Page 1

Carrier

Instaitation, Start-Up

at|d Service Instructions

Air-Cooled Condensing Units

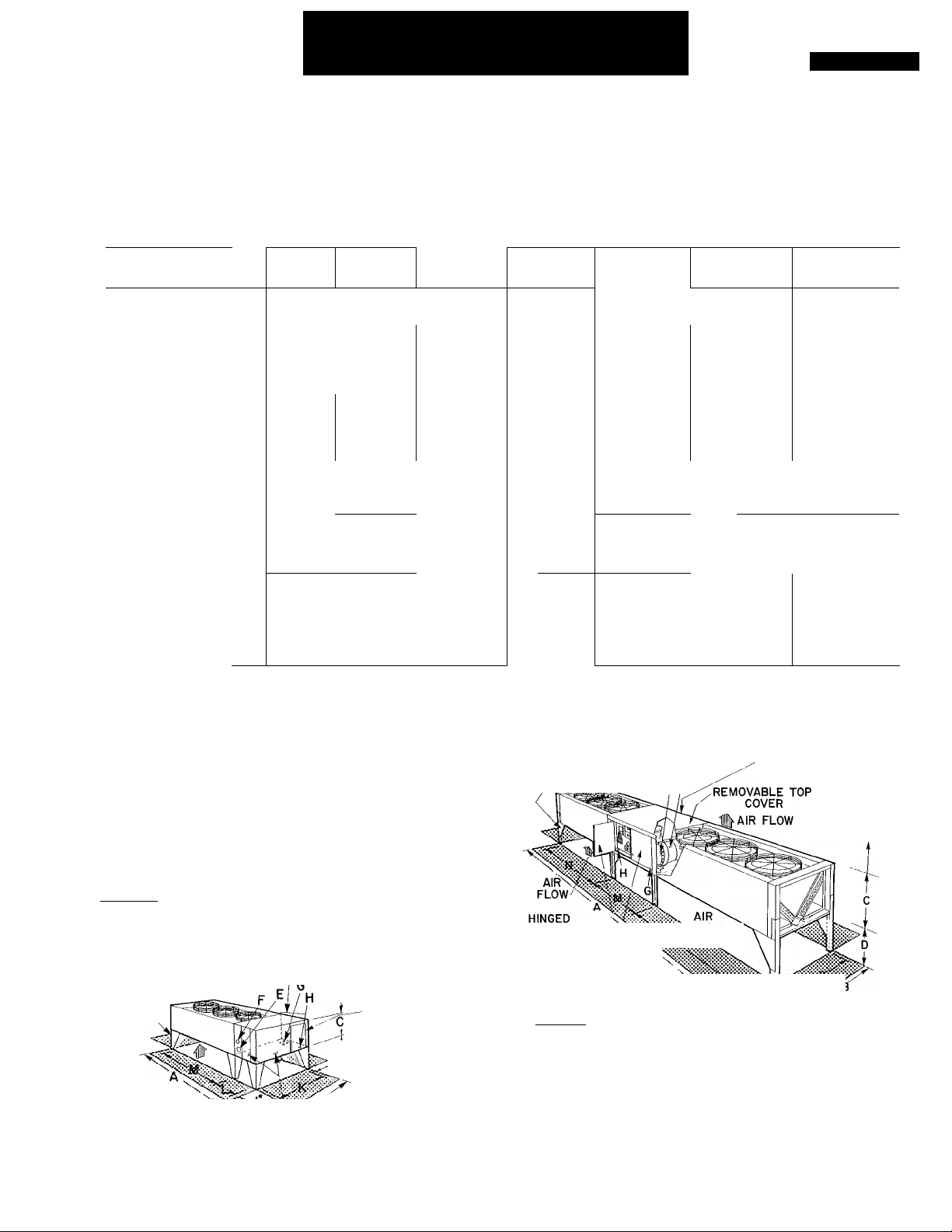

Table 1 — Dimensions

024 thru 084

38AD

024 028

DIMENSIONS (ft-in

Length

Width

Height w/o Legs

Leg Height

Mtg Holes

Corner Legs

Middle Legs

CONNECTIONS (in

Suction (ODM)

Liquid (ODM) %

OPENINGS (in.)

Suction

Liquid

Control (4 holes)

Power

*Unit 38AB084 has two suction connections

.)

A

В

C

D 1-0 or 2-0 1 —6 or 2—2

0- 1У2

li

( J

Ik

3- 8V4

0- OVe

3-10

L

M

N

- -

)

E

F

1- %

G

H

3~

38AD

11У4

2-

4Ve

0- 1У2

3- 8У4

0- 0%

3-10

1- У

13-0

3-3Ve

9-4Уа

1-Ув

2-У

Ув

З-Ув

12

38AD

044

-10%

- 2

1 - 8

2

-У

5

- 7У

2

-У

- 7У

3

- 7Уб

-юу

8

2-У

V

38AD

034

4-ЮУ4 6 - ОУ4

3- 1У 3

0- ly

4- 7У4

0- оу

4- 8У 5

4 5

1- У4

2

1-У

5

ЗВАВ

054

24-4

3-11У

2- 4У

Ì —4 ог 2—0 1-6

0- 1Уб

3- 8У

0- ОУв

3-10

2-У4

1

З-У4

38АВ

064 084

4-1ОУ4

3-

Г/в

ОГ 2—2

0-

4-

7У

ОУв

0-

r/i6

1 _8 ог 2-4

4- 8У

9

-4У

-ЗУ4

5

-5У

9

2

-Ve*

1

38АВ

24-4

6- ОУ4

3- 1Ув

0- ly

5- 9У4

0- ОУв

5-10У

(2)5

3

%

(2) ЗУ

REMOVABLE HINGED CONTROL

TOP COVER g|4, BOX DOOR

\0NLY) REQUIRED OVERHEAD

AIRFLOW# \^'; / /

_ _____

_ |H o"U

GUSSET

\ ^^si|^4-0"(B0TH SIDES)

38AD024

028, 034

4-0-Ny/ REMOVABLE

(BOTH SIDES)^ END PANELS

HINGED ACCESS DOOR-

CONTROL BOXi

AIR FLOW

GUSSET

38AD044

A..'- -’ll —

------------

(BOTH SIDES) end panels

REQUIRED OVERHEAD

AIR SPACE

8-0"

HINGED POWER

BOX DOOR

?

4'-0"(B0TH SIDES)

^removable

GUSSET '‘t

CONTROL \,

BOX COVERS \

38AB054,

064,084

• AIR FLOW THRU

Fig. 1 — Dimensions

AIR FLOW

CONDENSER

BOTTOM PANEL

OPENING

E F

(BOTH SIDES)

Certified dimension drawings are available on request

REMOVABLE REAR

m SPACE FOR SERVICE

PANEL

4'-0"

(BOTH SIDES)

AND AIR FLOW

REQUIRED

OVERHEAD

AIR SPACE

8'-0"

©Carrier Corporation 1972

Form 38AD-6SI

Page 2

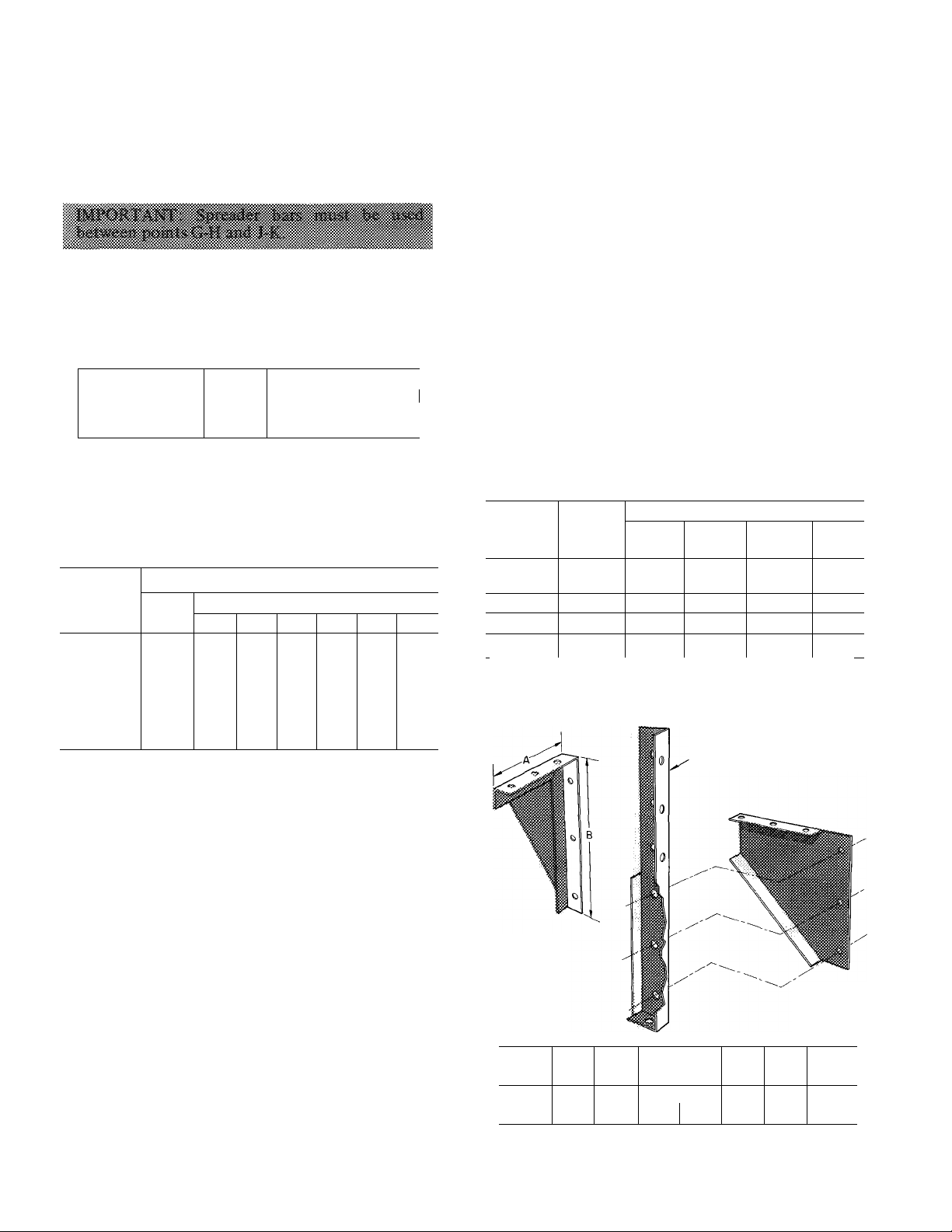

Lift unit at points G,H, J, and K (Fig. 2). Use

eyebolts and washers supplied in parts package. Do

not sling unshielded unit Skidded unit may be

slung, provided sling does not contact unit sides.

Do not roll unskidded unit on pipes or wooden

pilings.

COM PR

SECTION

4-

4 ^

COIL 1

Ml SECTION 1

f j

r A -

“! . p

COIL

SECTION

COIL

SECTION

COMPR

SECTION :

^ -

Erect UnifeusMf^legs and gussets attached to unit

base skid(s) or frame. Adjust all corner legs to

desired height before attaching to unit.

38AD024,028,034 AND 044 UNITS - Block up

or suspend unit. With field-supplied bolts, bolt

corner leg and angle gusset to each corner of unit.

Bolt two center legs to bottom of unit where

compressor and coil sections meet. Lower unit.

38AB054,064 AND 084 UNIT - Block up or

suspend compressor (with coil) section. Bolt corner

leg and angle gusset to each corner at coil end. Bolt

two center legs to compressor end. Allow one set

of holes to project out past compressor section.

Bolt two center legs to bottom of unit where

compressor and coil sections meet. Lower unit.

Block up or suspend coil (only) section. Bolt

two corner legs and angle gussets to coil return

bend end. Butt coil (only) section against com

pressor compartment, allowing cod to rest on leg

projections. Remove top cover on compressor

compartment and bolt sections together at legs and

sides.

Table 3 — Legs and Gussets Provided

Fig. 2 — Weight Distribution and Lifting Points

Table 2 — Weight Distribution

WEIGHT (lb)

UNIT

38AD024

38AD028

38AD034

38AD044

38AB054

38AB064

38AB084

Total

1750 175

1900

2300

3200

3145 180

3830 245

4960 327

178 178 521

263 263 767

359

A B C D E

Leg Location

175 575

359 770

605 607

712 714

913 327

913

125

575

565

767 120 120

810 441

181

244

125

207 251

461

-

F

-

-

-

SKID REMOVAL

Remove the four bolts (each section) holding

top frame in place and lift frame from unit

(38AD024 thru 044 and 38AB054,064 units).

Compressor (with coil) Section — Raise and block

up one side of unit 8 inches. Remove the three

exposed hold-down bolts from base skid. Lower

unit and repeat on opposite side.

Coil (only) Section (38AB054,064 and 084) —

Raise and block up one end of unit 8 inches.

Remove the two exposed hold-down bolts from

base skid. Lower unit and repeat on opposite end.

ERECTING AND INTEGRATING ONE UNIT

Position Units 38AD028,044 and 38AB054,

064,084 so air flow is unrestricted on all sides and

on top (Fig. 1).

38AD024,034: any side except compressor end

may be installed against a wall if high leg setting is

used and other three sides are unrestricted.

Place 38AB and 38AD units on high leg setting if

accessory damper is used.

QUANTITY

38AB 38AD

024,028

-

-

054,064

084

‘Parts packages in units contain all mounting fasteners required

for attaching legs and gussets

CENTER LEG

A(in.)

B(in.)

‘Only 044 units use one-piece legs

034

044

38AD

024

16

24 24

Corner

Leg

- - 4 -

-

38AD

38AD 38AD

028 034 044

16 18 0

Center

Leg

4

4

4

CORNER LEG

26 20

Angie

Gusset

2

2

-

38AB

054 064

16

24

Fig. 3 — Legs and Gussets

Parts

Pkg*

4

- 1

4 1

ANGLE

GUSSET

38AB 38AB

084

18

26 28

20

1

1

Page 3

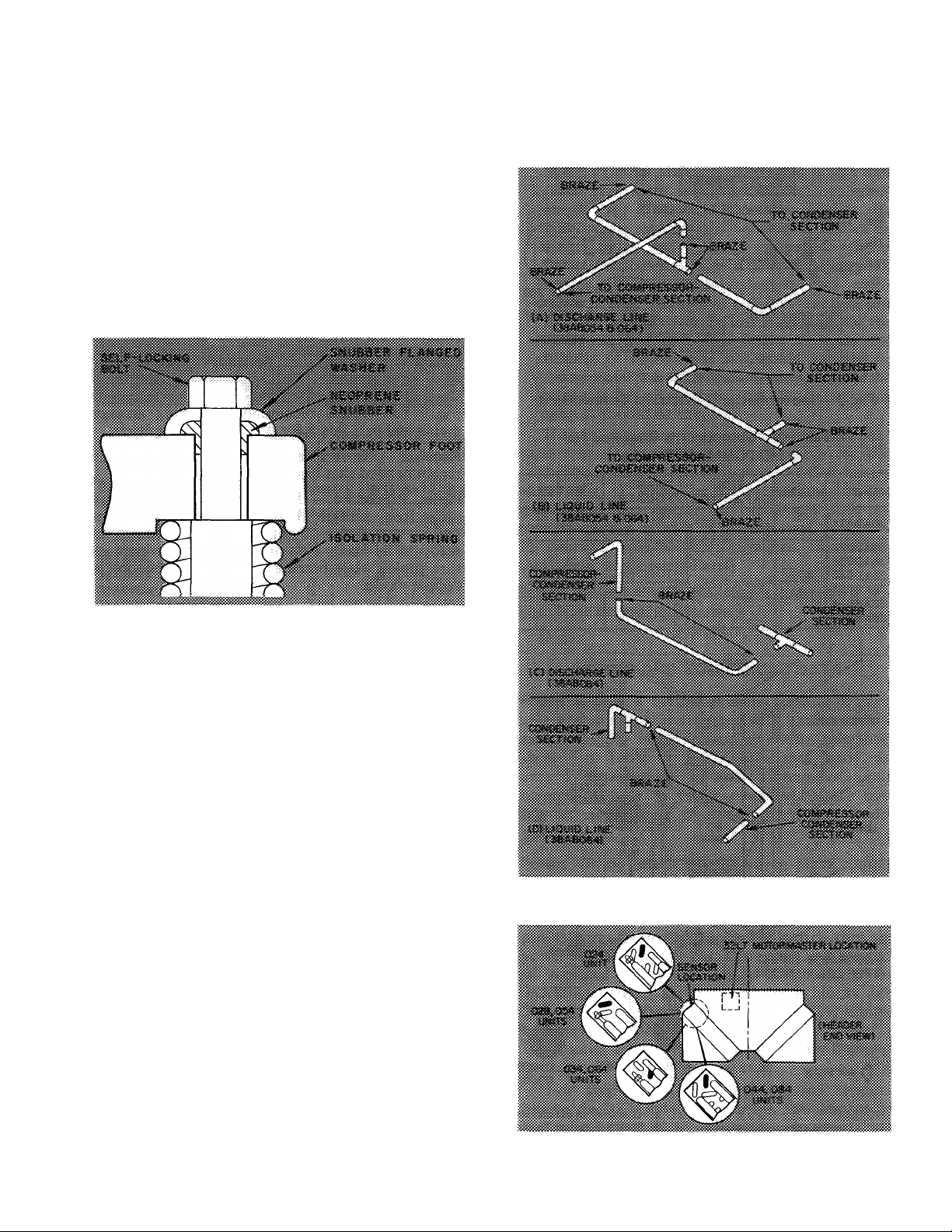

Compressor Mounting

38AD024,028,034 UNITS - As shipped, com

pressor is held down by special self-locking bolts

and plain lockwashers. After unit is installed,

remove the self-locking bolts one at a time and

reassemble with flanged washers and neoprene

snubbers as shown in Fig. 4. Special flanged wash

ers and neoprene snubbers are shipped in a cloth

bag tied to one of the compressor feet. Tighten all

four bolts. Then, loosen each until the flanged

washer can be moved sidewise.

38AD044, 38AB054,064 AND 084 UNITS (com

pressors are mounted on a common support

channel) — Remove the four shipping bolts from

mounting channels prior to start-up.

208- and 230-volt units, outdoor fan motor no. 1

(OFMj), located nearest the compressor, may be

used with MOTORMASTER without modification.

For 460- and 575-volt units, refer to Tabled for

field-supplied components needed with

MOTORMASTER.

Fig. 4 — Compressor Mounting

(38AD024,028 and 034)

Fan Thermostat — Route the thermostat control

bulb and capillary (located in compressor section)

thru grommeted hole in compressor section base

pan. Do not kink capillary. Position bulb in inlet

air stream and secure to inlet air flange adjacent to

compressor section. Use clamp and screw provided

in parts package.

If accessory head pressure control damper

section is used, secure bulb to air inlet side of

damper. Use hole in damper frame.

Integrate Unit (38AB054,064 and 084 only) —

Connect refrigerant piping between the two sec

tions, using materials furnished with unit. Arrange

discharge and liquid lines as shown in Fig. 5 and

braze as indicated.

Electrically connect unit control box and junc

tion box on coil (only) section by using flexible

fan conduit furnished in the unit. Use the mating,

quick-connect, polarized plugs furnished in the two

sections to make the wire connections.

Motormaster® (32 Series) Head Pressure Controller

— Refer to MOTORMASTER Instructions shipped

with this accessory, plus the following information.

Control box and sensor location is shown in

Fig. 6.

Electrical connections are shown in Fig. 7.

Refer to unit label diagram as required. On 200-,

Fig. 5 — Refrigerant Connections

Fig. 6 - MOTORMASTER Control Box

and Sensor Location

Page 4

*Use 230-vo)t controller with 200-,208- or 230-volt motors

Fig. 7 — Motormaster® Electrical Connections

Table 4 — Components Required for

MOTORMASTER Use

UNIT MODEL

38AD024

38AD028

38AD034

38AD044

38AB054

38AB064

38AB084

600

100

600

100

RUN

CAPACITOR

HC96LH020

HC96LH030

TRANS

FORMER

HT01AH951

HT01AH959

HT01AH952

HT01AH954

MOTOR

HC46VL220or

HC46VL221

HC52TE230

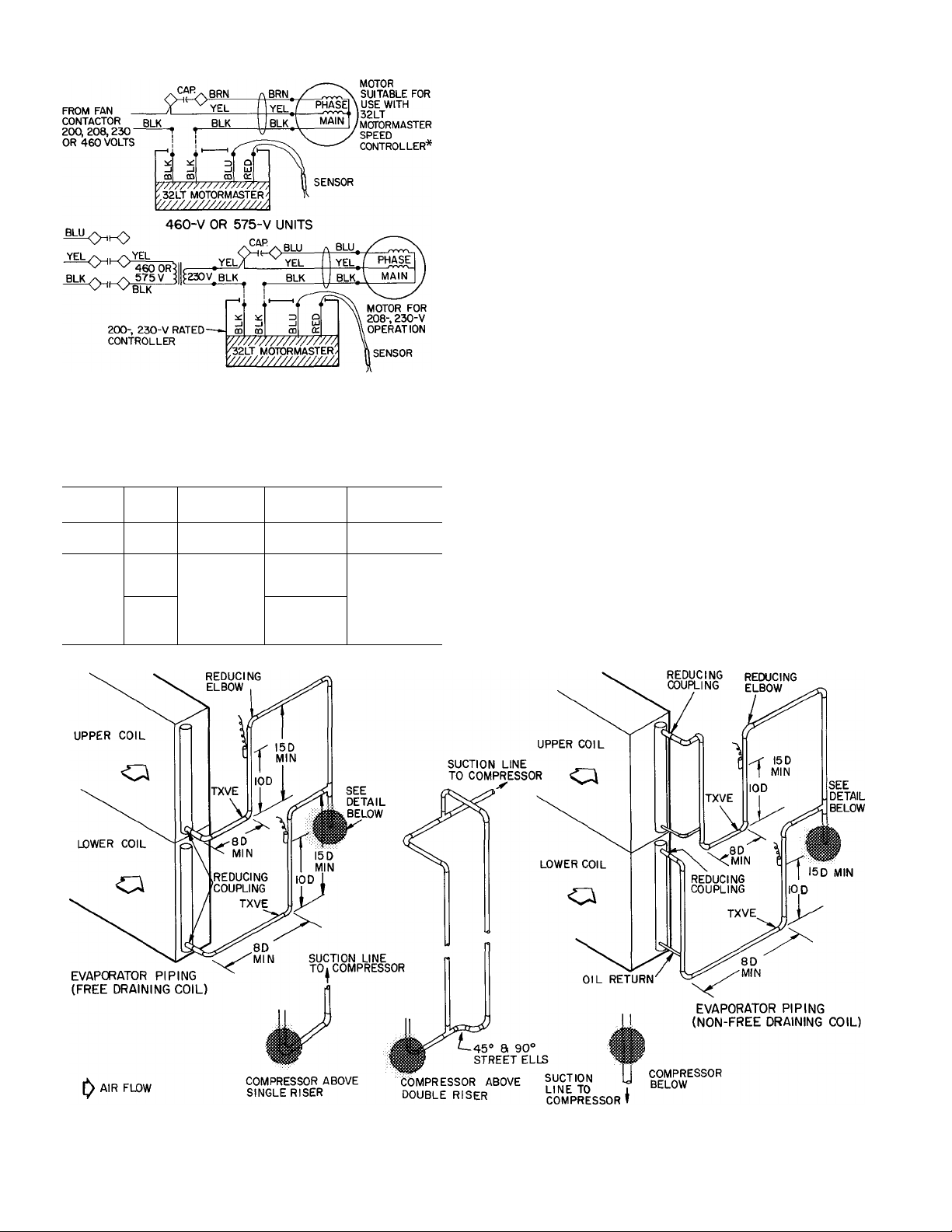

REFRIGERANT PIPING

Refrigerant Line Sizes will depend on length of

piping required between condensing unit and evap

orator. Consideration must be given to liquid lift

and to compressor oil return. Refer to Part 3 of

Carrier System Design Manual for line sizing

information and Fig. 8 for recommended piping

details.

Single Pumpout Control — All units are factory

wired to operate on single pumpout control and

require a field-supplied liquid line solenoid valve,

sized for minimum pressure drop, to be installed

immediately ahead of each expansion valve. If unit

is to be used with a chiller, wiring modifications

may be necessary. Refer to 38AB Application

Data, Chilled Water Applications.

Refrigerant Drier and Moisture Indicator — A

filter-drier(s) and a liquid-moisture indicator are

shipped with unit for field installation. Refer to

Fig. 9 for typical recommended piping arrange

ments and to Table 5 for physical data on driers.

Receiver — No receiver is provided with unit. It is

recommended that one not be used.

Piping Procedure — Do not remove plastic dust

plugs from suction and liquid line stubs in com

pressor compartment until piping connections are

ready to be made. Pass nitrogen or other inert gas

thru piping while brazing, to prevent formation of

copper oxide.

NOTES

1 Lower split first on, last off

T7T

2 D as used in 8D etc, indicates the pipe diameter size as a measure of length

3 TXVE indicates Thermostatic Expansion Valve Equalizer Connection

Fig. 8 — Typical Piping Connections for Face Split Coils

Page 5

Fig. 9 — Recommended Filter-Drier(s)

and Sight Glass Locations

Table 5 — Filter-Drier Replacement Parts and Data

FILTER-DRIER

UNIT

38AD024

38AD028 KH43LE12) 2

38AD034

38AD044 KH49EA030

38AB054 KH49EA120 1

38AB064

38AB084 KH49EA040

* Replaceable cores only

Part No, Qty

KH43LE123

KH43LE121

KH49EA120

Conn.

Size

1

2

1

1

1

Replacement

Part No.

Same

=/s

%

%

iVs

iVs KH29EZ050*

iVs KH29EZ050*

Some

Same

KH29EZ050* 2

KH29EZ050* 2

Core

Qty

riser must be at least 15 pipe diameters high

and the bulb should be fastened 10 pipe

diameters above the preceding elbow.

3. Size the suction line from near evaporator thru

the 15 diameter long riser for high velocity.

Enter the suction pipe sizing charts in Carrier

System Design Manual at corrected design tons

(each evaporator split) and 80 feet equivalent

length (for 2° loss). Choose the smaller size

pipe, when reading falls between two sizes on

chart. Since the selection of suction piping

recommended for high velocity is approxi

mately 20 ft equivalent length, this sizing

method will result in about 0.5° friction loss

for that section. If a 2° loss is allowed for the

entire suction line, this leaves 1.5° for the

balance of suction line and should be sized on

that basis. This high-velocity sizing should be

adequate for oil return up the 15 diameter long

riser. It should be checked.

If an oil return connection at the bottom of the

suction header is supplied with an evaporator, this

connection must be teed in ahead of first mixing

elbow (Fig. 8). When the compressor is below the

evaporator, the riser at the evaporator does not

have to extend as high as the top level. After the

15 diameter riser has been provided, the suction

0

0

0

may elbow down immediately.

Safety Relief — A fusible plug is located on unit

liquid line before liquid valve.

2

3

WIRING AND ELECTRICAL DATA

Install field-supplied thermostatic expansion

valve in liquid line ahead of each evaporator

section. For two-step cooling, the solenoids used

must be wired to be opened by control from a

two-step thermostat

For example; two solenoids may be used with

three TXV’s — one of the solenoids serving a liquid

line feeding two of the TXV’s. When three

solenoids are used with three TXV’s, two of the

solenoids must be tied in parallel with the thermo

stat to serve the one liquid line feeding the two

TXV’s. The third solenoid operates independently

for the other step of cooling.

Suction Piping at Evaporator and TXV Bulb

Location

The purpose of these recommendations is to

achieve good mixing of the refrigerant leaving the

evaporator suction header for proper sensing by

the TXV bulb.

1. A minimum of two 90° elbows must be

installed upstream of the expansion valve bulb

location.

2. The thermal bulb must be strapped to a vertical

riser following the second elbow of item 1. This

Power Supply — Electrical characteristics of avail

able power supply must agree with unit nameplate

rating. Supply voltage must be within tolerances

shown in Table 6. Phase unbalance must not

exceed 2%. Operation of unit on improper supply

voltage or with excessive phase unbalance con

stitutes abuse and is not covered by Carrier

Warranty.

Power Wiring — All power wiring must comply

with applicable local and national codes. Install a

field-supplied branch circuit disconnect switch of a

type that can be locked “Off’ or “Open.” Run

power wires from the disconnect switch thru the

power opening (H on Fig. 1) on unit and connect

to terminal block just inside the opening. On

38AB084, there are two terminal blocks (on

208-volt and 230-volt units only). Each is limited

to 350 MCM maximum wire size (see Table 7).

These units are provided with two power openings

to accommodate two conduit runs.

For access to power opening and terminal

blocks on 38AD044, unlatch the two latches on

the outer hinged door and swing open outer door.

Remove screws on barrier panel and remove barrier

to expose wiring.

Page 6

Table 6 — Electrical Data (3-Phase, 60-Hz)

f

Shaded values are LRA drawn by first winding of

part-winding start units (not standard on 38AB054,064,

but may be field modified) See Note 1 Larger value is

total LRA.

FLA — Full Load Amps

ICF — Maximum Instantaneous Current Flow (sum of LRA of

LRA Locked Rotor Amps

MWA — Minimum Wire Amps per NEC, Section 430-24 Values

*Units are suitable for use on electrical systems where voltage

tUnits 38AB084 (208-, 230-volt only) have two power connections

last compressor to start and FLA of all other motors in

unit, and control circuit current)

based on maximum of 1% voltage drop in line.

supplied to the unit terminals is never below or above the listed

limits

Maximum wire size is 350 MCM each

*

On 38AD024 thru 034 units, power terminal

block is in the control box. Remove the outer

panel and remove the no. 10 screw on the door.

Swing open door, remove screws on barrier panel

and remove barrier panel. On 38AB054,064 and

084 units, remove two screws holding hinged sheet

metal barrier and swing open barrier.

Condenser fans must rotate clockwise when

viewed from above. If necessary, correct direction

of fan rotation by interchanging any two power

input wires at disconnect switch.

NOTES

1 Dual compressor units have a 4- to 12-second delay between

first- and second-compressor start-up Units are supplied with

either across-the-line or part-winding start, depending on unit

size and voltage Refer to Electrical Data table Where two LRA

values are shown, units are part-winding start, (all others are

across-the-line)

2 Units have factory-installed circuit breakers and/or pullout fuses

that meet NEC requirements for branch circuit over-current

protection and in-sight disconnect Consult local codes

3 Maximum Incremental Current Inrush during start-up is LRA

drawn by first winding of part-winding start unit (shaded area)

or across-the-line LRA of largest compressor when part-winding

start is not available

4 Fans no 1 and 4 have single-phase speed control motors on 208-

and 230-volt units

5 Units 38AB054 and 064 which have two contactors, can be

converted to part-winding start by addition of two time-delay

relays (Carrier part no FIN67SK001 for 208- and 230-volt units,

or no HN67SK002 for 460-and 575-volt units) Two additional

contactors are also required with 460- and 575-volt units to be

wired same as other part-wind compressors

Affix crankcase heater decal to unit disconnect

switch.

Control Circuit Wiring — Internal control voltage

on 38AD units is 115 volts. Internal control

voltage on 208- and 230-volt 38AB units is the

same as unit voltage. On 460- and 575-volt 38AB

units, it is 115 volts. All control circuit wiring must

comply with applicable local and national codes.

Remote control wiring must enter unit control box

thru control opening (G on Fig. 1) and connect to

terminal block inside the control box.

772

Page 7

Table 7 — Maximum Field Wire Sizes

UNIT

38AD

38 A B

CT — Compression Terminal (attached to terminal block)

TB — Terminal Block (with integral compression terminal)

SIZE

024,028,034

044

054,064

084

VOLTS

(60-Hzy

208

230

460

575

460

575

208

230

208

230

460

575

All 6 AWG to 350 MCM-

WIRE SIZE CONN.

6 AWG to 350 MCM

14 AWG to 2/0

6 AWG to 350 MOV!

6 AWG to 350 MCM

6 AWG to 3/0

TB

CT

TB

CT

CT

TB

&[1]--

[E--

0--

------------

lEh

E

--------------------------------

CR — Control Relay TC — Thermostat, Cooling

LLS — Liquid Line Solenoid

TB — Terminal Board (at unit) *Field Supplied

J<d_

TC2*

TWO STEP COOLING

38AB054, 064 AND 084

LEGEND

--"fea--

---------

Field Wiring

T

I

-I -

Fig. 10 — Control Circuit Wiring with Line Voltage

(115, 208- or 230-volt) Thermostat

, J

LINE VOLTAGE REMOTE CONTROL - Install

field-supplied line voltage thermostat(s) as shown

in Fig. 10 for two-step cooling. Wire liquid line

solenoid as shown.

LOW-VOLTAGE REMOTE CONTROL - Install

field-supplied accessories as shown in Fig. 11 or

Fig. 12 for either two-step cooling or two-step

cooling, one-step heating. Wire liquid line solenoids

as shown.

START-UP

Preliminary Checks

1. Compressor oil level must be visible at sight

glass in each compressor crankcase. Add oil if

necessary.

2. Each compressor must float freely on its

mounting springs.

3. All internal wiring connections must be tight,

and all barriers and covers must be in place.

Toggle switches for units 38AB054.,064 and 084

must be in “On” position.

4. Electrical power source must agree with unit

nameplate rating.

5. All service valves must be open.

6. Fan cycling thermostat sensing bulb must be in

air stream under fan no. 1.

7. Crankcase heater must be firmly locked into

the compressor crankcase.

Leak Test the entire refrigerant system by the

Pressure Method described in the Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-6.

Use R-22 at approximately 25 psig backed up with

an inert gas to a total pressure not to exceed 245

psig.

Evacuate and Dehydrate the entire refrigerant

system by either of the methods described in the

Carrier Standard Service Techniques Manual,

Chapter 1, Section 1-7.

l-2i

38AB,054,064. 0^

SDRl

CR)

-----

---------------

•SDRir^

L-ll]

------

AHA — Adjustable Heat

cc — Cooling Compensator

CR — Control Relay

HD — Heating Device

IFR

IMS

LLS — Liquid Line Solenoid

R — Relay (Accessory)

SDR — Solenoid Dropping Relay *Field Supplied

Anticipator

— Indoor Fan Relay

— Indoor Motor Starter

(i^

—@k3^-

THERMOSTAT HHOTATOTZ

SUBBASE HH93AZ080

LEGEND

SR — Solenoid Relay

TB -- Terminal Board

TC — Thermostat, Cooling

TH — Thermostat, Heating

— Factory Wired

■ - Field Wired

-1 Terminal Board Conn.

n

at Unit

Fig. 11 — Control Circuit Wiring with

24-Volt Accessories (38AB Units Only)

—-ii

772

Page 8

CONTROL POWER AT 38AD UNIT

tll5-l-60 VOLT t

CR — Control Relay

HD — Heating Device

IFC — Indoor Fan Contactor

IFR — Indoor Fan Relay

LLS — Liquid Line Solenoid

R — Heating Relay (field-supplied 24-volt sealed coil, 10VA

SDR — Solenoid Dropping Relay

TB

TC

TH

--------------

------------^Jumper removed only when separate 24-volt power sources are

fTo control heating device and provide automatic indoor fan

maximum rating)

— Terminal Board

— Thermostat, Cooling

— Thermostat, Heating

Factory Wiring

Field Wiring

available for heating and cooling

operation on heating

Fig. 12 — Control Circuit Wiring with 24-Volt

Accessories (38AD units only)

Preliminary Charge — Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-8,

for charging methods and procedures mentioned

below.

Charge system with approximately 25 lb of R-22

(75 lb for 38AD044, 38AB054,064 and 084 units)

by the Liquid Charging Method and Charging by

Weight Procedure.

Energize the Branch Circuit, set space thermostat

above ambient. Close field disconnect switch and

turn on unit circuit breakers. Be sure compressor

crankcase heater(s) is operating. Allow crankcase

heater(s) to operate a minimum of 24 hours before

starting unit.

To Start Unit, set space thermostat below ambient,

to ensure circuit operation. On 38AD044 and

38AB084, push control circuit reset button(s).

After starting unit, there will be a delay of about

' 15 seconds (12 seconds on 38AD044 and

38AB084) before first compressor starts.

Charging System

1. Block condenser coils to maintain 125 F con

densing temp at 280 psig, then add additional

charge to clear sight glass. (If long liquid lines

or vertical lifts greater than 25 ft are used, a

liquid line sight glass should be installed at

condensing unit and used for charging

purposes.)

2. After sight glass has cleared, additional charge

must be added per Table 8, to flood subcooler

circuits in condensers.

After Charging the System, allow unit to run for

about 20 minutes. Stop unit and check compressor

oil level. Add oil only if necessary to bring oil into

view in sight glass. If oil is added, run unit for

additional 10 minutes. Stop unit and check oil

level. If level is again low, add oil only after

determining that piping system is designed for

proper oil return and that the system is not leaking

oil. Check the operation of all safety controls.

Replace all service panels. Be sure that control

panel door is closed tightly.

Table 8 — Charging Data (R-22)

REFRIG CHG (lb)

UNIT

38AD024

38AD028

38AD034 7 99

38AD044 15

38AB054

38AB064 10

38AB084

*For maximum system capacity without receiver

fAt 120 F condensing temp with condenser 80% full of

liquid

NOTE

Values shown do not include charging requirements for

cooling coils and piping

Sub-cooler

Coil*

8

8

12

21

REFRIG

STORAGE

CAP. (Ib)t

70

77

161

154

198

322

SERVICE

Capacity Control is by either one or two suction

pressure actuated unloaders. Each controls two

cylinders. Unloaders are factory set (see Table 9)

but may be field adjusted. No. 1 unloader is on

cylinder bank on same side of compressor as

terminal box.

CONTROL SET POINT (cylinder load point) is

adjustable from 0 to 85 psig. To adjust, turn

control set point adjustment nut (Fig. 13) clock

wise to its bottom stop. In this position, set point

is 85 psig. Then, turn adjustment counterclockwise

to desired control set point. Every full turn

counterclockwise decreases set point by 7.5 psig.

PRESSURE DIFFERENTIAL (difference between

cylinder load and unload points) is adjustable from

6 to 22 psig. To adjust, turn pressure differential

adjustment screw (Fig. 13) counterclockwise to its

back stop position. In this position, differential is 6

psig. Then, turn adjustment clockwise to desired

pressure differential. Every full turn clockwise

increases differential by 1.5 psig.

772

Page 9

Table 9 — Physical Data

UNIT

OPER WT (lb)

REFRIGERANT

Oper Chg (lb)*

COMPRESSOR

Number

Model

Cylinders 4 4

Oil (pt)

Crankcase Htr

Pro tection

Cap. Control

No. 1

Load

Unload

No. 2 Unioader Settings (psig)

Load

Unload

COND FANS

Number

Rpm

Diam (in.)

Motor Hp (ea)

Cfm

COND COIL

Sections

Face (sq ft) 35 4 39 0

Capacity (lb)t 70 77

ELEC CONTROLS

Pre^surestat Dual

, Cutout

High ^ ^ .

Cut-in

, Cutout

Low ^ ^ .

Cut-in

Pressurestat Capacity Control

Cutout

Cut-in

Pressurestat

Cutout

Thermostat

No. 1

No. 2

Thermostat

PRESS. RELIEF

DISCHARGE LINE

CHECK VALVE

38AD024

1750

28 0 30 5

1

0ÓED250 06EE266

14

76 78

58 60

-

3 3 3 3

1140 1140

26 30 30 30

18,200

1

— —

- -

38AD028

1900 2300 ' 3200 3145 3830

1

14 19

Solid State &. Ckt Bkr Thermotector & Ckt Bkr

76 76

58 58

1

25,200 28,200

1

29 Psig

44 Psig 45 Psig

1 1

38AD034

35 5

1

06EE275

6

78

60 66

1140

1

1 2

49 6 60 4 78 0

99

38AD044 38AB054 38AB064

R-22

66 0

Reciprocating Hermetic — 1750 rpm

2

06EA

250

5 Psi Above Suction Pressure

Opens

06ED

4 4

14

Suction Pressure Cylinder Unioader(s

Unloader Settings (ps

88

Axic 1 Flow;

1 140

31,000

161

Time Guard Circuit**

29 Psig 29 Psig

57 Psig

87 Psig

1 Pressure Contro

Oi

Fan Cycling

Opens, 70 F;

Opens, 57 F;

Discharge Line

290 F; Closes, 210 F

Fusibl

2

06EA

250

14

1 25 Watts

Direct Drive

Plafe Fins; 3-rowt

375 Psig

275 Psig

Closes, 75 F

Closes, 62 F

e Plug

57 0

2

06EE

250

4

14

-

-

-

-

275

6

19

g)

79

66

76

58

6

1140

30

50,400

154 198 322

1

2

71

0

2

06EA

275

6

19

~

-

-

-

06EE

275

6

19

79

66

76

58

S

1140 1 140

30 30

56,400

2

99 2

63 Psig

57 Psig

87 Psig

2

38AB084

4960

132 0

06EA

299

6

19

Solid State

& Ckt Bkr

-

-

_

-

62,000

120 8

2

06EE

299

6

19

79

66

76

58

6

2

2

■*Approximate charge for maximum system capacity Holding charge

factory supplied with all units

fUnit 38AD044 and 38AB084 have 4 row coil

Time Guard Circuits

BASIC FUNCTIONS OF TIME GUARD CIRCUIT

on all units provide for normal (12 to 15 sec)

momentary delays after the thermostat closes and

before compressor(s) start. The circuit also pro

vides for a longer delay (4 min 45 sec to 5 min

30 sec) in the event of thermostat short cycling or

momentary power failure.

^Storage capacity at 120 F condensing temp with condenser 80%

full of liquid

**Short-cycle protection

38AD024 THRU 044 UNITS

In addition to the basic functions, timers in

these units provide additional delays for oil

pressure switch bypass (40 sec), winter start

provision (150 sec) bypass of low-pressure switch

and part-winding start (1 sec), if used.

772

Page 10

38AB084UNIT

Timers in this unit provide basic function, plus

40 sec bypass for oil failure switch and 1 sec delay

to accomplish part-winding start.

For specific sequence for each unit, refer to

Timing Charts in Fig. 14.

CONTROL

SET POINT

ADJUSTMENT

NUT

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

VALVE BODY

BYPASS

PISTON

Control Circuit Reset

38AD024 THRU 044 AND 38AB084 - Control

circuit locks out on these units in the event of oil

pressure loss, excessive motor temperatures, or

excessive discharge temperatures Reset is

accomplished by pushing reset button(s) in unit

control box.

38AB054 AND 064 — Loss of oil pressure or

excessive motor temperatures cause control circuit

lock out on these units Reset is accomplished by

pushing reset button on oil failure safety

switch(es). All other safety controls on each unit

are automatic reset, with restart accomplished

through unit timers.

Oil Pressure Safety Control (OPS) for each com

pressor will stop unit if oil pressure differential is

not established or maintaineci at either compressor.

If OPS stops unit, determine and correct the

cause (such as loss of compressor oil or flooded

compressor) before restarting unit. Failure to do so

will constitute abuse. Equipment failure due to

abuse is not covered by the Warranty To restart

unit, push manual reset button in unit control box

(except 38AB054 and 064 units). Reset button is

on OPS on 38AB054 and 064.

i BBi :

1 €10

AMI

ÇÂÂ2~

)BB|

1BB2

DIFFERENTIAL SCREW'

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 13 — Capacity Control Valve

)^l2SECî2 —H

■

1 h—1 SEC m.5

H

-----

1 h—5SEC i2

) EEi i i

1 1— ^

--------------------

ri

38AD024 THRU 044 UNITS

-4-45 SEC

38AB054 THRU 064 UNITS

NOTE- BLACK INDICATES CLOSED CONTACTS

38AB084 UNITS

Fig. 14 — Timing Charts

40 SEC î 5

-5MIN----------------------

F—2-6 SEC

i

Compressor Motor Protection on 38AD024 thru

^ 044 and 38AB084 consists of three temperature

sensors (one for each phase) embedded in the

motor windings, and solid state modules in unit

control box.

Sensors are part of a temperature bridge. If a

motor winding overheats, the bridge circuit will

unbalance and a silicone-controlled rectifier in the

module will de-energize a relay which opens a set

of normally open contacts in the module and stops

the compressor.

If one sensor fails, it can be jumped with a

i

75-ohm, 2-watt resistor. When checking or testing

module, do not apply more than 6 volts across

sensor terminals. Many test instruments exceed this

voltage rating; check before using.

If a component in a module fails on 38AD024

thru 044, the entire module must be replaced. On

38AB084, the transformer is external to the

module and may be replaced separately. Replace

transformer with a Carrier specified balanced

transformer.

To restart compressor after shutdown due to

motor protection trip, push control circuit reset

button in unit control box.

Safety Relief — All 38AB,AD units are protected

against excessive pressure by a fusible plug inserted

in the liquid line.

^ Winter Start Control — On 38AB units (not

necessary on 38AD units because the timer

supplies this function), install a liquid line pressurestat (Carrier part no. HK02AB026) and evaporator

freeze-up protector (defrost thermostat, Carrier

part no. HH22UA025).

38AD control circuits incorporate a 150 sec

onds timed bypass of the low-pressure switch to

in

Page 11

allow unit to start under low-ambient conditions.

An evaporator freezestat must also be installed in

series with the control thermostat(s) to prevent

coil freeze-up (See lower part of Fig 15 — EDT

Wiring section.)

LIQUID LINE PRESSURESTAT - Connect to

system liquid line service valve port. Connect

switch into control circuit as shown on unit label

diagram or in Fig. 15. Pressurestat is set to cutout

at 5 psig with a differential of 10 psig. Do not

change setting

DEFROST THERMOSTAT - Position switch so

that moisture cannot enter switch insulator. Install

control with approximately 2 in. of top of thermo

stat capillary passing thru lower part of evaporator

cod and with remainder of capillary inserted

between fins on entering air side of coil. Connect

thermostat electrical contacts into indoor cooling

thermostat circuit or in series with compressor

holding coil.

Thermostat is set to cut out at 25 F and cut in

at 55 F. Contact rating is 16 amps and 230 volts.

As evaporator coil frosts, cod fin temperature

drops to thermostat cutout setting, and stops

compressor. Evaporator fans keep running to

defrost cod with room air. As indoor coil defrosts,

fin temperature will rise to thermostat cut-in

setting. Compressor starts when cooling is required.

NOTE. Use a defrost thermostat on all systems

operating with outdoor temperatures below 45 F.

Fan Adjustment — When replacing a fan, adjust fan

until top surface of hub plate is below the top of

the orifice ring as indicated in Fig. 16. Then,

tighten both setscrews, located over the keyway of

the fan hub of the motor shaft. Seal recessed area

of fan hub bore with Permagum to prevent rusting.

Fig. 15 — Unit Wiring Changes for

Winter Start Control

Lubrication

FAN MOTORS have permanently lubricated bear

ings. No provisions for lubrication are made.

COMPRESSOR has its own od supply. Loss of oil

due to a leak in the system should be the only

reason for adding oil after the system has been in

operation.

To Add or Remove Compressor Od

1.

Stop compressor and close suction service valve.

Pump down compressor to 2 psig. Stop com

pressor and close discharge shutoff valve.

Relieve crankcase pressure by disconnecting

2.

line, at compressor, which goes to low-pressure

connection of od safety switch.

3.

Add oil thru oil filter connection.

4.

Remove od thru drain plug in bottom cover.

Remove small amounts of od thru od discharge

connection with compressor running.

3»^ A

...............................

i Fan

............

roft

L " '

38AD034

3SAD044

38aS«54

38A8iSii4

Fig. 16 — Fan Adjustment

11

Page 12

i

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 4 Form 38AD-6S1 Supersedes 38AD-5SI Printed in U.S.A. 37 3 4-72 Codes B and MS Catalog No. 533-860

Loading...

Loading...