Carrier 30XA080-500 User Manual

External Pump Control

Installation Instructions

Part No. 00EFN900003200A

30XA080-500

Accessory

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Configuration (All Sizes) . . . . . . . . . . . . . . . . . . . . . . . . . 2

Test Pump Control Output . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning

equipment can be hazardous due to system pressures, electrical

components, and equipment location.

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on air-conditioning equipment, observe

precautions in the literature, on tags, stickers, and labels

attached to the equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Use care in handling and installing this accessory.

Be sure power to equipment is shut off before performing

installation, maintenance or service. Lock out and safetytag all disconnects. Be aware that there may be more than

one disconnect. Serious personal injury from electric shock

could result.

GENERAL

This accessory provides required components to integrate

control of an external pump into the 30XA chiller control. As

part of the chiller control, the pump will be commanded on

or off based on the chiller operation. The pump will also be

monitored through the chiller control for its status. Any corresponding alarms will be reported if the pump does not operate

normally.

One accessory package is required for 30XA080-500 units.

INSTALLATION

Examine the package contents for correct part numbers. If

any of the components are missing or damaged, file a claim

with the shipping company and notify your Carrier representative. See Table 1 for accessory package contents. Refer to

Fig. 1-3 for wiring details, and see Fig. 4 and 5 for board

mounting locations.

The following material is field-supplied:

• 18 AWG (American Wire Gage) wires for pump control

wiring

• Wire terminals and wire ties

Table 1 — Accessory Package Contents

ITEM

NO.

1 Pump Board 32GB500432E 1

2 Harness Assembly TH70400864 1

3 24 V Circuit Breaker (CB14) HH83ZB001 1

4 No. 8 Screw A6X10004352 4

5 Board Mounting Standoff A6X10004434 4

6 Communication Cable Assembly TH70400852 1

7 Wire Nut HY89TB010 5

8 2-Pin Connector 1757019 1

To install the 30XA external pump accessory complete the

following steps.

1. Disconnect unit power.

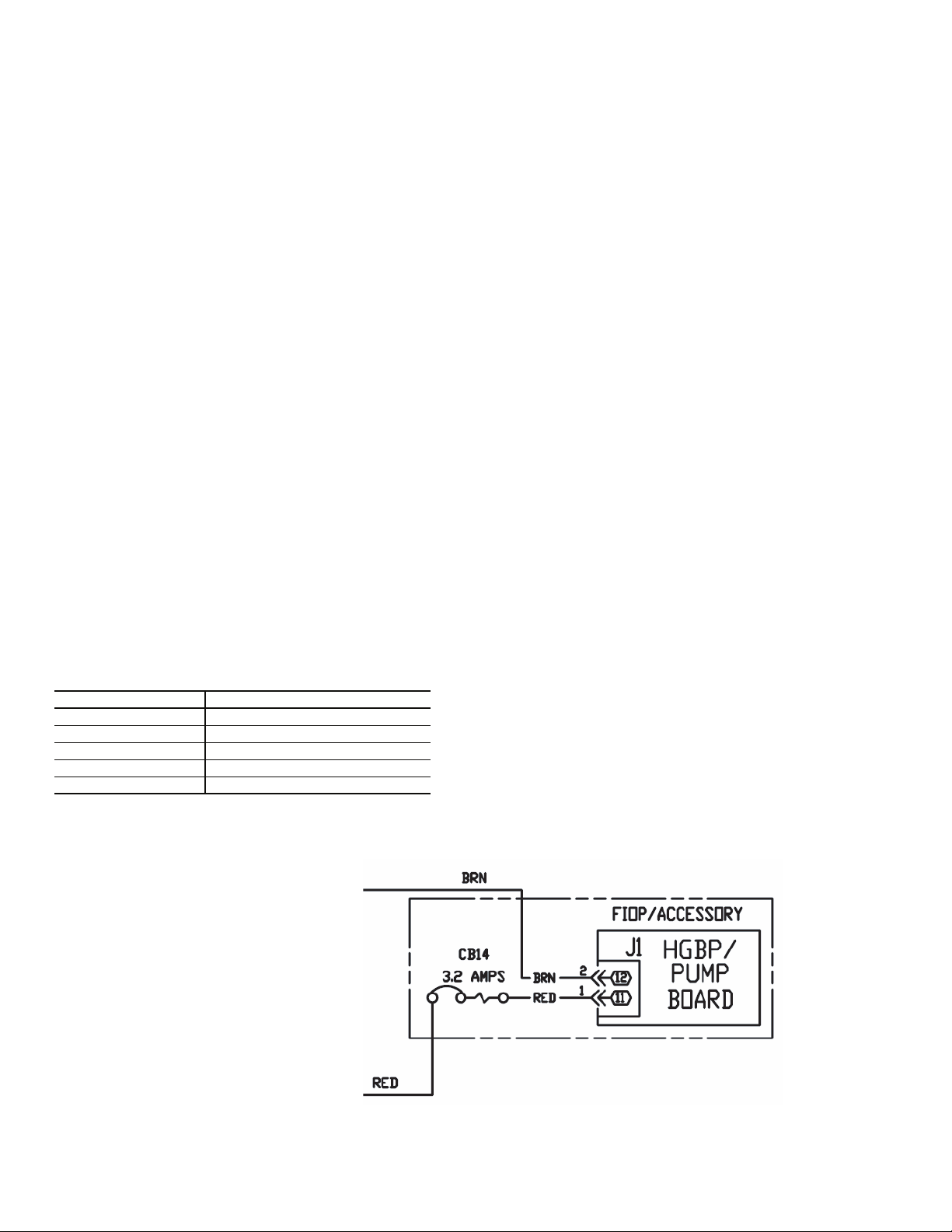

2. Set the board address switch on the pump board as shown

in Fig. 2. Mount the pump board in the main control panel

with the No. 8 screws. See Fig. 4 and 5 for the board

mounting location.

NOTE: Mounting standoffs are required for 30XA080120 units, 200/230, 380v and 30XA140-500 units, all

voltages.

3. Mount the 24 v circuit breaker (CB14) in the CB14

mounting hole on the display mounting bracket. See

Fig. 4 and 5 for the mounting hole location. The display

mounting bracket can be easily removed by loosening the

four mounting screws on the corners.

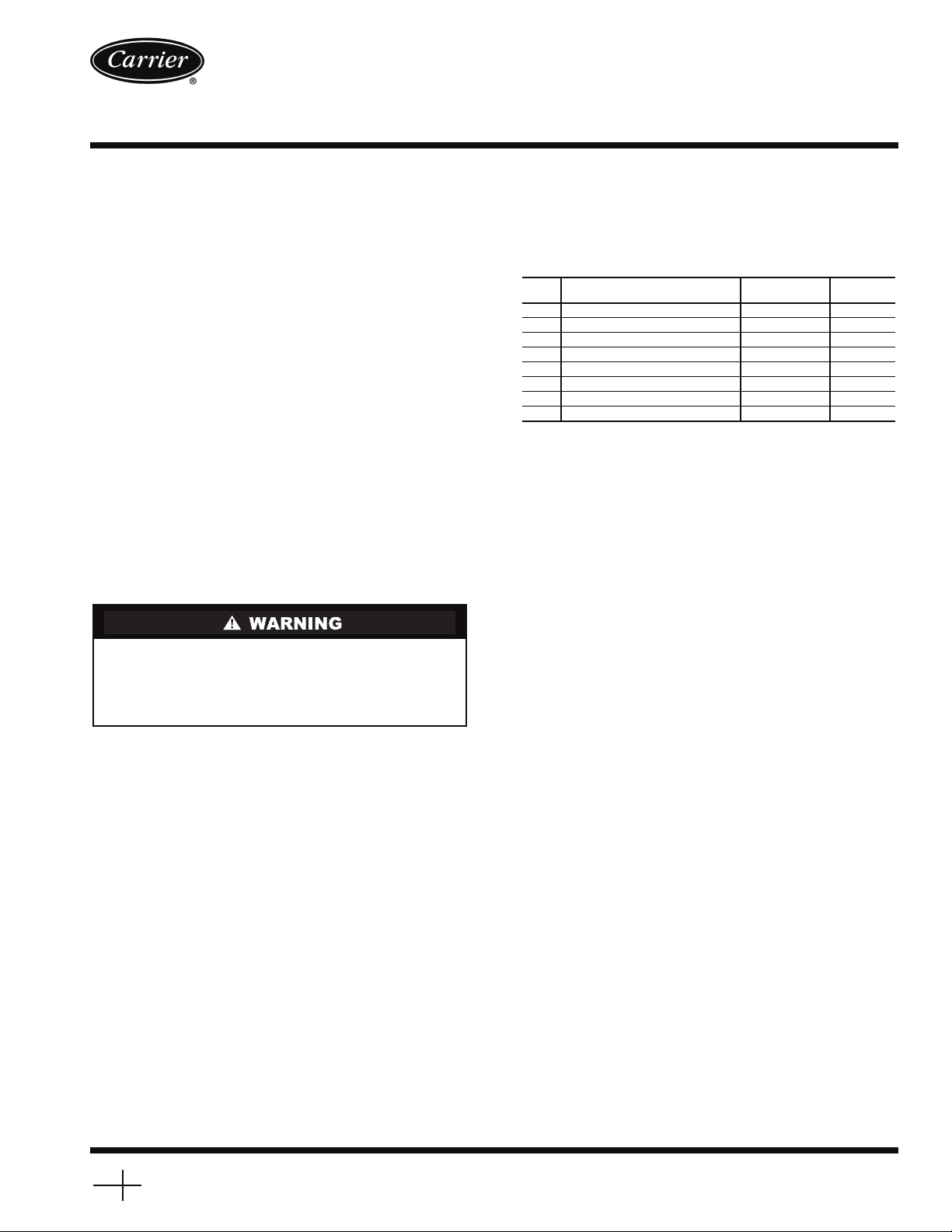

4. Connect the 24 v power from TB10-X1 (30XA080-120

units, 460/575 v only) or TB11-X1 (all other units and

voltages) to CB14 with a red wire in the harness assembly

(Item 2). Find a 2-pin plug marked J1-11,12 with a red

wire and a brown wire in the harness assembly. Connect

the plug to the pump board J1. On the other end, connect

the red wire from the plug to CB14 and the brown wire to

TB10-X2 (30XA080-120 units, 460/575 v only) or

TB11-X2 (all other units and voltages). Refer to Fig. 1.

5. Connect TB5-11, 13 to pump board CH1 and TB5-13, 15

to pump board CH2 per Fig. 2 with the harness assembly

provided (Item 2). Use the pins on the back of TB5.

NOTE: If only one pump is available in the system (no

backup pump), the wiring for pump board CH2 is not

required.

6. For 30XA080-120, 200/230 v, 380 v and all 30XA140-500

units, disconnect the 3-pin plug on MBB (main base board)

J9B (or EMM board J9A) for communication and plug it in

to the pump board J9. Use the communication cable assembly (Item 6) to connect between pump board J9 and MBB

J9B (or EMM board J9A when EMM board exists). The

communication cable in the TH70400864 harness will not

be used. For 30XA080-120, 460 v, and 575 v units, connect

the 3-pin plug of the communication cable in the harness

assembly (Item 2) to the pump board J9 and splice the other

end of the cable to the communication network using the

wire nuts provided (Item 7). Be sure to splice the wires

with the same color together to ensure correct polarity.

DESCRIPTION PART NO. QUANTITY

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

Catalog No. 04-53300013-01 Printed in U.S.A. Form 30XA-8SI Pg 1 9-06 Replaces: New

7. Wire the coils of pump contactors (PMP1-A1, A2 and

PMP2-A1, A2) to TB5-11 and 13 (pump 1) and TB5-13

and 15 (pump 2) as shown in Fig. 2 with field-supplied

18 AWG wires and wire terminals.

NOTE: If only one pump is available in the system (no

backup pump), the wiring for PMP2 is not required.

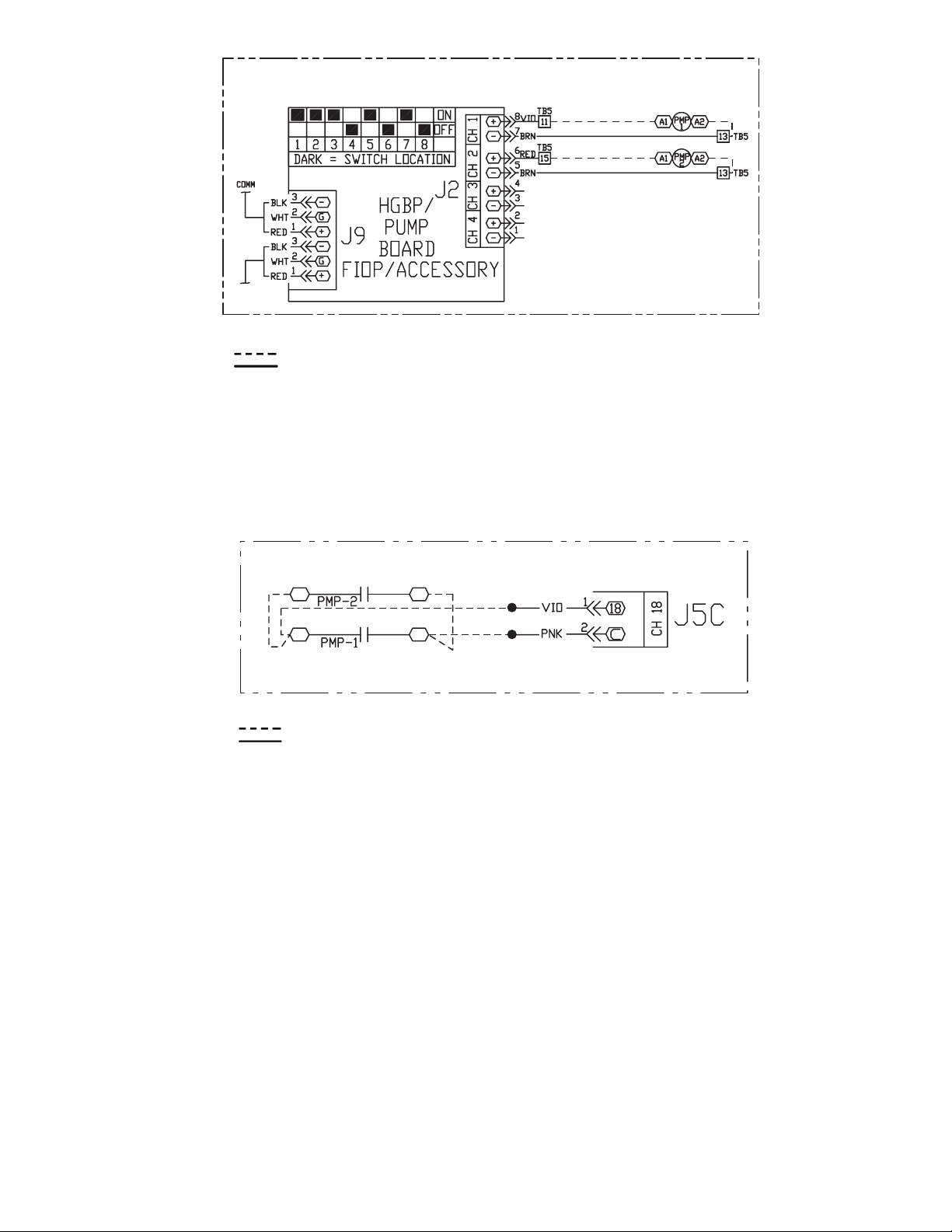

8. Locate the main base board in the main control panel.

Refer to Fig. 3. Near CH18 (J5C) of the board, there are

violet and pink wires tied up outside the wire duct terminated with wire nuts. These wires are for pump auxiliary

contact wiring. Remove the wire nuts and connect the two

wires to the pump auxiliary contacts per Fig. 3 with fieldsupplied wiring. Some units may not be supplied with the

J5C connector and the violet and pink wires. A 2-pin connector (Item 8) is supplied if these parts are not present.

Wire the pump contactor auxiliary contacts to the 2-pin

connector. Insert the 2-pin connector into MBB-J5C.

NOTE: If only one pump is available in the system (no

backup pump), the wiring for PMP-2 is not required.

Configuration (All Sizes) — The control must be

configured for pump control operation. Use the Navigator™ or

the Touch Pilot™ display to configure the system. To configure

the system with the Navigator display, follow the steps below.

1. Set the Enable/Off/Remote switch to OFF position.

2. Press ESCAPE until the Select a Menu Item is displayed

on the screen. Use the arrow key to select the Configuration mode LED.

3. Press ENTER, then use the arrow key to select the

sub-mode ‘OPTN’, press ENTER.

4. Press the down arrow key until ‘PUMP’ is displayed.

5. Press the ENTER key twice. The word ‘PASS’ and

‘WORD’ will flash.

6. Press 0 1 1 1 then ENTER key so that ‘0’ flashes.

7. Use arrow keys to change value to one of the descriptions

in Table 2.

Table 2 — Pump Control Configuration Options

CONFIGURATION DESCRIPTION

0 No Pump Control

1 1 Pump Only

2 2 Pumps Auto*

3 PMP 1 Manual

4 Pump2 Manual*

*Used with dual pumps.

8. The unit is now configured for pump control.

To configure the system with the Touch Pilot display, follow

the steps below.

1. Ensure the unit is in Local Off operating mode by looking

at the left upper corner of the group display. If the unit is

not in Local Off mode, push the Start/Stop (0/1) button to

switch it to the Local Off mode.

2. Push the Main Menu button on the bottom line of display,

and then follow the path Config

→

USER to the USER

table.

3. Scroll down the screen by pushing scroll down button or

page down button until Cooler Pumps Sequence is

displayed. Push Cooler Pumps Sequence and the Point

Data menu will display.

4. Push the Modify button within the Point Data menu. If

the login menu displays, log in with the password of

3333, then press the OK button to confirm the input. The

value of CCN variable cpumpseq will display. Enter 1, 2,

3, or 4 per Table 2 and press the OK button to confirm the

input.

5. Push the Home button. A save confirmation menu will

display. Press the OK button to confirm.

6. The unit is now configured for pump control.

Test Pump Control Output — Use the Navigator or

Touch Pilot display, the instructions given in the Controls,

Start-Up, Operation Service and Troubleshooting manual and

the Service Test mode to verify proper operation of pump

output. Be sure to turn off the fuse or circuit breaker for the

pump(s) and verify that the pump contactor(s) is being

energized during the test. For the Navigator display, illuminate

the Service Test LED, enter the TEST mode, enable the test

request, (‘T.REQ’) and test outputs (‘PMP.1’, ‘PMP.2’). For the

Touch Pilot display, from the main menu, follow the

Status

→

QCK_TST1, enable the Quick Test, and test outputs

(‘Water Exchanger Pump 1’, ‘Water Exchanger Pump 2’).

Once the outputs have been tested, the installation is complete.

Return the Enable/Off/Remote contact switch to the desired

position. Restore power to the pumps.

TB10-X2 (080-120 SIZES, 460/575 V)

TB11-X2 (ALL OTHER UNITS)

TB10-X1 (080-120 SIZES, 460/575 V)

TB11-X1 (ALL OTHER UNITS)

Fig. 1 — Pump Board 24 V Power Wiring

a30-4444

2

LEGEND

Field Installed Wiring

Factory Installed Wiring

Fig. 2 — Pump Board Address Switch and Wiring for Pump Output

AUX CONTACTS

a30-4445

AUX CONTACTS

LEGEND

Field Installed Wiring

Factory Installed Wiring

Fig. 3 — Pump Interlock Wiring on Main Base Board

a30-4446

MAIN BASE BOARD

3

Loading...

Loading...