Page 1

Carrier

Centrifugal Fan Air-Cooled Condenser

Installation Instructions

09FA

INTRODUCTION

The 09FA Centrifugal Air-Cooled Condensers

are designed for indoor installations. If outdoor

installation is desired, a weather enclosure must be

constructed around the unit.

UNIT LOCATION

Allow sufficient clearance for:

1. Removal of fan shaft and coil.

2. Service of fan motor, bearings, damper motor

and linkage (at least 30 inches)

3. Unit air supply (minimum distance of 4 feet

from ceiling, wall, or floor when supplied from

one side only).

PRE-INSTALLATION

1 File claim with shipping company if shipment is

damaged or incomplete.

2. Examine unit nameplate to verify that electrical

requirements match available power supply.

3. Rotate fans by hand. Check for freedom of

rotation and secureness to fan shaft.

4. Remove shipping straps from skid and unit.

INSTALLATION

Observe the following-

1. When rigging, do not support unit weight by

fan shaft extension or coil connections Put

rigging medium completely around unit, using

spreader bars to ensure that sling lifts at the

skid without touching the unit sides.

2. Remove coil piping connection protective caps

only when ready to connect piping.

3. Exercise reasonable care not to bend or muti

late coil fins.

4. On bypass units, where bypass is not desired,

block off opening with a strip of sheet metal

(field-supplied) and secure.

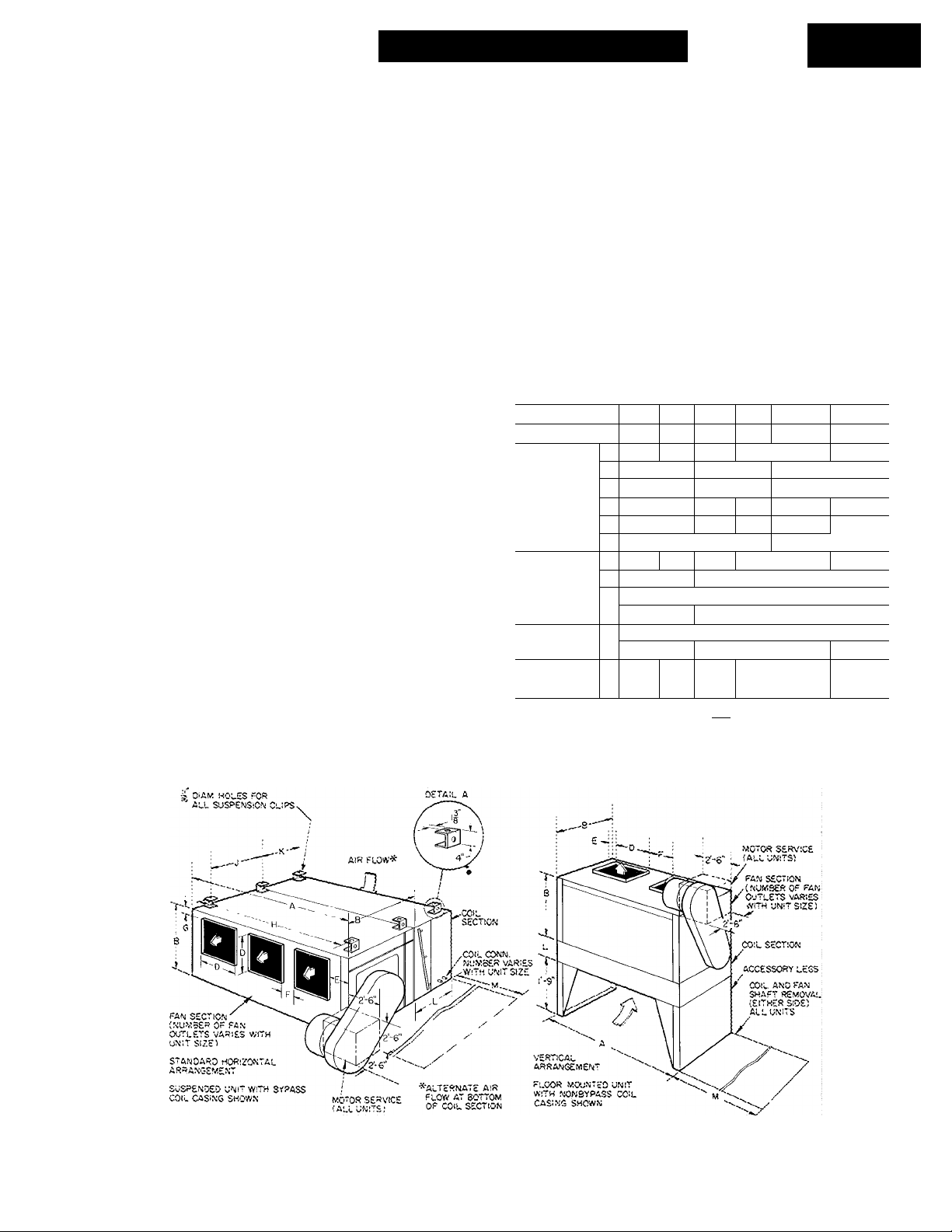

Unit Mounting (Fig. 1 and Table 1)

HORIZONTAL ARRANGEMENT (Standard)

1 Remove plug buttons covering captive nuts

used to fasten suspension clips.

Table 1 — Dimensions (ft-in.) and

Mounting Information

UNIT 09FA

OPTG WT (lb)*

DIM. FAN

SECTION

DIM SUSPENSION

CLIPS

DIM. COIL

SECTION!

DIM. SERV

ICE AREA

3 Nonbypass Coi

'^Includes fan .section; coi I section with nonbypass coil cosi

taining condensing coil with operating charge

tRefer to Fig 3 for coil connections

006 008 012

725 980

A

3-1OV2

B

1- 9

D

0-11 Va

E

0- 6

F

0-10% 0-9‘/2 1- 0% 2-1%

G

H

3- 7%

J

1- 2

;- 3 I

K

1- 9

1- 3

L

1- 9

M

5- 6 7-2 6- 8

1080 1410

5-6% 4-11%

2-4

1 -4%

6- 0%

0%

5-3% 4-8%

1-9 i 2-5%

I 1 Bypass Coi I

016 024 028

1720

7- 1% 9-9

3-0‘/2

1 -8%

I-IV16 0-ll“4e

1- 7%

0-1

6-10%2

1-1OV2 1 2- 1V2

I

1-1OV2

8- 9

034 044

2290

O-IF/16

1- 3%

9- 6%

2- 7%

11-5

ng con-

© Carrier Corporation 1968

Certified dimension drawings available on request

Fig. 1 — Dimensions

09FA-1SI

Page 2

2. Bolt suspension clips (supplied), one near each

corner of fan section and one near each end of

coil section. Tighten bolts (supplied) securely.

3. Lift unit into position.

4. Pass threaded hanger rod (field-supplied) thru

each suspension clip.

5. Fasten with nuts (field-supplied).

VERTICAL ARRANGEMENT

1. Bolt legs (accessory) to inlet side of coil

section, using 5/8 in. - 11 captive nuts (located

on inward flanges of coil section) and bolts

(supplied). Tighten securely.

2. Rotate motor end bells 90 degrees so drain

holes are at bottom. Rotating end bells must be

performed by an authorized vendor’s motor

repair shop.

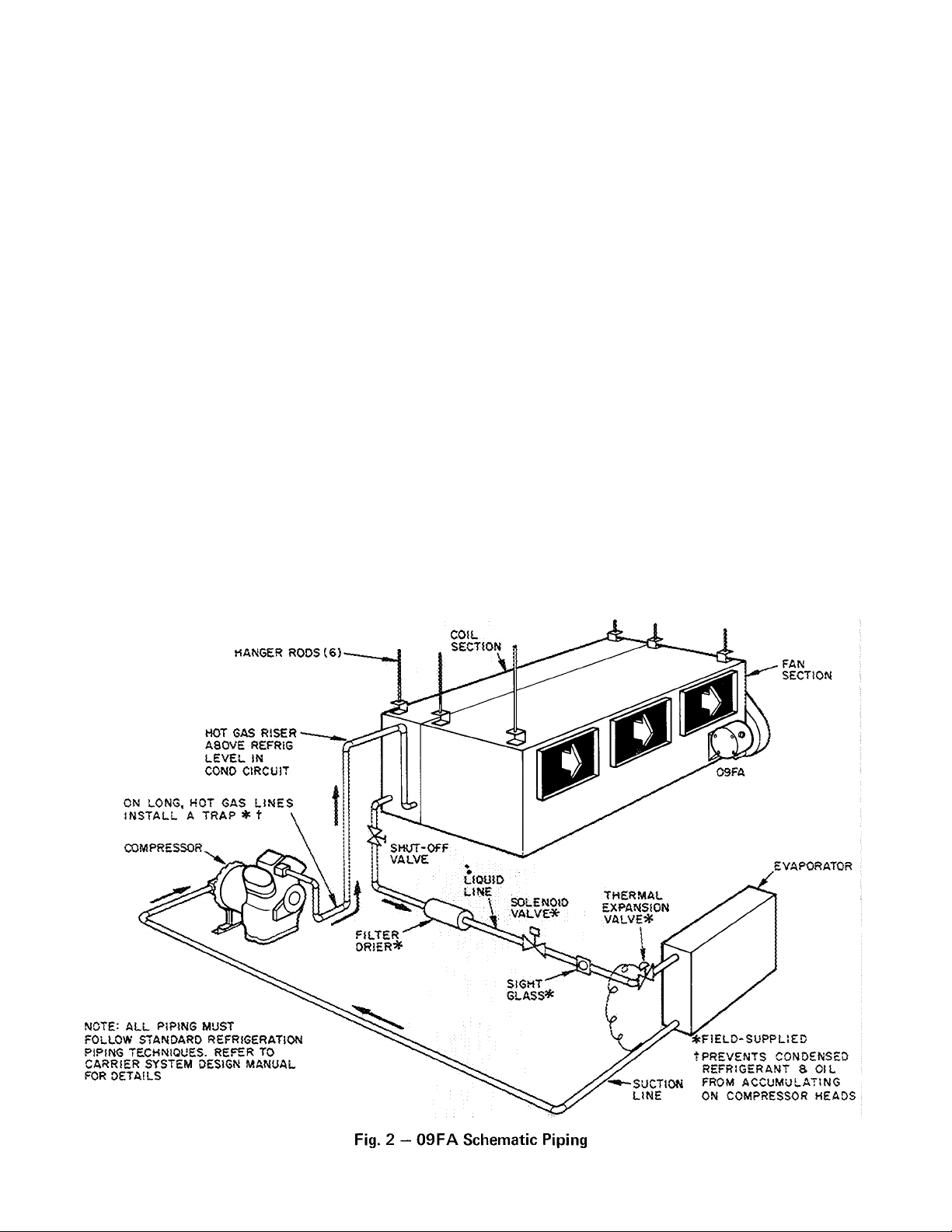

Refrigerant Piping

GENERAL — All field leak and pressure testing

should be in accordance with local code require

ments. If no local code exists, use American

Standard Safety Code for Mechanical Refrigeration

(A.S.A. B9.1).

Eor leak testing procedures, refer to the Carrier

Standard Service Techniques Manual, Chapter 1,

Section 1-6.

Refrigerant line sizing depends on length of

lines between various sections of the refrigerant

system. Consider the amount of liquid lift and

drop in the system as well as proper compressor oil

return. Consult Carrier System Design Manual, Part

3, for proper piping sizes and design.

Liquid and hot gas connections for any one

split are same size so coil may be reversed for

opposite-hand connection, but must be piped for

counter flow in any case.

LIQUID SHUT-OEF VALVE AND SIGHT GLASS

— Shut-off valve is not supplied with units. It is

strongly recommended that a full line size liquid

shut-off valve be field supplied near condenser to

allow for servicing parts of the refrigerant circuit.

A field-supplied, moisture-indicating sight glass is

recommended for use in charging and servicing the

system. Refer to Fig. 2 for location.

The American Standard Safety Code for

Mechanical Refrigeration (A.S.A. B9.1, 1964, para

graph 12.1) states as follows: “Every refrigerating

system shall be protected by a pressure relief

device unless so constructed that the pressures due

to fire conditions will be safely relieved by some

part of the system.” Since the 09FA units have no

pressure relief device, it should be field supplied

and installed. When the split coil is used with

multiple systems, each system must have a pressure

relief.

COIL CONNECTIONS - Refer to Eig. 2, 3. Make

connections.

Page 3

_

p“® o

^37.5%

25%

UNIT 09FA

UNIT 09FA044

o-

o

a

COIL CONN. SIZES (IN.)

UNIT

SIZE

006

008

012

016

024

028

034

044*

^CONNECTION SIZES ARE ODM AND ARE

SHIPPED LESS MANIFOLD. ALL MANIFOLD

LINE CONNECTION SIZES ARE |1 IN. ODM

LARGE SMALL

__

—

—

l|

If

If

If

If

—

-

5

8

5

6

5

8

ALL MANIFOLDS MUST BE FIELD INSTALLED

№ LIQUID

Q HOT GAS

ACCESSORY MANIFOLD (044 SIZE ONLY) ALL

OTHER MANIFOLDS MUST BE FIELD SUPPLIED.

□

Fig. 3 — Coil Face Splits and Connections

Electrical Wiring — Refer to Table 2; motor

manufacturer’s wiring diagram, supplied with

motor; and motor starter (field-supplied) wiring

diagram.

All wiring must comply with applicable local

and national codes.

Table 2 — Electrical Data (60-Cycle, 3-Phase)

UNIT

09FA

006 2 184

008

012 208

016

024 5 215

028

034 10

044 15

For ful I load amps, locked rotor amps, and wire sizing

amps, refer to National Electrical Code or motor man

ufacturer's recommendations.

VOLTS

220/440 1750

HP RPM

3 213

Final Inspection Check List

1. Remove debris from unit interior.

0

2. Check lubrication of fan shaft and motor

bearings. Follow fan motor manufacturer’s

NEMA

FRAME

256 U

284 U

STANDARD

(044 COIL)

recommendations. Fan bearings are prelubri

cated and require no further lubrication the

first year of operation. Refer to 09FA Start-Up

and Service Instructions for detailed bearing

lubrication.

3. Check secureness of motor and mounting

bracket.

4. Check sheave alignment and belt tension.

5. Check secureness of fan shaft bearings.

6. Check secureness of sheaves to fan and motor

shafts.

7. Recheck fan wheels for:

a. Freedom of rotation within fan housings.

b. Concentric alignment with fan housing inlet

opening.

c. Balance with fan shaft.

d. Secureness to fan shaft.

NOTE; If needed, refer to 09FA Start-Up and

Service Instructions for points 4, 5, 6, and 7.

8. Check direction of fan wheel rotation. Refer to

arrow on bearing plate nearest motor for proper

rotation.

9. Check fan speed.

Page 4

Manufacturer reserves the right to change any product specifications without notice

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 5 Form09FAdSI New Printed in U S A 1070 4-68 Codes C and MC Catalog No 530-933

Loading...

Loading...