Page 1

38AE

012,014,016

HEATING & COOLING

Air-Cooled Condensing Units

Installation, Start-Up and Service Instructions

50 and 60 Hz

INSTALLATION

Step 1 — Complete Pre-Installation Checks

UNCRATE UNIT — Remove unit packaging except for

the top skid assembly, which should be left in place until

after the unit is rigged into place.

INSPECT SHIPMENT — File claim with shipping com

pany if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical Code

(NEC, U.S.A.) for special installation requirements.

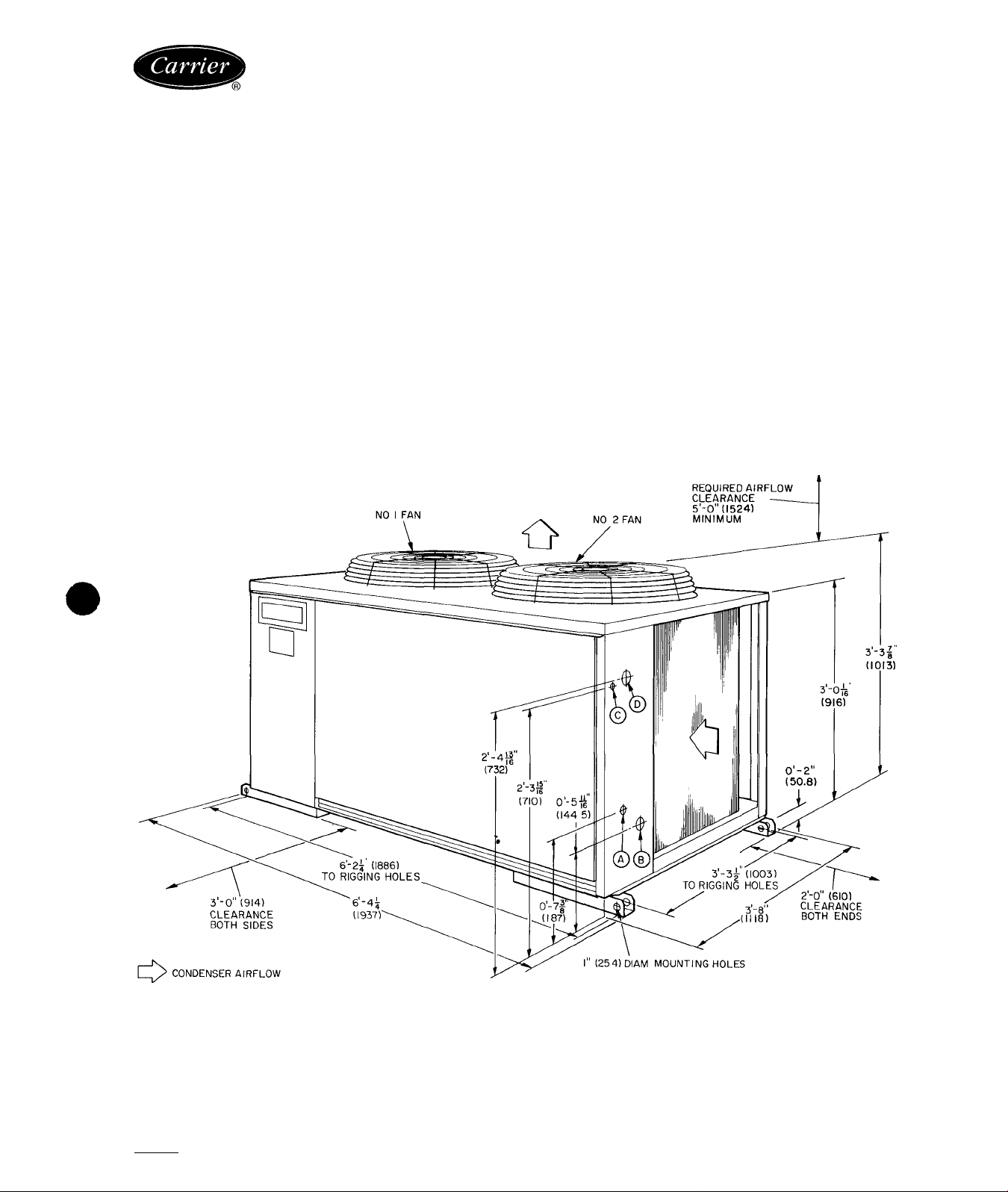

• Allow sufficient space for airflow clearance, wiring, re

frigerant piping, and servicing unit. See Fig. 1. See

Fig. 2 for unit component locations.

• Locate unit so that outdoor coil (condenser) airflow is

unrestricted on all sides and above.

• Unit may be mounted on a level pad directly on the base

channels or mounted on raised pads at support points.

See Table 2 for weight distribution based on recom

mended support points.

NOTE: If vibration isolators are required for a particular

installation, use the data in Table 2 to make the proper

selection.

A — 1V4 in. (32) diam. knockout for %-in. (16) ODM liquid line connection

B — 1%in (44 5)diam knockout for 1’/a in (28 6) (38AE012); 1%in (35) suction line connection (38AE014,016)

C — %-in (22.2) diam knockout for control power

D — 2-in (50 8) diam knockout for unit power

LEGEND

Certified dimension drawings are available on request.

NOTES:

1

SERVICE AREAS - Allow 3 ft (914) on both

sides and 2 ft (610) on both ends of unif for

servicing

Dimensions in parentheses are in (mm)

Fig. 1 - Physical Data and Dimensions (ft-in.)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|1 |1 PC 111 Catalog No 533-816 Printed in U S.A. Form 38AE-17SI Pg 1 4-92 Replaces: 38AE-10SI

Tab 3a 2a

Page 2

Table 1 — Physical Datrf^

ENGLISH

UNIT 38AE 012 014

OPERATING WEIGHT (lb)

REFRIGERANT (lb)‘ 22

COMPRESSOR

Model No.

Oil (pt)

Crankcase Heater Watts

Unloader Setting (pslg)

Load

Unload

OUTDOOR-AIR FANS

No. ...Rpm

Diameter (in.)

Motor Hp

Nominal Cfm Total

OUTDOOR COIL

Face Area (sq ft)

Storage Capacity (lb)t

CONTROLS

Pressurestat Settings (pslg)

High Cutout

Cut-in

Low Cutout

Cut-in

FUSIBLE PLUG

NEMA — National Electrical Manufacturing Association

‘Unit is factory supplied with holding charge only.

tStorage capacity is measured at liquid saturated temperatures of 125 F for

38AE012; 123 F for 38AE014; and 130 F for 38AE016

732 779

Reciprocating, Hermetic, 6 Cylinder;

06DD824 1 06DD328 I 06DD537

27 2

1750 Rpm

10

75

70 ± 1

60 ± 2

Axial Flow, Direct Drive

2 1075

24

V2

8800

29.2

40.3

395 ± 10

295 ± 10

29 ± 4

200 F

016

789

39 8

SI

UNIT 38AE

OPERATING WEIGHT (kg) 333 354

REFRIGERANT (kg)*

COMPRESSOR

Model No.

Oil (L)

Crankcase Heater Watts

Unloader Setting (kPa)

Load

Unload

OUTDOOR-AIR FANS

No. ...Rps

Diameter (mm)

Motor Hp

Nominal L/s Total

OUTDOOR COIL

Face Area (sq m)

Storage Capacity (kg)f

CONTROLS

Pressurestat Settings (kPa)

High Cutout

Cut-in

Low Cutout

Cut-in

FUSIBLE PLUG

NEMA — National Electrical Manufacturing Association

‘Unit is factory supplied with holding charge only

tStorage capacity is measured at liquid saturated temperatures of 51 7 C for

38AE012; 50 6 C for 38AE014; and 54 4 C for 38AE016

012 014

10

Reciprocating, Hermetic, 6 Cylinder;

06DD824 1 06DD328 | 06DD537

124

29.2 Rps

4.73

75

483 ± 6 9

414 ±13 8

Axial Flow, Direct Drive

2...17.9

610

1/2

4153

2.71

183 18.1

2724 ± 68 9

2034 ± 68 9

200 ± 27.6

414 ± 0

93 3 C

016

359

103

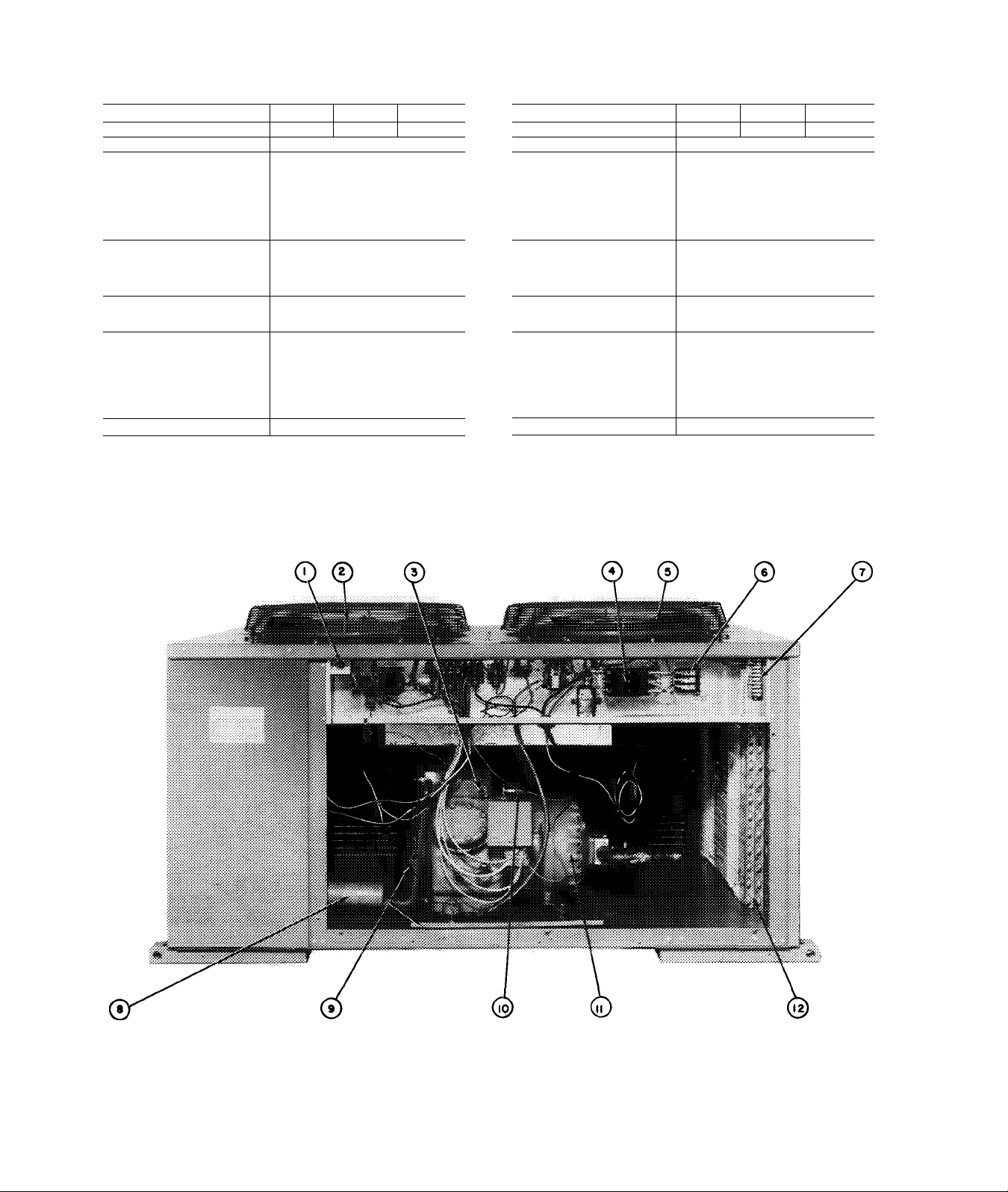

Low-Voltage Fuse

1 2 - No. 1 Fan

High-Pressure Switch

3 -

4 - Circuit Breakers

5 — No. 2 Fan

6 — Terminai Biock 1 (Unit Power)

7 — Terminal Block 2 (Control Power)

8 — Muffler

Fig. 2 — Component Locations

LEGEND

— Hot Gas Bypass Piping Stub (%-in ODM)

9

— Low-Pressure Switch

10

— Compressor

11

— Wraparound Coil

12

Page 3

Table 2 — Weight Distribution

UNIT

38AE

r

012

014

016

Oper

Wt

732 (333) 142 (65)

779 (354)

789 (359) 143 (65)

WEIGHT - lb (kg)

Support Point

A B C

138 (63) 225 (102)

143 (65)

140 (64) 247 (112)

143 (65) 250 (114)

COIL

D

227(103)

249 (113)

253 (115)

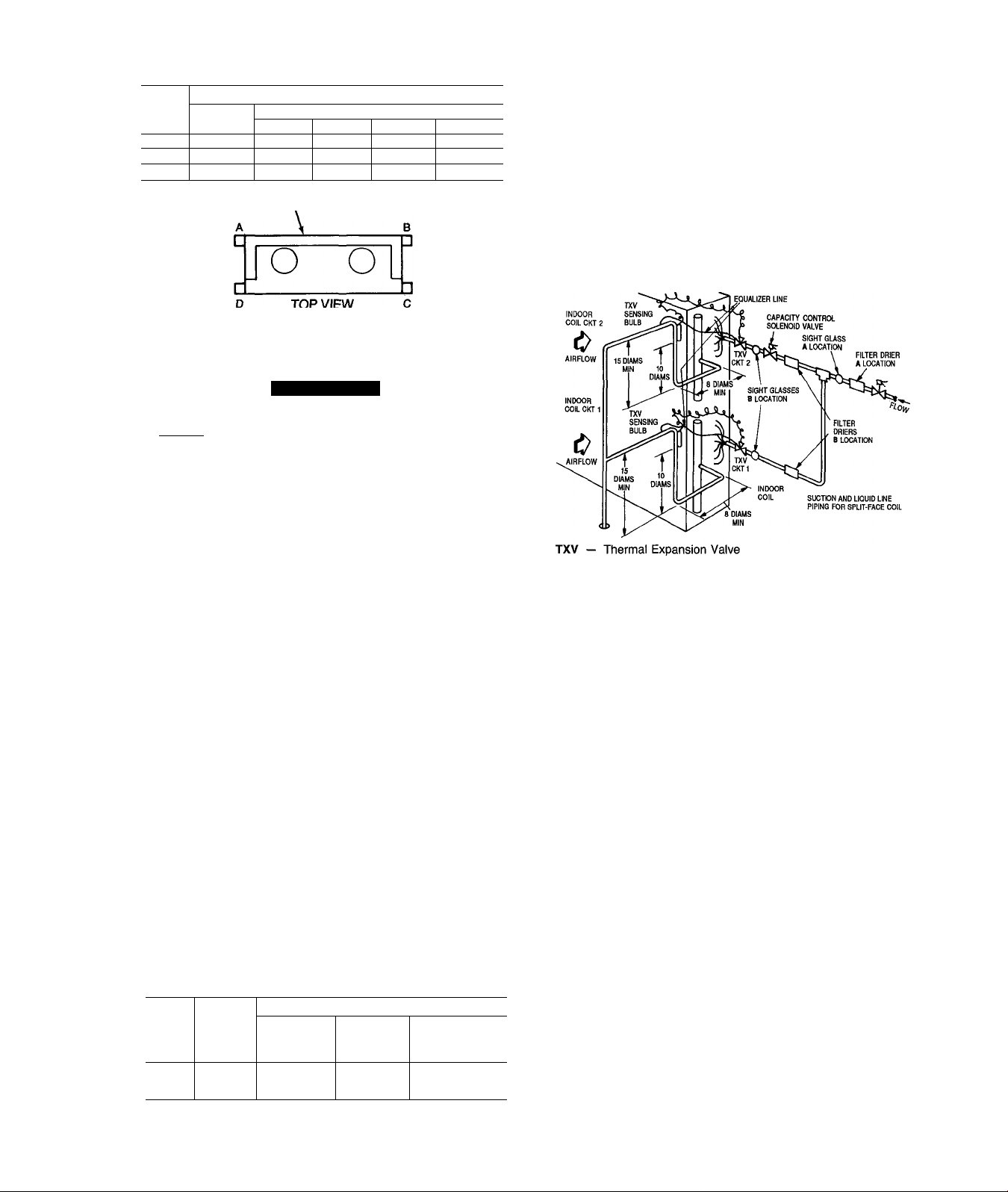

INSTALL FILTER DRIER(S) AND MOISTURE INDICATOR(S) — Every unit should have a filter drier and liquidmoisture indicator (sight glass). In some applications, de

pending on space and convenience requirements, it may be

desirable to install 2 filter driers and sight glasses. One fil

ter drier and sight glass may be installed at A locations in

Fig. 3. Or, 2 filter driers and sight glasses may be installed

at B locations.

Select the filter drier for maximum unit capacity and min

imum pressure drop. Complete the refrigerant piping from

indoor unit to outdoor unit before opening the liquid and

suction lines at the outdoor unit.

TOP VIEW

Step 2 — Rig and Mount the Unit

A CAUTION

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rig

ging only. For this purpose, the transverse base channels

extend beyond the sides of the unit, with holes provided in

end plates to attach cables or hooks. Rig with top skid pack

aging assembly in place to prevent unit damage by the rig

ging cable. As further protection for the coil faces, plywood

sheets may be placed against the sides of the unit, behind

the cables. Run the cables to a central suspension point so

that the angle from the horizontal is not less than 45 de

grees. Raise and set the unit down carefully.

If it is necessary to roll the unit into position, mount the

unit on longitudinal rails, using a minimum of 3 rollers.

Apply force to the rails, not the unit. If the unit is to be

skidded into position, place it on a large pad and drag it by

the pad. Do not apply any force to the unit.

Raise from above to lift unit from the rails or pad when

unit is in final position.

COMPRESSOR MOUNTING — As shipped, the compres

sor is held tightly in place by self-locking bolts. Before

starting unit, loosen self-locking boits until the

flanged washer is stiil snug but can be moved side

ways with finger pressure. Do not remove ship

ping bolts.

Step 3 — Complete Refrigerant Piping

Connections

SIZE REFRIGERANT LINES - Consider the length of

piping required between outdoor unit and indoor unit (evap

orator), the amount of liquid lift, and compressor oil re

turn. See Table 3 and also refer to Part 3 of Carrier System

Design Manual for design details and line sizing. Refer to

indoor installation instructions for additional information.

Table 3 - Liquid Line Data

MAX

UNIT

38AE

*lnlet and outlet.

NOTE: Figures shown are for units operating at 45 F (7.2 C) saturated suction

and 95 F (35 C) entering air

ALLOW.

LIQUID

LIFT

ft(m)

52 (15 8) 7 (48.3)

012

67 (20.4) 7 (48 3)

014

016

82 (25) 7 (48 3)

Max Allow.

Press. Drop

psig (kPa)

LIQUID LINE

Max Allow.

Temp

Loss

•F (”C)

2(1 1) %

2(1 1)

2(1 1)

Filter Drier and

Sight Glass

Flare Conn.*

in. (mm)

Ye

Ys

Fig. 3

INSTALL LIQUID LINE SOLENOID VALVE - SOLE

NOID DROP — It is recommended that a solenoid valve

be placed in the main liquid line (see Fig. 3) between con

densing unit (38AE) and fan coil (40RR, 40RE). This valve

prevents refrigerant migration (which causes oil dilution) to

the compressor during the off cycle at low outdoor ambient

temperatures. The solenoid should be wired in parallel with

the compressor contactor coil. This means of electrical con

trol is referred to as solenoid drop control.

INSTALL LIQUID LINE SOLENOID VALVE (OP

TIONAL) - CAPACITY CONTROL - If 2-step cooling

is desired, place a solenoid valve in the location shown in

Fig. 3.

DO NOT USE A RECEIVER — No receiver is provided

with the unit. It is recommended that one NOT be used.

MAKE PIPING CONNECTIONS - Do not remove plas

tic dust plugs from suction and liquid line stubs in the com

pressor compartment until piping connections are ready to

be made. Pass nitrogen or other inert gas through piping

while brazing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve(s) to

indoor section. If 2 thermostatic expansion valves are in

stalled for 2-step cooling, install field-supplied liquid line

solenoid valve ahead of the second expansion valve.

Locations of Sight Glass(es)

and Filter Drier(s)

Page 4

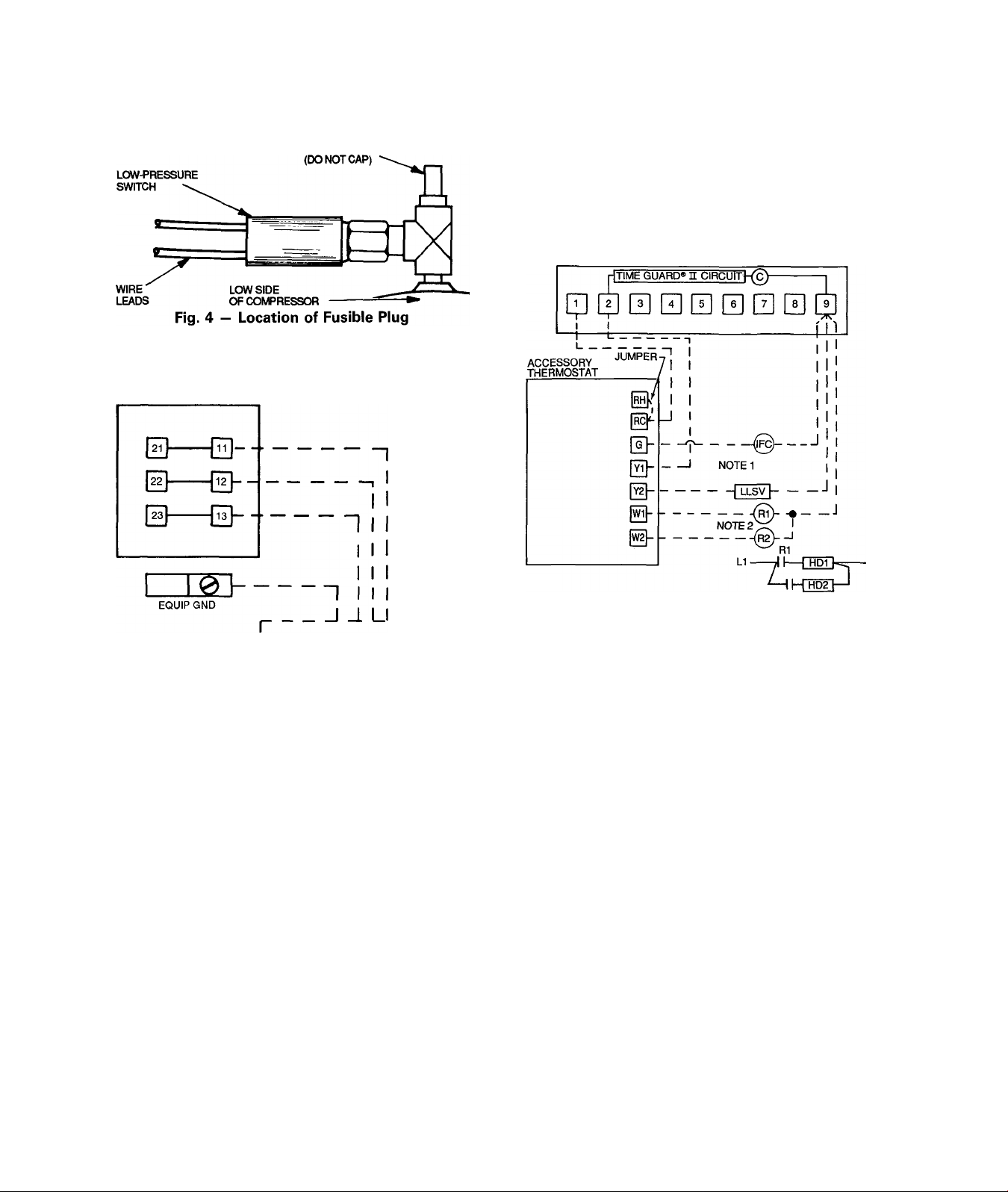

PROVIDE SAFETY RELIEF — A fusible plug is located

on the compressor crankcase (Fig. 4). Do not cap this plug.

If local code requires additional safety devices, install them

as directed.

FUSIBLE PLUG

TERMINAL BOARD (JB^) IN

38AE CONTROL BOX

Route power wires through opening in unit end panel to

connection in unit control box as shown on unit label dia

gram and Fig. 5. Unit must be grounded.

Affix crankcase heater warning sticker to unit disconnect

switch.

CONTROL CIRCUIT WIRING - Control voltage is 24 v.

See Fig. 6 and unit label diagram for field-supplied wiring

details. Route control wires through opening in unit end

panel to connection in unit control box.

TERMINAL BOARD (TB2) IN 38AE CONTROL BOX

I DISCONNECT PER NEC, USA. |

I_______________________________I

LEGEND

EQUIP GND — Equipment Ground

NEC — National Electrical Code

----------

Field Wiring

Fig. 5 - Main Power Supply Wiring

Step 4 - Complete Electrical Connections

POWER WIRING — Unit is factory wired for voltage shown

on nameplate. Provide adequate fused disconnect switch within

sight from unit and readily accessible from unit, but out of

the reach of children. Lock switch open (off) to prevent

power from being turned on while unit is being serviced.

Disconnect switch, fuses, and field wiring must comply with

national and local code requirements.

LEGEND

C

HD IFC LLSV R -

----------

----------NOTES:

1. Combination LLSV plus IFC va should not exceed 30 va.

2. Do not exceed 5 va (24 vac) per coil.

3. If va values shown in Notes 1 and 2 must be exceeded,

Compressor Contactor

Heating Device

Indoor-Fan Contactor

Liquid Line Solenoid Valve

Relay

Field Wiring

Factory Wiring

accessory relay transformer package 38AE900001.

R2

Fig. 6 “ Remote Thermostat Wiring

L2

use

Page 5

Table 4 - Electrical Data

(3 Ph/60 Hz)

UNIT

UNIT

38AE

012

Model

501

201

601

101

501

201

601

101

501

201

601

101

Nameplate

208-230 187

208-230 187 253

208-230 187 253 87 5

Volts

Supplied*

Min Max 1

380 342

460

575

380 342 418

460

575 518

380

460

575 518

414 528 29 1

518 660

414 528 31 7

342 418 49 3

414 528 40 7 124

253 62.5

418 35.0

660

660

MCA

22.8 67 35 157

69.3 199

38 0

25.6 73

33 0

ICF

178

101 50

112 60 26 5

274 125

153 80

100

MOCP

(Fuse)

100 43 6

81 40

100 49 3

84

50

40 17.9

60

50

(3 Ph/50 Hz)

UNIT

UNIT

38AE

FLA — Full Load Amps (Fan Motors)

ICF — Maximum Instantaneous Current Flow during start-up (LRA of compressor plus total FLA of fan motors)

kW — Total Fan Motor Input (kilowatts)

LRA — Looked Rotor Amps

MCA — Minimum Circuit Amps per NEC (U S.A ), Section 430-24

MOCP — Maximum Overcurrent Protection (amps)

RLA — Rated Load Amps (Compressor)

•Units are suitable for use on electrical systems where voltage supplied to the unit terminals is not below or above

the listed limits

Model

803 230

903 400 342

803 230

903 400 342 457 34 0 89 50

803

903

Name-

plate

230

400

Volts

Min

198

198

198

342

Supplied*

MCA

Max

264

457

264

264 66 9

457

47 5 134 75

31 4 80 50

51 0

43 0

ICF

149 75

206 100

121

MOCP

(Fuse)

COMPR FAN MOTORS (Single Phase)

RLA

32 9

20.0

35 7

22 1

47 9

29 3

LRA

170

93

77

62

191

104

69

266

145

120

96

COMPR

LRA

128 29 35

74 2.9 3.5

143

83 29 3.5

200 2.9 35

115

RLA

24 0

20.0

22 1 80

63 6

36.0

29 3

23 8

60

Total

Fans

FLA (ea)

Fan No.

4.3

4.3

23

1.8

43

43

23

1.8

43

43

2.3

1.8

FAN MOTORS

230 V (Single Phase)

Total

Fans

2

37

37

1 9

1.8

37

37

1 9

1.8

37

37

1 9

1 8

FLA (ea)

Fan No.

1 2

29

29

kW

3.5

35

START-UP

Evacuate and Dehydrate the entire refrigerant sys

tem by either of the methods described in Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-7.

Leak Test the entire refrigerant system by the pressure

method described in Carrier Standard Service Techniques

Manual, Chapter 1, Section 1-6. Use R-22 at approxi

mately 25 psig (172.4 kPa) backed up with an inert gas to

a total pressme not to exceed 245 psig (1689 kPa).

Before starting the unit, the crankcase heaters must be

on for 24 hours to be sure all the refrigerant is out of the

oil. To energize the crankcase heaters, proceed as follows.

1. Set the space thermostat above ambient so there will be

no demand for cooling.

2. Close the field disconnect.

3. Turn the fan circuit breaker on. Leave the compressor

circuit breakers off. The crankcase heaters are now

energized.

Before Starting Unit check the following:

1. Compressor oil level must be at least within sight in the

compressor sight glass. Add oil if necessary (see Table

1 and Oil Charge section).

2. Compressor holddown bolts must be snug, but not tight.

Refer to Compressor Mounting section and tag on com

pressor foot.

3. All internal wiring connections must be tight; all barri

ers and covers must be in place.

4. Electrical power source must agree with unit nameplate

rating.

5. All service valves must be open.

6. Crankcase heater must be firmly locked into the com

pressor crankcase.

Page 6

Preliminary Charge — Refer to Carrier Standard Serv

ice Techniques Manual, Chapter 1, Section 1-8. By the liq

uid charging method and charging by weight procedure, charge

the units with approximately the following amounts of R22: 38AE012, 22 lb (10 kg); 38AE014, 23 lb (10.5 kg);

38AE016, 23 lb (10.5 kg). See Table 5.

Table 5 — Charging Data (R-22)

REFRIGERANT CHARGE - lb (kg)

UNIT

Required Charge

38AE

012

014 4.8 (2.2)

016

Above Clear

Sight Glass

3.0 (1.4) 22 (10)

3 4 (1 5) 23 (10.5)

Outdoor Unit

Total Charge

(Approx)

23 (10.5) 123 (50.6)

CONDENSING

TEMP

DURING

CHARGING - F (C)

125 (51.7)

130 (54.4)

Start the Unit — The field disconnect is closed, the

fan circuit breaker is closed, and the space thermostat is set

above ambient temperature so that there is no demand for

cooling. Only the crankcase heaters are energized. After

the heaters have been on for 24 hours, the unit can be started.

Close the compressor circuit breakers, and then reset the

space thermostat below ambient temperature, so that a call

for cooling is ensured.

Energize Branch Circuit — Set room thermostat above

ambient temperature. Close field disconnect switch. Be sure

that compressor crankcase heaters are operating. Allow crank

case heaters to operate a minimum of 24 hours before start

ing unit.

To Start Unit set room thermostat below ambient. Af

ter starting unit, there will be a delay of at least 3 seconds

before compressor starts.

Oil Charge (see Table 1) —Allow unit to run for about

20 minutes. Stop unit and check compressor oil level. Add

oil only if necessary to bring oil into view in sight glass.

Use only Carrier-approved compressor oil. Approved oils

are:

Witco Chemical Corp.............................................Suniso 3GS

Texaco, Inc

Petroleum Specialties Co.........................................Cryol 150

.....................................................................

WF32

Do not reuse drained oil or use any oil that has been ex

posed to atmosphere. Procedures for adding or removing

oil are given in Carrier Standard Service Techniques Man

ual, Chapter 1, Refrigerants.

If oil is added, run unit for additional 10 minutes. Stop

unit and check oil level. If level is still low, add oil only

after determining that piping system is designed for proper

oil return and that the system is not leaking oil.

On demand for additional cooling capacity, the second

stage (TC2) of the cooling thermostat closes, energizing a

field-supplied liquid line solenoid valve (LLS) which opens.

This increases the suction pressure, causing the compressor

to operate at higher capacity.

When fan switch is set at AUTO., the indoor-air fan cy

cles with the compressor. When the switch is set at CONT,

the indoor-air fan runs continuously.

At shutdown, the Time Guard® II timer prevents the com

pressor from restarting for approximately 5 minutes.

In addition, a field-supplied solenoid valve wired in par

allel with the compressor contactor coil, shuts off the liquid

line to prevent refrigerant migration back to the compressor

during the off cycle.

Heating — The heating thermostat (TH) energizes a field-

supplied relay which operates heating controls and ener

gizes the indoor-fan relay. When the fan switch is set at

AUTO., the indoor-air fan cycles with the heating control.

The indoor-air fan runs continuously when the fan switch is

set at CONT.

Fan Cycling is employed for head pressure control. The

no. 2 fan responds to liquid line pressure, cycling on at ap

proximately 257 psig (1772 kPa) and off at approximately

126 psig (869 kPa).

Winter Start Control (If Required) — install Ac

cessory Package 38AE900021.

SERVICE

Capacity Control — A suction pressure-actuated un

loader controls 2 cylinders and provides capacity control.

Unloaders are factory set (see Table 1), but may be field

adjusted:

CONTROL SET POINT (cylinder load point) is adjustable

from 0 to 85 psig (586 kPa). To adjust, turn control set

point adjustment nut (Fig. 7) clockwise to its bottom stop.

In this position, set point is 85 psig (586 kPa). Then, turn

adjustment counterclockwise to desired control set point.

Every full turn counterclockwise decreases set point by 7.5

psig (51.7 kPa).

PRESSURE DIFFERENTIAL (difference between cylinder

load and unload points) is adjustable from 6 to 22 psig (41.4

to 152 kPa). To adjust, turn pressure differential adjust

ment screw (Fig. 7) counterclockwise to its back stop po

sition. In this position, differential is 6 psig (41.4 kPa).

Then, turn adjustment clockwise to desired pressure differ

ential. Every full turn clockwise increases differential by

1.5 psig (10.3 kPa).

Check Operation of all safety controls. Replace all

service panels. Be sure that control panel cover is closed

tightly.

OPERATING SEQUENCE

Cooling — When the first stage (TCI) of the cooling

thermostat closes, the timer starts. After approximately 3

seconds, the timer activates the compressor and fan motor

no. 1 contactor. When the liquid pressure builds to approx

imately 257 psig (1772 kPa), fan motor no. 2 is energized.

Page 7

Head Pressure Control by means of/an cycling is a

standard feature of 38AE012-016 units. The no. 2 fan cy

cles in response to changes in liquid pressure. The switch

cycles the fan off at 126 ± 4 psig (869 ± 28 kPa) as pres

sure decreases, and cycles back on at 257 (-1-5, -0) psig

(1772 [-f 103, -0] kPa).

CONTROL

SET POINT

ADJUSTMENT

NUT

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

VALVE BODY

BYRASS

PISTON

Winter-Start Control (If Required) - install Ac

cessory Package 38AE900021.

Crankcase Heater prevents refrigerant migration and

compressor oil dilution during shutdown whenever com

pressor is not operating. It is wired into the control circuit,

cycling with the compressor, off when compressor is run

ning, and on when compressor cycles off.

Both compressor service valves must be closed when

ever crankcase heater is deenergized for more than 6 hours.

The crankcase heater is operable as long as the control cir

cuit is energized.

Outdoor Fans — Each fan is supported by a formed-

wire mount bolted to the fan deck and covered with a wire

guard. The exposed end of the motor shaft is covered with

a rubber boot. In case a fan motor must be repaired or re

placed, be sure the rubber boot is put back on when the fan

is reinstalled and be sure the fan guard is in place before

starting the unit. Figure 9 shows the proper position of the

mounted fan. Fan motors have permanently lubricated

bearings.

DIFFERENTIAL SCREW'

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 7 — Compressor Capacity Controi Unloader

Time Guard® II Circuit provides for a delay of ap

proximately 5 minutes before restarting compressor after shut

down from safety device action.

On start-up, the Time Guard II timer causes a delay of

approximately 3 seconds after thermostat closes.

On compressor shutdown, the timer recycles for approx

imately 5 minutes. During this time, the compressor cannot

restart.

Refer to Fig. 8 and to label diagram on unit.

TIME DELAY TIMING SEQUENCE

----------

T1-T2

RUNNING TIME

p«

------

3SEC

-------------------------

wimmmmmmimiri.

----------

»■

5 MIN

»■

WIA DENOTES CLC6ED CONTACTS

Fig. 8 — Timer Sequence Chart

Lubrication

FAN MOTORS have sealed lubrication bearings. No pro

visions for lubrication are made.

COMPRESSOR has its own oil supply. Loss of oil due to a

leak in the system should be the only reason for adding oil

after the system has been in operation. See Oil Charge

section.

Page 8

Cleaning Coils — The coils can be cleaned with a vac

uum cleaner, washed out with water, blown out with com

pressed air, or brushed (do not use wire brush). Fan motors

are drip-proof but not waterproof.

Clean outdoor coil annually or as required by location or

outdoor air conditions. Inspect coil monthly, and clean as

required. Fins are not continuous through coil sections; dirt

and debris may pass through first section, become trapped

between the 2 rows of fins (38AE012) or 3 rows of fins

(38AE014, 016) and restrict outdoor airflow. Use a flash

light to determine if dirt or debris has collected between

coil sections. Clean coil as follows:

1. Turn off unit power.

2. Remove screws holding rear comer posts and top cover

in place. Pivot top cover up 12 to 18 in. (305 to 457

mm) and support with a rigid support. See Fig. 10.

3. Remove clips securing tube sheets together at the return

bend end of the coil. Carefully spread the ends of the

coil rows apart by moving the outer sections. See

Fig. 11.

4. Using a water hose, or other suitable equipment, flush

down between the sections of coil to remove dirt and

debris.

5. Clean the remaining surfaces in the normal manner.

6. Reposition outer coil sections.

7. Reinstall clips which secure tube sheets.

8. Replace top cover and rear comer posts.

Fig. 10 — Pivot and Support Top Cover

RIGID

SUPPORT

Page 9

TROUBLESHOOTING

PROBLEM SOLUTION

COMPRESSOR DOES NOT RUN

Contactor Open

1. Power off

2. Fuses blown in field power circuit 2 After finding cause and correcting, repiace with correct size

3. Transformer dead 3. Replace transformer if primary windings are receiving power.

4. Thermostat circuit open 4. Check thermostat setting.

5. Time Guard® il circuit defective

6. Circuit breaker tripped

7. Low-pressure switch open

8. High-pressure switch open

9. Loose electrical connections

10. Compressor stuck 10. See 06D compressor service literature.

11. Compressor motor thermostat open 11. Check for excessive motor temperature.

Contactor Closed

1. Compressor leads loose

2. Motor windings open

3. Single phasing

COMPRESSOR CYCLES ON HIGH-PRESSURE SWITCH

Outdoor Fan On

1. High-pressure switch faulty

2. Airflow restricted

3. Air recirculating

4. Noncondensables in system

5. Refrigerant overcharge 5. Purge as required

6. Line voltage incorrect

7. Refrigerant system restrictions

Outdoor Fan Off

1. Fan slips on shaft

2. Motor not running

3. Motor bearings stuck

4. Motor overload open

5. Motor burned out

COMPRESSOR CYCLES ON LOW-PRESSURE SWITCH

Indoor-Air Fan Running

1. Filter drier plugged

2. Expansion valve power head defective

3. Low refrigerant charge

Airflow Restricted

1. Coil iced up

2. Coil dirty

3. Air filters dirty

4. Dampers closed

Indoor-Air Fan Stopped

1. Electrical connections loose

2. Fan relay defective

3. Motor overload open

4. Motor defective

5. Fan belt broken or slipping

1. Restore power

fuse.

5. Repiace Time Guard ii circuit.

6. Check for excessive compressor current draw aiiowabie (140%

FLA maximum).

7. Check for refrigerant undercharge, obstruction of indoor airflow,

or whether compressor suction shutoff valve is fully open Make

sure liquid line solenoid (if used) is open.

8. Check for refrigerant overcharge, obstruction of outdoor airflow,

air in system, or whether compressor discharge valve is fully

open. Be sure outdoor fan(s) is operating

9. Tighten all connections.

1. Check connections.

2 See 06D compressor service literature.

3. Replace blown fuse

1 Replace switch.

2 Remove obstruction.

3. Clear airflow area.

4 Purge and recharge as required.

6. Consult power company

7. Check or replace filter drier, expansion valve, etc.

1 Tighten fan hub setscrews.

2. Check power and capacitor.

3. Replace bearings

4. Check overload rating. Check for fan blade obstruction

5. Replace motor.

1. Replace filter drier.

2. Replace power head.

3 Add charge. Check low-pressure switch setting

1. Check refrigerant charge

2. Clean coil fins.

3. Clean or replace filters.

4 Check damper operation and position.

1 Tighten all connections.

2. Replace relay.

3. Power supply

4. Replace motor.

5. Replace or tighten belt

Page 10

TROUBLESHOOTING (cont)

PROBLEM SOLUTION

COMPRESSOR RUNNING BUT COOLING INSUFFICIENT

Suction Pressure Low

1. Refrigerant charge low

2. Head pressure low

3. Air filters dirty

4. Expansion valve power head defective

5. Indoor coll partially iced

6. Indoor airflow restricted

Suction Pressure High

1. Compressor valve defective

2. Head load excessive

UNIT OPERATES TOO LONG OR CONTINUOUSLY

1. Low refrigerant charge

2. Control contacts fused

3. Air in system

4. Partially plugged expansion valve or filter drier

SYSTEM IS NOISY

1. Piping vibration

2. Compressor noisy

COMPRESSOR LOSES OIL

1. Leak in system

2. Crankcase heaters not energized during shutdown

3. Improper interconnecting piping design

FROSTED SUCTION LINE

1. Expansion valve admitting excess refrigerant

HOT LIQUID LINE

1. Shortage of refrigerant due to leak

2. Expansion valve opens too wide

FROSTED LIQUID LINE

1. Restricted filter drier

COMPRESSOR WILL NOT UNLOAD

1. Defective unloader

2. Defective capacity control solenoid valve (if used)

3. Miswired capacity control liquid line solenoid (if used)

4. Weak, broken, or wrong valve body spring

COMPRESSOR WILL NOT LOAD

1. Miswired capacity control liquid line solenoid (if used)

2. Defective capacity control solenoid valve (if used)

3. Plugged strainer (high side)

4. Stuck or damaged unloader piston or piston ring(s)

1. Add refrigerant

2. Check refrigerant charge.

Check outdoor-air fan thermostat settings.

3 Clean or replace filters.

4. Replace power head.

5. Check low-pressure setting.

6. Remove obstruction.

1. See 06D compressor service literature.

2 Check for open doors or windows in vicinity of fan coil.

1. Add refrigerant.

2. Replace control.

3. Purge and evacuate system.

4. Clean or replace.

1. Support piping as required.

2. Check valve plates for valve noise Replace compressor if bear

ings are worn

1. Repair leak.

2. Check wiring and relays Check heater and replace if defective.

3 Check piping for oil return. Replace if necessary.

1. Adjust expansion valve.

1. Repair leak and recharge.

2. Adjust expansion valve.

1. Remove restriction or replace.

1 Replace unloader.

2 Replace valve.

3 Rewire correctly.

4. Replace spring

1. Rewire correctly.

2. Replace valve.

3 Clean or replace strainer.

4 Clean or replace the necessary parts

10

Page 11

Page 12

f

Copyright 1992 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book! 1 II PC 111 Catalog No. 533-816 Printed in U S A. Form 38AE-17Si Pg 12 4-92 Repiaces: 38AE-10Si

Tab 3a 2a

Loading...

Loading...