Page 1

38AF

HEATING & COOLING

Air-Cooled Condensing Units

Installation, Start-Up and Service Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install or service air conditioning equipment.

Untrained personnel can perform basic maintenance,

such as cleaning and replacing filters. All other opera

tions should be performed by trained service personnel.

When working on air conditioning equipment, observe

precautions in literature and on tags and labels attached

to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instruc

tions thoroughly. Consult local building codes and

National Electrical Code (NEC) for special installation

requirements.

A WARNING

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power if

applicable. Electrical shock can cause personal injury.

UNIT 38AF

OPER WEIGHT (lb)

REFRIGERANT*

COMPRESSOR

Oil (pts)

Crankcase Heater Watts

CONDENSER AIR FAN

Number...Rpm

Diameter (in.)

Motor Hp (NEMA)

Nominal Cfm Total

CONDENSER COIL

Face Area (sq tt)

Storage Capacity (lb)f

CONTROLS

Pressurestat Settings

FUSIBLE PLUG

*Unit is factory supplied with holding charge only.

tStorage capacity of condenser coil with coil 80% full of liquid R-22

at 124 F

Table 1 — Physical Data

007 008

300 400

22 22

46 8 0

40

Propeller; Direct Drive

1 1075 1 1075

22 22

'/2 v?

3500 4300

108

168 18 0

High Cutout

Cut-in

Low Cutout

Cut-In

426 ± 7 psig

320 ± 20 psig

27 ± 4 psig

67 ± 7 psig

200 F

40

17 7

INSTALLATION

Step 1 — Complete Pre-Installation Checks

UNCRATE UNIT — Remove unit packaging except for

the top skid assembly and wood bumpers, which should

be left in place until after unit is rigged into place.

INSPECT SHIPMENT — File claim with shipping com

pany if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical

Code (NEC) for special installation requirements.

• Allow sufficient space for airflow clearance, wiring,

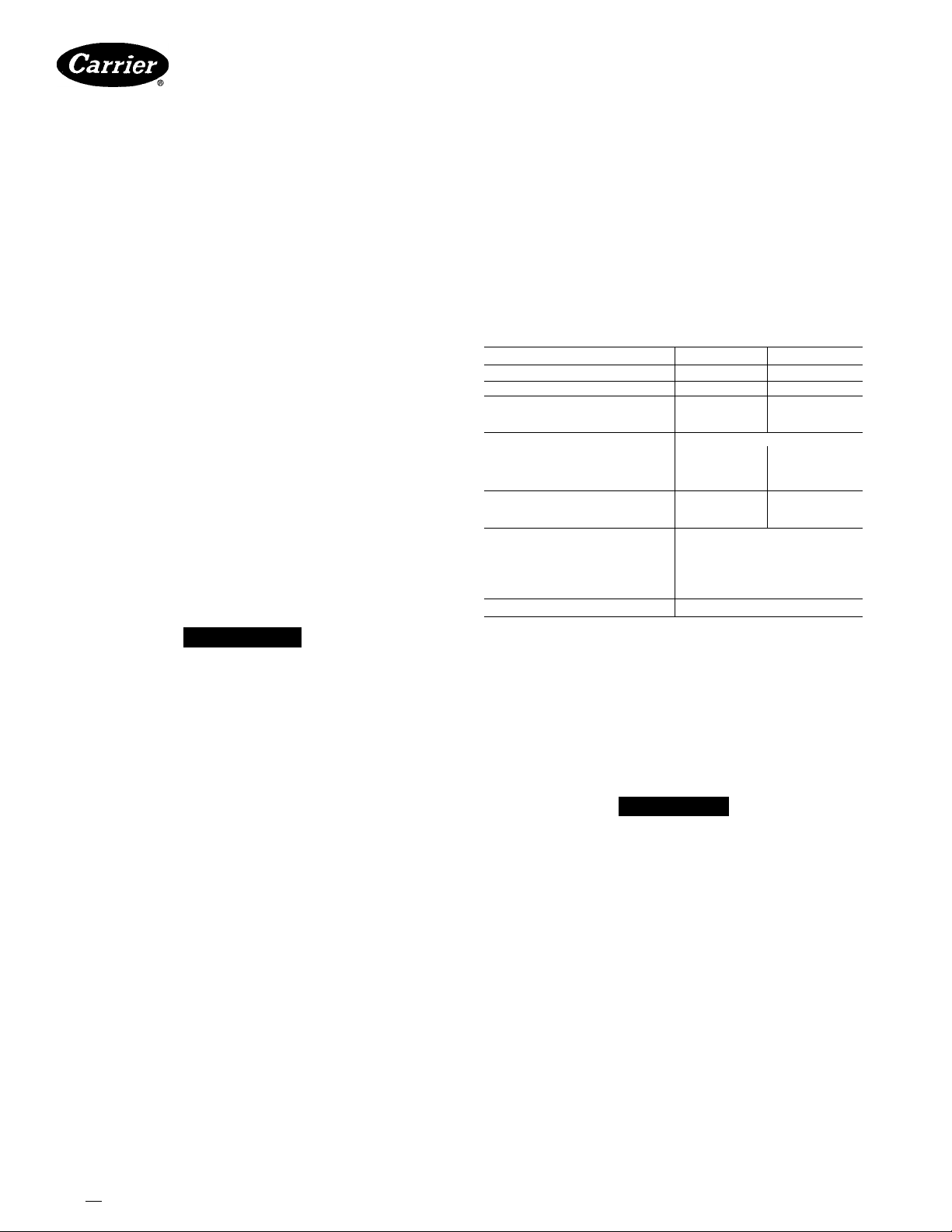

refrigerant piping, and servicing unit. See Fig. 1.

• Locate unit so that condenser airflow is unrestricted

on all sides and above. Refer to Fig. 1.

• Unit may be mounted on a level pad directly on base

channels or mounted on raised pads at support points.

See Table 2 for weight distribution based on recom

mended support points.

NOTE: If vibration isolators are required for a parti

cular installation, use data in Table 2 to make proper

selection.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

BookM |4 PC111 Catalog No 563-852 PrintedinUSA Form38AF-1SI Pg 1 4-85 Replaces: New

Tab I3al2a

For replacement items use Carrier Specified Parts

Step 2 — Rig and Mount the Unit

A CAUTION

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead

rigging only. Traverse base channels are provided with

1 -1 / 2 in. rigging holes that are located 1 -3/ 4 in. from each

end. Rig with top skid packaging assembly and wood

bumper strips in place to prevent unit damage by rigging

cable. As further protection for coil faces, plywood sheets

may be placed against sides of unit, behind cables. Run

cables to a central suspension point so that angle from the

horizontal is not less than 45 degrees. Raise and set unit

down carefully.

If it is necessary to roll unit into position, mount unit

on longitudinal rails, using a minimum of 3 rollers. Apply

force to rails, not unit. If unit is to be skidded into posi

tion, place it on a large pad and drag it by the pad. Do not

apply any force to unit.

Raise from above to lift unit from rails or pad when

unit is in final position.

Page 2

38AF

HEATING & COOLING

Step 3 — Complete Refrigerant Piping

Connections

SIZE REFRIGERANT LINES — Consider length of

piping required between condensing unit and evaporator,

amount of liquid lift, and compressor oil return. See

Table 3 and also refer to Part 3 of Carrier System Design

Manual for design details and line sizing. Refer to evap

orator installation instructions for additional information.

USE FILTER DRIER AND MOISTURE INDICATOR

— The filter drier is factory supplied. Moisture indicator

(sight glass) is a field-installed option and should be

installed just after liquid line shutoff valve. Do not use a

receiver; there is none provided with unit and one should

not be used.

MAKE PIPING CONNECTIONS — Remove block-off

in corner post and unsweat caps from liquid and suction

lines.

NOTE: Unit is shipped with R-22 holding charge. System

pre.ssure must be relieved before unsweating caps.

Pass nitrogen or other inert gas through piping while

brazing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve(s)

to evaporator section. If 2 thermostatic expansion valves

are installed for 2-step cooling, install field-supplied

liquid line solenoid valve ahead of the second expansion

valve.

Air-Cooled Condensing Units

PROVIDE SAFETY RELIEF —A fusible plug is located

in unit liquid line. Do not cap this plug. If local code;

requires additional safety devices, install as directed.

Step 4 — Complete Electrical Connections

POWER WIRING — Unit is factory wired for voltage

shown on nameplate. Provide adequate fused disconnect

switch within sight of unit, readily accessible, but out of

reach of children. Provision for locking switch open (ofO

is advisable to prevent power from being turned on while

unit is being serviced. Disconnect switch, fuses, and field

wiring must comply with National Electrical Code and

local code requirements.

Route power wires through opening in unit side panel

and connect in unit control box as shown on unit label

diagram and Fig. 2. Unit must be grounded.

Affix crankcase heater warning sticker to unit dis

connect switch.

CONTROL CIRCUIT WIRING — Control voltage is

24 volts. See Fig. 3 and unit label diagram for fieldsupplied wiring details. Route control wires through

opening in unit side panel to connection in unit con

trol box.

if" HOLE FIELD POWER SUPPLY

DIMENSIONS (ft-in.)

UNIT 38AF 007 008

Length A 2-9

Width

Height

Base Rail Width D 0-10'/2

Minimum Support

Lift opening

separation

NOTE Units may be installed with any one side, except compressor access

side, within one ft of wall or other airflow obstruction as long as remaining

sides have at least 3 ft clearance Compressor side access is always 3 feet

Units may be located side by side with a minimum of 3ft between units

Allow at least a 5-ft clearance above the unit

B 2-9 2- 8Va

c 2-8

E 0-4 0- 4

F

1- 0’/4

4- 0%

2-11 '/s

O-IO'/j

1-10

Fig. 1 — Dimensions (ft-in.)

Table 2 — Weight Distribution

WEIGHT (lb)

UNIT 38AF

007 300

008 410

Oper

Wt

A B C

54

75

Support Point

78 100

116

D

68

133 86

LEFT

l-b rigging HOLE (8)

REAR

RIGHT

i HOLE

CONTROL

POWER

FRONT

TOP VIEW

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 14 PC111 Catalog No 563-852 PrintedInUSA Form38AF-1SI Pg2 4-85 Replaces: New

Tab |3al2a

For replacement items use Carrier Specified Parts

Page 3

38AF

HEATING A COOLING

Table 3 — Liquid Line Data

MAX

UNIT 38AF

007

008

NOTE: Values shown are for units operating at 45 F saturated suction

and 95 F entering air

3-PHASE

CONN TO

DISCONNECT

PER N E C

NOTE: Pigtail connections can use copper or aluminum wire Factorysupplied connectors must be used when aluminum wire is used

ALLOWABLE

LIQUID

LIFT (it)

70

70

___________________________

-GROUND LEAD

. SPLICE CONNECTIONS

FIELD WIRING

FACTORY WIRING

Max Allowable

Pressure Drop

LIQUID LINE

(psi)

7

7

------

GROUNDING LUG

3-PHASE COND UNIT

Max Allowable

Temp Loss

(F)

2

2

YEL-

BLK-

-BLU -

Fig. 2 — Line Power Connections

JUMPER

TERMINAL

BLOCK

UNIT

CONTROL

BOX

Air-Cooled Condensing Units

Table 4 — Electrical Data (3-Ph/60-Hz)

UNIT FAN

38AF

007

008

FLA — Full Load Amps

ICF — Maximum Instantaneous Current Flow

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps per NEC Section 430-24

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps (compressor)

•Units are suitable for use on electrical systems where voltage supplied

to the unit terminals is not below or above the listed limits

tFan motor is single phase

j230 volts

Volts

Nameplate

208-230

460 414

575 518 666

208-230

460 414 528

575 518 666 76 188 25 2 9Í

Supplied*

Min Max

187

187

ICF

253 140 36 3 60 29

71

528

58

253 186 44 4

93

MOCP

MCA

(Fuse)

166 25

14.9

20 9

20

60 29

25 1 5

FLAT

Before starting unit, crankcase heaters must be on for '

24 hours to be sure all refrigerant is out of the oil. To

energize crankcase heaters, proceed as follows; set space

thermostat above ambient so there will be no demand for

cooling. Close field disconnect. The crankcase heaters '

are now energized.

Evacuate and Dehydrate entire refrigerant system

by either of the methods described in Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-7.

Charge System — Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-8.

Using liquid charging method and charging by weight

procedure, charge to a clear sight glass. After proper

charge has been determined, indicate this amount on

unit’s aluminum informative plate section entitled

“Refrig./System R-22.”

To Start Unit — Assuring that crankcase heater has

been on for 24 hours and field disconnect is closed, set

room thermostat below ambient. Unit compressor will

start after a 15-second delay.

COM

PRESSOR

RLA LRA

26 7 137

1 5 12 1 69

2.9t 9.6 55

32 5 183

152 91

124

73

SERVICE

Crankcase Heater prevents refrigerant migration and

compressor oil dilution during shutdown when com

Fig. 3 — Remote Thermostat Wiring

pressor is not operating. If crankcase heater is daenergized for more than 6 hours, both compressor service

valves must be closed.

START-UP

Preliminary Checks

1. Check that all internal wiring connections are tight

and that all barriers, covers and panels are in place.

2. Field electrical power source must agree with unit

nameplate rating.

3. All service valves must be open.

4. Crankcase heaters must be firmly seated into com

pressor crankcase.

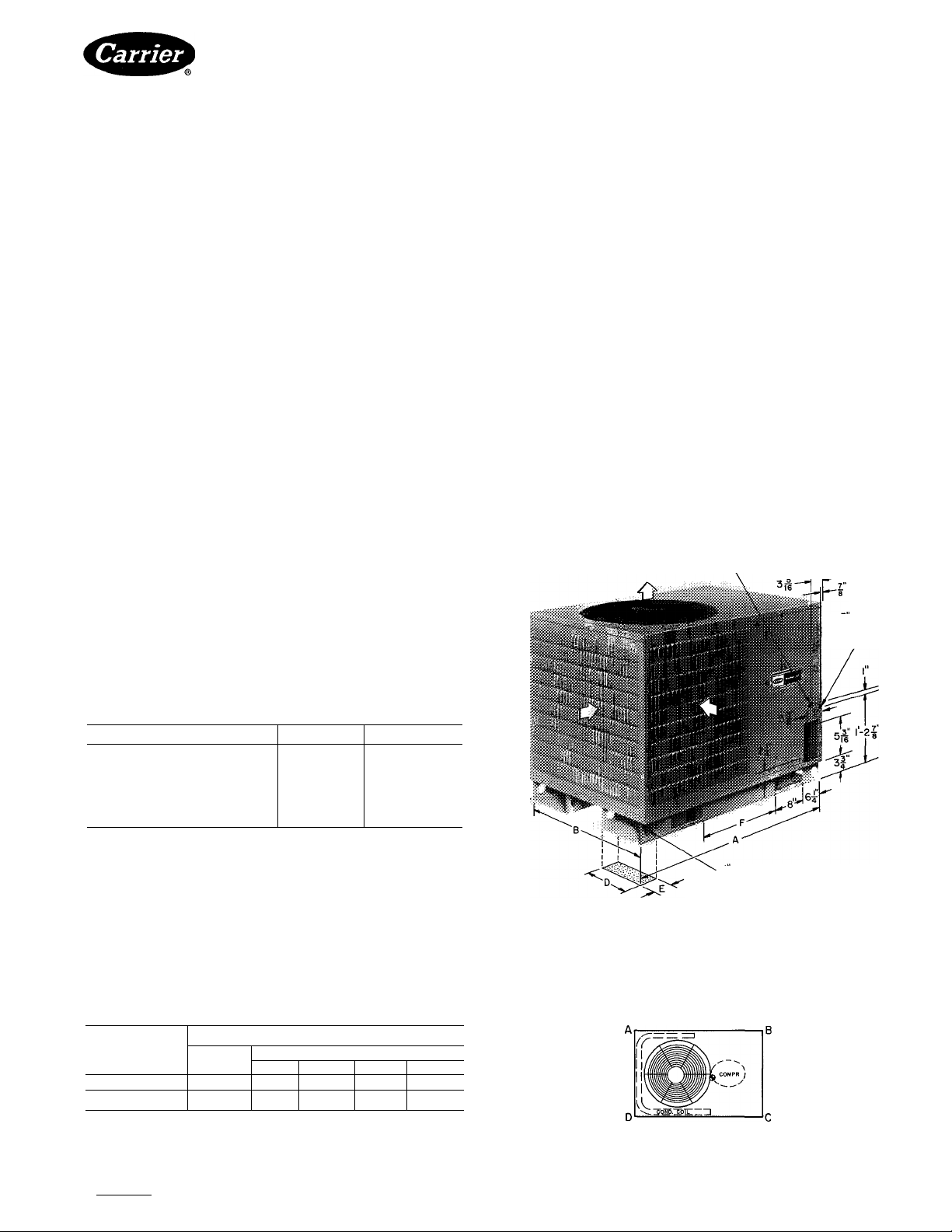

Condenser Fan is supported by a reinforced wire

guard to which the fan motor is bolted.

Figure 4 shows proper mounted fan position.

Lubrication

FAN MOTORS have permanently sealed, lubricated

bearings. Do not oil.

COMPRESSOR also has its own oil supply.

CONDENSER FAN ADJUSTMENT (Fig. 4) — Shut

off unit main power supply. Remove condenser fan

assembly (grille, motor, motor cover and fan) and loosen

fan hub setscrews. Adjust fan height as shown in Fig. 4.

Leak Test entire refrigerant system by pressure method

described in Carrier Standard Service Techniques

Manual, Chapter 1, Section 1-6. Use R-22 at approxi

mately 25 psig backed up with an inert gas to a total

pressure not to exceed 245 psig.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 14 PC111 Catalog No 563-852 PrintedinUSA Form38AF-1SI Pg3 4-85 Replaces: New

Tab I3al2a

For replacement items use Carrier Specified Parts.

Tighten setscrews and replace fan assembly.

Cleaning Coils ^ Coils can be cleaned with a vacuum

cleaner, washed out with water, blown out with com

pressed air, or brushed (do not use wire brush). Fan

motors are drip proof but not waterproof.

Page 4

38AF

1

HEATING A COOLING

Clean coil annually or as required by location or out

door air conditions. Inspect coil monthly, and clean as

required. Fins are not continuous through coil sections.

Dirt and debris may pass through first section, become

trapped between the row of fins and restrict condenser

airflow. Use a flashlight to determine if dirt or debris

has collected between coil sections. Clean coil as follows:

1. Turn off unit power.

2. Disconnect fan motor leads. Note position of leadsfor

reconnection.

3. Remove screws holding top cover in place. Do not

remove fan motor or orifice.

4. Remove top cover assembly from unit (see Fig. 5).

Be especially careful not to damage coil fins.

5. Using a water hose, or other suitable equipment, flush

down between the sections of coil to remove dirt and

debris.

6. Clean the remaining surfaces in the normal manner.

,7. Reposition outer coil sections. Reinstall top cover

assembly. Make certain fan motor leads are in com

pressor compartment before replacing screws. Care

must be taken to prevent damage to coil fins.

8. Reconnect fan motor leads.

9. Replace all screws.

Air-Cooled Condensing Units

MOTOR

Fig. 4 — Condenser Fan Adjustment

OUTLET

NOTE: Top cover must come off

Fig. 5 — Pivot and Support Top Cover

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

Book|1 |4 PC111 Catalog No 563-852 PrintedinUSA Form38AF-1Sl Pg4 4-85 Replaces: New

Tab l3al2a

For replacement items use Carrier Specified Parts.

Page 5

38AF

HEATING & COOLING

TROUBLESHOOTING GUIDE

COMPRESSOR DOES NOT RUN

Contactor Open

Power off — restore power.

Fuses blown — replace with correct fuses after finding

cause and correcting.

Transformer dead — replace transformer if primary

windings are receiving power.

Thermostat circuit open — check thermostat setting.

Circuit breaker tripped — check for excessive com

pressor current draw (140% FLA maximum allowable).

Low-pressure switch open — check for refrigerant under

charge or obstruction of indoor airflow.

High-pressure switch open — check for refrigerant over

charge or obstruction of outdoor airflow.

Connections loose — tighten all connections.

Compressor stuck — see compressor service literature.

Compressor motor thermostat open — check for exces

sive motor temperature.

Contactor Closed

Compressor leads loose — check connections.

Motor windings open — see compressor service

literature.

Single phasing — replace blown fuse.

COMPRESSOR CYCLES ON

HIGH-PRESSURE SWITCH

Condenser Fan On

High-pressure switch faulty — replace switch.

Airflow restricted — remove obstruction.

Air recirculating — clear airflow area.

Noncondensables in system — purge and recharge as

required.

Refrigerant overcharge — purge as required.

Line voltage incorrect — consult power company.

Refrigerant system restrictions — check or replace filter

drier, expansion valve, etc.

Condenser Fan Off

Fan slips on shaft — tighten fan hub setscrews.

Motor not running — check power and capacitor.

Motor bearings stuck — replace bearings.

Motor overload open — check overload rating. Check for

fan blade obstruction.

Motor burned out — replace motor.

Air-Cooled Condensing Units

COMPRESSOR CYCLES ON

LOW-PRESSURE SWITCH

Evaporator Air Fan Running

Filter drier plugged — replace filter drier.

Expansion valve power head defective — replace power

head.

Low refrigerant charge — add charge. Check low-

pressure switch setting.

Airflow Restricted

Evaporator coil iced up — check refrigerant charge.

Evaporator coil dirty — clean coil fins.

Indoor air filter dirty — clean or replace filters.

Indoor air dampers closed — check damper operation

and position.

Evaporator Air Fan Stopped

Electrical connections loose — tighten all connections.

Fan relay defective — replace relay.

Motor overload open — power supply.

Motor defective — replace motor.

Fan belt broken or slipping — replace or tighten belt.

COMPRESSOR RUNS BUT

COOLING INSUFFICIENT

Suction Pressure Low

Refrigerant charge low — add refrigerant.

Head pressure low — check refrigerant charge. Check

condenser air fan thermostat settings.

Indoor air filters dirty — clean or replace filters.

Expansion valve power head defective — replace power

head.

Evaporator coil partially iced — check low-pressure

setting.

Evaporator airflow restricted — remove obstruction.

Suction Pressure High

Compressor valves defective — see compressor service

literature.

Heat load excessive — check for open doors or windows.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|l |4 PC111 Catalog No 563-852 PrintedinUSA Form38AF-1SI Pg5 4-85 Replaces; New

Tab 13a12a

For reolacement items use Carrier Soecitied Parts

Page 6

38AF

HEATING & COOLING

Air-Cooled Condensing Units

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 11 14 PC111 Catalog No 563-852 PhntedinUSA Form38AF-1SI Pg6 4-85 Replaces: New

For renlacement Items use Carrier Specified Parts.

Loading...

Loading...