Page 1

50LJQ008,012 (50 Hz)

Single-Package Rooftop Heat Pump Units

Installation, Start-Up and Service

Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS .................. 1

INSTALLATION ............................ 1-16

Step 1 — Provide Unit Support .............. 1

• ROOF CURB

• SLAB MOUNT

Step 2 — Field Fabricate Ductwork ........... 1

Step 3 — Make Field Connection for

Condensate Disposal .........................3

Step 4 — Rig and Place Unit ................. 3

Step 5 — Make Electrical Connections ....... 7

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

• HEAT ANTICIPATOR SETTINGS

Step 6 — Adjust Indoor-Fan Speed ...........13

START-UP ................................17-19

SERVICE ..................................19-21

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning equipment

can be hazardous due to system pressure and electrical components. Only trainedandqualified service personnel should

install, repair or service air conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service personnel. When working on air conditioning equipment, observe precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply.

Follow all safetycodes. Wearsafety glasses andwork gloves.

Use quenching cloth for unbrazing operations. Have fire extinguisher available for all brazing operations.

Before performing service or maintenance operations on

unit, turn offmain power switch to unit. Electrical shock

could cause personal injury.

INSTALLATION

Unit is shipped in the vertical configuration. To convert to

horizontal configuration, remove side duct opening covers.

Using the same screws, install covers on vertical duct openings with the insulation-side down. Seals around duct openings must be tight.

IMPORTANT: An external filter kit MUST be used,

or the filters MUST be field-installed outside the unit

on horizontal applications with accessory economizer

or two-position damper. Otherwise, the economizer or

two-position must be partially removed to access the

filters. The area of the field-installed filters should be

equal to the area of the factory-installed filters.

Step 1 — Provide Unit Support

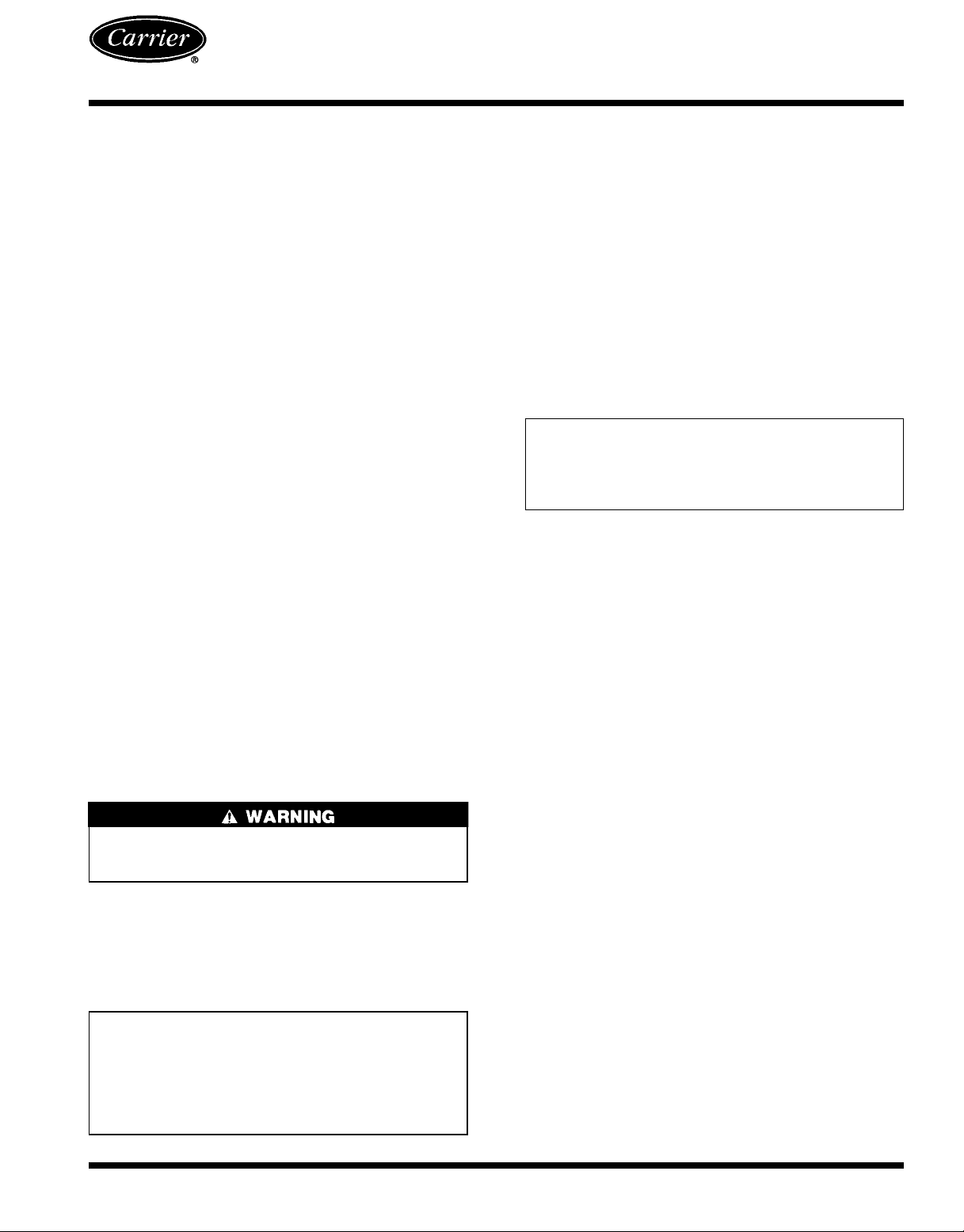

ROOF CURB — Assemble and install accessory roof curb

in accordance with instructions shipped with curb. See

Fig. 1. Install insulation, cant strips, roofing and counter flashing as shown. Ductwork must be attached to curb, not to the

unit. If electric or control power is to be routed through the

curb, attach the accessory thru-the-curb service connection

plates to the roof curb in accordance with the accessory installation instructions. Connection plates must be installed

before unit is set in roof curb.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for a watertight seal. Install gasket supplied with the roof curb as shown in Fig. 1. Improperly applied gasket also can result in air leaks and poor

unit performance.

Curb should be level. Unit leveling tolerances are shown

in Fig. 2. This is necessary for unit drain to function properly. Refer to Accessory Roof Curb Installation Instructions

for additional information as required.

SLAB MOUNT (Horizontal Units Only) — Provide a level

concrete slab that extends a minimum of 152 mm (6 in.) beyond unit cabinet. The slab should be 203 mm (8 in.) thick

with 102 mm (4 in.) above grade. Install a gravel apron in

front of outdoor coil air inlet to prevent grass and foliage

from obstructing airflow. In areas where high snowfall

occurs, increase height of slab to ensure that snow does not

block coil.

NOTE: Horizontal units may be installed on a roof curb if

required.

Step 2 — Field Fabricate Ductwork — On verti-

cal discharge units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. For horizontal

applications, field-supplied flanges should be attached to horizontal discharge openings and all ductwork attached to the

flanges. Insulate and weatherproof all external ductwork, joints

and roof openings with counter flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with applicable fire codes.

Aminimumclearance to combustibles is not required around

ductwork on vertical discharge units. On horizontal discharge units, a minimum clearance of 25 mm (one in.) is

required for the first 305 mm (12 in.) of ductwork.

Cabinet return-air static shall not exceed −87 Pa

(−.35 in. wg) with economizer or −112Pa (−.45 in. wg) without economizer.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 015-015 Printed in U.S.A. Form 50LJQ-C1SI Pg 1 1-92 Replaces: New

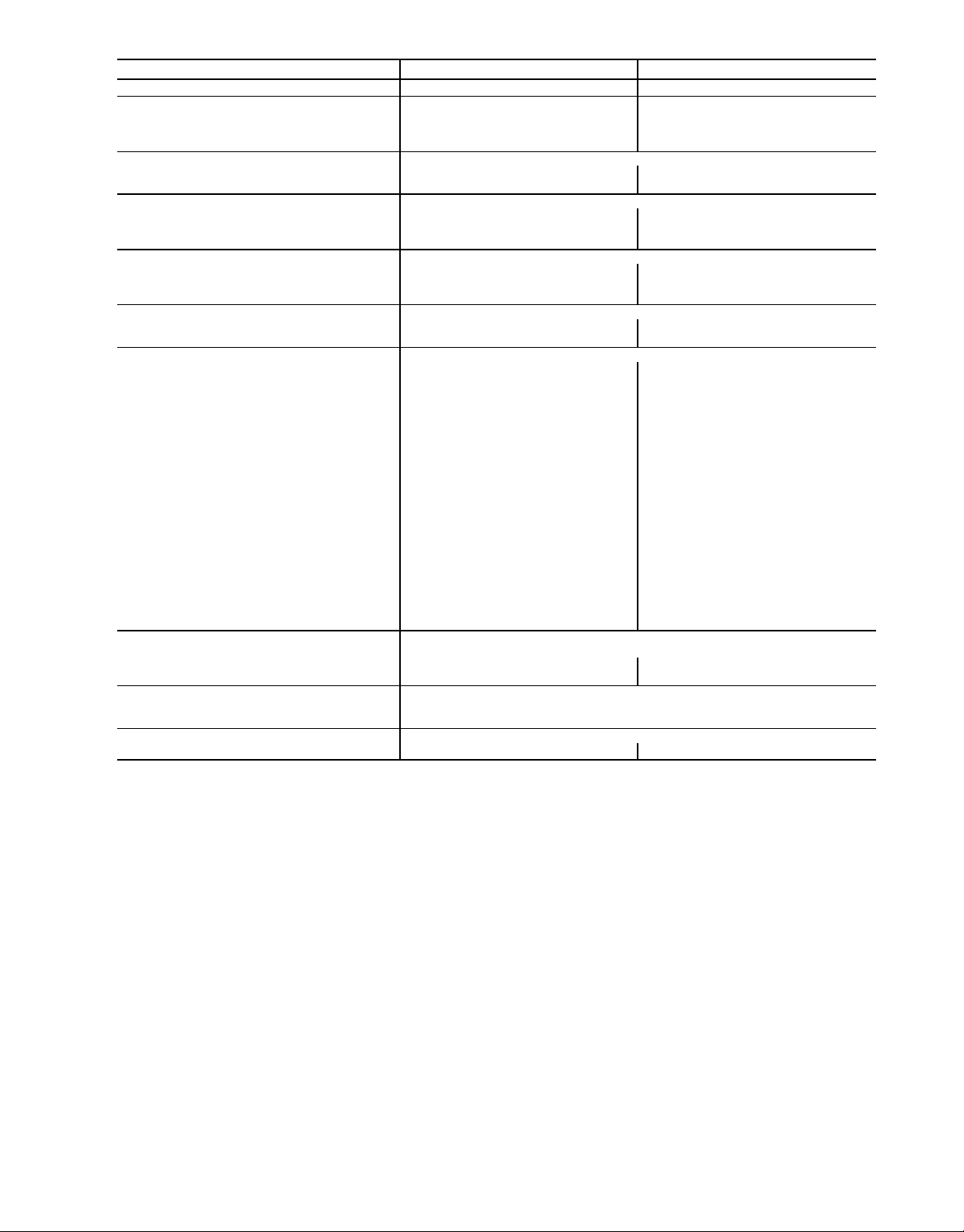

Page 2

ROOF CURB

ACCESSORY

50DJ901371

50DJ901381

‘‘A’’ UNIT SIZE

18-29

[356]

50LJQ008,012

28-09

[610]

UNIT SIZE ‘‘F’’ POWER ‘‘G’’ CONTROL

50LJQ008,012

19 [25] NPT or

29 [51] NPT

NOTES:

1. Roof curb accessory is shipped unassembled.

2. Insulated panels: 25 mm (one in.) thick polyurethane foam, .8 Kg (1

3. Dimensions in [ ] are in millimeters.

4. Roof curb: 16-gage steel.

5. Attachductworktocurb (flanges of duct rest on curb).

6. Service clearance 1219 mm (4 ft) on each side.

3

⁄49 [19] NPT 50DJ901311

7. Direction of airflow.

8. Control and power service plates are part of a separately shipped accessory package.

3

⁄4lb) density.

CONNECTOR

PKG. ACC.

Fig. 1 — Roof Curb Dimensions

2

Page 3

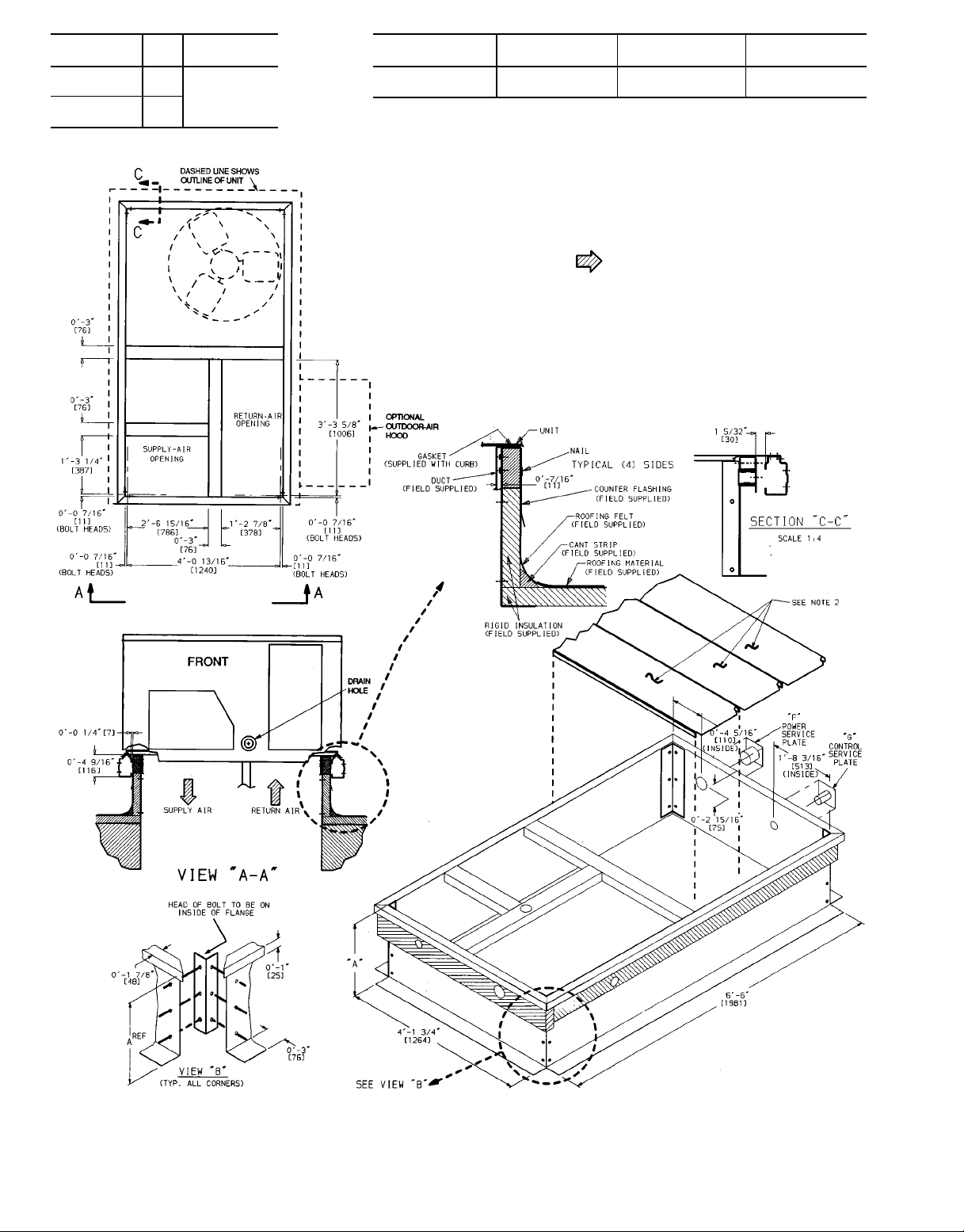

MAXIMUM ALLOWABLE DIFFERENCE

A-B B-C A-C

mm in. mm in. mm in.

13 .5 25 1.0 25 1.0

Fig. 2 — Unit Leveling Tolerance

Step 3 — Make Field Connection for CondensateDisposal —

See Fig. 3. A3⁄4-in. FPT connection is located on the side of

the unit. Use a trap at least 100 mm (4 in.) deep, and protect

against freeze-up.

If drain line is run to a drain, pitch line away from unit at

25 mm (one in.) per 3 m (10 ft) of run. Do not use a pipe size

smaller than the unit connection.

Units must have an external trap added.

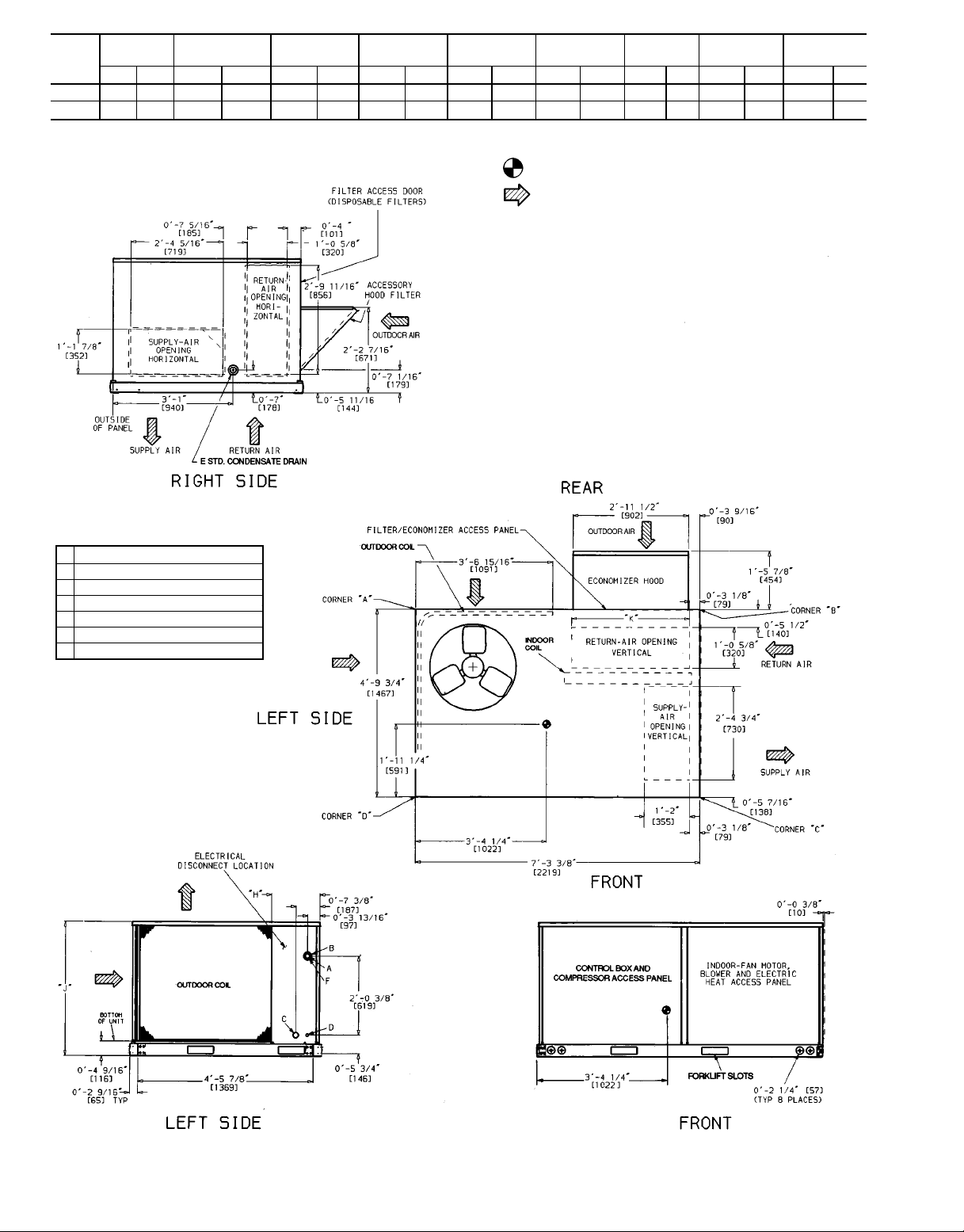

Step4 — Rig andPlace Unit — Inspect unit for trans-

portation damage. File any claim with transportation agency.

Keep unit upright and do not drop. Spreader bars are not

required if top crating is left on unit. Rollers may be used to

move unit across a roof. Level by using unit frame as a reference. See Tables 1A and 1B and Fig. 4 for additional information. Operating weight is shown in Tables 1A and 1B

and Fig. 4.

Lifting holes are provided in base rails as shown in

Fig. 4 and 5. Refer to rigging instructions on unit.

All panels must be in place when rigging.

POSITIONING — Maintain clearance around and above unit

to provide proper air flow and service access. See Fig. 5.

Position unit on roof curb so that the following clearances

are maintained; 6 mm (

1

⁄4in.) clearance between roof curb

and base rails on each side and front of unit: 29 mm (15⁄

in.) clearance between roof curb and rear of unit (see Fig. 1,

section C-C).

Do not install unit in an indoor location. Do not locate

unit air inlet near exhaust vents or other sources of contaminated air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

After unit is in position, remove polyethylene shipping wrapper and rigging skid.

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 100 mm (4 in.) trap is recommended.

Fig. 3 — External Trap Condensate Drain

32

NOTES:

1. Dimensions in ( ) is in millimeters.

2. Hood rigging shackles through holes in base rail, as shown in

detail ‘‘A’’. Holes in base rails are centered around the unit center

of gravity. Use wooden top skid when rigging to prevent rigging

straps from damaging unit.

3. Weightsdonotincludeeconomizer .SeeTables1A and 1B for economizer weights.

All panels must be in place when rigging.

Fig. 4 — Rigging Details

UNIT

50LJQ

008 840 381 87.38 2219 40.25 1022 41.31 1050

012 940 426 87.38 2219 40.25 1022 48.31 1253

MAX

WEIGHT

lb kg in. mm in. mm in. mm

‘‘A’’ ‘‘B’’ ‘‘C’’

DIMENSIONS

3

Page 4

Table 1A — Physical Data (SI)

BASE UNIT 50LJQ 008 012

NOMINAL CAPACITY (kW) 23.2 28.8

OPERATING WEIGHT (kg)

Unit 381 426

With Economizer 401 446

Roof Curb 101 101

COMPRESSOR

Quantity 22

Oil (ml) (each compressor) 1627 2071

REFRIGERANT TYPE

Operating Charge (kg)

Circuit 1 3.7 4.0

Circuit 2 3.2 3.9

OUTDOOR FAN

Quantity...Diameter (mm) 1...660 1...660

Nominal L/s 2900 3260

Motor BkW...r/s .25...16.0 .25...16.0

OUTDOOR COIL

Rows...Fins/m 2...669 2...669

Total Face Area (sq m) 1.9 2.3

INDOOR FAN

Size (mm) 381 x 381 381 x 381

Type Drive Belt Belt

Nominal L/s 1200 1600

Motor BkW per NEC* 1.12 1.50

Maximum Continuous BkW 1.79 2.16

Motor Frame 56 56

Fan r/s Range 10.30-14.70 11.50-15.00

Motor Bearing Type Ball Ball

Maximum Fan r/s 26.7 26.7

Motor Pulley Pitch Diameter

A/B (mm)

Fan Pulley Pitch Diameter (mm) 140 178

Belt — Type...Length (mm) A...1219 A...1295

Pulley Center Line Distance (mm) 425-489 464-527

Fan Shaft Diameter at Pulley (mm) 25 25

Speed Change per Full Turn of

Movable Pulley Flange (r/s)

Movable Pulley Maximum Full

Turns from Closed Position

Factory Setting — Full Turns Open 55

Factory Speed Setting (r/s) 10.3 11.5

INDOOR COIL Enhanced Copper Tubes, Aluminum Double Wavy Fins,

Rows...Fins/m 3...590 3...590

Total Face Area (sq m) .74 .93

OUTDOOR-AIR INLET SCREENS Cleanable

Quantity...Size (mm)

RETURN-AIR FILTERS Disposable

Quantity...Size (mm)

Enhanced Copper Tubes, Aluminum Fins, Acutrol™ Feed Device

61/86 86/112

.88 .70

55

4...406 x 508 x 50 4...508 x 508 x 50

LEGEND

BkW — Brake Kilowatt

NEC — National Electrical Code (U.S.A. Standard)

*Used to determine wire sizing per NEC.

Hermetic

R-22

Propeller

Centrifugal

Acutrol Feed Device

1...508 x 635 x 25

1...406 x 635 x 25

4

Page 5

Table 1B — Physical Data (English)

BASE UNIT 50QJ 008 012

NOMINAL CAPACITY (tons) 6.6 8.2

OPERATING WEIGHT (lb)

Unit 840 940

With Economizer 884 984

Roof Curb 223 223

COMPRESSOR

Quantity 22

Oil (fluid oz) (each compressor) 55 70

REFRIGERANT TYPE

Operating Charge (lb-oz)

Circuit 1 8-2 8-14

Circuit 2 7-0 8-10

OUTDOOR FAN

Quantity...Diameter (in.) 1...26 1...26

Nominal Cfm 6100 6900

Motor Hp...Rpm

OUTDOOR COIL

Rows...Fins/in. 2...17 2...17

Total Face Area (sq ft) 20.5 25.0

INDOOR FAN

Size (in.) 15x15 15x15

Type Drive Belt Belt

Nominal Cfm 2600 3400

Horsepower per NEC* 1.5 2.0

Maximum Continuous Bhp 2.4 2.9

Motor Frame 56 56

Fan Rpm Range 622-882 692-896

Motor Bearing Type Ball Ball

Maximum Fan Rpm 1600 1600

Motor Pulley Pitch Diameter

A/B (in.)

Fan Pulley Pitch Diameter (in.) 5.5 7.0

Belt — Type...Length (in.) A...48 A...51

Pulley Center Line Distance (in.) 16.75-19.25 18.25-20.75

Fan Shaft Diameter at Pulley (in.) 11

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full

Turns from Closed Position

Factory Setting — Full Turns Open 55

Factory Speed Setting (Rpm) 620 690

1

⁄3...960

Enhanced Copper Tubes, Aluminum Fins, Acutrol™ Feed Device

2.4/3.4 3.4/4.4

52 42

55

INDOOR COIL Enhanced Copper Tubes, Aluminum Double Wavy Fins,

Rows...Fins/in. 3...15 3...15

Total Face Area (sq ft) 8.0 10.0

OUTDOOR-AIR INLET SCREENS Cleanable

Quantity...Size (in.)

RETURN-AIR FILTERS

Quantity...Size (in.) 4...16 x 20 x 2 4...20 x 20 x 2

LEGEND

Bhp — Brake Horsepower

NEC — National Electrical Code (U.S.A. Standard)

*Used to determine wire sizing per NEC.

Hermetic

R-22

Propeller

Centrifugal

Acutrol Feed Device

1...20 x 25 x 1

1...16 x 25 x 1

Disposable

1

⁄3...960

5

Page 6

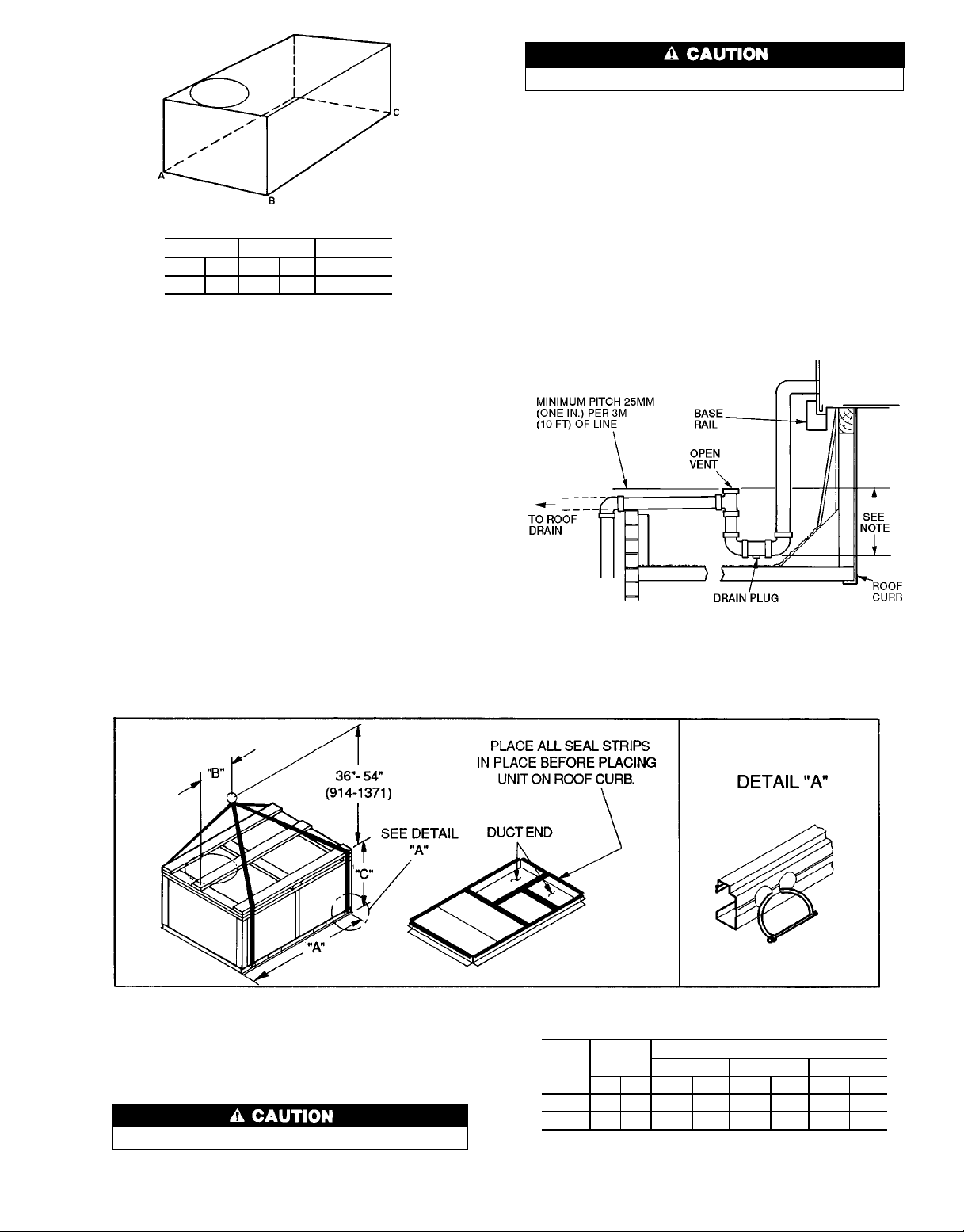

UNIT

50LJQ

STD. UNIT

WEIGHT

Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Ft-in. mm Ft-in. mm Ft-in. mm

ECONOMIZER

WEIGHT

CORNER

WEIGHT ‘‘A’’

CORNER

WEIGHT ‘‘B’’

CORNER

WEIGHT ‘‘C’’

CORNER

WEIGHT ‘‘D’’

008 840 381 44 20 182 83 156 71 231 105 271 123 2-0

012 940 426 44 20 204 93 174 79 259 117 303 137 1-2

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of gravity.

3. Direction of airflow.

4. Ductwork to be attached to accessory roof curb only.

5. Minimum clearance (local codes or jurisdiction may prevail):

a. Bottom to combustible surfaces (when not using curb) 25 mm

(one in.).

b. Condenser coil, for proper airflow, 914 mm (36 in.) one side,

305 mm (12 in.) the other. The side getting the greater clearance is optional.

c. Overhead 1524 mm (60 in.) to assure proper outdoor fan

operation.

d. Between units, control box side, 1067 mm (42 in.).

e. Between unit and ungrounded surfaces, control box side, 914

mm (36 in.).

f. Between unit and block or concrete walls and other grounded

surfaces, control box side 1067 mm (42 in.).

g. Horizontal supply and return end, zero mm (zero in.).

6. With the exception of the clearance for the outdoor coil as stated

in notes 5b and c, a removable fence or barricade requires no

clearance.

‘‘H’’ ‘‘J’’ ‘‘K’’

7

⁄8632 3-55⁄161050 2-911⁄16856

7

⁄8378 4-15⁄161253 3-03⁄8924

CONNECTION SIZES

3

⁄89 dia [35] field power supply hole

A 1

1

⁄29 dia [64] power supply knockout

B 2

3

⁄49 dia [44] charging-port hole

C 1

7

⁄89 dia [22] field control wiring hole

D

3

⁄49-14 NPT condensate drain

E

F 29 dia [51] power supply knockout

Fig. 5 — Base Unit Dimensions

6

Page 7

Step 5 — Make Electrical Connections

Unit cabinet must have uninterrupted, unbroken electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of electrical wire connected to unit ground

lug in control compartment, or conduit approved for electrical ground when installed in accordance with U.S.A.

National Electrical Code (Ref: ANSI/NFPA 70-1987)

or equivalent local electrical codes. Failure to follow this

warning could result in the installer being liable for personal injury of others.

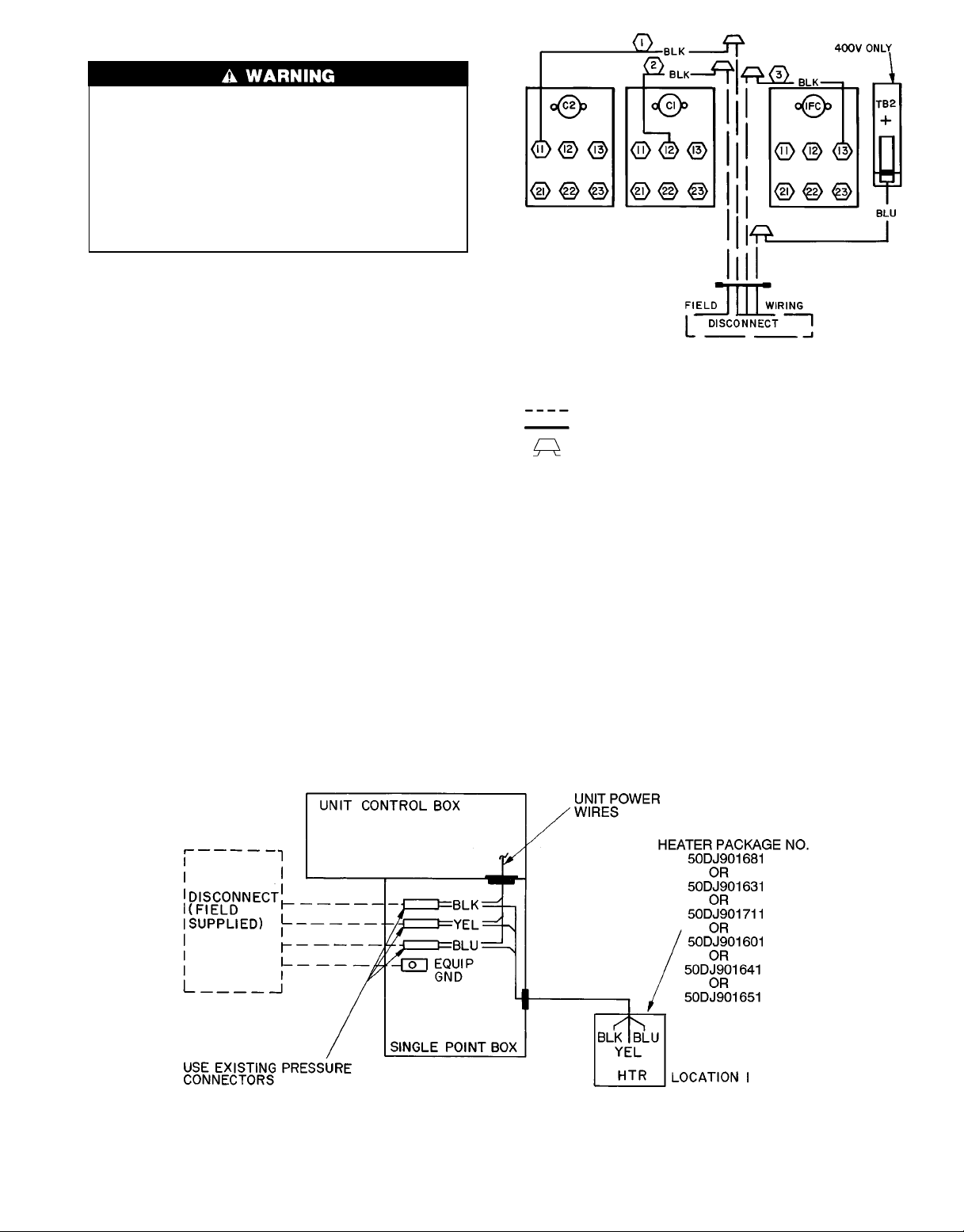

FIELD POWER SUPPLY — Pigtails are provided for field

wire connections. Use factory-supplied splices or copper/

aluminum connector.

When installing units, provide a disconnect per local codes.

All field wiring must comply with local requirements.

Install conduit through side panel openings. For units without electric heat, install conduit between disconnect and control box. Install power lines to terminal connections as shown

in Fig. 6. For units with electric resistance heat, refer to Table

2 to determine appropriate power wiring figure (Fig.7-13)

and route lines as indicated in appropriate figure.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (also see

Table 2). On 3-phase units, voltages between phases must be

balanced within 2% and the current within 10%. Use the formula shown in Table 2, Note 3 to determine the % voltage

imbalance. Operation on improper line voltage or excessive

phase imbalance constitutes abuse and may cause damage to

electrical components. Such operation would invalidate any

applicable Carrier warranty.

When electric heat is installed, remove knockouts for appropriate size conduit from unit block-off panel and single

point box. Install conduit (rigid or electro-metallic tubing)

through conduit drip boot as shown in Fig. 14. Drip boot

eliminates the need for water tight conduit fittings at the single

point box. Refer to Fig. 15 for component locations.

LEGEND

C—Contactor

IFC — Indoor-Fan Contactor

TB — Terminal Block

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Fig. 6 — Power Wiring Connections

LEGEND FOR FIG. 7-13

EQUIP — Equipment

FU — Fuse

GND — Ground

HTR — Heater

TB — Terminal Block

Fig. 7 — Electric Heater Power Wiring Connections — 50LJQ, 220-3-50 and 400-3-50;

Single Point Kit 50DJ902021 and 50DJ902071

7

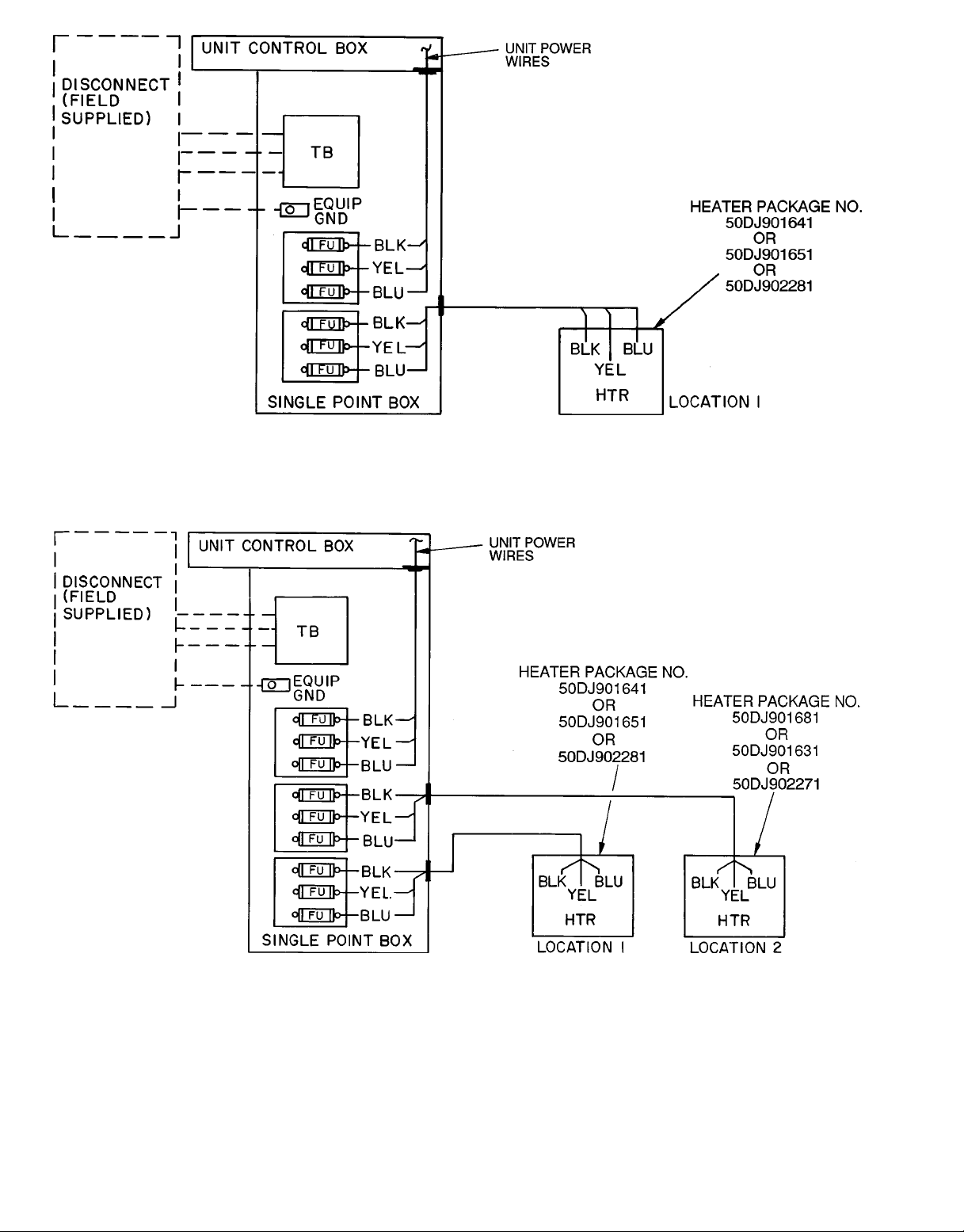

Page 8

Fig. 8 — Electric Heater Power Wiring Connections — 50LJQ, 400-3-50;

Single Point Kit 50DJ902041 and 50DJ902101

Fig. 9 — Electric Heater Power Wiring Connections — 50LJQ, 400-3-50;

Single Point Kit 50DJ902061 and 50DJ902121

8

Page 9

Fig. 10 — Electric Heater Power Wiring Connections — 50LJQ, 220-3-50;

Single Point Kit 50DJ902031 and 50DJ902081

Fig. 11 — Electric Heater Wiring Connections — 50LJQ, 220-3-50;

Single Point Kit 50DJ902051 and 50DJ902111

LEGEND FOR FIG. 7-13

EQUIP — Equipment

FU — Fuse

GND — Ground

HTR — Heater

TB — Terminal Block

9

Page 10

Fig. 12 — Electric Heater Power Wiring Connections — 50LJQ, 220-3-50;

Single Point Kit 50DJ902091

Fig. 13 — Electric Heater Power Wiring Connections — 50LJQ, 220-3-50;

Single Point Kit 50DJ902131

LEGEND FOR FIG. 7-13

EQUIP — Equipment

FU — Fuse

GND — Ground

HTR — Heater

TB — Terminal Block

10

Page 11

Table 2 — Electrical Data

UNIT

50LJQ

008

012

VOLTAGE

NOMINAL

V-PH-HZ

220-3-50 198 242 15.3 82.0 1.5 1.5 5.8

400-3-50 360 440 7.7 41.0 1.5 1.5 2.6

220-3-50 198 242 19.6 105.0 1.5 2.0 7.5

400-3-50 360 440 10.4 55.0 1.5 2.0 3.5

RANGE

Min Max RLA LRA FLA Hp FLA

COMPR

(each)

OFM IFM ELECTRIC HEAT POWER SUPPLY

LEGEND

COMPR — Compressor

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor-Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

OFM — Outdoor-Fan Motor

RLA — Rated Load Amps

*Heaters are field-installed only. Heater capacity (kW) is based on

heater voltage of 230 v or 400 v.If power distribution voltage to unit

varies from rated heater voltage, heater kW will vary

accordingly.

†Fuse or HACR circuit breaker.

**Requires 2 heater packages.

NOTES:

1. MCA and MOCP values are calculated in accordance with NEC

(National Electric Code) (U.S.A. Standard), Article 440.

2. Motor RLA and FLA values are established in accordance with UL

(Underwriters’ Laboratories) Standard 465 (U.S.A. Standard).

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the % voltage imbalance.

% Voltage Imbalance

= 100 x

max voltage deviation from average voltage

Use the following formula to determine

average voltage

ELECTRIC HEAT

Nominal

kW*

— — 41.7 50 — —

9.5 24.7 70.3 80 10 711

14.6 38.0 85.7 90 10 601

22.7 59.0 130.0 150 11 611

29.3 76.2 158.5 175 11 621

38.8 100.9 179.5 200 12 711, 621**

10.5 15.2 21.4 25 7 681

12.5 18.0 44.0 45 7 631

21.0 30.3 59.3 60 8 641

25.0 36.1 66.5 70 8 651

31.5 45.5 78.3 80 9 681, 641**

— — 53.1 60 — —

9.5 24.7 81.6 90 10 711

14.6 38.0 97.1 100 10 601

29.3 76.2 141.3 150 11 621

43.9 114.1 190.9 200 13 601, 621**

10.5 15.2 28.4 35 7 681

12.5 18.0 51.0 60 7 631

21.0 30.3 66.3 70 8 641

25.0 36.1 73.5 80 8 651

31.5 45.5 85.2 90 9 681, 641**

37.5 54.2 96.6 100 9 631, 651**

FLA MCA MOCP†

Example: Supply voltage is 400-3-50.

AB = 393 v

BC = 403 v

AC = 396 v

Average Voltage =

Determine maximum deviation from average voltage.

(AB) 397 − 393=4v

(BC) 403 − 397=6v

(AC) 397 − 396=1v

Maximum deviation is 6 v.

Determine % voltage imbalance.

% Voltage Imbalance = 100 x = 1.5%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

POWER WIRING

FIG. NO.

= = 397

6

397

ELECTRIC HEAT

PART NO.

50DJ901—

393 + 403 + 396

3

1192

3

11

Page 12

DISCONNECT

MOUNTING

LOCATION

Fig. 14 — Conduit Installation

EMT OR RIGID

CONDUIT

(FIELDSUPPLIED)

MAIN

CONTROL

BOX

BRACKET AND

CONDUIT DRIP

BOOT

CENTER POST

MANUAL RESET

LIMIT SWITCH

LOCATION

(HIDDEN)

HEATER

COVERS

15 to 23 m (51 to 75 ft), use no. 16 AWG insulated

wire (35 C minimum). For over 23 m (75 ft), use no. 14

AWG insulated wire (35 C minimum). See Table 3 for wire

conversions.

1. If unit is mounted on roof curb and accessory thru-thecurb service plate connection is used, route wire through

connection plate.

2. Pass control wires through the hole provided on unit (see

connection D, Connection Sizes table, Fig. 5).

3. Feed wire through the raceway built into the corner post

to the 24-v barrier located on the left side of the control

box. See Fig. 17. The raceway provides the UL (U.S.A.

Standard) required clearance between high- and lowvoltage wiring.

4. Connect thermostat wires to screw terminals of lowvoltage connector. The connector plugs into the control

board and may be removed to make connection. Plug connector back into the control board after making connection or unit will not operate.

HEAT ANTICIPATORSETTINGS — Set first-stage heat anticipator settings at 1.0. Set second-stage heat anticipator settings at 0.6. For units with optional electric heat,

set anticipator for second stage as shown in Table 4.

HEATER

WIRING

LABEL

HEATER

MOUNTING

BRACKET

SINGLE

POINT

BOX

SINGLE POINT

BOX MOUNTING

SCREWS

CONTROL WIRE

TERMINAL

BLOCK

HEATER

MODULE

(LOCATION 1)

HEATER

MODULE

(LOCATION 2)

Fig. 15 — Component Location

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation instructions included with the accessory. Locate thermostat assembly on a solid wall in the conditioned space to sense average temperature in accordance with thermostat installation

instructions.

Route thermostat cable or equivalent single leads of colored wire from subbase terminals to low-voltage connections on unit (shown in Fig. 16) as described in Steps 1-4

below.

NOTE: For wire runs up to 15 m (50 ft), use no. 18 AWG

(American Wire Gage) insulated wire (35 C minimum). For

Table 3 — American/European Wire Conversions

AMERICAN EUROPEAN

Industry

Standard Size

18 AWG 0.82 1.0

16 AWG 1.30 1.5

14 AWG 2.08 2.5

12 AWG 3.30 4.0

10 AWG 5.25 6.0

8 AWG 6.36 10.0

6 AWG 13.29 16.0

4 AWG 21.14 25.0

3 AWG 26.65 —

2 AWG 33.61 35.0

1 AWG 42.39 50.0

1/0 AWG 53.49 —

2/0 AWG 67.42 70.0

3/0 AWG 85.00 95.0

4/0 AWG 107.19 120.0

250 kcmil 126.64 150.0

300 kcmil 151.97 —

350 kcmil 177.90 185.0

400 kcmil 202.63 240.0

500 kcmil 253.29 300.0

600 kcmil 303.95 —

LEGEND

AWG — American Wire Gage

kcmil — Thousand Circular Mils

American

Conversion

2

(mm

)

Industry

Standard

Size (mm2)

Table 4 — Unit Voltage

220 400

Heater kW Anticipator Setting Part No. 50DJ901— Heater kW Anticipator Setting Part No. 50DJ901—

9.5 0.3 711 10.5 0.3 681

14.6 0.3 601 12.5 0.3 631

22.7 0.6 611 21.0 0.3 641

29.3 0.6 621 25.0 0.3 651

38.8 0.9 711, 621* 31.5 0.6 681, 641*

43.9 0.9 711, 621* 37.5 0.6 631, 651*

*Requires 2 heater packages.

12

Page 13

UNIT

CONTROL

BOARD

BAT — Battery

C—Contactor

CB — Circuit Breaker

DAT — Discharge-Air Thermistor

EMC/EMFC — Energy Management Closed

EMO/EMFO — Energy Management Open

EQUIP — Equipment

GND — Ground

HR — Heater Relay

IFC — Indoor-Fan Contactor

Fig. 16 — Field Wiring Connections

LEGEND

OFC — Outdoor-Fan Contactor

P—Plug

TB — Terminal Board

TRAN — Transformer

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Tables 5A and 5B show fan rps and rpm at motor pulley

settings. Refer to Tables 6-13 to determine fan speed

settings.

Fan motor pulleys are factory set for speed shown in

Tables 1A and 1B.

RACEWAY

Fig. 17 — Field Control Wiring Raceway

Step 6 — Adjust Indoor-Fan Speed — Adjust in-

door fan speed to meet jobsite conditions.

For units with electric resistance heating, required minimum L/s (cfm) is 1062 (2250) for 50LJQ008 and 1416 (3000)

or 50LJQ012, with the following exceptions.

UNIT

50LJQ

012

UNIT

VOLTAGE

220 50.0

400 50.0

HEATER

kW

UNIT

CONFIG-

URATION

Horizontal

or Vertical

Horizontal

or Vertical

REQUIRED

MINIMUM

L/s Cfm

1534 3250

1605 3400

To change fan speed:

a. Shut off unit power supply.

b. Loosen belt by loosening fan motor mounting nuts. See

Fig. 18.

c. Loosen movable pulley flange setscrew (see Fig. 19).

d. Screw movable flange toward fixed flange to increase speed

and away from fixed flange to decrease speed. Increasing

fan speed increases load on motor. Do not exceed maximum speed specified in Tables 1A and 1B.

e. Set movable flange at nearest keyway of pulley hub and

tighten setscrew (see Tables 1A and 1B for speed change

for each full turn of pulley flange).

To align fan and motor pulleys:

a. Loosen fan pulley setscrews.

b. Slide fan pulley along fan shaft.

c. Make angular alignment by loosening motor from mount-

ing plate.

To adjust belt tension (see Fig. 18):

a. Loosen fan motor mounting bolts.

b. Slide motor mounting plate away from fan scroll for proper

belt tension (13 mm [

1

⁄2-in.] deflection with one finger)

and tighten mounting bolts.

c. Adjust bolt and nut on motor mounting plate to secure

motor in fixed position.

13

Page 14

MOTOR MOUNTING

NUTS AND BOLTS

Fig. 18 — Belt-Drive Motor Mounting

T able 5A — Fan R/s at Motor Pulley Settings (SI)

Fig. 19 — Indoor-Fan Pulley Adjustment

50LJQ

1

0

⁄

2

111⁄2221⁄2331⁄2441⁄25

MOTOR PULLEY TURNS OPEN

008 14.70 14.26 13.82 13.38 12.94 12.50 12.06 11.62 11.18 10.74 10.30

012 15.00 14.65 14.30 13.95 13.60 13.25 12.90 12.55 12.20 1 1.85 11.50

T able 5B — Fan Rpm at Motor Pulley Settings (English)

50LJQ

1

0

⁄

2

008 882 856 830 804 778 752 726 700 674 648 622

012 896 875 855 834 814 794 774 753 733 712 692

MOTOR PULLEY TURNS OPEN

1

1

⁄

2

221⁄2331⁄2441⁄25

14

Page 15

Table 6 — Fan Performance (SI), 50LJQ008 (50 Hz) — Horizontal Discharge Units

AIRFLOW

(L/s)

1100 7.9 0.35 9.4 0.50 10.6 0.68 11.7 0.85 12.7 1.03 13.6 1.25 14.4 1.46 14.9 1.69 15.1 1.92 15.0 2.15

1200 8.3 0.42 9.8 0.59 11.0 0.78 12.0 0.95 13.0 1.15 13.9 1.36 14.8 1.58 15.5 1.82 16.0 2.06 16.4 2.31

1300 8.8 0.51 10.2 0.69 11.3 0.88 12.4 1.08 13.3 1.28 14.2 1.49 15.0 1.72 15.8 1.96 16.5 2.21 17.1 2.47

1400 9.2 0.60 10.6 0.80 11.7 0.99 12.7 1.22 13.7 1.42 14.5 1.63 15.3 1.87 16.1 2.12 16.9 2.38 — —

1500 9.7 0.71 11.0 0.91 12.1 1.12 13.0 1.35 14.0 1.59 14.8 1.81 15.6 2.04 16.4 2.30 — — — —

1600 10.1 0.82 11.3 1.04 12.5 1.28 13.4 1.49 14.3 1.75 15.2 2.00 15.9 2.24 — — — — — —

1700 10.6 0.93 11.8 1.20 12.9 1.44 13.8 1.67 14.7 1.92 15.5 2.20 — — — — — — — —

50 100 150 200 250 300 350 400 450 500

r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW

EXTERNAL STATIC PRESSURE (Pa)

Table 7 — Fan Performance (SI), 50LJQ012 (50 Hz) — Horizontal Discharge Units

AIRFLOW

(L/s)

1300 7.6 0.30 8.9 0.41 10.2 0.56 11.1 0.64 12.1 0.77 13.1 0.92 13.9 0.93 14.0 0.52 15.0 1.13 15.6 1.32

1400 8.0 0.40 9.3 0.51 10.5 0.64 11.4 0.75 12.4 0.88 13.3 1.01 14.1 1.11 14.6 0.96 15.4 1.32 16.0 1.42

1500 8.4 0.48 9.6 0.60 10.7 0.72 11.8 0.86 12.7 0.99 13.5 1.12 14.3 1.26 15.1 1.35 15.7 1.49 16.4 1.54

1600 8.8 0.58 10.0 0.69 11.1 0.82 12.1 0.96 12.9 1.10 13.8 1.24 14.5 1.38 15.3 1.54 16.0 1.64 16.7 1.72

1700 9.1 0.69 10.3 0.78 11.3 0.93 12.3 1.07 13.2 1.22 14.0 1.37 14.8 1.52 15.5 1.66 16.3 1.84 17.0 1.95

1800 9.5 0.81 10.7 0.90 11.7 1.05 12.6 1.20 13.5 1.36 14.3 1.52 15.0 1.67 15.8 1.83 16.4 1.99 17.2 2.17

1900 9.9 0.95 11.0 1.02 12.0 1.18 12.9 1.34 13.8 1.50 14.6 1.68 15.3 1.83 16.0 2.00 16.7 2.16 17.3 2.33

2000 10.3 1.11 11.4 1.17 12.3 1.32 13.2 1.48 14.1 1.66 14.9 1.83 15.6 2.01 16.3 2.18 17.0 2.36 17.6 2.53

2100 10.7 1.29 11.8 1.33 12.7 1.47 13.5 1.65 14.4 1.84 15.1 2.00 15.9 2.20 16.6 2.38 — — — —

2200 11.2 1.48 12.1 1.51 13.1 1.64 13.9 1.83 14.6 2.01 15.4 2.20 16.2 2.38 — — — — — —

2300 11.6 1.70 12.5 1.71 13.4 1.83 14.2 2.01 15.0 2.20 15.7 2.41 — — — — — — — —

50 100 150 200 250 300 350 400 450 500

r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW

EXTERNAL STATIC PRESSURE (Pa)

Table 8 — Fan Performance (SI), 50LJQ008 (50 Hz) — Vertical Discharge Units

AIRFLOW

(L/s)

1100 8.7 0.42 10.1 0.59 11.1 0.75 12.2 0.93 13.1 1.12 14.0 1.30 14.8 1.51 15.7 1.77 16.4 2.02 17.2 2.35

1200 9.3 0.52 10.5 0.69 11.6 0.87 12.6 1.05 13.5 1.26 14.3 1.46 15.1 1.66 15.9 1.88 16.7 2.14 17.4 2.44

1300 9.8 0.64 11.0 0.81 12.1 1.01 13.0 1.20 13.9 1.41 14.7 1.63 15.5 1.84 16.2 1.98 16.9 2.29 17.6 2.56

1400 10.4 0.77 11.5 0.94 12.6 1.16 13.5 1.37 14.3 1.58 15.1 1.80 15.9 2.04 16.6 2.27 17.3 2.51 — —

1500 11.0 0.92 12.0 1.10 13.0 1.33 13.9 1.56 14.7 1.78 15.5 2.00 16.3 2.25 17.0 2.50 — — — —

1600 11.6 1.08 12.6 1.28 13.5 1.50 14.4 1.76 15.2 2.00 16.0 2.23 16.7 2.47 — — — — — —

1700 12.2 1.26 13.1 1.48 14.0 1.70 14.9 1.97 15.7 2.23 16.4 2.48 — — — — — — — —

50 100 150 200 250 300 350 400 450 500

r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW

EXTERNAL STATIC PRESSURE (Pa)

Table 9 — Fan Performance (SI), 50LJQ012 (50 Hz) — Vertical Discharge Units

AIRFLOW

(L/s)

1300 8.4 0.37 9.6 0.51 10.8 0.61 11.7 0.69 12.6 0.81 13.3 0.90 14.3 1.05 15.1 1.27 15.9 1.48 16.7 1.67

1400 8.8 0.46 10.0 0.59 11.1 0.71 12.0 0.82 12.9 0.93 13.7 1.04 14.5 1.17 15.4 1.35 16.2 1.56 16.8 1.75

1500 9.2 0.55 10.4 0.68 11.5 0.81 12.4 0.94 13.2 1.06 14.0 1.19 14.8 1.26 15.6 1.44 16.4 1.62 17.1 1.83

1600 9.7 0.65 10.8 0.79 11.8 0.93 12.8 1.07 13.6 1.19 14.4 1.33 15.1 1.46 15.8 1.59 16.5 1.72 17.3 1.91

1700 10.2 0.75 11.2 0.91 12.2 1.06 13.1 1.20 13.9 1.34 14.7 1.48 15.4 1.63 16.1 1.76 16.7 1.89 17.4 2.04

1800 10.6 0.87 11.7 1.05 12.6 1.20 13.5 1.35 14.3 1.51 15.0 1.65 15.7 1.80 16.4 1.95 17.1 2.10 17.7 2.24

1900 11.1 1.01 12.1 1.19 13.0 1.35 13.9 1.52 14.7 1.68 15.4 1.84 16.1 1.99 16.8 2.14 17.4 2.31 18.0 2.46

2000 11.6 1.16 12.5 1.35 13.4 1.52 14.3 1.69 15.0 1.86 15.8 2.04 16.5 2.21 17.1 2.36 17.7 2.53 — —

2100 12.0 1.32 13.0 1.53 13.8 1.70 14.6 1.88 15.4 2.07 16.1 2.25 16.8 2.43 — — — — — —

2200 12.5 1.50 13.4 1.71 14.3 1.91 15.1 2.09 15.8 2.29 16.5 2.48 — — — — — — — —

2300 13.0 1.70 13.9 1.91 14.7 2.13 15.5 2.31 16.2 2.52 — — — — — — — — — —

r/s — Wheel Speed (Revolutions per Second)

Bkw — Fan Shaft Power (kW)

NOTES:

1. Boldface indicates field-supplied drive required.

2. indicates field-supplied motor and drive required.

3. Maximumusableoutput power (BkW) on the 50LJQ008 unit is1.79

(2.40 Bhp) with standard 1.12 BkW (1.5 hp) motor. The maximum

usable output power (BkW) increases to 2.16 (2.90 Bhp) on the

50LJQ012 unit with standard 1.5 BkW (2 hp) motor. Extensive

50 100 150 200 250 300 350 400 450 500

r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW r/s BkW

LEGEND

EXTERNAL STATIC PRESSURE (Pa)

motor and electrical testing on the Weathermaker I units ensures

that the full power range of the motor can be utilized with confidence. Using the fan motors up to the power ratings shown will

not result in nuisance tripping orprematuremotor failure. Unit warranty will not be affected.

4. Use of field-supplied motor may affect wire sizing. Contact

Carrier representative to verify.

5. Values include losses for filters, unit casings and wet coils.

6. Motor drive range is 10.30 to 14.70 r/s (622 to 882 rpm) on the

50LJQ008and11.50to 15.00 r/s (692 to 896 rpm) on the 50LJQ012.

All other r/s (rpms) will require a field-supplied drive.

15

Page 16

Table 10 — Fan Performance (English), 50LJQ008 (50 Hz) — Horizontal Discharge Units

AIRFLOW

(Cfm)

2200 459 0.42 549 0.62 625 0.83 691 1.06 753 1.31 805 1.58 842 1.87 857 2.16 851 2.45 823 2.70

2400 482 0.50 569 0.71 645 0.95 708 1.18 768 1.40 824 1.72 872 2.01 909 2.32 931 2.64 935 2.96

2600 507 0.59 592 0.82 663 1.08 727 1.32 784 1.58 839 1.87 891 2.17 936 2.49 973 2.82 999 3.16

2800 533 0.71 615 0.95 683 1.20 747 1.49 802 1.75 855 2.04 906 2.35 954 2.67 997 3.01 1034 3.36

3000 559 0.83 637 1.09 704 1.35 765 1.66 823 1.94 872 2.22 921 2.54 969 2.88 1014 3.22 — —

3200 585 0.96 660 1.24 727 1.52 785 1.83 841 2.15 892 2.45 939 2.76 984 3.10 ————

3400 610 1.10 682 1.41 750 1.72 806 2.01 860 2.36 912 2.69 958 3.01 1002 3.34 ————

3600 636 1.25 707 1.60 772 1.93 828 2.23 880 2.57 930 2.95 978 3.29 ——————

3800 661 1.41 733 1.82 795 2.15 852 2.48 901 2.80 949 3.20 — ———————

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

EXTERNAL STATIC PRESSURE (in. wg)

Table 11 — Fan Performance (English), 50LJQ012 (50 Hz) — Horizontal Discharge Units

AIRFLOW

(Cfm)

3000 484 0.55 560 0.70 631 0.87 690 1.03 747 1.20 800 1.38 850 1.52 879 1.38 925 1.81 964 1.92

3200 505 0.66 579 0.81 646 0.98 708 1.16 761 1.34 812 1.51 862 1.71 908 1.85 944 2.01 984 2.09

3400 527 0.78 599 0.93 664 1.11 724 1.30 775 1.48 827 1.67 873 1.85 920 2.07 963 2.21 1001 2.31

3600 548 0.92 619 1.05 680 1.24 738 1.43 794 1.64 840 1.83 888 2.04 931 2.23 976 2.47 1017 2.62

3800 571 1.08 639 1.19 698 1.39 756 1.60 810 1.81 856 2.02 901 2.23 945 2.44 986 2.65 1029 2.89

4000 593 1.25 659 1.35 717 1.56 773 1.78 823 1.98 875 2.22 915 2.42 960 2.65 1000 2.87 1039 3.10

4200 616 1.45 680 1.53 737 1.74 789 1.95 841 2.18 889 2.41 934 2.65 972 2.87 1015 3.12 1053 3.34

4400 639 1.67 701 1.73 757 1.92 807 2.16 858 2.41 903 2.62 951 2.89 990 3.12 1028 3.36 — —

4600 662 1.91 722 1.95 777 2.13 827 2.38 874 2.62 921 2.87 965 3.11 1008 3.39 ————

4800 686 2.17 744 2.20 797 2.36 846 2.62 891 2.85 938 3.14 980 3.37 ——————

5000 710 2.45 766 2.47 816 2.61 866 2.86 910 3.12 934 3.39 — ———————

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

EXTERNAL STATIC PRESSURE (in. wg)

Table 12 — Fan Performance (English), 50LJQ008 (50 Hz) — Vertical Discharge Units

AIRFLOW

(Cfm)

2200 503 0.50 585 0.71 653 0.92 716 1.15 772 1.38 824 1.63 884 1.95 934 2.30 916 2.64 1019 3.09

2400 534 0.61 613 0.84 677 1.06 738 1.30 794 1.55 844 1.81 892 2.08 944 2.40 987 2.76 1039 3.20

2600 565 0.74 639 0.97 703 1.20 761 1.46 816 1.74 866 2.01 913 2.29 957 2.58 1004 2.91 1050 3.31

2800 597 0.89 665 1.12 731 1.40 786 1.66 839 1.93 889 2.23 935 2.52 978 2.62 1019 3.13 1061 3.47

3000 629 1.06 694 1.29 759 1.59 812 1.88 862 2.15 911 2.46 957 2.78 1000 3.09 1040 3.41 — —

3200 662 1.25 724 1.50 785 1.80 840 2.11 887 2.41 934 2.71 980 3.04 1022 3.38 ————

3400 696 1.46 756 1.73 811 2.02 868 2.37 914 2.69 959 3.00 1003 3.32 ——————

3600 729 1.69 787 1.98 839 2.27 894 2.64 942 2.99 984 3.32 ————————

3800 763 1.95 819 2.27 869 2.56 920 2.92 970 3.31 — —————————

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

EXTERNAL STATIC PRESSURE (in. wg)

Table 13 — Fan Performance (English), 50LJQ012 (50 Hz) — Vertical Discharge Units

AIRFLOW

(Cfm)

3000 532 0.64 605 0.81 670 0.97 725 1.12 778 1.28 825 1.43 874 1.60 926 1.82 974 2.11 1012 2.36

3200 557 0.75 628 0.93 690 1.10 746 1.28 796 1.44 844 1.61 888 1.70 934 1.94 988 2.18 1025 2.47

3400 583 0.88 651 1.06 711 1.25 767 1.44 815 1.61 863 1.79 907 1.97 947 2.14 991 2.32 1038 2.57

3600 609 1.01 674 1.22 732 1.42 787 1.61 836 1.80 880 1.98 926 2.18 966 2.36 1004 2.54 1045 2.74

3800 535 1.16 698 1.39 755 1.59 808 1.80 857 2.01 901 2.20 943 2.39 985 2.60 1023 2.79 1059 2.98

4000 662 1.33 722 1.57 778 1.78 829 2.01 878 2.22 922 2.44 962 2.63 1003 2.84 1042 3.06 1078 3.26

4200 689 1.52 746 1.77 801 1.99 851 2.23 898 2.45 943 2.69 983 2.91 1021 3.11 1060 3.34 — —

4400 715 1.72 772 1.99 825 2.22 873 2.46 919 2.71 963 2.94 1004 3.19 1042 3.41 ————

4600 742 1.94 797 2.22 848 2.48 896 2.72 940 2.98 984 3.22 1025 3.48 ——————

4800 770 2.18 823 2.46 872 2.75 919 3.00 963 3.27 — —————————

5000 797 2.44 849 2.73 897 3.04 943 3.30 ————————————

Rpm — Wheel Speed (Revolutions per Minute)

Bhp — Fan Shaft Power (Brake Horsepower)

NOTES:

1. Boldface indicates field-supplied drive required.

2. indicates field-supplied motor and drive required.

3. Maximumusable output power (Bhp) on the50LJQ008 unit is 2.40

(1.79 BkW) with standard 1.5hp (1.12 BkW) motor. The maximum

usable output power (Bhp) increases to 2.90 Bhp (2.16

BkW) on the 50LJQ012 unit with standard 2 hp (1.5 BkW) motor.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

LEGEND

EXTERNAL STATIC PRESSURE (in. wg)

Extensive motor and electrical testing ontheWeathermakerI units

ensures that the full power range of the motor can be utilized with

confidence. Using the fan motors up to the power ratings shown

will not result in nuisance tripping or premature motor failure. Unit

warranty will not be affected.

4. Use of field-supplied motor may affect wire sizing. Contact

Carrier representative to verify.

5. Values include losses for filters, unit casings, and wet coils.

6. Motor drive range is 622 to 882 rpm (10.30 to 14.70 r/s) on the

50LJQ008and692to896rpm (11.50to 15.00 r/s) on the 50LJQ012.

All other rpms (r/s) will require a field-supplied drive.

16

Page 17

START-UP

IMPORTANT:Energizecrankcase heaters 24 hours prior

to base unit start-up to remove entrapped refrigerant

from the oil. Heaters are energized as long as there is

power to the unit.

Unit Preparation — Make sure that unit has been in-

stalled in accordance with these installation instructions and

applicable codes.

Return-Air Filters — Make sure correct filters are in-

stalled in unit (see Tables 1A and 1B). Do not operate unit

without return-air filters.

Compressor Mounting — Compressors are inter-

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring — Check all electrical connections in

unit control boxes; tighten as required.

Refrigerant Service Ports — Each refrigerant sys-

tem has 3 Schrader-type service gage ports: one on the suction line, one on the liquid line and one on the compressor

discharge line. Be sure that caps on the ports are tight.

Cooling — To start unit, turn on main power supply. Set

system selector switch at COOL position and fan switch at

AUTO. position. Adjust thermostat to a setting below room

temperature. Compressor starts on closure of contactor.

Check unit charge. Refer to Refrigerant Charge section on

page 20.

Reset thermostat at a position above room temperature.

Compressor will shut off.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting thermostat at a position above room temperature shuts unit off temporarily until space temperature

exceeds thermostat setting.

Heating — To start unit, turn on main power supply.

Set thermostat at HEATposition and a setting above room

temperature, fan at AUTO. position.

First stage of thermostat energizes Compressor no. 1 and

Compressor no. 2; second stage energizes the electric heat

(where applicable). Check heating effectsat air supply grille(s).

If unit does not energize, reset limit switch (located on

indoor-fan scroll) by depressing button located between terminals on the switch.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting heating selector lever below room temperature will shut unit off temporarily until the space temperature falls below thermostat setting.

Safety Relief — A soft-solder joint at the suction line

fitting provides pressure relief under abnormal temperature

and pressure conditions.

Ventilation (Continuous Fan) — Set fan and sys-

tem selector switches at ON and OFF positions, respectively. Indoor fan operates continuously to provide constant

air circulation.

Operating Sequence (See Fig. 20)

COOLING — With accessory economizer — Upon a re-

quest for cooling from the space thermostat, terminals Y1

and G will be energized with 24 v.As a result, the indoor-fan

contactor (IFC), indoor-fan motor (IFM), and reversing valve

solenoids (RVS1 and RVS2) will be energized and the

economizer damper blade will open to minimum position.

Note that if the indoor fan is on when the space thermostat

calls for cooling, terminal G is already energized and the

economizer damper blade is at minimum position.

If the outdoor-air temperature is below the outdoor-airthermostat (OAT) setting, then the position of the damper blade

will be determined by the temperature of the discharge air as

sensed by the discharge-air thermistor (DAT). The damper

blade will slide open for 5 seconds, and rest for 30 seconds

until the proper discharge-air temperature is obtained. The

damper blade will modulate to different positions to maintain this discharge-air temperature.

If the thermostat calls for a second stage of cooling

by supplying 24 v to Y2, the outdoor-fan contactor (OFC)

and Compressor contactor no. 1 (C1) will be energized,

which will bring on the outdoor fan and Compressor no. 1,

respectively.

When the thermostat is satisfied, Y2 will be deenergized

first, which will deenergize the outdoor fan and Compressor

no. 1. When the indoor fan is deenergized, the economizer

will return to a fully closed position.

If the outdoor-air temperature is above the OAT setting,

the economizer will move to the minimum position and the

unit will operate as described in Cooling, Units Without

Accessory Economizer section below.

Without accessory economizer — Upon a request for cooling from the space thermostat, terminals Y1 and G will be

energized with 24 v. As a result, the indoor-fan contactor

(IFC), outdoor-fan contactor (OFC) and Compressor contactor no. 1 (C1) will be energized, which in turn will energize the indoor fan, outdoor fan and Compressor no. 1,

respectively.

If the space thermostat calls for a second stage of cooling

by supplying 24 v to Y2, Compressor contactor no. 2 (C2)

will be energized, thus energizing Compressor no. 2.

When the space thermostat is satisfied, Y2 will be deenergized first, which will deenergize Compressor no. 2.

Upon a further drop in space temperature, Y1 will be deenergized which will deenergize Compressor no. 1, and the

outdoor and indoor fans.

HEATING — Upon a request for heating from the space thermostat, terminal W1 will be energized with 24 v. On units

with economizer, the economizer damper blade will move to

minimum position regardless of the outdoor-air temperature, and the unit will operate as described in Cooling, Without Accessory Economizer section above. The IFC, OFC,

C1 and C2 will be energized. The reversing valves switch

position and the indoor fan, outdoor fan, Compressor no. 1,

and Compressor no. 2 are energized.

If the space temperature continues to fall while W1 is energized, W2 will be energized with 24 v, and the heater contactor(s) (HC) willbe energized, which will energize the electric

heater(s).

When the space thermostat is satisfied, W2 will be deenergized first, and the electric heater(s) will be

deenergized.

Upon a further rise in space temperature, W1 will be deenergized,and the reversing valve solenoids (RVS1and RVS2)

will be energized. On units with economizer, the economizer damper blade will move to the fully closed position.

DEFROST — When the temperature of the outdoor coil drops

below 28 F as sensed by the defrost thermostat (DFT2) and

the defrost timer is at the end of a timed period

(adjustable at 30, 50 or 90 minutes). RVS1 and RVS2 are

energized and the OFC is deenergized. This switches the

17

Page 18

NOTES:

1. In heating mode, economizer damper blade will move to the minimum position, and unit will operate as described for units without

economizer, regardless of outdoor air temperature.

2. The temperatures given in the graph are for demonstration purposes only and may vary depending on which thermostat is used.

LEGEND

C—Contactor

HC — Heater Contactor

IFC — Indoor-Fan Contactor

OAT — Outdoor-Air Thermostat

OFC — Outdoor-Fan Contactor

RVS — Reversing Valve Solenoid

W—Heating Stage

X—Contact Energized

Y—Cooling Stage

UNITS WITH ECONOMIZER

AVERAGE OUTDOOR-AIR TEMPERATURE GREATER THAN OAT SETTING

Thermostat Demand G Y1 Y2 W1 W2 C1 C2 IFC OFC RVS1 RVS2 HC

Second Stage Cooling XX X X X X X X X

First Stage Cooling XX X X X X X

Deadband (Offset)

First Stage Heating XXXX

Second Stage Heating XXXXX X

AVERAGE OUTDOOR-AIR TEMPERATURE LESS THAN OAT SETTING, BUT GREATER THAN −2 C (28 F)

Thermostat Demand G Y1 Y2 W1 W2 C1 C2 IFC OFC RVSI RVS2 HC

Second Stage Cooling XXX X X X X X

First Stage Cooling XX X X X

Deadband(Offset)

First Stage Heating XXXX

Second Stage Heating XXXXX X

UNITS WITHOUT ECONOMIZER

AVERAGE OUTDOOR-COIL TEMPERATURE LESS THAN −2C (28 F)

Thermostat Demand G Y1 Y2 W1 W2 C1 C2 IFC OFC RVSI RVS2 HC

Second Stage Cooling XX X X X X X X X

First Stage Cooling XX X X X X X

Deadband (Offset)

First Stage Heating XXXX

Second Stage Heating XXXXX X

AVERAGE OUTDOOR-COIL TEMPERATURE GREATER THAN −2 C (28 F)

Thermostat Demand G Y1 Y2 W1 W2 C1 C2 IFC OFC RVSI RVS2 HC

Second Stage Cooling XX X X X X X X X

First Stage Cooling XX X X X X X

Deadband (Offset)

First Stage Heating XXXX

Second Stage Heating XXXXX X

Fig. 20 — Typical Operating Sequence

18

Page 19

position of the reversing valves and shuts off the outdoor

fan. The electric heaters (if installed) will be energized. On

units with economizer,the economizer damperblade will move

to the fully closed position.

The unit continues to defrost until the coil temperature as

measured by DFT2 reaches 65 F or the duration of defrost

cycle completes a 10-minute period.

During the defrost mode, if circuit 1 defrosts first, RVS1

will oscillate between heating and cooling modes until the

defrost mode is complete.

At the end of the defrost cycle, the electric heaters (if installed) will be deenergized; the reversing valves switch and

the outdoor-fan motor will be energized. On units with economizer, the economizer damper blade will move to the minimum position. The unit will now operate in the heating mode.

If the space thermostat is satisfied during a defrost cycle,

the unit will continue in the defrost mode until the time or

temperature constraints are satisfied.

SERVICE

When servicing unit, shut off all electrical power to unit

to avoid shock hazard or injury from rotating parts.

Cleaning — Inspect unit interior at the beginning of each

heating and cooling season and as operating conditions

require.

Fig. 21 — Cleaning Outdoor Coil

INDOOR COIL

1. Turn unit power off. Remove indoor coil access panel.

2. If accessory economizer is installed, remove economizer

by disconnecting Molex plug and removing economizer

mounting screws. Refer to Accessory Economizer Installation Instructions for more details.

3. Slide filters out of unit.

4. Clean coil using a commercial coil cleaner or dishwasher

detergent in a pressurized spray canister.Washboth sides

of coil and flush with clean water. For best results, backflush toward return-air section to remove foreign

material.

5. Flush condensate pan after completion.

6. Reinstall economizer and filters.

7. Reconnect wiring.

8. Replace access panels.

OUTDOOR COIL — Inspect coil monthly. Clean outdoor

coil annually, and as required by location and outdoor air

conditions.

2-Row Coils— Clean coil as follows:

1. Turn off unit power.

2. Remove top panel screws on outdoor-coil end of unit.

3. Remove outdoor-coil corner post. See Fig. 21. To hold

top panel open, place coil corner post between top panel

and center post. See Fig. 22.

4. Remove device holding coil sections together at return

end of outdoor coil. Carefully separate the outer coil section 75 to 100 mm (3 to 4 in.) from the inner section. See

Fig. 23.

5. Use a water hose or other suitable equipment to flush down

between the 2 coil sections to remove dirt and debris. Clean

the outer surfaces with a stiff brush in the normal manner.

Fig. 22 — Propping Up Top Panel

Fig. 23 — Separating Coil Sections

6. Reposition the outer coil panel section and remove the

coil corner post from between the top panel and center

post. Secure the sections together.

7. Install the coil corner post, coil center post and replace

all screws.

19

Page 20

CONDENSATE DRAIN — Check and clean each year at

start of cooling season. In winter, keep drain dry or protect

against freeze-up.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions require

it. Replacement filters must be same dimensions as original

filters.

OUTDOOR-AIR INLET SCREENS — Clean screens with

steam or hot water and a mild detergent. Do not use disposable filters in place of screens.

Lubrication

COMPRESSORS — Each compressor is charged with correct amount of oil at the factory.

FAN-MOTOR BEARINGS — Fan motor bearings are of

the permanently-lubricated type. No further lubrication is

required. No lubrication of outdoor- or indoor-fan motors is

required.

Outdoor-Fan Adjustment (Fig. 24)

Refrigerant Charge — Amount of refrigerant charge

is listed on the unit nameplate (also refer to Tables 1A and

1B). Refer to Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants section.

Unit panels must be in place when unit is operating dur-

ing charging procedure.

LOW CHARGE HEATING OR NO CHARGE — Use stand-

ard evacuating techniques. After evacuating system, weigh

in the specified amount of refrigerant (refer to Tables 1A and

1B).

LOW CHARGE COOLING — Use Cooling Charging Chart,

Fig. 25 and 26. Vary refrigerant until the conditions of the

chart are met. Note the charging chart is different from type

normally used. Chart is based on charging the units to the

correct superheat for the various operating conditions. Accurate pressure gage and temperature sensing device are required. Connect the pressure gage to the service port on the

suction line. Mount the temperature sensing device on the

suction line and insulate is so that outdoor ambient temperature does not affect the reading. Indoor-air L/s (cfm) must be

within the normal operating range of the unit.

TO USE COOLING CHARGING CHART— Take the outdoor ambient temperature and read the suction pressure gage.

Refer to chart to determine what suction temperature should

be. If suction temperature is high, add refrigerant. If suction

temperature is low, carefully blow some of the charge. Recheck the suction pressure as charge is adjusted.

Example: (Fig. 26) (Circuit 1)

Outdoor Temperature ....................29C(85F)

Suction Pressure ...................483kPa(70psig)

Suction Temperature should be .............7C(46F)

(Suction Temperature may vary ± 3° C (5° F)

Fig.24 — Outdoor-Fan Adjustment

1. Shut off unit power supply.

2. Remove outdoor-fan assembly (grille, motor,motor cover

and fan) and loosen fan hub setscrews.

3. Adjust fan height as shown in Fig. 24.

4. Tighten setscrews and replace outdoor-fan assembly.

If Chargemastert charging device is used, temperature and

pressure readings must be accomplished using the charging

chart.

20

Page 21

Fig. 25 — Cooling Charging Charts, 50LJQ008

Fig. 26 — Cooling Charging Charts, 50LJQ012

21

Page 22

Page 23

Page 24

Copyright 1992 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 015-015 Printed in U.S.A. Form 50LJQ-C1SI Pg 24 1-92 Replaces: New

Loading...

Loading...