Page 1

AQUASNAP

30RA/RH “B”

30RY/RYH “B”

PRO-DIALOG Control

Operation and maintenance instructions

Page 2

TABLE OF CONTENTS

1 - SAFETY CONSIDERATIONS..................................................................................................................................................4

1.1 - General .................................................................................................................................................................................4

1.2 - Avoid electrocution ..............................................................................................................................................................4

2 - GENERAL DESCRIPTION ......................................................................................................................................................4

2.1 - General .................................................................................................................................................................................4

2.2 - Abbreviations used ...............................................................................................................................................................4

3 - HARDWARE DESCRIPTION..................................................................................................................................................5

3.1 - General .................................................................................................................................................................................5

3.2 - Electrical supply to boards ...................................................................................................................................................5

3.3 - Light emitting diodes on boards...........................................................................................................................................5

3.4 - The sensors ...........................................................................................................................................................................5

3.5 - The output controls...............................................................................................................................................................5

3.6 - Connections at the user's terminal block ..............................................................................................................................6

3.6.1 - General description ......................................................................................................................................................6

3.6.2 - Volt-free contact on/off/cooling/heating without multiplexing ..................................................................................8

3.6.3 - Volt-free contact on/off/cooling/heating with multiplexing........................................................................................8

3.6.4 - Demand limit or setpoint volt-free contact for single-circuit units .............................................................................8

3.6.5 - Demand limit volt-free contact for dual-circuit units ..................................................................................................8

3.6.6 - Water setpoint selection volt-free contact with multiplexing for dual-circuit units....................................................8

4 - SETTING UP PRO-DIALOG CONTROL ..............................................................................................................................9

4.1 - Local interface general features............................................................................................................................................9

4.2 - Unit start/stop control .........................................................................................................................................................10

4.2.1 - Description................................................................................................................................................................. 10

4.2.2 - Stopping the unit in local mode .................................................................................................................................10

4.2.3 - Starting unit and selecting an operating type............................................................................................................. 10

4.3 - Menus .................................................................................................................................................................................11

4.3.1 - Selecting a menu ........................................................................................................................................................11

4.3.2 - Selecting a menu item................................................................................................................................................ 11

4.3.3 - Modifying the value of a parameter/access to a sub-menu........................................................................................11

4.3.4 - Expand display...........................................................................................................................................................12

4.3.5 - Description of the Information menu.........................................................................................................................15

4.3.6 - Description of the Temperatures menu......................................................................................................................17

4.3.7 - Description of the Pressures menu.............................................................................................................................17

4.3.8 - Description of the Setpoints menu............................................................................................................................. 17

4.3.9 - Description of the Inputs menu..................................................................................................................................18

4.3.10 - Description of the Outputs/Tests menu ...................................................................................................................19

4.3.11 - Description of the configuration menu ....................................................................................................................22

4.3.12 - Description of the Alarms menu ..............................................................................................................................28

4.3.13 - Description of the Alarms History menu .................................................................................................................28

4.3.14 - Runtime menu description .......................................................................................................................................28

2

Page 3

5 - PRO-DIALOG CONTROL OPERATION ............................................................................................................................29

5.1 - Start/stop control ................................................................................................................................................................29

5.2 - Heating/cooling operation ..................................................................................................................................................30

5.2.1 - General.......................................................................................................................................................................30

5.2.2 - Heating/cooling selection ..........................................................................................................................................30

5.3 - Evaporator water pump control ..........................................................................................................................................31

5.4 - Control interlock contact ....................................................................................................................................................31

5.5 - Evaporator heater control ................................................................................................................................................... 31

5.6 - Control point.......................................................................................................................................................................31

5.6.1 - Active setpoint ...........................................................................................................................................................31

5.6.2 - Reset...........................................................................................................................................................................33

5.7 - Demand limit ......................................................................................................................................................................33

5.8 - Night mode .........................................................................................................................................................................33

5.9 - Capacity control..................................................................................................................................................................33

5.10 - Head pressure control .......................................................................................................................................................33

5.11 - Defrost function................................................................................................................................................................34

5.12 - Additional electric heater stage control ............................................................................................................................34

5.13 - Control of a boiler ............................................................................................................................................................34

5.14 - Master/slave assembly...................................................................................................................................................... 34

5.15 - Controlling Pro-Dialog units with a System Manager .....................................................................................................34

6 - DIAGNOSTICS - TROUBLESHOOTING ............................................................................................................................35

6.1 - General ...............................................................................................................................................................................35

6.2 - Displaying alarms...............................................................................................................................................................35

6.3 - Resetting alarms .................................................................................................................................................................35

6.4 - Alarm codes........................................................................................................................................................................35

Each of the following drawings is replaced in the whole document by the corresponding explanation:

GENERAL LEGEND

Start/stop button

Return key

Down arrow

Up arrow

DELTA T. Example: temperature difference between entering and leaving heat exchanger temperatures

means character is flashing

The cover graphics are solely for illustration and forms no part of any offer for sale or any sale contract. The manufacturer

reserves the right to change the design at any time without notice.

3

Page 4

1 - SAFETY CONSIDERATIONS

2 - GENERAL DESCRIPTION

1.1 - General

Installation, start-up and servicing of equipment can be

hazardous if certain factors particular to the installation are not

considered: operating pressures, presence of electrical

components and voltages and the installation site (elevated

plinths and built-up up structures). Only properly qualified

installation engineers and highly qualified installers and

technicians, fully trained for the product, are authorised to

install and start-up the equipment safely. During all ser vicing

operations all instructions and recommendations which appear

in the installation and service instructions for the product, as

well as on tags and labels fixed to the equipment and

components and accompanying parts supplied separately, must

be read, understood and followed.

• Apply all standard safety codes and practices.

• Wear safety glasses and gloves.

• Use the proper tools to move heavy objects. Move units

carefully and set them down gently.

1.2 - Avoid electrocution

Only personnel qualified in accordance with IEC (International

Electrotechnical Commission) recommendations may be

permitted access to electrical components. It is particularly

recommended that all sources of electricity to the unit be shut

off before any work is begun. Shut off the main power supply

at the main circuit breaker or isolator.

IMPORTANT: This equipment uses and emits

electromagnetic signals. Tests have shown that the equipment

conforms to all applicable codes with respect to

electromagnetic compatibility.

RISK OF ELECTROCUTION: Even when the main circuit

breaker or isolator is switched off, certain circuits may still

be energised, since they may be connected to a separate power

source.

RISK OF BURNS: Electrical currents cause components to

get hot either temporarily or permanently. Handle power

cable, electrical cables and conduits, terminal box covers and

motor frames with great care.

Fan start-up:

ATTENTION: In accordance with the operating conditions

the fans can be cleaned periodically. A fan can start at any

time, even if the unit has been shut down.

2.1 - General

Pro-Dialog is a system for controlling single or dual-circuit

30RA/RY air-cooled liquid chillers or air-to-water 30RH/RYH

heat pumps. Pro-Dialog controls compressor start-up needed to

maintain the desired heat exchanger entering or leaving water

temperature. In cooling mode it controls the operation of the fans

to maintain the correct condensing pressure in each circuit. For

heat pump units it controls and optimises the defrost cycles of

each circuit in order to minimize the heating capacity

reduction. Safety devices are constantly monitored by ProDialog to ensure their safe operation. Pro-Dialog also gives

access to a Quick Test program covering all inputs and outputs.

All PRO-DIALOG controls can work in accordance with three

independent modes:

• Local mode: the machine is controlled by commands from

the user interface.

• Remote mode: the machine is controlled by remote

contacts (volt-free contacts).

• CCN mode: the machine is controlled by commands from

the Carrier Comfort Network (CCN). In this case, a data

communication cable is used to connect the unit to the

CCN communication bus.

The operating mode must be chosen with the Start/Stop button

described in section 4.2.1. When the PRO-DIALOG system

operates autonomously (Local or Remote mode) it retains all of

its own control capabilities but does not offer any of the

features of the CCN network.

2.2 - Abbreviations used

In this manual, the refrigeration circuits are called circuit A and

circuit B. The compressors in circuit A are labelled A1, A2 and

A3. Those in circuit B are B1, B2 and B3.

The following abbreviations are used fr equently:

CCN : Carrier Comfort Network

CCn : Operating type: CCN

LED : Light Emitting Diode

LOFF : Operating type: Local Off

L-On : Operating type: Local On mode

L-Sc : Operating type: Local On following a time schedule

MASt : Operating type: master unit (master/slave assembly)

rEM : Operating type: by remote contacts

SCT : Saturated Condensing Temperature

SIO : Sensor Bus (internal communication bus linking the

basic board to the slave boards)

SST : Saturated Suction Temperature

TXV : Thermal Expansion Valve

4

Page 5

3 - HARDWARE DESCRIPTION

5

6

8

3.2 - Electrical supply to boards

3.1 - General

Figure 1

4

1

9

3

10

Legend

1 CCN connector

2 Red LED, status of the board

3 Green LED, communication bus SIO

4 Orange LED, communication bus CCN

5 Remote master board customer control connection contacts

6 Remote slave board customer control connection contacts

7 Master board customer connection relay outputs

8 Slave board customer connection relay outputs

9 Master NRCP basic board

10 Slave NRCP basic board

3

2

The control system consists of an NRCP-BASE board for

single-circuit units and two NRCP-BASE boards (a master and

a slave board) for dual-circuit units. Heat pump units equipped

with optional additional heater stages use an additional board,

type PD-AUX. All boards communicate via an internal SIO bus.

The NRCP-BASE boards continuously manage the information

received from the various pressure and temperature probes. The

NRCP-BASE master board incorporates the program that

controls the unit.

The user interface consists of two display blocks with up to 26

LEDs and 16 buttons (according to unit type). It is connected

to the main basic board and gives access to a full array of

control parameters.

All boards, except the PD-RCPM board, are supplied from a

common 24 V a.c. supply referred to earth.

CAUTION: Maintain the correct polarity when connecting

the power supply to the boards, otherwise the boards may be

damaged.

In the event of a power supply interrupt, the unit restarts

automatically without the need for an external command.

However, any faults active when the supply is interrupted are

saved and may in certain cases prevent a circuit or unit from

restarting.

3.3 - Light emitting diodes on boards

All boards continuously check and indicate the proper

operation of their electronic circuits. A light emitting diode

(LED) lights on each board when it is operating properly.

• The red LED flashing for a 2 second period on the NRCPBASE board indicates correct operation. A different rate

indicates a board or a software failure.

• On dual-circuit units or units equipped with optional

board, the green LED flashes continuously on all boards

to show that the board is communicating correctly over its

internal bus. If the LED is not flashing, this indicates a

SIO bus wiring problem.

• The orange LED of the master board flashes during any

communication via the CCN bus.

3.4 - The sensors

Pressure sensors

Two types of electronic sensors are used to measure the suction

and discharge pressure in each circuit.

Thermistors

The evaporator water sensors are installed in the entering and

leaving side. The outdoor temperature sensor is mounted below

the control box. An optional water system temperature sensor

can be used for master/slave assembly control (in the case of

leaving water control).

In heat pump units a sensor placed on an air heat exchanger

pipe ensures defrost operation.

5

Page 6

3.5 - The controls

3.6 - Connections at the user's terminal block

Evaporator pumps

The controller can regulate one or two evaporator pumps and

takes care of automatic change-over between pumps.

Evaporator heater

It protects the evaporator (and the pipe heater for units without

pump) against freezing if the unit is off.

Boiler

This relay output authorises start/stop of a boiler.

Condensate defrost heater

This heater is used for heat pump units and is located at the

bottom of the air heat exchanger of each circuit. It prevents ice

build-up, if defrost cycles are initiated at low outdoor

temperatures.

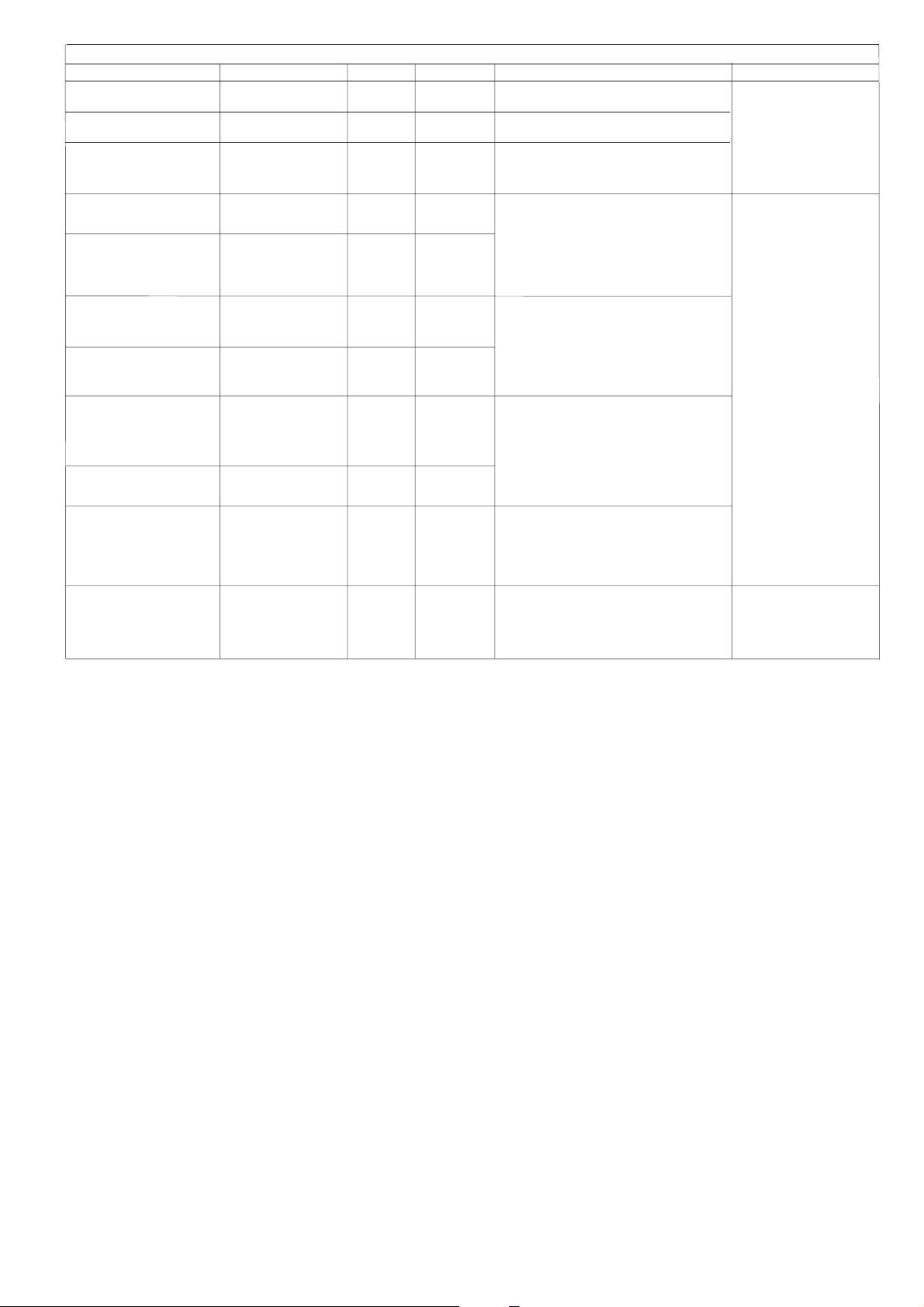

SINGLE-CIRCUIT UNITS

Description

Alarm relay output

Boiler relay output

Connector/channel

J3 / CH24

J3 / CH25

Terminal

30 - 31

37 - 38

Board

NRCP-BASE

NRCP-BASE

3.6.1 - General description

The contacts below are available at the user's terminal block on

the NRCP-BASE board (see figure 1). Some of them can only

be used if the unit operates in remote operating type (rEM).

The following table summarises the connections at the user’s

terminal block.

Remarks

Indicates alarms

Boiler start/stop control output.

See section 5.13.

Remarks

Volt-free contact 24 V a.c.

48 V d.c. max, 20 V a.c. or

V d.c., 3 A max, 80 mA min,

external power supply .

Contact 1:

start/stop/heat/cool

Contact 2:

start/stop/heat/cool

Contact 3:

demand limit selection or

setpoint selection

User safety loop input

Connection to CCN

J4 / CH8

J4 / CH9

J4 / CH10

J4 / CH11a

J12

32 - 33

63 - 64

73 - 74

34 - 35

1 - 2 - 3

NRCP-BASE

NRCP-BASE

NRCP-BASE

NRCP-BASE

NRCP-BASE

The contacts are used for unit start/stop and

heat/cool control. The y are only taken into

account if the unit is under remote operation

control (rEM).

See the description of these contacts in

sections 3.6.2 and 3.6.3.

Depending on the configuration, this dry

contact can be used for remote setpoint

selection or demand limit selection (see

sections 4.3.11.3 and 3.6.4).

- The remote setpoint selection contact is

only taken into account if the unit is in

remote control operating type.

- The remote demand limit selection contact

is active whatever the operating type of the

unit.

This contact is mounted in series with the

water flow control contact. It can be used for

any customer safety loop that requires that

the unit is stopped, if it is open.

If it is unused this contact must be bridged.

An RS-485 bus is used for connection to the

CCN.

- Pin 1: signal +

- Pin 2: ground

- Pin 3: signal -

Connector: 4 pin

WAGO 734-104 pitch 3.5.

One per board needed.

24 V a.c., 20 mA

Connector: 8 pin WAGO

734-168, pitch 3.5

Connector: 3 pin WAGO

231-303, pitch 5.08

6

Page 7

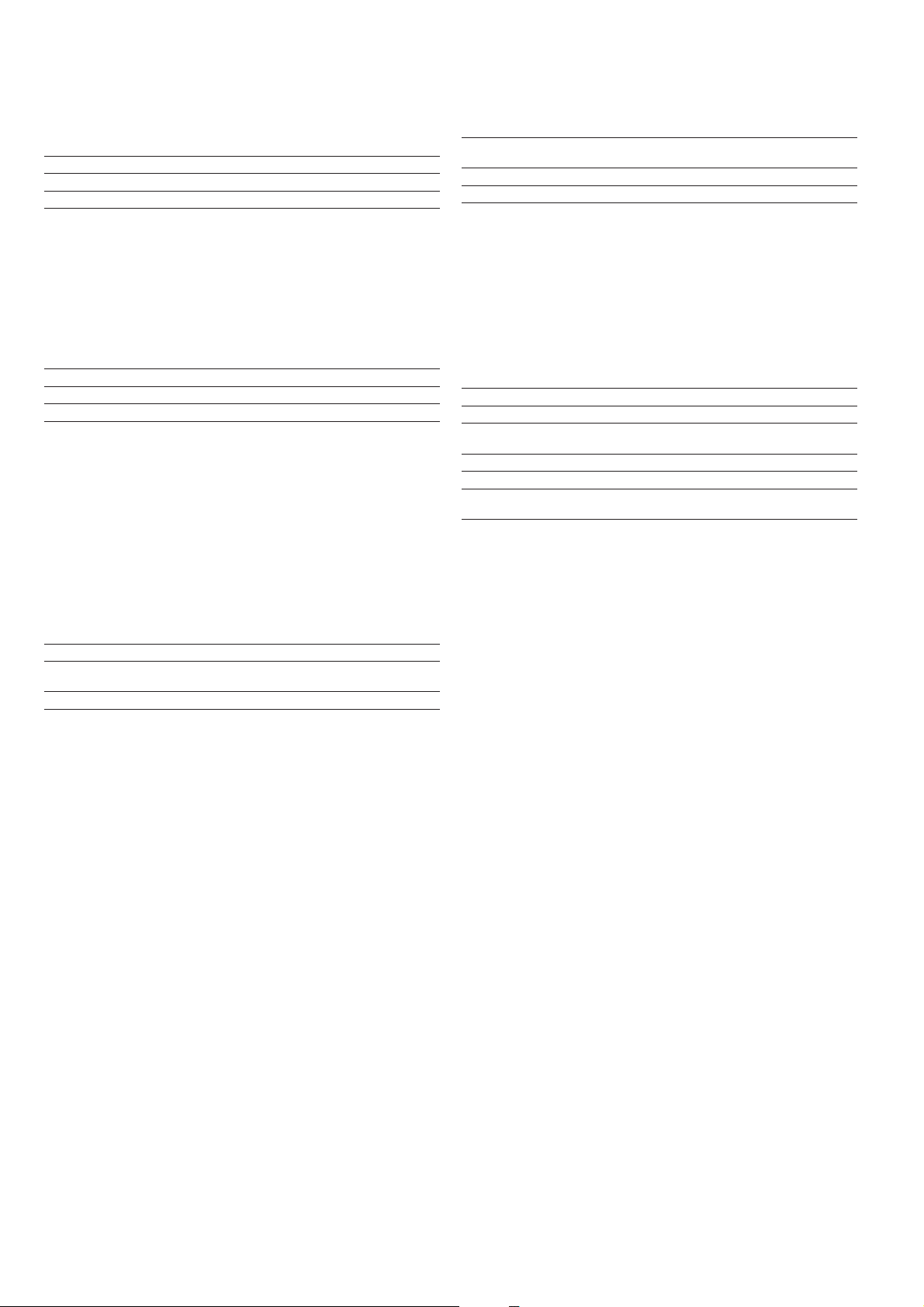

DUAL-CIRCUIT UNITS

Description

Alarm relay output

circuit A

Alarm relay output

circuit B

Boiler relay output

Contact 1:

start/stop/heat/cool

Contact 2:

start/stop/heat/cool

Contact 3:

demand limit selection

Contact 4:

demand limit selection

Contact 5:

setpoint selection

Control contact 6:

setpoint selection

User safety loop input

Connection to CCN

Connector/channel

J3 / CH24

J3 / CH24

J3 / CH25

J4 / CH8

J4 / CH9

J4 / CH10

J4 / CH10

J4 / CH8

J4 / CH9

J4 / CH11a

J12

Terminal

30A - 31A

30B - 31B

37 - 38

32 - 33

63 - 64

73 - 74

75 - 76

65 - 66

67 - 68

34 - 35

1 - 2 - 3

Board

Master NRCPBASE

Slave NRCPBASE

Master NRCPBASE

Master NRCPBASE

Master NRCPBASE

Master NRCPBASE

Slave

NRCP-BASE

Slave

NRCP-BASE

Slave

NRCP-BASE

Master

NRCP-BASE

Master

NRCP-BASE

Remarks

Indicates alarms/alerts f or circuit A*

Indicates alarms/alerts f or circuit B*

Boiler start/stop control output.

See section 5.13.

The contacts are used for unit start/stop and

heat/cool control. The y are only taken into

account if the unit is under remote operation

control (rEM).

See the description of these contacts in

sections 3.6.2 and 3.6.3.

These dry contacts are used for demand

limit selection. See description of these

contacts in section 3.6.5.

The remote demand limit selection contact is

active whatever the operating type of the

unit.

These dry contacts are used for setpoint

selection.

They are only taken into account if the unit is

in remote control operating type (rEM).

See the description of these contacts in

sections 3.6.6.

This contact is mounted in series with the

water flow control contact. It can be used for

any customer safety loop that requires that

the unit is stopped, if it is open.

If it is unused this contact must be bridged.

An RS-485 bus is used for connection to the

CCN.

- Pin 1: signal +

- Pin 2: ground

- Pin 3: signal -

Remarks

Volt-free contact 24 V a.c.

48 V d.c. max, 20 V a.c. or

V d.c., 3 A max, 80 mA min,

external power supply .

Connector: 4 pin

WAGO 734-104 pitch 3.5.

One per board needed.

24 V a.c., 20 mA

Connector: 8 pin WAGO

734-168, pitch 3.5

Connector: 3 pin WAGO

231-303, pitch 5.08

* The operation of these relays can vary depending on the user configuration. See section ‘Description of the User 2 configuration sub-menu’.

7

Page 8

3.6.2 - Volt-free contact on/off/cooling/heating without

multiplexing

If the automatic heating/cooling changeover function is not

selected (see sections 4.3.11.3, 5.1 and 5.2) the operation of

contacts 1 and 2 is as follows:

OFF ON cooling ON heating

Contact 1 Open Closed Closed

Contact 2 - Open Closed

Contact status not significant

3.6.3 - Volt-free contact on/off/cooling/heating with

multiplexing

If the automatic heating/cooling changeover function is

selected (see sections 4.3.11.3, 5.1 and 5.2) the operation of

contacts 1 and 2 is multiplexed:

OFF ON cooling ON heating ON auto

Contact 1 Open Closed Closed Open

Contact 2 Open Open Closed Closed

NOTE: The automatic changeover function (ON auto) selects

the cooling or heating mode based on the outdoor

temperature (see section 5.2).

3.6.5 - Demand limit volt-free contact for dual-circuit units

On dual-circuit units the operation of the demand limit

selection contacts is multiplexed. The demand limit setpoints are

adjustable in the setpoint menu (see section 4.3.8).

100% Limit 1 Limit 2 Limit 3

(no limit)

Contact 3 Open Closed Open Closed

Contact 4 Open Open Closed Closed

3.6.6 - Water setpoint selection volt-free contact with

multiplexing for dual-circuit units

On dual-circuit units the operation of the cold water or hot

water setpoint selection contacts is multiplexed. The set-points

are adjustable in the setpoint menu (see section 4.3.8). Auto

means that the active setpoint is determined by the setpoint

schedule (see section 5.6.1).

Cooling mode

Setpoint 1 Setpoint 2 Setpoint 3 Auto

Contact 5 Open Open Closed Closed

Contact 6 Open Closed Open Closed

Heating mode

Setpoint 1 Setpoint 2 Setpoint 3 Auto

Contact 5 Open Open Closed Closed

Contact 6 Open Closed Open Closed

3.6.4 - Demand limit or setpoint volt-free contact for singlecircuit units

On single-circuit units contact 3 determines the selection of

demand limit or setpoint, based on the configuration (see User

Configuration 1 menu).

Demand limit selection Setpoint selection

100% Limit 1 Setpoint 1 Setpoint 2

(no limit)

Contact 3 Open Closed Open Closed

8

Page 9

4 - SETTING UP PRO-DIALOG CONTROL

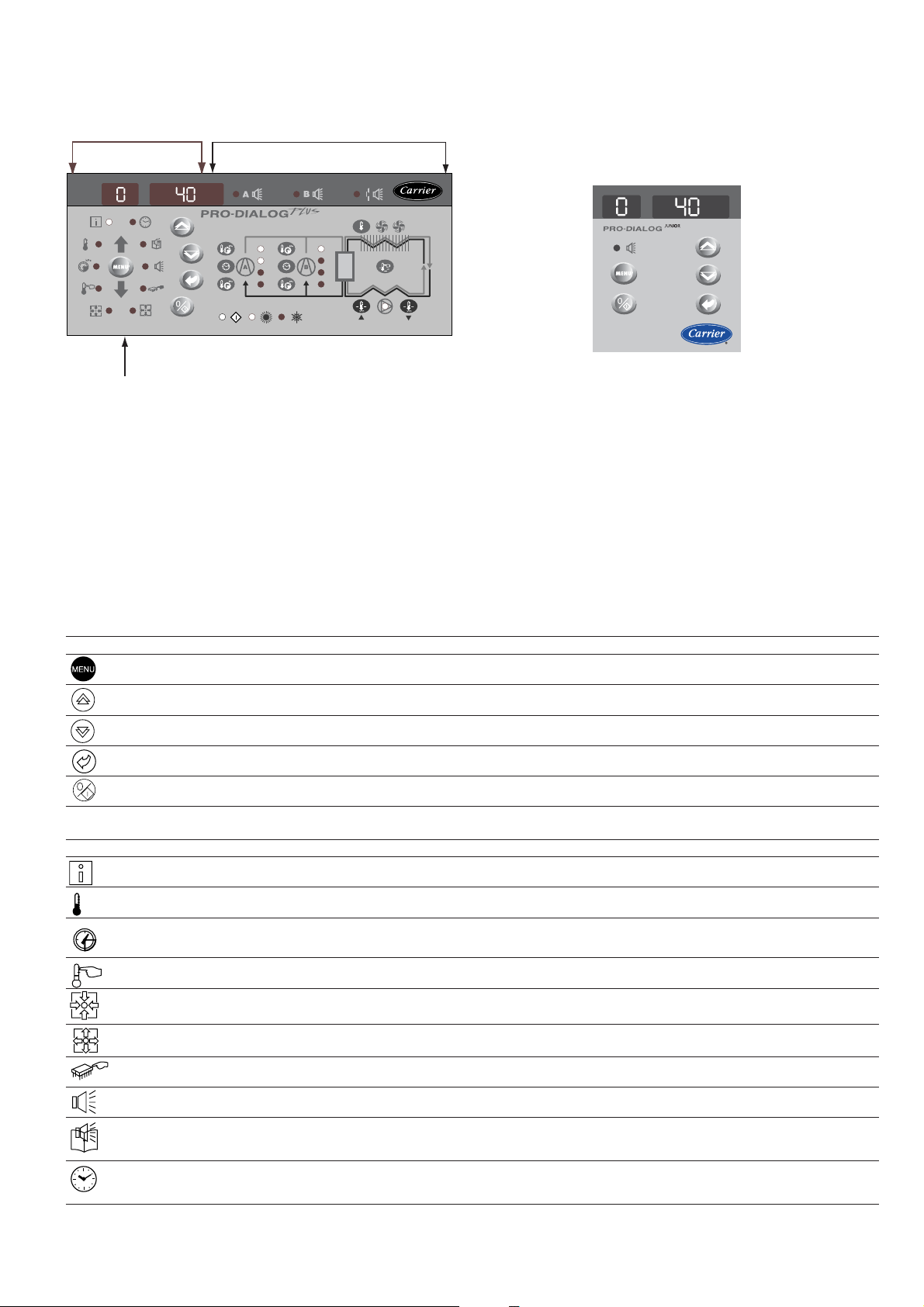

4.1 - Local interface general features

MAIN INTERFACE SUMMARY INTERFACE

MENU BLOCK

PRO-DIALOG PLUS INTERFACE

The local interface enables a number of operating parameters to

be displayed and modified.

• A two-digit display showing the number of the item

selected.

PRO-DIALOG JUNIOR INTERFACE

• A four-digit display showing the contents of the item

The interface consists of two distinct parts: the main interface

(left-hand section) and the summary interface (right-hand section).

selected.

• LEDs and buttons for unit start/stop, menu selection,

menu item selection and value adjustment.

Main interface

It gives access to all PRO-DIALOG data and operating functions.

It consists of:

PRO-DIALOG Junior interface: On some units the local user

interface consists only of a simplified main interface (left-hand

section) that is identical to the main interface described below,

but does not include the menu block diodes.

MAIN INTERFACE

BUTTON NAME DESCRIPTION

Menu Permits the selection of a main menu. Each main menu is represented by an icon. The icon is lit if active.

Up arrow Permits scrolling through the menu items (in the two-digit display). If the modification mode is active this button authorises

Down arrow Permits scrolling through the menu items (in the two-digit display). If the modification mode is active this button authorises

Enter Gives access to the modification mode, validates a modification or displays expanded item description.

Start/stop Authorises start or stop of the chiller in local mode or modification of its operating type.

MAIN INTERFACE MENU LED'S

LED* NAME DESCRIPTION INTERFACE DISLAY

INFORMATION menu Displays the general operating parameters for the unit. Information

increase of the value of any parameter.

decrease of the value of any parameter.

TEMPERATURES menu Displays the unit operating temperatures. Temperatures

kPa

* Not available on the PRO-DIALOG Junior interface.

PRESSURES menu Displays the unit operating pressures. Pressures

SETPOINTS menu Displays the unit setpoints and enables them to be modified. Setpoints

INPUTS menu Displays the status of the unit digital and analogue inputs. Inputs

OUTPUTS/TESTS menu Displays the status of the unit outputs and enables them to be tested. Outputs

CONFIGURATIONS menu Displays the unit configuration and enables it to be modified. Confguration

ALARMS menu Displays active alarms. Alarms

ALARMS HISTORY menu Displays the history of the alarms. History

RUNTIMES menu Displays the operating times and number of starts for the unit and the Runtimes

compressors.

9

Page 10

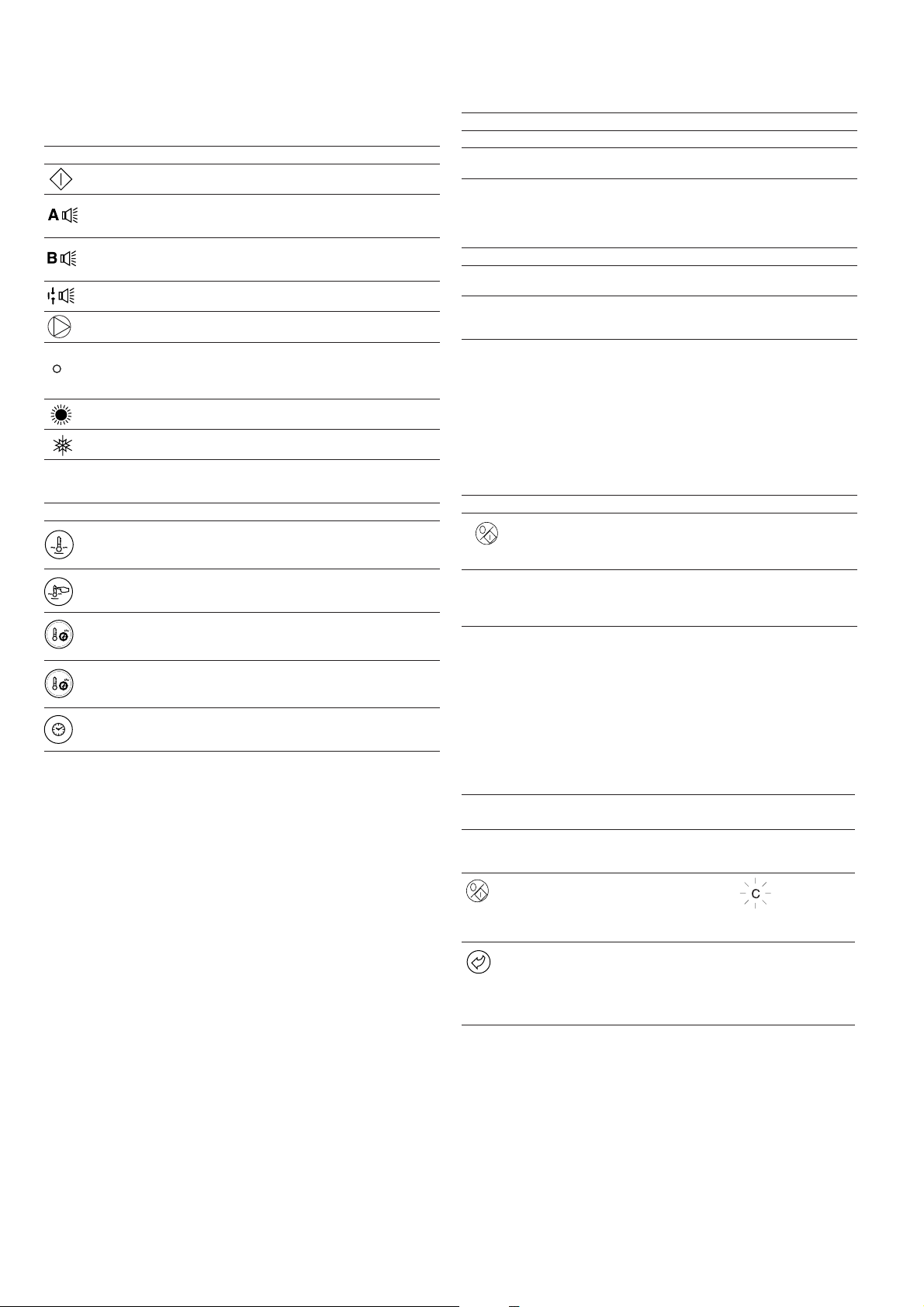

The summary interface (right hand section) includes a mimic

diagram of the unit, together with push-buttons and LEDs. It

gives quick access to the main operating parameters of the unit.

SUMMARY INTERFACE LEDs*

LED INDICATION WHEN LIT

Green LED:

The unit is authorised to start or is already running

Red LED:

- Lit: circuit A or unit shut down by alarm

- Flashing: circuit A or unit running with alarm present

Red LED:

- Lit: circuit B or unit shut down by alarm

- Flashing: circuit B or unit running with alarm present

Red LED:

Water flow switch default or user safety loc k open.

Green LED:

The evaporator pump is running.

Yellow LEDs:

From top to bottom - start/stop status of compressor A1, A2 and A3

or B1, B2 and B3. Flashing LED indicates that the circuit is in the

protection or defrost mode (A or B).

Green LED:

The unit operates in heating mode.

Green LED:

The unit operates in cooling mode.

* Not available on the PRO-DIALOG Junior interface.

SUMMARY INTERFACE PUSH BUTTONS*

BUTTON DISPLAY

Blue button: evaporator leaving or entering water temperature in °C

Gray button: outdoor air temperature in °C

Control point (setpoint + reset) in °C

Press 1: circuit A/B discharge pressure in kPa

Press 2: circuit A/B saturated condensing temperature in °C

Press 1: circuit A/B suction pressure in kPa

Press 2: circuit A/B saturated suction temperature in °C

Press 1: compressor A1/B1 operating hours in h/10 or h/100

Press 2: compressor A2/B2 operating hours in h/10 or h/100

Press 3: compressor A3/B3 operating hours in h/10 or h/100

* Not available on the PRO-DIALOG Junior interface.

4.2 - Unit start/stop control

4.2.1 - Description

The unit start/stop can be controlled by one of the following

methods:

• Locally on the actual unit (Local control type)

• By remote control with the aid of user contacts (remote

control type)

• By CCN control with the aid of the CCN (CCN control

type)

The main interface includes a Start/Stop button which can be

used to stop or start the unit in the local operating type or to

select the remote or CCN operating type.

The following operating types can be selected using the

Start/Stop button:

OPERATING TYPES

4 DIGIT DISPLA Y DESCRIPTION

LOFF Local Off. The unit is halted in local mode.

L-On Local On. The unit is in local control mode and is

L-Sc* Local On - timer control. The unit is in local control

CCN* CCN. The unit is controlled by CCN commands.

rEM* Remote. The unit is controlled b y remote control

MAST* Master Unit. The unit runs as a master in a two unit

Legend

* Displayed if the configuration requires it.

Section 5.1 gives a more detailed description of the commands to start/stop

the unit, analysed by operating type.

authorised to start.

mode. It is authorised to start if the period is occupied.

If the timer program for unit operation is unoccupied,

the unit remains shut down until the period becomes

occupied.

contacts.

lead/lag arrangement. This is displayed if the unit is

configured for master/slave control.

4.2.2 - Stopping the unit in local mode

The unit can be stopped in local mode at any time by pressing

the Start/Stop button.

TO STOP THE UNIT

BUTTON ACTION 2-DIGIT DISPLAY 4-DIGIT DISPLAY

Press the Start/Stop C LOFF

button for less than

4 seconds (one short

press is enough).

If the button is t LOFF

released, the unit stops

without the need for

further action.

4.2.3 - Starting unit and selecting an operating type

The unit can be started in local mode, or unit operating type

can be changed at any time using the Start/Stop button. In the

example that follows, the unit is stopped (LOFF) and the user

wants to start the unit in local mode.

START UP WITH THE PREVIOUSLY USED OPERA TING TYPE WHEN THE UNIT

IS STOPPED IN LOCAL MODE (LOFF)

BUTTON ACTION

The unit is in local stop mode. The

previously used operating type is local on

(L-ON)

Press the Start/Stop button for 4 seconds

(one short press-down is sufficient). L-ON

illuminates immediately. "C" flashes in the

2-digit display to show that the controller is

awaiting confirmation.

Press the Enter button to confirm the

operating type. "t" is displayed in the 2-digit

display to indicate the operating type

selected. If the Enter button is not pressed

soon enough, the controller will cancel the

change and remain in the stop mode.

2-DIGIT 4-DIGIT

DISPLAY DISPLAY

LOFF

L-On

t L-On

The available operating types are described in the following

table.

10

Page 11

CHANGING THE OPERATING TYPE

BUTTON ACTION

Continually press the operating type

selection button for more than 4 seconds.

Hold down the Start/Stop button.

The available operating types are displayed

one by one until the button is released.

Release the Start/Stop button if the

operating type you want is displayed (in this

example L-On). "C" flashes in the 2-digit

display to show that the controller is

awaiting confirmation.

Press the Enter button to confirm the

operating type selected (in this example:

L-On). "t" is displayed in the 2-digit display

to indicate the operating type selected. If the

Enter button is not pressed soon enough,

the controller will cancel the change and

continue to use the previous operating type.

2-DIGIT 4-DIGIT

DISPLAY DISPLAY

C LOFF

L-On

L-Sc

rEM

L-On

t L-On

4.3 - Menus

4.3.1 - Selecting a menu

The MENU button authorises you to select a menu from the 10

main menus that are available. Each time you press this button

one of the 10 LEDs lights up in turn alongside each of the

icons representing a main menu. The active menu is the one

against which the LED is lit. If a menu is empty then its LED is

not lit. To scroll quickly through the menus, hold the MENU

button down.

4.3.3 - Modifying the value of a parameter/access to a submenu

Press the Enter button for more than 2 seconds to enter the

modification mode or to select a sub-menu. This lets you correct

the value of an item or select a sub-menu with the aid of the up

and down Arrow buttons (if you are authorised to overwrite the

item concerned). When modification mode is activated, the LED

for the main menu to which the item belongs as well as the 2digit display flash in the menu block. Once the required value is

obtained, press the Enter button again to validate the c hange or

to acc e s s t h e sub-m e nu. The LED for the menu to which the

item and the 2-digit display belong then stops flashing,

indicating that modification mode no longer applies.

In modification mode, the value to be modified increases or

decreases in steps of 0.1 every time you press the Arrow

buttons. Holding one of these buttons down increases the rate

of increase or decrease.

NOTE: The access to a sub-menu may require entering a

password. This is automatically requested. See section

4.3.11.2.

The following example shows how to modify the value of item

1 in the Setpoint menu.

4.3.2 - Selecting a menu item

The up and down Arrow buttons let you scroll through the

menu items. Menu item numbers are displayed in the two-digit

display. The item number increases or decreases every time you

press the up or down Arrow button. The menu items that are not

in use or incompatible with the configuration are not displayed.

The value or status associated with the active item is displayed

in the four-digit display. To scroll quickly through the items,

hold the up or down Arrow button down.

The following example shows how to access item 3 in the

Pressures menu.

SELECTING A MENU ITEM

OPERATION PRESS MENU LED ITEM NUMBER

Press the MENU button until the 0

LED marked PRESSURE lights.

Note: On the PRO-DIALOG Junior

interface the menu LEDs are not

available. Instead, each time the

menu button is pressed, the name

of the active menu is dsplayed in

the 4-digit display. In this example,

press the MENU button until

PRESSURE is displayed in the

4-digit display.

BUTTON 2-DIGIT

DISPLAY

kPa

Press one of the Arrow buttons 1

until the two-digit display shows 3

(item number 3).

kPa

2

3

11

Page 12

4.3.4 - Expand display

Pressing the Enter button causes a 23 character text expansion to

be scrolled across the four-digit display. All user menus

provide an expansion of the current displayed parameters. If

the expansion is complete the four-digit display reverts to item

value. This function can be inhibited through the User

Configuration menu.

MODIFYING THE VALUE OF A PARAMETER

OPERA TION PRESS BUTTON MENU LED ITEM NUMBER ITEM VALUE

Hold on the MENU button until the LED for SETPOINT lights.

PRO-DIALOG Junior interface: Press the menu button, until SETPOINTS is

displayed in the 4-digit display

Press one of the Arrow buttons until the two-digit display shows 1

(item number 1- cooling setpoint 2).

The value for setpoint 2 is displayed in the four-digit display (6.0°C in this

example).

2-DIGIT DISPLAY 4-DIGIT DISPLAY

0

0 SEtPoint

1

1 6.0

Press the Enter button for more than 2 seconds to enable the value associated

with item 1 to be modified.

The Setpoint menu LED and the two-digit displa y flash indicating that modification

mode is active.

Keep pressing the Down Arro w b utton until the value 5.7 is displa y ed in the f ourdigit display. The Setpoint menu LED and the two-digit displa y keep flashing.

Press the Enter button again to validate the change. The new setpoint is 5.7°C .

The Setpoint menu LED and the two-digit display stop flashing, indicating that

modification mode no longer applies.

1

1

1

1

1 5.7

6.0

5.9

5.8

5.7

12

Page 13

MENU STRUCTURE

MAINTENANCE

[MAintEnAnCE]

ALARMS

RUNTIME 2

[RuntiME 2]

RUNTIME 1

[RuntiME 1]

[FACtorY]

FACTORY

SERVICE

[SErviCE]

SUB-SUB-MENUS

SUB-MENUS

HSM

[HSM]

[MAStEr SLAvE]

MASTER/SLAVE

[SErviCE 2]

SERVICE 2

[SErviCE 1]

SERVICE 1

[brodCASt]

BROADCAST

NOTE: The items in brackets show what is

displayed on the user interface.

MAIN MENUS

USER

[USEr]

[dAtE]

HOUR + DATE

[HoLidAy]

HOLIDAYS

SCHEDULE 2

[SCHEduLE 2]

SCHEDULE 1

[SCHEduLE 1]

USER 2

[USEr 2]

USER 1

[USEr 1]

[HoLidAy 1]

HOLIDAYS 1

[PEriod 1]

PERIOD 1

[PEriod 1]

PERIOD 1

[HoLidAy 3]

[HoLidAy 2]

HOLIDAYS 3

HOLIDAYS 2

[PEriod 3]

PERIOD 3

[PEriod 2]

PERIOD 2

[PEriod 3]

[PEriod 2]

PERIOD 3

PERIOD 2

SUB-SUB-SUB-MENUS

[HoLidAy 4]

HOLIDAYS 4

[PEriod 4]

PERIOD 4

[PEriod 4]

PERIOD 4

[HoLidAy 5]

HOLIDAYS 5

[PEriod 5]

PERIOD 5

[PEriod 5]

PERIOD 5

[HoLidAy 7]

HOLIDAYS 6

[PEriod 6]

PERIOD 6

[PEriod 6]

PERIOD 6

[HoLidAy 7]

HOLIDAYS 7

[PEriod 7]

PERIOD 7

[PEriod 7]

PERIOD 7

[HoLidAy 8]

HOLIDAYS 8

[PEriod 8]

PERIOD 8

[PEriod 8]

PERIOD 8

- - -

- - -

- - -

[HoLidAy15]

HOLIDAYS 15

[HoLidAy16]

HOLIDAYS 16

TATUS TEMPERATURES PRESSURES SETPOINTS INPUTS OUTPUTS CONFIGURATION ALARMS ALARMS HISTORY

13

Page 14

Menu tree structure

RUNTIMES

SUB-MENU:

Runtimes 1

SUB-MENU:

Runtimes 2

ALARMS HIST

Historic alarm code

1**

Historic alarm code

2**

ALARMS

Number of active

alarms/resets**

Active alarm code 1**

SUB-MENU:

Maintenance--

Historic alarm

code 3**

Historic alarm code

4**

Historic alarm code

Active alarm code 2**

Active alarm code 3**

Active alarm code 4**

-

-

5**

Historic alarm code

6**

Historic alarm code

Active alarm code 5**--

-

7**

Historic alarm code

8**

-

-

-

Historic alarm code

9**

Historic alarm code

10**--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

MENU

CONFIG

SUB-MENU: User

Configuration (USEr)

SUB-MENU:

Service Configuration

OUTPUTS

Compressor status

circuit A

Compressor status

circuit B*

INPUTS

Contact 1: on/off/

heating/cooling

Contact 2: on/off/

heating/cooling

SETPOINTS

Cooling setpoint 1

Cooling setpoint 2

PRESSURES

Discharge pressure

circuit A

Suction pressure

circuit A

(SErviCE)

SUB-MENU:

Factory Configuration

(FACtorY)--

Two-speed fan

status circuit A

Two-speed fan

Contact 3: demand

limit/setpoint

selection

Contact 4: demand

Heating setpoint 1*

Heating setpoint 2*

Discharge pressure

circuit B*

Suction pressure

-

status circuit B*

Single-speed fan

status, crt A + B*

Water pump 1

limit selection*

Contact 5: setpoint

selection*

Contact 6: setpoint

Heating setpoint 3*

Auto changeover

circuit B*--

-

-

status*

Water pump 2

status*

Water heat

selection*

Safety loop status

Water pump

threshold (heating

mode)*

Auto changeover

threshold (cooling

mode)*

Setpoint demand

-

-

-

-

exchanger + air heat

exchanger heater

status, circuit A-Alarm circuits A and

operation contact

status*

Fault contact, com-

pressor, circuit A*

Fault contact, com-

limitation 1*

Setpoint demand

limitation 2*

Setpoint demand

-

-

-

B status

Boiler status*

pressor, circuit B*--

limitation 3*

Ramp loading*

-

-

-

-

Speed, fan A in %*

Speed, fan B in %*

Reversing valve,

circuit A*

-

-

Cooling - zero reset

threshold*

Cooling - full reset

threshold*

Cooling - full reset

value*

-

-

-

-

-

-

Reversing valve,

circuit B*

Status, heater

stages*

Local interface test

-

-

-

Heating - zero reset

threshold*

Heating - full reset

threshold*

Heating - full reset

value*

-

-

-

14

TEMP

Evaporator water

entering temp.

Evaporator water

STATUS

Default display

Mode

1

0

ITEM

leaving temp.

Outdoor tempera-

ture

Chiller occupied

mode*

2

Saturated discharge

temperature circuit

A

Saturated suction

temp. circuit A

Saturated discharge

Minutes left

Cooling/heating

selection*

Cooling/heating

3

4

5

temperature circuit

B*

Saturated suction

temp. circuit B*

Defrost temperature,

status*

Unit capacity in%Capacity circuit

6

7

circuit A*

A in %*

Defrost temperature,

circuit B*

System water

temperature*--

Capacity circuit

B in %*

Heater stages in

%*

Present demand

8

9

10

limit in %

Present lag limit

in %*

11

-

-

-

Setpoint in local

control*

Setpoint

occupied mode*

Active setpoint

12

13

14

-

-

Control point

Controlled water

temperature

15

16

Legend

* Displayed if the configuration requires it

** Displayed if the alarm exists

- Not in use

Page 15

4.3.5 - Description of the Information menu

INFORMATION MENU (3)

ITEM FORMAT UNITS

0

±nn.n °C

LOFF L-On L-Sc CCn rEM MASt -

OFF rEADY dELAY -

StOPPing running triPout OvErridE dEFrOSt -

OCCUPIEd UNOCCUPIEd -

COOL HEAT StAndbY BotH -

ALArM ALErt -

MAStEr SLAvE -

1 [1] nn

-

2 [2] -

occu

unoc

Forc

3 nn.n minutes

4 [2] -

HEAt COOL Auto -

5 [2]

HEAt COOL StbY both -

Forc 6 nnn %

7 nnn %

8 [2] nnn %

9 [2] nnn %

10 nnn

Forc %

11 [2] nnn %

12 [2] -

SP-1

SP-2

SP-3

AUtO

13 [2] -

occu

unoc

Forc

DESCRIPTION

Automatic display mode. It cycles through the following displays:

1: Controlled water temperature: temperature of the water that the unit tries to maintain at the control point.

2: Unit operating type

Local Off

Local On

Local On - based on unit clock. Displayed if the CCN/clock board is installed.

CCN Control. Displayed if the CCN/clock board is installed.

Remote Control

Master unit

3: Unit status

Off: Unit is stopped and not authorised to start.

Ready: Unit is authorised to start

Delay: Unit is in delay at start-up. This delay is active after the unit has been switched on. The delay can be

configured in the User Configuration menu.

Stopping: Unit is currently stopping.

On: Unit is running or authorised to start.

Fault shutdown.

Limit: The operating conditions do not allo w total unit operation.

Defrost: One circuit is in defrost mode.

4. Unit occupied/unoccupied status

Occupied: Unit in occupied mode

Unoccupied: Unit in unoccupied mode

5. Heating/cooling operating mode

Cooling: Unit operates in cooling mode

Heating: Unit operates in heating mode

Standby: Unit is in auto cooling/heating changeover mode, and is in standby

Both: The unit operates in cooling (compressors) and heating (boiler). Only with HSM operation.

6: Alarm mode

Alarm: Unit is totally stopped because of failure.

Alert: Unit is in failure but not completely stopped.

7: Master/Slave status

Master: The master/slave control is active and the unit is the master

Slave: The master/slave control is active and the unit is the slave

Active mode codes. Each active mode is displayed in turn. This Item is masked when nil. Pressing the enter button when a mode

code is displayed causes a character text expansion to be scrolled accross the four-digit display. See the description in the following

table

This item indicates the current unit occupied/unoccupied mode. Displayed if the CCN/clock board is installed.

Occupied

Unoccupied

The value is displayed in turn with 'Forc' when the unit is in CCN control and if this variable if forced through CCN.

Start-up delay. This item indicates the minutes left before the unit can be started. This delay at start-up is alw ays active after the unit

has been switched on. The delay can be configured in the User Configuration 1 menu.

Heating/cooling on selection: This item is accessible in read/write, if the unit is in local control mode. It is only displayed, if the unit is

in LOFF, L-On or L-Sc operating type. Display ed for heat pumps or if the unit controls a boiler.

Heating mode selection

Cooling mode selection

Automatic heating/cooling mode changeover selection. Only displayed if the auto changeover function is selected (User Configuration

1 menu).

Heating/cooling mode. This item indicates whether the unit is in cooling or heating. Displayed if the unit controls a boiler.

Heating

Cooling

Standby: Unit is in auto cooling/heating changeover mode, and is in standby.

Both: The unit operates in cooling (compressors) and heating (boiler). Only with HSM operation.

The value is displayed in turn with 'Forc' when the unit is in CCN control and if this variable if forced through CCN.

Total active capacity of unit. It is the percentage of compressor capacity used by the unit.

Total active cap acity of circuit A. It is the percentage of compressor capacity used by on circuit A..

Total active capacity of circuit B. It is the percentage of compressor capacity used by on circuit B. Dual-circuit units only.

Active electric heating stages. Only displayed for heat pumps and if the unit controls additional electric heating stages.

Present demand limit. This is the authorised operating capacity of the unit. See section 5.7.

The value is displayed in turn with 'Forc' when the unit is in CCN control and if this variable if forced through CCN.

Present lag chiller demand limit. Displayed when the master/slave control is selected.

Setpoint select in local mode. This point is read/write accessible. Displayed only when the unit is LOFF, L-On or L-Sc operating type.

SP-1 = cooling/heating setpoint 1

SP-2 = cooling/heating setpoint 2

SP-3 = heating setpoint 3

AUtO = active setpoint depends on schedule 2 (setpoint selection schedule). See section 5.6.1 & 4.3.11.6.

Setpoint occupied mode. Displayed if the CCN/clock board is installed.

Occupied: cooling setpoint 1 is active

Unoccupied: cooling setpoint 2 is active

The value shall be displayed in turn with 'Forc' when the unit is in CCN control and if this variable if forced through CCN.

15

Page 16

INFORMATION MENU (3) continued

ITEM FORMAT UNITS

14 ±nn.n °C

15 ±nn.n

Forc °C

16 ±nn.n °C

1 This item is masked when nil.

2 This item is displayed in certain unit configurations only.

3 Access to this menu is read-only except for item 10 that can be forced when the unit is in Local operating type.

DESCRIPTION OF OPERATING MODES (ITEM 1 OF THE INFORMATION MENU)

MODE # MODE NAME

1 Delay at start-up active

2 2nd cooling/heating setpoint active

3 3rd heating setpoint active

4 Setpoint reset active

5 Auto heating/cooling changeover

active

6 Demand limit active

7 Ramp loading active

8 Water or air heat exchanger

heater active

9 Evaporator pump reversal in effect

10 Evaporator pump periodic start

11 Night condensing mode

12, 13 Low suction temperature protection

14, 15 High pressure protection

16, 17 Defrost

18 Low water entering temperature

protection in heating mode

19, 20 Hot gas protection in heating mode

21, 22 Low suction temperature protection

in heating mode

23 Boiler active

24 Electric heating stages active

25 Unit in SM control

26 Master/slave link active

27 Low outside temperature protection

DESCRIPTION

Active setpoint. This is the current cooling/heating setpoint: it refers to cooling setpoint 1 or cooling/heating setpoint 2. See section

5.6.1.

Control point. This is the setpoint used by the controller to adjust the temperature of the leaving or entering w ater (according to

configuration).

Control point = active setpoint + reset. See section 5.6

The value is displayed in turn with 'Forc' when the unit is in CCN control and if this variable if forced through CCN.

Controlled water temperature. Water temperature that the unit tries to maintain at the control point.

DESCRIPTION

The delay at start-up operates after the unit has been switched on. If the delay has not expired, the mode is

active. The delay is configured in the User Configuration 1 menu.

The second cooling/heating setpoint is active. See section 5.6.1

The third heating setpoint is active. See section 5.6.1

In this mode, the unit uses the reset function to adjust the leaving water temperature setpoint. See section 5.6.

If the unit is in auto mode, the heating/cooling changeover is automatic, based on the outdoor temperature. See

section 5.2.

In this mode, the demand at which the unit is authorised to operate is limited. See section 5.7.

Ramp loading is active. In this mode, the rate of water temperature drop or rise (heating mode) in °C/min is limited

to a preset value in order to prevent compressor overloading. Ramp function must be configured (see User

Configuration 1 menu). Ramp values can be modified (see Setpoint menu).

The water or air heat exchanger heater is active. See section 5.5.

The unit is fitted with two evapor ator water pumps and reversal between pumps is in effect. See section 5.3.

The unit is stopped and the pump is started each day at 14.00 p.m. for two seconds. This function needs to be

configured in the User Configuration 1 menu. See section 5.3 & 4.3.11.3.

The night mode is active. Fan runs at low speed (if permitted by operating conditions) and unit capacity can be

limited. See section 5.8 & 4.3.11.3.

12 = circuit A & 13 = circuit B. Protection f or evaporator low suction temperature circuit is active. In this mode,

circuit capacity is not authorised to rise and the circuit can be unloaded.

14 = circuit A & 15 = circuit B. The unit is in cooling or heating mode. The circuit is in high pressure protection

mode because the HP protection threshold has been exceeded. Circuit has been unloaded and the circuit

capacity is not authorised to rise.

16 = circuit A & 17 = circuit B. The unit is in heating mode, and the defrost sequence is active on the relevant

circuit.

The unit is in heating mode and compressor start is not authorised, as the entering water temperature is below

10°C.

19 = circuit A & 20 = circuit B. The unit is in heating protection mode and hot gas discharge protection is active. In

this mode, the circuit capacity cannot increase, and the circuit may be unloaded or go into defrost mode.

21 = circuit A & 22 = circuit B. The unit is in heating mode and low suction temperature protection is active. In this

mode, circuit capacity is not authorised to rise and the circuit can be unloaded or go into defrost mode.

The unit controls a boiler and this is operating. See section 5.13.

The unit controls additional electric heating stages, and these are operating. See section 5.12.

Unit is in control of a System Manager (FSM, CSM III or HSM).

Unit is connected to a secondary unit by a master slave link and the master/slave modes are active.

The unit is in heating mode, and compressor start-up is not permitted, when the outside air temperature is lower

than the value configured in item 12 of the User 1 configuration menu. See the relevant section.

16

Page 17

4.3.6 - Description of the Temperatures menu

4.3.7 - Description of the Pressures menu

TEMPERATURES MENU [2]

ITEM FORMAT UNITS COMMENTS

0 ±nn.n °C Water heat exchanger entering water tempera-

1 ±nn.n °C Water heat exchanger leaving water tempera-

2 ±nn.n °C Outdoor temperature

3 ±nn.n °C Saturated discharge temperature, circuit A

4 ±nn.n °C Saturated suction temperature, circuit A

5 [1] ±nn.n °C Saturated discharge temperature, circuit B

6 [1] ±nn.n °C Saturated suction temperature, circuit B

7 [1] ±nn.n °C Defrost temperature, circuit A

8 [1] ±nn.n °C Defrost temperature, circuit B

9 [1] ±nn.n °C Chilled water system temperature. Used for

1 This item is displayed in certain unit configurations only

2 Access to this menu is read-only.

ture

ture

master/slave control.

4.3.8 - Description of the Setpoints menu

SETPOINTS MENU [2]

ITEM FORMAT UNITS RANGE

0 ±nn.n °C See table below

1 ±nn.n °C See table below

2 nnn °C See table below

3 [1] nnn °C See table below

4 [1] nn.n °C See table below

5 [1] ±nn.n °C 3.8 to 50

6 [1] ±nn.n °C 0 to 46

7 nnn % 0 to 100

8 [1] nnn % 0 to 100

9 [1] nnn % 0 to 100

10 ±nn.n °C/min 0.1 to 1.1

11 [1] ±nn.n °C See table below

12 [1] ±nn.n °C See table below

13 [1] ±nn.n °C See table below

14 [1] ±nn.n °C See table below

15 [1] ±nn.n °C See table below

16 [1] ±nn.n °C -16 to 16

COMMENTS

This item lets you display and modify Cooling setpoint 1*

This item lets you display and modify Cooling setpoint 2*

This item lets you display and modify Heating setpoint 1*, only display ed for heat pumps.

This item lets you display and modify Heating setpoint 2*, only display ed for heat pumps.

This item lets you display and modify Heating setpoint 3*, only display ed for heat pumps.

Automatic changeover threshold, cooling mode. This item lets you display and modify the outdoor

temperature threshold at which the unit changes over in cooling mode. See section 5.2. Displayed only if

the auto cooling/heating changeover function is selected.

Automatic changeover threshold, heating mode. This item lets you display and modify the outdoor

temperature threshold at which the unit changes over in heating mode. Displayed only if the auto cooling/

heating changeover function is selected and if the unit is a heat pump. The heating threshold must be

3.8°C below the cooling threshold, otherwise the new setpoint will be rejected.

Demand limit 1 setpoint. Limitation by volt-free contact. This item is used to define the maximum

capacity that the unit is authorised to use, if the demand limit contact(s) activate limit 1. Contact control

depends on the unit type and configuration. See sections 3.6.4 and 3.6.5.

Demand limit 2 setpoint. Limitation by volt-free contact. This item is used to define the maximum

capacity that the unit is authorised to use, if the demand limit contact(s) activate limit 2. Contact control

depends on the unit type and configuration. Displayed and used only for dual-circuit units. See section

3.6.5 for the contact control description.

Demand limit 3 setpoint. Limitation by volt-free contact. This item is used to define the maximum

capacity that the unit is authorised to use, if the demand limit contact(s) activate limit 3. Displayed and

used only for dual-circuit units. See section 3.6.5 for the contact control description.

Cooling or heating ramp loading rate. This parameter is only accessible if the ramp function is

validated in the User Configuration 1 menu. This item refers to the rates of temperature drop in °C in the

evaporator. When capacity loading is effectively limited by the ramp, mode 7 is active.

Zero reset threshold, cooling mode**

Full reset threshold, cooling mode**

Full reset value, cooling mode**

Zero reset threshold, heating mode**

Full reset threshold, heating mode**

Full reset value, heating mode**

PRESSURES MENU [2]

ITEM FORMAT UNITS COMMENTS

0 nnnn kPa Discharge pressure, circuit A .

Relative pressure.

1 nnn kPa Suction pressure, circuit A.

Relative pressure.

2 [1] nnnn kPa Discharge pressure, circuit B.

Relative pressure.

3 [1] nnn kPa Suction pressure, circuit B.

Relative pressure.

1 This item is displayed in certain unit configurations only.

2 Access to this menu is read-only

1 This item is displayed in certain unit configurations only.

2 All points contained in this table can be modified.

* Those setpoints can be used for entering or leaving water temperature control. By default the unit controls the evaporator entering fluid temperature.

Leaving fluid temperature control requires a parameter modification in the Service Configuration menu.

** These parameters are only accessible when reset based on OAT or delta T has been selected in the User Configuration 1 menu. See section 4.3.11.3 & 5.6.2.

17

Page 18

LEAVING WATER TEMPERATURE CONTROL

SETPOINT - °C R-22/R-407C

Minimum cooling value

Water 5.0

Medium brine 0.0

Brine -10.0

Maximum cooling value 20.0

Feedback setpoint, cooling 6.0

Minimum heating value 20.6

Maximum heating value 56.1

Feedback setpoint heating 48.0

ENTERING WATER TEMPERATURE CONTROL

SETPOINT - °C R-22/R-407C

Minimum cooling value

Water 10.0

Medium brine 6.1

Brine -3.9

Maximum cooling value 26.1

Feedback setpoint, cooling 12.0

Minimum heating value 14.4

Maximum heating value 50.0

Feedback setpoint heating 42.0

4.3.9 - Description of the Inputs menu

INPUTS MENU [2]

ITEM FORMAT UNITS

0 oPEn/CLoS -

COMMENTS

Remote contact 1 status.

If the auto cooling/heating changeover function is not selected (User Configuration 1), this contact is used to start and

stop the unit. If the auto cooling/heating changeover function is selected, this contact is multiplexed with contact 2 to

permit starting and stopping the unit and the selection of heating/cooling/auto. This contact is only v alid, if the unit is in

the remote operating control (rEM) mode. See section 3.6 for the description of the connections of this contact.

RESET THRESHOLDS IN COOLING OR HEATING MODE

Reset threshold Zero Full

Reset based on outdoor -10 to 51 °C -10 to 51 °C

air temperature

Reset based on 0 to 11.1 °C 0 to 11.1 °C

Delta T

1 [1] oPEn/CLoS -

2 oPEn/CLoS -

3 oPEn/CLoS -

4 [1] oPEn/CLoS -

5 [1] oPEn/CLoS -

6 [1] oPEn/CLoS -

7 oPEn/CLoS -

8 [1] b1b2b

9 [1] b1b2b

1 This item is displayed in certain unit configurations only

2 Access to this menu is read-only.

3

3

-

-

Remote contact 2 status.

If the auto cooling/heating changeover function is not selected (User Configuration 1), this contact is used to select the

heating or cooling mode. If the auto cooling/heating changeover function is selected, this contact is multiplexed with

contact 1 to permit starting and stopping the unit and the selection of heating/cooling/auto. This contact is only valid, if

the unit is in the remote operating control (rEM) mode. See section 3.6 for the description of the connections of this

contact.

Remote contact 3 status.

The operation of this contact depends on the unit type.

Single-circuit unit: this contact can be used either to limit unit demand or to select a setpoint, as described in User

Configuration. If this contact is used for selecting a setpoint it is only active if the unit is in the remote operating control

mode. If the contact is used to limit the demand of the unit, it is active in all operating types.

Open contact: unit capacity is not limited or unit control is based on setpoint 1.

Closed contact: unit capacity is limited at limit setpoint 1 or unit control is based on setpoint 2.

See section 4.3.11.3 for the configuration of contact 3 - section 5.6.1 for the description of the setpoint selection section 5.7 for the description of the demand limit function and 3.6 for the description of the connection of contact 3 for

single-circuit units.

Dual-circuit units: this contact is multiplexed with contact 4 to permit the selection of a demand limit point. This

contact is active in all operating types. See section 3.6.5 for the description of this contact and section 5.7 for the

description of the demand limit function.

Remote contact 4 status.

This contact is only used for dual-circuit units: this contact is multiplexed with contact 3 to permit selection of a

demand limit value. This contact is active in all operating types. See section 3.6.5 f or the description of this contact

and section 5.7 for the description of the demand limit function.

Remote contact 5 status.

This contact is only used for dual-circuit units: this contact is multiplexed with contact 6 to permit selection of a

setpoint. This contact is only active in the remote operating control mode. See section 3.6.6 for the description of this

contact and section 5.6.1 for the description of the setpoint selection function.

Remote contact 6 status.

This contact is only used for dual-circuit units: this contact is multiplexed with contact 5 to permit selection of a

setpoint. This contact is only active in the remote operating control mode. See section 3.6.6 for the description of this

contact and section 5.6.1 for the description of the setpoint selection function.

Interlock status. When this contact opens the unit stops or is prevented from starting and an alarm is created. This

contact is used to control the water flow . In addition, a customer safety device can be connected in series with this

contact (see section 3.6).

Water pump run contact status. When this contact opens while an evaporator pump has received a command to be

on then a pump failure alarm is tripped.

Compressor feedback contacts, circuit A b1 = feedback A1 b2 = feedback A2 b3 = feedback A3

Compressor feedback contacts, circuit B b1 = feedback B1 b2 = feedback B2 b3 = feedback B3

18

Page 19

4.3.10 - Description of the Outputs/Tests menu

4.3.10.1 - General

This menu displays the status of the controller outputs. Moreover, when the machine is fully stopped (LOFF) the outputs

can be activated for manual or automatic tests (the access to the

tests is password controlled).

4.3.10.2 - Menu description

OUTPUTS STATUS & TESTS MENU [2] [3]

ITEM FORMAT UNITS

0b

1 [1] b1b2b

2 StoP

3 [1] StoP

4 [1] b

5 [1] On

6 [1] On

7On

8b

9 [1] On

10 [1] nnn

11 [1] nnn

12 [1] b

1b2b3

tESt

FAIL

Good -

3

tESt

FAIL

Good -

LOW

HIGH

tESt -

LOW

HIGH

tESt -

1b2

OFF

tESt

FAIL

Good

Forc -

OFF

tESt

FAIL

Good

Forc -

OFF

tESt -

1b2

tESt -

OFF

tESt -

tESt %

tESt %

1b2

tESt

-

DESCRIPTION

Circuit A compressors, command status

b

= compressor A1

1

b2 = compressor A2

b3 = compressor A3

In test mode, the Arrow buttons display 001, 010 and 100 in succession, so as to force the status of the compressor outputs

in turn. During the test phase, power to the compressor is s witched on for 10 seconds only. It is then not possible to restart the

compressor for a further 30 seconds. When the test is completed the following is displayed:

- Fail: displayed if the test has failed because the compressor was not started or run in reverse rotation.

- Good: displayed if test was successful

Circuit B compressor, dual-circuit unit s only

b

= compressor B1

1

b2 = compressor B2

b3 = compressor B3

In test mode... as above

Two-speed fan status, circuit A

Stop = fan is stopped

Low = fan is in low speed

High = fan is in high speed

Two-speed fan status, circuit B

Stop = fan is stopped

Low = fan is in low speed

High = fan is in high speed

Single-speed fan status

b

= fan A2

1

b2 = fan B2

Only for dual-circuit units

Evaporator water pump #1 command status. Not displayed if the unit does not control a pump.

On: pump is running

Stop: pump is stopped

Forc: this item is displayed only when the unit is stopped locally (LOFF). selecting this item authorises turning on the

pump with no delay and for an unlimited length of time. The pump will remain on until any button of the user interface is

pressed: it is then immediately stopped. If the unit is in CCN control, then the pump status is displayed in turn with "Forc"

if the pump status if forced through CCN.

During the test phase, power to the pump is switched on for 10 seconds only. When the test is completed the f ollowing is

displayed:

- Fail: displayed if the test has failed because the pump was not started

- Good: displayed if the test was successful

Evaporator water pump #2 command status. Not displayed if the unit does not control a secondary pump.

On: pump is running

Stop: pump is stopped

Forc: this item is displayed only when the unit is stopped locally (LOFF). selecting this item authorises turning on the

pump with no delay and for an unlimited length of time. The pump will remain on until any button of the user interface is

pressed: it is then immediately stopped. If the unit is in CCN control, then the pump status is displayed in turn with "Forc"

if the pump status if forced through CCN.

During the test phase, ...as above

Water or air heat exchanger heater command status

See sections 5.5 and 5.11

Alarm output command status

b1 = alarm circuit A

b2 = alarm circuit B

In test mode, the Arrow buttons display 01 and 10 in succession, so as to force each alarm output status in turn.

Boiler command status. Displa yed if the unit controls a boiler. See section 5.13.

Variable fan speed, circuit A. Displayed if the unit controls a variable-speed fan.

Variable fan speed, circuit B. Dual-circuits only and if the unit controls a variable-speed fan.

4-way reversing cycle valve status. In test mode, the arrow keys successively display 01 and 10, in order to authorise the

test for each valve in turn.

b1 = valve circuit A

b2 = valve circuit B

This item is only displayed for heat pump units.

19

Page 20

OUTPUTS STATUS & TESTS MENU [2] [3] continued

ITEM FORMA T UNITS

13 [1] b

14 [1] YES -

15 Auto tESt -

1 This item is displayed in certain unit configurations only.

2 Testing authorised only if the unit is in Local Off and all compressors are off.

3 Password needed only for testing.

“Test” Displayed in turn with the item value during tests.

1b2b3b4

tESt

no tESt %

DESCRIPTION

Additional heating stage status.

b

= stage 1

1

b2 = stage 2

b3 = stage 3

b4 = stage 4

In test mode the arrow keys successively display 0001, 0010, 0100 and 1000 to force the status of each electric heating stage

in turn.

This item is only displayed for heat pump units controlling additional electric heater stages. See section 5.12.

Used for local interface test only . Lights or flashes all LEDs and blocks, so as to check that they are working properly .

Automatic test. Selecting this item activates the automatic test function.

4.3.10.3 - Manual tests

This function allows the user to test the outputs individually, if

the machine is completely shut down (LOFF). To carry out a

manual test use the arrow keys to access the output to be tested

and press the Enter key (longer than 2 seconds) to activate the

modification mode. The password is automatically requested, if it

has not previously been verified. The Outputs/Test LED on the

user interface begins to flash. Enter the desired test value and

again press Enter to start the test. 'TESt' is displayed on the 4digit display alternately with the value tested. The Outputs/Test

LED stops flashing. Press the Enter key or an arrow key to stop

the test.

4.3.10.4 - Automatic tests

The automatic test function verifies the integrity of the analogue entries and activates the outputs in sequence. For each test

't XX' is displayed on the user interface. 'xx' indicates the

number of the test in progress. When a test has been completed ,

the following test is automatically activated.

A message may appear, asking the operator for a validation

with the Enter key, if the control cannot automatically verify a

sensor value or an output status. If the value read or the output

status is incorrect, the operator must press a different key (not

the Enter key) to cancel the automatic test procedure.

If a test fails, an error message and an error code are displayed. The automatic test procedure is interrupted.

When all tests have been completed, an end-of-test message

appears.

The table below describes the messages shown on the user

interface during the automatic test sequence.

TEXT DESCRIPTION

Thermistor test failed [XX] Test number XX of the thermistor has failed

Pressure test failed [XX] Test number XX of the pressure sensor has

failed

Output test failed [XX] Output test number XX has failed

Input test failed [XX] Input test number XX has failed

Press enter if test [XX] correct Request for the operator to validate test XX

OAT [value] press enter if Request for the operator to validate the

test [XX] correct outdoor air temperature value displayed.

T est number XX

Auto test completed Automatic test completed

20

Page 21

The table below describes the different sequences of the

automatic test.

TEST NUMBER

0

1

2