Carrier 320720-751, 320720-761 User Manual

320720---751 thru ---761

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock, or

other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory--authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

include in literature and attached to the unit. Consult local

building codes, the current editions of the National Fuel Gas

Code (NFGC) NFPA 54/ANSI Z223.1 and the National

Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of the National Standards

of Canada CAN/CSA--B149.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is

used to identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced

installation, reliability, or operation.

!

WARNING

FIRE, EXPLOSION AND ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Before installing or servicing system, always turn off main

electrical and gas supplies to unit and tag with appropriate

lockout. There may be more than one disconnect switch.

.

Primary Cell Inlet Panel Kit

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing furnaces.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in improper and

dangerous operation.

Label all wires prior to disconnection when servicing

controls.

INTRODUCTION

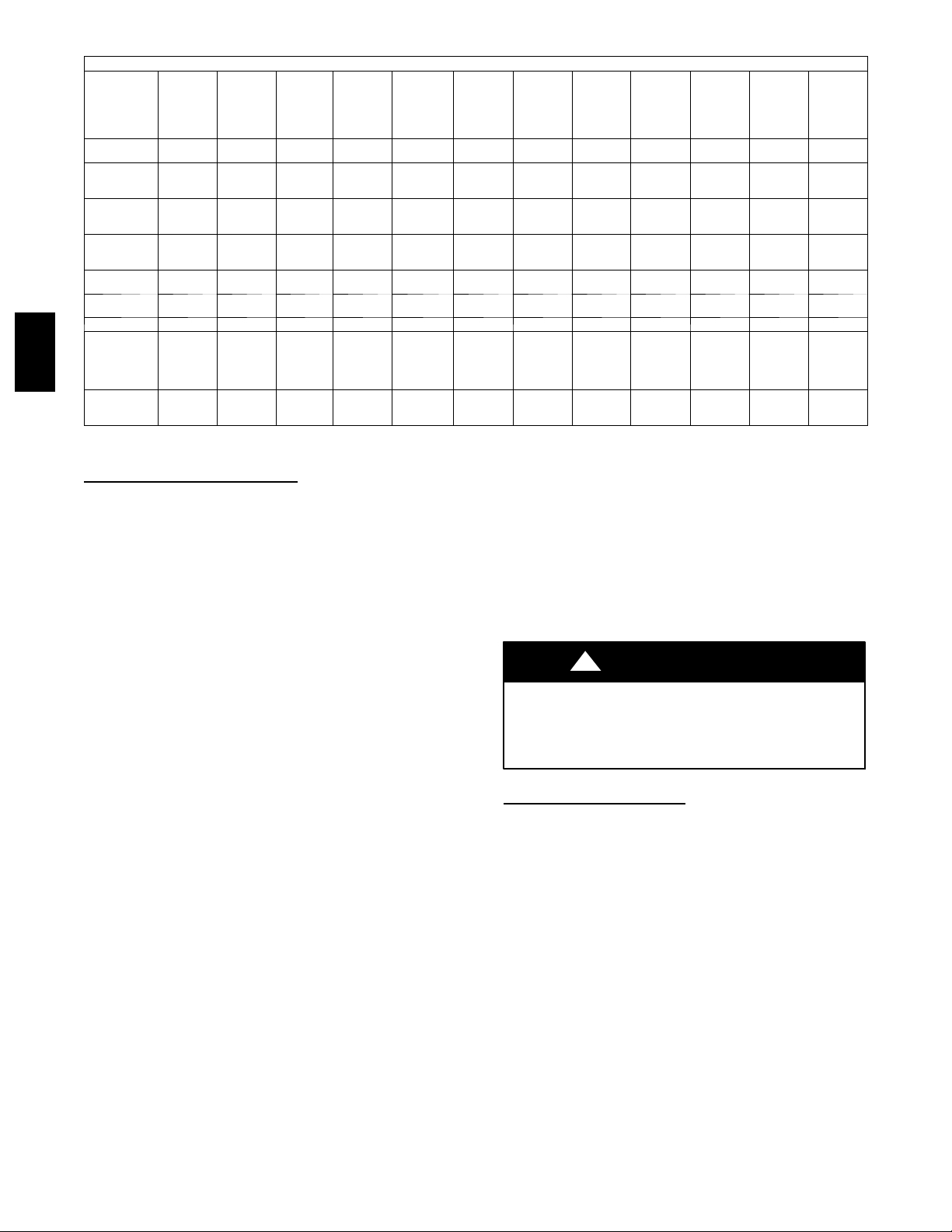

This instruction covers installation of the Primary Cell Inlet Panel

Kit Part No. 320720--751, --753, --754, --755, --756, --757, --758,

--760 and --761 in 40--in. (1016 mm) tall, condensing gas

furnaces. See Table 1 for kit usage.

NOTE: A releasing agent such as PAM cooking spray or

equivalent (must not contain corn or canola oil, halogenated

hydrocarbons nor aromatic contents to prevent inadequate seal)

and RTV sealant (G.E. 162, G.E. 6702, or Dow--Corning 738)

are needed before starting installation. DO NOT substitute any

other type of RTV sealant. G.E. 162 (P771--9003) is available

through RCD in 3--oz tubes.

DESCRIPTION AND USAGE

Use this Primary Cell Inlet Panel Kit when replacement of a

factory--installed primary cell inlet panel is required.

This Primary Cell Inlet Panel Kit contains the following items:

Primary Cell Inlet Panel 1

Burner Box Gasket 1

Cell Mounting Screw No. 8D X 3/8--in.(10 mm) 25 max

Installation Instructions 1

1

320720

Table1–KitUsage

340AAV

340MAV

KIT PART

NO.

320720--- 751

320720--- 753

320720--- 754

Prior to S/N

3002A14578

320720--- 755

320720--- 756

320720--- 757

320720--- 758 --- --- --- --- --- --- --- --- 42040 42040 --- --- --- --- --- --- 040--- 14 040---14 --- ---

320720--- 760 60080 60080 60080 --- ---

320720--- 761

After S/N

3002A14577

350AAV

350MAV

353AAV

490AAV

24040

36040

24060

36060

48060

36080

48080

48100

60100

60120

60140

36080

48080

345MAV 351DAS

24040

36040

24060

36060

48060

36080

48080

--- --- --- --- --- --- --- ---

48100

60100

60120 --- --- 60120 60120 60120

36080

48080

--- --- --- --- --- --- --- ---

--- ---

36080

48080

36080

48080

352AAV

352MAV

353BAV

PG9MXA

36060 42060 42060

36080

48080

48100

--- --60100

36080

48080

355MAV

--- --- --- ---

42080

(Series A)

60100 60100

42080

(Series B

and later)

60080

--- --- --- ---

UNIT

355AAV

355BAV

355CAV

PG9UAA

--- --- --- --- --- --- --- --- --- ---

42080

60080

58MCA

58MCB

58MEB

58MXA

58MXB

040--- 08

040--- 12

060--- 08

060--- 12

060--- 16

080--- 12

080--- 16

100--- 16

100--- 20

120--- 20

140--- 20

080--- 20 080---20 --- ---

080--- 12

080--- 16

58MSA

040--- 08

040--- 12

060--- 08

060--- 12

060--- 16

080--- 12

080--- 16

100--- 16

100--- 20

120--- 20 120---20 120--- 20 120---20

080--- 12

080--- 16

58MEC

58MTA

58MTB

060--- 12 060--- 14 060---14

080--- 12

080--- 16

100--- 16

100--- 20

080--- 12

080--- 16

--- --- --- --- --- ---

58MVB

58UVB

58MVC

--- --- --- ---

100--- 20 100---20

080--- 14

080--- 20

--- --- --- ---

58MVP

080--- 14

(Series

100)

080--- 14

(Series

110 and

later)

080--- 20

PG9MAA

PG9MAB

24040

36040

24060

36060

48060

36080

48080

48100

60100

60120

60140

60080

36080

48080

--- ---

INSTALLATION

Remove Whole Cell Panel Assembly

See Fig. 1 and Fig. 2 for furnace component locations. See Fig. 3

for expanded view of heating system components.

NOTE: Actual component locations may vary depending on

model and series.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Remove blower access panel.

4. Disconnect field power supply wires from J--box.

5. Remove two screws securing J--box.

6. Remove two screws securing top filler panel and rotate

panel upwards to remove or allow the heat exchanger to

be removed from front of furnace.

7. Disconnect combustion--air intake pipe from intake housing and move pipe out of furnace casing.

8. Disconnect gas supply pipe from gas valve using backup

wrench.

9. Disconnect vent pipe from inducer housing by loosening

coupling clamp on inducer outlet. If coupling has 2

clamps, loosen clamp on vent pipe side. Move pipe out of

furnace casing.

10. If control center is located in burner compartment of furnace, remove blower motor leads, transformer wires, door

switch wires, and auxiliary limit switch wires (if present)

from control center and pull wires through blower shelf.

11. If control center is located in blower compartment of furnace, disconnect wires from flame sensor, hot surface igniter, overtemperature switch, gas valve, pressure

switch(es), inducer motor, limit switch, and J--box, then

pull wires through blower shelf.

12. Remove two screws securing blower to blower shelf (four

screws on 120 and 140 sizes).

13. Remove two screws next to blower mounting screws that

secure blower shelf to cell panel.

14. Remove three screws from each side of cell panel.

15. If control center is located in burner compartment of furnace, remove control center by removing screw and pressing tabs inward.

16. If control center was removed from furnace casing, secure

control center (and J--box) to manifold for removal purposes only.

17. Disconnect field drain connection from condensate trap.

18. Disconnect drain and relief port tube from condensate trap.

19. Remove condensate trap from furnace casing or blower

shelf.

20. Remove whole cell panel assembly with heat exchanger,

burner box, inducer assembly, J--box (if applicable), and

control center (if applicable) attached through front of furnace.

!

CAUTION

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

Whole cell panel assembly is heavy. Get help to remove and

lift assembly.

Remove Burner Box Assembly

1. If not previously disconnected, disconnect wires or connectors to overtemperature switch, gas valve, igniter, and

flame sensor.

2. Remove pressure switch tube from intake housing.

3. Remove two screws attaching intake housing to burner

box, and rotate intake housing away from burner box for

removal.

4. Disconnect pressure tubing from gas valve.

5. Remove screws attaching burner box to cell panel.

NOTE: Burner box cover, manifold, gas valve, and burner

assembly should be removed as one assembly.

2

Loading...

Loading...