Page 1

Product

Data

a30-4659.eps

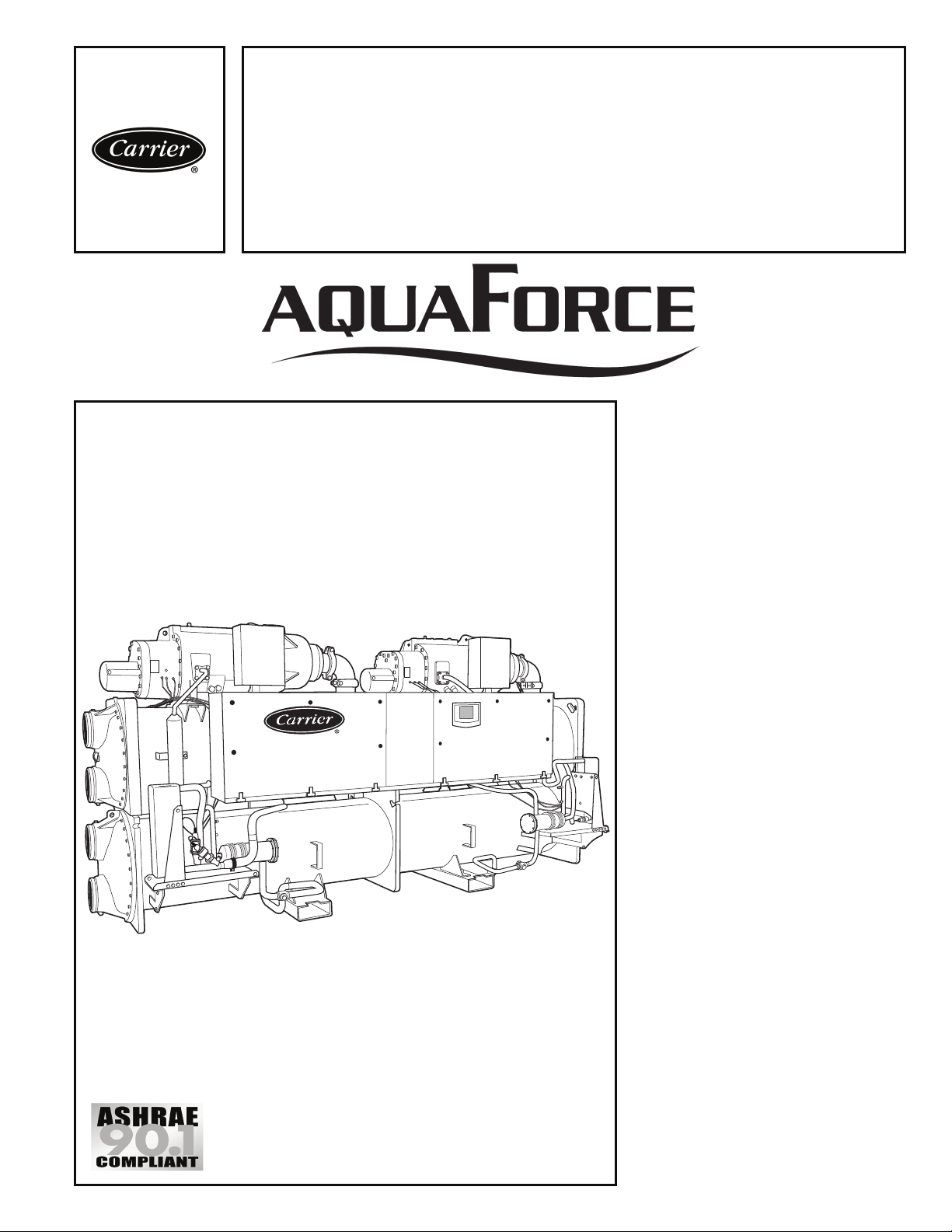

AQUAFORCE

®

30XW325-400

Water-Cooled Liquid Screw

Chillers

325 to 400 Nominal Tons

(1133 to 1354 kW)

®

Carrier's AquaForce 30XW chillers

provide a great combination of performance and compact footprint for

cooling and heat recovery applications. These chillers provide excellent

reliability and efficiency at true operating conditions without compromising

the environment.

• Chlorine-free R-134a HFC

refrigerant

• Positive displacement, twin screw

compressors

• AHRI (Air Conditioning, Heating,

and Refrigeration Institute) certified

efficiencies to 0.468 kW per ton

IPLV (integrated part load value)

• Dual independent refrigerant

circuits

• Compact footprint, less than 48 in.

(1219 mm) wide

• Easy to use controls

Features/Benefits

Quality design and

construction make the

AquaForce 30XW chillers an

excellent choice for modern,

efficient chilled water plants.

Small footprint

The 30XW chillers feature a compact

footprint and are delivered as a single

complete package less than 48 in.

(1219 mm) wide for easy installation

and minimal indoor space. The 30XW

chiller footprints may be up to 30%

smaller when compared to other chillers and may require less mechanical

room floor space and smaller concrete

pads.

Copyright 2009 Carrier Corporation Form 30XW-2PD

Page 2

Features/Benefits (cont)

Easy installation

The AquaForce® 30XW screw chillers

are shipped with starter and unit

mounted flow switch installed and can

be shipped with a full R-134a refrigerant charge to minimize installation

time. The unit provides single point

power connection (using optional control power transformer) and quick, easy

piping connections (using Victaulictype clamp on couplings). The 30XW

200-v, 230-v, 460-v, and 575-v units

are designed in accordance with UL

(Underwriters Laboratory) and UL

Canada (Underwriters Laboratory,

Canada) standards to minimize electrical inspection time.

Dual circuits

Dual independent refrigerant circuits

provide reliable, dependable cooling,

excellent part load operation, and

redundancy. Each circuit includes its

own compressor, electronic expansion

valve, filter drier, and sight glass to

assure operation.

High efficiency

The Aquaforce 30XW screw chiller

efficiency levels meet or exceed energy

efficiency requirements of ASHRAE

(American Society of Heating, Ventilation and Air Conditioning Engineers)

90.1 2007 and CSA (Canadian Standards Association) for both full load and

part load operation and is certified to

AHRI standards.

Per AHRI 550/590, chillers operate at

design conditions less than one percent

of the time. As a result, superior part

load efficiency is required for today's

chilled water applications. The 30XW

chillers deliver integrated part-load

values (IPLV) as low as 0.468 kW per

ton at AHRI conditions while offering

the ability to operate in a broad range

of applications and climates. This

exceptional performance has a significant impact on energy savings and cost

of ownership.

Heat recovery

The Aquaforce 30XW screw chiller

provides up to 140 F (60 C) leaving

condenser water (requires 300 psig

[2068 kPa] condenser option) when

applied in heat recovery applications.

Further, the 30XW unit heat control

mode can be utilized to maintain a constant leaving condenser water temperature. Low source controls provide

evaporator suction protection to prevent nuisance trips when operating in

heat recovery applications. This flexible capability allows a chiller to meet

both cooling and heating requirements

providing a high level of interchangeability within a chilled water plant.

Environmental leadership

Carrier has long been committed to the

environment and its sustainability. The

Aquaforce 30XW screw chiller provides customers with a high-efficiency,

chlorine free, long-term solution unaffected by refrigerant phase outs.

Carrier's decision to utilize non-ozone

depleting R-134a refrigerant provides

customers with a safe and environmentally sound choice without compromising efficiency. In addition, R-134a

refrigerant was given an A1 safety rating by ASHRAE, meaning that it is

among the safest refrigerants available.

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,8

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

Selection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19,20

Typical Control Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-28

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-32

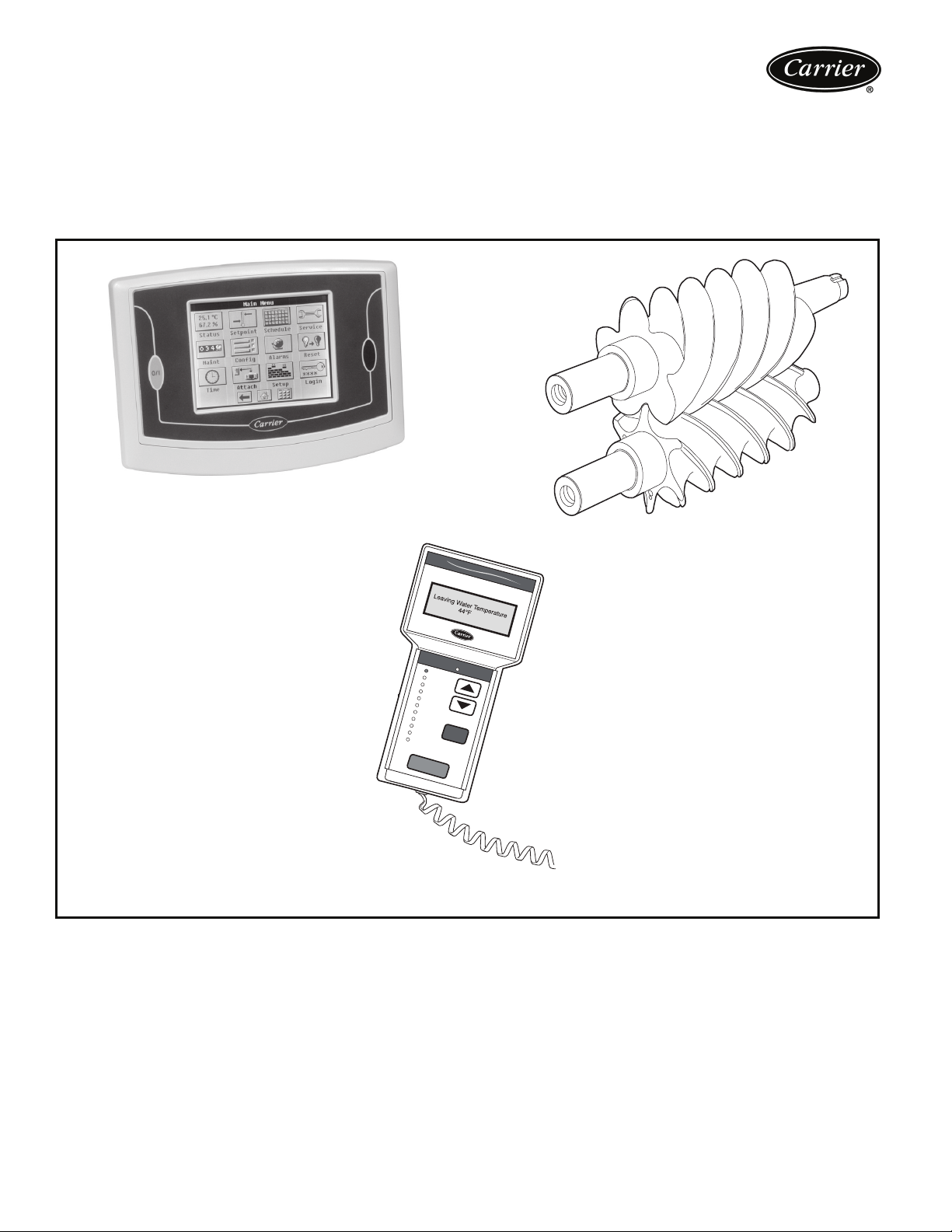

Positive displacement screw

compression

Positive displacement compression

ensures stable operation under all load

conditions without the possibility of

compressor surge. High-efficiency

rotary twin screw compressors with

infinitely variable slide valves allow the

chillers to exactly match actual load

conditions, delivering excellent part

load performance.

Factory testing

A quick start-up is assured once installation is complete, since each 30XW

unit is manufactured at an ISO (International Organization for Standardization) 9001:2000 listed manufacturing

facility to ensure quality. In addition, all

30XW units that are shipped with a full

charge of R-134a refrigerant are tested

under load at the factory to provide

reliable start-up.

Low starting current (inrush)

Dual circuit units stage the start up of

the compressors thereby reducing the

over all current draw by up to 40%.

Constant or variable evaporator flow

Aquaforce 30XW screw chillers are

suitable for constant or variable evaporator flow.

Hermetic motor

The Aquaforce 30XW chiller utilizes

motors that are hermetically sealed

from the machine room. Refrigerant is

used to cool the motor windings.

Carrier's hermetic design eliminates:

• Compressor shaft seals that require

maintenance and increase the likelihood of refrigerant leaks.

• Machine room cooling requirements

associated with air-cooled motors,

which dissipate heat to the mechanical room.

• High noise levels common with aircooled motors, which radiate noise

to the machine room and adjacent

areas.

• Shaft alignment problems that occur

with open-drive designs during startup and operation, when equipment

temperature variations cause thermal expansion.

Positive pressure design

Positive pressure designs eliminate the

need for costly low pressure containment devices, reducing the initial cost

2

Page 3

of the system. The AquaForce® 30XW

chiller's positive pressure design

ensures that air, moisture and other

performance degrading contaminants

are not sucked inside the chiller. Purge

units and their associated maintenance

are no longer necessary.

Refrigerant isolation valves

The refrigerant isolation valves enable

service personnel to store the refrigerant charge in the evaporator or condenser during servicing. These valves

also allow the refrigerant to be stored

inside the chiller during shipment from

the factory minimizing start-up time.

During servicing, the in-chiller storage

reduces refrigerant loss and eliminates

time-consuming transfer procedures.

As a self-contained unit, the AquaForce

30XW chiller does not require additional remote storage systems.

Optional suction service valves

The optional suction service valves

allow for further isolation of the compressor from the evaporator vessel.

Marine container shipment

The compact design allows for container shipment to export destinations,

ensuring quality while reducing shipping cost.

Heat exchangers

The Aquaforce 30XW chillers utilize

mechanically cleanable shell and tube

evaporators and condensers available

with a complete line of waterbox

options to meet project specific

requirements. One, two, and three

pass arrangements are available to

meet a wide variety of flow conditions.

Nozzle in head and marine waterboxes

are available to meet 150 psig

(1034 kPa) and 300 psig (2068 kPa)

piping requirements.

Heat exchanger features include:

ASME certified construction

An independent agency certifies the

design, manufacture, and testing of all

heat exchangers to American Society

of Mechanical Engineers (ASME) standards, ensuring heat exchanger safety,

reliability and long life. The ASME

U-stamp is applied to the refrigerant

side of the evaporator and condenser

and is applied to the water side of these

heat exchangers when 300 psig

(2068 kPa) marine waterboxes are

provided.

Electronic thermal-dispersion flow

switch

An electronic thermal-dispersion flow

switch switch is included with the evaporator. The switch is factory installed

and tested and contains no moving

parts for high reliability.

High performance tubing

Carrier's AquaForce chillers utilize

advances in heat transfer technology

providing compact, high-efficiency

heat exchangers. Tubing with

advanced internally and externally

enhanced geometry improves chiller

performance by reducing overall resistance to heat transfer while reducing

fouling.

Evaporator tube expansion

Evaporator tube expansion at center

support sheets prevents unwanted tube

movement and vibration, thereby

reducing the possibility of premature

tube failure. Tube wall thickness is

greater at the expansion location, support sheets, and end tube sheets, to

provide maximum strength and long

tube life.

Closely spaced intermediate support sheets

Support sheets prevent tube sagging

and vibration, thereby increasing heat

exchanger life.

Refrigerant filter isolation valves

These valves allow filter replacement

without pumping down the chiller,

reducing service time and expense.

Microprocessor controls

The AquaForce 30XW screw chiller

controls communicate in easy to understand English, making it as easy as possible to monitor and control each

chiller while maintaining fluid temperatures. Controls are available with

French, Portuguese and Spanish as

standard configuration options. These

controls result in higher chiller reliability, simplified training and correspondingly lower operational and

maintenance costs.

Two user interface options are available, the Touch Pilot™ display and the

Navigator™ module.

The Touch Pilot display is an easy to

use touch screen display that provides

simple navigation for configuration and

control of the 30XW units.

Carrier's exclusive handheld Navigator display provides convenience and

powerful information in the palm of

your hand. The Navigator display helps

technicians to quickly diagnose problems and even prevent them from

occurring.

All 30XW units are ready to be used

with Carrier Comfort Network

devices.

Controls features include:

Automatic capacity override

This function unloads the compressor

whenever key safety limits are

approached, increasing unit life.

Chilled liquid reset

Reset can be accomplished manually or

automatically from the building management system. For a given capacity,

reset allows operation at slower compressor speeds, saving energy when

warmer chilled liquid can be used.

Demand limiting

This feature limits the power draw of

the chiller during peak loading conditions. When incorporated into the

CCN building automation system, a red

line command holds chillers at their

present capacity and prevents any

other chillers from starting. If a load

shed signal is received, the compressors are unloaded to avoid demand

charges whenever possible.

Ramp loading

Ramp loading ensures smooth pulldown of liquid loop temperature and

prevents a rapid increase in compressor power consumption during the

pulldown period.

Automated controls test

The test can be executed prior to startup to verify that the entire control system is functioning properly.

365-day real time clock

This feature allows the operator to program a yearly schedule for each week,

weekends, and holidays.

Occupancy schedules

Schedules can be programmed into the

controller to ensure that the chiller

operates when cooling is required and

remains off when not needed by the

tenants or process.

®

(CCN)

3

Page 4

Features/Benefits (cont)

Extensive service menu

Unauthorized access to the service

menu can be password-protected.

Built-in diagnostic capabilities assist in

troubleshooting and recommend

proper corrective action for pre-set

alarms, resulting in greater up time.

TOUCH PILOT™ DISPLAY

Alarm file

This file maintains the last 50 time and

date-stamped alarm and alert messages

in memory. This function reduces troubleshooting time and cost.

a30-4456

SMOOTH ROTARY COMPRESSOR

Comfort

Link

Configuration data backup

Non-volatile memory provides protection during power failures and

eliminates time consuming control

reconfiguration.

30-562

TWIN-SCREW DESIGN

MODE

Alarm Status

Run Status

Service Test

Temperatures

Pressures

Setpoints

Inputs

Outputs

Configuration

Time Clock

ESC

Operating Modes

Alarms

ENTER

a30-3924

OPTIONAL NAVIGATOR™ DISPLAY

4

Page 5

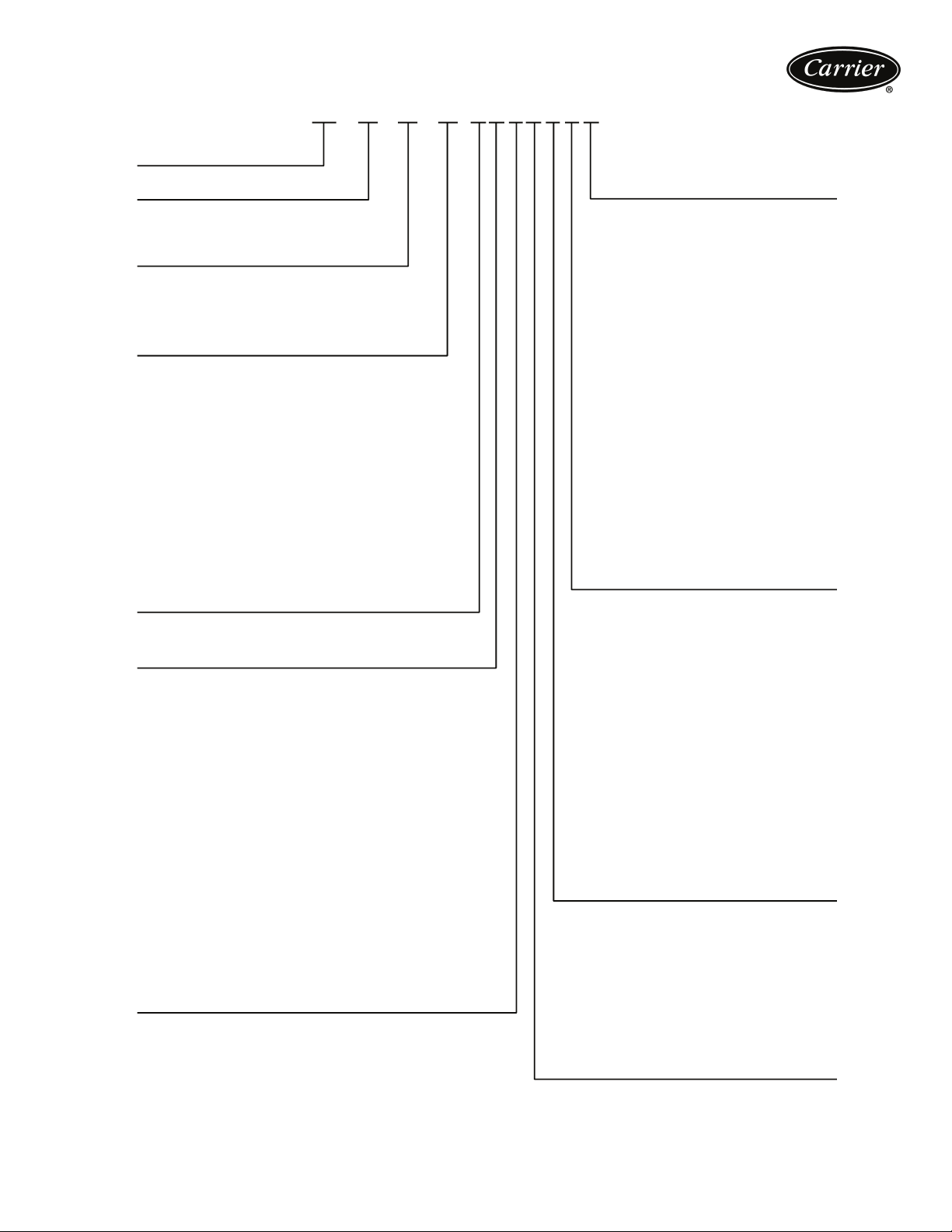

Model number nomenclature

30XW – 325 6 – – – 4 – 3 B

30XW – AquaForce® Water-Cooled

Screw Chiller

Design Series

Unit Size (Nominal Tons) (kW)

325 – 325 (1133)

350 – 350 (1206)

400 – 400 (1354)

Voltage

1 – 575-3-60

2 – 380-3-60

4 – 230-3-60

6 – 460-3-60

7 – 200-3-60

Condenser Options

- – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Discharge Connections (Std)

0 – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Suction Connections

1 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Connections

2 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Connections

3 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Discharge Connections

4 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Suction Connections

5 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Connections

6 – 2 Pass, NIH, 300 psig (2068 kPa), Flange,

7 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Discharge Connections

8 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Suction Connections

9 – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Discharge Connections

B – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Suction Connections

C – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Connections

D – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Su

F – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Connections

G – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Suction Connections

H – 1 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

J – 1 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

K – 1 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

L – 1 Pass, MWB, 300 ps

Heat Machine

- – Std Condenser/Comfort Cooling (Std)

M – Heat Machine Condenser/Comfort Cooling

Evaporator Options

- – 2 Pass, NIH, 150 psig (1034 kPa), Victaulic, Discharge Connections (Std)

0 – 2 P ass, NIH, 150 psig (1034 kPa), Victaulic, Suction Connections

1 – 2 P ass, NIH, 150 psig (1034 kPa), Flange, Discharge Connections

2 – 2 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Connections

– 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Discharge Connections

3

4 – 2 Pass, NIH, 300 psig (2068 kPa), Victaulic, Suction Connections

5 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Connections

6 – 2 Pass, NIH, 300 psig (2068 kPa), Flange, Suction Connections

7 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Discharge Connections

8 – 2 Pass, MWB, 150 psig (1034 kPa), Victaulic, Su

9 – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Discharge Connections

B – 2 Pass, MWB, 300 psig (2068 kPa), Victaulic, Suction Connections

C – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Connections

D – 2 Pass, MWB, 150 psig (1034 kPa), Flange, Suction Connections

F – 2 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Connections

G – 2 Pass, MWB, 300 psig (2068 kPa), Fl

– 1 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

H

J – 1 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

K – 1 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

L – 1 Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Leaving

M – 3 Pass, NIH, 150 psig (1034 kPa), Flange, Discharge Leaving

N – 3 Pass, NIH, 150 psig (1034 kPa), Flange, Suction Leaving

P – 3 Pass, NIH, 300 psig (2068 kPa), Flange, Discharge Leaving

Q – 3 Pass, NIH, 300 psig (2068 kPa), Flange, Suction Leaving

R – 3 Pass, MWB, 150 psig (1034 kPa), Flange, Discharge Leaving

S – 3 Pass, MWB, 150 psig (1034 kPa), Flange, Suction Leaving

Pass, MWB, 300 psig (2068 kPa), Flange, Discharge Leaving

T – 3

V – 3 Pass, MWB, 300 psig (2068 kPa), Flange, Suction Leaving

ig (2068 kPa), Flange, Discharge Leaving

Suction Connections

ction Connections

ction Connections

ange, Suction Connections

LEGEND

CPT — Control Power Transformer MWB — Marine Waterbox

EMM — Energy Management Module NIH — Nozzle-In-Head

GFCI — Ground Fault Circuit Interrupter XL — Across-the-Line Start

LON — Local Operating Network

*Evaporator insulation is standard.

Packaging/Charging Options

B – R-134a Refrigerant with Bag (Std)

C – R-134a Refrigerant with Crate Over Bag

D – Nitrogen Refrigerant with Bag

F – Nitrogen Refrigerant with Crate Over Bag

Controls/Communications Options

- – Navigator™ Displa

0 – Navigator Dis pla y, EMM

1 – Navigator Dis pla y, GFCI Service Option

2 – Navigator Dis pla y, EMM, GFCI Service Option

3 – Touch Pilot™ Display (Std)

4 – Touch Pilot, EMM

5 – Touch Pilot, GFCI S ervice Option

6 – Touch Pilot, EMM, GFCI S ervice Option

7 – Navigator Dis pla y, BACnet™ Translator

8 – Navigator Dis pla y, EMM, BACnet Tra nslator

9 – Navigator Dis pl

BACnet Translator

B – Navigator Display, EMM, GFCI Service Option,

BACnet Translator

C – Touch Pilot Display (Std), BACnet Translator

D – Touch Pilot Display, EMM, BACnet Translator

F – Touch Pilot Display, GFCI Service Option,

BACnet Translator

G – Touch Pilot Display, EMM, GFCI Service Option,

BACnet Translator

H – Navigator Dis

J – Navigator Display, EMM, LON Trans lator

K – Navigator Display, GFCI Service Option,

LON Translator

L – Navigator Display, EMM, GFCI Service Option,

LON Translator

M – Touch Pilot Display (Std), LON Translator

N – Touch Pilot Display, EMM, LON Translator

P – Touch Pilot Display, GFCI

LON Translator

Q – Touch Pilot Display, EMM, GFCI Service

Option, LON Translator

Electrical Options

- – Single Point, XL Starter, Terminal Block

(Std 380, 460, 575-v)

0 – Single Point, Wye-Delta Sta rter, Terminal

Block (Std 200,230-v)

3 – Dual Point, XL Starter, Terminal Block

4 – Dual Point, Wye-Delta S tarter, Terminal Block

7 – Single Point, XL S tarter, Non-Fused Disconnect

8 – Single Point, Wye-Delta, Non-Fus

C – Dual Point, XL Starter, Non-Fused Disconnect

D – Dual Point, Wye-Delta Starter, Non-Fused

Disconnect

H – Single Point, XL Starter, Terminal Block, CPT

J – Single Point, Wye-Delta S tarter, Terminal

Block, CPT

M – Dual Point, XL Starter, Terminal Block, CPT

N – Dual Point, Wye-Delta Starter, Terminal

Block, CPT

R – Single Point, XL Starter, Non-Fused

Disconnect, CPT

S – Single Point, Wye-Delta, Non-Fused

Disconnect, CPT

– Dual Point, XL Starter, Non-Fused

W

Disconnect, CPT

X – Dual Point, Wye-Delta Starter, Non-Fused

Disconnect, CPT

Refrigeration Circuit Options

4 – Sta nda rd Unit

6 – With Suction Service Valves

D – With Minimum Load Control

G – With Suction Service Valves and Minimum

Load Control

N – With Condenser Insulation for Heat Machine

Q – With Suction Service Valves and Condenser

Insulation for Heat Machine

X – With Minimum Load Control and Condenser

Insulation for Heat Machine

Z – With Suction Service Va

Control and Condenser Insulation for

Heat Machine

y

ay, GFCI Service Option,

play, LON Translator

Service Option,

ed Disconnect

*

lves, Minimum Load

a30-4744

Quality Assurance

Certified to ISO 9001:2000

5

Page 6

Capacity ratings

30XW

UNIT SIZE

325 322 1132.5 204.8 773 48.8 15.6 46.5 967 61.0 10.9 32.5 0.636 0.468

350 343 1206.3 215.7 824 52.0 17.5 52.2 1029 64.9 12.3 36.7 0.629 0.471

400 385 1354.0 242.8 924 58.3 21.5 64.1 1155 72.9 15.2 45.3 0.631 0.474

AHRI — Air Conditioning, Heating and Refrigeration Institute

IPLV — Integrated Part Load Value

NOTES:

1. Certified in accordance with AHRI Standard 550/590 at standard

rating conditions.

2. Standard rating conditions are as follows:

Evaporator Conditions:

Condenser Conditions:

CAPACITY

Ton s

Leaving Water Temperature: 44 F (6.7 C)

Flow: 2.4 gpm per ton (0.043 L/s per kW)

Entering Water Temperature: 85 F (29.4 C)

Flow: 3.0 gpm per ton (0.054 L/s per kW)

Output

(kW)

LEGEND

INPUT

POWE R

(kW)

EVAPORATOR

FLOW

gpm L/s

EVAPORATOR

PRESSURE DROP

Ft of

Wate r

kPa gpm L/s

3. IPLV is a single number part-load efficiency value calculated from

4. Contact Carrier for custom ratings.

5. Data shown for standard chiller with 2 pass, nozzle-in-head (NIH)

CONDENSER

FLOW

Fouling Factor (Evaporator):

0.00010 hr x sq ft x F per Btuh (0.000018 m

Fouling Factor (Condenser):

0.00025 hr x sq ft x F per Btuh (0.000044 m2 x K per W)

the system full-load efficiency values and corrected for a typical

building air-conditioning application.

waterboxes.

CONDENSER

PRESSURE DROP

Ft of

Water

kPa

FULL LOAD

EFFICIENCY

(kW/Ton)

2

x K per W)

IPLV

(kW/Ton)

6

Page 7

Physical data

30XW325-400 UNIT PHYSICAL DATA — ENGLISH

30XW UNIT SIZE 325 350 400

NOMINAL CAPACITY (tons) 325 350 400

UNIT WEIGHT (lb) (Operating/Shipping) 14,319/13,163 14,515/13,369 14,759/13,489

COMPRESSORS Semi-hermetic, twin screw

Compressor Speed (rpm) 3500

Compressor Model Number (qty) 06TU483 (2) 06TU554 (2)

Unloading Type Slide Valve

Minimum Step Capacity % (standard) 15%

Optional % 10%

Economizer No Yes

Temperature Relief Valve Connection (in. SAE Flare) (each circuit) —3/8

REFRIGERANT HFC, R-134a

Charge (lb) Circuit A 260 270

Charge (lb) Circuit B 260 270

OIL POE, SW-220

Charge (gal.) Circuit A 4

Charge (gal.) Circuit B 4

EVAPORATOR

Net Fluid Volume (gal.) 76.0

Maximum Refrigerant Pressure (psig) 220

Maximum Water Side Pressure (psig)

Standard 150

Optional 300

Water Connections

Inlet and Outlet (in.)

1-Pass NIH or MWB Flange (optional) 6

1-Pass NIH Victaulic (optional) 8

2-Pass NIH or MWB Flange (optional) 6

2-Pass NIH Victaulic (standard) 8

2-Pass MWB Victaulic (optional) 6

3-Pass NIH or MWB Flange (optional) 6

3-Pass NIH Victaulic (optional) 8

Drain (in. NPT)

Relief Valve Connection (in. NPTF)

Quantity Per Circuit 1

Relief Valve Setting (psig) 220

Flow Rate (lb air/min) 31.7

CONDENSER

Net Fluid Volume (gal.) 82.6

Maximum Refrigerant Pressure (psig)

Standard Condenser 220

Heat Machine 300

Maximum Water Side Pressure (psig)

Standard 150

Optional 300

Heat Machine 300

Water Connections

Inlet and Outlet (in.)

1-Pass NIH or MWB Flange (optional) 6

1-Pass NIH Victaulic (optional) 8

2-Pass NIH or MWB Flange (optional) 6

2-Pass NIH Victaulic (standard) 8

2-Pass MWB Victaulic (optional) 6

Drain (in. NPT)

Relief Valve Connection (in. NPTF) (Standard/Heat Machine)

Quantity Per Circuit 2/2

Relief Valve Setting (psig) 220/300

Flow Rate (lb air/min) 31.7/46.6

Temperature Relief Valve Connection (in. SAE Flare)

Discharge Line (Qty per Circuit) 1

Liquid Line (Qty per Circuit) 1

CHASSIS DIMENSIONS (ft-in.)

Length 13 - 3

Width 3 - 11 3/

Height 6 - 6 11/

LEGEND

HFC — Hydrofluorocarbon

MWB — Marine Waterbox

NIH — Nozzle-In-Head

NPTF — National Pipe Thread Female

POE — Polyolester

SAE — Society of Automotive Engineers

3

/4 / 3/

3

/

8

3

/

4

3

/

8

4

1

/

4

3

/

4

8

16

7

Page 8

Physical data (cont)

30XW325-400 UNIT PHYSICAL DATA — SI

30XW UNIT SIZE 325 350 400

NOMINAL CAPACITY (kW) 1133 1206 1354

UNIT WEIGHT (kg) (Operating/Shipping) 6495/5971 6584/6064 6695/6119

COMPRESSORS Semi-hermetic, twin screw

Compressor Speed (r/s) 58.3

Compressor Model Number (qty) 06TU483 (2) 06TU554 (2)

Unloading Type Slide Valve

Minimum Step Capacity % (standard) 15%

Optional % 10%

Economizer No Yes

Temperature Relief Valve Connection (in. SAE Flare) (each circuit) —

REFRIGERANT HFC, R-134a

Charge (kg) Circuit A 117.9 122.5

Charge (kg) Circuit B 117.9 122.5

OIL POE, SW-220

Charge (L) Circuit A 15.1

Charge (L) Circuit B 15.1

EVAPORATOR

Net Fluid Volume (L) 287.7

Maximum Refrigerant Pressure (kPa) 1517

Maximum Water Side Pressure (kPa)

Standard 1034

Optional 2068

Water Connections

Inlet and Outlet (in.)

1-Pass NIH or MWB Flange (optional) 6

1-Pass NIH Victaulic (optional) 8

2-Pass NIH or MWB Flange (optional) 6

2-Pass NIH Victaulic (standard) 8

2-Pass MWB Victaulic (optional) 6

3-Pass NIH or MWB Flange (optional) 6

3-Pass NIH Victaulic (optional) 8

Drain (in. NPT)

Relief Valve Connection (in. NPTF)

Quantity Per Circuit 1

Relief Valve Setting (kpa) 1517

Flow Rate (kg air/min) 14.38

3

/

8

3

/

4

CONDENSER

Net Fluid Volume (L) 312.7

Maximum Refrigerant Pressure (kPa)

Standard Condenser 1517

Heat Machine 2068

Maximum Water Side Pressure (kPa)

Standard 1034

Optional 2068

Heat Machine 2068

Water Connections

Inlet and Outlet (in.)

1-Pass NIH or MWB Flange (optional) 6

1-Pass NIH Victaulic (optional) 8

2-Pass NIH or MWB Flange (optional) 6

2-Pass NIH Victaulic (standard) 8

2-Pass MWB Victaulic (optional) 6

Drain (in. NPT)

Relief Valve Connection (in. NPTF) (Standard/Heat Machine)

Quantity Per Circuit 2/2

Relief Valve Setting (kpa) 1517/2068

Flow Rate (kg air/min) 14.38/21.1

Temperature Relief Valve Connection (in. SAE Flare)

Discharge Line (Qty per Circuit) 1

Liquid Line (Qty per Circuit) 1

3

/4 / 3/

3

/

8

1

/

4

CHASSIS DIMENSIONS (mm)

Length 4057.7

Width 1203.3

Height 1998.7

LEGEND

HFC — Hydrofluorocarbon

MWB — Marine Waterbox

NIH — Nozzle-In-Head

NPTF — National Pipe Thread Female

POE — Polyolester

SAE — Society of Automotive Engineers

3

/

8

4

8

Page 9

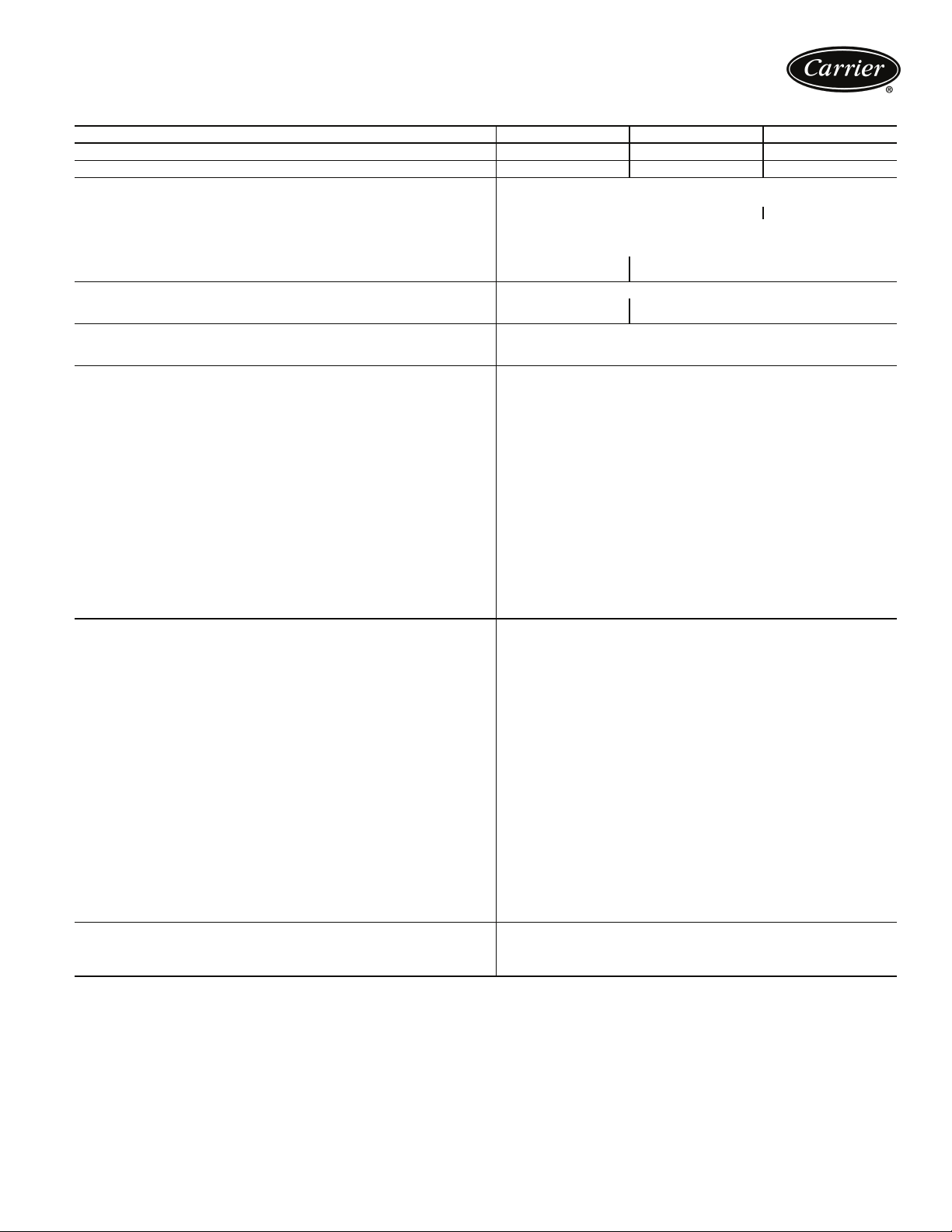

Options and accessories

ITEM

Controls Options

Navigator Hand-Held Display XX

Remote Enhanced Display X

BACnet Translator Control XX

LON Translator Control XX

Energy Management Module XX

Evaporator Options

One-Pass Evaporator Head X

Three-Pass Evaporator Head X

Marine Waterboxes X

Flanged Connections X

Suction Service Valve X

300 psig (2068 kPa) Operating Pressure X

Condenser Options

Heat Machine Condenser X

One-Pass Condenser Head X

Marine Waterboxes X

Flanged Connections X

300 psig (2068 kPa) Operating Pressure X

Starter Options

Wye-Delta Starter X

Dual Point Power X

Non-Fused Disconnect X

Control Transformer X

115-v GFCI Convenience Outlet X

Unit Options

Minimum Load Control X

Temperature Reset Sensor X

Nitrogen Charge X

Crate for Shipment X

Vibration Pads X

Vibration Isolation Springs X

FACTORY-

INSTALLED

OPTION

FIELD-

INSTALLED

ACCESSORY

Factory-installed options

Navigator™ module provides a portable, hand-held dis-

play for convenient access to unit status, operation, configuration and troubleshooting diagnostics capability. The

four-line, 20-character LCD (liquid crystal display) display

provides clear language information in English, French,

Spanish, or Portuguese. The Navigator module features an

industrial grade extension chord and magnets located on

the back of the weatherproof enclosure to allow attachment to sheet metal components for hands free operation.

BACnet™ translator control provides an interface

between the chiller and BACnet Local Area Network

(LAN, i.e., MS/TP EIA 485). The BACnet translator control is also available as a field-installed option.

LON translator control provides an interface between

the chiller and Local Operating Network (LON, i.e., LONWorks FT-10A ANSI/EIA-709.1). The LON translator

control is also available as a field-installed option.

Energy management module provides energy management capabilities to minimize chiller energy consumption.

Several features are provided with this module including

leaving fluid temperature reset, cooling set point reset or

demand limit control from a 4 to 20 mA signal, 2-point

demand limit control (from 0 to 100%) activated by a

remote contact closure, and discrete input for "Ice Done"

indication for ice stage system interface.

The 300 psig (2068 kPa) evaporator operating

pressure option allows operation for water-side pressure

up to 300 psig (2068 kPa).

The 300 psig (2068 kPa) condenser operating

pressure option allows operation for water-side pressure

up to 300 psig (2068 kPa).

Minimum load control allows additional capacity reduc-

tion for unit operation below the minimum step of unloading via hot gas bypass.

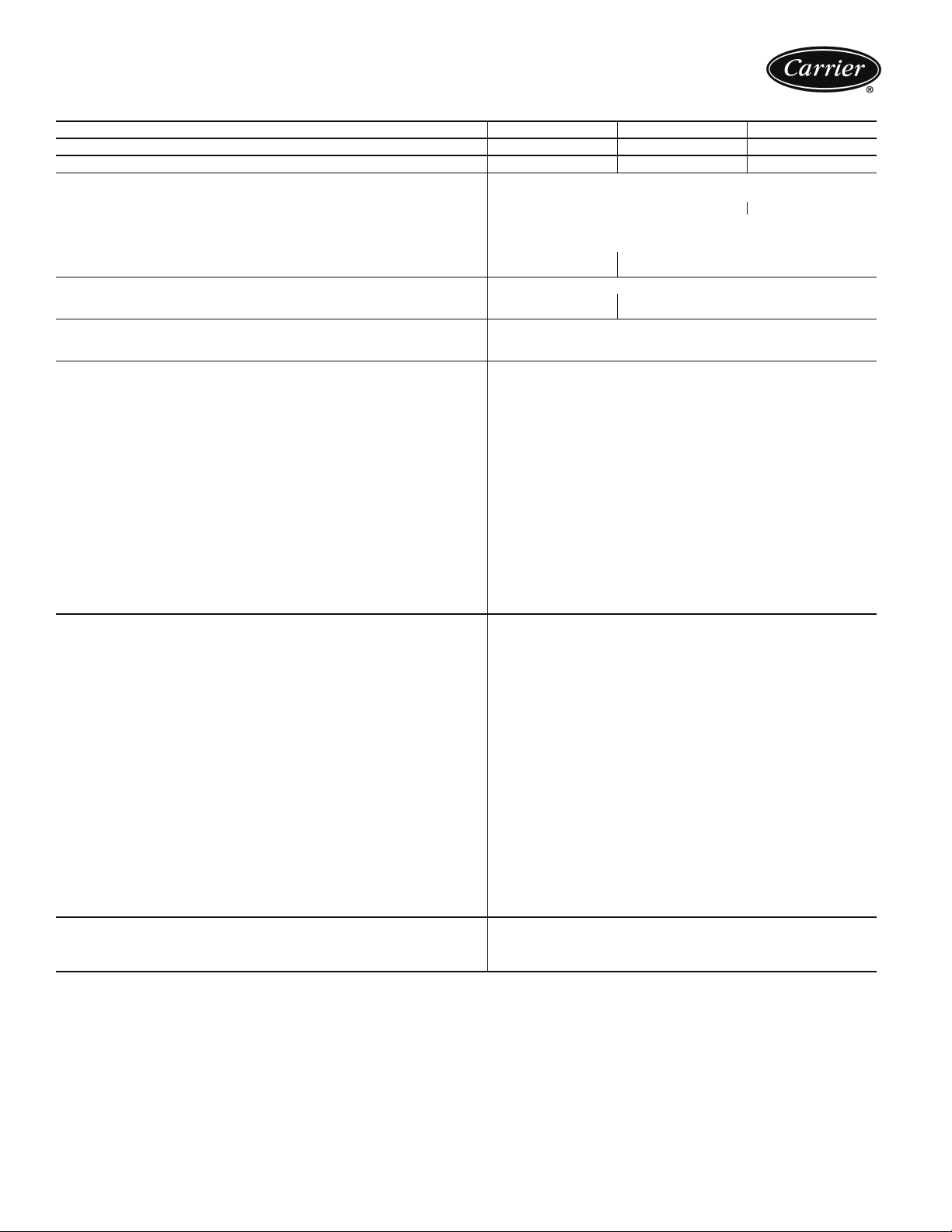

Marine waterboxes provide water piping connections

extending from the side of the waterbox (as opposed to

extending from the end of the waterbox). This option also

includes a removable bolt on waterbox cover allowing

access to the heat exchanger tubes without breaking the

existing field piping. This option is available for both the

evaporator and condenser.

a30-4684.eps

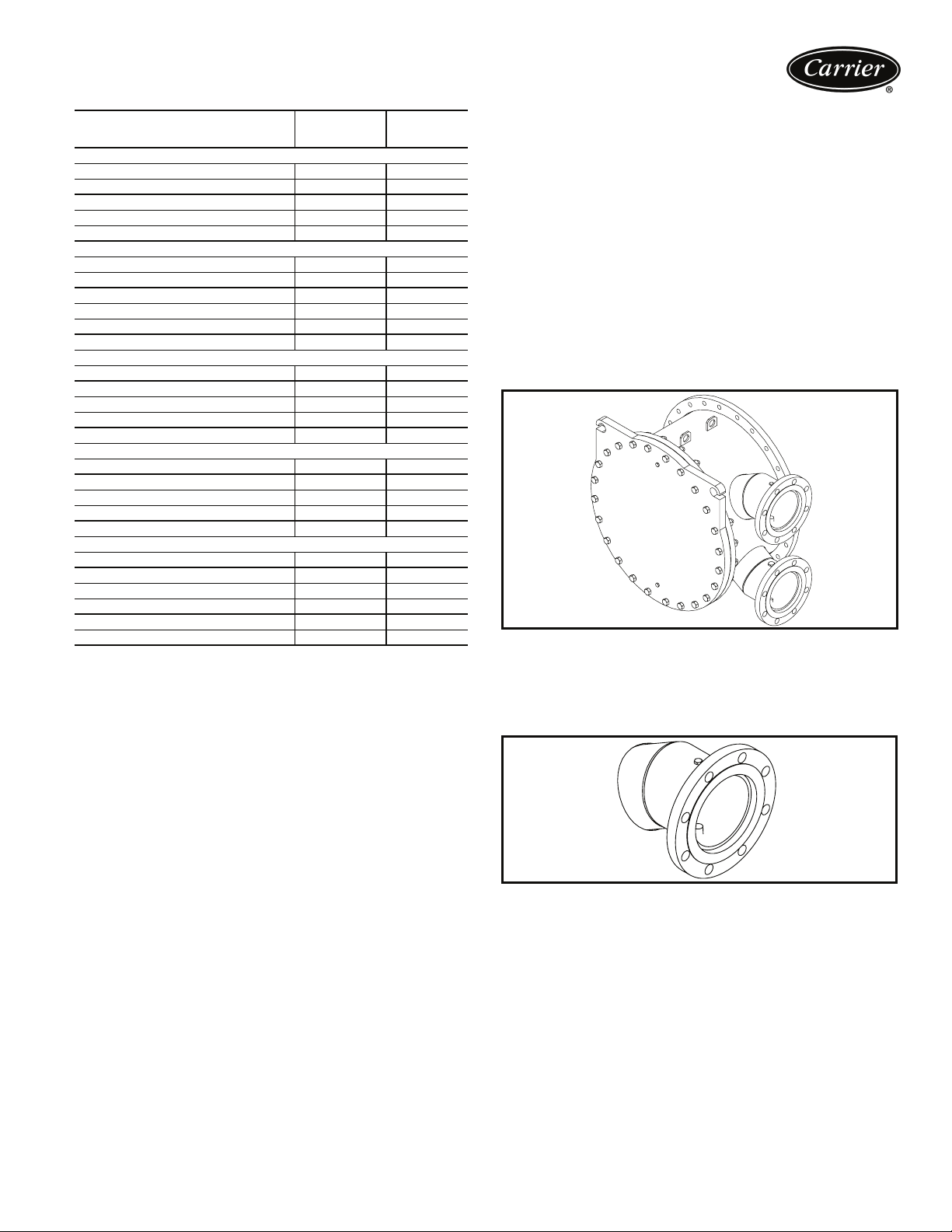

Flanged connection option provides an ANSI (American National Standards Institute) flange on the end of the

chiller water piping for connection to a customer supplied

mating flange in the field piping. This option is available

for both the evaporator and condenser.

a30-4685

One-pass evaporator provides a lower pressure drop

through the evaporator for applications with low delta T

(temperature) or high flow or where the evaporators are

piped in a series or side stream arrangement. One-pass

evaporator is only available with flanged connections and

with discharge end leaving water connection.

Three-pass evaporator provides a greater efficiency for

brine applications and in applications with a high delta T

and low flow. Three-pass evaporator is only available with

flanged connections.

Heat machine condenser allows operation with up to

140 F (60 C) leaving condenser water temperature (see

E-CAT for selections). In addition, this option provides

factory-installed thermal insulation on the condenser,

condenser flow switch and leaving condenser water

9

Page 10

Options and accessories (cont)

temperature sensor to facilitate operating in HEAT mode.

Heat machine units require 300 psig (2068 kPa) option

and field-installed thermal insulation on the compressor

discharge piping and waterbox heads because of high

temperature.

One-pass condenser provides a lower pressure drop

through the condenser for applications with low delta T

(temperature) or high flow or where the condensers are

piped in a series. The one-pass condenser option is only

available with flanged connections and with a discharge

end leaving water connection.

Wye-delta start is an alternate starting method which

reduces the inrush current when starting the compressor.

Wye delta start is standard on 208-v, and 230-v units,

optional for 380-v, 460-v, and 575-v.

Dual point power provides a means for connecting two

sources of power to dual compressor 30XW chillers. One

source of power is wired to operate the compressor on the

A circuit and one source of power is wired to operate the

compressor on the B circuit of the chiller.

Non-fused disconnect provides a no load, lockable,

through the door handle disconnect for unit power on the

chiller. On dual point power, one disconnect is provided for

each of the two main power supplies. This disconnect does

not remove the control circuit from power supply.

Control transformer is sized to supply the needs of the

control circuit from the main power supply.

115-v GFCI convenience outlet includes 4 amp GFI

(ground fault interrupt) receptacle. Convenience outlet is

115-v female receptacle. Not available with 380-v units.

Nitrogen charge provides a 15 lb (6.8 kg) charge of

nitrogen instead of a full factory charge of R-134a refrigerant to keep the chiller refrigerant circuit dry during shipment. This option is recommended for applications where

the unit will be disassembled prior to installation. Units

shipped with a nitrogen charge will receive an electrical

continuity test at the factory prior to shipment.

Crate for shipment provides a wooden crate around the

chiller. The chiller is bagged prior to being placed in the

crate. This option is recommended for export orders.

Suction service valves allow for further isolation of the

compressor from the evaporator vessel.

Field-installed accessories

Remote enhanced display is a remotely mounted

indoor 40-character per line, 16-line display panel for unit

monitoring and diagnostics.

BACnet™ translator control provides an interface

between the chiller and BACnet Local Area Network

(LAN, i.e., MS/TP EIA 485). The BACnet translator control is also available as a factory-installed option.

LON translator control provides an interface between

the chiller and Local Operating Network (LON, i.e., LONWorks FT-10A ANSI/EIA-709.1). The LON translator

control is also available as a factory-installed option.

Energy management module provides energy management capabilities to minimize chiller energy consumption.

Several features are provided with this module including

leaving fluid temperature reset, cooling set point reset or

demand limit control from a 4 to 20 mA signal, 2-point

demand limit control (from 0 to 100%) activated by a

remote contact closure, and discrete input for "Ice Done"

indication for ice stage system interface.

Temperature reset sensor provides temperature reset

capability from either the occupied space or outdoor temperature sensor.

NOTE: Temperature reset capability using return temperature is standard.

Vibration isolation pads are neoprene pads for installation under the chiller feet at the jobsite.

Vibration springs provide a set of non-siesmic spring

isolators for installation at the jobsite.

Navigator™ module provides a portable, hand-held display for convenient access to unit status, operation, configuration and troubleshooting diagnostics capability. The

four-line, 20-character LCD (liquid crystal display) display

provides clear language information in English, French,

Spanish, or Portuguese. The Navigator module features an

industrial grade extension chord and magnets located on

the back of the weatherproof enclosure to allow attachment to sheet metal components for hands free operation.

Field-supplied and field-installed insulation

Evaporator waterbox insulation must be field installed.

When insulating waterboxes, allow for service access and

removal of covers. To estimate waterbox cover areas, refer

to the following figure.

Insulation for discharge piping between the compressor and condenser must be field installed on heat machine

units. Refer to the following figure.

Condenser waterbox insulation must be field installed

on heat machine units. When insulating waterboxes, allow

for service access and removal of covers. To estimate

waterbox cover areas, refer to the following figure.

10

Page 11

FIELD-SUPPLIED AND FIELD-INSTALLED INSULATION

EVAPORATOR WATERBOX

INSULATION NEEDED

CONDENSER WATERBOX

INSULATION NEEDED (HEAT

MACHINE UNITS ONLY)

DISCHARGE PIPING

INSULATION NEEDED (HEAT

MACHINE UNITS ONLY)

EVAPORATOR WATERBOX

INSULATION NEEDED

EVAPORATOR WATERBOX

INSULATION NEEDED

CONDENSER WATERBOX

INSULATION NEEDED (HEAT

MACHINE UNITS ONLY)

NOTES:

1. Field-installed insulation for standard units shown in light gray.

2. Field-installed insulation for heat machine units shown in dark gray.

3. Back of the unit shown.

a30-4686

11

Page 12

Dimensions

a30-4745

SEE NIH EVAPORATOR

DETAIL FOR NOZZLE

MEASUREMENTS

SUCTION

END

30XW UNIT DIMENSIONS

EVAPORATOR

DISCHARGE

END

SEE NIH CONDENSER

DETAIL FOR NOZZLE

MEASUREMENTS

MLV (OPTIONAL)

CONDENSER

STANDARD 30XW UNIT DIMENSIONS

30XW UNIT

SIZE

OPERATING

WEIGHT, lb [kg]

325 14,319 [6495] 3734 [1694] 3828 [1736] 3337 [1514] 3420 [1551] 6-

350 14,515 [6584] 3785 [1717] 3880 [1760] 3383 [1535] 3467 [1573] 6-

400 14,759 [6695] 3848 [1745] 3946 [1790] 3439 [1560] 3526 [1599] 6-

NOTES:

1. Weights shown for standard chiller (2 pass with NIH, victaulic waterboxes).

2. See page 14 for unit mounting locations.

MOUNTING LOCATION WEIGHT, lb [kg] DIMENSIONS (ft-in. [mm])

1234ABC

3

/8 [1837] 6-3/8 [1837]3/8 [9.53]

3

/8 [1837] 6-3/8 [1837]3/8 [9.53]

3

/8 [1837] 6-3/8 [1837]3/8 [9.53]

30XW UNIT AND WATERBOX DIMENSIONS

CONNECTIONS PASSES

WATERBOX

(EVAP/COND)

NIH/NIH

NIH/MWB

Same Ends

MWB/NIH

MWB/MWB

2 Pass

NIH/NIH

NIH/MWB

MWB/NIH

Opposite Ends

MWB/MWB

NIH/NIH Flange 14-5

1 or

3 Pass

NIH/MWB Flange

MWB/NIH Flange 15,244 [6915] 15,440 [6894] 15,684 [7114]

MWB/MWB Flange 15,581 [7067] 15,777 [7063] 16,021 [7267]

NOTES:

1. Operating weight includes weight of water, refrigerent, and oil.

2. Denotes center of gravity.

3. Dimensions shown in ft-in. [mm] unless noted.

4. The recommended service clearance around the machine is 3 ft [914.4 mm].

5. Victaulic nozzles are standard on all units. A flow switch can be factory-installed in evaporator inlet victaulic nozzle.

6. Maximum fluid side pressure of condenser or evaporator is 150 psig [1034 kPa] (standard) or 300 psig [2068 kPa] (optional).

7. Operating weight includes weight of water, refrigerant, and oil.

NOZZLE

TYPE

Victaulic 13-3

Flange 13-9

D

ft-in. [mm]

3

/4 [4057]

1

/16 [4193] 14,651 [6646] 14,847 [6646] 15,091 [6845]

E

ft-in. [mm]Fft-in. [mm]

Victaulic

Flange 14,739 [6685] 14,935 [6685] 15,179 [6885]

Victaulic 14,489 [6572] 14,685 [6572] 14,929 [6772]

Flange 14,746 [6689] 14,768 [6689] 15,012 [6809]

13-11

5

/8 [4258]

3

/8 [1210] 6-611/16 [1999]

3-11

Victaulic 14,668 [6653] 14,864 [6653] 15,108 [6853]

Flange 14,834 [6729] 15,030 [6729] 15,274 [6928]

Victaulic 13-6

Flange 14-4

Victaulic 14-2

Flange 14-6

Victaulic 14-2

Flange 14-8

Victaulic

Flange 14,834 [6729] 15,030 [6729] 15,274 [6928]

5

/16 [4123]

7

/16 [4380] 14,651 [6646] 14,847 [6646] 15,091 [6845]

3

/16 [4323] 14,498 [6576] 14,694 [6576] 14,938 [6776]

15

/16 [4443] 14,739 [6685] 14,935 [6685] 15,179 [6885]

13

/16 [4339] 14,489 [6572] 14,685 [6572] 14,929 [6772]

3

/16 [4475] 14,746 [6689] 14,768 [6689] 15,012 [6809]

11

/16 [4539]

14-10

5

/8 [4410] 14,828 [6726] 15,024 [6726] 15,268 [6925]

11

/16 [4539]

14-10

3

/8 [1210] 6-611/16 [1999]

3-11

MLV (OPTIONAL)

LEGEND

MLV — Minimum Load Valve

MWB — Marine Waterbox

NIH — Nozzle-In-Head

SSV — Suction Ser vice Valve

MAX UNIT OPERATING WEIGHT lb [kg]

325 350 400

14,319 [6495] 14,515 [6495] 14,759 [6695]

14,498 [6576] 14,694 [6576] 14,938 [6776]

14,319 [6495] 14,515 [6495] 14,759 [6695]

14,668 [6653] 14,864 [6653] 15,108 [6853]

15,223 [6905] 14,768 [6896] 15,012 [6809]

12

Page 13

INCOMING CONTROL

POWER 1 x 7/8”

KNOCKOUT

DOOR CLEARANCE SPACE

EVAP

SUCTION

END

a30-4755

3 3/16”

[81 mm]

SUCTION

END

30XW UNIT DIMENSIONS (cont)

DOOR CLEARANCE SPACE

D

INCOMING CONTROL

POWER 1 x 7/8”

KNOCKOUT

DISCHARGE

END

a30-4748

a30-4747

END

DISCHARGE

13

Page 14

Dimensions (cont)

30XW UNIT DIMENSIONS (cont)

WATERBOX FLANGE DETAIL

NIH EVAPORATOR

DISCHARGE DISCHARGEDISCHARGE

a30-4725

a30-4751

MOUNTING

LOCATIONS

NIH CONDENSER

DISCHARGE

a30-4688

a30-4749

DISCHARGE

SUCTION SUCTIONSUCTION

UNIT

30XW325-400

NUMBER OF

PASSESAin. (mm)Bin. (mm)

26

10 (0)0 (0)68

36

a30-4752

DISCHARGE DISCHARGEDISCHARGE

SUCTION SUCTIONSUCTION

UNIT

30XW325-400

NUMBER OF

PASSESAin. (mm)Bin. (mm)

27

1 0 (0) 0 (0) 6 —

37

CONNECTION SIZE

1

/16 (154) 61/16 (154) 6 8

1

/16 (154) 61/16 (154) 6 8

Flange Victaulic

MARINE EVAPORATOR

CONNECTION SIZE

1

/2 (191) 71/2 (191) 6 6

1

/2 (191) 71/2 (191) 6 —

Flange Victaulic

UNIT

30XW325-400

a30-4750

UNIT

30XW325-400

SUCTION

NUMBER OF

PASSESAin. (mm)Bin. (mm)

26

1 0 (0) 0 (0) 6 8

3

/4 (171) 63/4 (171) 6 8

SUCTION

CONNECTION SIZE

Flange Victaulic

MARINE CONDENSER

DISCHARGE DISCHARGE

SUCTION SUCTION

NUMBER OF

PASSESAin. (mm)Bin. (mm)

27

1 0 (0) 0 (0) 6 —

3

/8 (187) 73/8 (187) 6 6

CONNECTION SIZE

Flange Victaulic

14

Page 15

Selection procedure

Carrier’s packaged selection program provides quick,

easy selection of Carrier’s water-cooled chillers. The program considers specific temperature, fluid and flow

requirements among other factors such as fouling and altitude corrections.

Before selecting a chiller, consider the following points:

Leaving water (fluid) temperature (LWT)

• The LWT must be at least 40 F (4.4 C) or greater.

• If the LWT requirement is greater than 60 F (15.5 C), a

mixing loop is required.

Entering water (fluid) temperature (EWT)

• If the EWT requirement is greater than 70 F (21.1 C), a

mixing loop is required. The EWT should not exceed

70 F (21.1 C) for extended operation. Pulldown can be

accomplished from 95 F (35 C).

Evaporator flow rate or evaporator delta-T:

• The evaporator delta-T (EWT – LWT) must fall between

5 and 20° F (2.8 and 11.1° C) while still meeting the

maximum entering requirements.

• For larger or smaller delta-T applications, a mixing loop

is required. If the evaporator flow is variable, the rate of

change of flow should not exceed 10% per minute.

The loop volume in circulation must equal or exceed

3 gallons per nominal ton (3.2 L per kW) of cooling for

temperature stability and accuracy in normal air conditioning applications. In process cooling applications,

there should be 6 to 10 gallons per ton (6.5 to 10.8 L

per kW). To achieve this loop volume, it is often necessary to install a tank in the loop. The tank should be baffled to ensure there is no stratification, and that water

(or brine) entering the tank is adequately mixed with liquid in the tank. See Water Loop Volume in the Application Data section.

Evaporator pressure drop:

• A high evaporator pressure drop can be expected when

the evaporator delta-T is low. A mixing loop can help to

alleviate this situation.

• The three-pass evaporator option is recommended to

increase performance when the evaporator delta T is

high. This is particularly helpful with brine applications.

Condenser pressure drop:

• A high condenser pressure drop can be expected when

the condenser delta-T is low. A one-pass condenser can

help lower pressure drop.

Series chillers:

• One-pass heat exchangers can help lower pressure

drop when heat exchangers are placed in series.

Water quality, fouling factor:

• Poor water quality can increase the required evaporator

fouling factor.

• Higher than standard fouling factors lead to lower

capacity and higher input kW from a given chiller size

compared to running the same application with better

water quality (and lower fouling factors).

Temperature reset:

• Return water (standard)

• Outside air temperature (standard)

• Space temperature (accessory sensor required)

• 4 to 20 mA (requires an energy management module)

Demand limit:

• 2-step (requires an energy management module)

• 4 to 20 mA (requires an energy management module)

• CCN Loadshed

Performance data

EVAPORATOR AND CONDENSER FLOW RATES

EVAPORATOR CONDENSER NOMINAL

Leaving Fluid/Entering Fluid

Minimum Maximum

30XW UNIT

Two pass 411 25.9 1481 93.4 494 31.1 1974 124.5 790 49.8 987 62.3

325

One pass 790 49.8 3126 197.2 987 62.3 3290 207.6 790 49.8 987 62.3

Three pass 247 15.6 987 62.3 — — — — 790 49.8 — —

Two pass 433 27.3 1557 98.2 519 32.7 2076 131.0 830 52.4 1038 65.5

350

One pass 830 52.4 3287 207.4 1038 65.5 3460 218.3 830 52.4 1038 65.5

Three pass 260 16.4 1038 65.5 — — — — 830 52.4 — —

Two pass 486 30.7 1751 110.4 584 36.8 2334 147.3 934 58.9 1167 73.6

400

One pass 934 58.9 3696 233.1 1167 73.6 3890 245.4 934 58.9 1167 73.6

Three pass 292 18.4 1167 73.6 — — — — 934 58.9 — —

*Maximum condenser fluid temperature shown for standard condensing

option. Heat machine option may have leaving fluid temperatures up to

140 F (60 C).

40 F (4.4 C)/

45 F (7.2 C)

Minimum

Flow Rate

GPM L/s GPM L/s GPM L/s GPM L/s GPM L/s GPM L/s

60 F (15.6 C)/

70 F (21.1 C)

Maximum

Flow Rate

Minimum Entering

65 F (18.3 C) 118 F (47.8 C)*

Fluid

Minimum

Flow Rate

Maximum Leaving

Fluid

Maximum

Flow Rate

Evaporator Condenser

Nominal

Flow Rate

Nominal

Flow Rate

15

Page 16

Performance data (cont)

30XW325-400 EVAPORATOR MARINE WATERBOX

(kPa)

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

ft wg

40.00

35.00

30.00

25.00

20.00

15.00

3

pass

pass

pass

2

1

Pressure Drop

(29.8)

(14.9)

(0)

10.00

5.00

0.00

0 500 1000 1500 2000 2500 3000

(0) (31.5) (63.1) (94.6) (126.2) (157.7) (189.3)

Evaporator Flow Rate

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over

the entire range of evaporator water flow rates represented.

A30-4691

gpm

(L/s)

30XW325-400 EVAPORATOR NIH FLANGE

(0)

ft wg

40.00

1 pass

35.00

pass

3

pass

2

30.00

25.00

20.00

15.00

10.00

5.00

0.00

0 500 1000 1500 2000

(0) (31.5) (63.1) (94.6) (126.2)

Evaporator Flow Rate

gpm

(L/s)

A30-4692

(kPa)

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

Pressure Drop

(29.8)

(14.9)

LEGEND

NIH — Nozzle-In-Head

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over the

entire range of evaporator water flow rates represented.

16

Page 17

(kPa)

p

30XW325-400 EVAPORATOR NIH VICTAULIC

ft wg

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

40.00

35.00

30.00

25.00

20.00

15.00

pass

3

pass

pass

2

1

Pressure Drop

(29.8)

(14.9)

LEGEND

NIH — Nozzle-In-Head

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over the

entire range of evaporator water flow rates represented.

(0)

10.00

5.00

0.00

0 500 1000 1500 2000 2500 3000

(0) (31.5) (63.1) (94.6) (126.2) (157.7) (189.3)

Evaporator Flow Rate

gpm

(L/s)

A30-4693

30XW325-400 CONDENSER MARINE WATERBOX

2 pass

1

ass

gpm

(L/s)

(0)

ft wg

40.00

35.00

30.00

25.00

20.00

15.00

10.00

5.00

0.00

(kPa)

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

Pressure Drop

(29.8)

(14.9)

0 500 1000 1500 2000 2500 3000 3500

(0) (31.5) (63.1) (94.6) (126.2) (157.7) (189.3) (220.8)

Condenser Flow Rate

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over the

entire range of condenser water flow rates represented.

A30-4694

17

Page 18

Performance data (cont)

30XW325-400 CONDENSER NIH FLANGE

(kPa)

ft wg

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

40.00

35.00

30.00

25.00

20.00

15.00

2 pass

1 pass

Pressure Drop

(0)

LEGEND

10.00

5.00

0.00

0 500 1000 1500 2000 2500

(0) (31.5) (63.1) (94.6) (126.2) (157.7)

Condenser Flow Rate

gpm

(L/s)

A30-4695

(29.8)

(14.9)

NIH — Nozzle-In-Head

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over the entire

range of evaporator water flow rates represented.

30XW325-400 CONDENSER NIH VICTAULIC

(kPa)

(119.4)

(104.4)

(89.5)

(74.6)

(59.7)

(44.8)

Pressure Drop

(29.8)

(14.9)

LEGEND

NIH — Nozzle-In-Head

NOTE: The table above represents pressure drops only. The table does not imply that the chiller can be properly applied over the

entire range of evaporator water flow rates represented.

(0)

ft wg

40.00

35.00

2 pass

1 pass

30.00

25.00

20.00

15.00

10.00

5.00

0.00

0 500 1000 1500 2000 2500 3000 3500

(0) (31.5) (63.1) (94.6) (126.2) (157.7) (189.3) (220.8)

Condenser Flow Rate

gpm

(L/s)

A30-4696

18

Page 19

Controls

Microprocessor

The chiller microprocessor controls overall unit operation

and controls a number of processes simultaneously. These

processes include internal timers, reading inputs, analog to

digital conversions, display control, diagnostic control, output relay control, demand limit, capacity control, head

pressure control, and temperature reset. Some processes

are updated almost continuously, others every 2 to 3 seconds, and some every 30 seconds. The microprocessor

routine is started by switching the emergency ON-OFF

switch to the ON position.

Control sequence

Pre-start — After control switches on, the prestart takes

place. The microprocessor checks itself, and if configured,

energizes the evaporator and condenser pumps to the

internal (or CCN) time schedule (or input occupied signal

from an external system) and waits for temperature to

stabilize.

Start-up — The chiller will receive a call for cooling when

chilled fluid temperature increases above the set point plus

a dead band, or if an override start command is received.

If flow has been proven, the first compressor starts 1 to 3

minutes after the call for cooling. The controlled pulldown

feature limits compressor loading on start up to reduce

demand on start up and unnecessary compressor usage.

Capacity control — On the first call for cooling, the

microprocessor starts the compressor on the lead circuit.

The microprocessor maintains leaving fluid temperature

set point through intelligent positioning of the slide valve.

As the load increases above the compressor's capacity, the

compressor on the lag circuit is started and both compressors are staged together.

Maintaining set point — The control monitors entering

and leaving chilled water temperature to anticipate

changes in cooling load. The speed at which capacity is

added or reduced is controlled by temperature deviation

from set point and rate of temperature change of the

chilled fluid. The basic logic for determining when to add

or remove capacity is a time band integration of deviation

from set point plus rate of change of leaving fluid temperature. When leaving-fluid temperature is close to the set

point and slowly moving closer, logic prevents additional

capacity. Accuracy depends on loop volume, loop flow

rate, load and condenser water temperatures.

Return fluid temperature compensation — No adjustment for cooling range or evaporator flow rate is required

because the control automatically compensates for cooling

range by measuring both return fluid temperature and leaving fluid temperature.

Low temperature override — This feature prevents

LWT (leaving water temperature) from overshooting the

set point to prevent nuisance low suction temperature

trips.

High temperature override — This feature allows the

chiller to add capacity quickly during rapid load variations.

Temperature reset (chilled water reset) — When

latent loads in the conditioned space are reduced, it may be

possible to reset the leaving chilled water temperature set

point to a warmer temperature thereby reducing compressor power usage and saving energy. Three reset options

are offered. With any chilled water reset application, humidity control should be considered since higher coil temperatures will reduce latent capacity. For details on applying a reset option, refer to the Controls, Start-Up, Operation, Service and Troubleshooting guide.

Return fluid temperature reset — This feature

increases LWT set point as return (entering) fluid temperature decreases (indicating load decrease). This option may

be used where return fluid temperature provides accurate

load indication. No additional hardware is required.

Outdoor-air temperature reset — This feature

increases LWT set point as outdoor ambient temperatures

decreases (indicating load decrease). This reset should only

be applied where outdoor ambient temperature is an indication of load. A field-installed thermistor is required.

Space temperature reset — This feature increases the

LWT as space temperature decreases (indicating load

decrease). This reset should only be applied where space

temperature is an indication of load. A field-supplied thermistor is required.

Minimum load control — The main base board (MBB)

responds to the supply chilled water temperature to match

cooling load requirements and controls the minimum load

control valve. The minimum load control valve allows hot

gas to pass directly into the evaporator circuit permitting

the unit to operate at lower loads with less compressor

cycling. Minimum load control should be given consideration when operation is anticipated below the minimum

unloading step.

Pull down control — If pulldown control has been

selected (adjustable setting), no additional capacity is added

as long as the difference between fluid temperature and the

set point is greater than 4 F (2.2 C) and rate of change in

leaving water temperature is greater than the 90 seconds

since the last capacity change, compressors will continue

to run unless a safety device trips. This prevents rapid

cycling and also helps return oil during short operating

periods.

Maximum operating pressure control — If the entering fluid temperature is 95 F (35 C) and the saturated suction temperature is 50 F (10 C) or higher, the maximum

operating pressure (MOP) feature limits the suction to keep

the chiller online. The control automatically starts the

chiller in the unloaded state to eliminate the potential of

compressor overload due to high head pressure or low suction pressure.

Equalized run time — The controller will equalize run

time on each circuit through the lead / lag feature. If a circuit becomes disabled, the control will automatically set the

active circuit to lead, keeping the chiller online at a reduced

capacity.

Sensors — Thermistors are used to control temperature

sensing inputs to the microprocessor. No additional thermistor sensors are required for leaving chilled water temperature, optional return water reset, or outdoor air reset.

The following sensors can be used on 30XW units:

• Evaporator leaving fluid temperature (T1)

19

Page 20

Controls (cont)

• Evaporator entering fluid temperature (T2)

• Suction gas temperature (T4 - Circuit A, T7 - Circuit B)

• Economizer gas temperature (T5 - Circuit A, T11 Circuit B) (sizes 350, 400 only)

• Space temperature (T8)

• Discharge gas temperature (T9 - Circuit A, T10 Circuit B)

• Condenser entering fluid temperature (T12)

• Condenser leaving fluid temperature (T13)

• Compressor motor temperature

There are 3 (size 325) or 4 (sizes 350, 400) refrigerant

pressure transducers used in each circuit for sensing suction, discharge, oil, and economizer (sizes 350, 400) pressure. The microprocessor uses these inputs to control

capacity.

• Saturated condensing temperature

• Evaporator saturation temperature

Electronic expansion valve (EXV) — The EXV controls refrigerant flow to the evaporator for different operating conditions by varying an orifice size to increase or

decrease the flow area through the valve based on microprocessor input. The orifice is positioned by a stepper

motor through approximately 3,600 discrete steps and is

monitored every 3 seconds.

Safeties

Abnormal conditions — All control safeties in the chiller

operate through compressor protection board, control

relays or the chiller microprocessor. Loss of feedback signal to the MBB will cause the compressor(s) to shut down.

For other safeties, the microprocessor makes appropriate

decision to shut down a compressor due to a safety trip or

bad sensor reading and displays the appropriate failure

code on the display. Chiller holds in safety mode until

reset; it then reverts to normal control when the unit is

reset.

Low-pressure safety — This safety will shut down the

chiller and display the appropriate alarm code if the system

pressure drops below configured minimums.

High-pressure safety — This safety will shut down the

chiller and display the appropriate alarm code if the compressor discharge pressure increases to 185 psig for standard condenser units or 250 psig for high condensing or

heat machine units.

Compressor anti-cycling — This feature monitors compressor starts to limit compressor cycling during periods of

low load.

Loss of flow protection — This feature will shut off the

chiller if the detected flow is below the configured minimum flow rate. Thermal dispersion flow switches are

installed in 30XW chillers to confirm evaporator flow.

Sensor failures — The microprocessor monitors temperature and pressure sensors to ensure readings are

within the expected range. Loss of communication to a

sensor or readings outside of the expected range will

prompt corrective action.

Other safeties — Other safety features include electric

overload, thermal overload protection, oil pressure, loss of

refrigerant charge, loss of phase protection, reverse

rotation protection (prevents compressor start), current

imbalance, and ground current.

Demand limit function — This function can be used to

limit the total power draw of the chiller to a user-defined

set point. The optional energy management module is

required and can provide either 2-step or 4 to 20 mA

demand limit. This optional electronic board interfaces

with the microprocessor to control the number of compressors operating and their operating capacity to limit

power consumption to the user specified value.

The microprocessor can control the number of compressors operating and their operating capacity to limit power

consumption to the user specified value.

Diagnostics — The microprocessor includes a service

test feature that displays the condition of each sensor and

switch in the chiller and allows the observer to check for

proper operation of the compressors. Refer to the Controls, Start Up, Operation, Service and Troubleshooting

guide for further information.

Default settings — To facilitate quick start-ups, 30XW

chillers are pre-configured with a default setting that

assumes stand-alone operation with a 44 F (6.6 C) chilled

water set point. Configuration settings will be based on any

options or accessories included with the unit at the time of

manufacturing. Date and time are set to U.S.A. Eastern

Time zone and will need reconfiguring based on location

and local time zone. If operation based on occupancy

schedule is desired, the schedule must be set during

installation.

Additional information — Detailed information on controls and operation is available in the Controls, Start-Up,

Operation, Service and Troubleshooting guide included

with each unit. Packaged Service Training programs are

also available. Contact your local Carrier representative for

more information.

20

Page 21

Typical control wiring schematics

30XW UNIT CONTROL WIRING SCHEMATIC

a30-4697

LEGEND

AWG — American Wire Gage NEC — National Electrical Code

CB — Circuit Breaker PMP — Chilled Water Pump

COM — Communication Port PMPI — Chilled Water Pump Interlock

EMM — Energy Management Module TB — Ter m i na l B lo c k

EQUIP GND — Equipment Ground Field Power Wiring

FIOP — Factory-Installed Option Field Control Wiring

MLV — Minimum Load Valve Factory-Installed Wiring

NOTES:

1. Factory wiring is in accordance with UL 1995 standards. Field modifications or additions must be in compliance with all applicable codes.

2. Wiring for main field supply must be rated 75C minimum. Use copper for

all units. Incoming wire size range for the terminal block is #4 AWG to

500 kcmil for single point power (two conductors per phase). Incoming

wire size range for the terminal blocks for dual point power option is

#4 AWG to 500 kcmil for single point power (one conductor per phase).

Incoming wire size range for 200/300-v models is 3/0 to 500 kcmil for single point power (one conductor per phase).

3. Terminals 9 and 10 of TB5 are for field external connections for remote

on-off. The contacts must be rated for dry circuit application capable of

handling a 24-vac load up to 50 mA.

4. Terminals 1 and 2 of TB5 are for external connections of chilled water

pump interlock. The contacts must be rated for dry circuit application

capable of handling a 24-vac load up to 50 mA.

5. Terminals 11 and 13 of TB5 are for control of chilled water pump 1

(PMP 1) starter. Terminals 15 and 13 of TB5 are for control of chilled

water pump 2 (PMP 2) starter. Remove factory-installed jumper when

using pump interlock. The maximum load allowed for the chilled water

pump relay is 5-va sealed, 10-va inrush at 24-v. Field power supply is not

required.

6. For control of chilled water pumps, a set of normally open contacts rated

for dry circuit application must be supplied from field-supplied pump

starter relay. Connect contacts directly to connector at main base board

channel 18.

7. Terminals 12 and 13 of TB5 are for an alarm relay. The maximum load

allowed for the alarm relay is 10-va sealed, 25-va inrush at 24-v. Field

power supply is not required.

8. Make appropriate connections to TB6 as shown for energy management

board options. The contacts for occupancy override, demand limit, and

ice done options must be rated for dry circuit application capable for handling a 24-vac load up to 50 mA.

9. Terminal blocks TB5 and TB6 are located in the display panel box for all

units. Refer to certified dimensional drawing for each unit to get the exact

locations.

10. Refer to certified dimensional drawings for exact locations of the main

power and control power entrance locations.

11. For control of condenser pump, connect field-supplied relay (max 5-va

sealed, 10-va inrush at 24-v) directly to connector at main base board

channel 22.

12. For head pressure control option, 0-10-vdc signal wires are factoryinstalled (violet and brown) from HGBP/COND board channel 9. Refer to

controls manual for application with field-supplied water regulating valve.

21

Page 22

Application data

Unit storage

Store chiller and starter indoors, protected from construction dirt and moisture. Inspect under shipping tarps, bags,

or crates to be sure water has not collected during transit.

Keep protective shipping covers in place until machine is

ready for installation. Assure that the inside of the protective cover meets the following criteria:

• Temperature is between 40 F (4.4 C) and 120 F

(48.9 C)

• Relative humidity is between 10% and 80% (noncondensing)

Chiller location

Unit should be located indoors on a level surface in an area

with temperatures between 50 F (10 C) and 104 F (40 C).

Clearance should be provided around the unit for service

and local code requirements. See dimensional drawings for

specific unit clearance requirements. Consideration should

be given to using rubber-in-shear pads. For applications

other than ground to slab, it is recommended spring isolators are used to minimize structure borne transmission.

Acoustic consideration should be given near sound sensitive areas.

Relief valve vent lines:

1. Vent per local code requirements.

2. Each chiller has 2 relief valves on the evaporator, 2

on the condenser and one relief valve on each compressor discharge line.

Evaporator flow range

For minimum and maximum evaporator flow rates please

see the Evaporator and Condenser Flow Rates table. A

high flow rate is generally limited by the maximum pressure drop that can be tolerated by the unit. The 30XW

chillers are designed for a full load temperature rise of 5 to

20 F (2.8 to 11.1 C). See the Carrier selection program for

pressure drop values and performance.

Minimum evaporator flow

When system design conditions require a lower flow (or

higher temperature rise) than the minimum allowable evaporator flow rate, please follow the recommendations

below.

• Multiple smaller chillers may be applied in series, each

providing a portion of the design temperature rise.

• Try increasing the number of passes in the evaporator

(1, 2, or 3 passes available).

• Evaporator fluid may be recirculated to raise the flow

rate to the chiller. The mixed temperature entering the

evaporator must be maintained to a minimum of at least

5 F (2.8 C) above the leaving chilled fluid temperature and a maximum of no more than 20 F (11.1 C)

above the leaving chilled fluid temperature.

NOTE: Recirculation flow is shown below.

Maximum evaporator flow

RECIRCULATION FLOW

Strainers

A screen strainer with minimum screen size of 20 mesh

must be installed within 10 ft (3 m) of the inlet pipe connection to both the evaporator and condenser to prevent

debris from damaging internal tubes of the evaporator. The

pump strainer shall not be used to meet this requirement.

Oversizing chillers

Oversizing chillers by more than 15% at design conditions

should be avoided as the system operating efficiency is

adversely affected (resulting in greater or excessive electrical demand). When future expansion of equipment is anticipated, install a single chiller to meet present load

requirements and add a second chiller to meet the additional load demand. It is also recommended that 2 smaller

chillers be installed where operation at minimum load is

critical. The operation of a smaller chiller loaded to a

greater percentage over minimum is preferred to operating

a larger chiller at or near its minimum recommended value.

Operation at its minimum load should only be done intermittently, not for long periods of time. Minimum load control should not be used as a means to allow oversizing

chillers.

Evaporator water temperature

Maximum leaving fluid temperature for the unit is 60 F

(15.5 C). The unit can start and pull down with up to 95 F

(35 C) entering fluid temperature. For sustained operation,

it is recommended the fluid temperature not exceed 70 F

(21.1 C). Water flowing through the evaporator should

never exceed 100 F (37.8 C). Minimum leaving water temperature is 40 F (4.4 C).

CHILLER EVAPORATOR

a30-4698

The maximum evaporator flow (approximately 5 F

(2.8 C) rise results in a practical maximum pressure drop

through the evaporator. Optional marine waterboxes may

help reduce pressure drop by a small amount. If this is

insufficient, a return fluid may bypass the evaporator to

keep the pressure drop through the evaporator within

acceptable limits. This permits a higher delta T with lower

fluid flow through the evaporator and mixing after the

evaporator.

NOTE: Bypass flow is shown below.

BYPASS FLOW

CHILLER EVAPORATOR

a30-4699

22

Page 23

Variable evaporator flow rates

⋅°⋅

Variable flow rates may be applied to a standard chiller.

The unit will, however, attempt to maintain a constant

leaving fluid temperature. In such cases minimum flow

must be in excess of minimum flow given in the

Evaporator and Condenser Flow Rates table, and minimum loop volume must be in excess of 3 gallons per ton

(3.21 L per kW). Combined flow rate and change in load

must not change by more than 10% per minute. Additional

loop volume may be necessary to ensure fluid is not quickly

recirculated back to the chiller before the chiller has

adjusted to the previous change in flow rate and load

condition.

Water loop volume

The loop volume in circulation must equal or exceed 3 gal.

per nominal ton (3.2 L per kW) of cooling for temperature

stability and accuracy in normal air-conditioning applications. In process cooling applications, there should be 6 to

10 gallons per ton (6.5 to 10.8 L per kW). To achieve this

loop volume, it is often necessary to install a tank in the

loop. The tank should be baffled to ensure there is no stratification, and that water (or brine) entering the tank is adequately mixed with liquid in the tank. See Tank installation

drawing.

TANK INSTALLATION

BAD

GOOD

concentration of at least 15 F (8.3 C) below the leaving

fluid temperature set point. If chiller fluid lines are in an

area where ambient conditions fall below 34 F (1.1 C), it is

recommended that an antifreeze solution be added to protect the unit and fluid piping to a temperature 15 F

(8.3 C) below the lowest anticipated temperature. For

corrections to performance, refer to the chiller selection

program.

NOTE: Use only antifreeze solutions approved for heat

exchanger duty. Use of automotive antifreeze is not recommended because of the fouling that can occur once their

relatively short-lived inhibitors break down.

Multiple chillers

Where multiple chillers are required, or where standby

capability is desired, chillers may be installed in parallel.

Units may be of the same or different sizes. However,

evaporator flow rates must be balanced according to the

recommendations of each chiller to ensure proper flow.

Unit software is capable of controlling two units as a single plant. Refer to the Controls, Start-Up, Operation, Service and Troubleshooting guide for further details.

Dual chiller control