Page 1

Application Data

COMPRESSOR PHYSICAL DATA

OPEN-DRIVE COMPRESSORS

Operating Requirements

Discharge Temperature

High Compression Ratio

Suction Gas Superheat

. . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Keeping Liquid Refrigerant Out of

Compressor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Compressor Capacity Notes

Compressor Features and Accessories

Capacity Control

Hot Gas Bypass

Motor Selection Data

Drive Packages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

BOOSTER COMPRESSORS FOR REFRIG-

ERANT 12, 22, 502, AND 507/404A

Booster Application Data

Rating Basis

“R” Factors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . 29

Multistage System Pointers

Safety Factors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . 2-29

. . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . 4

. . . . . . . . . 29-37

. . . . . . . . . . . . . . . . . . . . . 29

CONTENTS

Page

Open-Drive Compressors

Water-Cooled Condensers

Determining Intermediate Pressure

Gas Desuperheating

Liquid Cooling

Oil Separators and Lubrication

Control Pressurestat for Booster

Application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Discharge Valve Springs

Water-Cooled Heads

Motor Selection Data

Compressor Starting Torque

Selection Procedure

CONDENSERS

Condenser Physical Data

Condenser Selection Considerations

Condenser Duty

Pulldown

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fouling and Fouling Factors

Water Circuiting Arrangements

Economics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Condenser Performance with

Ethylene Glycol

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-40

. . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5F,H

09RH

Page

. . . . . . . . . . . . . 31

. . . . . . . . . . . 37

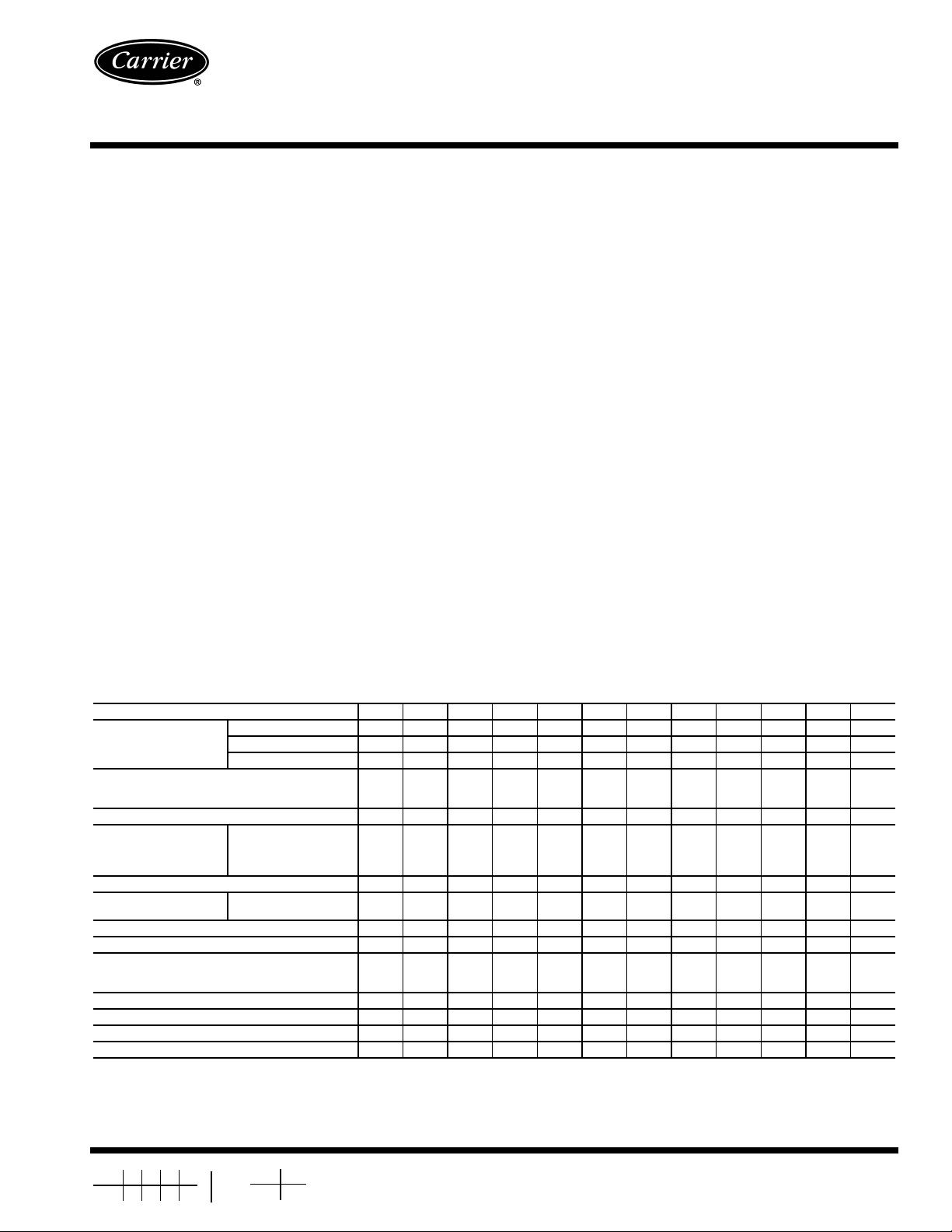

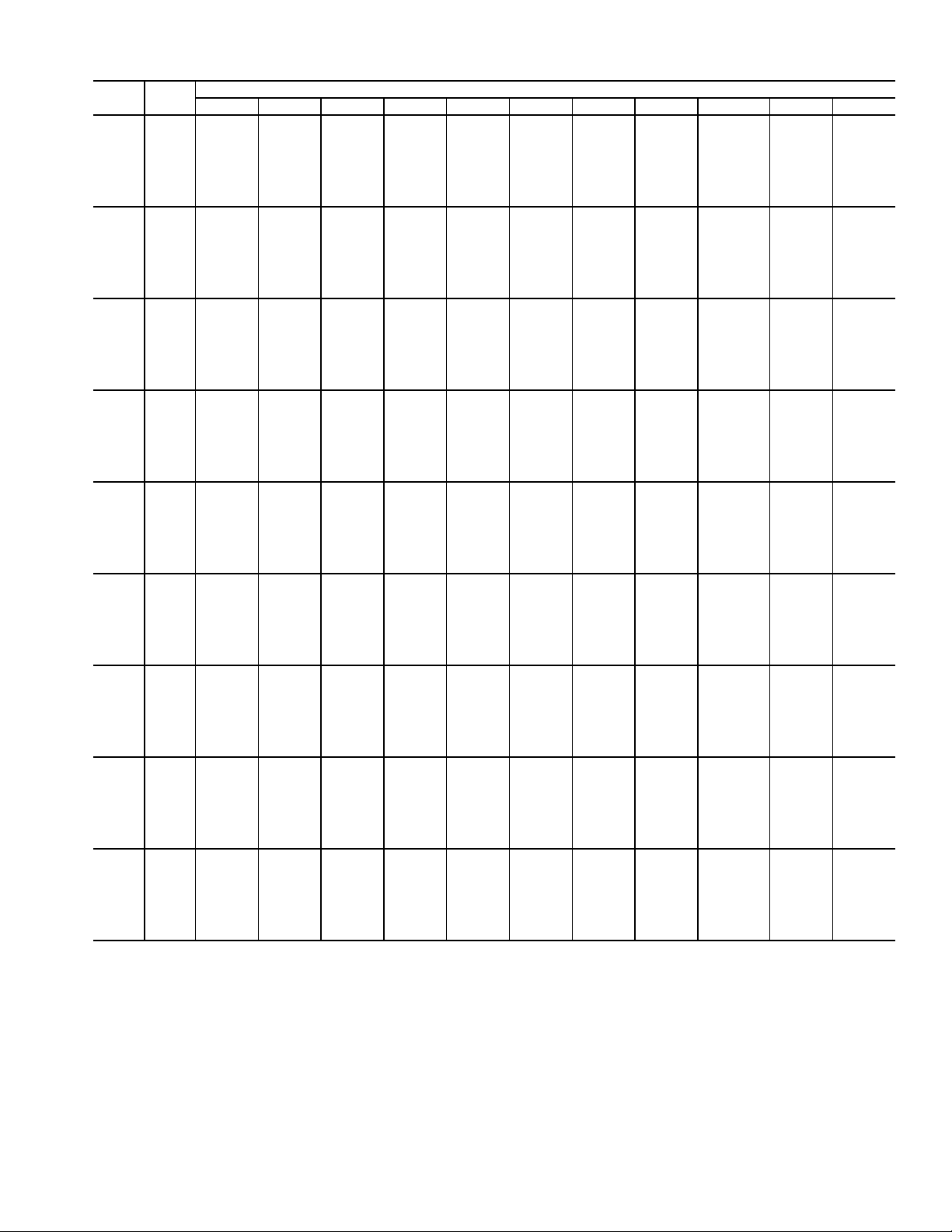

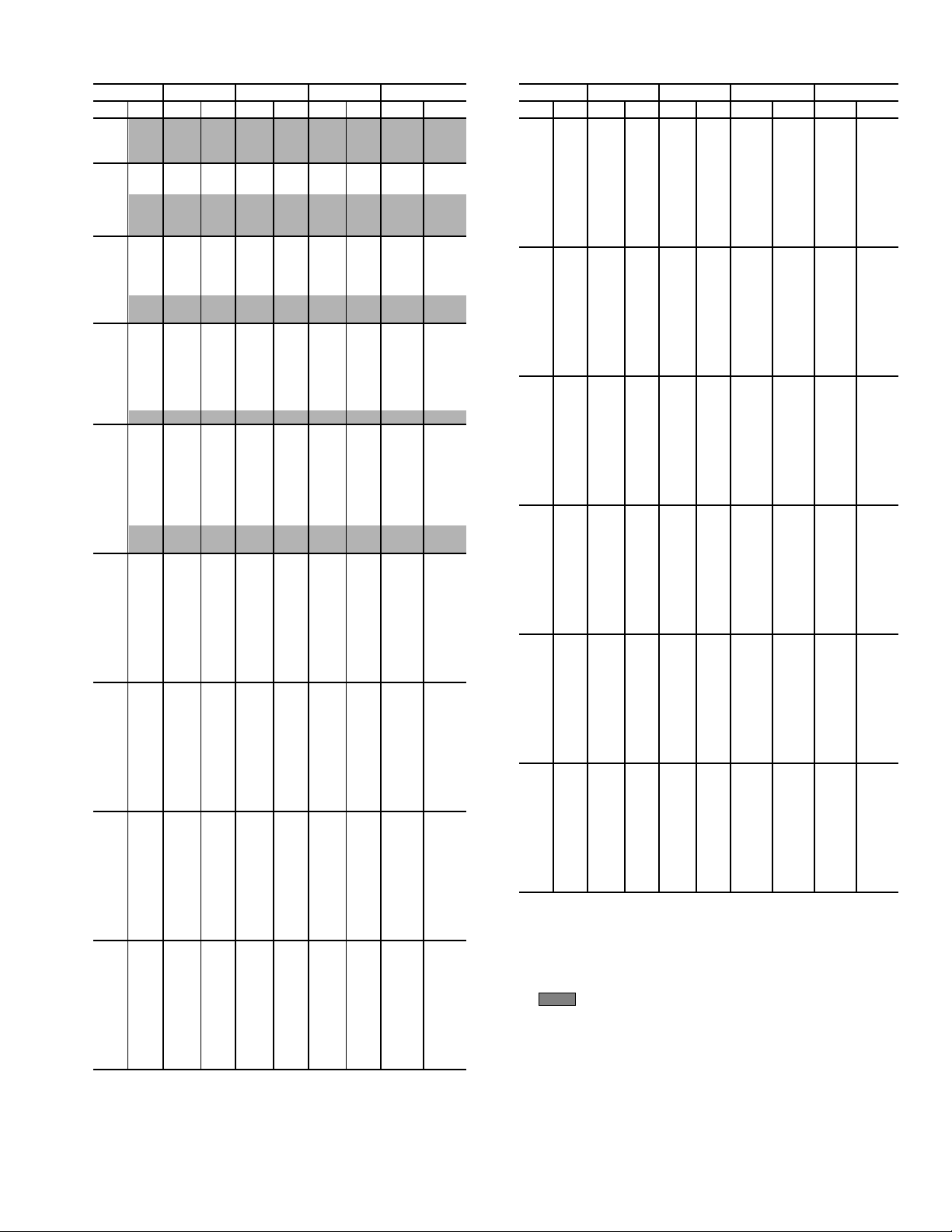

COMPRESSOR PHYSICAL DATA (Table 1)

Table 1 — Open-Drive Compressors

COMPRESSOR MODEL 5F20 5F30 5F40 5F60 5H40 5H46 5H60 5H66 5H80 5H86 5H120 5H126

Nominal Horsepower R-12, R-134a

R-22

R-502, R-507/404A

Number of Cylinders

Bore (in.)

Stroke (in.)

Displacement Cfm at 1750 Rpm

Ratings in Tons* R-12, R-134a

Max Speed (rpm)

Min Speed (rpm) For Lubrication

Net Oil Pressure (psig)†

Oil Charge (pt)

Normal Oil Level in Sight Glass

Min Oil Pressure for Unloader Action (psig)

Suction Line ODF (in.)

Discharge Line ODF (in.)

Bare Compressor Weight (lb)

LEGEND *40 F saturated suction, 105 F saturated discharge, 15 F superheat, 0° F

C.L. —

ODF —

Center Line

Outside Diameter Female (in.)

R-22

R-502

R-507/404A

For Unloader Action

10 15 20 25 40 60 60 75 75 100 125 150

10 15 20 25 40 60 60 75 75 100 125 150

2

19.8 29.8 39.8 59.6 92.4 115.5 138.4 173.0 184.7 231.0 276.8 346.0

5.18 7.76 10.5 15.7 24.7 30.6 37.0 45.9 49.5 61.1 74.0 91.8

8.46 12.7 16.8 25.3 39.6 49.1 59.4 73.8 79.2 98.2 119.0 145.0

8.85 13.2 17.7 26.5 40.5 50.2 60.9 75.4 81.2 100.7 122.0 151.2

8.40 12.56 16.77 25.17 38.48 47.72 57.73 71.58 76.98 95.47 115.47 143.19

1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750

400 400 400 400 400 400 400 400 400 400 400 400

600 700 800 900 800 800 900 900 1100 1100 900 900

45 45 45 45 45 45 45 45 45 45 45 45

C.L. C.L.

22 28 35 35 35 35 35 35 35 35 35 35

1

7

175 215 355 400 610 610 795 795 1115 1115 1580 1580

1

57

23464466881212

1

22222

55

1

/

/

10 15 25 40 40 50 50 75 75 100

2

/221/221/221/231/431/431/431/431/431/431/431/

1

/

12 13 18 18 21 21 41 41 61 61

2

3

3

/

″

8

Above

Above

C.L.

C.L.

/815/815/821/825/825/831/831/831/831/841/841/

13/813/815/821/821/831/831/831/831/841/841/

8

3

/437/

/

″

8

C.L. C.L. C.L. C.L. C.L. C.L. C.L . C.L.

subcooling.

†Net oil pressure = oil pressure gage reading – suction pressure. The

above oil pressure is typical with mineral or alkylbenzene oils. A slight

increase in oil pressure may result with the use of PolyolEster (POE) oil.

16

23/437/

16

23/437/

16

23/437/

16

4

8

8

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2244

Tab 2a4a3a4b

Book 3

New PC 802 Catalog No. 510-509 Printed in U.S.A. Form 5F,H/09RH-2XA Pg 1 8-02 Replaces: 5F,H/09RH-1XA

Ta b D E 1

Page 2

OPEN-DRIVE COMPRESSORS

These compressors are designed to operate with Refriger-

ants 12, 22, 134a, 502, or 507/404A. See Table 1.

Operating Requirements —

a reciprocating compressor depends on 3 fundamental

requirements:

1. Prevention of excess discharge temperature.

2. Adequate compressor lubrication.

3. A clean and dry system.

Discharge Temperature —

discharge valves within the cylinders is a controlling factor.

Some cooling of the discharge gas occurs before reaching the

discharge stop valve, thus when water-cooled heads are used,

this cooling is greater than it is without water cooling. To prevent excessive temperature at the compressor discharge valves,

the following temperatures, when measured immediately

following the discharge stop valve, must never be exceeded:

For nonwater-cooled heads . . . . . . . . . . . . . . . . . . 275 F max

For water-cooled heads . . . . . . . . . . . . . . . . . . . . . 250 F max

The approximate discharge gas temperature can be found

by using the following equation:

T2 = T

Where:

T

= Discharge temperature, F absolute

2

T1= Suction temperature, F absolute (including

superheat)

= Discharge pressure, psia

P

2

P1= Suction pressure, psia

N = Compression exponent of the gas (see T able 2)

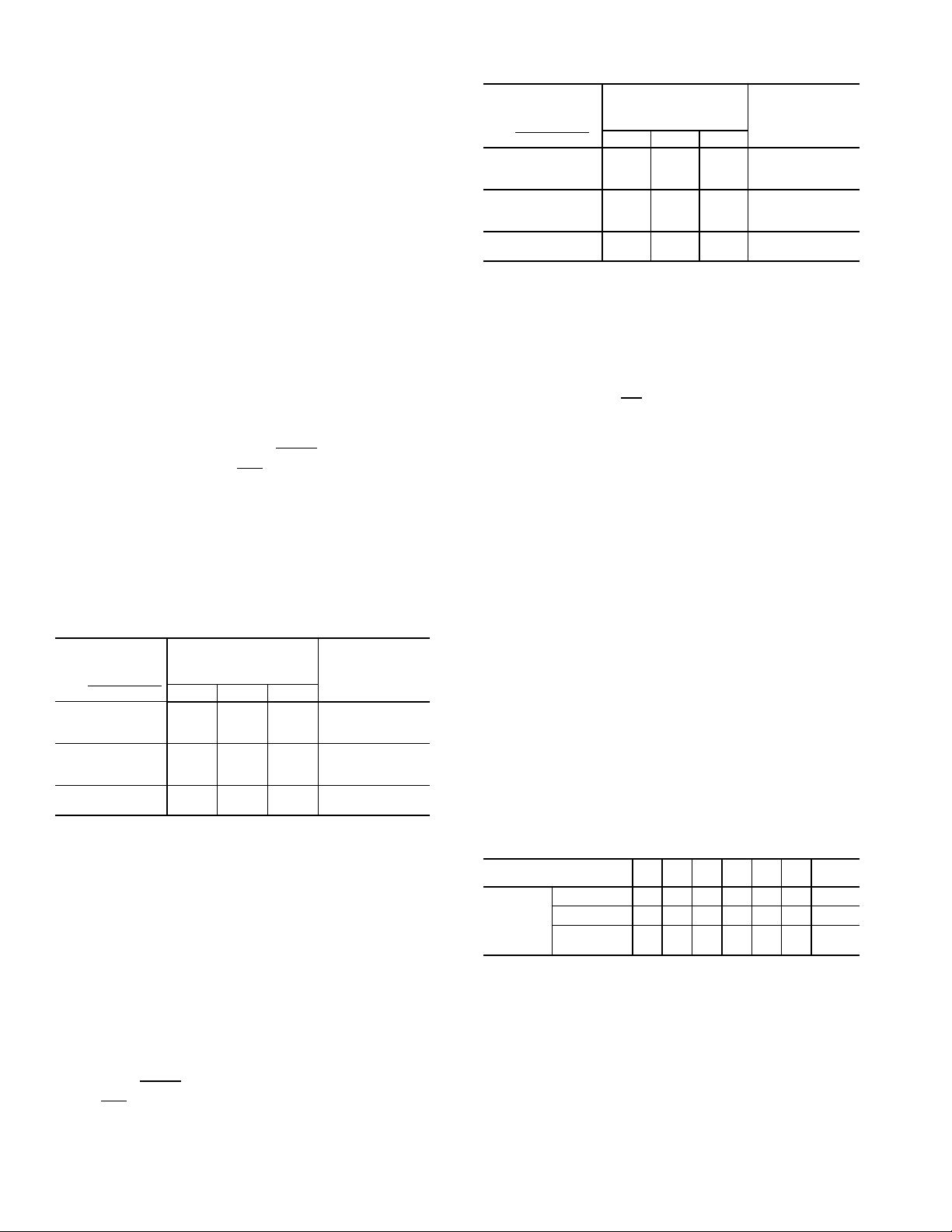

Table 2 — Compression Exponent “N”

COMPRESSION

RATIO

Discharge

=

Suction psia

2

3

4

5

6

8

10

12

*For R-134a and R-507/404A refer to the Carlyle Compressor Selection

program (http://www.carlylecompressor.com/TechnicalInfo/Carwin.htm) to

determine discharge temperature. The selection program can also be

used for R-22 and R-502 in place of the discharge temperature formulas.

R-12 R-22 R-502

1.216 1.325 1.234 1.240

1.191 1.258 1.216 1.218

1.177 1.240 1.206 1.205

1.172 1.234 1.197 1.199

1.166 1.232 1.190 1.196

1.160 1.228 1.178 1.192

1.155 1.225 1.169 1.187

1.150 1.224 1.161 1.182

The value of compression exponent “N” depends upon the

properties of gas compressed, degree of cooling in compressor

jacket, leakages, etc.

To simplify discharge temperature calculations, the preceding formula may be stated in the following form:

T2 = [(460 + T1) x C] – 460

Where:

T2 = Discharge temperature, F actual

T1 = Suction gas temperature, F actual (including

superheat)

N – 1

C =

(P2)

P1

N

Values for “C” at various compression ratios ar e listed in

T able 3.

(P2)

1

WITHOUT

WATER-COOLED

HEADS*

Satisfactory operation of

The temperature at the

N – 1

N

P1

WATER-COOLED

HEADS

WITH

R-22

Table 3 — “C” Factors

COMPRESSION

RATIO

Discharge psia

=

Suction psia

2

3

4

5

6

8

10

12

*For R-134a and R-507/404A refer to the Carlyle Compressor Selection

program (http://www.carlylecompressor.com/TechnicalInfo/Carwin.htm) to

determine discharge temperature. The selection program can also be

used for R-22 and R-502 in place of the discharge temperature formulas.

WITHOUT

WATER-COOLED

HEADS*

R-12 R-22 R-502

1.14 1.17 1.13 1.15

1.19 1.25 1.22 1.22

1.23 1.31 1.27 1.27

1.26 1.36 1.30 1.31

1.29 1.40 1.33 1.34

1.33 1.47 1.37 1.40

1.36 1.53 1.40 1.44

1.38 1.57 1.41 1.47

WITH

WATER-C OOL ED

HEADS

R-22

Example:

Refrigerant 12

P

Compression Ratio

2

= 8

P

1

Factor C = 1.33

Suction Temperature, T1 = 0° F saturated, superheated

to 65 F

Solution:

T2 = [(460 + 65) x 1.33] – 460

= 698 – 460

= 238 F

Although exponents are shown for high compression ratios,

these are for information only. Rating tables define allowable

selection and operation limits.

High Compression Ratio —

Avoid compressor operation at compressor ratios exceeding those covered in the rating

tables. For operating conditions outside the limits shown in

these tables, use 2-stage compression. Care must be taken to

prevent the compressor from pulling down to levels outside the

rating tables.

Suction Gas Superheat —

Excessive suction gas superheat will result in abnormally high discharge temperatures,

which must be avoided. When using Refrigerants 12, 134a, 502,

and 507/404A it is recommended that the actual suction gas

temperature not exceed the v alues in Table 4.

Table 4 — Actual Suction Gas Temperature

Limits (F) Refrigerants 12, 134a, 502, and

507/404A*

SATURATED SUCTION

GAS TEMP

Actual

Suction

Gas Temp

*With Refrigerant 22, the suction gas superheat should never exceed

25 F for continuous operation.

R-12

R-134a

R-502

R-507/404A

–60 –50 –40 –30 –20 –10

— — 35 45 55 65 65

—————— 65

25 35 45 55 65 65 65

0 AND

ABOVE

Keeping Liquid Refrigerant Out of Compressor —

liquid particles in suction gas must be kept out of the compressor by proper system design and compressor control. Under

operating conditions, presence of unevaporated liquid refrigerant in the compressor tends to break down oil film on cylinder

walls, resulting in increased wear and loss of machine capacity.

expansion valve will prevent excessive amounts of liquid from

entering the compressor.

Liquid refrigerant, or excessive amounts of entrained

During compressor operation, proper adjustment of the

2

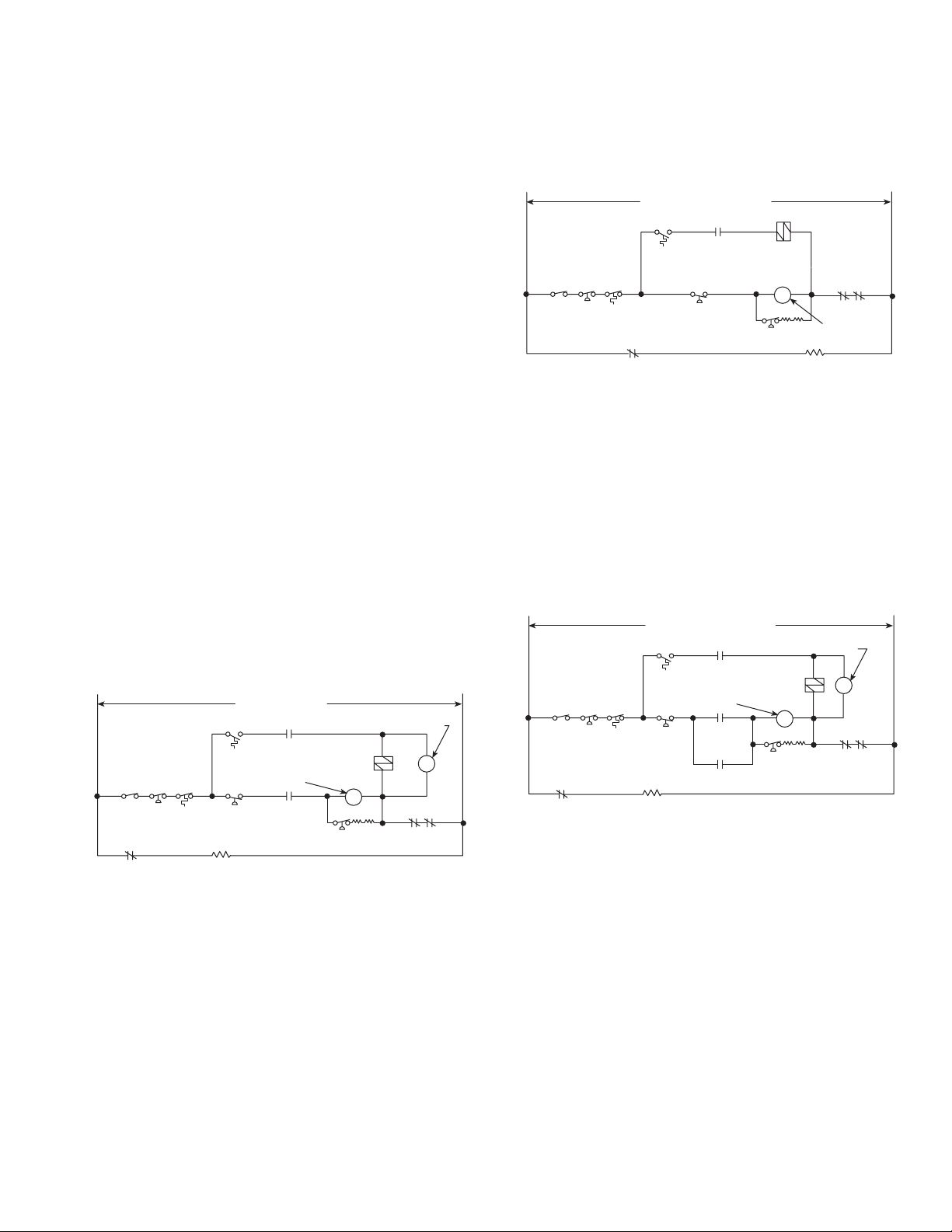

Page 3

During compressor shutdown, gravity, thermal action and

HIGHPRESS.

SWITCH

AUTOOFF

SWITCH

OIL

FAILURE

SWITCH

LOWPRESS.

SWITCH

COMPR

STARTER

THERMO

EVAP

AUX

CONT

SOLENOID

VALV E

OIL FAILURE

SWITCH

OVERLOADS

CONTROL POWER CIRCUIT

COMPR

AUX CONT

CRANKCASE

HEATERS

Fig. 2 — Automatic Pumpdown Control

HIGHPRESS.

SWITCH

AUTOOFF

SWITCH

OIL

FAILURE

SWITCH

LOWPRESS.

SWITCH

COMPR

STARTER

THERMO

EVAP

AUX CONT

SOLENOID

VALV E

OIL FAILURE

SWITCH

OVERLOADS

CONTROL POWER CIRCUIT

COMPR

AUX CONT

CRANKCASE

HEATERS

PUMPOUT

RELAY CONTACT

COMP

AUX

CONTACT

PUMPOUT

RELAY

COIL

Fig. 3 — Single Pumpout Control

refrigerant absorption can result in a refrigerant and oil mixture

in compressor crankcase. Gravity flow can be prevented by the

use of recommended loops, but thermal action and the absorption of refrigerant by lubricating oil cannot be prevented by

piping design.

For the above reasons, the compressor must be controlled

during idle times by one of the following methods.

MINIMUM PROTECTION — The minimum protection that

Carrier will allow is shown in Fig. 1. Actuated control thermostat energizes crankcase heater and closes the liquid line

solenoid valve simultaneously. With crankcase heaters

energized, the crankcase temperature is always held above

shutdown temperature in the evaporator coil and there will be

no refrigerant migration to the crankcase.

With this type of control, a control relay is required and

crankcase heaters have to be energized when the compressor is

not operating.

The control relay coil is locate d in parallel with the liquid

line solenoid, and a normally open control relay contact is

added in series with the compressor starter and other auxiliary

safety devices.

When the thermostat calls for cooling, the solenoid valve

opens and control relay is energized. This closes the relay

contact and, if other safety devices are in their normal position,

compressor will start. Simultaneously, the normally closed

compressor auxiliary contact will open, removing crankcase

heaters from the circuit.

When the thermostat is satisfied, the solenoid will close and

control relay is deenergized. This opens relay contacts and

compressor stops. This causes compressor auxiliary contacts to

close, energizing crankcase heaters.

Specifications are sometimes written to call for a degree of

protection greater than that afforded by the standard method. If

this is the case, either single pumpout or automatic pumpdown

control may be required.

protection against liquid refrigerant accumulating in the

compress or cr an kc as e.

Do not use pumpdown control with dry expansion coolers

as it may cause frost pinching or freeze-up. Do not use

pumpdown control with dry expansion coolers if it is anticipated that there will be short bursts of system operation, as this

will result in a gradual loss of oil.

SINGLE PUMPOUT CONTROL (Fig. 3) — Pumpout control is not as effective as pumpdown control in keeping liquid

refrigerant out of the crankcase. However, it is usually satisfactory when used with crankcase heaters if pumpdown is not

acceptable.

Single pumpout control is similar to pumpdown control,

except that a pumpout relay is added, a normally open c ompressor auxiliary contact is necessary, and energizing of crankcase heaters is required at end of each operating cycle.

CONTROL POWER

AUTOOFF

SWITCH

COMPR

AUX CONT

HIGHPRESS.

SWITCH

OIL

FAILURE

SWITCH

CRANKCASE

HEATERS

THERMO

LOWPRESS.

SWITCH

Fig. 1 — Minimum Protection

AUTOMATIC PUMPDOWN CONTROL (Fig. 2) — Pumpdown control is the most effective means of compressor control

in keeping liquid refrigerant out of the crankcase on system

shutdown.

In the basic pumpdown control sequence, the thermostat

controls the liquid line solenoid valve to stop or start the flow

of refrigerant to the evaporator as required.

The pumpdown control system permits compressor cycling

if a system malfunction allows low side pressure to rise.

Although this cycling is sometimes considered objectionable, it

illustrates need for maintenance attention and provides positive

EVAP

AUX CONT

COMPR

STARTER

CONTROL

RELAY

SOLENOID

VALV E

OIL FAILURE

SWITCH

CONTROL

RELAY

OVERLOADS

With single pumpout control, when the thermostat is satisfied, the compressor pumps down once and stops. It starts

again only when the thermostat calls for cooling. In pumpdown

control, the compressor cycles only on the low-pressure switch,

regardless of thermostat demands.

Do not use pumpout control with dry expansion coolers as it

may cause frost pinching or freeze-up.

MANUAL PUMPDOWN — The compressor may be controlled manually without the use of pumpdown, or single

pumpout control, and without crankcase heaters, provided t he

system is at all times under control of a qualified operator. The

operator will pump down the system by use of manual valves

and will keep liquid, suction and discharge valves closed when

the machine is not operating.

3

Page 4

Compressor Capacity Notes

1. Compressor capacities are based on 1750 rpm and 15 F

subcooling for all unit sizes and refrigerants.

2. Multiplying factors for other rpm:

RPM 1450 1160

Capacity

Bhp

0.835 0.674

0.798 0.602

See Multiplying Factors chart on page 31.

3. Liquid subcooling greater than (less than) 15 F incorporated in ratings increases (decreases) system c apacity by

1

/2 of 1% for each degree of subcooling. When correcting

for subcooling, brake horsepower does not change.

4. Refrigerant temperatures shown in Table 5 are saturation

temperatures corresponding to pressures indicated at

compressor. Actual gas temperatures are higher because

of superheat.

5. Capacities are based on actual suction gas tempera-

tures to compressor of 65 F for R-12, R-134a, R-502,

and R-507/404A. (This assumes superheat is obtained

from liquid suction inter changer or in evaporator.)

Capacity corrections, other than for rated suction gas

temperatures, may be obtained by using Rating Basis and

Capacity Multipliers Tables 6 and 7. Refrigerant-22

suction gas superheat for ratings (15 F) normally occurs

because of expansion valve operation and line losses.

Therefore, R-22 ratings can be used without adjustment.

An alternate method for capacity correction is to run the

Carlyle Selection program to obtain performance ratings

at other than 65 F return gas temperature.

Compressor ratings and capacities are included in

T ables 8-12.

Compressor Features and Accessories

WAT ER - COOLED HEADS AND OIL COOLERS — Water

cooled heads are typically not necessary for R-12 or R-134a

applications within the range of compressor ratings shown in

this publication. For R-502, or R-507/404A at the shaded conditions shown in the compressor ratings tables, water-cooled

heads may be necessary, if the discharge temperature is greater

than 275 F. The discharge temperature will increase with return

gas temperature.

When operating conditions are such that suction gas

becomes highly superheated and/or the compression ratio is

high, it is recommended that an oil cooler be used on the compressor. An oil cooler is required on increased displacement

compressors (5H46, 66, 86, and 126) on installations where

compressor(s) can be subjected to extended periods of continuous, fully unloaded operation. These periods do not afford

sufficient removal of compression and friction heat, and could

result in overheating of the running gear, shaft seal and crankcase oil. The addition of an oil cooler removes excessive

heat, ensuring increased life expectancy of compressor and

components.

Extended periods of continuous, fully unloaded operation

will occur usually on variable-volume installations that use hot

gas bypass to maintain conditions under all load situations.

Without hot gas bypass, the compressor will usually cycle on

the low-pressure switch (or temperature controlling device)

giving time for seal, oil and crankcase to cool.

On multiple-compressor installations where all units are

manifolded into one refrigerant circuit, the controls should be

designed to cycle off compressors at light loads to put maximum output on the still operative compressor. It is always

desirable for the compressor to operate with as many cylinders

as possible in loaded condition.

Water-cooled oil cooler package is available from the

factory and is easily field installed on all 5 Series compressors.

Refer to 5F,H Compressor Ratings to determine when oil

coolers are required. These ratings, however, do not indicate oil

cooler requirements during periods of extended continuous

operation under fully unloaded operation. This should be

determined on individual job basis.

W ater flow through compressor heads (and w ater-cooled oil

coolers, if used) must be shut off when the compressor is not

running to prevent refrigerant vapors from condensing at the

compressor during OFF cycles. For this purpose a solenoid

valve is recommended in the water supply line to compressor

heads.

Values listed in Table 13 assume a water temperature rise of

30 degrees. Oil cooler and water-cooled heads must be piped in

series, with the oil cooler first. Leaving water temperature

should be between 100 F and 120 F, w ith 120 F being maximum allowable temperature. Maximum working pressure for

water-cooled heads is 125 psi.

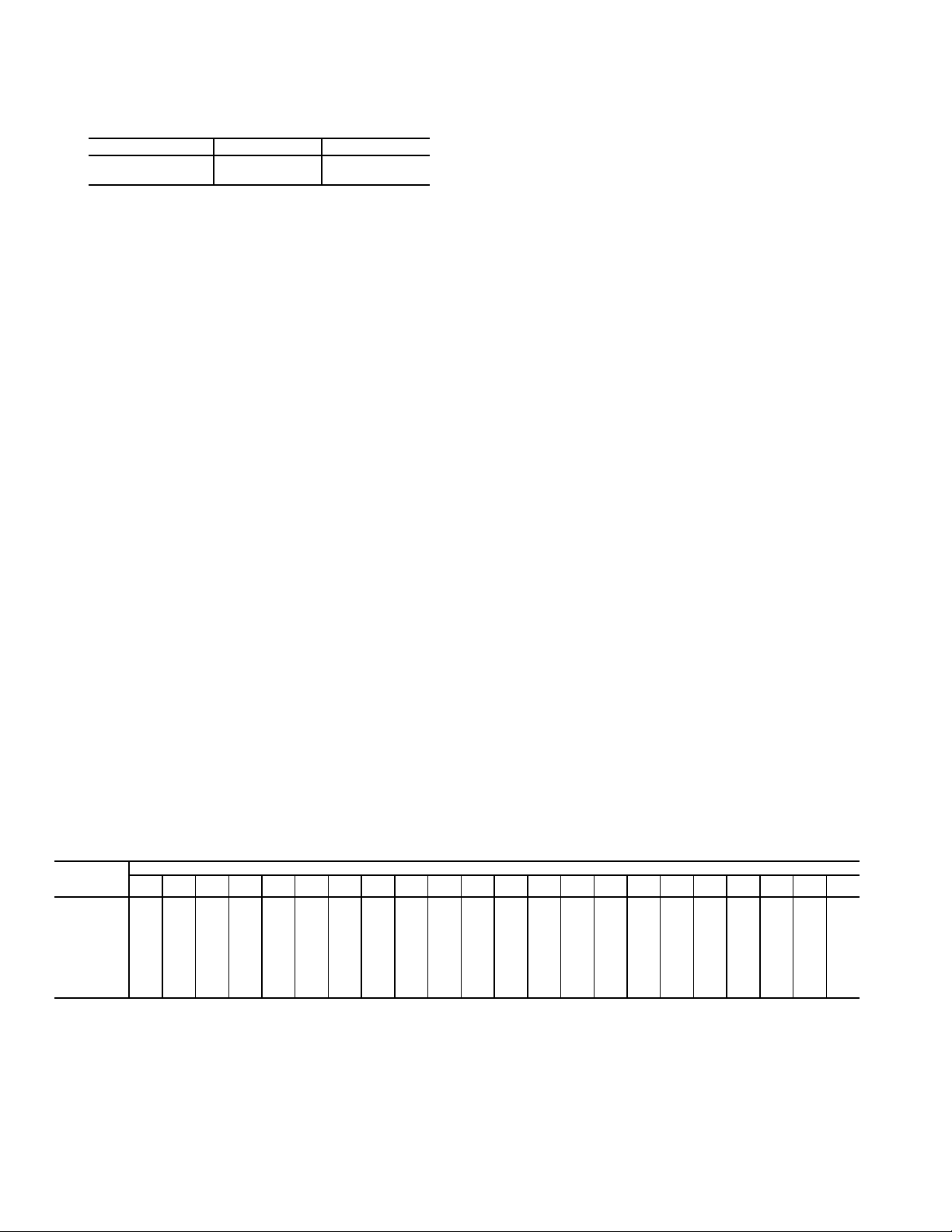

Total Heat Rejection (tons) = Compressor Capacity (tons) x Heat Rejection Factor*

Table 5 — Total Heat Rejection Factors

SAT.

DISCHARGE

TEMP (F)

80 1.610 1.547 1.490 1.439 1.391 1.344 1.300 1.256 1.214 1.176 1.168 1.160 1.155 1.150 1.142 1.138 1.129 1.121 1.118 1.112 1.110 1.105

90 — 1.590 1.526 1.472 1.422 1.373 1.327 1.282 1.238 1.196 1.190 1.180 1.178 1.171 1.165 1.157 1.150 1.142 1.138 1.135 1.129 1.122

100 — 1.630 1.570 1.513 1.461 1.409 1.361 1.312 1.267 1.222 1.215 1.205 1.202 1.200 1.190 1.180 1.175 1.165 1.162 1.158 1.150 1.143

105 — 1.655 1.595 1.538 1.483 1.431 1.380 1.330 1.283 1.237 1.232 1.220 1.219 1.215 1.205 1.194 1.189 1.178 1.175 1.170 1.162 1.155

110 ——1.622 1.564 1.508 1.454 1.402 1.350 1.301 1.253 1.248 1.238 1.235 1.228 1.220 1.208 1.200 1.192 1.190 1.185 1.178 1.168

120 ——1.698 1.628 1.565 1.508 1.451 1.395 1.341 1.288 1.280 1.270 1.265 1.261 1.251 1.240 1.232 1.222 1.220 1.215 1.205 1.195

130 —————1.567 1.506 1.445 1.383 1.327 1.320 1.310 1.300 1.295 1.285 1.275 1.268 1.255 1.250 1.248 1.238 1.225

140 ——————1.565 1.500 1.430 1.368 1.355 1.345 1.338 1.332 1.318 1.310 1.300 1.290 1.288 1.280 1.270 1.255

145 ———————1.526 1.455 1.390 1.378 1.365 1.355 1.350 1.340 1.330 1.320 1.310 1.300 1.298 1.285 1.270

*Complete capacity corrections before calculating for total heat rejection (refer to Compressor Capacity Note 5).

–60–50–40–30–20–100 102030323435363840424445464850

SATURATED SUCTION TEMPERATURES (F)

4

Page 5

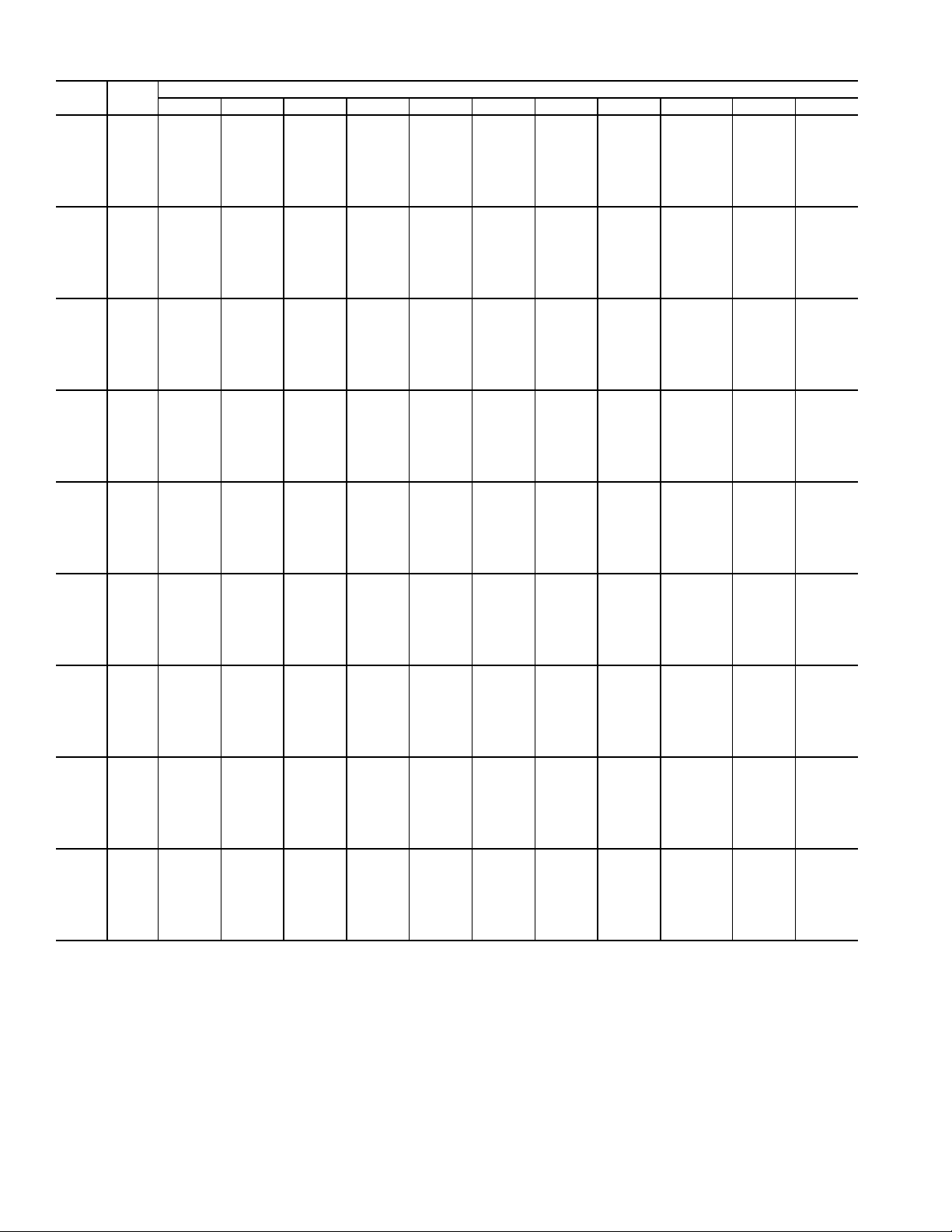

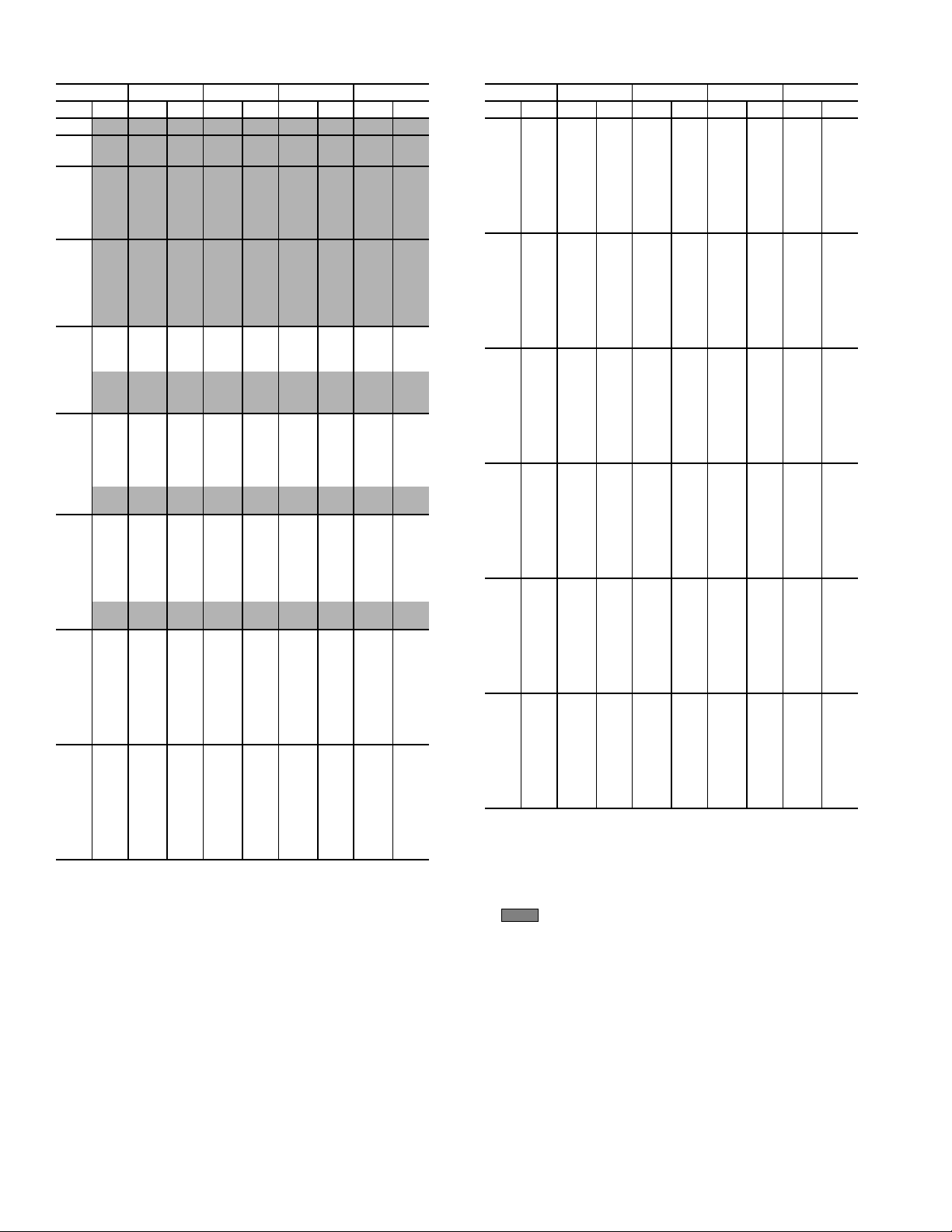

Table 6 — Rating Basis and Capacity Multipliers for R-12 and R-134a*

SST

–30

–20

–10

SDT —

SST —

*R-134a capacity multipliers start at 0° F SST and above.

SDT

(F)

0

10

20

30

40

50

(F)

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

Saturated Discharge Temperature

Saturated Suction Temperature

–30 –20 –10 0 10 20 30 40 50 60 65

0.963 0.966 0.970 0.973 0.977 0.981 0.985 0.989 0.993 0.998 1.000

0.951 0.956 0.960 0.965 0.970 0.976 0.981 0.986 0.992 0.997 1.000

0.938 0.944 0.950 0.957 0.963 0.970 0.977 0.983 0.990 0.997 1.000

0.923 0.931 0.939 0.947 0.955 0.964 0.972 0.980 0.988 0.996 1.000

0.906 0.916 0.926 0.936 0.945 0.958 0.966 0.976 0.986 0.995 1.000

0.887 0.899 0.912 0.924 0.936 0.949 0.960 0.972 0.983 0.994 1.000

0.865 0.880 0.895 0.910 0.924 0.939 0.953 0.967 0.980 0.993 1.000

— 0.968 0.971 0.974 0.978 0.982 0.985 0.989 0.994 0.998 1.000

— 0.957 0.962 0.967 0.971 0.976 0.981 0.987 0.992 0.997 1.000

— 0.946 0.952 0.953 0.964 0.971 0.977 0.984 0.990 0.997 1.000

— 0.932 0.940 0.948 0.956 0.964 0.972 0.980 0.988 0.996 1.000

— 0.917 0.927 0.937 0.947 0.957 0.967 0.976 0.986 0.995 1.000

— 0.900 0.912 0.925 0.937 0.949 0.960 0.972 0.983 0.994 1.000

— 0.880 0.895 0.910 0.925 0.939 0.953 0.967 0.980 0.993 1.000

——0.973 0.976 0.979 0.983 0.986 0.990 0.994 0.998 1.000

——0.964 0.968 0.973 0.977 0.982 0.987 0.992 0.997 1.000

——0.953 9.959 0.965 0.971 0.978 0.984 0.990 0.997 1.000

——0.940 0.949 0.957 0.965 0.973 0.981 0.988 0.996 1.000

——0.928 0.938 0.948 0.957 0.967 0.977 0.986 0.995 1.000

——0.913 0.925 0.937 0.949 0.961 0.972 0.983 0.994 1.000

——0.896 0.910 0.925 0.939 0.953 0.967 0.980 0.993 1.000

———0.978 0.981 0.984 0.987 0.991 0.994 0.998 1.000

———0.970 0.974 0.979 0.983 0.988 0.993 0.998 1.000

———0.961 0.967 0.973 0.979 0.985 0.991 0.997 1.000

———0.951 0.958 0.965 0.973 0.981 0.989 0.996 1.000

———0.939 0.949 0.958 0.968 0.977 0.986 0.995 1.000

———0.926 0.938 0.950 0.961 0.972 0.983 0.995 1.000

———0.911 0.925 0.939 0.953 0.967 0.980 0.994 1.000

————0.983 0.984 0.989 0.992 0.995 0.998 1.000

————0.976 0.980 0.984 0.989 0.993 0.998 1.000

————0.969 0.974 0.980 0.985 0.991 0.997 1.000

————0.960 0.967 0.974 0.982 0.989 0.996 1.000

————0.950 0.959 0.968 0.977 0.987 0.996 1.000

————0.939 0.950 0.962 0.973 0.984 0.995 1.000

————0.926 0.940 0.954 0.967 0.981 0.994 1.000

—————0.988 0.990 0.993 0.995 0.998 1.000

—————0.982 0.986 0.990 0.994 0.998 1.000

—————0.976 0.981 0.986 0.992 0.997 1.000

—————0.969 0.975 0.982 0.989 0.996 1.000

—————0.961 0.969 0.978 0.987 0.996 1.000

—————0.951 0.962 0.973 0.984 0.995 1.000

—————0.941 0.954 0.968 0.981 0.994 1.000

——————0.992 0.994 0.996 0.999 1.000

——————0.988 0.991 0.994 0.998 1.000

——————0.983 0.987 0.992 0.997 1.000

——————0.977 0.983 0.990 0.997 1.000

——————0.971 0.979 0.987 0.996 1.000

——————0.963 0.974 0.984 0.995 1.000

——————0.955 0.968 0.981 0.994 1.000

———————0.996 0.997 0.999 1.000

———————0.992 0.995 0.998 1.000

———————0.989 0.993 0.998 1.000

———————0.985 0.991 0.997 1.000

———————0.980 0.988 0.996 1.000

———————0.975 0.985 0.995 1.000

———————0.969 0.981 0.994 1.000

————————0.998 0.999 1.000

————————0.996 0.999 1.000

————————0.994 0.998 1.000

————————0.992 0.997 1.000

————————0.989 0.996 1.000

————————0.986 0.995 1.000

————————0.982 0.994 1.000

LEGEND

RETURN GAS TEMPERATURE (F)

5

Page 6

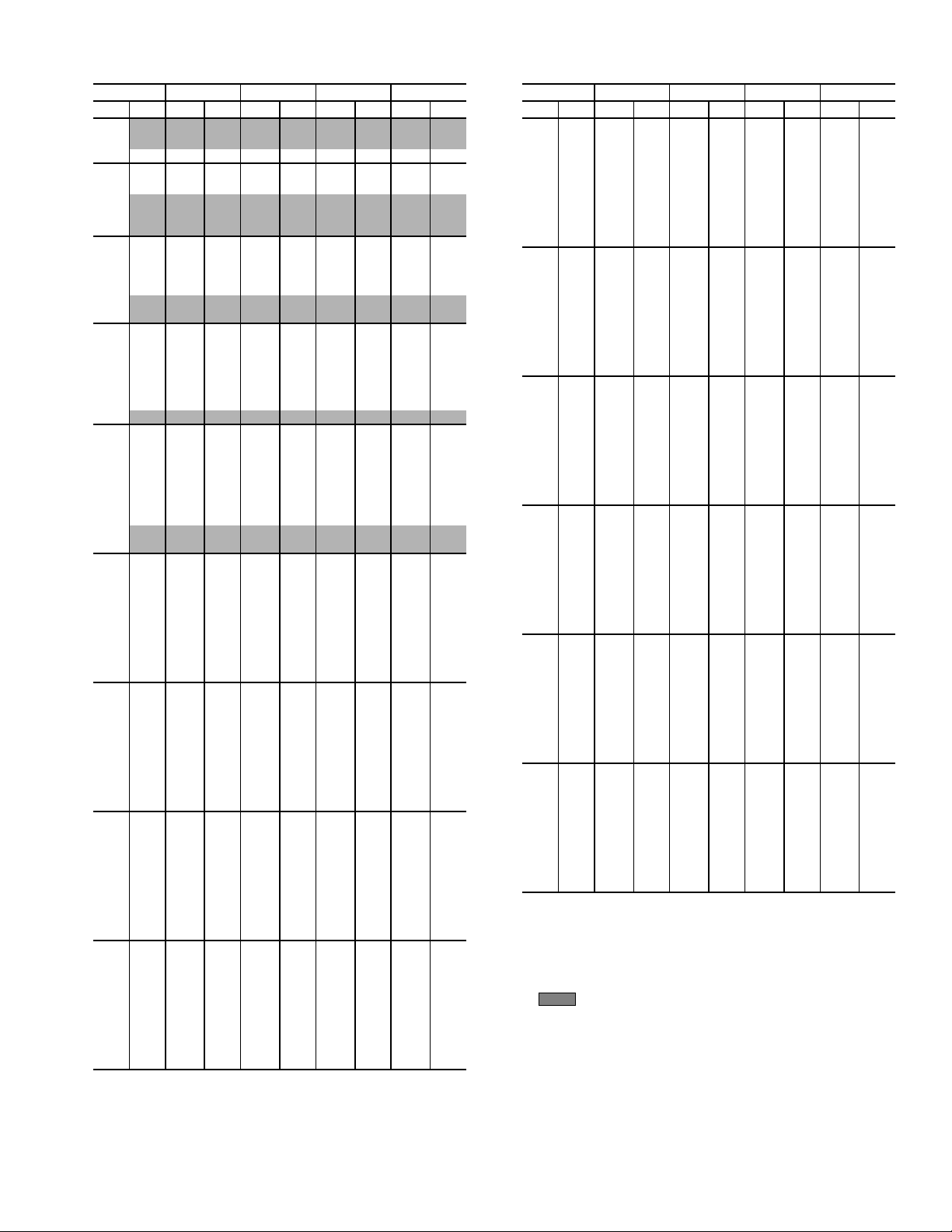

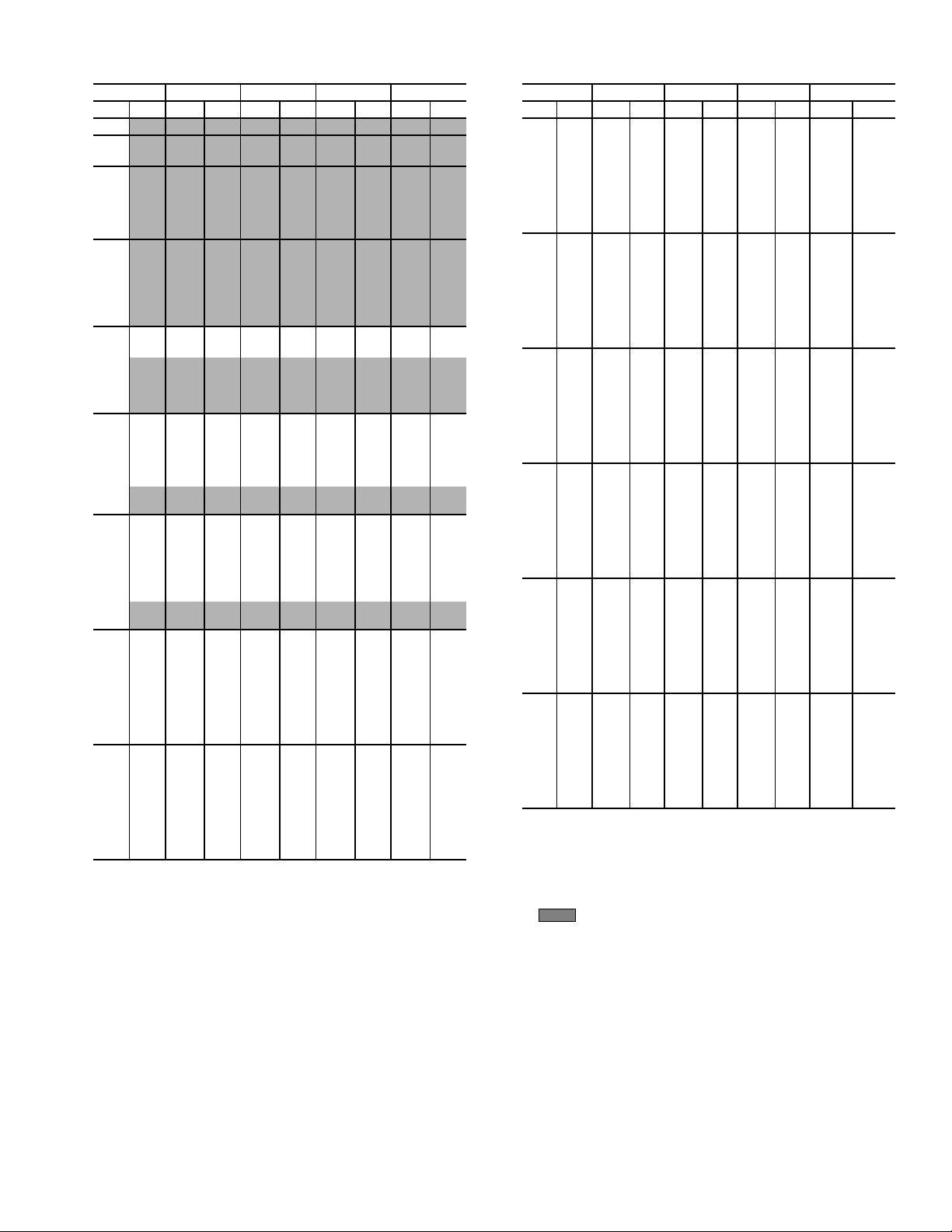

Table 7 — Rating Basis and Capacity Multipliers for R-502 and R-507/404A

SST

(F)

–30

–20

–10

0

10

20

30

40

50

SDT

(F)

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

90

100

110

120

130

140

150

RETURN GAS TEMPERATURE (F)

–30 –20 –10 0 10 20 30 40 50 60 65

0.913 0.922 0.931 0.941 0.950 0.959 0.968 0.977 0.986 0.995 1.000

0.893 0.905 0.916 0.928 0.939 0.956 0.962 0.973 0.984 0.995 1.000

0.870 0.884 0.899 0.913 0.927 0.941 0.954 0.967 0.981 0.994 1.000

0.843 0.861 0.879 0.896 0.913 0.929 0.945 0.961 0.977 0.992 1.000

0.812 0.834 0.855 0.876 0.896 0.916 0.935 0.954 0.973 0.991 1.000

0.774 0.801 0.826 0.852 0.876 0.900 0.923 0.946 0.968 0.989 1.000

0.728 0.760 0.792 0.822 0.851 0.880 0.908 0.935 0.961 0.987 1.000

— 0.925 0.933 0.942 0.951 0.960 0.969 0.978 0.987 0.996 1.000

— 0.906 0.918 0.929 0.940 0.951 0.962 0.973 0.984 0.995 1.000

— 0.886 0.900 0.914 0.928 0.941 0.955 0.968 0.981 0.994 1.000

— 0.862 0.879 0.896 0.913 0.930 0.946 0.962 0.977 0.992 1.000

— 0.833 0.855 0.876 0.896 0.916 0.935 0.954 0.973 0.991 1.000

— 0.800 0.826 0.851 0.876 0.899 0.923 0.945 0.968 0.989 1.000

— 0.758 0.796 0.821 0.850 0.879 0.907 0.935 0.961 0.987 1.000

——0.936 0.944 0.953 0.961 0.970 0.978 0.987 0.996 1.000

——0.920 0.931 0.942 0.952 0.963 0.974 0.984 0.995 1.000

——0.901 0.915 0.927 0.942 0.955 0.968 0.981 0.994 1.000

——0.880 0.897 0.914 0.930 0.946 0.962 0.977 0.992 1.000

——0.855 0.876 0.896 0.916 0.935 0.954 0.973 0.991 1.000

——0.825 0.850 0.875 0.899 0.923 0.945 0.968 0.989 1.000

——0.788 0.819 0.849 0.878 0.907 0.934 0.961 0.987 1.000

———0.947 0.955 0.963 0.971 0.979 0.988 0.996 1.000

———0.933 0.943 0.954 0.964 0.974 0.985 0.995 1.000

———0.917 0.930 0.943 0.956 0.969 0.981 0.994 1.000

———0.898 0.915 0.931 0.947 0.962 0.978 0.993 1.000

———0.876 0.896 0.916 0.936 0.955 0.973 0.991 1.000

———0.850 0.875 0.899 0.922 0.945 0.968 0.989 1.000

———0.817 0.848 0.877 0.906 0.934 0.961 0.987 1.000

————0.958 0.965 0.973 0.980 0.988 0.996 1.000

————0.946 0.956 0.965 0.975 0.985 0.995 1.000

————0.932 0.945 0.957 0.970 0.982 0.994 1.000

————0.916 0.932 0.947 0.963 0.978 0.993 1.000

————0.897 0.917 0.936 0.955 0.973 0.991 1.000

————0.874 0.898 0.922 0.945 0.968 0.989 1.000

————0.846 0.876 0.905 0.933 0.961 0.987 1.000

—————0.968 0.975 0.982 0.988 0.996 1.000

—————0.958 0.967 0.977 0.986 0.995 1.000

—————0.947 0.959 0.971 0.982 0.994 1.000

—————0.933 0.948 0.963 0.978 0.993 1.000

—————0.917 0.936 0.955 0.973 0.991 1.000

—————0.898 0.922 0.945 0.968 0.989 1.000

—————0.875 0.904 0.933 0.960 0.987 1.000

——————0.978 0.984 0.990 0.997 1.000

——————0.970 0.978 0.987 0.996 1.000

——————0.961 0.972 0.983 0.994 1.000

——————0.950 0.964 0.979 0.993 1.000

——————0.937 0.956 0.974 0.991 1.000

——————0.922 0.945 0.968 0.989 1.000

——————0.903 0.932 0.960 0.987 1.000

———————0.986 0.991 0.997 1.000

———————0.980 0.988 0.996 1.000

———————0.974 0.984 0.995 1.000

———————0.966 0.980 0.993 1.000

———————0.956 0.974 0.991 1.000

———————0.945 0.968 0.989 1.000

———————0.931 0.959 0.987 1.000

————————0.994 0.998 1.000

————————0.990 0.997 1.000

————————0.985 0.995 1.000

————————0.981 0.994 1.000

————————0.975 0.992 1.000

————————0.968 0.989 1.000

————————0.959 0.987 1.000

SDT —

SST —

LEGEND

Saturated Discharge Temperature

Saturated Suction Temperature

6

Page 7

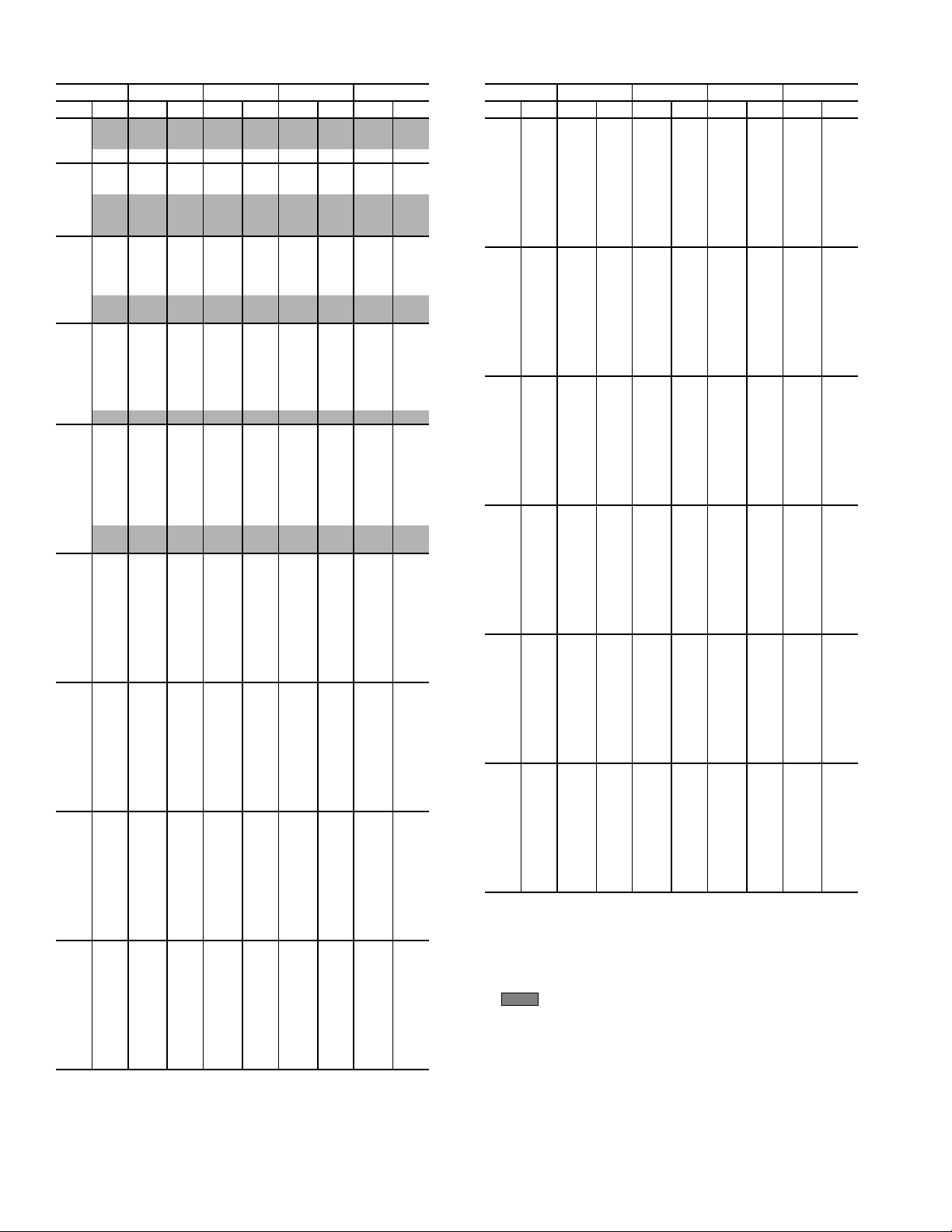

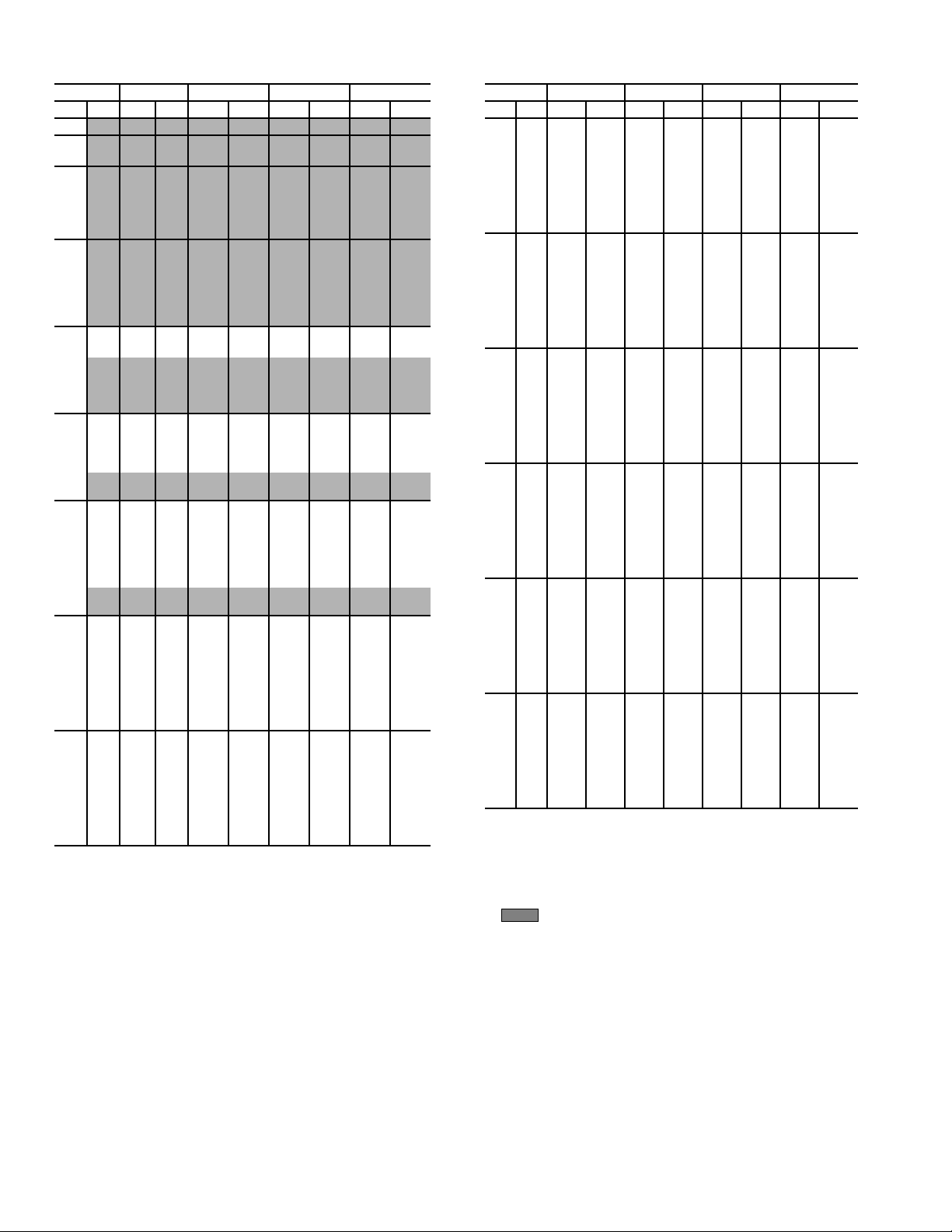

Table 8 — Compressor Ratings; R-12

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

0.6 1.7 1.0 2.7 1.3 3.4 2.0 5.3

80

0.5 1.6 0.8 2.6 1.1 3.3 1.6 5.1

90

–40

–30

–20

–10

0

10

20

30

40

0.4 1.5 0.6 2.4 0.9 3.1 1.3 4.7

100

1.0 2.2 1.5 3.4 2.0 4.2 3.0 6.6

80

0.8 2.2 1.3 3.3 1.8 4.3 2.6 6.6

90

0.7 2.1 1.1 3.2 1.5 4.2 2.2 6.4

100

0.6 2.1 1.0 3.2 1.4 4.2 2.0 6.3

105

0.6 2.0 0.9 3.1 1.3 4.1 1.9 6.1

110

1.4 2.6 2.2 4.0 2.9 5.1 4.3 8.0

80

1.3 2.7 1.9 4.1 2.6 5.2 3.8 8.1

90

1.1 2.7 1.7 4.1 2.3 5.3 3.4 8.1

100

1.0 2.7 1.6 4.1 2.1 5.3 3.1 8.1

105

0.9 2.7 1.5 4.0 2.0 5.3 2.9 8.0

110

0.8 2.6 1.2 3.9 1.7 5.2 2.5 7.8

120

2.0 3.1 3.0 4.6 3.9 5.9 5.9 9.2

80

1.8 3.2 2.7 4.8 3.6 6.2 5.4 9.5

90

1.6 3.3 2.4 4.9 3.2 6.4 4.8 9.8

100

1.5 3.3 2.3 5.0 3.0 6.5 4.5 9.8

105

1.4 3.3 2.1 5.0 2.8 6.5 4.3 9.9

110

1.2 3.3 1.9 5.0 2.5 6.6 3.7 9.8

120

1.0 3.2 1.6 4.9 2.2 6.6 3.2 9.7

130

2.6 3.4 4.0 5.2 5.2 6.6 7.9 10.3

80

2.4 3.6 3.6 5.5 4.8 7.0 7.2 10.9

90

2.2 3.8 3.3 5.7 4.4 7.4 6.6 11.3

100

2.1 3.9 3.1 5.8 4.1 7.6 6.2 11.5

105

1.9 3.9 3.0 5.9 3.9 7.7 5.9 11.7

110

1.7 4.0 2.6 6.0 3.5 7.9 5.3 11.9

120

1.5 4.0 2.3 6.0 3.1 8.1 4.7 12.0

130

1.3 4.0 2.0 6.0 2.7 8.1 4.1 11.9

140

1.2 4.0 1.9 5.9 2.5 8.1 3.8 11.8

145

3.4 3.7 5.1 5.6 6.8 7.1 10.3 11.1

80

3.1 4.0 4.8 6.1 6.3 7.8 9.5 12.0

90

2.9 4.3 4.4 6.4 5.8 8.3 8.7 12.8

100

2.7 4.4 4.2 6.6 5.5 8.6 8.3 13.1

105

2.6 4.5 4.0 6.8 5.3 8.8 7.9 13.4

110

2.4 4.7 3.6 7.0 4.8 9.2 7.1 13.9

120

2.1 4.8 3.2 7.2 4.3 9.5 6.4 14.2

130

1.9 4.9 2.8 7.3 3.8 9.7 5.7 14.4

140

1.7 4.9 2.7 7.3 3.6 9.8 5.3 14.4

145

4.3 3.9 6.6 5.9 8.7 7.5 13.1 11.6

80

4.0 4.3 6.1 6.5 8.1 8.3 12.1 12.8

90

3.7 4.7 5.6 7.0 7.5 9.1 11.2 13.9

100

3.6 4.8 5.4 7.3 7.2 9.4 10.8 14.4

105

3.4 5.0 5.2 7.5 6.9 9.8 10.3 14.9

110

3.1 5.3 4.7 7.9 6.3 10.4 9.4 15.7

120

2.8 5.5 4.3 8.2 5.7 10.9 8.5 16.4

130

2.5 5.7 3.8 8.5 5.1 11.3 7.7 16.8

140

2.4 5.8 3.6 8.6 4.8 11.5 7.2 17.0

145

5.5 4.0 8.2 6.0 10.9 7.7 16.4 11.7

80

5.1 4.5 7.7 6.8 10.2 8.7 15.3 13.3

90

4.7 5.0 7.1 7.5 9.5 9.7 14.2 14.8

100

4.5 5.2 6.9 7.8 9.1 10.1 13.7 15.5

105

4.4 5.4 6.6 8.1 8.7 10.6 13.1 16.1

110

4.0 5.8 6.1 8.7 8.0 11.4 12.1 17.3

120

3.7 6.2 5.5 9.2 7.3 12.1 11.1 18.3

130

3.3 6.4 5.0 9.6 6.7 12.8 10.0 19.1

140

3.1 6.6 4.8 9.8 6.3 13.0 9.5 19.5

145

6.7 3.9 10.1 5.9 13.5 7.7 20.3 11.4

80

6.3 4.5 9.5 6.9 12.7 8.9 19.0 13.4

90

5.9 5.1 8.9 7.7 11.8 10.1 17.7 15.2

100

5.7 5.4 8.6 8.2 11.4 10.6 17.1 16.1

105

5.5 5.7 8.3 8.6 11.0 11.2 16.5 16.9

110

5.1 6.2 7.6 9.3 10.1 12.2 15.3 18.5

120

4.7 6.7 7.0 10.0 9.3 13.2 14.0 19.9

130

4.2 7.1 6.4 10.6 8.5 14.0 12.8 21.1

140

4.0 7.3 6.1 10.9 8.1 14.4 12.2 21.7

145

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

7.0 3.8 10.5 5.9 14.1 7.6 21.1 11.2

80

6.6 4.5 9.9 6.8 13.2 8.9 19.8 13.3

90

6.2 5.2 9.3 7.8 12.3 10.1 18.5 15.3

100

5.9 5.5 8.9 8.2 11.9 10.7 17.9 16.2

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler when using a liquidsuction interchanger, or when 50 degrees of superheat is

exceeded.

2. Refer to Table 5 for Total Heat Rejection.

5.7 5.8 8.6 8.6 11.5 11.3 17.2 17.1

110

5.3 6.3 8.0 9.4 10.6 12.4 15.9 18.7

120

4.9 6.8 7.4 10.2 9.8 13.4 14.7 20.2

130

4.5 7.2 6.8 10.8 8.9 14.3 13.4 21.5

140

4.2 7.4 6.4 11.1 8.5 14.7 12.8 22.1

145

7.3 3.8 11.0 5.8 14.7 7.5 22.0 11.0

80

6.9 4.5 10.3 6.8 13.8 8.9 20.6 13.2

90

6.4 5.2 9.6 7.8 12.9 10.1 19.3 15.3

100

6.2 5.5 9.3 8.2 12.4 10.8 18.6 16.2

105

6.0 5.8 9.0 8.7 12.0 11.4 18.0 17.2

110

5.5 6.4 8.3 9.5 11.1 12.5 16.7 18.9

120

5.1 6.9 7.7 10.3 10.2 13.5 15.4 20.4

130

4.7 7.4 7.1 11.0 9.4 14.5 14.1 21.8

140

4.5 7.6 6.8 11.3 8.9 15.0 13.5 22.5

145

7.5 3.8 11.2 5.8 15.0 7.5 22.4 10.9

80

7.0 4.5 10.5 6.8 14.0 8.9 21.1 13.2

90

6.6 5.2 9.9 7.8 13.1 10.2 19.7 15.3

100

6.3 5.5 9.5 8.3 12.7 10.8 19.0 16.3

105

6.1 5.8 9.2 8.7 12.2 11.4 18.4 17.2

110

5.7 6.4 8.5 9.6 11.3 12.5 17.0 19.0

120

5.2 6.9 7.9 10.4 10.4 13.6 15.7 20.6

130

4.8 7.4 7.2 11.1 9.6 14.6 14.4 22.0

140

4.6 7.6 6.9 11.4 9.2 15.1 13.8 22.6

145

7.6 3.7 11.4 5.7 15.3 7.5 22.9 10.8

80

7.2 4.5 10.7 6.8 14.3 8.8 21.5 13.1

90

6.7 5.2 10.1 7.8 13.4 10.2 20.9 15.3

100

6.5 5.5 9.7 8.3 12.9 10.8 19.4 16.3

105

6.2 5.8 9.4 8.7 12.5 11.4 18.8 17.2

110

5.8 6.4 8.7 9.6 11.6 12.6 17.4 19.0

120

5.3 7.0 8.1 10.4 10.7 13.7 16.1 20.7

130

4.9 7.5 7.4 11.1 9.8 14.7 14.7 22.2

140

4.7 7.7 7.1 11.5 9.4 15.2 14.1 22.8

145

7.9 3.7 11.9 5.6 15.9 7.4 23.8 10.6

80

7.5 4.4 11.2 6.8 14.9 8.8 22.4 13.0

90

7.0 5.2 10.5 7.8 14.0 10.2 21.0 15.2

100

6.7 5.5 10.1 8.3 13.5 10.8 20.3 16.3

105

6.5 5.8 9.8 8.8 13.0 11.5 19.6 17.3

110

6.0 6.5 9.1 9.7 12.1 12.7 18.2 19.2

120

5.6 7.1 8.4 10.5 11.2 13.9 16.8 20.9

130

5.1 7.6 7.7 11.3 10.3 14.9 15.4 22.5

140

4.9 7.8 7.4 11.7 9.8 15.4 14.7 23.2

145

8.2 3.6 12.3 5.6 16.5 7.3 24.8 10.4

80

7.8 4.4 11.6 6.6 15.5 8.8 23.3 12.8

90

7.3 5.2 10.9 7.8 14.5 10.2 21.8 15.2

100

7.0 5.5 10.5 8.3 14.1 10.9 21.1 16.3

105

6.8 5.9 10.2 8.8 13.6 11.5 20.4 17.3

110

6.3 6.5 9.5 9.8 12.6 12.8 18.9 19.3

120

5.8 7.1 8.8 10.7 11.7 14.0 17.5 21.1

130

5.3 7.7 8.1 11.5 10.7 15.1 16.1 22.8

140

5.1 7.9 7.7 11.8 10.3 15.7 15.4 23.5

145

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

7

Page 8

Table 8 — Compressor Ratings; R-12 (cont)

UNIT 5H40 5H46 5H60 5H66

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

3.2 9.1 4.0 11.9 4.9 13.1 6.1 17.1

80

2.7 8.8 3.4 11.5 4.1 12.7 5.2 16.6

90

–40

–30

–20

–10

0

10

20

30

40

2.2 8.4 2.8 11.0 3.4 12.1 4.3 15.8

100

4.9 11.1 6.0 14.4 7.3 16.0 9.1 20.8

80

4.3 11.0 5.3 14.3 6.4 15.9 8.0 20.7

90

3.7 10.7 4.6 13.9 5.6 15.5 6.9 20.3

100

3.4 10.5 4.2 13.7 5.1 15.3 6.4 19.9

105

3.1 10.3 3.9 13.4 4.7 15.0 5.9 19.5

110

6.9 13.0 8.6 16.9 10.4 18.9 13.0 24.6

80

6.2 13.1 7.7 17.1 9.4 19.2 11.6 24.9

90

5.5 13.1 6.8 17.1 8.3 19.2 10.3 24.9

100

5.1 13.0 6.4 17.0 7.8 19.1 9.7 24.8

105

4.8 12.9 6.0 16.8 7.3 18.9 9.0 24.7

110

4.1 12.6 5.1 16.4 6.3 18.4 7.8 24.1

120

9.5 14.9 11.7 19.3 14.2 21.7 17.7 28.3

80

8.6 15.3 10.7 19.9 12.9 22.4 16.1 29.1

90

7.8 15.5 9.6 20.2 11.7 22.8 14.5 29.7

100

7.3 15.6 9.1 20.3 11.0 22.9 13.7 29.8

105

6.9 15.6 8.6 20.3 10.4 23.0 13.0 29.9

110

6.1 15.5 7.6 20.2 9.2 22.9 11.5 29.8

120

5.3 15.3 6.6 19.9 8.0 22.5 10.0 29.4

130

12.6 16.6 15.5 21.6 18.8 24.3 23.4 31.6

80

11.6 17.3 14.3 22.5 17.3 25.5 21.5 33.1

90

10.5 17.9 13.0 23.3 15.8 26.4 19.6 34.3

100

10.0 18.1 12.4 23.6 15.1 26.7 18.7 34.8

105

9.5 18.3 11.8 23.8 14.3 27.0 17.8 35.1

110

8.5 18.5 10.6 24.1 12.9 27.4 16.0 35.6

120

7.6 18.6 9.4 24.1 11.4 27.5 14.2 35.8

130

6.6 18.4 8.3 24.0 10.0 27.3 12.5 35.6

140

6.2 18.3 7.7 23.8 9.4 27.1 11.7 35.3

145

16.3 18.0 20.1 23.5 24.4 26.5 30.2 34.5

80

15.1 19.2 18.6 24.9 22.6 28.2 28.0 36.7

90

13.9 20.1 17.1 26.2 20.8 29.7 25.8 38.6

100

13.3 20.5 16.4 26.7 19.9 30.3 24.7 39.4

105

12.7 20.9 15.7 27.2 19.0 30.9 23.6 40.2

110

11.5 21.5 14.2 27.9 17.3 31.8 21.4 41.4

120

10.4 21.9 12.8 28.4 15.6 32.4 19.3 42.4

130

9.2 22.0 11.4 28.7 13.9 32.7 17.3 42.6

140

8.7 22.1 10.8 28.7 13.1 32.8 16.3 42.7

145

20.7 19.1 25.5 24.9 30.9 28.1 38.3 36.6

80

19.3 20.7 23.7 26.9 28.8 30.5 35.7 39.7

90

17.9 22.1 22.0 28.7 26.7 32.7 33.1 42.5

100

17.2 22.7 21.1 29.5 25.6 33.6 31.8 43.7

105

16.5 23.3 20.3 30.3 24.6 34.5 30.5 44.8

110

15.1 24.3 18.6 31.6 22.6 36.0 28.0 46.8

120

13.7 25.1 16.9 32.6 20.5 37.2 25.5 48.4

130

12.4 25.6 15.3 33.3 18.6 38.1 23.1 49.6

140

11.7 25.8 14.5 33.6 17.6 38.4 21.9 50.1

145

25.9 19.7 31.8 25.7 38.6 29.1 47.9 37.8

80

24.2 21.8 29.8 28.4 36.1 32.2 44.8 41.9

90

22.6 23.7 27.8 30.8 33.7 35.0 41.8 45.6

100

21.7 24.6 26.8 31.9 32.4 36.4 40.3 47.3

105

20.9 25.4 25.8 33.0 31.2 37.6 38.8 48.9

110

19.3 26.8 23.8 34.9 28.8 39.8 35.8 51.8

120

17.7 28.1 21.8 36.5 26.5 41.7 32.8 54.3

130

16.1 29.1 19.9 37.8 24.1 43.3 29.9 56.3

140

15.3 29.5 18.9 38.3 23.0 44.0 28.5 57.2

145

31.9 19.7 39.2 25.6 47.5 29.0 58.9 37.8

80

30.0 22.4 36.9 29.1 44.6 33.0 55.4 43.0

90

28.0 24.8 34.5 32.2 41.8 36.7 51.9 47.7

100

27.1 25.9 33.3 33.7 40.4 38.4 50.1 50.0

105

26.1 27.0 32.2 25.1 39.0 40.1 48.4 52.1

110

24.2 29.0 29.9 37.7 36.2 43.1 44.9 56.0

120

22.4 30.8 27.6 40.0 33.4 45.8 41.5 59.5

130

20.5 32.3 25.3 42.0 30.7 48.1 38.1 62.6

140

19.6 33.0 24.2 42.8 29.3 49.1 36.4 63.9

145

UNIT 5H40 5H46 5H60 5H66

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

33.2 19.6 40.8 25.5 49.4 28.9 61.3 37.6

80

31.2 22.4 38.4 29.1 46.5 33.1 57.7 43.0

90

29.2 24.9 36.0 32.4 43.6 36.9 54.1 48.0

100

28.3 26.1 34.8 34.0 42.1 38.7 52.3 50.4

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler when using a liquidsuction interchanger, or when 50 degrees of superheat is

exceeded.

2. An oil cooler is recommended for all long stroke compressors

(5H46,66,86 and 126).

3. Refer to Table 5 for Total Heat Rejection.

27.3 27.3 33.6 35.5 40.7 40.5 50.5 52.6

110

25.3 29.4 31.2 38.2 37.8 43.6 46.9 56.8

120

23.4 31.2 28.8 40.6 34.9 46.5 43.4 60.5

130

21.5 32.9 26.5 42.7 32.1 49.0 39.8 63.7

140

20.5 33.6 25.3 43.7 30.7 50.1 38.1 65.2

145

34.6 19.5 42.5 25.3 51.4 28.7 63.8 37.4

80

32.5 22.4 40.0 29.1 49.4 33.1 60.1 43.0

90

30.5 25.1 37.5 32.6 45.4 37.1 56.4 48.3

100

29.5 26.3 36.3 34.2 43.9 39.0 54.5 50.7

105

28.5 27.5 35.0 35.8 42.4 40.8 52.7 53.1

110

26.4 29.7 32.6 38.7 39.5 44.2 49.0 57.5

120

24.4 31.7 30.1 41.2 36.5 47.2 45.3 61.4

130

22.5 33.5 27.7 43.5 33.6 49.9 41.7 64.9

140

21.5 34.2 26.5 44.5 32.1 51.1 39.9 66.4

145

35.3 19.4 43.3 25.2 52.4 28.6 65.1 37.2

80

33.2 22.4 40.8 29.1 49.4 33.1 61.3 43.0

90

31.1 25.1 38.3 32.6 46.3 37.2 57.5 48.4

100

30.1 26.4 37.0 34.3 44.8 39.1 55.6 50.9

105

29.1 27.6 35.8 35.9 43.3 41.0 53.8 53.3

110

27.0 29.9 33.3 38.9 40.3 44.4 50.0 57.8

120

25.0 31.9 30.8 41.5 37.3 47.5 46.3 61.9

130

23.0 33.7 28.3 43.9 34.3 50.3 42.6 65.4

140

22.0 34.6 27.1 44.9 32.9 51.5 40.8 67.1

145

36.0 19.3 44.2 25.1 53.5 28.5 66.4 37.1

80

33.9 22.4 41.6 29.1 50.4 33.0 62.5 43.0

90

31.8 25.2 39.1 32.7 47.3 37.3 58.7 38.5

100

30.7 26.5 37.8 34.4 45.8 39.2 56.8 51.1

105

29.7 27.7 36.5 36.1 44.2 41.1 54.9 53.5

110

27.6 30.1 34.0 39.1 41.2 44.7 51.1 58.1

120

25.5 32.2 31.5 41.8 38.1 47.9 47.3 62.3

130

23.5 34.0 29.0 44.2 35.1 50.7 43.6 66.0

140

22.5 34.9 27.7 45.3 33.6 52.0 41.7 67.6

145

37.4 19.1 46.0 24.8 55.6 28.2 69.0 36.7

80

35.2 22.3 43.3 29.0 52.4 32.9 65.1 42.9

90

33.1 25.2 40.7 32.8 49.2 37.4 61.1 48.6

100

32.0 26.6 39.4 34.6 47.7 39.4 59.1 51.3

105

30.9 27.9 38.0 36.3 46.1 41.4 57.2 53.9

110

28.8 30.4 35.4 39.5 42.9 45.2 53.3 58.8

120

26.7 32.6 32.8 42.4 39.8 48.5 49.4 63.1

130

24.6 34.6 30.3 44.9 36.7 51.5 45.5 67.1

140

23.5 35.5 29.0 46.1 35.2 52.9 43.6 68.8

145

38.9 18.9 47.8 24.5 57.8 27.9 71.7 36.3

80

36.6 22.2 45.0 28.8 54.5 32.8 67.7 42.7

90

34.4 25.3 42.3 32.8 51.2 37.4 63.6 48.7

100

33.3 26.7 41.0 34.7 49.6 39.6 61.6 51.5

105

32.2 28.1 39.6 36.5 48.0 41.7 59.5 54.2

110

30.0 30.7 36.9 39.9 44.7 45.6 55.5 59.3

120

27.8 33.0 34.3 42.9 41.5 49.1 51.5 63.9

130

25.7 35.1 31.6 45.6 38.3 52.3 47.6 68.1

140

24.6 36.1 30.3 46.9 36.7 53.8 45.6 70.0

145

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

8

Page 9

Table 8 — Compressor Ratings; R-12 (cont)

UNIT 5H80 5H86 5H120 5H126

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

6.6 17.5 8.2 22.8 9.8 25.8 12.2 33.4

80

5.6 17.0 7.0 22.1 8.3 24.9 10.3 32.4

90

–40

–30

–20

–10

0

10

20

30

40

4.6 16.2 5.8 21.1 6.9 23.7 8.6 30.8

100

9.8 21.3 12.2 27.7 14.7 31.5 18.3 40.9

80

8.8 21.1 10.8 27.5 12.9 31.3 16.0 40.6

90

7.5 20.7 9.3 27.0 11.2 30.6 13.9 39.7

100

6.9 20.4 8.6 26.5 10.3 30.1 12.8 39.1

105

6.4 20.0 8.0 26.0 9.5 29.5 11.8 38.3

110

13.9 25.2 17.3 32.7 20.9 37.3 25.9 48.4

80

12.5 25.4 15.5 33.1 18.7 37.8 23.3 49.0

90

11.1 25.4 13.8 33.1 16.6 37.7 20.6 49.0

100

10.4 25.3 13.0 33.0 15.6 37.6 19.3 48.8

105

9.7 25.2 12.1 32.8 14.6 37.3 18.1 48.5

110

8.4 24.6 10.5 32.0 12.6 36.3 15.6 47.3

120

19.0 28.9 23.6 37.6 28.5 43.0 35.4 55.7

80

17.3 29.7 21.5 38.7 25.9 44.2 32.2 57.2

90

15.6 30.3 19.4 39.4 23.4 45.0 29.0 58.5

100

14.8 30.4 18.4 39.6 22.1 45.2 27.5 58.8

105

13.9 30.5 17.3 39.7 20.9 45.3 25.9 58.9

110

12.3 30.4 15.4 39.6 18.5 45.1 22.9 58.7

120

10.8 30.0 13.4 39.0 16.1 44.4 20.0 57.9

130

25.1 32.3 31.2 42.0 37.7 48.1 46.8 62.4

80

23.1 33.8 28.7 44.0 34.6 50.4 43.0 65.4

90

21.1 35.0 26.2 45.5 31.6 52.1 39.2 67.7

100

20.1 35.5 25.0 46.1 30.1 52.8 37.4 68.6

105

19.1 35.8 23.7 46.6 28.7 53.4 35.6 69.4

110

17.2 26.3 21.4 47.3 25.7 54.1 31.9 70.3

120

15.3 36.5 19.0 47.5 22.9 54.3 28.4 70.6

130

13.5 36.2 16.8 47.2 20.1 53.9 25.0 70.2

140

12.6 36.0 15.7 46.9 18.8 53.5 23.3 69.7

145

32.5 35.3 40.3 45.8 48.8 52.5 60.5 68.1

80

30.1 37.5 37.3 48.8 45.1 55.9 56.0 72.5

90

27.7 39.4 34.4 51.3 41.6 58.8 51.6 76.3

100

26.5 40.3 32.9 52.4 39.8 60.0 49.4 78.0

105

25.3 41.0 31.5 53.3 38.0 61.1 47.2 79.4

110

23.0 42.2 28.6 54.9 34.6 62.9 42.9 81.8

120

20.8 43.0 25.8 55.9 31.2 64.1 38.7 83.4

130

18.6 43.4 23.1 56.5 27.9 64.7 34.6 84.2

140

17.5 43.5 21.8 56.6 26.2 64.8 32.6 84.4

145

41.2 37.5 51.1 48.7 61.8 55.8 76.7 72.3

80

38.4 40.6 47.6 52.8 57.6 60.5 71.5 78.5

90

35.6 43.4 44.2 56.4 53.4 64.7 66.3 84.0

100

34.2 44.6 42.4 58.0 51.3 66.6 63.7 86.4

105

32.8 45.8 40.7 59.5 49.3 68.3 61.1 88.7

110

30.1 47.8 37.4 62.1 45.2 71.3 56.0 92.7

120

27.4 49.4 34.0 64.2 41.1 73.7 51.0 95.8

130

24.8 50.5 30.8 65.8 37.2 75.5 46.1 98.2

140

23.5 51.0 29.2 66.3 35.2 76.1 43.7 99.0

145

51.4 38.7 63.8 50.3 77.2 57.5 95.8 74.7

80

48.1 42.8 59.7 55.7 72.3 63.8 89.7 82.8

90

44.9 46.6 55.7 60.6 67.4 69.5 83.6 90.2

100

43.2 48.3 53.7 62.9 64.9 72.1 80.6 93.6

105

41.6 50.0 51.7 65.0 62.5 74.6 77.6 96.8

110

38.4 52.9 47.7 68.8 57.7 79.0 71.6 102.6

120

35.3 55.4 43.8 72.0 53.0 82.7 65.7 107.5

130

32.2 57.4 40.0 74.7 48.3 85.8 59.9 111.6

140

30.6 58.3 38.0 75.8 46.0 87.1 57.0 113.3

145

63.3 38.6 78.5 50.3 95.1 57.4 117.9 74.7

80

59.5 43.9 73.8 57.2 89.4 65.4 110.9 85.0

90

55.7 48.8 69.1 63.5 83.7 72.8 103.8 94.5

100

53.8 51.1 66.8 66.5 80.8 76.2 100.3 99.0

105

52.0 53.3 64.5 69.3 78.0 79.5 96.8 103.2

110

48.2 57.2 59.9 74.5 72.4 85.5 89.9 111.0

120

44.5 60.8 55.3 79.0 66.9 90.8 83.0 118.0

130

40.9 63.8 50.8 83.0 61.4 95.4 76.2 124.0

140

39.1 65.2 48.5 84.8 58.7 97.5 72.8 126.7

145

UNIT 5H80 5H86 5H120 5H126

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

65.9 38.5 81.8 50.0 99.0 57.1 122.8 74.3

80

62.0 44.0 76.9 57.3 93.1 65.5 115.5 85.1

90

58.1 49.1 72.1 63.9 87.2 73.2 108.2 95.1

100

56.2 51.5 69.7 67.0 84.3 76.8 104.6 99.8

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler when using a liquidsuction interchanger, or when 50 degrees of superheat is

exceeded.

2. An oil cooler is recommended for all long stroke compressors

(5H46,66,86 and 126).

3. Refer to Table 5 for Total Heat Rejection.

54.2 53.8 67.3 70.0 81.4 80.3 101.0 104.2

110

50.4 58.0 62.5 75.4 75.6 86.6 93.9 112.5

120

46.6 61.8 57.8 80.3 69.9 92.3 86.8 119.9

130

42.8 65.0 53.1 84.6 64.3 97.2 79.7 126.4

140

40.9 66.5 50.8 86.5 61.4 99.4 76.2 129.2

145

68.6 38.2 85.1 49.7 103.0 56.7 127.8 73.9

80

64.6 44.0 80.1 57.3 96.9 65.5 120.3 85.2

90

60.6 49.4 75.1 64.2 90.9 73.6 112.8 95.6

100

58.0 51.9 72.6 67.5 87.9 77.4 109.1 100.5

105

56.6 54.3 70.2 70.6 84.9 81.0 105.4 105.2

110

52.6 58.7 65.3 76.4 79.0 87.7 98.0 113.9

120

48.7 62.7 60.4 81.6 73.1 93.7 90.7 121.7

130

44.8 66.2 55.6 86.1 67.2 99.0 83.4 128.6

140

42.8 67.8 53.2 88.2 64.3 101.3 79.8 131.7

145

70.0 38.1 86.8 49.5 105.0 56.5 130.3 73.6

80

65.9 44.0 81.7 57.2 98.9 65.5 122.7 85.1

90

61.8 49.5 76.7 64.4 92.8 73.7 115.1 95.8

100

59.8 52.1 74.2 67.7 89.7 77.6 111.3 100.8

105

57.8 54.5 71.7 70.9 86.7 81.3 107.6 105.6

110

53.7 59.1 66.7 76.8 80.7 88.2 100.1 114.6

120

49.7 63.2 61.7 82.2 74.7 94.4 92.7 122.6

130

45.8 66.8 56.8 86.9 68.7 99.8 85.3 129.7

140

43.8 68.4 54.4 89.0 65.8 102.3 81.6 132.9

145

71.4 37.9 88.5 49.3 107.1 56.3 132.9 73.3

80

67.2 44.0 83.4 57.2 100.9 65.4 125.2 85.1

90

63.1 49.6 78.2 64.5 94.7 73.9 117.5 96.0

100

61.0 52.2 75.7 67.9 91.6 77.8 113.7 101.1

105

59.0 54.7 73.2 71.2 88.5 81.6 109.8 106.0

110

54.9 59.4 68.1 77.3 82.4 88.7 102.2 115.2

120

50.8 63.6 63.1 82.7 76.3 95.1 94.7 123.5

130

46.8 67.3 58.1 87.6 70.3 100.7 87.2 130.8

140

44.8 69.0 55.7 89.8 67.3 103.2 83.5 134.1

145

74.2 37.5 92.0 48.8 111.4 55.7 138.1 72.6

80

69.9 43.8 86.7 57.0 105.0 65.2 130.2 84.8

90

65.7 49.7 81.5 64.7 98.6 74.1 122.3 96.3

100

63.5 52.5 78.8 68.3 95.4 78.2 118.4 101.6

105

61.4 55.1 76.2 71.7 92.2 82.2 114.4 106.8

110

57.2 60.0 71.0 78.1 85.9 89.6 106.6 116.4

120

53.1 64.5 65.8 83.9 79.7 96.4 98.8 125.2

130

48.9 68.4 60.7 89.0 73.4 102.3 91.1 133.0

140

46.9 70.2 58.2 91.4 70.4 105.0 87.3 136.5

145

77.1 37.0 95.6 48.2 115.7 55.0 143.6 71.7

80

72.7 43.6 90.2 56.8 109.1 64.9 135.4 84.5

90

68.3 49.8 84.8 64.8 102.6 74.2 127.3 96.4

100

66.2 52.7 82.1 68.5 99.3 78.5 123.2 102.0

105

64.0 55.4 79.4 72.1 96.1 82.7 119.2 107.4

110

59.6 60.6 74.0 78.8 89.6 90.5 111.1 117.6

120

55.3 65.3 68.7 84.9 83.1 97.6 103.1 126.8

130

51.1 69.5 63.4 90.4 76.7 103.9 95.2 135.0

140

49.0 71.4 60.8 92.9 73.5 106.8 91.2 138.8

145

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

9

Page 10

Table 9 — Compressor Ratings; R-22

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

–40

–30

–20

–10

0

10

20

30

40

1.0 2.6 1.5 4.0 2.1 5.3 3.0 7.9

80

1.5 3.4 2.3 5.1 3.1 6.7 4.6 10.0

80

1.3 3.3 2.0 5.0 2.7 6.7 4.1 10.0

90

2.2 4.1 3.3 6.1 4.4 8.0 6.6 12.1

80

1.9 4.2 3.0 6.2 4.0 8.3 6.0 12.4

90

1.7 4.2 2.6 6.3 3.5 8.4 5.3 12.4

100

1.6 4.2 2.5 6.2 3.3 8.4 4.9 12.4

105

1.5 4.1 2.3 6.2 3.1 8.4 4.6 12.3

110

3.0 4.7 4.6 7.1 6.1 9.3 9.2 14.1

80

2.7 4.9 4.2 7.4 5.5 9.8 8.3 14.7

90

2.5 5.1 3.8 7.6 5.0 10.1 7.5 15.1

100

2.3 5.1 3.5 7.6 4.7 10.3 7.1 15.2

105

2.2 5.1 3.3 7.7 4.5 10.4 6.7 15.3

110

1.9 5.1 2.9 7.7 4.0 10.5 5.9 15.2

120

4.0 5.3 6.1 7.9 8.1 10.4 12.2 15.8

80

3.7 5.6 5.6 8.4 7.5 11.1 11.2 16.8

90

3.4 5.9 5.1 8.8 6.8 11.7 10.2 17.6

100

3.2 6.0 4.9 9.0 6.5 12.0 9.7 17.9

105

3.0 6.1 4.6 9.1 6.2 12.2 9.3 18.1

110

2.7 6.3 4.2 9.3 5.5 12.6 8.3 18.5

120

5.3 5.8 8.0 8.6 10.6 11.3 15.9 17.1

80

4.9 6.2 7.4 9.3 9.8 12.3 14.7 18.6

90

4.5 6.7 6.8 10.0 9.0 13.2 13.6 19.8

100

4.3 6.9 6.5 10.2 8.6 13.6 13.0 20.3

105

4.1 7.0 6.2 10.5 8.3 13.9 12.4 20.8

110

3.7 7.3 5.7 10.9 7.5 14.6 11.3 21.6

120

3.3 7.5 5.1 11.2 6.8 15.1 10.1 22.2

130

6.8 6.0 10.2 9.1 13.6 11.9 20.4 17.9

80

6.3 6.7 9.5 10.0 12.6 13.2 19.0 19.9

90

5.8 7.3 8.8 10.9 11.7 14.4 17.6 21.6

100

5.6 7.6 8.5 11.3 11.2 14.9 16.9 22.4

105

5.4 7.8 8.1 11.6 10.8 15.5 16.2 23.2

110

4.9 8.3 7.4 12.3 9.9 16.4 14.8 24.5

120

4.5 8.7 6.8 12.8 9.0 17.3 13.5 25.6

130

4.2 8.8 6.4 13.1 8.5 17.6 12.8 26.0

135

8.5 6.1 12.8 9.2 17.1 12.1 25.6 18.1

80

8.0 7.0 12.0 10.5 16.0 13.8 24.0 20.6

90

7.4 7.8 11.2 11.6 14.9 15.3 22.3 23.0

100

7.1 8.1 10.8 12.1 14.3 16.0 21.5 24.1

105

6.9 8.5 10.4 12.6 13.8 16.7 20.7 25.1

110

6.3 9.1 9.6 13.5 12.7 18.0 19.1 26.9

120

5.8 9.7 8.8 14.3 11.6 19.2 17.5 28.6

130

5.5 9.9 8.4 14.7 11.1 19.7 16.7 29.3

135

10.6 6.0 15.9 9.1 21.2 12.0 3.18 17.4

80

9.9 7.0 14.9 10.6 19.9 14.0 29.9 20.6

90

9.3 8.0 14.0 12.0 18.6 15.9 28.0 23.6

100

9.0 8.5 13.5 12.7 18.0 16.8 27.0 25.0

105

8.7 8.9 13.0 13.3 17.3 17.7 26.1 26.4

110

8.0 9.8 12.1 14.5 16.1 19.3 24.2 28.9

120

7.4 10.5 11.2 15.6 14.8 20.9 22.3 31.1

130

7.1 10.9 10.7 16.1 14.2 21.6 21.3 32.1

135

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

11.0 5.9 16.5 9.0 22.1 11.9 33.2 17.2

80

10.4 7.0 15.6 10.5 20.8 14.0 31.2 20.5

90

9.7 8.0 14.6 12.0 19.4 15.9 29.2 23.7

100

9.4 8.5 14.1 12.7 18.8 16.9 28.2 25.1

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler and water-cooled

heads.

2. Refer to Table 5 for Total Heat Rejection.

9.0 9.0 13.6 13.4 18.1 17.8 27.2 26.5

110

8.4 9.9 12.7 14.7 16.8 19.5 25.3 29.2

120

7.7 10.7 11.7 15.8 15.5 21.2 23.3 31.5

130

7.4 11.0 11.2 16.4 14.9 21.9 22.4 32.6

135

11.5 5.9 17.2 8.9 23.1 11.8 34.6 16.9

80

10.8 7.0 16.2 10.5 21.7 14.0 32.5 20.4

90

10.1 8.1 15.2 12.0 20.3 16.0 30.5 23.7

100

9.8 8.6 14.7 12.8 19.6 17.0 29.5 25.2

105

9.5 9.0 14.2 13.5 18.9 17.9 28.4 26.7

110

8.8 10.0 13.2 14.8 17.6 19.7 26.4 29.4

120

8.1 10.8 12.2 16.1 16.2 21.4 24.4 32.0

130

7.8 11.2 11.7 16.6 15.6 22.2 23.4 33.1

135

11.7 5.8 17.6 8.8 23.5 11.8 35.3 16.8

80

11.1 7.0 16.6 10.5 22.1 13.9 33.2 20.3

90

10.4 8.1 15.6 12.1 20.7 16.0 31.1 23.7

100

10.0 8.6 15.0 12.8 20.0 17.0 30.1 25.2

105

9.7 9.1 14.5 13.5 19.3 18.0 29.1 26.7

110

9.0 10.0 13.5 14.9 18.0 19.8 27.0 29.6

120

8.3 10.9 12.5 16.2 16.6 21.6 25.0 32.2

130

7.9 11.3 12.0 16.7 15.9 22.4 24.0 33.3

135

12.0 5.8 17.9 8.8 24.0 11.7 36.0 16.6

80

11.3 7.0 16.9 10.5 22.6 13.9 33.9 20.2

90

10.6 8.1 15.9 12.1 21.2 16.0 31.8 23.6

100

10.2 8.6 15.4 12.8 20.5 17.0 30.7 25.2

105

9.9 9.1 14.9 13.6 19.8 18.0 29.7 26.8

110

9.2 10.1 13.8 15.0 18.4 19.9 27.6 29.7

120

8.5 10.9 12.8 16.3 17.0 21.7 25.5 32.3

130

8.1 11.4 12.3 16.8 16.3 22.5 24.5 33.6

135

12.5 5.7 18.7 8.6 25.0 11.6 37.5 16.2

80

11.8 6.9 17.6 10.4 23.5 13.9 35.3 20.0

90

11.0 8.0 16.6 12.1 22.1 16.0 33.1 23.6

100

10.7 8.6 16.0 12.9 21.3 17.1 32.1 25.2

105

10.3 9.1 15.5 13.6 20.6 18.1 31.0 29.9

110

9.6 10.1 14.4 15.1 19.2 20.1 28.8 29.9

120

8.9 11.1 13.4 16.4 17.8 21.9 26.7 32.7

130

8.5 11.5 12.9 17.1 17.0 22.8 25.6 34.0

135

13.0 5.6 19.4 8.5 26.1 11.4 39.0 15.8

80

12.2 6.8 18.3 10.3 24.5 13.8 36.8 19.8

90

11.5 8.0 17.2 12.0 23.0 16.0 34.5 23.5

100

11.1 8.6 16.7 12.9 22.3 17.1 33.4 25.2

105

10.7 9.2 16.2 13.7 21.5 18.2 32.3 26.9

110

10.0 10.2 15.1 15.2 20.0 20.2 30.1 30.1

120

9.3 11.2 14.0 16.6 18.5 22.2 27.9 33.0

130

8.9 11.6 13.4 17.3 17.8 23.1 26.8 34.4

135

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

10

Page 11

Table 9 — Compressor Ratings; R-22 (cont)

UNIT 5H40 5H46 5H60 5H66

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

5.0 12.8 6.2 16.7 7.6 18.7 9.4 24.4

80

–40

7.5 15.9 9.3 20.6 11.4 23.3 14.1 30.4

80

–30

–20

–10

0

10

20

30

40

6.6 15.7 8.3 20.5 10.0 23.2 12.5 30.2

90

10.7 18.9 13.3 24.6 16.1 28.0 20.0 36.4

80

9.7 19.2 12.0 24.9 14.5 28.4 18.1 36.9

90

8.6 19.2 20.7 24.9 13.0 28.4 16.1 37.0

100

8.1 19.1 10.0 24.8 12.2 28.3 15.2 36.9

105

7.5 18.9 9.4 24.6 11.4 28.1 14.2 36.6

110

14.7 21.9 18.1 28.5 22.0 32.4 27.3 42.2

80

13.4 22.6 16.5 29.4 20.1 33.5 25.0 43.6

90

12.1 23.0 15.0 29.9 18.2 34.2 22.6 44.5

100

11.5 23.2 14.2 30.1 17.3 34.4 21.5 44.8

105

10.9 23.2 13.5 30.2 16.4 34.5 20.3 45.0

110

9.6 23.1 12.0 30.1 14.5 34.4 18.1 44.9

120

19.5 24.6 24.1 32.0 29.2 36.5 36.2 47.5

80

18.0 25.8 22.2 33.6 26.9 38.4 33.4 49.9

90

16.4 26.8 20.3 34.8 24.7 39.9 30.6 51.9

100

15.7 27.2 19.4 35.3 23.5 40.4 29.2 52.6

105

14.9 27.5 18.5 35.7 22.4 40.9 27.9 53.3

110

13.5 27.9 16.7 36.2 20.2 41.6 25.2 54.1

120

25.3 26.9 31.2 35.0 37.8 39.9 46.9 52.0

80

23.5 28.8 29.0 37.4 35.1 42.7 43.6 55.6

90

21.7 30.3 26.7 39.4 32.5 45.1 40.3 58.7

100

20.8 31.0 25.6 40.3 31.1 46.1 38.6 60.0

105

19.9 31.6 24.6 41.0 29.8 47.1 37.0 61.2

110

18.1 32.5 22.4 42.3 27.2 48.6 33.8 63.2

120

16.4 33.2 20.3 43.1 27.2 48.6 33.8 63.2

130

32.3 28.6 39.7 37.2 48.1 42.5 59.7 55.3

80

30.1 31.2 37.1 40.5 44.9 46.4 55.8 60.3

90

28.0 33.4 34.5 43.4 41.8 49.8 51.9 64.7

100

26.9 34.4 33.2 44.7 40.2 51.3 49.9 66.7

105

25.8 35.3 31.9 45.9 38.7 52.7 48.0 68.6

110

23.8 36.9 29.3 48.0 35.6 55.2 44.1 71.8

120

21.7 38.2 26.8 49.7 32.5 57.2 40.4 74.4

130

20.7 38.7 25.5 50.3 31.0 58.0 38.5 75.5

135

40.4 29.5 49.8 38.4 60.2 43.9 74.8 57.1

80

37.9 32.9 46.7 42.7 56.5 48.9 70.2 63.7

90

35.4 35.9 43.6 46.7 52.9 53.5 65.6 69.6

100

34.2 37.3 42.1 48.5 51.0 55.6 63.3 72.4

105

32.9 38.6 40.6 50.2 49.2 57.6 61.0 74.9

110

30.5 40.9 37.5 53.2 45.5 61.2 56.5 79.6

120

28.0 43.0 34.5 55.8 41.9 64.3 52.0 83.7

130

26.8 43.8 33.0 57.0 40.1 65.6 49.8 85.4

135

50.1 29.5 61.6 38.3 74.5 43.8 92.5 57.0

80

47.1 33.7 58.0 43.8 70.2 50.2 87.1 65.3

90

44.2 37.6 54.4 48.9 65.9 56.1 81.7 73.0

100

42.7 39.4 52.6 51.2 63.7 58.8 79.1 76.5

105

41.3 41.1 50.8 53.5 61.6 61.4 76.4 80.0

110

38.4 44.3 47.3 57.6 57.3 66.3 71.1 86.3

120

35.5 47.2 43.7 61.3 53.0 70.6 65.8 91.9

130

34.0 48.5 42.0 63.0 50.9 72.6 63.2 94.4

135

UNIT 5H40 5H46 5H60 5H66

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

52.2 29.3 64.1 38.1 77.6 43.6 96.3 56.7

80

49.1 33.7 60.4 43.8 73.2 50.2 90.8 65.4

90

46.1 37.8 56.7 49.2 68.7 56.4 85.3 73.4

100

44.6 39.7 54.9 51.7 66.5 59.3 82.5 77.2

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler and water-cooled

heads.

2. An oil cooler is recommended for all long stroke compressors

(5H46,66,86 and 126).

3. Refer to Table 5 for Total Heat Rejection.

43.1 41.6 53.1 54.0 64.3 62.1 79.8 80.8

110

40.1 44.9 49.4 58.4 59.9 67.2 74.3 87.4

120

37.1 47.9 45.7 62.3 55.5 71.8 68.8 93.4

130

35.6 49.3 43.9 64.1 53.3 73.8 66.1 96.1

135

54.3 29.1 66.8 37.8 80.8 43.3 100.3 56.3

80

51.2 33.7 63.0 43.8 76.2 50.2 94.6 65.4

90

48.1 38.0 59.2 49.4 71.7 56.7 88.9 73.8

100

46.6 40.0 57.3 52.0 69.4 59.7 86.1 77.7

105

45.0 41.9 55.4 54.5 67.1 62.6 83.3 81.5

110

41.9 45.5 51.6 59.1 62.5 68.0 77.6 88.5

120

38.8 48.7 47.8 63.3 58.0 72.9 72.0 94.8

130

37.3 50.1 46.0 65.2 55.7 75.1 69.1 97.7

135

55.4 29.0 68.2 37.6 82.5 43.1 102.4 56.1

80

52.3 33.7 64.3 43.8 77.8 50.2 96.6 65.3

90

49.1 38.1 60.4 49.5 73.2 56.8 90.8 73.9

100

47.5 40.1 58.5 52.2 70.9 59.9 87.9 78.0

105

46.0 42.1 56.6 54.7 68.5 62.9 85.0 81.8

110

42.8 45.7 52.7 59.5 63.9 68.4 79.3 89.0

120

39.7 49.0 48.9 63.7 59.3 73.4 73.6 95.5

130

38.1 50.5 47.0 65.7 57.0 75.7 70.7 98.5

135

56.6 28.8 69.5 37.4 84.1 42.9 104.5 55.8

80

53.4 33.7 65.6 43.7 79.4 50.2 98.6 65.3

90

50.2 38.1 61.7 49.6 74.7 56.9 92.7 74.1

100

48.6 40.2 59.7 52.3 72.3 60.1 89.8 78.2

105

47.0 42.3 57.8 54.9 70.0 63.1 86.9 82.1

110

43.8 46.0 53.9 59.8 65.3 68.8 81.0 89.5

120

40.6 49.4 50.0 64.2 60.6 73.9 75.2 96.2

130

39.0 50.9 48.0 66.2 58.3 76.3 72.3 99.3

135

58.9 28.5 72.4 37.0 87.6 42.4 108.7 55.3

80

55.6 33.6 68.3 43.6 82.7 50.0 102.6 65.1

90

52.3 38.2 64.3 49.7 77.8 57.0 96.6 74.3

100

50.6 40.4 62.3 52.6 75.4 60.4 93.6 78.6

105

49.0 42.5 60.2 55.3 73.0 63.6 90.6 82.7

110

45.7 46.5 56.2 60.4 68.1 69.5 84.5 90.5

120

42.4 50.1 52.2 65.1 63.3 74.9 78.5 97.5

130

40.8 51.7 50.2 67.2 60.9 77.4 75.5 100.8

135

61.3 28.2 75.3 36.5 91.1 41.9 113.1 54.6

80

57.8 33.4 71.1 43.4 86.1 49.8 106.8 64.8

90

54.4 38.3 67.0 49.8 81.1 57.1 100.6 74.4

100

52.7 40.6 64.9 52.8 78.6 60.6 97.5 78.9

105

51.0 42.8 62.8 55.6 76.0 63.9 94.4 83.2

110

47.6 46.9 58.6 61.0 71.0 70.2 88.2 91.4

120

44.3 50.7 54.5 65.9 66.1 75.9 82.0 98.8

130

42.6 52.4 52.4 68.2 63.6 78.5 78.9 102.2

135

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

11

Page 12

Table 9 — Compressor Ratings; R-22 (cont)

UNIT 5H80 5H86 5H120 5H126

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

10.2 24.9 12.7 32.5 15.2 36.9 18.9 48.0

80

–40

15.2 31.0 18.9 40.3 22.8 46.1 28.3 59.9

80

–30

–20

–10

0

10

20

30

40

13.5 30.8 16.8 40.1 20.1 45.7 25.0 59.5

90

21.5 37.1 26.8 48.3 32.3 55.3 40.1 71.9

80

19.4 37.6 24.1 49.0 29.1 56.1 36.1 72.9

90

17.3 37.7 21.6 49.1 26.0 56.1 32.2 73.1

100

16.3 37.6 20.3 48.9 24.4 55.9 30.3 72.8

105

15.3 37.3 19.1 48.6 22.9 55.5 28.4 72.3

110

29.3 43.0 36.5 56.0 44.0 64.2 54.7 83.4

80

26.8 44.4 33.3 57.8 40.2 66.3 49.9 86.2

90

24.3 45.4 30.2 59.0 36.5 67.7 45.3 88.1

100

23.1 45.6 28.7 59.4 34.6 68.1 42.9 88.6

105

21.9 45.8 27.2 59.6 32.8 68.3 40.7 88.9

110

19.5 45.7 24.2 59.5 29.1 68.1 36.2 88.7

120

38.9 48.5 48.3 63.0 58.4 72.4 72.4 93.9

80

35.9 50.9 44.6 66.2 53.8 76.1 66.8 98.8

90

32.9 52.9 40.9 68.8 49.3 79.0 61.2 102.7

100

31.4 53.6 39.0 69.8 47.1 80.1 58.5 104.2

105

29.9 54.3 37.2 70.6 44.9 81.0 55.7 105.4

110

27.0 55.1 33.6 71.7 40.5 82.3 50.3 107.2

120

50.4 53.1 62.5 69.0 75.7 79.3 93.9 102.9

80

46.8 56.8 58.1 73.8 70.3 84.8 87.2 110.1

90

43.3 59.9 53.7 77.9 64.9 89.5 80.6 116.3

100

41.5 61.2 51.5 79.6 62.3 91.5 77.3 119.0

105

39.8 62.4 49.4 81.2 59.7 93.3 74.0 121.3

110

36.3 64.4 45.1 83.8 54.4 96.2 67.6 125.2

120

64.1 56.5 79.6 73.5 96.3 84.4 119.4 109.6

80

59.9 61.6 74.3 80.1 89.9 92.0 111.6 119.5

90

55.7 66.1 69.1 86.0 83.6 98.8 103.8 128.3

100

53.6 68.1 66.6 88.6 80.5 101.8 99.9 132.3

105

51.5 70.0 64.0 91.0 77.4 104.6 96.0 136.0

110

47.4 73.2 58.9 95.2 71.2 109.5 88.3 142.4

120

43.3 75.8 53.9 98.7 65.1 113.4 80.7 147.6

130

41.3 76.9 51.4 100.0 62.0 115.0 77.0 149.7

135

80.3 58.4 99.7 76.0 120.6 87.1 149.6 113.2

80

75.4 65.1 93.5 84.7 113.2 97.2 140.4 126.3

90

70.5 71.1 87.4 92.5 105.8 106.3 131.3 138.1

100

68.0 73.9 84.4 96.1 102.1 110.5 126.7 143.5

105

65.6 76.5 81.4 99.5 98.4 114.4 122.1 148.7

110

60.7 81.2 75.3 105.7 91.1 121.5 113.1 158.0

120

55.9 85.3 69.4 110.9 83.9 127.6 104.1 166.0

130

53.5 87.0 66.4 113.2 80.3 130.3 99.6 169.5

135

99.4 58.2 123.2 75.8 149.2 86.8 185.1 113.0

80

93.6 66.7 116.1 86.9 140.5 99.6 174.3 129.5

90

87.8 74.6 109.0 97.0 131.9 111.4 163.6 144.8

100

84.9 78.2 105.4 101.7 127.5 116.9 158.2 151.9

105

82.1 81.7 101.8 106.2 123.2 122.1 152.9 158.7

110

76.4 88.1 94.8 114.6 114.6 131.7 142.2 171.2

120

70.7 93.7 87.7 121.9 106.1 140.3 131.6 182.4

130

67.8 96.3 84.2 125.3 101.8 144.2 126.4 187.5

135

UNIT 5H80 5H86 5H120 5H126

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

103.5 57.9 128.4 75.4 155.4 86.3 192.8 112.5

80

97.6 66.8 121.0 87.0 146.5 99.7 181.7 129.7

90

91.6 75.0 113.7 97.6 137.6 112.0 170.7 145.7

100

88.7 78.8 110.0 102.6 133.1 117.8 165.2 153.1

105

42

44

45

46

48

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require an oil cooler and water-cooled

heads.

2. An oil cooler is recommended for all long stroke compressors

(5H46,66,86 and 126).

3. Refer to Table 5 for Total Heat Rejection.

85.7 82.5 106.3 107.3 128.7 123.3 159.7 160.3

110

79.8 89.3 99.0 116.1 119.8 133.5 148.7 173.5

120

73.9 95.3 91.8 124.0 111.0 142.6 137.7 185.4

130

71.0 98.0 88.1 127.5 106.6 146.7 132.3 190.8

135

107.8 57.5 133.7 74.9 161.9 85.6 200.8 111.7

80

101.7 66.8 126.1 87.0 152.7 99.6 189.4 129.7

90

95.6 75.4 118.6 98.1 143.5 112.6 178.0 146.4

100

92.5 79.4 114.8 103.3 138.9 118.6 172.3 154.2

105

89.5 83.2 111.0 108.3 134.3 124.4 166.6 161.7

110

83.4 90.4 103.4 117.6 125.2 135.2 155.3 175.7

120

77.3 96.8 95.9 125.9 116.1 144.8 144.0 188.3

130

74.3 99.7 92.2 129.7 115.5 149.2 138.4 194.0

135

110.0 57.3 136.5 74.6 165.2 85.3 204.9 111.2

80

103.8 66.8 128.7 86.9 155.8 99.6 193.3 129.6

90

97.6 75.5 121.0 98.3 146.5 112.8 181.8 146.7

100

94.5 79.7 117.2 103.6 141.8 119.0 176.0 154.7

105

91.4 83.6 113.4 108.7 137.2 124.9 170.2 162.4

110

85.2 90.9 105.7 118.3 127.9 136.0 158.7 176.7

120

79.0 97.5 98.1 126.8 118.6 145.9 147.2 189.7

130

76.0 100.5 94.3 130.7 114.0 150.4 141.5 195.6

135

112.3 57.0 139.2 74.3 168.5 84.8 209.1 110.7

80

105.9 66.7 131.4 86.8 159.0 99.4 197.3 129.5

90

99.6 75.7 123.6 98.5 149.6 113.0 185.6 147.0

100

96.5 79.9 119.7 103.9 144.8 119.3 179.7 155.2

105

93.3 83.9 115.8 109.2 140.1 125.4 173.8 163.1

110

87.0 91.4 108.0 118.9 130.7 136.7 162.1 177.8

120

80.8 98.2 100.2 127.7 121.3 146.9 150.5 191.0

130

77.7 101.3 96.4 131.8 116.6 151.6 144.7 197.1

135

116.8 56.4 144.9 73.4 175.4 83.9 217.6 109.6

80

110.3 66.5 136.8 86.6 165.6 99.1 205.4 129.1

90

103.8 75.9 128.8 98.7 155.8 113.2 193.3 147.4

100

100.5 80.3 124.7 104.5 151.0 119.9 187.3 156.0

105

97.3 84.5 120.7 109.9 146.1 126.3 181.2 164.2

110

90.8 92.4 112.7 120.2 136.4 138.2 169.2 179.6

120

84.4 99.5 104.7 129.5 126.7 149.0 157.1 193.7

130

81.1 102.8 100.7 133.8 121.8 153.9 151.1 200.1

135

121.5 55.6 150.7 72.5 182.4 82.7 226.3 108.2

80

114.8 66.2 142.4 86.2 172.4 98.6 213.8 128.5

90

108.1 76.0 134.1 98.9 162.3 113.4 201.3 147.6

100

104.8 80.6 129.9 104.9 157.3 120.3 195.1 156.6

105

101.4 85.0 125.8 110.6 152.2 127.0 188.9 165.2

110

94.7 93.3 117.5 121.4 142.2 139.5 176.4 181.4

120

88.1 100.8 109.3 131.2 132.2 150.9 164.0 196.1

130

84.7 104.3 105.2 135.7 127.2 156.1 157.8 203.8

135

Brake Horsepower

Capacity (Tons)

Saturated Discharge Temperature (F)

Saturated Suction Temperature (F)

12

Page 13

Table 10 — Compressor Ratings; R-502

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

0.4 1.6 0.6 2.5 0.9 3.4 1.3 5.1

80

–60

0.8 2.4 1.2 3.7 1.6 5.0 2.4 7.3

80

0.6 2.2 0.9 3.4 1.3 4.7 1.9 6.8

90

–50

–40

–30

–20

–10

0

10

20

30

0.5 2.0 0.7 3.0 1.1 4.4 1.5 6.2

100

0.4 1.8 0.6 2.8 0.9 4.1 1.3 5.8

105

1.2 3.2 1.9 4.9 2.5 6.5 3.8 9.6

80

1.0 3.1 1.6 4.7 2.2 6.4 3.2 9.4

90

0.8 3.0 1.3 4.5 1.8 6.2 2.6 9.0

100

0.7 2.9 1.2 4.3 1.6 6.1 2.4 8.7

105

0.7 2.8 1.0 4.2 1.5 5.9 2.1 8.4

110

0.5 2.5 0.8 3.7 1.2 5.5 1.6 7.7

120

1.8 4.0 2.8 6.0 3.7 8.0 5.5 12.0

80

1.6 4.0 2.4 6.0 3.2 8.1 4.8 12.0

90

1.3 4.0 2.1 6.0 2.8 8.1 4.1 11.9

100

1.2 3.9 1.9 5.9 2.6 8.1 3.8 11.7

105

1.1 3.9 1.7 5.8 2.4 8.0 3.5 11.6

110

0.9 3.7 1.4 5.5 2.0 7.8 2.9 11.0

120

2.6 4.8 3.9 7.1 5.2 9.4 7.8 14.2

80

2.3 4.9 3.4 7.3 4.6 9.8 6.9 14.6

90

2.0 5.0 3.0 7.4 4.0 10.0 6.0 14.7

100

1.8 5.0 2.8 7.4 3.8 10.1 5.6 14.8

105

1.7 5.0 2.6 7.4 3.5 10.1 5.2 14.7

110

1.4 4.9 2.2 7.3 3.0 10.1 4.4 14.5

120

3.5 5.5 5.3 8.2 7.0 10.7 10.5 16.2

80

3.1 5.7 4.7 8.5 6.3 11.3 9.4 17.0

90

2.7 5.9 4.2 8.8 5.6 11.8 8.4 17.5

100

2.6 6.0 3.9 8.9 5.2 12.0 7.8 17.7

105

2.4 6.0 3.7 9.0 4.9 12.1 7.4 17.9

110

2.1 6.1 3.2 9.1 4.3 12.4 6.4 18.0

120

4.6 6.0 6.9 9.0 9.1 11.8 13.8 17.9

80

4.1 6.4 6.3 9.6 8.3 12.7 12.5 19.1

90

3.7 6.8 5.6 10.1 7.5 13.4 11.2 20.1

100

3.5 6.9 5.3 10.3 7.1 13.8 10.6 20.5

105

3.3 7.1 5.0 10.5 6.7 14.1 10.0 20.9

110

2.9 7.3 4.4 10.8 5.9 14.6 8.8 21.4

120

5.9 6.5 8.9 9.7 11.8 12.7 17.7 19.2

80

5.4 7.0 8.1 10.5 10.7 13.8 16.2 20.9

90

4.9 7.5 7.4 11.2 9.7 14.9 14.7 22.3

100

4.6 7.8 7.0 11.6 9.3 15.4 13.9 23.0

105

4.4 8.0 6.6 11.9 8.8 15.8 13.2 23.6

110

3.9 8.3 5.9 12.4 7.8 16.6 11.8 24.6

120

7.4 6.7 11.2 10.1 14.9 13.3 22.4 19.9

80

6.8 7.5 10.3 11.2 13.7 14.7 20.5 22.1

90

6.2 8.2 9.4 12.1 12.5 16.1 18.8 24.1

100

5.9 8.5 9.0 12.6 11.9 16.7 17.9 25.1

105

5.6 8.8 8.5 13.0 11.3 17.3 17.0 25.9

110

5.1 9.3 7.7 13.8 10.2 18.5 15.3 27.5

120

9.3 6.8 13.9 10.2 18.6 13.5 27.9 19.9

80

8.5 7.7 12.9 11.5 17.1 15.3 25.7 22.7

90

7.8 8.6 11.8 12.8 15.7 17.0 23.6 25.4

100

7.5 9.0 11.3 13.4 15.0 17.8 22.6 26.6

105

7.1 9.4 10.8 14.0 14.3 18.5 21.5 27.7

110

6.5 10.1 9.8 15.0 13.0 20.0 19.5 29.9

120

UNIT5F205F305F405F60

SST SDT Cap. Bhp Cap. Bhp Cap. Bhp Cap. Bhp

9.7 6.8 14.5 10.2 19.4 13.5 29.1 19.8

80

8.9 7.7 13.4 11.6 17.9 15.3 26.8 22.8

90

8.2 8.6 12.3 12.9 16.4 17.1 24.7 25.5

100

32

34

35

36

38

40

45

50

LEGEND

Bhp —

Cap. —

SDT —

SST —

NOTES:

1. Shaded ratings require water-cooled heads, if the discharge temperature exceeds 275 F.

2. An oil cooler is required when SST is below –20 F.

3. Refer to Table 5 for Total Heat Rejection.

7.8 9.1 11.8 13.5 15.7 17.9 23.6 26.8

105

7.5 9.5 11.3 14.1 15.0 18.8 22.5 28.0

110

6.8 10.3 10.2 15.2 13.6 20.3 20.4 30.3

120

10.1 6.7 15.1 10.1 20.2 13.4 30.3 19.6

80

9.3 7.7 14.0 11.6 18.6 15.4 28.0 22.8

90

8.6 8.7 12.9 13.0 17.1 17.2 25.8 25.6

100

8.2 9.1 12.3 13.6 16.4 18.1 24.6 27.0

105

7.8 9.6 11.8 14.2 15.7 18.9 23.5 28.3

110

7.1 10.4 10.7 15.4 14.2 20.6 21.4 30.7

120

10.3 6.7 15.4 10.1 20.6 13.4 30.9 19.6

80

9.5 7.7 14.3 11.6 19.0 15.4 28.6 22.7

90

8.7 8.7 13.2 13.0 17.5 17.3 26.3 25.7

100

8.4 9.2 12.6 13.7 16.8 18.2 25.2 27.1

105

8.0 9.6 12.1 14.3 16.0 19.0 24.1 28.4

110

7.3 10.4 11.0 15.5 14.5 20.7 21.8 30.9

120