Page 1

Carrier

Start-Ito cmd

Senrìce Instructions

5 ü

Heat Pump - Outdoor Unit

Table 1 — Physical Data

'~oig

; 1750 Rpm

06DA537

Direct Drive

13 Per Incl

о D

5

15_^

65+3

272

178

016

22

45

6

10

75 ^

3

1 120

22

%

13,000

26 2

51

364

264

29

54

70

75

57

62

UNIT 38ЛС ___ _ ___,

OPERAJJNG WЕЮH]!,(I

REFRIGERANT

Ope rating Charge (lb)*

’comp'ressor'''^"

Model

Cyl inders

Oil (pts)

Crankcase Heater (watts)

Outdoor FANS

Number

Rpm; 60-Hertz 1 120

Diameter (in.) 22

Motor hp

OUTDOOR COIL

Face Area (sq ft)

Capacity (lb)t ^

PRESSURESTAT

(Cut-in (psig)

Low

(Cut-in (pstg)

Liquid Line

Cutout (psig)

Cut-in (psig)

Thermostat^

Defrost

n- u I- jOpens (F)

Discharge

Fan Cycling

*Approximate charge with 25 feet of interconnecting piping

Use appropriate charging charts for actual charging of unit

tRefrigerant storage capacity at 120 F condensing temperature

with condenser 80 percent full of liquid

(Closes (F)

No. (F)

N.. 3 lÿ'"- <■=>

oses (F)

lens (F)

oses (F)

012.....

890 ____ _

500 '

_36 _

Recip Herme

06DA337

6

10

_ 75 ^

Propel I

2

кз

_

___

__

Plate Fins;

18 4

32

320

245

42

60

65

3-Rc

17

45 + 3

INITIAL START-UP

Evacuate and Dehydrate the entire refrigerant

system by either of the methods described in

Carrier Standard Service Techniques Manual.

Leak Test entire refrigerant system by Pressure

Method described in Carrier Standard Service

Techniques Manual. Use refrigerant specified for

unit at approximately 25 psig backed up with an

inert gas to a total pressure not to exceed 250 psig.

Before Starting Unit, check the following:

1. Compressor oil level must be at least within

sight in compressor oil sight glass. Add oil if

necessary.

2. Compressor hold-down bolts must be snug but

not tight. Refer to installation instructions or

tag on compressor foot.

3. All internal wiring connections must be tight;

all barriers and covers must be in place.

4. Electrical power source must agree with unit

nameplate rating.

5. All service valves must be open.

6. Fan cycling thermostat (head pressure control)

sensing bulb must be in air flow under fan no. 1.

7. Crankcase heater must be firmly locked into

compressor crankcase.

Energize Branch Circuit — Close field disconnect

switch to energize compressor crankcase heater.

Make sure room thermostat is set in a manner to

prevent unit(s) from starting at this time.

Heating/Cooling Thermostat (HH03AT064) has an

adjustable heat anticipator for both first- and

second-stage heating circuits.

SETTINGS — Set adjustment lever for first-stage

anticipator at 0.24 (left-hand side). Set adjustment

lever for second-stage anticipator (right-hand side)

as follows:

One Strip Heater - 0.21

Two Strip Heaters — 0.42

Three Strip Heaters — 0.63

Outdoor Thermostat — Refer to 40RT strip heater

Installation Instructions for details on adjustments

of this thermostat (if used).

To Start Unit — After compressor crankcase heater

has been on for at least 3 hours set room

thermostat so unit will start on desired cycle.

On initial start of 38AC016, unit should be run

for 20 minutes on heating cycle so any con

taminants will be collected in larger drier.

HEATING — Place thermostat selector to “Heat”

and set temperature selector above room ambient.

COOLING — Place thermostat selector to “Cool”

and set temperature selector below room ambient.

To Charge System — Refer to Carrier Standard

Service Techniques Manual, Chapter 1, for charging

methods and procedures mentioned below. Refer

to charging charts as applicable.

1. Be sure to use the correct refrigerant (see

charging chart).

2. Regulate refrigerant drum valve to maintain

suction pressure at 49 psig on 38AC012 and 80

psig on 38AC016 while charging.

©Carrier Corporation 1969

Form 38AC-2SS

Page 2

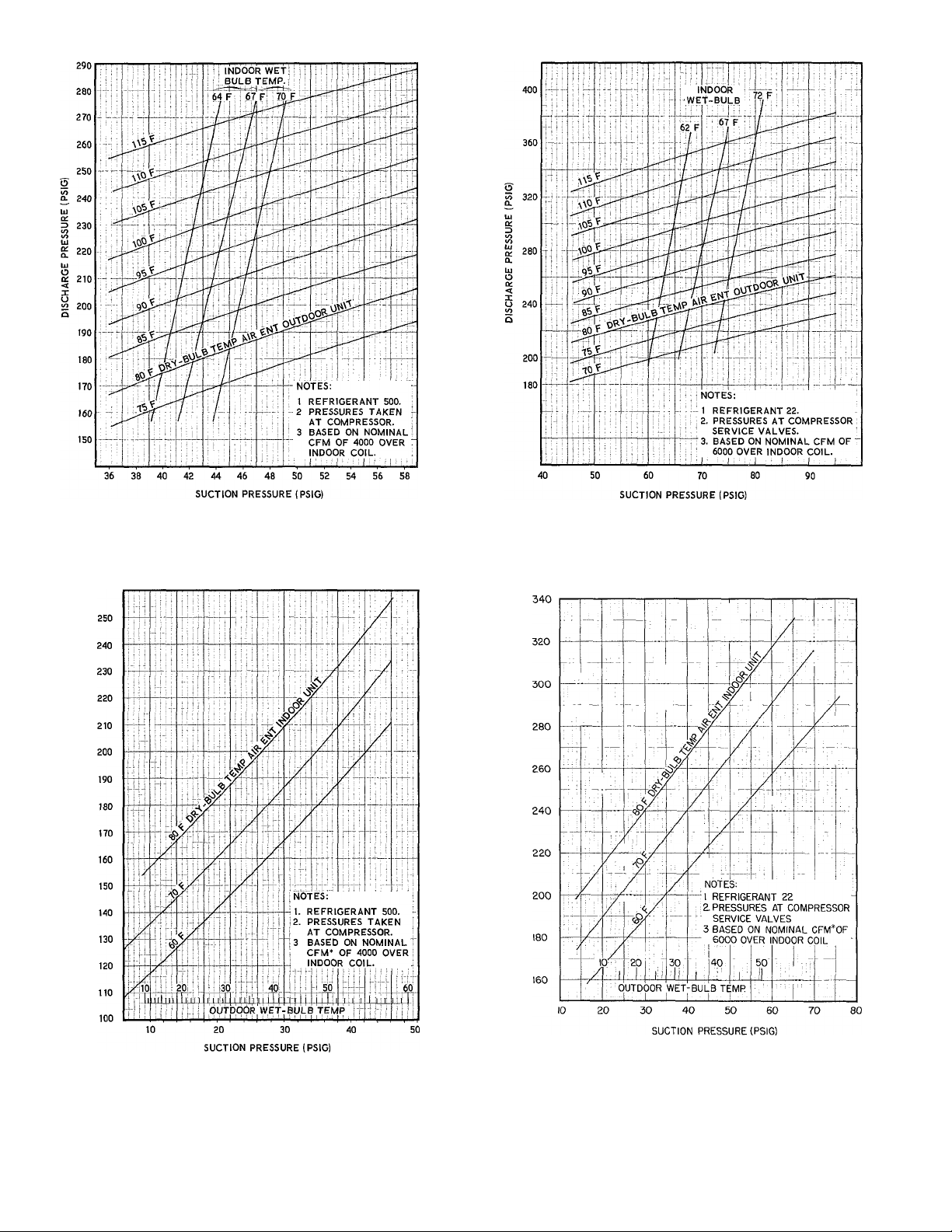

COOLING CYCLE

Oi

Ill

O

Q.

o

V)

O

38AC012 with 40RT012 Indoor Unit

38AC016 with 40RT016 Indoor Unit

HEATING CYCLE

38AC012with 40RT012 Indoor Unit

‘Minimum cfm that will allow the unitsto operate at 80 F indoor return air and 65 F

operating efficiency of system and reduce operating costs

Fig. 1 - Charging Charts

38AC016 with 40RT016 I ndoor Unit

wb outdoor air on heating cycle. Higher air quantities increase

2

Page 3

NOTE: Do not depend on sight glass when

charging unit. Use the charging chart. ■

3. Allow system to operate for about 20 minutes.

Take temperature and pressure readings and

check values with the charging chart.

After Charging System, allow unit to run for about

20 minutes. Stop unit and check compressor oil

level. Add oil only if necessary to bring oil into

view in sight glass. If oil is added, run unit for

additional 10 minutes. Stop unit and check oil

level. If level is again low, add oil only after

determining that piping system is designed for

proper oil return and that system is not leaking oil.

Check operation of all safety controls. Replace all

service panels. Be sure that control panel door is

closed tightly.

SERVICE

Defrost Control, consisting of a defrost timer and a

defrost thermostat, interrupts normal system

heating operation if enough frost forms on outdoor

coil to impair overall unit performance. Defrost

control simultaneously stops outdoor fans and

de-energizes reversing valve solenoid to return

system to cooling cycle (outdoor unit as con

denser; indoor unit as evaporator). Defrost cycle is

90 minutes for 38AC012 and 60 minutes for

38AC016.

For the heat pump to defrost, two conditions

are necessary:

1. Defrost timer contacts must be closed.

2. Refrigerant temperature from outdoor unit

must be cold enough (43± 3 F) to cause defrost

thermostat contacts to close.

Liquid Line Low-Pressure Control (LLP) is con

nected in liquid line to work with compressor

internal thermostat and discharge thermostat to

provide loss-of-charge protection during the heating

cycle. Control is mounted in control box.

With a high side leak, pressure gradually

decreases until low pressure control stops the

compressor.

With a low side leak there will always be some

pressure in the liquid line. However, compressor

motor temperature will increase because of in

sufficient suction gas cooling. This causes internal

thermostat or discharge line thermostat to actuate

and stop compressor. When compressor stops,

system pressure equalizes and contacts on pressure

control open. The compressor cannot restart until

leak is repaired and system recharged.

Low-Pressure Control (LP) is a single-pole switch

connected into the refrigerant system at com

pressor suction connection and into 24-volt control

circuit. Control provides loss-of-charge protection

and freeze-up protection during cooling cycle and

is inoperative during heating cycle. See Table 1 for

pressure settings.

Head Pressure Control (Fan-Cycling Thermostat) —

A feeler bulb in the outdoor coil inlet airstream

senses temperature of air entering coil to control

no. 2 fan on 38AC012 and no. 2 and 3 fans on

38AC016. Open and close temperatures are shown

in Table 1.

Accessory Motormaster^M head pressure con

trol for no. 1 fan (if used) allows operation at

lower ambients. See accessory instructions.

Time Guard Circuit for compressor causes a

5-minute delay before restarting compressor after

shutdown for any reason. On starting, the Time

Guard Timer causes a delay of 15 seconds after

thermostat closes before compressor will start. On

compressor shutdown, the timer recycles for 4

minutes 45 seconds. During this time the com

pressor cannot restart.

Safety Relief — A rupture disc in the accumulator

and a relief valve in the compressor provides

pressure relief under abnormal temperature and

pressure conditions.

Electric Resistance Crankcase Heater is inserted

into the compressor crankcase. It is operated from

the normally closed contacts of the holding relay

and is automatically energized when the com

pressor stops. This heater keeps crankcase warm to

prevent oil dilution by refrigerant and ensures good

lubrication and minimizes loss of oil during

start-up.

If power to unit has been off for an extended

period of time, energize crankcase heater at least 3

hours prior to starting compressor.

Compressor Section — Remove top and end panel

for access to this section. Additional access to

expansion valve, distributor and coil piping is

available by removing inboard fan, motor-support

panel assembly and coil end baffle between com

pressor section and coil section. Remove fan and

motor-support panel assembly by removing six

sheet metal screws, three cap screws and dis

connecting fan cable at control box. Then remove

coil end baffle.

Fan Adjustment — Turn unit power off. Remove

fan guard and loosen fan hub setscrew. Adjust fan

until surface of hub is 3/8 in. below top of venturi

rim as shown in Fig. 3. Then, tighten setscrew on

flat of motor shaft. Seal fan hub recess with

permagum to prevent hub from rusting to motor

shaft.

Lubrication

OUTDOOR FAN MOTORS have sealed bearings.

No provisions are made for lubrication.

COMPRESSOR has its own oil supply. Loss of oil

due to a leak in the system should be the only

reason for adding oil after system has been in

operation.

To Add or Remove Compressor Oil — Refer to

Carrier Standard Service Techniques Manual,

Chapter 1.

Page 4

38AC016 WITH 40RT016

Heating Cycle

9 Hot gas from compressor flows thru muffler to reversing

valve

o Hot gas is directed to header on indoor coils. In these coils

hot gas is condensed to a liquid This liquid flows out thru

feeder tubes to the distributors where it passes thru the side

outlet TXV B and B-| are closed because of high equalizing

pressure

o Liquid flows thru check valve C proceeding to outdoor unit.

O Liquid flows thru filter-drier, TXV (A), distributor, and

feeder tubes into outdoor coil where it is evaporated into a

vapor (Entire outdoor coil is an evaporative surface during

this cycle )

0

Cool vapor from outdoor coil subcooler is pulled thru check

valve A and meets with gas flowing from remainder of

outdoor coil (check valve B closed).

0 Cool vapor flows thru reversing valve where it is directed to

accumulator and into compressor suction valve to repeat

cycle.

38AC PIPING LEGEND

HEATING CYCLE 0

COOLING CYCLE @ ~i

COMPRESSOR

----------

SOLENOID OPERATED

REVERSING VALVE

(SOLENOID ENERGIZED ON HEATING

DE-ENERGIZED ON COOLING)

Cooling Cycle

JA;! Hot gas from compressor flows thru muffler to reversing

valve

i®) Hot gas is directed to header on outdoor coil (check valve A

closed)

Header directs hot gas to individual coil circuits where it is

condensed to liquid.

Liquid out of outdoor coil makes 180 degree turn in

distributor and flows thru tubes to and thru subcooler. TXV

(A) is closed because of high equalizing pressure.

Subcooled liquid flows thru check valve B and toward indoor

unit

i":'i Liquid continues thru filter-drier, expansion valve B and

B-) into distributors and into indoor coils Check valve C is

closed.

Cool vapor flows out of indoor coil back to reversing valve

where it is directed to accumulator and then to compressor

suction valve to repeat cycle.

38AC012 WITH 40RT012

These combinations follow the same basic diagram with two

exceptions

There is only one coil on the indoor unit and therefore only

one expansion valve. Also the 40RT012 is provided with a

subcooling coil which performs two functions

On heating cycle it is full of liquid which tends to balance the

refrigerant charge while providing subcooling.

On cooling cycle a check valve prevents liquid refrigerant

from entering the subcooler coil; this portion has vapor only.

Fig. 2 — Heat Pump Cycle (Heating and Cooling)

MOISTURE INDICATOR

SIGHT GLASS

Page 5

Table 2 — Electrical Data (3-Ph, 60-Hz)

UNIT

MODEL

38AC

012

38AC

016

FLA — Full Load Amps

FU — Fuse (max allowable amps; dual element)

ICF — Maximum Instantaneous Current Flow (during start-up:

LRA

NDSV

WSA

*Unit 38AC012 has two; Unit 38AC016 has three

VOLTS NDSV

^■ 430

208

550

230

640

430

540

640

sum of LRA for compressor plus FLA for all other motors

in the unit)

— Locked Rotor Amps

— Nominal Distribution System Voltage (Application Range)

Motors and controls will operate satisfactorily 10 percent

above and 10 percent below NDSV

— Wire Sizing Amps per NEC Tables 310-12 thru 310-15

Values are sums of 125 percent of FLA of compressor plus

F LA of all other motors in the unit

220^240165 5

460

440-480;^30 9

208'

230 1220-230181 7

460 440-480)39 0

WSAÍ ICF

208 172 6

208 ”|90’^'

197 ó

178 6

89.5

273 'S

249 8

125 7

FU

s'?

75

35

100

90

45

COMPR_

FLA LRÁ

50 C

191

45 0

172

86

22.2

64 C

266'

58 0

240

29.0

12c

FANS*

FLA,fe£)

3 2

3.2

1.6

3 2

3 2

1 6

TROUBLESHOOTING GUIDE

HEATING AND COOLING CYCLE

Compressor Will Not Run (Contactor Open)

Power off — restore power.

Transformer defective — replace transformer.

Thermostat defective — clean or replace ther

mostat.

Control relay defective — clean contacts or

replace coil.

Compressor contactor defective -- clean con

tacts or replace coil.

Holding relay defective — clean contacts or

replace coil.

Timer motor or switch defective — replace

timer.

Electrical connections loose — check and

tighten all electrical connections

Pressurestat open — check setting or replace if

defective.

Reversing valve relay defective — replace relay.

Compressor Will Not Run (Contactor Closed)

Disconnect switch open or fuse(s) blown —

restore power or replace fuses.

Compressor leads loose — tighten connections.

Compressor motor windings open ^ replace

compressor motor.

Compressor seized — check compressor

bearings.

Compressor Cycles on Protective Device

Compressor is hot — replace broken valves or

head gaskets. Check reversing valve positioning.

Overload defective — replace overload.

Line voltage outside allowable limits or 3-phase

imbalance — request assistance from power

company.

High load condition — check system charge

andjor purge noncondensables.

Compressor Cycles on High Pressure Switch

Refrigerant overcharge — purge until charge is

correct. See charging chart

Noncondensables in system — purge and

recharge.

Discharge line restricted — remove restriction.

Reversing valve damaged — replace or repair

reversing valve.

Fan cycling on overload — check fan motor

capacitor, fan motor compressor leads or fan

relay.

Filter or coils dirty — clean or replace filter.

Clean coils.

HEATING CYCLE (INSUFFICIENT HEATING)

Compressor Runs (Low Suction and Low Head

Pressure; Outdoor Fan Stopped)

Defrost relay defective — replace relay.

Outdoor fan motor leads loose — tighten motor

connections

Fan motor protection open — replace motor.

Fan motor burned out — replace motor.

Page 6

Compressor Runs (Low Suction and Low Head

Pressure; Outdoor Fan Running)

Suction valve partially closed — open valve.

Filter-drier restricted — replace filter-drier.

Expansion valve restricted or clogged — replace

expansion valve and filter-drier.

Indoor check valve defective — replace check

valve.

System undercharged — add refrigerant; see

charging chart.

Outdoor coil dirty — clean coil.

Outdoor coil heavily frosted — check defrost

circuit electrical connections. Check physical

contact between defrost thermostat sensing

bulb and liquid line. Replace defrost relay,

defrost thermostat, defrost timer or reversing

valve.

Compressor Runs (High Suction Pressure and Low

Superheat)

Compressor flooding — check position and/or

seal of outdoor check valve. Check expansion

valve operation.

Outdoor check valve leaking or backwards —

replace check valve.

Outdoor expansion valve stuck open — replace

expansion valve.

Electric Resistance Strip Heater Not Operating

Outdoor thermostat defective — check capillary

tubing for pinches Check to be sure sensing

bulb senses true outdoor temperature.

Outdoor thermostat set too low - reset

thermostat.

Heater relay or contactor defective — replace

relay or contactor

Fuses blown — replace fuses

Fuse link open — replace fuse link.

Heater element broken — replace element.

Overtemperature thermostat defective or open

— replace overtemperature thermostat or check

air flow over heater element enclosure.

Defective room thermostat second stage —

replace thermostat assembly.

COOLING CYCLE (INSUFFICIENT COOLING)

Compressor Cycles on High Pressure Switch

Outdoor air restricted or recirculating — clean

debris from coils or fans Remove shrubbery or

foliage. Install baffles to improve air flow.

Outdoor fan stopped — check fan power,

operation of fan relay or defrost relay. Replace

defective or damaged parts.

Compressor Cycles on Low Pressure Switch

(Indoor Fan Stopped)

Indoor fan motor or relay defective — replace

motor or relay. Check motor protection.

Electrical connections loose — check and

tighten all connections.

Fan belt sUps or is broken — adjust belt tension

or replace belt.

Compressor Cycles on Low Pressure Switch

(Indoor Fan Running)

Indoor air coil iced up — check expansion valve

and refrigerant charge.

Refrigerant charge low — add charge; see

charging chart.

Expansion valve closed or plugged ^ clean or

replace expansion valve.

Filter-drier restricted — replace filter-drier.

Outdoor check valve restricted or backwards —

replace check valve.

Compressor Runs (Low Suction Pressure)

Coil frosted — clean or replace air filter.

Ducts restricted — clean ductwork.

Dampers partially closed — adjust dampers

correctly.

Refrigerant charge low — add charge; see

charging chart.

Liquid line restricted — replace filter-drier if

restricted. Replace expansion valve power

element if defective. Replace outdoor check

valve if stuck.

Compressor Runs

(High Suction; Low Head Pressure)

Reversing valve hung up or leaks internally —

replace reversing valve.

Compressor valves or head gasket defective —

replace valves or gasket.

Compressor Runs

(High Suction Pressure; Low Superheat)

Compressor flooding — check position and/or

seal of indoor check valve. Check expansion

valve operation.

Indoor expansion valve stuck open — replace

expansion valve.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 12 Form 38AC-2SS Supersedes 38AC-1SS Printed in U S A. 4-69 Codes B and MS Catalog No 533-806

Loading...

Loading...