Page 1

HEATING L

COOLlNG

30GT

1

K,HL

/ckage

SAFETY CONSIDERATIONS

Installing, starting-up and servicing air conditioning

equipment can be hazardous due to system pressures,

electrical components and equipment location,

Only trained, qualified installers and service technicians should install, start up and service this equipment.

When working on air conditioning equipment, observe

precautions in the literature and on tags, stickers and

labels attached to the equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Use care in handling equipment.

INTRODUCTION

These instructions cover field installation of the Acces-

sory Hot Gas

ByPass Valve and solenoid pilot valve on

the following chi lers:

30HK,HL015 through 060 (50 and 60 Hz)

30GB040,045,055,070 (60 Hz), Flotronic’”

30GB040,046,050,055,070 (50 Hz), Flotronic’”

30GB075 through 200 (50 and 60 Hz), Flotronic’”

30GTOl5,025,030,035 (60 Hz)

30GT020,025,030 (50 Hz)

On Flotronic chillers with no unloaders or 2 unloaders,

the accessory hot gas bypass must be added to both

circuits because of

ati

automatic lead-lag feature.

INSTALLATION

Step 1

age includes hot gas bypass va ve, solenoid pilot valve

and instructions. Examine each item. If any part is

damaged or missing, file a claim immediately with the

shipping agent.

Step 2

-

Examine

-

Install Piping

Packa

e Contents

B

-

Pack-

I II

COOLER

w&i+

STUB

(SEALED FROM

SEE NOTE I

TXV -

TH ER MOSTATI.C EXPANSION VALVE

b &

FACTORY PIPING

---

b a---

FIELD PIPING

NOTES:

1. %-in. OD for 30HI5,HL and 30GT;

2. The bypass valve In this package has %-in. connections and can be used directly on 30HK,HL and 30GT units.

3. On 30GB units, a change from

’

FACTORY

1

FIELD-SUPPLIED BYPASS LINE

Fig. 1- Schematic Piping;

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC111 Catalog No. 533-039

I

I mm

S/sin.

d--t

3

LINE

BYPASS VALVE {;.OD CONN.) SEE NOTE 2

%-in.

OD for 30GB.

to gin. must be made either at the valve or at the stubs.

30HK,HLO15-060; 30GT015-035

Printed in U.S.A. Form 30G,H-1 SI

SUCTION LINE

LIQUID

LINE (CIRCUIT ~0.1)

;;;BN&<A;ED

HOT GAS DISCHARGE

RI

FROM FACTORY

c

CONDENSER

2-89

1

1

Replaces: 30GB,H-1SI

Page 2

.-

UNITS 30HK,HLO15-060 and

Bvnass

Line - Connect the field-supplied line to the

factory-provided stubs in the discharge line

circuit no. 1 compressor and in the circurt no. 1

between expansion valve and cooler (stubs are sealed

from factory).

Bypass Valve - Install the valve in the

close to the cooler as possible. This

storage between valve and cooler when valve is closed

and prevents flood of liquid refrigerant when the valve

opens. To ensure proper closing, install the bypass valve

in a horizontal section of the bypass line, with the pilot

valve installed vertically (coil on top).

Solenoid Pilot Valve - Install on the bypass valve at the

external equalizer

outlet side of the pilot valve is a l/4-in. SAE thread. Run

a l/4-in. OD tube from this connection to the thermostatic expansion valve (TXV) equalizer line, If the

connection is made directly to the TXV, use a

x l/4-in. female flare tee. If the connection is made into

the equalizer line, use a standard l/4-in. FL tee.

@/&in.

$?TO%-035

OD sweat connection). The

(See Fig. 1.)

*fro-m

hquld

bypass

mimmrzes

l/4-in.

the

line,

line as

liquid

FL

FLOTLWWW” UNITS,

Bypass Line - Install field-supplied line between the

header on inlet side of lead coil and the entrance to the

cooler. Two factory-sealed stubs are provided in each

circuit, one on the lead coil header and one on the liquid

line between the Flotronic expansion valve (EXV) and

the cooler.

NOTE: The 30GB 1 lo-200 units have 2 stubs in the high

side of each circuit, one on each lead coil header; it is

necessary to connect piping to only one of these stubs.

Bvpass Valve - Install the valve in the bypass line as

close to the cooler as possible. This minimizes liquid

storage between the valve and cooler when valve is

closed and prevents flood of liquid refrigerant when the

valve opens. To ensure proper closing, install the by ass

valve in a horizontal section of the bypass line, witRthe

pilot valve installed vertically (coil on top).

Solenoid Pilot Valve - Install on the bypass valve at

the external equalizer. The outlet side of the pilot valve is

a l/4-in. SAE thread. Run a l/4-in. OD tube from this

connection to the suction valve of the lead compressor

in the circuit.

30GB040-200

(See Fig. 2.)

SUCTION LINE VALVE

EXV- ELECTRONIC EXPANSION VALVE

TXV- THERMOSTATIC EXPANSION VALVE

-FACTORY

NOTE: Circuit 2 should be piped same as circuit 1. The %-in, tube should be connected to the lead compressor in both circuits.

PIPING

CKT CKT CKT

b

b

040-

060

CKT

&o

Fig. 2 -Schematic Piping; 3OGBO40-200, with Electronic Controls (Flotronic)

E=ZaFIELD

p&J

TT

q

ma

150 175 200

PIPING

TiT

pJ

070 075,080

pJ&-JpJ

Compressor numbers, viewed facing compressor side of unit.

CKT CKT CKT CKT CKT CKT

&j

&g

$J

p-&

CKT

j-?JpJa

q l2Jlml-g

090,100 110,125

TT

m

CKT

b

pJ

q 2pJ

YT

IxJTJmB

2

Page 3

Step 3 -Dehydrate and Recharge Circuit

When

piping has been completed, leak test the assembly

-

and replace the filter drier, or core(s) for circuit no. 1.

On single-compressor chillers (30HK,HLO 15,025 and 030

for 60 Hz, 020,025 for 50 Hz; 30GT) the filter drier itself

must be replaced.

After core (or drier) replacement, evacuate, dehydrate

and recharge the circuit. Procedures for evacuation,

dehydration and charging are detailed in Carrier Stand-

ard Service Techniques Manual, Chapter 1, Refrig-

erants, Sections 6 and 7.

Step 4 -Install Control Wiring

RI R2

TIME DELAY

MODULE

600K

RESISTOR

4x”r,ct-4-

TIME DELAY

MODULE

HGS

Be sure all power to the unit is off before proceeding.

I

1

Wires between field-installed components and unit

control box must be enclosed in conduit. Wire size is

no. 16 AWG minimum. Wire-end terminals required on

field wires are indicated in the Combined Legend for

Fig. 3 - 8.

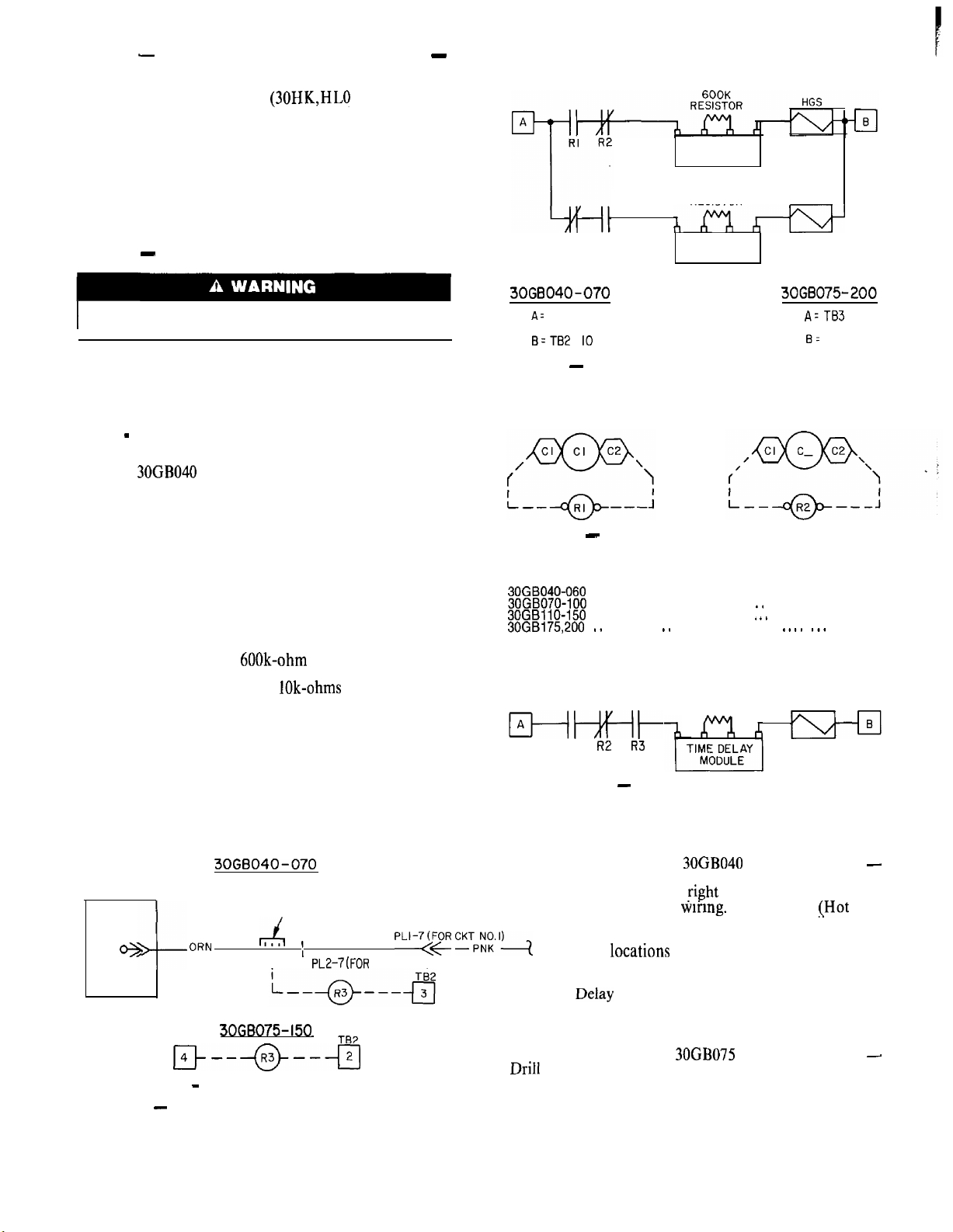

UNITS 30GB040 THROUGH 070 FLOTRONIC (See

Fig. 3.) - Control logic allows the hot gas bypass to be

energized only on the first stage of capacity.

A unit with 2 unloaders has the automatic lead/lag

feature which allows starting of either circuit, and

thus must have 2 hot gas bypass packages, one per circuit

(see Fig. 4).

On the 040-060 units, R3 should energize with compressor no. 2. On the 070 unit. R3 energizes with compressor no. 3. In both instances, it is the lead compressor

on circuit no. 2 (see Fig. 5.)

The time delay module must be set for a one-minute

delay by connecting a 600k-ohm resistor between the

center terminals of the module (see Fig. 6). (One second

of time delay results from each lOk-ohms of resistance.)

NOTES:

1. Relays R 1 and R2 apply to all units.

2. R3 applies only to units with a single unloader. Units

with no unloaders or 2 unloaders do not require R3.

3. 30GB 175 and 200 units do not use unloaders.

3OGB040-070 3066075-200

A= TB2 4

cl

B=TB2

IO

q

AzTB3

6:

TB2 2

Fig. 4 -Hot Gas Solenoid Wiring, Units with

No Unloaders or Two Unloaders

Fig. 5

Connect R2 in parallel with lead compressor in circuit 2:

30GB040-060

30GB070-100

30GBliO-150

30GB175,200 . ., . . . . . . . , . ., . . . . . . . . . . . . . . . . . ,. *. .

(Refer to Fig. 2 for compressor locations.)

RI and R2 Coil Wiring, All Units

-

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Comp 2

. . . . . . . . . . . . . . . . . , . . . . . . . . . . *. . . . . . . . . . Comp 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

600K

RESISTOR

iwt

RI R2 R3

Fig. 6 - Hot

Single

Gas Solenoid Wiring,

Unloader Units

I +.

. . . . . . . . Comp 4

.,.

Comp 5

HGS

ell

I

cl

cl

~

I

30G6040-070

RELAY

BOARD

J6

e

PIN 4

4--

NOTE: 3063175,200 - R3 DOES NOT APPLY.

ORNr4,

30GB075-150

TB4 TE2

r--a--+J

FIELD SPLICE

I

,

PL2-7(FOR CKT NO.21

I

Fig. 3 -R3 Coil Wiring (R3 used only with

units having a single unloader)

PLI-‘(YR CKTF”,;.‘)

FLOTRONIC’” UNITS, 30GB040 THROUGH 070

Drill a hole to accommodate a standard conduit fitting

in bottom of control box at fight end, adjacent to existing

entrance hole for control wiring. Locate HGR

(,Hot

Gas

Bypass Relay) in right side of control box adjacent to

existing relays. Using the HGR base as a template, mark

mountmg hole locations and drill appropriate hole. Run

conduit from the bypass valve to the control box and wire

relays into control circuit as shown in Fig. 4. Relays

and Time DeIay Module should be installed in the upper

left corner of the control box, above the transformer.

FLOTRONIC UNITS, 30GB075 THROUGH 200

Driil 2 holes in the bottom right of the control box, next

to the compressor conduit holes, to accommodate stand-

ard conduit fittings. Run conduit from the bypass valve

to the control box and wire relays into control circuit

as shown in Fig. 4.

-

-

Page 4

ALL FLOTRONIC UNITS - Units require control

relays

tained

R) and Time Delay Module. They may be ob-

!

rom your Carrier distributor under the following

Carrier Part Numbers:

Rl and R2

R3

Time Delay Module

115-v

23Cbv

24-v

UNITS 30HK,HL015 THROUGH

HN61KK041 DPDT

HN61KK913 DPDT

HN61 KK040

30HK501602

DPDT

060 (Except 020,

60 Hz, and 0 15, 50 Hz.)

IMPORTANT: On 30HK,HL 2-compressor units,

the SEQUENCE switch on the control panel must

be in the l-2 position to obtain hot gas bypass

operation.

Run the conduit from the bypass valve to one of the

knockouts provided on the right side of the unit control

box. Connect the control wires as shown in Fig. 7.

UNITS

30GTO15

THROUGH 035 (except 020, 60 Hz,

and 015, 50 Hz) - Connect control wires as shown in

Fig. 8. At LLSV, connect to existing splice containing

white wire.

-j+------+g+----+J-

TB2

HGS

A. CONNECTIONS FOR SINGLE-COMPRESSOR UNITS

(60~~: 015,025,030;

-me--

,B.

CONNECTIONS FOR TWO-COMPRESSOR UNITS

(50 AND 60HZ:

See Combined Legend.

Fig. 7

-

040,050,060;

Hot Gas Bypass Field Wiring;

50~z:

------

HGS

020,025)

30HK,HL Units

TB2

-El--

TB2

50HZ: 0301

OPERATION AND ADJUSTMENT

The bypass valve is factory set to begin opening when

suction pressure drops to about 62 psig. This pressure

corresponds to a chllled water controller set point of

approximately 44 F. If the chilled water set point is lower

than 44 F, it will be necessary to decrease the bypass valve

setting for proper operation. Conversely, for

chllled

water

y;

set points above 44 F, the bypass valve setting must be

increased. A change in condensing temperature will also

require a change in bypass valve set point. As condensing

temperature decreases, decrease the bypass

vaIve

set

point until it opens at the desired conditions.

i,--------

See Combined Legend.

Refer to unit wiring label inside front access door for complete

wiring schematic.

Fig. 8

Hot Gas Bypass

-

COMBINED LEGEND

(Fig. 3 - 8)

FiGS 1

LLSV

TB

TC2

----

Compressor Contactor

Hot Gas Bypass Solenoid (Splice Conn)

Liquid Line Solenoid Valve

-

Terminal Block

-

-

Temperature Controller (X-in. Female Quick-Conn)

cl

Terminal on TB

0

Terminal on Control Component

Factory Wiring

Field Wiring

(#6

Ring Conn)

--e---t-

HGS

Fierd

Wiring; 30GT Units

(%-in.

Female Quick-Conn)

LLSV

i

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5c

-+

PC171

Catalog No. 533-039

Printed in U.S.A. Form 30G,H-1

S1

PC4

4

2-89 Replaces: 30GB,WlSI

Loading...

Loading...