Page 1

PRO-DIALOG

AQUASNAP

30RA / 30RH

control

U

A

Q

L

R

I

T

E

Y

T

S

I

G

E

R

S

'

D

Y

O

A

S

S

U

R

A

N

C

E

L

L

•

I

S

1

O

0

9

0

INST ALLA TION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

30RA/30RH

Air-cooled liquid chillers and reversible air-to-water heat pumps

with integrated hydronic module

For the use of the control system, refer to the Pro-Dialog Plus control manual.

Contents

Page

Physical data ................................................................................................................................. 2/3

Electrical data ................................................................................................................................ 2/3

Dimensions and location of hydraulic connections ....................................................................... 4

Clearance and electric cables ....................................................................................................... 4

General information and hydronic module ................................................................................... 5

Water connections......................................................................................................................... 6/8

Electrical connections.................................................................................................................... 9

Refrigerant charge......................................................................................................................... 9/10

Electronic control........................................................................................................................... 10

Start-up .......................................................................................................................................... 11

Compressor replacement.............................................................................................................. 11

Pump replacement ........................................................................................................................ 11

Unit protection devices .................................................................................................................. 11/12

Operating limits and operating range ............................................................................................ 12

Maintenance .................................................................................................................................. 13

Final recommendations ................................................................................................................. 13

Troubleshooting............................................................................................................................. 14

Start-up check list

Start up date _____________________

Equipment sold by: ___________________________________________ Contract No:____________________________

Installed by: _________________________________________________ Contract No:____________________________

Site address _______________________________________________________________________________________

Equipment type and serial No: 30RA___________________________________________________________

30RH___________________________________________________________

ELECTRICAL DA T A:

Supply voltage Ph 1: ____________ V Ph 2:____________ V Ph 3:_____________V

Nominal voltage: ____________________________________ V % network voltage _______________________

Current draw Ph 1: ____________ A Ph 2: ____________ A Ph 3: _____________ A

Control circuit voltage:________________________________ V Control circuit fuse _____________________ A

Main circuit breaker rating_____________________________________________________________________________

PHYSICAL DA T A:

Coil: Plate heat exchanger:

Entering air temp.:_______________________ °C Entering water temp.:__________________ °C

Leaving air temp.: _______________________ °C Leaving water temp.: __________________ °C

Pressure drop (water): _________________ kPa

SAFETY DEVICE SETTING:

High pressure switch: cut-out: _____________ kPa cut-in: _____________________ kPa

ENGLISH

Oil level ___________________________________________________________________________________________

OPTIONS:

Commissioning engineer (name) _______________________________________________________________________

Customer agreement

Name: ________________________________ Date: ______________________________

Note: Complete this start-up list at the time of installation

GB - 1

Page 3

30RA

Physical data and electrical data - Model RA

Table I: Physical data - Model RA

30RA 017 021 026 033

Net cooling capacity* kW 17.70 21.60 25.80 31.70

Operating weight

without hydronic module kg 200 220 250 285

with hydronic module kg 220 240 280 315

Refrigerant charge R-407C kg 4.80 5.13 6.41 7.70

Compressor One scroll compressor

Evaporator One plate heat exchanger

Net water volume l 1.50 1.88 2.16 2.82

Water connections (MPT gas) inches 1 1 1-1/4 1-1/4

Maximum water pressure kPa 1000 1000 1000 1000

(unit without hydronic module)

Hydronic module Pump, mesh filter, expansion tank, flow switch, pressure gauges, automatic air purge valve and drain plug,

Pump One single-speed pump

Available pressure** kPa 138 126 150 138

Water inlet connection (MPT gas) inches 1-1/4 1-1/4 1-1/4 1-1/4

Water outlet connection (MPT gas) inches 1 1 1-1/4 1-1/4

Closed expansion tank water volume l 8 8 8 8

Water fill system (option)

Inlet/outlet diameter (MPT gas) inches 1/2 1/2 1/2 1/2

Condenser One, copper tubes and aluminium fins

Tube diameter inches 3/8 3/8 3/8 3/8

No. of rows 2 3 2 3

Tubes/row 52 52 60 60

Fin spacing mm 1.81 1.81 1.81 1.81

Fan Two,axial type with two speeds

Diameter mm 500 500 610 610

No. of blades 5 5 5 5

Air flow (high speed) l/s 2450 2222 3278 3000

Fan speed (high speed) r/s 12.83 12.91 11.05 10.96

flow control valve and safety valve.

* The ratings indicated refer to an evaporator entering/leaving temperature of 12/7 °C,and air entering the condenser at 35 °C.

** At nominal water flow rate.

Table II: Electrical data - Model RA

30RA 017 021 026 033

Power supply V-ph-Hz 400-3-50 / 400-3-50+N

Voltage range V 360-440

Nominal power input* kW 6.43 8.57 9.56 12.39

Effective power input** kW 6.54 8.72 9.75 12.60

Nominal current drawn* A 10.75 15.50 18.80 24.55

Effective current drawn** A 10.95 15.75 19.10 24.95

Maximum power drawn*** kW 7.87 10.8 12.23 14.95

Maximum current drawn** A 13.50 20.00 22.50 28.00

Starting current A 87 132 134 139

Pump power input kW 0.65 0.68 0.89 0.93

* Based on an outdoor entering air temperature of 35 °C db,an evaporator entering water temperature of 12 °C and an evaporator leaving water temperature of 7 °C,unit without hydronic

module

** The power and current values indicated refer to Eurovent Standard conditions.

*** The power and current values indicated refer to an evaporator leaving water temperature of 10 °C and condenser entering air temperature of 46 °C.

GB - 2

Page 4

30RH

Physical data and electrical data - Model RH

ENGLISH

Table I: Physical data - Model RH

30RH 017 021 026 033

Net cooling capacity* kW 16.70 21.60 24.60 29.00

Net heating capacity** kW 18.80 24.80 27.80 34.00

Operating weight

without hydronic module kg 235 265 285 315

with hydronic module kg 255 285 315 345

Refrigerant charge R-407C kg 7.15 7.84 9.30 11.00

Compressor One scroll compressor

Control system Pro Dialog-Plus

Refrigerant-water heat exchanger One plate heat exchanger

Net water volume l 1.50 1.88 2.16 2.82

Water connections (MPT gas) inches 1 1 1-1/4 1-1/4

Maximum water pressure kPa 1000 1000 1000 1000

(unit without hydronic module)

Hydronic module Pump, mesh filter, expansion tank, flow switch, pressure gauges, automatic air purge valve and drain plug,

Pump One single-speed pump

Available pressure*** kPa 142 125 155 149

Water inlet connection (MPT gas) inches 1-1/4 1-1/4 1-1/4 1-1/4

Water outlet connection (MPT gas) inches 1 1 1-1/4 1-1/4

Drain tap coupling (MPT gas) inches 1/2 1/2 1/2 1/2

Closed expansion tank water volume l 8 8 8 8

Water fill system (option)

Inlet/outlet diameter (MPT gas) inches 1/2 1/2 1/2 1/2

Refrigerant-air heat exchanger One, copper tubes and aluminium fins

Tube diameter inches 3/8 3/8 3/8 3/8

No. of rows 3 2 3 4

Tubes/row 52 60 60 60

Fin spacing mm 1.81 1.81 1.81 1.81

Fan Two, axial type with two speeds

Diameter mm 500 610 610 610

No. of blades 5 5 5 5

Air flow (high speed) l/s 2222 3611 3111 3333

Fan speed (high speed) r/s 12.83 10.83 11.67 11.83

flow control valve and safety valve.

* *The ratings indicated refer to an evaporator entering/leaving temperature of 12/7 °C,and air entering the condenser at 35 °C.

** The ratings indicated refer to a condenser entering/leaving temperature of 40/45 °C,and air entering the condenser at 7 °C d.b.and 6 °C w.b.

*** At nominal water flow rate during cooling.

Table II: Electrical data - Model RH

30RH 017 021 026 033

Power supply V-ph-Hz 400-3-50 / 400-3-50+N

Voltage range V 360-440

Nominal power input* kW 6.21 7.95 9.13 11.83

Effective power input** kW 6.30 8.10 9.30 12.00

Nominal current drawn* A 10.75 14.80 18.70 23.65

Effective current drawn** A 10.90 15.05 19.05 24.00

Maximum power drawn*** kW 7.87 10.8 12.23 14.95

Maximum current drawn*** A 13.50 20.00 22.50 28.00

Starting current A 87 132 134 139

Pump power input kW 0.65 0.68 0.89 0.93

* Based on an outdoor entering air temperature of 35 °C db, an evaporator entering water temperature of 12 °C and an evaporator leaving water temperature of 7 °C, unit without hydronic

module

** The power and current values indicated refer to Eurovent Standard conditions.

*** The power and current values indicated refer to an evaporator leaving water temperature of 10 °C and a condenser entering air temperature of 46 ° C.

GB - 3

Page 5

30RA/30RH

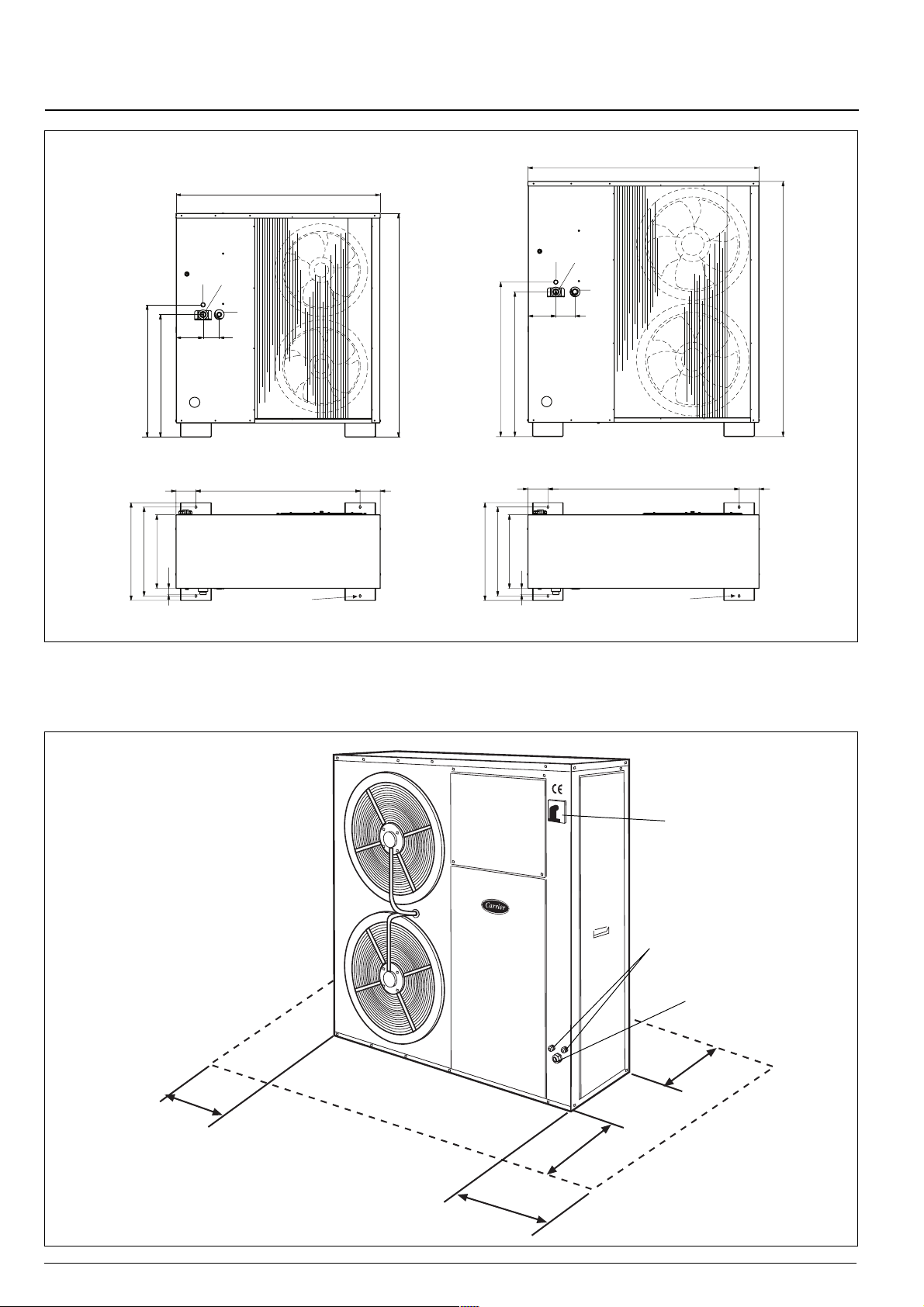

Dimensions and location of hydraulic connections (mm)

Mod. 30RA 017 - 021

Mod. 30RH 017

859

635

578

1328

3

1

2

175 105

796

130 130

478

40

1068

12x20

1453.5

635

1003

578

478

940

40

3

180 125

Mod. 30RA 026 - 033

1503

Mod. 30RH 021 - 026 - 033

1

2

1657.5

1243130 130

12x20

1. Water inlet 2. Water outlet 3. 3/4” gas safety valve outlet

200

200

Main switch

Grommet: 1 Pg 29 and 2 Pg 16 for power

supply and control cables entry

GB - 4

700

400

Page 6

30RA/30RH

General information and hydronic module

Unit installation

Read this instruction manual thoroughly before starting the

installation.

This unit complies with low-voltage (EEC/73/23) and electromagnetic compatibility (EEC/89/336) directives.

• The installation must be carried out by a qualified installer.

• Follow all current national safety code requirements.

In particular ensure that a properly sized and connected ground

wire is in place.

• Check that voltage and frequency of the mains power supply are

those required; the available power must be adequate to operate

any other possible appliances connected to the same line.

Also ensure that national safety code requirements have been

followed for the mains supply circuit.

• After installation thoroughly test the system operation and

explain all system functions to the owner.

• Leave this manual with the owner for consultation during future

periodic maintenance.

• Be sure the unit and its components are checked periodically to

look for loosen, damaged or broken components.

In case of persisting defects, the unit may cause personal injury

or property damage.

IMPORTANT:

During the unit installation make first the hydronic

connections and then electrical connections. If unit is

uninstalled first disconnect electrical cables, then the

hydronic connections.

WARNING:

Disconnect the mains power supply switch before servicing

the system or handling any internal parts of the unit.

All mains supply circuits must be disconnected.

• The manufacturer declines any liability for damage resulting from

modifications or errors in the electrical or hydronic connections.

• Failure to observe the installation instructions or use of the unit

under conditions other than those indicated in Tables “Operating

limits”, will immediately void the unit warranty.

• Failure to observe electric safety codes may cause a fire hazard

in case of short circuits.

• Inspect equipment for damage due to improper transportation or

handling: file an immediate claim with the shipping company.

Do not install or use damaged units.

• During unit operation, some of the refrigerant circuit elements

could reach a temperature in excess of 70

qualified personnel should access areas protected by access

panels.

• In case of any malfunctioning turn the unit off, disconnect the

mains power supply and contact a qualified service engineer.

• All of the manufacturing and packaging materials used for

your new appliance are compatible with the environment

and can be recycled.

• Dispose of the packaging material in accordance with local

requirements.

• This equipment contains refrigerant R407-C that must be

disposed of in a proper manner. When disposing of the unit after

its operational life, remove it carefully. The unit must then be

delivered to an appropriate disposal center or to the original

equipment dealer.

• Carefully recover refrigerant within this unit before final disposal

or when servicing. Never vent refrigerant to atmosphere.

Choosing the installation site

• This unit should not be installed in an explosive atmosphere.

• The unit can operate in normal radioelectric atmospheres in

residential, commercial and light industrial installations.

For other applications, please consult Carrier.

• In the case of heat pump operation with an outdoor temperature

of less than 0 °C the unit must be installed at least 300 mm

above ground level.

o

C so only trained and

This is necessary to prevent ice from accumulating on the frame

and to permit correct operation also in the event of heavy

snowfalls.

The unit must be levelled on both axes (the tolerance is less than

2 mm per metre).

• In some cases it may be necessary to fit deflectors against

strong winds and to stop snow from hitting the coil directly.

These deflectors must be installed so that the normal air

circulation is not obstructed.

Siting the unit

Check that:

- The location is able to support unit operating weight (Table I).

- There is sufficient space for servicing and air flow around the

unit (see “Clearances”figure).

- The selected site is without dust or foreign material which could

obstruct the coil.

- When installing the unit on the ground, the selected site is not

subject to flooding.

- The installation is in accordance with local rules and standards

governing the installation of air conditioning equipment.

- Vibration absorbers have been provided throughout the

installation to prevent noise from being transmitted.

Transport

1. Use spreader bars to lift the unit to avoid damage to the

panels. Avoid violent movements.

2. Never roll or swing the unit more than 15°.

IMPORTANT:

Ensure that all unit panels are fixed in place before moving

the unit. Raise and set down the unit carefully.

IMPORTANT:

Always ensure that the unit is levelled correctly.

Hydronic module

The hydronic module is factory-installed.

This eliminates the need to install the necessary components

on-site, making the unit more compact and easy to install.

ENGLISH

Automatic purge

Pressure gauge for

hydraulic circuit

static pressure

Flow switch

Safety valve

Arrangement for

possible installation

of automatic fill kit

option

Expansion vessel

Mesh filter*

Flow control valve*

Hydronic module

drain valve

Pump drain plug

Pump

* Factory-supplied,

fit during

installation

GB - 5

Page 7

30RA/30RH

Water connections

Typical water circuit diagram for units without hydronic module

Legend for units without

hydronic module:

30RA - RH unit

without hydronic

module

Fan coil units

Water circulating

pump

Expansion vessel

Pressure gauges

Manual shut-off

valves

Mesh filter

Pressure couplings

Thermometers

Flow switch

Automatic purge valve

Hydraulic circuit drain

valve

Charge valve

Flexible coupling

Safety valve

Plate-type heat

exchanger drain valve

Typical water circuit diagram for units with hydronic module

Legend for units with

hydronic module:

30RA - RH unit with

hydronic module

Fan coil units

Pressure gauges

Manual shut-off

valves

Pressure couplings

Thermometers

Plate-type heat

exchanger drain valve

Charge valve

Flexible coupling

Shut-off valve with

Pressure reducer

Hydraulic circuit drain

Mesh filter *

Flow control valve *

* Factory-supplied, fit

incorporated stop

valve

during installation

NOTE:

If the automatic

fill kit option is used on the unit,

fitting an extra charging

valve is unnecessary.

GB - 6

Power supply

Automatic fill kit option

Page 8

30RA/30RH

Water connections

Ethylene glycol curve

C

°

Freezing temperature of water- ethylene glycol mixture

ENGLISH

ATTENTION:

The pump leakproof

components are not suitable

for use with propylene

glycol.

Weight concentration of ethylene glycol in water %

Make the plate heat exchanger hydraulic connections with the

necessary components, using material which will guarantee that

the screwed joints are leakproof.

The typical hydraulic circuit diagram shows a typical water circuit

installation in an air conditioning system.

For an application with a water circuit, the following

recommendations must be taken into account:

1. The pump must be fitted immediately before of the heat

exchanger and after the connection to the system return (unit

without hydronic module).

2. It is advisable to install shut-off valves to allow isolation of the

most important circuit components, as well as the heat

exchanger itself.

These valves (ball, globe or butterfly valves) should produce a

minimum loss of charge when they are open.

3. Provide unit and system drains and vents at the lowest system

point.

4. Install purges in the higher sections of the installation.

5. Pressure ports and pressure gauges should be installed

upstream and downstream of the water pump (unit without

hydronic module).

6. Thermometers should be installed in the unit water inlet and

outlet.

7. All piping must be adequately insulated and supported.

Installation of the following components is obligatory:

1. A flow switch should be installed in a straight horizontal stretch

with a length of at least five times the line diameter on either

side.

The flow switch must be positioned in the exchanger inlet pipe.

It must be electrically connected in accordance with the wiring

diagram (only unit without hydronic module).

If this is not possible, the installation should incorporate a

protection device which is activated when there is no water

circulating in the heat exchanger.

2.The presence of particles in the water can lead to obstructions

in the heat exchanger.

CAUTION:

Using water with glycol may

make it necessary to change the

configuration of the control

system.

It is therefore necessary to protect the heat exchanger inlet with

an extractable mesh filter.

The filter mesh gauge must be at least 10 mesh/cm

The standard supply of the unit with hydronic module includes a

mesh filter to be fitted during installation.

3.After assembling the system, or repairing the circuit, the whole

system must be thoroughly cleaned with special attention paid

to the state of the filters.

4.Pump flow rate control is made through a flow control valve

supplied with the unit with hydronic module, which must be

installed on the delivery pipe during installation.

5.In case of water refrigeration at temperatures lower than 5°C, or

if the unit is installed in areas where temperatures drop below

0°C, water must be mixed with a proper quantity of ethylene

glycol (see the curve above).

Use the curve to determine the correct ethylene glycol

concentration for the temperature.

Frost protection

The plate heat exchanger and the water connections of the

hydronic module pump may be damaged in spite of the anti-freeze

protection system these units are fitted with.

Frost protection of the plate heat exchanger and of the circuit

inside the hydronic module is always guaranteed down to -10°C

by the electric heaters that are automatically activated if needed.

The power supply to the electric heaters of the plate heat

exchanger and to the internal circuit of the hydronic module must

never be interrupted.

IMPORTANT:

Both the appliance main switch (Q1) and the auxiliary

protection switch for the electric heaters (QF101) must

always be in the closed position (the positions of Q1 and

QF101 are indicated in the wiring diagram).

2

.

GB - 7

Page 9

30RA/30RH

W ater connections

Water pressure drop of the unit without hydronic module

Pressure drop , kPa

Water flow rate, l/s

Outlet available static pressure of the unit with hydronic module

A. 30RA-RH 017

B. 30RA-RH 021

C. 30RA-RH 026

D. 30RA-RH 033

GB - 8

Available static pressure, kPa

A. 30RA-RH 017

B. 30RA-RH 021

C. 30RA-RH 026

D. 30RA-RH 033

Water flow rate, l/s

Page 10

30RA/30RH

Electrical connections and refrigerant charge

Electrical connections

WARNING:

To prevent electrical shock or equipment damage, make sure

disconnects are open before electrical connections are made.

If this action is not taken, personal injury may occur.

Power supply cable size and external connection must be made by

the installer according to the unit installation characteristics and the

applicable standards. The power supply and earthing multicore

cable of the unit must be connected to the main disconnecting

switch by passing it through the grommet on the front pedestal

after removing the lateral access panel. The maximum section

allowable for flexible copper cable is 25 mm

Before connection, check that phase sequence L1 – L2 – L3 is

correct.

Take special care when making the earth connection.

The maximum permitted voltage and current imbalance is 10% of

the values indicated in Table II.

Contact your local power company for correction of an incorrect line

voltage.

Before selecting the power supply line fuses - which must be of the

type "gG" - check the voltage and the size indicated on the unit

name plate is.

WARNING:

Operation of the unit on improper line voltage constitutes

abuse and is not covered by the Carrier warranty.

IMPORTANT:

To ensure the correct unit power supply (cable entry,

conductor cross section, protection devices etc.), consult the

electrical data table, the wiring diagram supplied with the unit

and the applicable standards concerning the installation of air

conditioning equipment.

Never operate a unit if the voltage imbalance exceeds 2%.

The following formula must be used to determine the percentage of

voltage imbalance.

Voltage imbalance (%) =

———————————————————————————-

Example:

Nominal supply: 400-3-50

AB = 404 V

BC = 399 V

AC = 394 V

Average voltage =

Determine maximum deviation from average voltage

AB = 404 - 400 = 4

BC = 400 - 399 = 1

AC = 400 - 394 = 6

Largest deviation is 6 volts. Percentage voltage imbalance is

therefore:

6 x 100 = 1,5 %

400

Largest deviation from average voltage x 100

Average voltage

404 + 399 + 394 = 399 ≈ 400 V

3

2

.

Motor

Liquid refrigerant charge

Checking the charge

WARNING:

When adjusting the refrigerant charge always ensure that

water is circulating in the heat exchanger to prevent any

possibility of freezing up. Damage caused by freezing is not

covered by the product warranty.

30RA-RH units are shipped with a full operating charge of

refrigerant. Refer to Table I.

If it is nevertheless necessary to add more refrigerant, run the unit

for some time in cooling mode and then slowly add liquid refrigerant

into the suction side until there are no bubbles in the sight glass.

WARNING:

To ensure proper operation of 30RA-RH units there must be at

least 5 K of subcooling as the liquid refrigerant enters the

expansion valve.

30RA-RH units use a HFC-407C refrigerant charge. For your

information, we are reproducing here some extracts from the official

publication dealing with the design, installation, operation and

maintenance of air conditioning and refrigeration systems and the

training of people involved in these activities, agreed by the air

conditioning and refrigeration industry.

Refrigerant guidelines

Refrigeration installations must be inspected and maintained

regularly and rigorously by specialists. Their activities must be

overseen and checked by properly trained people.

To minimise discharge to the atmosphere, refrigerants and

lubricating oil must be transferred using methods which reduce

leaks and losses to a minimum.

• Leaks must be repaired immediately.

• Service valves fitted to the flow and return lines permit charge

transfer to a suitably arranged external container.

• It is indispensable to use a dedicated transfer station.

• Compressor lubricating oil contains refrigerant. Any oil drained

from a system during maintenance must therefore be handled and

stored accordingly.

• Refrigerant under pressure must never be discharged to the

atmosphere.

Recharging liquid refrigerant

CAUTION:

30RA-RH units are charged with liquid HFC-407C refrigerant.

This non-azeotropic refrigerant blend consists of 23% R-32, 25% of

R-125 and 52% R-134a, and is characterised by the fact that at the

time of the change in state the temperature of the liquid/vapour

mixture is not constant, as with azeotropic refrigerants.

All checks must be pressure tests, and the appropriate pressure/

temperature ratio table must be used for the interpretation of the

values.

Leak detection is especially important for units charged with

refrigerant R-407C.

Depending on whether the leak occurs in the liquid or in the vapour

phase, the proportion of the different components in the remaining

fluid is not the same.

ENGLISH

CAUTION:

The installer must install protection devices, as required by

the applicable legislation.

NOTE:

Regularly carry out leak checks and immediately repair any

leak found.

GB - 9

Page 11

30RA/30RH

Refrigerant charge and electronic control

Undercharge

If there is not enough refrigerant in the system, this is indicated by

gas bubbles in the moisture sight glass.

There are two possibilities:

• Small undercharge (bubbles in the sight glass, no significant

change in suction pressure).

- After detection and repair the unit can be recharged.

- The replenishment of the charge must always be done in the

cooling mode, slowly introducing liquid refrigerant at the suction

side, until there are no bubbles in the sight glass.

• Significant undercharge (large bubbles in the sight glass,

significant drop in suction pressure).

- Completely drain the refrigerant charge, using a refrigerant

recovery unit. After detection and repair check the charge with

the unit off, drain the system and recharge the full amount of

liquid refrigerant (see Table I) on the suction and discharge side.

- The refrigerant container used must contain a minimum of 10%

of its initial charge.

WARNING:

If brazing is to be done, the refrigerant circuit must be filled with

nitrogen.

Combustion of refrigerant produces toxic phosgene gas.

IMPORTANT:

- Never use the compressor as a vacuum pump.

- Always add refrigerant via the suction line.

- Refrigerant must be added very slowly.

- The complete refrigerant charge must never be filled into the

suction line.

- Do not overcharge the system with refrigerant.

Electronic control

Operation and control of all units is carried out via the electronic

control.

The instructions supplied with the control include comprehensive

descriptions.

PRO-Dialog Plus electronic control

PRO-DIALOG Plus is an advanced numeric control system that

combines complex intelligence with great operating simplicity.

PRO-DIALOG Plus constantly monitors all machine parameters

and safety devices, and precisely manages the operation of

compressor and fans for optimum energy efficiency .

It also controls the operation of the water pump.

A powerful control system

The PID control algorithm with permanent compensation for the

difference between entering and leaving water temperature and

anticipation of load variations regulates compressor operation for

intelligent leaving water temperature control.

To optimise power absorption, the PRO-DIALOG PLUS

automatically re-calibrates the set point of the entering water

temperature based on the outside air temperature to one of the two

pre-set values (occupied building and of an unoccupied building for

example).

PRO-DIALOG Plus control is auto-adaptive for full compressor

protection. The system permanently optimises compressor run

times according to the application characteristics (water loop

inertia), preventing excessive cycling. In most comfort air

conditioning applications this feature makes a buffer tank

unnecessary.

Clear and easy-to-use control system

The operator interface is clear and user-friendly: LEDs and two

numeric displays ensure immediate verification of all unit operating

data.

10 menus offer direct access to all machine controls, including a

history of possible faults, for rapid and complete chiller fault

diagnosis.

Extended communications capabilities

PRO-DIALOG Plus allows remote control and monitoring of the

unit through a wired connection: start/stop, cooling/heating mode

selection (only 30RH unit), power demand limit or dual set-point

and customer safety lock.

The system permits remote signalling of any general anomaly for

each refrigerant circuit.

Three independent time schedules permit definition of: chiller

start/stop, operation at the second set-point (e.g. unoccupied

mode), and operation at low fan speed (e.g. during the night).

This option also permits cascade operation of two units and

remote control via communication bus (RS 485 serial port).

GB - 10

Page 12

30RA/30RH

Start-up, compressor and pump replacement, unit protection devices

ENGLISH

Start-up

Unit start-up is done by the electronic control described above, and

must always be carried out under the supervision of a qualified air

conditioning engineer.

Necessary checks/precautions before start-up

- Ensure that all electrical connections are properly tightened.

- Ensure that the unit is level and well-supported.

- Check that the hydraulic circuit has sufficient water flow and that

the pipe connections correspond to the installation diagram.

- Ensure that there are no water losses. Check the correct

operation of the valves installed.

- All panels should be fitted and firmly secured with the

corresponding screws.

- Make sure that there is sufficient space for servicing and

maintenance purposes.

- Ensure that there are no refrigerant leaks.

- Confirm that the electrical power source agrees with the unit

nameplate rating, wiring diagram and other documentation for the

unit.

- Ensure that the power supply corresponds to the applicable

standards.

- Make sure that compressors float freely on the mounting springs.

Compressor replacement

As the compressors are hermetic, when an internal fault occurs,

the compressor must be replaced.

This must be done as detailed below:

- Disconnect the unit from the electrical supply.

- Remove the access panels.

- Remove the gas from the refrigerant circuit using recovery

equipment to avoid harming the atmosphere.

- Electrically disconnect the compressor.

- Unbraze or unscrew the suction and discharge lines, taking care

not to damage the rest of the components.

- Remove the compressor fastenings.

- Replace the compressor, ensuring that it contains sufficient oil.

- Braze or screw in the lines.

- Connect the compressor according to the wiring diagram.

- Evacuate the compressor.

- Introduce the quantity of refrigerant indicated on the nameplate

through the service couplings located on the high and low

pressure side.

NOTE:

This operation must be carried out by a qualified person.

Pump replacement

If the water pump needs to be replaced, proceed as follows:

- Disconnect the unit from the power supply.

- Remove the access panel.

- Electrically disconnect the pump.

- Empty all water from the hydronic module.

- Loosen the pipe unions a and c.

- Remove the four pump fixing screws b.

- Replace the pump.

- Fit the pump fixing screws b.

- Tighten the pipe unions a and c.

- Electrically connect the pump

- Connect the unit to the power supply

- Make sure the pump rotates in the right direction using the hole in

the back panel.

- Reinstall the lateral access panel.

Pipe union

Screw

Pipe union

Description of unit protection devices

The unit includes the following protection devices:

- Internal compressor protection.

- Fan motor internal thermal protection.

- Main switch.

- Anti-short-cycle protection.

- Thermomagnetic main switch.

- Thermomagnetic control switch.

- Fans and electric heaters thermomagnetic switch.

- Defrost thermostat.

- Fault detector for the temperature and pressure sensors.

- High pressurestat: this protects the unit against excessive

condensing pressure.

The high pressurestat has factory-fixed non-adjustable settings.

The appliance stops due to the intervention of the high pressure

alarm threshold, before the high pressurestat intervenes.

This function is performed by the electronic control device via a

pressure transducer.

- Low pressurestat: This function is performed by the electronic

control device via a pressure transducer.

Only on appliances with hydronic module

- Pump motor external thermal protection.

GB - 11

Page 13

30RA/30RH

-1

0

1

2

3

4

5

6

7

8

91011

12

13 14

-14

-10

-6

-2

2

6

10

14

18

22

26

30

34

38

42

46

50

Unit protection devices

, operating limits and operating range

Table III: Pressure switch settings

Cut-out Reset

High pressurestat 30 bar Manual

WARNING:

Alteration of factory settings other than the design set-point, without

manufacturer's authorisation, may void the warranty

In case of use other than the manufacturer configuration,

Service must be asked

for permission to change the Pro-Dialog Plus

.

Carrier

system configuration.

30RA - Operating limits

These units have been designed to operate within the following limits:

Evaporator Minimum°C Maximum°C

Water entering temp. (at start-up) 7,8

Water leaving temp. (in operation) 5** 13

Water entering temp. (at shut-down) - 55

Condenser

Air entering temperature -10 46

*

30

30RH - Operating limits

Cooling cycle

Plate heat exchanger Minimum°C Maximum°C

Water entering temp. (at start-up) 7.8

Water leaving temp. (in operation) 5** 13

Water entering temp. (at shut-down) - 55

Coil

Air entering temperature -10 46

Heating cycle

Plate heat exchanger Minimum°C Maximum°C

Water entering temp. (at start-up) 10 45

Water leaving temp. (in operation) 25 50

Water entering temp. (at shut-down) - 55

Coil Minimum

Air entering temperature -10 20

*

Contact Carrier if an entering water temperature lower than 7.8 °C is

necessary.

**

In case of operation with a leaving temperature of less than 5 °C, it is

necessary to add ethylene glycol to the water in circulation.

*

°C Maximum°C

30

NOTE:

For industrial process cooling applications, where high

stability of water temperature levels must be achieved, the

values above must be increased.

We recommend consulting the factory for these particular

applications.

Operating range - 30RA units

50

C

46

°

42

38

34

30

26

22

18

14

10

6

2

-2

-6

-10

Outdoor air temperature

-14

-1

1

0

Leaving water temperature °C

4

6

2

5

3

7

8

91011

12

13 14

Operating range - 30RH units

C

°

Outdoor air temperature

Minimum and maximum water flow rates in

the plate heat exchangers

30 RA RH

017 0,45 1,4 1,3

021 0,57 1,6 1,6

026 0,67 2,1 1,9

033 0,87 2,3 2,4

* Maximum water flow rate with an available static pressure of 50 kPa (units

with hydronicmodule)

** Maximum water flow rate at a plate heat exchanger pressure drop of

100 kPa (units without hydronic module)

Water circuit water content

Whatever the size of the system, the minimum content of the water

circuit is given by the following formula:

Volume = CAP

where CAP is the nominal system capacity (kW) at nominal

operating conditions of the installation.

Application N

Air conditioning 3.5

Industrial process cooling See note

This volume is necessary for stable operation and accurate

temperature control.

It is often necessary to add a buffer water tank to the circuit in order

to achieve the required volume.

GB - 12

Minimum flow Maximum flow Maximum flow

rate, l/s rate, l/s* rate, l/s**

x N = Litres

(kW)

Leaving water temperature °C

25

C

°

20

15

10

5

0

-5

-10

-15

Outdoor air temperature

20

25

Leaving water temperature °C

Notes:

1.

The temperature rise of the water through the plate heat exchanger = 5K.

2. Both the plate exchanger and the circuit inside the hydronic module

are protected against frost down to a temperature of -10°C.

Operating range with anti-freeze solution and with special

configuration of the Pro-Dialog control system.

30

35

40

45 50

55

Page 14

30RA/30RH

General maintenance, maintenance and final recommendations

General

ATTENTION:

Before starting any servicing or maintenance operation on the unit,

make sure that the power supply has been disconnected.

A current discharge could cause personal injury.

In order to obtain maximum performance from the unit special

attention should be paid to the following points.

- Electrical connections:

The supply voltage should be within the limits indicated in Table II.

Ensure that no faulty contacts exist in the terminal blocks,

contactor boards, etc.

Make sure that all the electrical connections are properly

tightened, and that all the electrical components (contactors,

relays, etc) are firmly secured to the corresponding rails.

Pay special attention to the condition of the connecting cables

between the control elements and the electrical box, and to that of

the unit power supply cable.

They should not be twisted and there should be no slits or notches

in the insulation.

Check that the starting and running consumptions are within the

limits specified in Table II.

- Water connections:

Make sure there are no water leaks from the system.

Should the unit be shutdown for long periods, open the drain valve

installed on the hydronic module and partially drain the pump and

the water pipes as well as the drain valve on the plate-type

exchanger, which must be installed on the hydraulic circuit.

This operation is essential if temperatures are expected to drop

below freezing.

If the unit is not drained, the main switch should remain connected

so that the defrost thermostat can operate.

Carefully clean the system water filter.

- Plate heat exchanger cleaning:

In some applications, for example when very hard water is used,

there is an increased tendency for fouling.

In these cases the installation of a descaling filter is

recommended.

The heat exchanger can always be cleaned by circulating a

cleaning fluid.

A weak acid solution should be used (5% phosphoric acid or, if

frequently cleaned 5% oxalic acid), and the cleaning fluid should be

pumped through the exchanger.

The tank installation can be permanent or, alternatively, the

connections can be prepared and, at any given time, a portable

cleaning device can be connected.

To achieve optimum cleaning the acid solution should be circulated

at a minimum of 1.5 times the normal operational flow speed, and

preferably in reverse direction.

The installation should then be flushed with large amounts of water

to totally remove the acid before the system is started up.

maintenance

Tank installation

Heat exchanger

Weak acid

solution tank

Cleaning should be done at regular intervals and should never be

left until the unit has become blocked.

The time intervals between cleaning depend on the quality of the

water used, but as a general rule it is advisable to clean it at least

once a year.

- Refrigerant circuit:

Ensure that there is no leakage of refrigerant or oil from the

compressor.

Check that the high and low side operating pressures are normal.

Check the cleanliness of the refrigerant-water heat exchangers by

checking the pressure drop across them.

- Controls:

Check the operation of all the electrical components, the high

pressurestat and of the high and low pressure transducers and

the water, air and defrost temperature detector.

Maintenance

Servicing recommendations

- Maintenance of the unit must be carried out by skilled personnel

only.

Nevertheless, the easiest operations, such as cleaning of the

battery and the unit external parts can be carried out by nonskilled personnel.

- For any operation on the unit follow thoroughly the instructions

shown in the manual and on the unit labels as well as the Safety

Standards.

Always wear the protective gloves and safety glasses. Pay

attention to burns when brazing.

- Use only Carrier Original Spare Parts when repair is required.

Always make sure the spare parts are installed correctly. Always

install the spare parts in the original position.

- Before replacing any of the elements in the cooling circuit, ensure

that the entire refrigerant charge is removed from both the high

and low pressure sides of the unit.

- The control elements of the cooling system are highly sensitive.

If they need to be replaced, care should be taken not to overheat

them with blowlamps whilst soldering.

A damp cloth should be wrapped around the component to be

soldered, and the flame directed away from the component body.

- Silver alloy soldering rods should always be used.

- If the total unit gas charge has to be replaced, the quantity should

be as given on the nameplate and the unit should be properly

evacuated beforehand.

- During unit operation all panels should be in place, including the

electrical box access panel.

- If it is necessary to cut the lines of the refrigerant circuit, tube

cutters should always be used and never tools which produce

burrs. All refrigerant circuit tubing should be of copper, specially

made for refrigeration purposes.

Final recommendations

The unit you have purchased has undergone strict quality control

procedures before leaving the factory.

All components, including the control systems and electrical

equipment, etc., are certified by our Quality Control Department,

and tested under the harshest possible operating conditions in our

laboratories. However, after leaving the factory, it is possible that

one or more of these elements may be damaged due to causes

beyond our control. In such an event, the user should not work

on any of the internal components, or subject the unit to

operating conditions which are not specified in this manual,

since serious damage may result and the guarantee would be

invalidated. Repair and maintenance work should always be left to

the installer.

All recommendations concerning unit installation are intended as a

guideline. The installer should carry out the installation according to

the design conditions and should comply with all applicable

regulations for air conditioning and refrigeration installations.

ENGLISH

NOTE:

The manufacturer does not accept responsibility for any

malfunctions resulting from misuse of the equipment.

GB - 13

Page 15

30RA/30RH

Troubleshooting

A list of possible faults, as well as the probable cause and

suggested solutions is shown as follows. In the event of a unit

malfunction it is recommended to disconnect the power supply and

ascertain the cause.

Symptoms Cause REMEDY

Unit does not start:

- No power supply;

CONNECT POWER SUPPLY.

- Main switch open;

CLOSE SWITCH.

- Low line voltage;

CHECK VOLTAGE AND REMEDY THE DEFICIENCY.

- A protection has tripped;

RESET.

- Contactor stuck open;

CHECK AND IF NECESSARY REPLACE CONTACTOR.

- Seized compressor;

CHECK AND IF NECESSARY REPLACE COMPRESSOR.

- Loose electrical connections;

CHECK CONNECTIONS.

Unit runs continuously or starts and stops frequently:

- Defective compressor contactor;

-

CHECK AND IF NECESSARY REPLACE CONTACTOR.

- Defective compressor;

CHECK AND IF NECESSARY REPLACE COMPRESSOR.

- Refrigerant losses;

CHECK AND ADD THE NECESSARY QUANTITY.

- Total water flow too low

CHECK FOR PRESSURE DROP IN THE HYDRAULIC CIRCUIT.

- Static pressure in the hydraulic circuit too low;

CHECK IT ON THE PRESSURE GAUGE AND RESTORE IT IF NECESSARY.

- Badly fitting panels;

INSTALL CORRECTLY.

Compressor loses oil:

- Leaking refrigeration circuit;

REPAIR LEAK.

Water loss:

- Defective entering or leaving connections;

CHECK AND TIGHTEN IF NECESSARY.

The unit does not defrost

(only for 30RH units):

- Four-way reversing valve faulty;

CHECK AND REPLACE THE VALVE IF NECESSARY.

- Defrost sensor broken;

CHECK AND REPLACE THE SENSOR IF NECESSARY.

Unit continuously cuts out at low pressure:

- Refrigerant losses;

CHECK AND ADD THE NECESSARY QUANTITY.

- Low water flow in the exchanger;

CHECK WATER PUMP.

- Unit start-up delay;

WAIT UNTIL THE SYSTEM HAS STABILISED.

Unit continuously cuts out at high pressure:

- Defective high pressurestat;

CHECK AND IF NECESSARY REPLACE PRESSURESTAT.

- Blocked expansion valve;

CHECK AND REPLACE IF NECESSARY.

- Blocked filter drier;

CHECK AND IF NECESSARY REPLACE FILTER.

- The outdoor fan/s does/do not work;

CHECK THE CONDITION OF THE FAN MOTOR/S AND ITS/THEIR ELECTRICAL

CONNECTIONS.

- Obstructed or dirty battery;

REMOVE THE OBSTRUCTION OR CLEAN THE BATTERY.

Abnormal system noise:

- Piping vibration;

SUPPORT PIPING.

- Noisy compressor;

CHECK AND CHANGE IF NECESSARY.

- Hissing expansion valve;

CHECK AND ADD REFRIGERANT IF NECESSARY.

GB - 14

Page 16

L010126H27 - 0405

Via R. Sanzio, 9 - 20058 Villasanta (MI) Italy - Tel. 039/3636.1

The manufacturer reserves the right to change any product specifications without notice.

Order No. 13024-74 April 2005. Supersedes Order No. 13024-74, June 2004. Printed in Italy

Loading...

Loading...