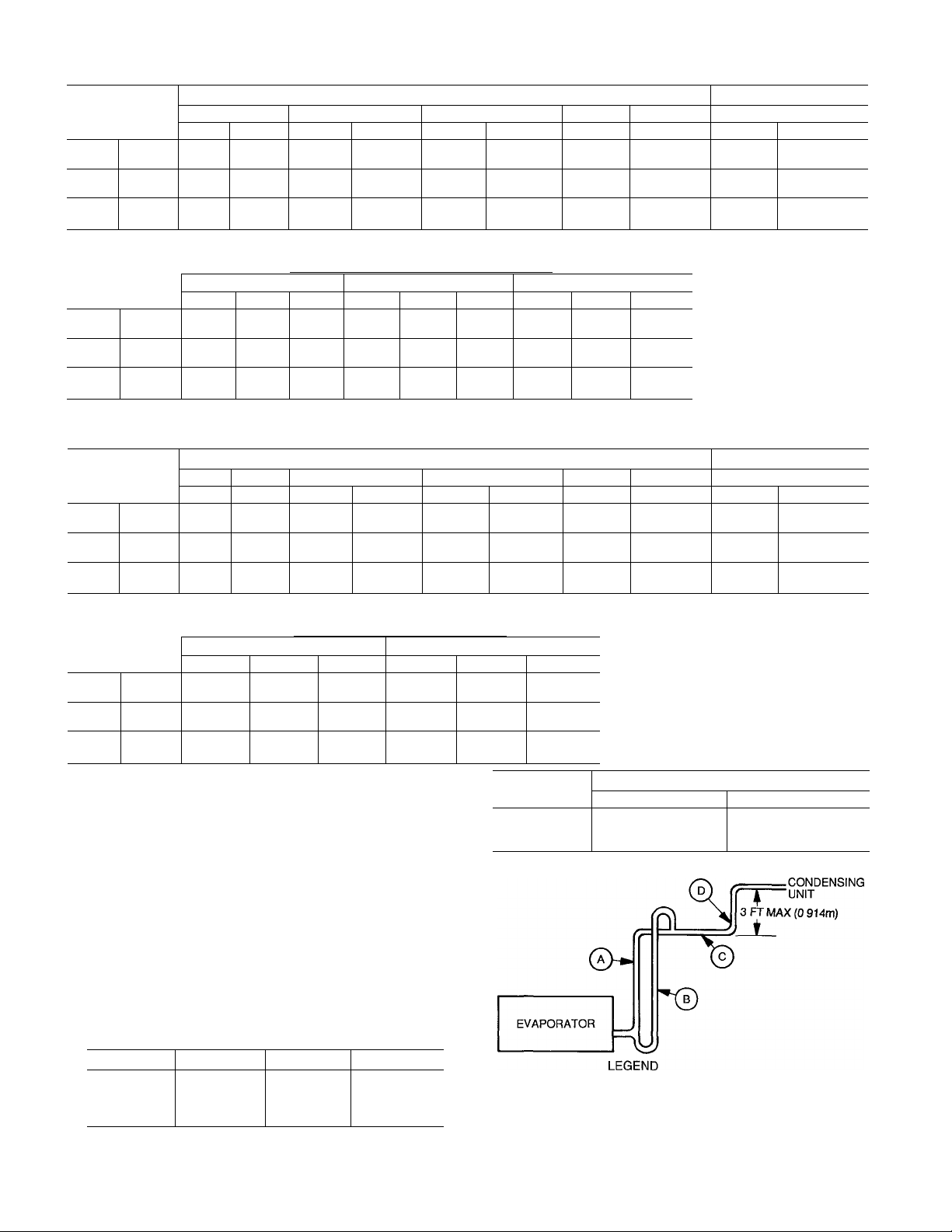

Solenoid Drop Refrigerant Control — All units

are factory wired to operate on solenoid drop refrigerant

control. A field-supplied liquid line solenoid valve must be

installed in the liquid line ahead of the indoor coil. See

Fig. 5. Wires from solenoid valve do not need to be in con

duit as coil voltage is 24 v (class 2 circuit).

A WARNING

Failure to properly install liquid line solenoid at the in

door unit as described, without Carrier authorization,

may VOID warranty.

Filter Drier and Moisture Indicator — Every unit

should have a filter drier and a sight glass (moisture indi

cator) field installed. Select the filter drier for maximum

unit capacity and minimum pressure drop. Figure 5 shows

recommended locations of filter drier(s) and sight glass(es).

Complete the refrigerant piping from the evaporator to the

condenser before opening the liquid and suction lines at the

condensing unit.

Receiver — No receiver is provided with the unit; it is

recommended that one not be used.

Piping Procedure — Do not remove run-around pipe

from suction and liquid line stubs until piping connections

TXV — Thermostatic Expansion Vaive

NOTES:

1. Lower section is first on and last off.

2. For more complete piping information, refer to Carrier System

Design Manual, Part 3, or E20-II refrigerant piping computer

program

Fig. 4 — Suction Line Piping to Unit with

2-Section Coil Split

fieLd-supplied

SOLENOID VALVE

SIGHT GLASS

Fig. 5 — Liquid Line Solenoid Valve,

Filter Drier(s), and Sight Glass Locations

are ready to be made. Pass nitrogen or other inert gas through

piping while brazing, to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve (TXV)

in liquid line ahead of each evaporator section.

SUCTION PIPING AT EVAPORATOR AND TXV BULB

LOCATION (See Fig. 5) — The purpose of these recom

mendations is to achieve good mixing of the refrigerant leav

ing the evaporator suction header for proper sensing by the

TXV bulb.

1. A minimum of two 90 degree elbows must be installed

upstream of the expansion valve bulb location.

2. The TXV sensing bulb should be located on a vertical

riser where possible. If a horizontal location is neces

sary, secure the bulb at approximately the 4 o’clock

position.

Copy continued on page 7.

Page 6

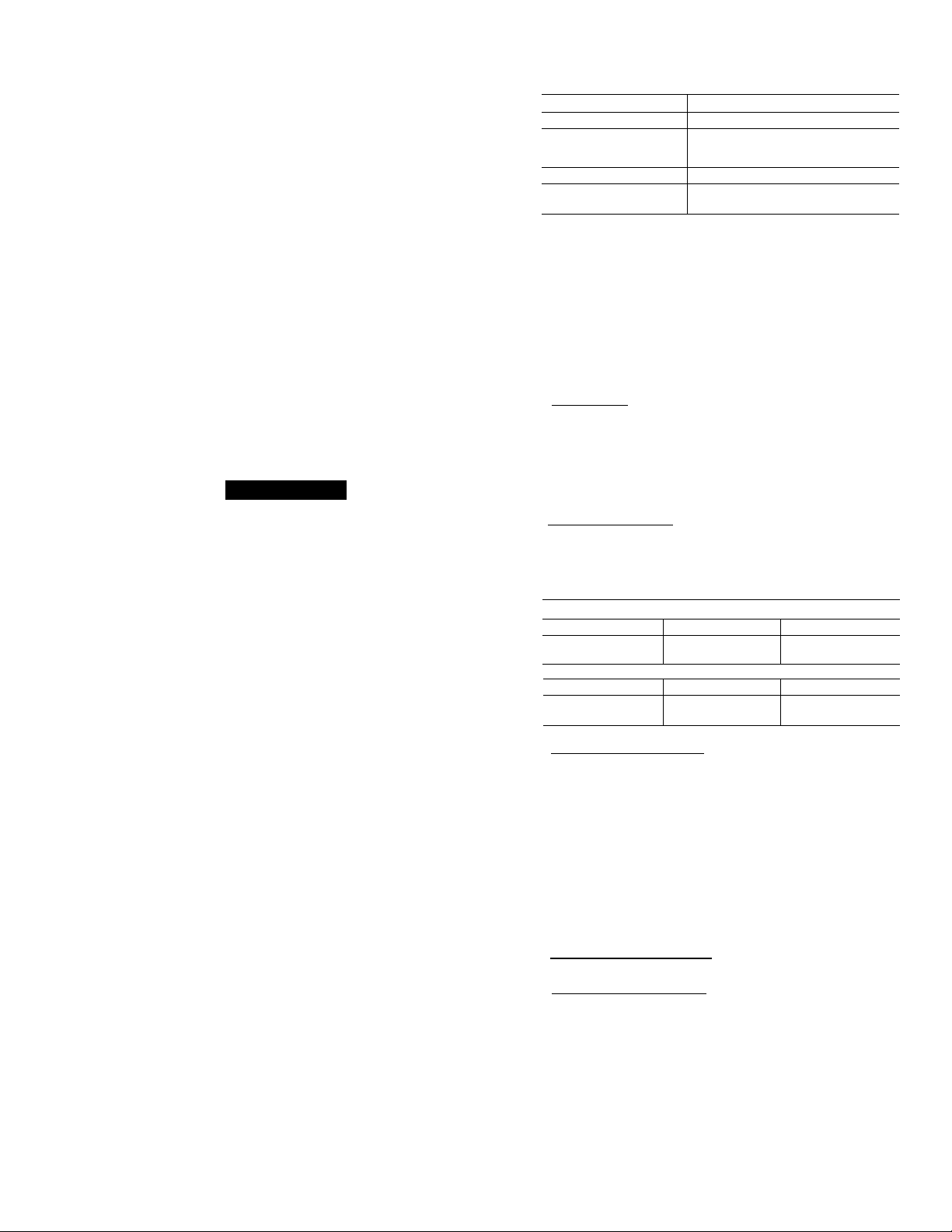

Table 2A — Refrigerant Piping Sizes — 60 Hz

SINGLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING FOR EACH CIRCUIT - ft

UNIT 38AH

024

028

034

Ckt 1

Ckt2

Ckt 1

Ckt 2

Ckt 1

Ckt 2

0-25 (0-7.6)

L

V2 1Ve

V2 1Ve

Vz

V2

Vz

Vz 1%

s

1У8 %

1У8 %

1У8 %

25-50 (7.6-15.2) 50-75 (15.2-22.9) 75-100

L S L s L

% 1% %

% 1% %

1% %

13/8

13/8

% 1% У8

DOUBLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING - ft (m)

UNIT 38AH

024

028

034

Ckt 1

Ckt 2

Ckt 1

Ckt 2

Ckt 1

Ckt 2

50-75 (15.2-22.9)

A

_ _ —

—

__

— —

1Уе

В С

—

_

13/8

- —

—

_

“

15/8

— — —

75-100 (22.9-30.5)

A

1Ув

1У8

1Уе

1Уе

1У8

В С

13/в

13/8 13/8

13/8

13/8

13/8

Table 2B — Refrigerant Piping Sizes — 50 Hz

SINGLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING FOR EACH CIRCUIT - ft

UNIT 38АН

0-25

(0-7.6)

L s

024

028

034

Ckt 1

Ckt 2

Ckt 1

Ckt 2

Ckt 1 Vz V/a

Ckt 2 Vz V/s

У2

У2

Vz

V2

1У8 3/e

1У8 3/8

1У8

1Va

DOUBLE SUCTION RISERS

LENGTH OF INTERCONNECTING PIPING - ft (m)

UNIT 38AH 75-100 (22.9-30.5)

A

024

028

034

Ckt 1

Ckt 2

Ckt 1

Ckt 2

Ckt 1 1У8

Ckt 2

LEGEND

L — Liquid Line

S — Suction Line

‘Double suction riser required if evaporator is below condensing

unit and 2 unloaders are used

tDouble suction riser required if evaporator is below condensing

unit and compressor is equipped with 2 unloaders. Note the only

time circuit no. 2 may be equipped with 2 unloaders is if it is serv

ing its own air handler and the unit does not require low ambient

operation (Motormaster® III control).

“Double suction riser required if evaporator is below condensing

unit and compressor has one or more unloaders

NOTES:

1. All line sizes are inches OD.

2. Standard unit comes with one pressure-operated unloader on cir

cuit no. 1. If unit serves one air handler, an additional unloader

may be field installed on circuit no 1 compressor only. If the unit

serves 2 separate air handlers and low-ambient operation is re

quired (Motormaster III control), each circuit’s compressor may

be equipped with only one unloader.

3 Equivalent line sizes in mm are as follows;

in. mm in.

У2

3/8 15.9

У8 22.2

1У8 28.6

1У8

1У8

1У8

1У8

1У8

12.7

25-50 (7.6-15.2) 50-75 (15.2-22.9) 75-100

L S L

13/8

13/8

%

3/s

3/8

3/8

13/8

13/8

13/8

13/8

В c A

13/8

13/e

13/8

13/8

13/8 13/8 13/8

13/8 13/8 13/e

13/8

13/8

13/8

15/e

mm

13/8 34 9

13/8 41.3

2Ув 54 0

1У8

1У8

1У8

IVe

13/8

13/8

13/8

%

%

13/8

13/8*

15/8

13/в

13/8 13/8 13/8

13/8 13/8 13/8

13/8 13/8

_

1Уз

1V8

13/в

s L

3/8

Vs

3/8

3/8

Vs

3/8

100-200 (30.5-61.0)

13/8

13/8

13/8

13/8

13/8

13/8

в c

13/8 13/8

13/8 13/8

13/8

13/8

13/8

13/8

UNIT 38AH

(g) — Suction Riser without Trap

(g) — Suction Riser with Trap

— Suction Line to Condensing Unit

— Use Single Suction Pipe Diameter Shown for 75 ft (22 9 m)

^ Interconnecting Pipe in Table Above

%

5/e

Ve

У8

У8

У8

100-200 (30.5-61.0)

А В

13/8

13/8

13/8

13/а

3/8

3/8

%

3/8

У8

Vs

13/8

13/8

2У8

2Ув

024

028

034

(m)

22.9-30.5) 100-200 (30.5-61.0)

У8

У8

L

s

13/8*

13/et

Vb

Vs

Vs

Vs

2Ув**

2У8**

2Уа**

21/8t

S

13/8*

13/8t

13/8*

13/et

13/8*

13/8

С

15/s

13/8

2У8

2У8

2У8

2Уа

(m)

22.9-30.5) 100-200 (30.5-61.0)

У8

L

s

13/8*

Vs

Vs

Vs

Vs

Vs

13/et

13/8**

13/8**

2У8*

2yet

S

13/8*

13/et

13/8*

13/et

15/8*

13/8

MAXIMUM LIQUID LIFT PER CIRCUIT

ft m

76

73

100

23.2

22.2

30.5

Page 7

3. Size the suction line from the evaporator through the

riser for high velocity. Suction piping for the high

velocity section should be selected for about 0.5° F

(0.3° C) frietion loss. If a 2° F (1.1° C) loss is allowed

for the entire suction line, 1.5° F (0.8° C) is left for the

balance of the suction line and it should be sized on that

basis. Check that the high-velocity sizing is ade

quate for oil return up the riser.

If an oil return connection at the bottom of this suction

header is supplied with an evaporator, this connection must

be teed-in ahead of first mixing elbow. When the condens

ing unit is below the evaporator, the riser at the evaporator

does not have to extend as high as the top level of a given

evaporator circuit. After a 15-diameter riser has been pro

vided, the suction line may elbow down immediately.

SAFETY RELIEF — A fusible plug is located on unit liq

uid line before the liquid valve. Other fusible plugs are

located on the compressor(s) and on the suction line(s).

VAV (Variable Air Volume) APPLICATIONS — Field-

supplied suction line accumulators (one per circuit)

(Replacement Components Division, Carrier Part

No. KH73LZ001) are required for VAV applications in

outdoor units.

A WARNING

Failure to install accumulator in outdoor unit VAV ap

plications may VOID warranty.

Power Supply — Electrical characteristics of available

power supply must agree with unit nameplate rating. Sup

ply voltage must be within limits shown in Table 3.

IMPORTANT: Operating unit on improper supply volt

age, or with excessive phase imbalance, constitutes

abuse and may affect Carrier warranty. See Unbal

anced 3-Phase Supply Voltage, page 8.

4. Maximum field wire sizes allowed by lugs on terminal

block are as follows:

V-PH-HZ

208/230-3-60

380-3-60

460-3-60

575-3-60

230-3-50

346-3-50

400-3-50

WIRE SIZE

350 kcmil (177.90 sq mm)

2/0 AWG (67 42 sq mm)

350 kcmil (177.90 sq mm)

2/0 AWG (67.42 sq mm)

5. Terminals for field power supply are suitable for cop

per, copper-clad aluminum, or aluminum conductors.

Insulation must be rated 167 F (75 C) minimum.

CONDENSER FANS — The fans must rotate counter

clockwise when viewed from above. If necessary, correct

direction of fan rotation by interchanging any 2 power

input wires at disconneet switch. Affix crankcase heater

decal (located in installer’s packet) to unit disconnect

switch.

FIELD CONNECTIONS

1. Main Power — Bring wires from the fused disconnect

switch through hole in bottom rail of unit to control box

(Fig. 6) and connect to terminals

11

13

12

on line side of terminal block TBl (see Fig. 7 or 8). To

comply with NEC Article 440-14, the disconnect must

be located within sight from and readily accessible from

the unit.

2.

24-v Control Power — Units have single point power

connections. Control circuit is directly connected inter

nally to unit. Maximum 24-v control circuit is 3.2 amps.

NOTE; For wire runs, use the following sizes of insu

lated wire;

Ft

0-50

No 18 AWG No 16 AWG No 14 AWG

35 C Min 35 C Min 35 C Min

0-15.2 15.2-22.9

0 82 sq mm 1.30 sq mm 2 08 sq mm

35 C Min 35 C Min 35 C Min

50-75

Over 75

Over 22.9

Power Wiring — All power wiring must comply with

applicable local and national codes. Install field-supplied

branch circuit fused disconnect(s) per NEC (National Eleetrical Code [U.S.A. Standard]) of a type that can be locked

OFF or OPEN. Disconnect(s) must be within sight from

and readily accessible from unit in compliance with NEC

Article 440-14.

GENERAL WIRING NOTES

1. A crankcase heater is wired in the eontrol cireuit so it is

always operable as long as power supply disconnect is

on, even if any safety device is open or unit stop-start

switch is off. It is protected by a 5-amp circuit breaker

in control power.

2. The power circuit field supply disconnect should never

be open except when unit is being serviced or is to be

down for a prolonged period. When operation is re

sumed, crankcase heater should be energized for 24 hours

before start-up. If unit is to be shut down for a pro

longed period, it is recommended that the suction and

discharge valves be closed to prevent an excessive ac

cumulation of refrigerant in the compressor oil.

3. Power entry is at compressor end only.

3. Control Circuit Interlock — An airflow switch may be

installed in the indoor air handler to prevent unit from

running when indoor air is not flowing. This switch

(Carrier part no. HR81JE001) is available from Service

Parts Center, or equivalent can be field supplied. This

should be electrically interlocked in the control circuit

as shown on the label diagram affixed to the access panel

on end of unit. Note that for a single air handler with

constant volume controls (those shown in Fig. 7 and 8),

the airflow switch must be used in combination with a

relay having 2 sets of normally open contacts (Carrier

part no. HN61KK040 or equivalent). For wiring, see

unit label diagram on inside of unit access door.

4. ModuPanel™ Connections — Refer to Fig. 9 and 10 for

field connections.

5. Transformer Connections — See unit wiring label diagram, notes 1 and 2, located behind compressor com

partment end access door.

IMPORTANT: Ensure power to the crankcase

heater is always on (except when servicing the

unit). If circuit breakers inside unit shut down

the compressor and condenser fans, crankcase heater

remains on.

Page 8

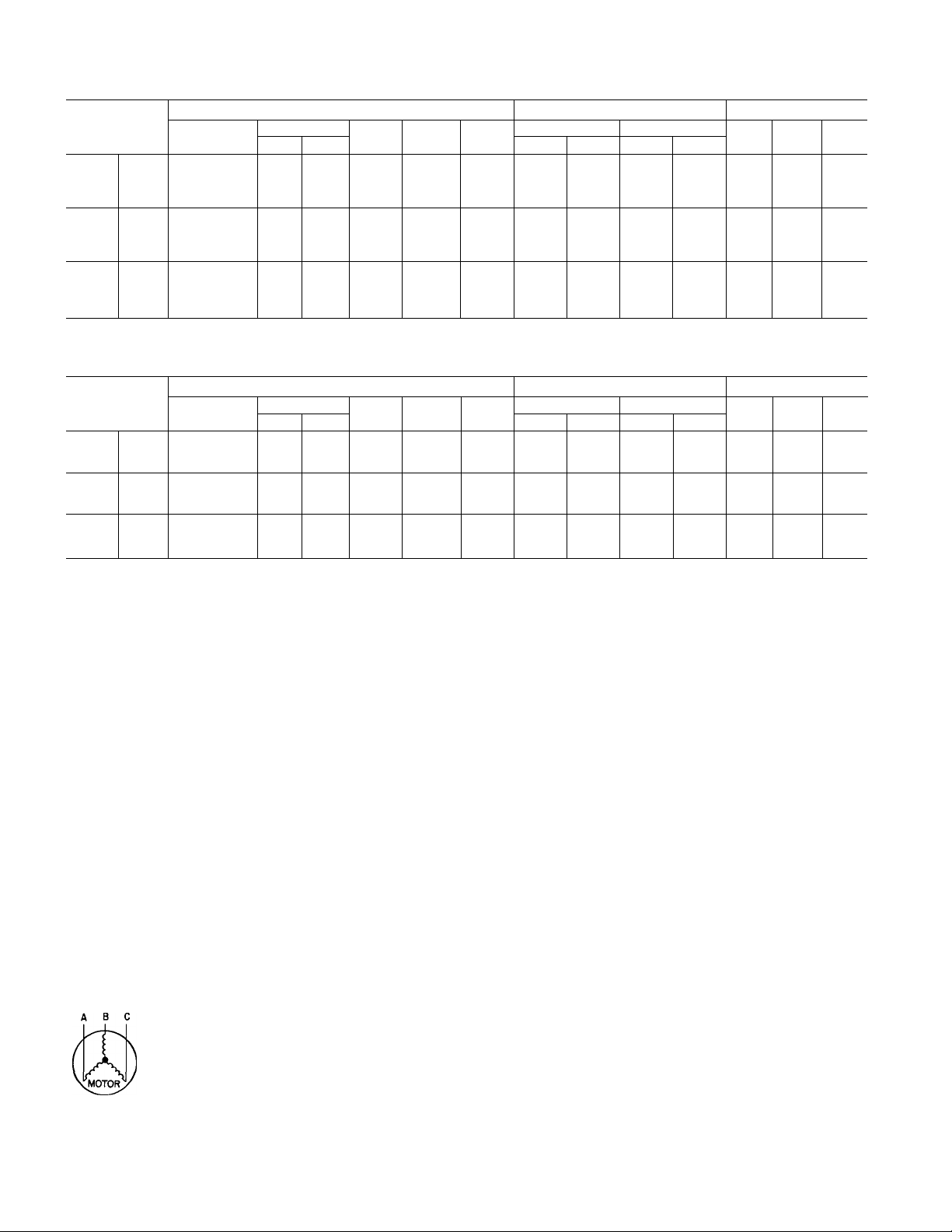

Table 3 — Electrical Data

60 HERTZ

UNIT 38AH

500

024

028

034

024 300 346

028

034

200

600

too

500

200

600 460

100 575

500

200

600

100

UNIT 38AH

800 230

900 400

800

300 346

900

800

300

900

Volts

3 Ph, 60 Hz

208/230

380

460

575

208/230

380

208/230

380

460

575

Volts

3 Ph, 50 Hz

230

400

230

346

400

UNIT COMPRESSOR

Supplied*

Min Max

187 254 100 8 125

342 418 61 8 80

414 508 50.3 60

632

518

254 110.5 150

187

342 418

414 508

632 47.1

518

254

187

342 418 77.0 110 256 8

414 508 65.8 90

632

518

MCA

42 1

135 5 175

MOCP

(Fuse)

50

67.2

55.9

53 3 70 193.8

90

70

60

ICF

408.4 39.3 39.3 198 198 2

193.8

204.2 196 196

168.4

468.4

215 8

234 2 22 1 22 1

188.8 19.7

506.4 43.6 63.6

340.2 22.1 30.0 114

50 HERTZ

UNIT COMPRESSOR

Supplied*

Min Max

254 101 2 125

198

311 380

342

400

198

311 380

342 400

198

311

342 400 65.1 90

MCA

254

254 135.9 175

380 78 1 110

1109 150

MOCP

(Fuse)

62.8 80 194.8 24 0

46.5 60 204 0 180

68.2

55.7

90

70

ICF

268.8 39.3 39.3

298 8 43.6

216.8

234 0

355 8 43.6 63 6 143

257.8 26.4 34.3 104 145 2 4.4 1

240 0 22 1 30 0 114

RLA LRA

Ckt 1

24 0

15.7

43.6

26 4 26 4

26.4 34 3 104

17.9 22 9

Ckt 1

26.4 26.4

22 1 22 1

Ckt 2 Cktl

24.0

157

43 6

19 7

RLA LRA

Ckt 2

24.0

18.0

43.6

Ckt 1 Ckt 2

FAN MOTORSt

Ckt 2

93 93

99 99

79 79

228 228

104 104

114 114

91

228 266

91 36

128 128

143 143 2

104 104 2

114 114 2 30

145

120

93 93

99 99

200

120

Qty

91

Qty

FLA

(ea)

6.2

2 39

2 3 1

2 3.4

2 62

2

39

2

3 1

3.4

2

2 62

2 39

2

3.1

2 34

FAN MOTORSt

FLA

(ea)

2 6.4

2 44 1

2

3.0

64

44 1

2 6.4

2 30

Hp

1

1

1

Hp

LEGEND

FLA — Full Load Amps

IGF — Maximum Instantaneous Current Flow during starting (the

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps (complies with National Electrical Code

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

point in the starting sequence where the sum of the LRA for

the starting compressor, plus the total RLA for all running com

pressors, plus the total FLA for all running fan motors is

maximum)

[NEC], Section 430-24) (U.S.A Standard)

UNBALANCED 3-PHASE SUPPLY VOLTAGE - Never

operate a motor where a phase imbalance in supply voltage

is greater than 2%. Use the following formula to determine

the percent voltage imbalance:

% Voltage Imbalance

— 100 max voltage deviation from average voltage

average voltage

Example: Supply voltage is 240-3-60.

AB = 243 V

BC =236 V

AC =238 V

Average Voltage =

243 -F236 -F238

= 239 V

’Units are suitable for use on electrical systems where volt

age supplied to unit terminals is not below or above listed

minimum and maximum limits

tAII fans are protected by a single circuit breaker.

Determine maximum deviation from average voltage:

(AB) 243 -239 =4 V

(BC) 239 -236 =3 V

(AC) 239 - 238 = 1 V

Maximum deviation is 4 v.

Determine percent voltage imbalance:

% Voltage Imbalance = 100 x

■ 1.1%

4

239

This amount of phase imbalance is satisfactory as it is

below the maximum allowable 2%.

IMPORTANT: Contact your local electric utility com

pany immediately if the supply voltage phase imbal

ance is more than 2%.

Page 9

CKTNO. 1

HINGED ACCESS DOOR

CKT NO 1COMPR

if''

FIELD CONTROL CIRCUIT WIRING

[22] 7/8' DIA (2)

CONTROL BOX

[22] 7/8 DIA

VAV CONTROL

[63-92] 2 l/2'-3 5/8 DIA

FIELD MAIN POWER SUPPLY

LEGEND

VAV — Variable Air Volume

NOTES;

1 There must be 4 ft [1220 mm] for ser

vice and for unrestricted airflow on all

sides of unit.

2 There must be 8 ft [2440 mm] clear

air space above unit

3. “C” is the package number indicates

copper coils

4 Dimensions in [ ] are in millimeters

5 The approximate operating weight of

the unit is shown below

6. Certified dimension drawing available

on request.

UNIT

38AH

024

024C

028

028C

034

034C

[63-92]

2 1/2"-3 5/8" DIA

FIELD POWER

ENTRY AND UFTING

CORNER WEIGHT - lbs [kg]

“1”

631.6

[286.5]

666 5

[302.3]

658.7

[298.8]

693.0

[314 3]

667 0

[302.5]

718 3

[325.8]

“2”

577.6

[262.0]

609 5

[276.5]

602.4

[273.3]

633 8

[287 5]

610 0

[276 7]

656.8

[297.9]

263 1

[119 3]

309.0

[140.2]

267 0

[121.1]

313.0

[142.0]

[130 7]

[156.4]

“3”

288.0

344.8

“4”

287.7

[130.5]

337 9

[153.3]

291 9

[132 4]

342 2

[155.2]

315.0

[142.9]

377.0

[171.0]

[22]

7/8' DIA (2)

FIELD CONTROL

POWER ENTRY

CENTER OF

GRAVITY^

A Dim.

in.

[mm]

40.0

[1016]

43.0

[1092]

39.3

[997]

42.3

[1073]

41 0

[1041]

44.0

[1117]

[22] 7/8 DIA

VAV

POWER ENTRY

B Dim.

in.

[mm]

32.8

[832]

TOTAL

UNIT

lb [kg]

1760

[798 3]

1923

[872.3]

1820

[825 6]

1982

[899 0]

1880

[853.0]

2097

[951.2]

10'-7 13/15'

SIDE VIEW

Fig. 6 — Dimensional Drawing — Units 38AH024, 028, 034

Page 10

3-WIRE COM BUS

! TO OTHER COMMUNICATING

f THERMOSTATS

0 o o o o o

1 2 1 2 FAN R.V.

COOL HEAT

TSR-01 RELAY PACK (MAXIMUM CONTACT

LOAD IS 1 AMP AT 24 V) (SEE NOTE 3.)

LEGEND

AUTO

C

CB

COM

GND

IFC

LLS

NEC

R.V.

TB

TC

Automatic Changeover

Contactor, Compressor

Circuit Breaker

Common

Ground

Indoor-Fan Contactor

Liquid Line Solenoid

National Electrical Code

(U.S.A. Standard)

Reversing Valve

Terminal Block

Thermostat, Cooling

Field Accessory Wiring

Field Control Wiring

Factory Wiring

Field Power Wiring

Indicates Common Potential;

Does Not Indicate Wiring

CARRIER COMMUNICATING

TEMP MONITOR

THERMOSTAT

(MODEL MS(T)OIES)

HEAT 2

HEAT1

COOL 2

COOL1

24 VAC (COMMON)

24 VAC (R)

THERMOSTAT*

o[^o[^o[^

CB5

24 V

TB2

[H

[C]

—

--[yT]

r

S

ra

—

-d]

—

--d]

--En]

S 1 ll

~Cr]

CB4

24 V

CB3

115 V t (ON 380-V UNITS. TB IS 230 V)

(346, 380,

400 V ONLY)

TB3

Illsi 1-

ICOMh

IlFClh

fCOMh

1 as2|--

ICOMh

1IFC2 1

ICOMi

1 1'

“1

11

1

'

( 1

ll

J_L,

■“I

_

“I

I

___

1

LLS1 (24 V)*

*Use thermostat wiring shown here for single air-handler

applications.

tCB3 protects control circuit at the following unit voltages:

CONTROL CIRCUIT

PROTECTED AT:

(V-Ph-Hz)

115-1-60

230-1-60

230-1-50

**For a single air handler, LLS valve no. 1 is to be used on the lower

(no. 1) evaporator circuit. The LLS valve no. 2 is to be used on the

upper (no. 2) evaportor circuit.

ttOnly one indoor-fan contactor is required on single air-handler

applications. Use Carrier accessory part no. 40RR900181 for indoor-

fan confacfor.

UNIT (V-Ph-Hz)

208/230-3-60

460-3-60

575-3-60

380-3-60

230-3-50

346-3-50

400-3-50

NOTES:

1. CB4 protects TB3 circuit; CBS protects TB2 circuits.

2. LLS1 and LLS2 are field supplied.

3. TB2 and TB3 are in 24-v circuits.

4. On the TSR-01 Relay Pack, the outside-air sensor, supply-air

sensor, and direct expansion coil sensor are available as

options.

Fig. 7 — Typical Wiring Schematic — Unit 38AH with Single Air Handler

I

Iz^j-i

TB1

ELD POWER SUPPLY

NEC DISCONNECT J

2 1/2” (63 mm) DIA HOLE

3 5/8" (92 mm) DIA HOLE

OR

Page 11

TSR-01 RELAY PACK (MAXIMUM CONTACT

LOAD IS 1 AMP AT 24 V) (SEE NOTE 3.)

TO OTHER COMMUNICATING

THERMOSTATS

CARRIER COMMUNICATING

TEMP MONITOR

THERMOSTAT

{MODEL MS(T)OIES)

FAN

HEAT 2

-----

HEAT1

------

COOL 2

8 0 COOL 1

1 |I®1 24 VAC

^111^—24 VAC —

----------

------------------

24 VAC — —

(COMMON)

FAN

-------

HEAT 2 —

HEAT1 —

COOL2 -

COOL1- -

(COMMON)

1

*CB3 protects control circuit at the following unit voltages;

THERMOSTAT NO. 1

CONTROL CIRCUIT

PROTECTED AT:

(V-Ph-Hz)

115-1-60 460-3-60

230-1-60 380-3-60

230-1-50

UNIT (V-Ph-Hz)

208/230-3-60

575-3-60

230-3-50

346-3-50

400-3-50

fuse Carrier accessory part no. 40RR900181 for indoor-

fan contactor.

"Install LLS valve no. 1 on the liquid line of the air handler

controlled by the 38AH circuit no. 1 thermostat. Install

LLS valve no. 2 on the liquid line of the air handler con

trolled by the 38AH circuit no. 2 thermostat.

NOTES:

1. Capacity control solenoid and liquid line (solenoid drop

refrigerant control) valves are field supplied.

2. CB4 protects TBS circuit; CBS protects TB2 circuit.

3. On the TSR-01 Relay Pack, the outside-air sensor, supplyair sensor, and direct expansion coll sensor are avail

able as options.

TSR-01 RELAY PACK (MAXIMUM CONTACT

LOAD IS 1 AMP AT 24 V) (SEE NOTE 3.)

3-WIRE COM BUS

TO OTHER COMMUNICATING

THERMOSTATS

CARRIER COMMUNICATING

TEMP MONITOR

THERMOSTAT

(MODEL MS(T)OIES)

Fig. 8 — Typical Wiring Schematic — Unit 38AH with 2 Air Handlers

R.V.

TB

Automatic Changeover

LEGEND

Contactor, Compressor

Circuit Breaker

Capacity Control Solenoid

Common

Ground

Indoor-Fan Contactor

Liquid Line Solenoid

National Electrical Code

^.S.A. Standard)

Reversing Valve

Terminal Block

Thermostat, Cooling

Field Accessory Wiring

Field Control Wiring

Factory Wiring

Field Power Wiring

Indicates Common

Potential; Does Not

Indicate Wiring

Page 12

LLSV CONTROL SCHEMATIC 124 VI

AFS — Airflow Switch LLSV

C — Contactor, Compressor LOR

CB — Circuit Breaker LPS

CLO — Compressor Lock-Out OPS

COM — Common PL

COTP — Compressor Overcurrent Protection SOLR

CR — Control Relay STAT

DISC — Disconnect TB

HPS — High-Pressure Switch TGD

IPC — Indoor-Fan Contactor TRAN

IPR — Indoor-Fan Relay U

kcmil — thousand circular mils VA

LLS — Liquid Line Solenoid VAV

NOTES TO FIG. 9 AND 10

Factory wiring is in accordance with National Electrical Code (NEC)

(U.S A. Standard) Field modifications or additions must be in com

pliance with all applicable codes

Wiring for field power supply must be rated 75 C minimum. Use

copper, copper-clad aluminum, or aluminum conductors Maxi

mum incoming wire size for main terminal block (TB1) is 350 max

kcmil (230 v). All other voltages 2/0 AWG (American Wire Gage)

maximum

Terminal blocks TB2, TB3, and TB4 are for external field control

connections Control connections are to be class 2 wiring.

Field-supplied components connected to TB3 (e.g., LLS1 and

LLS2) cannot exceed 75 va total inductive load at 24 vac, so that

Fig. 9 — Typical Wiring Schematic — VAV ModuPaner

One Dual-Circuit Condensing Unit with Air Handler

LEGEND

Liquid Line Solenoid Valve

Lock-Out Relay

Low-Pressure Switch

Oil Pressure Switch

Plug Assembly

Solenoid Relay

Thermostat

Terminal Block

Time Guard® Device

Transformer

Unloader (Solenoid)

Volt-Ampere

Variable Air Volume

TRAN1 does not become overloaded The air handler auxiliary

motor starter contacts must have a minimum rating of 30 va at

24 vac The airflow switch must have minimum contact rating of

125 va at 24 vac.

5. Replacement of factory wires must be with type 105 C wire or its

equivalent

6. Field-supplied liquid line solenoid valves installed at the evapo

rator are required on circuits no. 1 and 2 on all units

7. ModuPanel control is wired for one air handler only Re

move wire between TB2-2 to TB2-7 for ModuPanel control

applications

12

I I Terminal Block Connection

^—> Marked Terminal

Unmarked Terminal

O

Unmarked Splice

Field Accessory Wiring

Factory Wiring

Field Control Wiring

Field Power Wiring

Indicates Common Potential;

Does Not Represent Wiring

Page 13

( "

AFR

AFS

C

CB

CLO

COM

COTP

CR

DISC

HPS

IPC

IPR

kcmil

LLS

___

Airflow Relay

—

Airflow Switch

—

Contactor, Compressor

—

Circuit Breaker

—

Compressor Lock-Cut

—

Common

—

Compressor Cvercurrent Protection

—

Control Relay

—

Disconnect

—

High-Pressure Switch

—

Indoor-Fan Contactor

—

Indoor-Fan Relay

___

thousand circular mils

Liquid Line Solenoid

-

—

LLSV

LOR

LPS

OPS —

PL

SOLR

STAT

TB

TGD

TRAN

U

VA

VAV

Liquid Line Soienoid Valve I I

Lock-Out Reiay

—

Low-Pressure Switch ^ >

—

Oii Pressure Switch

Plug Assembly O

—

Solenoid Relay

—

Thermostat

—

Terminal Block

—

Time Guard® Device

—

Transformer

—

Unloader (Solenoid)

—

Volt-Ampere

—

Variable Air Volume

—

---------

__

______

______

______

Fig. 10 — Typical Wiring Schematic — VAV ModuPaner

Two Dual-Circuit Condensing Units

with Air Handler

13

Terminal Block Connection

Marked Terminal

Unmarked Terminal

^

Unmarked Splice

Field Accessory Wiring

Factory Wiring

Field Control Wiring

Field Power Wiring

Indicates Common Potential,

Does Not Represent Wiring

Page 14

PRE-START-UP

IMPORTANT: Before beginning Pre-Start-Up or

Start-Up, review Start-Up Checklist at the back of this

book. The Checklist assures proper start-up of a unit

and provides a record of unit condition, application

requirements, system information, and operation at ini

tial start-up.

A CAUTION

Do not attempt to start the condensing unit, even

momentarily, until the following steps have been com

pleted. Compressor damage may result.

System Check

1. Check all air handler(s) and other equipment auxiliary

components. Consult the manufacturer’s instructions re

garding any other equipment connected to the condens

ing unit. If unit has field-installed accessories, be sure

all are properly installed and correctly wired. If used,

airflow switch must be properly installed. See Fig. 9

or 10.

2. Backseat (open) compressor suction and discharge valves.

Now close valves one turn to allow refrigerant pressure

to reach test gages.

3. Open liquid line service valves.

4. Check tightness of all electrical connections.

5. Compressor oil level should be visible in sight glass.

Adjust the oil level as required. No oil should be

removed unless the crankcase heater has been ener

gized for at least 24 hours. See Service section. Oil

Charge on page 18.

6. Be sure unit is properly leak checked, dehydrated, and

charged. See Preliminary Charge, below.

7. Electrical power source must agree with nameplate

rating.

8. Crankcase heater must be firmly locked into compres

sor crankcase. Be sure crankcase is warm (heater must

be on for 24 hours before starting compressor).

9. Fan motors are 3-phase. Check rotation of fans during

first start-up check. Fan rotation is counterclockwise

as viewed from top of unit. If fan is not turning

counterclockwise, reverse 2 of the power wires.

10. Be sure compressor floats freely on the mounting springs

and that snubber washers can be moved with finger pres

sure. See Compressor Mounting, page 5, and Fig. 3

for loosening compressor bolts.

Leak Test and Dehydration — Leak test the entire

refrigerant system using soap bubbles and/or an electric

leak detector. Evacuate and dehydrate entire refrigerant sys

tem by use of methods described in GTAC II, Module 4,

System Dehydration.

Preliminary Charge — Refer to GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation for charg

ing methods and procedures. Charge each system with R-22

by the liquid charging method (through liquid service valve)

on the high side. See approximate refrigerant charge in

Table 1A or IB. Charge according to the values in the Charg

ing Chart, Eig. 11, page 16.

START-UP

Compressor crankcase heaters must be on for 24 hours

before start-up. To energize the crankcase heaters, set the

space thermostat above the ambient so there will be no de

mand for cooling. Close the field disconnect and turn on

the fan circuit breakers. Leave the compressor circuit break

ers off/open. The crankcase heaters are now energized.

After the heater has been on for 24 hours, the unit can be

started. If no time has elapsed since the preliminary charge

step has been completed, it is unnecessary to wait the

24-hour period.

Preliminary Checks

1. Ensure that compressor service valves are backseated.

2. Verify that each compressor floats freely on its mount

ing springs.

3. Check that electric power supply agrees with unit name

plate data.

4. Verify that compressor crankcase heaters are securely in

place.

5. Check that compressor crankcase heaters have been on

at least 24 hours.

6. Note that compressor oil level is visible in the sight glass.

7. Recheck for leaks using same procedure as previously

outlined in Pre-Start-Up section. Leak Test and De

hydration, this page.

8. If any leads are detected, evacuate and dehydrate as pre

viously outlined in Pre-Start-Up section. Leak Test and

Dehydration, this page.

Preliminary Oil Charge — Each compressor is fac

tory charged with oil (see Table lA or IB). When oil is

checked at start-up, it may be necessary to add or remove

oil to bring it to the proper level. One recommended oil

level adjustment method is as follows:

ADD OIL — Close suction service valve and pump down

crankcase to 2 psig (14 kPa). (Low-pressure switch must be

jumpered.) Wait a few minutes and repeat until pressure re

mains steady at 2 psig (14 kPa). Remove oil fill plug above

the bull’s-eye, add oil through plug hole, and replace plug.

Run compressor for 20 minutes and check oil level.

NOTE: Use only Carrier approved compressor oil. Ap

proved sources are:

Petroleum Specialties Inc

Texaco, Inc......................................................Capella WF-32

Witco Chemical Co...............................................Suniso 3GS

Do not use oil that has been drained out, or oil that has

been exposed to atmosphere.

REMOVE OIL — Pump down compressor to 2 psig

(14 kPag). Loosen the Ut-in. (6.4 mm) pipe plug at the com

pressor base and allow the oil to seep out past the threads

of the plug.

NOTE: The crankcase will be slightly pressurized. Do not

remove the plug, or the entire oil charge will be lost.

Small amounts of oil can be removed through the oil pump

discharge connection while the compressor is running.

.....................................

Cryol 150A

Start Unit — The field disconnect is closed, the fan cir

cuit breaker is closed and the space thermostats are set above

ambient so that there is no demand for cooling. Only the

crankcase heaters will be energized.

i

14

Page 15

Next, close the compressor circuit breakers and then re

set space thermostat TCI below ambient so that a call for

stage one cooling is ensured. If compressor does not start,

set thermostat lower.

NOTE: Do not use circuit breakers to start and stop the

compressor except in an emergency.

If 38AH is connected to a single 2-stage cooling thermo

stat (one fan coil), start-up of circuit no. 1 compressor will

be delayed from one second to 5 minutes from the time the

call for cooling is initiated (see Fig. 12). TC2 (thermostat

contacts 2) close l'/2° F (0.7° C) lower than TCI. After

these contacts close, start up of circuit no. 2 compressor

will be delayed from one second to 5 minutes from the time

the call for cooling is initiated (see Fig. 12).

A CAUTION

Never charge liquid into the low-pressure side of sys

tem. Do not overcharge. During charging or removal

of refrigerant, be sure indoor-fan system is operating.

Adjust Refrigerant Charge

NOTE: Actual start-up and all refrigerant charge modifica

tions should be done only under supervision of a qualified

refrigeration mechanic.

With all fans operating, adjust the refrigerant charge in ac

cordance with the unit charging charts located on the inside

of the control box doors and in Fig. 11.

Measure pressure at the liquid line service valve, being

sure Schrader depressor is used if required. Also, measure

liquid line temperature as close to the liquid service valve

as possible. Add charge until the pressure and temperature

conditions of the charging chart curve are met. If liquid

pressure and temperature point fall above curve, add charge.

If liquid pressure and temperature point fall below curve,

reduce the charge until the conditions match the curve.

If the sight glass is cloudy, check refrigerant charge again.

Ensure all fans are operating. Also ensure maximum

allowable liquid lift has not been exceeded. If charged per

chart and if the sight glass is still cloudy, check for a plugged

filter drier or a partially closed solenoid valve. Replace or

repair, as needed.

Check Compressor Oil Level — After adjusting the

refrigerant charge, allow each circuit to run fully loaded for

20 minutes. Running oil level should be within view of the

crankcase sight glass. Stop the compressors at the field power

supply disconnect and check the crankcase oil level. Add

oil only if necessary to bring the oil into view in the sight

glass. If oil is added, run the circuit for an additional 10

minutes, then stop and check oil level. If the level remains

low, check the piping system for proper design for oil re

turn; also, check the system for leaks.

If the initial check shows too much oil (too high in the

sight glass) remove oil to proper level. See Preliminary Oil

Charge, page 14, for proper procedure for adding and re

moving oil.

When the above checks are complete, repeat the proce

dure with the unit operating at minimum load conditions.

For this minimum load check, operate each circuit’s com

pressor individually and unloaded to minimum step.

Unload the compressor(s) by turning the control set point

adjustment nut counterclockwise until the adjustment nut

stops. The unloader is now at 0 psig (0 kPag) set point. If

electric actuated unloaders are installed, energize the sole

noid to unload the compressor.

Return unloader to original setting after checks are

complete.

Final Checks — Ensure all safety controls are operat

ing, control panel covers are on, and the service panels are

in place.

15

Page 16

500

500 1000 1500 2000 2500

NOTE: All outdoor fans must be operating

Fig. 11 - Units 38AH024-034 Charging Chart, 50/60 Hz (Circuits No. 1 and 2)

1000 1500 2000

LIQUID PRESSURE AT LIQUID VALVE (kPag)

UNITS 38AH024 AND 028

LIQUID PRESSURE AT LIQUID VALVE (kPag)

UNIT 38AH034

2500

TIME DELAY TIMING SEQUENCE

U

---------------— 1 SEC

1 V///////////////////22Z.

TIME GUARD® I

RUNNING TIME

--------------------------------------

----------------

DEVICE (CIRCUITS NO 1 AND 2)

—

-180 SEC-

DENOTES CLOSED CONTACTS

--------------------

RUNNING TIME

ACCESSORY WINTER-START KIT

(CARRIER PART NO. 38AE900021)

Fig. 12 — Timer Sequence Chart

16

►

5 MIN

---------

Page 17

SEQUENCE OF OPERATION

Single Air Handler, 2-Stage Cool Thermostat

— At start-up, the thermostat calls for first-stage cooling

(TCI closes) and with all safety devices satisfied, circuit

no. 1 control relay (CRl) closes, deenergizing the crank

case heater at compressor no. 1. The indoor-fan motor starts

immediately, and the liquid line solenoid valve (LLSV) for

solenoid drop refrigeration control on circuit no. 1 opens.

Outdoor-fan motor no.l and compressor no. 1 start after

one second. Fan no. 2 starts if the outdoor ambient is above

60 F (15.6 C).

On standard units, compressor no. 1 operates either fully

loaded or at one step of unloading depending on the suction

pressure, which in turn is dependent on the evaporator load

conditions. As cooling demand increases, TC2 of the 2-stage

thermostat energizes control relay no. 2. CR2 deenergizes

the crankcase heater at compressor no. 2 and brings on com

pressor no. 2 after one second. The LLSV for solenoid drop

refrigerant control (circuit no. 2) opens as soon as CR2 is

energized. On standard units, compressor no. 2 operates

fully loaded.

As cooling demand is satisfied, thermostat contacts TC2

break and deenergize CR2 which then deenergizes compres

sor no. 2 and energizes its crankcase heater. The LLSV on

circuit no. 2 closes, preventing refrigerant migration back

to compressor no. 2 during the off cycle. If the space tem

perature continues to decrease, stage 1 thermostat contacts

TCI break and deenergize CRl. Immediately after CRl is

deenergized, compressor no. 1 shuts off and its crankcase

heater is energized. The LLSV on circuit no. 1 closes, pre

venting refrigerant migration back to compressor no. 1

during the off cycle. Outdoor-fan motors no. 1 and 2 de

energize as soon as CRl is deenergized.

NOTE: If thermostat fan switch is in the auto position, the

indoor fan will cycle on and off as the thermostat calls for

cooling (or heating). If the fan switch is in the continuous

position, the fan will run as long as the outdoor unit is pow

ered up.

Two Air Handlers — Two 2-Stage Cool Ther

mostats (One Per Air Handler) — At start-up of

circuit no. 1, the thermostat controlling circuit no. 1 calls

for first stage of cooling when thermostat contact TCI closes.

If all safety devices are satisfied, circuit no. 1 control relay

CRl energizes which deenergizes the crankcase heater in

side compressor no. 1. The indoor-fan motor on the circuit

no. 1 fan coil starts immediately, and the main liquid line

solenoid valve (LLSV) for solenoid drop refrigerant control

on circuit no. 1 opens. Outdoor-fan motor no. 1 and com

pressor no. 1 start after one second. Fan no. 2 starts if the

outdoor ambient is above 60 F (15.6 C).

On standard units, compressor no. 1 operates either fully

loaded or at one step of unloading depending on the suction

pressure, which in turn is dependent on the evaporator load

conditions. As cooling demand increases, TC2 of the 2-stage

thermostat energizes the capacity control LLSV resulting in

full activity of the evaporator surface. The fully active

evaporator surface will raise the suction pressure until the

pressure-operated capacity control valve setting is ex

ceeded, so that the compressor becomes fully loaded.

The thermostat controlling circuit no. 2 calls for first stage

of cooling when thermostat contact TC2 closes. Assuming

all safety devices are satisfied, circuit no.2 control relay

CR2 energizes, which deenergizes the crankcase heater in

side compressor no. 2. The indoor-fan motor on circuit

no. 2 fan coil starts immediately, and the main LLSV for

solenoid drop refrigerant control on circuit no. 2 opens. Com

pressor no. 2 starts after one second. The outdoor fans are

already running if circuit no. 1 is running. If circuit no. 1 is

not running when thermostat no. 2 calls for cooling, the

outdoor fans are off. In this situation, outdoor-fan motor

no. 1 starts when compressor no. 2 starts. Outdoor-fan mo

tor no. 2 comes on if the outdoor ambient is above 60 F

(15.6 C).

As cooling demand is satisfied at thermostat no. 1 or 2

(whichever comes first), contacts TC2 break, and the ca

pacity control LLSV on that circuit is deenergized. This

prevents refrigerant flow through the upper (circpit no. 1 or

2) evaporator section causing the suction pressure to drop

and the compressor on that circuit to unload.

NOTE; Circuit no. 2 does not have a factory-installed un

loader. If desired, one must be added in the field.

As the space temperature drops further, the space ther

mostat contacts TCI open which will deenergize control re

lay CRl or CR2. Immediately after CRl or CR2 is deen

ergized, the compressor CRl or CR2 control is shut off and

its crankcase heater is energized. The LLSV on that circuit

closes, preventing refrigeration migration back to the com

pressor during the off cycle. Outdoor-fan motors no. 1 and

2 are deenergized only if the space thermostats for both cir

cuits no. 1 and 2 are not calling for cooling.

NOTE; If thermostat fan switch is in the auto position, the

indoor fan will cycle on and off as the thermostat calls for

cooling (or heating). If the fan switch is in the continuous

position, the fan will run as long as the outdoor unit is pow

ered up.

Restart — Manual reset of the 24-v control circuit is nec

essary if unit shutdown is caused by automatic reset de

vices (including COTP [compressor overcurrent protection]

and HPS [high-pressure switch]) or if shutdown is caused

by manual reset devices (including OPS [oil pressure switch]

and compressor circuit breaker protection). To restart the

unit when COTP or HPS has tripped {after COTP and HPS

have reset automatically), open and then close the thermo

stat contacts. Opening and then closing thermostat contacts

interrupt and reapply 24-v power to the compressor lockout

(CLOl and CL02) which resets the devices.

It is necessary to manually reset the compressor circuit

breaker and OPS at the unit if either of these safeties should

shut down the unit.

IMPORTANT: If either OPS trips, it must be reset

first before making and breaking the thermostat con

tacts to reset CLOl and CL02. If this procedure is

not followed, the CLOl and CL02 cannot reset.

If the LPS (low-pressure switch) is not closed, the call

for cooling is interrupted and the Time Guard® device is

activated. This deenergizes control relay(s) (CRl or CR2)

and deenergizes the compressor for a 5-minute time period.

At the end of this 5-minute period, if the LPS is closed, the

compressor restarts. If the system is low on charge, LPS

cannot reset and the unit will stay off on this safety.

Causes of Complete Unit Shutdown:

• interruption of supplied power

• open compressor overtemperature protection (COTP)

• compressor electrical overload protection (CB1 or CB2)

• open high-pressure or low-pressure safety switches

• open oil pressure switch

17

Page 18

SERVICE

A CAUTION

I Tum off all power to unit before proceeding.

Access for Servicing (See Fig. 13)

COMPRESSOR SECTION — The compressor compart

ment has 2 side doors and one front door for servicing, pro

viding access to compressors, all components of the refrig

eration system, electrical controls, and control box. After

opening the front door an inner cover must be removed for

access to control box.

OIL PRESSURE SAFETY SWITCH - Switch is reset by

opening either access door on either side of the unit. Circuit

no. 1 oil pressure safety switch is reset by opening the side

access door on the left side of the unit (as viewed from the

compressor end). Circuit no. 2 oil pressure safety switch is

reset by opening the side access door on the right side of

the unit. Circuit no. 1 liquid line service valve is located

directly below circuit no. 1 oil pressure switch. Circuit

no. 2 liquid line service valve is located directly below cir

cuit no. 2 oil pressure switch.

CONDENSER SECTION — Condenser-fan motors and fans

can be serviced by removal of outlet grilles or side panels.

If a fan motor is serviced, be sure the wire fan guard is in

place over each fan before starting unit. See Fig. 14 for

proper fan adjustment. Tighten fan hub securely on motor

shaft with setscrew which bears against the key. Be sure to

replace Permagum and rubber cap over end of motor shaft

to protect against moisture causing fan to rust on shaft. Re

check rotation of fan(s) after service work on motors.

Fan Adjustment (See Fig. 14)

Oil Charge — Compressors are factory charged with oil

as follows:

COMPRESSOR

06D824

06D328

06D537

When additional oil or a complete charge is required, use

only Carrier-approved compressor oil:

Petroleum Specialities

Texaco, Inc......................................................Capella WF-32

Witco Chemical Corp

IMPORTANT: Do not use drained oil or use oil that

has been exposed to atmosphere. Refer to GTAC II,

Module 5; Charging, Recovery, Recycling, and Rec

lamation for procedures to add oil. To remove excess

oil. Isolate the compressor by use of the service valves,

slowly relieve the internal pressure, and then use the

oil drain plug at the bottom of the compressor to re

move the excess oil.

..........................................

..........................................

AMOUNT

pints (liters)

10 (4.73)

10 (4.73)

10 (4.73)

________

Cryol 150A

Suniso 3GS

CONTROL SET POINT — The control set point (cylin

der load point) is adjustable from 0 to 85 psig (0 to

586 kPa). To adjust, turn control set point adjustment nut

(Fig. 15) clockwise to its bottom stop. In this position,

set point is 85 psig (0 to 586 kPa). Then tum adjustment

counterclockwise to desired control set point. Every full

turn counterclockwise decreases set point by 7.5 psig

(51.7 kPa).

PRESSURE DIFFERENTIAL - The pressure differential

(difference between cylinder load and unload points) is ad

justable from 6 to 22 psig (41 to 15.2 kPa). To adjust, tum

pressure differential adjustment screw (Fig. 15) counter

clockwise to its backstop position. In this position, differ

ential is 6 psig (41 kPa). Then, tum adjustment clockwise

to desired pressure differential. Every full turn clockwise

increases differential by 1.5 psig. (10.34 kPa).

Capacity Control, Electrically Operated Unload

ers (Variable Air Volume, Factory-Installed

Option Units) — Each controls 2 cylinders. Electric

unloaders are not field adjustable. Circuit no. 1 compressor

on this factoiy-installed option has 2 electric unloaders. For

service, replace any failed solenoid.

Oil Pressure Safety Switch (OPS) — In the con

trol circuit, switch stops the compressor and unit, if proper

oil pressure differential is not established at start-up or main

tained during operation. If OPS stops the unit, determine

the cause and correct before restarting unit. Failure to do so

will constitute abuse. Equipment failure due to abuse may

void the warranty.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual reset, am

bient compensated, magnetic breaker protects against

motor overload and locked rotor conditions.

COMPRESSOR OVERTEMPERATURE PROTECTION

(COTP) — A thermostat installed on compressor motor wind

ing reacts to excessively high winding temperatures and shuts

off the compressor.

TIME GUARD® Control — Control prevents compressor

from short cycling. See Sequence of Operation.

CRANKCASE HEATERS — Heaters minimize absorption

of liquid refrigerant by oil in crankcase during brief or ex

tended shutdown periods. The control circuit is maintained

if compressor fan motor circuit breakers are turned off. The

main disconnect must be on to energize crankcase heater.

IMPORTANT: Never open any switch or disconnect

that deenergizes the crankcase heaters unless unit is

being serviced or is to be shut down for a prolonged

period. After a prolonged shutdown on a service job,

energize the crankcase heaters for 24 hours before start

ing the compressor.

High-Pressure Switches — Switches have fixed,

nonadjustable settings. Switches are mounted on the

compressors.

Liquid Shutoff/Charging Valve — Valve is lo

cated inside the compressor compartment and is provided

with Vi-in. flare connection for field charging.

Capacity Control, Suction Pressure — Actu

ated Unloaders — Each controls 2 cylinders. Unload

ers are factory set (see Table lA or IB) but may be field

adjusted.

Low-Pressure Switches — Switches have fixed, non

adjustable settings. The switches are mounted on the

compressors.

TO CHECK — Slowly close liquid shutoff valve and allow

compressor to pump down. Do not allow compressor pump

down below 2 psig (13.8 kPa). Compressor should shut down

when suction pressure drops to cutout pressure in Table 4,

and should restart when pressure builds up to cut-in pres

sure shown.

18

Page 19

06D COMPRESSOR WITH PAN

OIL PRESSURE SWITCH AND LIQUID LINE SERVICE

VALVE LOCATIONS

CIRCUIT NO 1 CIRCUIT NO. 2

Fig. 13 — 38AH Unit with Access Panels Removed

19

Page 20

TOP OF FAN ORIFICE

FILL HOLE IN FAN HUB

CONTROL

SET POINT

ADJUSTMENT

-NUT

PROP LOCATION

60 Hz

38AH024-034

50 Hz

38AH024-034

“A” in. (mm)

3.5 (89)

4.3 (109)

Fig. 14 — Location of Prop on Motor Shaft

from Outside of Orifice Ring

Table 4 — Pressure Switch Settings, psig (kPa)

HIGH PRESSURE

Cutout Cut-in Cutout

426 ± 7 320 ± 20

(2937 ± 48) (2206 ± 138) 186 ± 21) (303 ± 34)

LOW PRESSURE

Cut-in

27 ± 3 44 ± 5

Winter Start Control — Purchase accessory Carrier

part no. 38AE900021 for winter start control.

Head Pressure Control — Control allows system to

operate at full capacity under low ambient temperature

conditions.

FAN CYCLING — These 38AH units have standard pro

vision for fully automatic intermediate-season head pres

sure control through condenser fan cycling. Fan no. 2 is

cycled by an outdoor-air thermostat which responds to out

door ambient temperature. The thermostat is loeated in the

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

BYPASS

PISTON RING

BYPASS PISTON

DIFFERENTIAL SCREW

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

POWER HEAD

VALVE BODY

Fig. 15 — Capacity Control Valve

lower divider panel between the compressor compartment

and condenser section. Through a hole in the panel, the

sensing element is exposed to air entering the no. 1 fan

compartment. Fan no. 1 is non-cycling. Table 5 shows the

operating settings of the air temperature switch.

Table 5 — Fan Cycling Controls

CONTROL BY

Temp — F (C)

NOTE: See Fig. 6 for fan arrangement.

SWITCH OPENS

60 ± 3 (15 6 ± 1.7) 70 ± 3 (21.1 ± 1.7)

SWITCH CLOSES

20

Page 21

TROUBLESHOOTING

PROBLEM

COMPRESSOR DOES NOT RUN

Contactor Open

1. Power off.

2. Fuses blown in field power circuit.

3. No control power.

4. Thermostat circuit open.

5. Time Guard® II device not operating.

6. Compressor circuit breaker tripped.

7. Safety device lock-out circuit active.

8. Oil pressure switch tripped.

9. See oil pressure switch section.

10. High-pressure switch open.

11. Compressor overtemperature switch open.

12. Loose electrical connections.

13. Compressor stuck.

Contactor Closed

1. Compressor leads loose.

2. Motor windings open.

3. Single phasing.

COMPRESSOR STOPS ON HIGH-PRESSURE

SWITCH

Outdoor Fan On

1. High-pressure switch faulty.

2. Reversed fan rotation.

3. Airflow restricted.

4. Air recirculating.

5. Noncondensables in system.

6. Refrigerant overcharge.

7. Line voltage incorrect.

8. Refrigerant system restrictions.

Outdoor Fan Off

1. Fan slips on shaft.

2. Motor not running.

3. Motor bearings stuck.

4. Motor overload open.

5. Motor burned out.

COMPRESSOR CYCLES ON LOW-PRESSURE

SWITCH

Indoor-Air Fan Running

1. Compressor suction service valve partially

closed.

2. Liquid line solenoid valve(s) fails to open.

3. Filter drier plugged.

4. Expansion valve power head defective.

5. Low refrigerant charge.

SOLUTION

1. Restore power.

2. After finding cause and correcting, replace with correct size

fuse.

3. Check secondary fuse(s); replace with correct type and size.

Replace transformer if primary windings receiving power.

4. Check thermostat setting.

5. Check Time Guard 11 devices.

6. Check for excessive compressor current draw. Reset breaker;

replace if defective.

7. Reset lock-out circuit at thermostat or circuit breaker.

8. See oil pressure switch section.

9. Check for refrigerant undercharge, obstruction of indoor air-

flow, or whether compressor suction shutoff valve is fully open.

Make sure liquid line solenoid valve(s) is open.

10. Check for refrigerant overcharge, obstruction of outdoor airflow, air in system, or whether compressor discharge valve is

fully open. Be sure outdoor fans are operating correctly.

11. Check for open condition. Allow for reset. Replace if defective.

12. Tighten all connections.

13. See 06D compressor service literature.

1. Check connections.

2. See 06D compressor service literature.

3. Check for blown fuse. Check for loose connection at compres-

sor terminal.

1. Replace switch.

2. Confirm rotation, correct if necessary.

3. Remove obstruction.

4. Clear airflow area.

5. Purge and recharge as required.

6. Purge as required.

7. Consult power company.

8. Check or replace filter drier, expansion valve, etc. Check that

compressor discharge service valve is fully open.

1. Tighten fan hub setscrews.

2. Check power and capacitor.

3. Replace bearings.

4. Check overload rating. Check for fan blade obstruction.

5. Replace motor.

1. Open valve fully.

2. Check liquid line solenoid valve(s) for proper operation.

Replace if necessary.

3. Replace filter drier.

4. Replace power head.

5. Add charge. Check low-pressure switch setting.

21

Page 22

TROUBLESHOOTING (cont)

PROBLEM

COMPRESSOR CYCLES ON LOW-PRESSURE

SWITCH (cont)

Airflow Restricted

1. Coil iced up.

2. Coil dirty.

3. Air filters dirty.

4. Dampers closed.

Indoor-Air Fan Stopped

1. Electrical connections loose.

2. Fan relay defective.

3. Motor overload open.

4. Motor defective.

5. Fan belt broken or slipping.

COMPRESSOR STOPS ON OIL PRESSURE

SWITCH

1. Oil level too low or too high.

2. Compressor is short cycling.

3. Crankcase heater off.

4. Low refrigerant charge.

5. Refrigerant floodback.

6. Evaporator coil is blocked or iced.

7. Evaporator fan not operating.

8. Distributor and/or TXV too large.

9. Suction riser too large.

10. Defective oil pressure switch.

11. Plugged oil pump inlet screen.

12. Faulty oil pump drive segment.

13. Worn oil pump.

14. Worn compressor bearings.

COMPRESSOR RUNNING BUT COOLING

INSUFFICIENT

Suction Pressure Low

1. Refrigerant charge low.

2. Head pressure low.

3. Air filters dirty.

4. Expansion valve power head defective.

5. Indoor coil partially iced.

6. Indoor airflow restricted.

Suction Pressure High

1. Unloaders not functioning.

2. Compressor valve defective.

3. Heat load excessive.

SOLUTION

1. Check refrigerant charge.

2. Clean coil fins.

3. Clean or replace filters.

4. Check damper operation and position.

1. Tighten all connections.

2. Replace relay.

3. Power supply.

4. Replace motor.

5. Replace or tighten belt.

1. Check oil level requirements; adjust oil level until within

view of sight glass when running.

2. Check for

a. Thermostat location and operation.

b. Safety device lockout circuit operation.

c. Low-pressure switch operation.

3. Check relay operation; replace crankcase heater(s), if

defective.

4. Adjust charge as required.

5. Adjust TXV superheat.

6. Check and correct as required.

7. Check and correct as required.

8. Check sizing at design conditions; change if incorrect for

current application.

9. Check line sizing at minimum design condition; change

piping if incorrect.

10. Check switch for proper operation; check capillary lines for

plugged lines.

11. Clean oil pump screen.

12. Replace drive segment.

13. Replace bearing head assembly.

14. Replace compressor; see 06D service instructions.

1. Add refrigerant.

2. Check refrigerant charge.

Check outdoor-air fan thermostat settings.

3. Clean or replace filters.

4. Replace power head.

5. Check low-pressure setting.

6. Remove obstruction.

1. Check unloader adjustments.

Check unloader setting.

2. See 06D compressor service literature.

3. Check for open doors or windows in vicinity of fan coil

22

Page 23

TROUBLESHOOTING (cont)

PROBLEM

UNIT OPERATES TOO LONG OR CONTINUOUSLY

1. Low refrigerant charge.

2. Control contacts fused.

3. Air in system.

4. Partiaily plugged expansion valve or filter drier.

SYSTEM IS NOISY

1. Piping vibration.

2. Compressor noisy.