Page 1

09DK054-084

HEATING & COOLING

Air-Cooled Condenser Units

50/60 Hz

à

Installation, Start-Up and

Service Instructions

Air-Cooled Packages

CONTENTS

Page

SAFETY CONSIDERATIONS ...

INSTALLATION .................................................

Step 1 — Complete Pre-Installation

Checks ............................................................................. 1

Step 2 — Rig and Place Unit ..........................................4

• RIGGING

• PLACING THE UNIT

Step 3 — Complete Refrigerant Piping

• GENERAL

• COIL REFRIGERANT PIPING INSTALLATION

• TUBING PACKAGE INSTALLATION

• THREE AND FOUR COIL SPLIT, COIL

CIRCUITING APPLICATIONS; 054-084 UNITS

• REFRIGERANT LINE SIZING

• LIQUID SHUTOFF VALVE AND SIGHT GLASS

• PRESSURE RELIEF

• REFRIGERANT RECEIVER

• LIQUID LIFT

Step 4 — Complete Electrical

Connections..................................................................21

• GENERAL

• FIELD CQNNECTIONS

• MAIN POWER WIRING

• CONTROL CIRCUIT POWER WIRING

• GENERAL WIRING NOTES

• DESCRIPTION OF CONTROLS

Step 5 — Add Accessories as Needed

START-UP..........................................................................29

System Evacuation and

Dehydration ..................................................................29

Charging Procedure........................................................29

Check Operation of Condenser Fan Motor

Controls and Rotation of Fans

SERVICE ......................................................................29-31

Cleaning Condenser Coils

Condenser Fans ..............................................................29

Lubrication

Head Pressure Control ..................................................29

• FAN CYCLING

.......................................................................

........................................

.....................

.....................

................................

SAFETY COIVISIDERATIOIMS

Installing, starting up, and servicing air-conditioning equip

ment can be hazardous due to system pressures, electrical

components, and equipment location (roofs, elevated struc

tures, etc.).

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance func

tions such as cleaning coils. All other operations should be

performed by trained service personnel.

,.. 1

1-28

28

29

29.

29

7

Fig. 1 — Model 09DK (084 Shown)

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to

the equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Keep quenching cloth and fire extinguisher nearby

when brazing. Use care in handling, rigging and setting bulky

equipment.

See Tables lA and IB for Physical Data.

ELECTRIC SHOCK HAZARD

Separate power sources (main and control cir

cuit power) are used for these units. Be sure

both main and control circuit powers are dis

connected before servicing.

INSTALLATION

Step 1 — Complete Pre-Installation Checks —

Examine for damage incurred during shipment. File claim

immediately with transit company if damage is found. Ver

ify that the nameplate electrical requirements match the avail

able power supply. Check the shipment for completeness.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 12 PC 111 Catalog No 530-953 Printed in U.S A Form 09DK-4SI Pg 1 4-93 Replaces: New

Tab 4a

Page 2

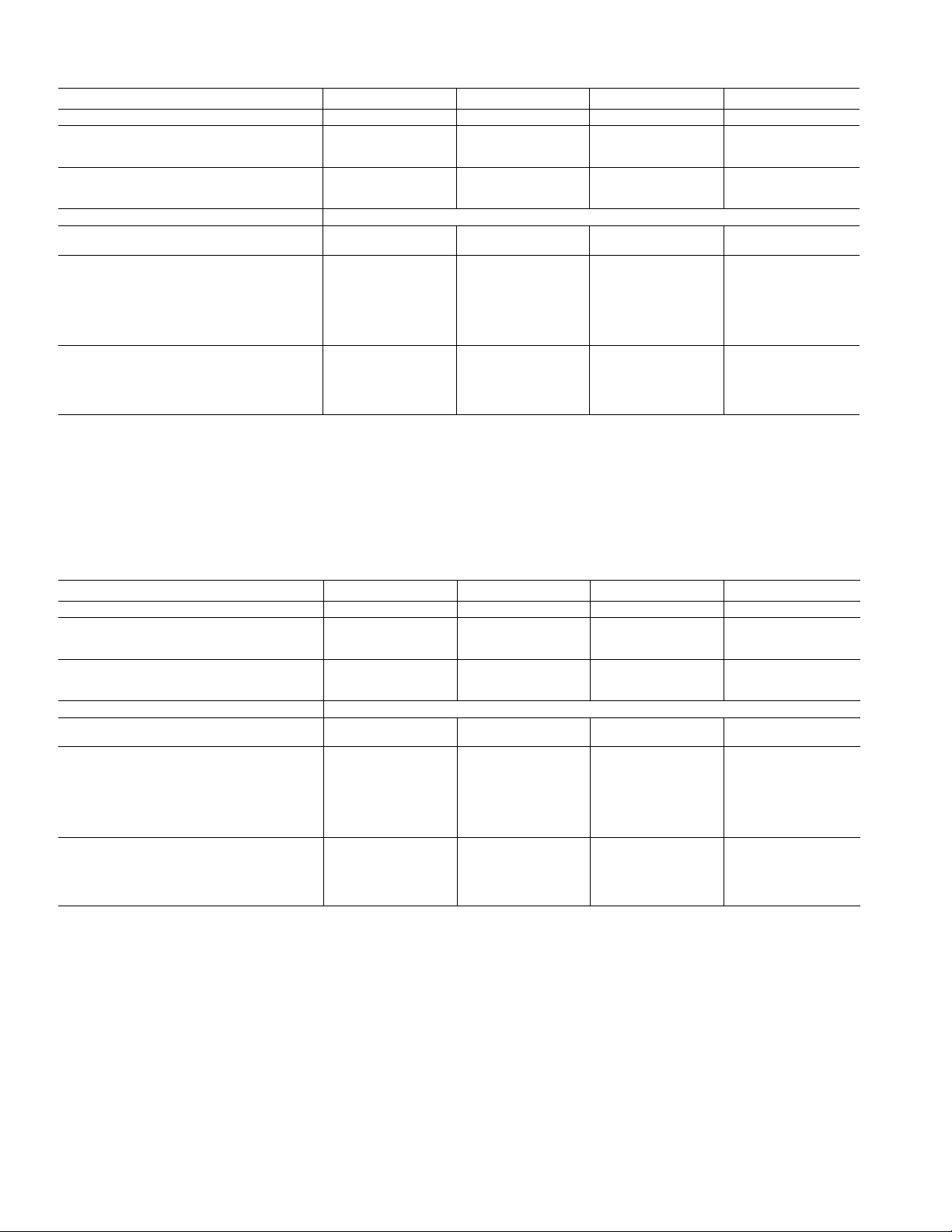

Table IA — Physical Data 60 fìz

English

09DK

NOMINAL TONS

OPERATING WEIGHT-lb

Cu-AI*

Cu-Cut

SHIPPING WEIGHT-lb“

Cu-AI‘

Cu-Cut

054

50

1695

1983

2010

2298 2569 2938 3403

REFRIGERANTS

NOMINAL HEAT REJECTION

(TONS)tt

CONDENSER FANS

No. of Blades

No. of Fans

Fan Diameter-In. 30

AIrflow-cfm

Fan Speed-rpm

Fan Motor-hp 1

CONDENSER COILS

Quantity 4

FIns/in. 17

No. of Rows

Total Face Area (sq ft)

65.8 78.6 95.4 103.5

4 4 4 4

4 4 6 6

35,000

1140 1140

2

80.5

TD — Temperature Difference = Saturated Condensing Temperature - Entering-Air Temperature

‘Copper tubes and aiuminum fins.

TCopper tubes and copper fins.

“Packaging option includes skid and coil protection.

ttNominal heat rejection based on refrigerant R-22, 15° F subcooling, and a 30° F temperature difference (TD).

064

60

1845 2200

2278 2617

2136 2521

R-134A, R-22, R-12, R-500, R-502

30 30 30

35,000 52,000 51,000

1 1 1

4 4 4

17 17 17

3 2

80.5 116.7 1167

074

70

1140 1140

084

80

2421

3099

2725

3

SI

09DK

NOMINAL kW

OPERATING WEIGHT-kg

Cu-AI*

Cu-Cut

SHIPPING WEIGHT-kg“

Cu-AI*

Cu-Cut

REFRIGERANTS

NOMINAL HEAT REJECTION

(kW)tt

CONDENSER FANS

No. of Blades

No. of Fans

Fan DIameter-mm

AIrflow-L/s

Fan Speed-r/s

Fan Motor-kW

CONDENSER COILS

Quantity

FIns/m

No. of Rows

Total Face Area (sq m)

TD — Temperature Difference = Saturated Condensing Temperature - Entering-Air Temperature

‘Copper tubes and aluminum fins.

tCopper tubes and copper fins.

“Packaging option includes skid and coil protection

ttNominal heat rejection based on refrigerant R-22, 8.3° C subcooiing, and a 16.7° C temperature difference (TD).

054 064 074

175.7 210.9 246.0 281.2

769

900

912 969 1144

1042 1165 1333 1544

231.3

4

4

762

16 520

19

.746

4

669

2 3 2 3

7.5

837 998

1033

R-134A, R-22, R-12, R-500, R-502

276 2 335.3

4

4

762 762

16 520 24 540

19 19

.746 .746

• 669 669

4 4 4

75 10.84 10.84

1187

4

6

084

1098

1406

1236

363 8

4

6

762

24 070

19

746

669

Page 3

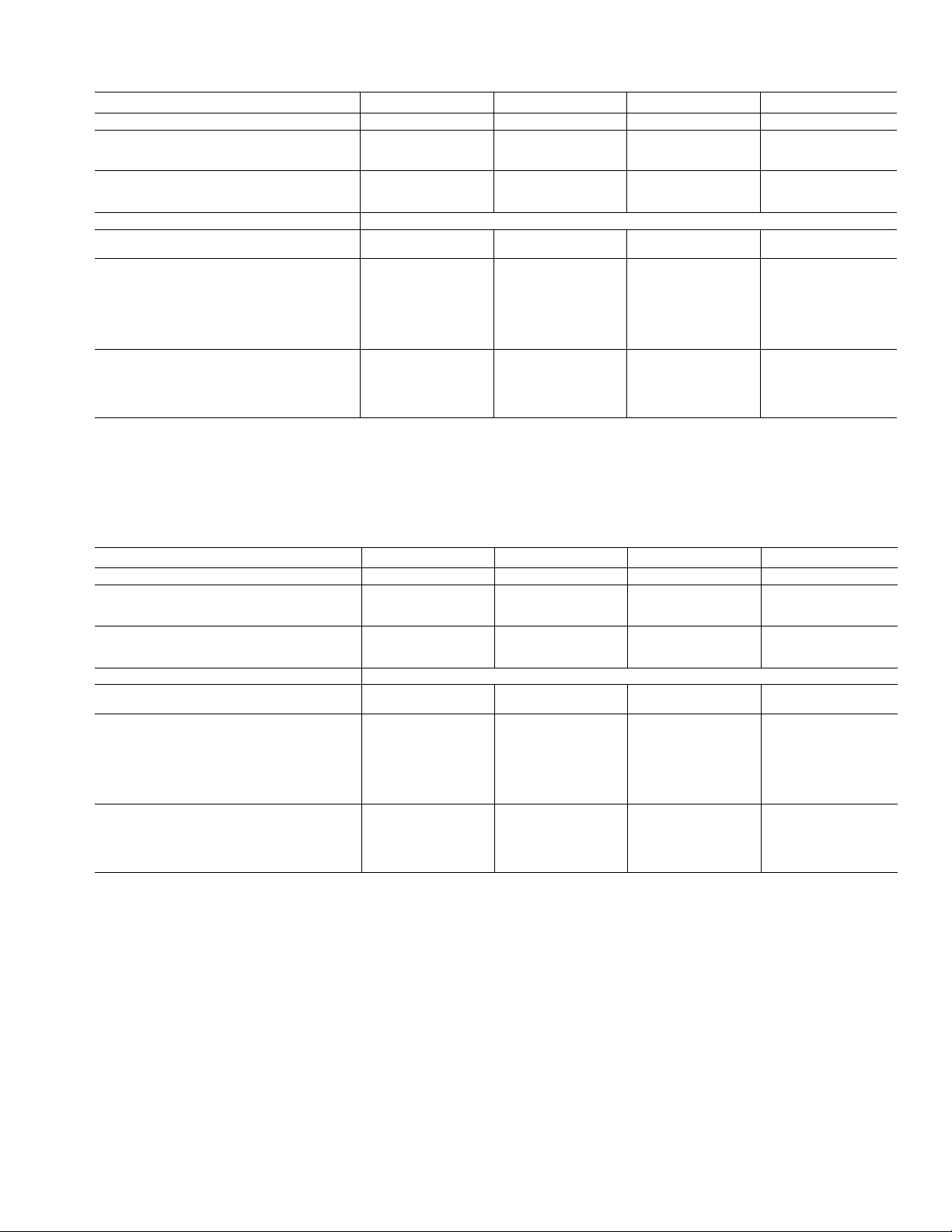

Table 1B — Physical Data 50 Hz

English

09DK

NOMINAL TONS

OPERATING WEIGHT-lb

Cu-AI*

Cu-Cut

SHIPPING WEIGHT-lb"

Cu-AI* 2010

Cu-Cut

REFRIGERANTS

NOMINAL HEAT REJECTION

(TONS)tt

CONDENSER FANS

No. of Blades

No. of Fans

Fan DIameter-ln. 30 30 30 30

AIrflow-cfm

Fan Speed-rpm 950 950 950 950

Fan Motor-hp 1 1

CONDENSER COILS

Quantity

Fins/in.

No. of Rows

Total Face Area (sq ft)

TD — Temperature Difference = Saturated Condensing Temperature - Entering-Air Temperature

'Copper tubes and aluminum fins

tCopper tubes and copper fins.

"Packaging option includes skid and coil protection.

ttNominal heat rejection based on refrigerant R-22, 15° F subcooling, and a 30° F temperature difference (TD).

054 064 074

50 60 70

1695 1845 2200

1983 2278

2298 2569

65.8 78.6

6 6 6 6

4 4 6 6

35,000 35,000 52,000 51,000

4 4 4 4

17 17 17 17

2

80.5 80.5 116.7 1167

2136 2521

R-134A, R-22, R-12, R-500, R-502

3

2617 3099

2938

95 4 103.5

1

2

084

80

2421

2725

3403

1

3

SI

09DK 054 064 074 084

NOMINAL kW

OPERATING WEIGHT-kg

Cu-AI*

Cu-Cut

SHIPPING WEIGHT-kg"

Cu-AI*

Cu-Cut

REFRIGERANTS

NOMINAL HEAT REJECTION

(kW)tt

CONDENSER FANS

No. of Blades

No. of Fans

Fan DIameter-mm 762 762 762 762

AIrflow-L/s 16 520 16 520 24 540 24 070

Fan Speed-r/s 15.8 15.8 15.8 15.8

Fan Motor-kW .746

CONDENSER COILS

Quantity

Fins/m 669 669 669 669

No. of Rows

Total Face Area (sq m)

TD — Temperature Difference = Saturated Condensing Temperature - Entering-Air Temperature

•Copper tubes and aluminum fins

tCopper tubes and copper fins

"Packaging option includes skid and coil protection.

ttNominal heat rejection based on refrigerant R-22, 8 3° C subcooling.

175 7

769 837 998

900 1033

912 969

1042

231.3 276.2 335.3 363.8

6

4

4

2

7.5

and a 16.7° C temperature difference (TD)

210 9 246 0

1165 1333

R-134A, R-22, R-12,R-500, R-502

6 6 6

4 6 6

746 746

4 4

3 2 3

7.5

281 2

1187 1406

1144

10 84 10 84

1098

1236

1544

.746

4

Page 4

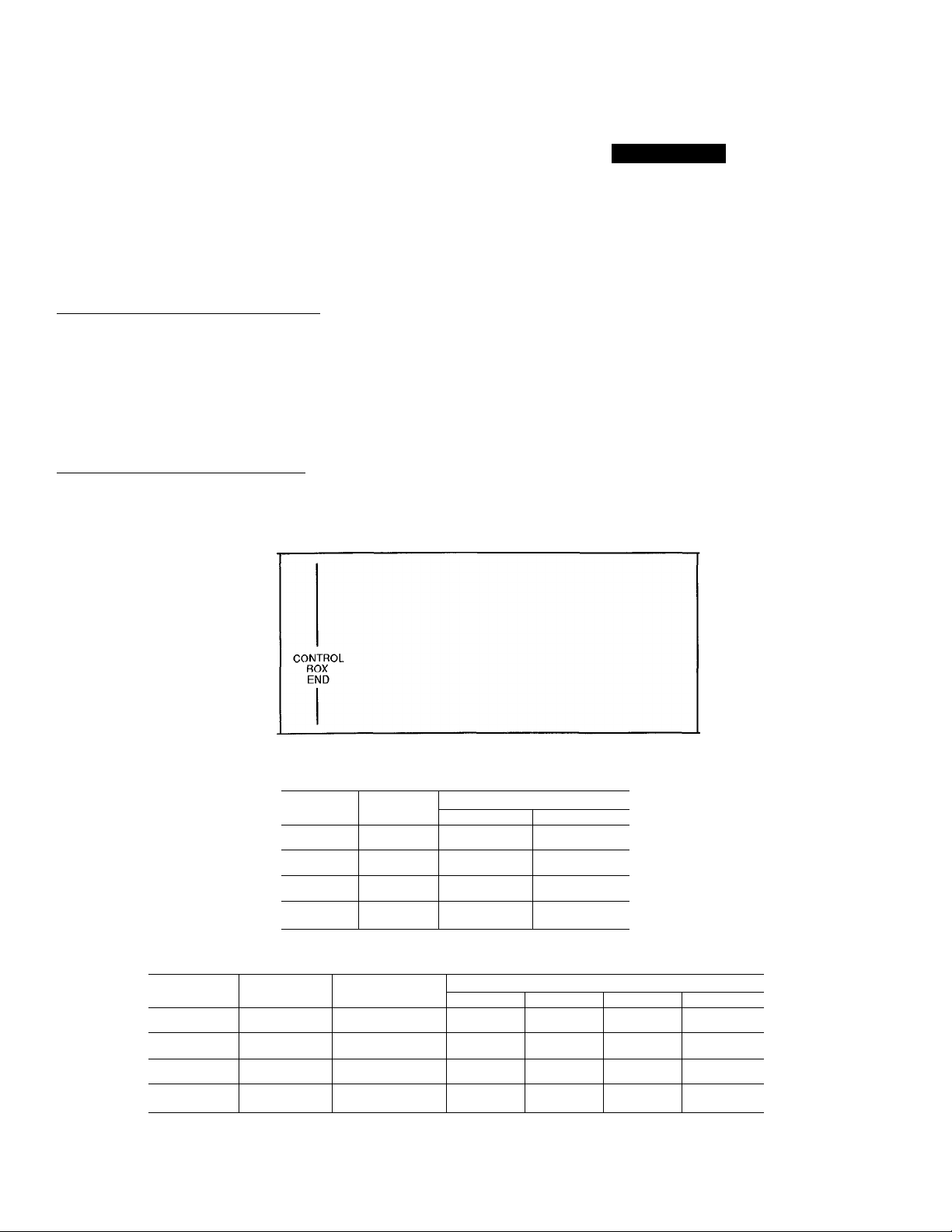

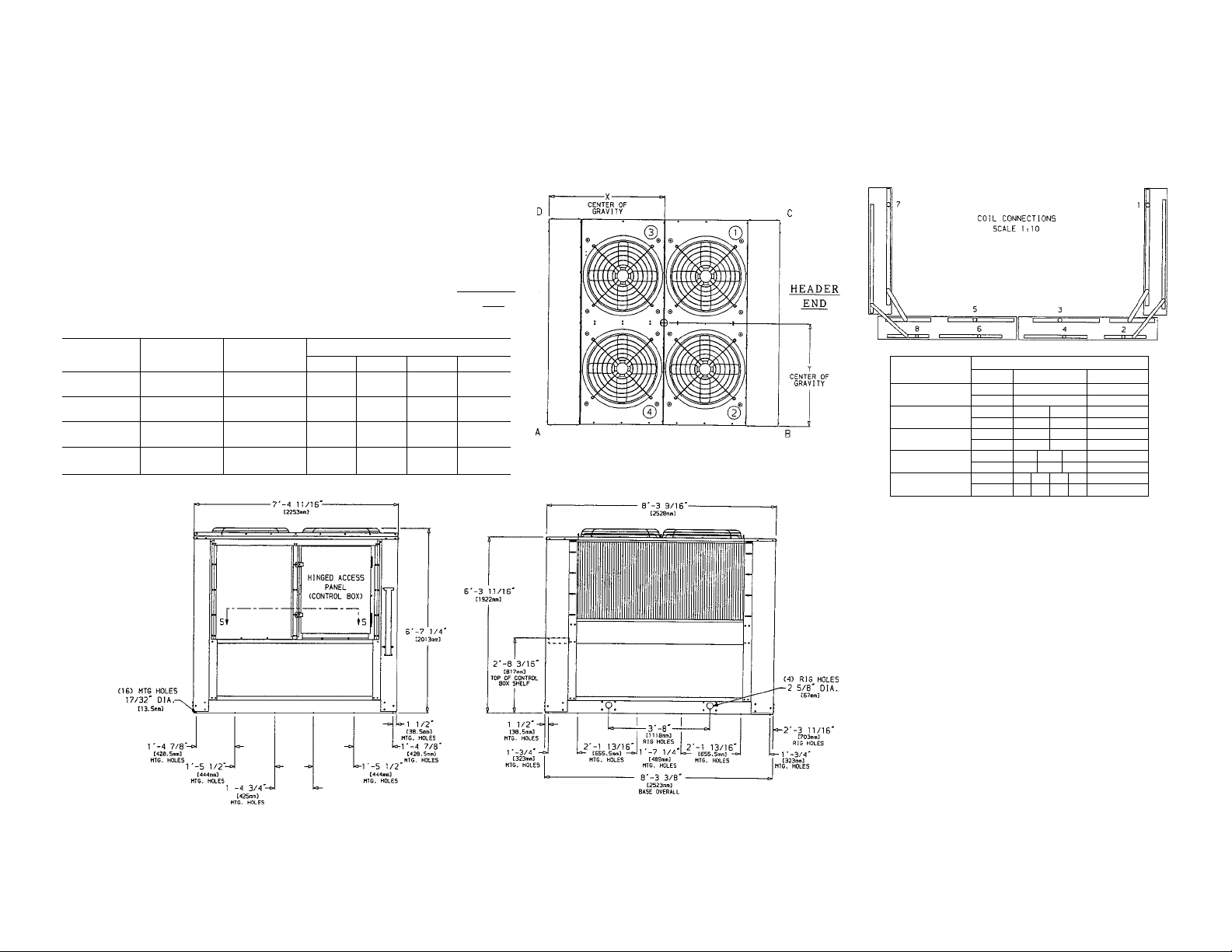

Step 2 — Rig and Place Unit

RIGGING — These units are designed for overhead rig

ging and this method should be used. Lifting holes are pro

vided in the frame base rails which are marked for rigging

(see rigging label on the unit). It is recommended that field

supplied pipes of sufficient length that extend beyond the

frame are passed through the holes. Attach cables, chains,

or straps to both ends of the pipes. Use spreader bars or a

frame to keep the cables, chains, or straps clear of the unit

sides. All cables should run to a central suspension point

so that the angle from the horizontal is not less than

45 degrees. See Fig. 2 and Table 1 for weight distribution

information. Standard coil protection packaging will pro

vide some protection to the unit. Raise and set the unit down

carefully.

Domestic Units With No Overhead Rigging— Standard con

denser packaging consists of coil protection only. Skids are

not provided as part of the standard packaging. If overhead

rigging is not available at the jobsite, place the unit on a

skid or pad by using jacks at the rigging points before drag

ging or rolling. When rolling, use a minimum of 3 rollers.

When dragging, pull the pad or skid. Do not apply pressure

to the unit. Raise from above to lift off the pad or skid

when in final position. See rigging section above for more

information.

Export and Domestic Units With Skids— All export units

are mounted on skids with vertical coil protection. Leave

the unit on the skid until it is in the final position. While on

the skid, the unit can be rolled, dragged or forked; do not

apply force to the unit. Use a minimum of 3 rollers when

rolling, and raise from above to remove the skid when unit

is in the final position. See rigging procedure above for more

information.

A CAUTION

Do not forklift these units unless attached to a skid de

signed for forklifting; damage to unit may occur. If uti

lizing a packaging option which includes a skid, the

forklift truck must have at least a 60-in. (1524 mm)

fork.

PLACING THE UNIT — Locate the condenser where an

adequate supply of inlet outdoor air is available. Do not lo

cate where the possibility of air recirculation exists, such as

under a roof overhang. Also, locate the condenser in an

area free from airborne dirt or other foreign material which

could clog the condenser coils. Refer to Fig. 3 and 4 for

airflow clearances. For multiple units, allow 8 ft (2440 mm)

separation between units for airflow and service. Placement

area must be level and strong enough to support operating

weight of the unit (Fig. 2 and Table 1). It is recommended

to bolt unit securely to pad when unit is positioned and lev

eled. Fasteners for mounting unit are field supplied. If vi

bration isolators are required for a particular installation,

refer to the unit weight distribution data table and diagram

below to help select the proper isolators.

Y - DIMENSION

UNIT 09DK

054

064

074

084

COIL TYPE*

*Cu-AI — Copper Tubes, Aluminum Fins

Cu-Cu — Copper Tubes, Copper Fins.

UNIT 09DK

054

064

074

084

COIL TYPE*

Cu-AI 1695 (769)

Cu-Cu

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

TOTAL WEIGHT

1983 (900)

1845 (837)

2278 (1033)

2200 (998)

2617 (1187)

2421 (1098)

3099 (1406) 843 (382) 751 (341)

*Cu-AI — Copper Tubes, Aiuminum Fins.

Cu-Cu — Copper Tubes, Copper Fins.

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

lb (kg)

X- DIMENSION

CENTER OF GRAVITY In. (mm)

X Dimension

48.1 (1222)

48.3 (1227)

48 2 (1224)

44,5 (1232)

56 7 (1440)

57.4 (1458)

57.1 (1450)

581 (1476)

A

452 (205) 425 (193)

524 (238) 497 (225)

489 (222)

598 (271)

618 (280)

722 (328)

673 (305)

Y Dimension

42 7 (1084)

42 9 (1090)

42 8 (1087)

43.1 (1095)

42 5 (1080)

42.8 (1087)

42 6 (1082)

43 0 (1092)

OPERATING CORNER WEIGHTS lb (kg)

B C D

462 (210)

571 (259) 542 (246) 568 (258)

526 (239)

630 (286)

581 (264)

396 (180) 422 (191)

468 (212)

434 (197)

486 (220)

589 (267)

541 (245) 626 (284)

709 (322)

494 (224)

459 (208)

571 (259)

675 (306)

796 (361)

Fig. 2 — Weight Distribution

Page 5

NOTES:

1. The approximate operating weight of the unit is:

09DK-054—

09DK-054-C

09DK-064—

09DK-064-C

2. Unit must have clearances for airflow as follows:

Top — Do not restrict in any way.

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

3. All units are shipped with a capacity split tubing kit. This kit may be used by

the field to obtain 100%, 50%/50% and 67%/33% capacity splits. To obtain

a 33%/33%/33% capacity split, coils must be manifolded by the field. Coils'

are factory circuited for a 33%/33%/17%/17% capacity split.

________

-------------

-------------

-------------

► 1695 lb [769 kg]

»■ 1983 lb [900 kg]

»• 1845 lb [837 kg]

»-2278 lb [1033 kg]

CONTROL BOX

END

UNIT

09DK-054—

09DK-054-C

09DK-064—

09DK-064-C

DIMENSION Y DIMENSION X

3'-6 11/16”

[1084 mm]

3'-6 7/8"

[1090 mm]

3'-6 3/4"

[1087 mm]

3’-7 1/8"

[1095 mm]

4'-1/8"

[1222 mm]

4'-5/16"

[1227 mm]

4'-3/16"

[1224 mm]

4'-1/2"

[1232 mm]

OPERATING CORNER WEIGHTS

A B

452 lb

[205 kg]

524 lb

[238 kg]

489 lb

[222 kg]

598 lb

[271 kg]

425 lb

[193 kg]

497 lb

[225 kg]

462 lb

[210 kg]

571 lb

[259 kg]

C

396 lb

[180 kg]

468 lb

[212 kg]

434 lb

[197 kg]

542 lb

[246 kg]

D

422 lb

[191 kg]

494 lb

[224 kg]

459 lb

[208 kg]

568 lb

[258 kg]

CAPACITY SPLIT

100%

50%/50%

67%/33%

33%/33%/33%

33%/33%/17%/17%

HOT GAS

LIQUID

HOT GAS

LIQUID

HOT GAS

LIQUID

HOT GAS 1

LIQUID

HOT GAS 1 7

LIQUID

TYPE

T-A 1/2'-

C224 7rain3

BASE OVERALL

CONNECTIONS

N0.5

1/3.5,7

2,4.6,8

5,7

1/3

2.4

6.8 7/8 I.D.

1.3,5 7

2.4.5 8

7

2 a 4.5

3 5

4

2 8

SIZE

1 1/8’ I.D.

7/8 I.D.

1 1/8' I.D.

1 1/8' I.D.

7/8 1.0.

3,51 1/8' I.D.

7/8 I.D.

1 1/8' I.D.

6 7/8 I.D.

Fig. 3 — Dimensions; 054 and 064 Units

Page 6

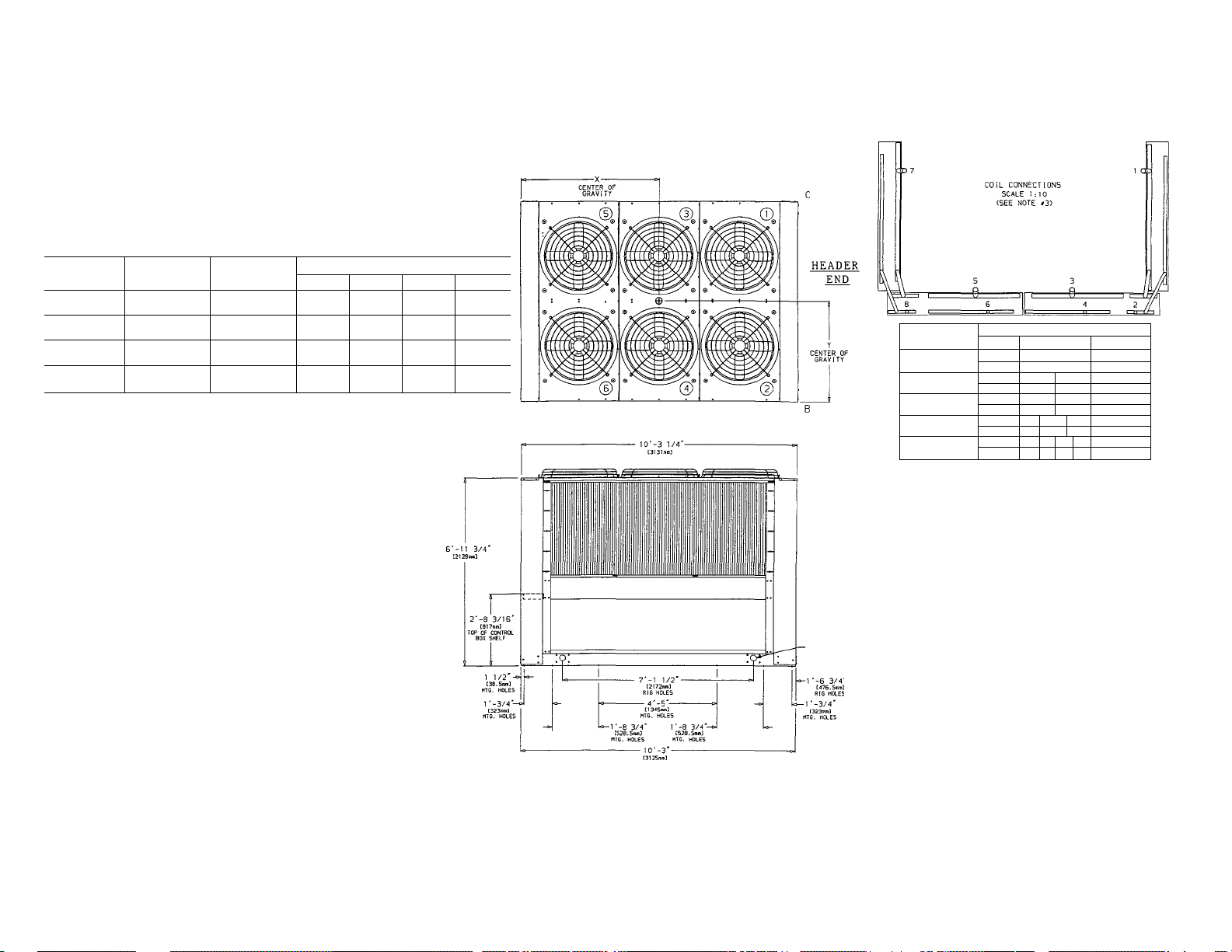

NOTES.

1. The approximate operating weight of the unit is:

09DK-074—

09DK-074-C

09DK-084

09DK-084--C

2. Unit must have clearances for airflow as follows:

Top — Do nof restrict in any way.

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

3. All units are shipped with a capacity split tubing kit. This kit may be used by

the field to obtain 100%, 50%/50% and 67%/33% capacity splits. To obtain

a 33%/33%/33% capacity split, coils must be manifolded by fhe field. Coils

are factory circuited for a 33%/33%/17%/17% capacity split.

_________

----------------

-----------------

--------------

2200 ib [998 kg]

»2617 ib [1187 kg]

»• 2421 ib [1098 kg]

»-3099 Ib [1406 kg]

09DK-074—

09DK-074-C

09DK-084—

09DK-084-C

Ov

DIMENSION Y

3’-6 1/2"

[1080 mm]

3'-6 13/16"

[1087 mm]

3'-6 5/8"

[1082 mm]

3'-7"

[1092 mm]

П6) MTG HOLES

17/32' DIA.—V

C13.5bb3

r-4 7/8'-

С42В.5в>т:

HT6. HOLES

DIMENSION X

Г-5 1/2'-

C444m}

HTG. HOLES

4'-8 11/16"

[1440 mm]

4'-9 3/8"

[1458 mm]

4'-9 1/8"

[1450 mm]

4'-10 1/8"

[1476 mm]

С22531ПЛ1

Г-4 3/4'-

L425cnir>3

MTG. HOLES

-?'-4 11/16'-

OPERATING CORNER WEIGHTS

A В

618 Ib

[280 kg]

722 Ib

[328 kg]

673 Ib

[305 kg]

843 Ib

[382 kg]

HINGED ACCESS

PANEL

(CONTROL BOX)

526 Ib

[239 kg]

630 Ib

[286 kg]

581 Ib

[264 kg]

751 Ib

[341 kg]

-Г-5 1/2'

C444nti3

MTG. HOLES

C

486 Ib

[220 kg]

589 Ib

[267 kg]

541 Ib

[245 kg]

709 Ib

[322 kg]

»-1 1/2'

[Se.Snnl

MTG. HOLES

• 7/8'

[428.Siw]

MTG. HOLES

D

571 Ib

[259 kg]

675 Ib

[306 kg]

6261b

[284 kg]

796 Ib

[361 kg]

base overall

(4) RIG HOLES

2 5/8' DIA.

СбТтт]

CAPACITY SPLIT

100%

50%/50%

67%/33%

33%/33%/33%

33%/33%/17%/17%

TYPE

HOT GAS 1,3.5.7

LIQUID 2.4.6,8 7/8 I.D.

HOT GAS

LIQUID

HOT GAS

LIQUID 2.4,5 8 7/8 I.D.

HOT GAS 1 7

LIQUID

HOT GAS17

LIQUID 2

CONNECTIONS

N0.5 SIZE

5,7

1.3

2,4 6,8 7/8 I.D.

7

1.3.S

3.5

2

8 4,6 7/8 I.D.

3 5

4

8

• 7'-4 1/2'

[224?готЗ

BASE Overall

1 3/8' I.D.

1 3/8' I.D.

1 3/8' I.D.

1 3/8' I.D.

1 3/8' I.D.

5 7/8 I.D.

Fig. 4 — Dimensions; 074 and 084 Units

Page 7

Step 3 — Complete Refrigerant Piping

GENERAL — All field leak and pressure testing should be

in accordance with local code requirements. If a local code

does not exist, use ASHRAE (American Society of Heat

ing, Refrigeration and Air Conditioning Engineers) Stan

dard 15, Safety Code for Mechanical Refrigeration.

For leak testing procedures, refer to the Carrier’s

“Refrigerant Service Techniques” Book, Form SM-IA.

For any parts that need to be removed, use a mini tubing

cutter. Perform phos-copper brazing on all field-made con

nections while protecting adjacent joints from heat.

Install or replace filter-drier(s). BEFORE CHARGING THE

SYSTEM, INSTALL OR REPLACE THE FILTERDRIER(S) CONNECTED TO THE LIQUID LINE WITHIN

THE INDOOR UNIT(S) TO PREVENT CONTAMINA

TION WITHIN THE SYSTEM.

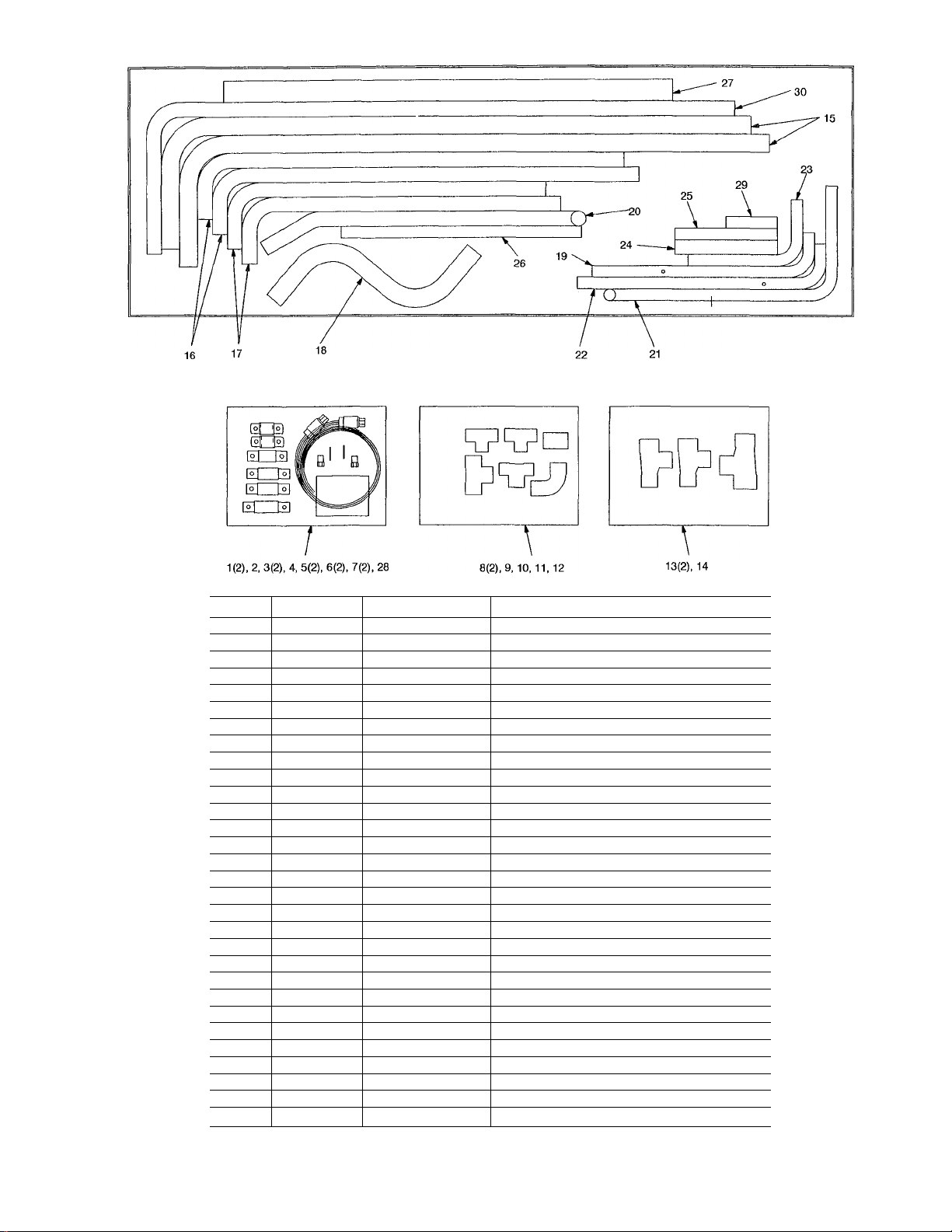

COIL REFRIGERANT PIPING INSTALLATION - Hot

gas and liquid connections are located on the same end and

are capped from the factory with a heat shrink-type cap,

which provides a clean joint for field piping. The coil cir

cuiting is designed to provide several selections of coil splits

to satisfy various applications (See Table 2), with piping

connections made in the field. In all cases where circuits

are field connected, the piping connections should be made

within the unit cabinet. The hot gas lines should enter and

the liquid lines should leave the condenser at the header

end of the unit.

As a standard item, a tubing package for headering, in

cluding two fan cycle pressure switches (FCPSs) and hard

ware is provided for the 100, 50/50, and 67/33% typical

condenser coil circuiting options. The tubing also provides

the ports for easy FCPS installations. The ports come with

a 1/4 in. male flare fitting and check valve for each FCPS

replacement. Tubing and FCPSs are field installed regard

less of circuiting. Tubing packages are not offered for the

33/33/33% and 33/33/17/17% coil circuiting options; tub

ing for these coil circuit options must be field fabricated

and installed. See Fig. 5 and 6 for tubing package contents.

NOTE: 67/33, 33/33/33 and 33/33/17/17 represent average

coil split combinations. Refer to sections below for actual

values for your particular coil split combination.

IMPORTANT: With the 67/33, 33/33/33, and 33/33/

17/17% capacity split options, 3 or 4 FCPSs are used.

For these applications, an accessory fan control kit is

required. See accessory installation instructions for more

information.

Figure 7 shows a typical piping application for a condenser

with a multiple-split system. Figure 8 shows the typical field

piping arrangements for the 09DK units. See Fig. 9 for coil

connection details. Figures 10 and 11 show typical factory

supplied coil circuiting and typical field installed 67/33%

coil split circuiting respectively.

TUBING PACKAGE INSTALLATION - Before install

ing, inspect the package contents. If any parts are missing

or damaged, file a claim with the shipping company and

notify your Carrier representative. A field supplied 3/8-in.

conduit (Greenfield conduit recommended) is required

according to UL/CSA (Underwriters’ Laboratories/

Canadian Standards Association) code for the FCPS field

wiring. Field supplied 3/8-in. conduit connectors are re

quired for connection to the junction box.

100% Coil Circuiting Applications: 054. 064 Units

1. Piping — Refer to Fig. 9 and 12 for field piping details

for 100% coil circuiting. Note that tubes 15 and 22 require

cut on the longer leg of the tube. Two 7/8-in. OD tubes,

approximately 3 in. (76.2 mm) long, must be cut from the

remaining tubes (tubes 21, 23, or 25) and brazed between

the tees (item 8) and coil header stubs. The remaining tubes

are not used in this application and may be discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies (item 5) to designated hole locations on

tubes 19 and 22. Insert valve cores (item 6), into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Install FCPSl and FCPS2

(item 7) at designated locations on tubes 19 and 22. Cut the

3/8-in. field-supplied FCPS conduit at a desired length to

fit between each FCPS location and the junction box on the

unit. Figure 11 shows a typical installation of the conduit.

Feed FCPS wires through each conduit and secure at the

switch by utilizing each conduit connector. See Fig. 13.

Secure the conduit at the junction box with 3/8-in. fieldsupplied conduit connectors. Wire FCPSl and FCPS2

according to Fig. 14. Clamp hot gas line, tube 27, at the

location specified in Fig. 12 using the 1 5/8-in. clamp

(item 4) and the 2 screws supplied. Clamp the liquid line,

tube 24, using the 1 1/8-in. clamp (item 2) and the 2 screws

provided.

50/50% Coil Circuiting Applications: 054 and 064 units

1. Piping — Refer to Fig. 9 and 15 for field piping details

for 50/50% coil circuiting. Note that tubes 21 and 22

require cuts on the longer leg of the tubes. Two 7/8-in.

OD tubes, approximately 3 in. (72.6 mm) long, must be

cut from the remaining tubes (21, 25, 26, or 29) and brazed

between the tees (item 8) and coil header stubs. The re

maining tubes are not used in this application and may be

discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies (item 5) to designated hole locations on

tubes 19 and 22. Insert valve cores (item 6) into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Install FCPSl and FCPS2

(item 7) at designated locations on tubes 19 and 22. Cut the

field-supplied 3/8-in. FCPS conduit at a desired length to

fit between each FCPS location and the junction box on the

unit. Figure 11 shows a typical installation of the conduit.

Feed FCPS wires through each conduit and secure at the

switch using each conduit connector. See Fig. 13. Secure

the conduit at the junction box with 3/8-in. field-supplied

conduit connectors. Wire FCPSl and FCPS2 according to

Fig. 14. Clamp hot gas lines, tube 15 at the location spec

ified in Fig. 15 using the two 1 3/8-in. clamps (item 3)

and 4 screws provided. Clamp the liquid lines, tubes 21

and 23, using the two 7/8-in. clamps (item 1) and the

4 screws provided.

09DK

054

064 100%

074 100%

084 100%

100% 50/50%

Table 2 — Coil Circuiting Options

09DK CIRCUITING OPTIONS

66/34

50/50%

50/50%

50/50%

66/34

68/32

67/33

34/34/32

34/34/32

32/32/36

33/33/33

34/34/16/16

34/34/16/16

32/32/18/18

33/33/17/17

Page 8

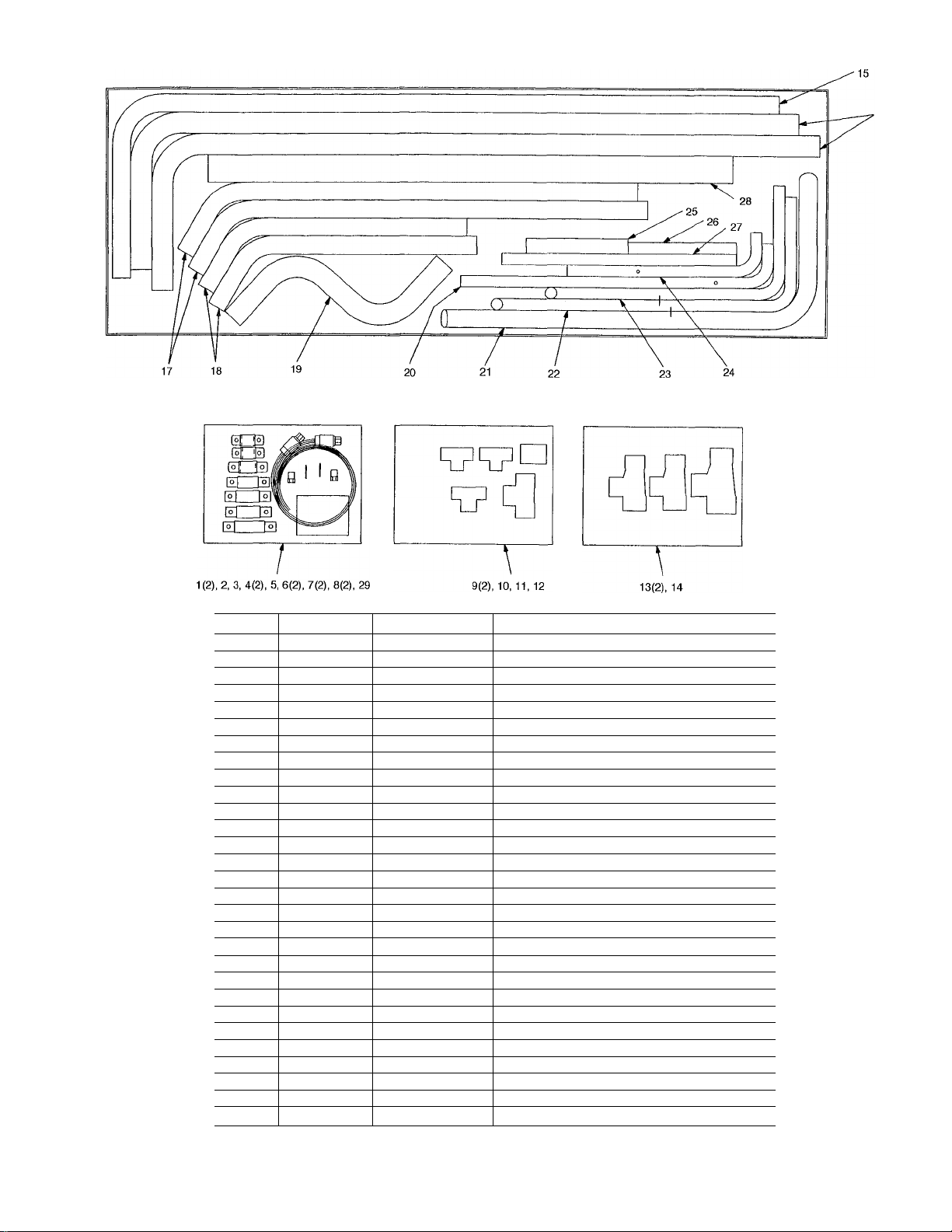

ITEM

QUANTITY NAME

1 2

a

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 2

18

19

20

21

22

23

24

25 1

26

27

28

29

30

Tube Clamp

1

2

1 Tube Clamp

2

2

2

2

1

1

1

1

2

1

2 Discharge Tuba

2

1

1

1

1

1 Liquid Tube

1 Liquid Tube

1

1

1

8

1

1

Tube Clamp

Tube Clamp 1 3/8 in.

Valve Body

Valve Core

Switch Fan cycle pressure switch

Tee

Tee

Tee

Solder Coupling 1 1/8 in.

Elbow, 90 Degree 1 1/8 in

Tee

Tee

Discharge Tube’ 1 1/8 in. CD X 32 11/32 in. Lx 5 1/16 in. W

Discharge Tube

Discharge Tube 1 3/8 in CD

Liquid Tube 7/8 in. CD X 16 13/16 in. L X 3 7/16 in. W

Discharge Tube

Liquid Tube 7/8 in. CD X 17 11/16 in. L

Straight Tube

Straight Tube 7/8 in. CD X 7 3/4 in. L

Straight Tube 7/8 in. OD X 18 1/4 in. L

Straight Tube 1 5/8 in. OD X 34 in. L

Screw 1/4 - 14 X 5/8 in long

Straight Tube 7/8 in OD X 3 7/8 in long

Discharge Tube

DESCRIPTION

7/8 in.

1 1/8 in.

1 5/8 in.

1/4 in. male flare fitting

-

7/8 in. X 7/8 in. X 7/8 in.

1 1/8 in X 1 1/8 in. X 1 1/8 in.

7/8 in. X 7/8 in. X 1 1/8 in.

1 3/8 in. X 1 1/8 in. X 1 1/8 in.

1 5/8 in X 1 3/8 in X 1 3/8 in.

1 3/8 in. CD X 44 23/32 in L x 10 1/16 in. W

1 1/8 in. CD X 24 5/32 in L x 5 1/16 in W

1 1/8 in. CD X 24 1/2 in. L

7/8 in CD X 18 13/16 in L X 3 7/16 in. W

7/8 in. CD x8 11/16 in. Lx 5 1/16 in. W

1 1/8 in. OD X 7 3/4 in. L

1 1/8 in OD X 44 19/32 in. L x 11 9/16 in. W

Fig. 5 — 09DK054,064 Tubing Package Contents

8

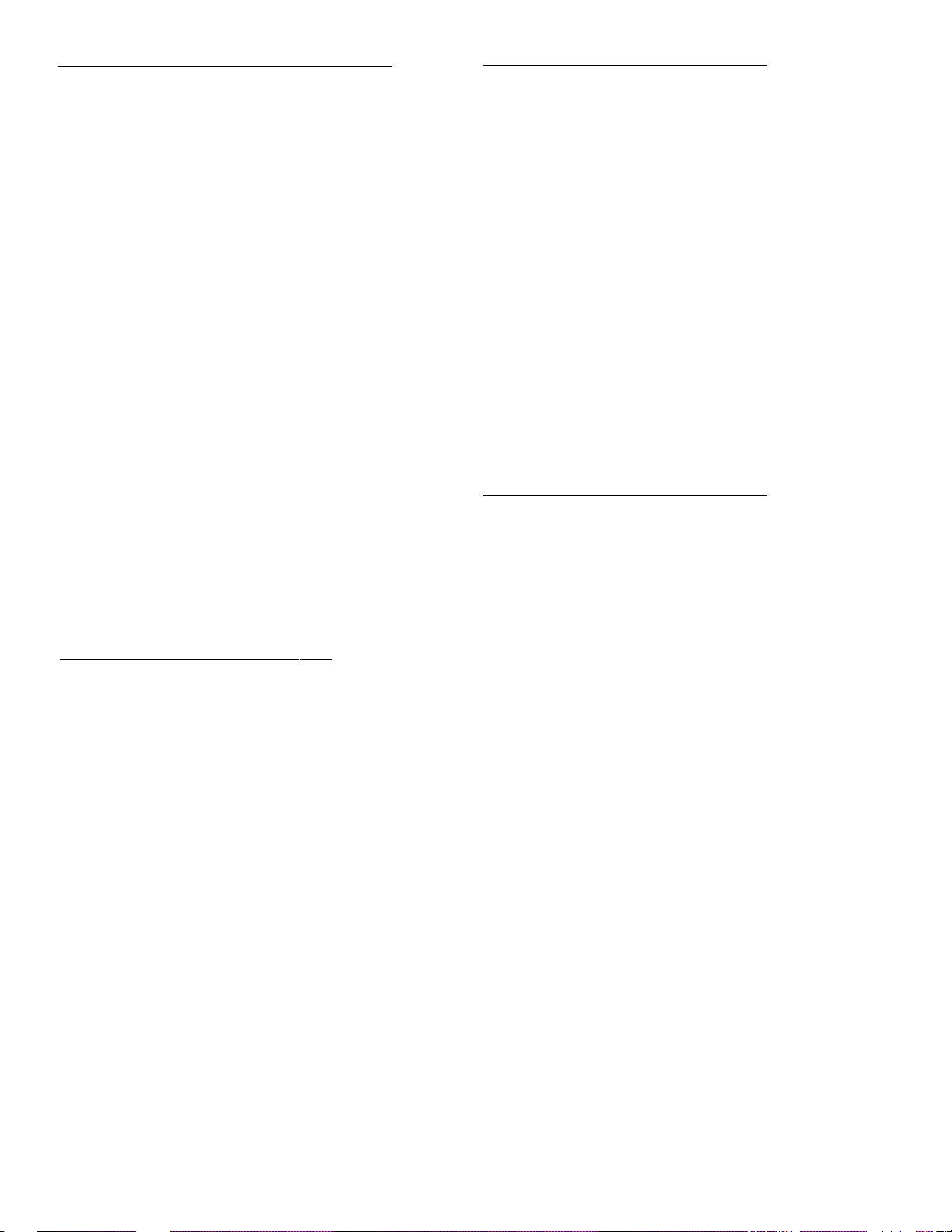

Page 9

• 16

ITEM

QUANTITY NAME

1 2

Tube Clamp

2 1 Tube Clamp

3

4

5

6

7

8

9

1 Tube Clamp

2

1

2

2

2 Siwitch

2

Tube Clamp

Tube Clamp

Valve Body

Valve Core -

Tee

10 1 Coupling

11 1 Tee

12 1 Tee

13 2 Tee

14 1 Tee

15

16

17 2

18

19

1

2

2

1

Discharge Tube

Discharge Tube

Discharge Tube

Discharge Tube

Discharge Tube

20 1 Liquid Tube

21 1

Discharge Tube

22 1 Liquid Tube

23

24

25

26

1 Liquid Tube

1

1 Straight Tube 1 1/8 in OD X 7 3/4 in L

1 Straight Tube 7/8 in. OD X 8 1/4 in. L

Liquid Tube 7/8 in. OD X 14 13/16 in. L X 3 7/16 in W

27 1 Straight Tube

28

29 8

1 Straight Tube 2 1/8 in OD X 40 in. L

Screw

DESCRIPTION

7/8 in

1 1/8 in.

1 3/8 in

1 5/8 in

2 1/8 in

1/4 in. male flare fitting

Fan cycle pressure switch

7/8 in. X 7/8 in X 7/8 in.

1 3/8 in. X 1 3/8 in.

7/8 in. X 7/8 in. X 1 1/8 in.

1 3/8 in. X 1 3/8 in X 1 3/8 in.

1 5/8 in. X 1 3/8 in. X 1 3/8 in

2 1/8 in X 1 5/8 in X 1 5/8 in

1 3/8 in CD X 50 25/32 in. L x 14 1/8 in. W

1 5/8 in CD X 50 29/32 in. L x 12 1/16 in. W

1 3/8 in CD X 34 1/2 in L X 4 3/4 in. W

1 3/8 in CD X 19 7/8 in. L X 4 3/4 in. W

1 5/8 in CD

7/8 in. OD X 23 13/16 in L X 3 7/16 in. W

1 3/8 in OD X 28 3/8 in. L

7/8 in OD X 23 1/4 in. L (074 Units only)

7/8 in. OD X 18 1/4 in L

7/8 in. OD X 17 7/8 in. L

1/4 in.-14 X 5/8 in long

Fig. 6 — 09DK074,084 Tubing Package Contents

Page 10

66/34% Coil Circuiting Applications: 054 and 064 Units

NOTE: To operate the 054 and 064 condenser units with

66/34% coil circuiting, an accessory fan control kit is

required. Refer to fan control kit installation instruc

tions for more information.

1. Piping — Refer to Fig. 9 and 16 for field piping details

for 66/34% coil circuiting. Note that tube 16 will require

cuts on the longer leg of the tube. Tube 16 will be used in

the two specified locations. A 7/8-in. OD tube, approxi

mately 3 in. (72.6 mm) long, must be cut from the remain

ing tubes (23 or 26) and brazed between the tee (item 8)

and coil header stub. The remaining tubes are not used in

this application and may be discarded.

2. Install Fan-Cycle Pressure Switches and Clamps — Braze 3

valve core bodies (item 5) to designated hole locations on

tubes 19, 21, and 22. Insert valve cores (item 6) into valve

core bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Note that the accessory fan

control kit is required for this coil circuiting. An extra FCPS

and valve assembly is provided with the kit. Install FCPSl,

FCPS2, and FCPS4 (item 7) at designated locations on tubes

19, 21, and 22. Cut the field-supplied 3/8-in. FCPS conduit

at a desired length to fit between each FCPS location and

the junction box on the unit. See Fig. 11 for typical conduit

installation. Feed FCPS wires through each conduit and se

cure at the switch by utilizing each conduit connector. See

Fig. 13. Secure the conduit at the junction box with 3/8-in.,

field-supplied conduit connectors. Wire FCPSl, FCPS2, and

FCPS4 according to Fig. 14 Note that FCPS2 and FCPS4

are wired in parallel. Fan 4 is shared by the 34% and 66%

refrigeration circuit. If either circuit needs the fan to be on,

it will be on. At the location specified in Fig. 16, clamp hot

gas lines, tubes 15 and 30, using a 1 3/8-in. clamp (item 3)

and a 1 1/8-in. clamp (item 2) with the 4 screws supplied.

Clamp the liquid lines, tubes 21 and 25, with 7/8-in. clamps

(item 1) and 4 screws provided.

100% Coil Circuiting Applications: 074 Units

1. Piping — Refer to Fig. 9 and 17 for field piping details

for 100% coil circuiting. Note that tube 16 requires a cut on

the longer leg of the tube. Two 7/8-in. OD tubes approxi

mately 3 in. (72.6 mm) long, must be cut from the remain

ing tubes (22 or 23) and brazed between the tees (item 9)

and coil header stubs. The remaining tubes are not used and

may be discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies (item 6) to designated hole locations on

tubes 20 and 24. Insert valve cores (item 7) into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169 to 339 mN-m). Install FCPSl and FCPS2

(item 8) at designated locations on tubes 20 and 24. Cut the

3/8-in. field-supplied FCPS conduit at a desired length to

fit between each FCPS location and the junction box on the

unit. See Fig. 11 for typical conduit installation. Feed FCPS

wires through each conduit and secure at the switch by uti

lizing each conduit connector. See Fig. 13. Secure the con

duit at the junction box with 3/8-in. field-supplied conduit

connectors. Wire FCPSl and FCPS2 according to Fig. 18.

Clamp hot gas line, tube 28, using 2 1/8-in. clamp (item 5)

at the location specified in Fig. 17 with the 2 screws sup

plied. Clamp the liquid line, tube 25, using 1 1/8-in. clamp

(item 2) and the 2 screws provided.

50/50% Coil Circuiting Applications: 074 Units

1. Piping — Refer to Fig. 9 and 19 for field piping details

for 50/50% coil circuiting. Note that tube 23 will require a

cut, located exactly at the location of the hole in the tube.

Tube 23 will be used in the two locations specified. Two

7/8-in. OD tubes, approximately 3 in. (72.6 mm) long, must

be cut from the remaining tubes (22, 26, or 27) and brazed

between the tees (item 9) and coil header stubs. The re

maining tubes are not used in this application and may be

discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies (item 6) to designated hole locations on

tubes 20 and 24. Insert valve cores (item 7) into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Install FCPSl and FCPS2

(item 8) at designated location on tubes 20 and 24. Cut the

3/8-in. field-supplied FCPS conduit at a desired length to

fit between each FCPS location and the junction box on the

unit. See Fig. 11 for typical conduit installation. Feed FCPS

wires through each conduit and secure at the switch by us

ing each conduit connector. See Fig. 13. Secure the con

duit at the junction box with 3/8-in. field-supplied conduit

connectors. Wire FCPSl and FCPS2 according to Fig. 18.

Clamp hot gas line, tube 16, at the location specified in

Fig. 19 using two 1 5/8-in. clamps (item 4) and 4 screws

supplied. Clamp the liquid lines, tubes 23, using the two

7/8-in. clamps (item 1) and the 4 screws provided.

68/32% Coil Circuiting Applications: 074 Units

NOTE: To operate the 074 condenser units with 68/32%

coil circuiting, an accessory fan control kit is required.

See accessory installation instructions for more infor

mation.

1. Piping — Refer to Fig. 9 and 20 for field piping details

for 68/32% coil circuiting. Note that tubes 17 and 20 re

quire euts on the longer leg of the tubes. Tube 17 will be

used in the two locations specified. Also, a 7/8-in. OD tube,

approximately 3 in. (72.6 mm) long, must be cut from the

remaining tubes (23 or 27) and brazed between the tee

(item 9) and eoil header stub. The remaining tubes are not

used in this application and may be discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 3

core bodies (item 6) to designated hole locations on tubes

20, 22, and 24. Insert valve cores (item 7) into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Note that the accessory fan

control kit is required for this coil circuiting. An extra FCPS

and valve assembly is provided with the kit. Install FCPSl,

FCPS2, and FCPS4 (item 8) at designated locations on tubes

20, 22, and 24. Cut the 3/8-in. field-supplied FCPS conduit

at a desired length to fit between each FCPS location and

the junction box on the unit. See Fig. 11 for typical conduit

installation. Feed FCPS wires through each conduit and se

cure at the switch by utilizing each conduit connector. See

Fig. 13. Secure the conduit at the junction box with 3/8-in.

field-supplied conduit connectors. Wire FCPSl, FCPS2 and

FCPS4 according to Fig. 18. Note that FCPS2 and FCPS4

are wired in parallel. Fan 4 is being shared by the 32% and

68% refrigeration circuit. If either circuit needs the fan to

be on, it will be on. At the location specified in Fig. 20,

clamp hot gas lines, tube 15 with a 1 3/8 in. clamp (item 3)

and tube 16 with a 1 5/8 in. clamp (item 4) with the

4 screws supplied. Clamp the liquid lines, tube 22 with a

7/8 in. clamp (item 1) and tube 25 with a 1 1/8 in. clamp

(item 2) with the 4 screws supplied.

10

Page 11

COMPRESSORS

SEE NOTE 1

09DK084 UNIT (LOCATED ABOVE OTHER COMPONENTS)

PRESSURE RELIEF DEVICES*

FILTER-DRIERS*

SEE NOTE 4

Fig. 7 — Typical Piping for 09DK Condenser With a Dual Split System

'Field supplied.

NOTES

1. Hot gas lines should rise above refrigerant level in con

denser circuit.

2. Trap should be installed on hot gas lines to prevent

condenser oil and refrigerant vapor migration from ac

cumulating on compressor heads during off cycle.

3. Pitch all horizontal lines downward in the direction of

refrigerant flow.

4. Refer to Carrier System Design Manual, part 3 for proper

piping sizes and design.

MOISTURE

■ INDICATORS*

(SIGHT GLASS)

SEE NOTE 4

Page 12

O-

054,064 Units

..

..........

O

FCPS2■

FCPS2■

FCPS2•

„1..

O

--------

T

1

1

fel-

0

A

' ii

1 FCPS4

34% 66%

li

50% / 50%

--------

100%

i i

r—o--*--o

til

—*-o

FCPS1

FCPS1

FCPS1

FCPS2

FCPS2

t a

34%

FCPS — Fan Cycle Pressure Switch

1-0

16%

FCPS4

Fig. 8

1. FCPS1 = Fan cycle pressure switch 1 cycles fan 3 in

response to condensing pressure.

2. FCPS2 = Fan cycle pressure switch 2 cycles fan 4 in

response to condensing pressure.

3. FCPS3 = Fan cycle pressure switch 3 cycles fan 3 in

O— -n

FCPS3

response to condensing pressure.

4. FCPS4 = Fan cycle pressure switch 4 cycles fan 4 in

response to condensing pressure.

5. In the above applications where a fan is being shared by two

different refrigeration circuits, the FCPSs (FCPS1 and 3 or

FCPS2 and 4) are in parallel so that if either circuit needs the

fan to be on, it will be on.

r-0

___a- - --

t- t

s_

FCPS1

ii

16%

Typical Field Piping Arrangements

34%

12

Page 13

074 Units

FCPS2■

FCPS2■

o-

;i

..........

--------------------------

O

--------

— o

I

i i

100%

■ ?—1 ^

lili

ill'

1 1 1 >

1 1 1 >

1 1 1 1

III

ill

1 1 1 1

Jí

--------------------------------------

tij

50% / 50%

1

o

■o

FCPS1

FCPS1

FCPS

FCPS2•

o

FCPS2-

r---0

Î

32%

Fan Cycle Pressure Switch

I I

r

fel.

0

V

1 FCPS4

32%

----------

1

1

1

1

1

1 FCPS4

1 ,

1 /

U !t ii It

32% 36%.

FCPS2 FCPS4

1—0

Í4

itii

68%.

FCPS3 1

|-0

__a.__

\ 1

FCPS3

1

----1

1

1

1

\r\

32%

o

O- -

a_

FCPS1

FCPS1

NOTES:

1 FCPS1 = Fan cycle pressure switch 1 cycles fan 3 in

response to condensing pressure.

2. FCPS2 = Fan cycle pressure switch 2 cycles fan 4 in

response to condensing pressure

3. FCPS3 = Fan cycle pressure switch 3 cycles fan 3 in

response to condensing pressure.

4. FCPS4 = Fan cycle pressure switch 4 cycles fan 4 in

response to condensing pressure

5 In the above applications where a fan is being shared by two

different refrigeration circuits, the FCPSs (FCPS1 and 3 or

FCPS2 and 4) are in parallel so that if either circuit needs the

fan to be on, it will be on

FCPS1

t a ¡i

18%.

18%

Fig. 8 — Typical Field Piping Arrangements (cent)

32%

13

Page 14

084 Units

........O

FCPS2-

FCPS2■

FCPS2 ■

ZI

..........

...................■ T"'"! r—^

O

î

33%

t i U

100%

1 '

1 » •

ill*

1 1 1 1

1 1 1 1

1 1 ! I

: ! ! !

H

li

50% / 50%

—-O- - L _

ÎÜ

■O

[4

FCPS4

lî il

67%

FCPS1

FCPS1

FCPS1

FCPS2

r---0

FCPS2

Î !i

33%

FCPS — Fan Cycle Pressure Switch

1 FCPS1 = Fan cycle pressure switch 1 cycles fan 3 in

response to condensing pressure.

2 FCPS2 = Fan cycle pressure switch 2 cycles fan 4 in

response to condensing pressure

3. FCPS3 = Fan cycle pressure switch 3 cycles fan 3 in

response to condensing pressure.

4. FCPS4 = Fan cycle pressure switch 4 cycies fan 4 in

response to condensing pressure

5. In the above applications where a fan is being shared by two

different refrigeration circuits, the FCPSs (FCPS1 and 3 or

FCPS2 and 4) are in parallel so that if either circuit needs the

fan to be on, it will be on.

FCPS4

O- -1

FCPS3

|-0

î a

17%

__a__

Î !

17%

a_

¡1

FCPS1

33%

Fig. 8 — Typical Field Piping Arrangements (cent)

14

Page 15

LEFTSIDE COILS

RIGHT SIDE COILS

054,064

PERCENT CAPACITY

SPLIT NUMBER

100

50/50

66/34

34/34/32

34/34/16/16

•Connection sizes reflect size of each coil header nozzle.

fA tubing package is factory supplied to facilitate field piping installation for the 100, 50/50 and 66/34 capacity split applications See installation instructions for more

information

LINE TYPE

Hot Gas 1,3,5,7

Liquid 2,4,6,8

Hot Gas

Liquid 2,4/6,8

Hot Gas 1,3,5/7

Liquid 2,4,6/8

Hot Gas

Liquid

Hot Gas

Liquid

COIL CONNECTION

1,3/5,7

1/7/3,5

2/8/4,6

1/7/3/5

2/8/4/6

COIL CONNECTION

in.-ODM*

1 1/8

7/8

1 1/8 1 3/8

7/8 7/8

1 1/8

7/8 7/8

1 1/8

7/8

1 1/8

7/8

TUBING CONNECTION

in. ODMf

1 5/8

1 1/8

1 3/8

(3) 1 1/8

(3) 7/8

074

PERCENT CAPACITY

SPLIT

100

50/50

68/32

32/32/36

32/32/18/18

•Connection sizes reflect size of each coil header nozzle

tA tubing package is factory supplied to facilitate field piping installation for the 100, 50/50 and 68/32 capacity split applications. See installation instructions for more

information.

LINE TYPE

Hot Gas

Liquid

Hot Gas 1,3/5,7

Liquid

Hot Gas 1,3,5/7

Liquid

Hof Gas

Liquid

Hot Gas

Liquid

COIL CONNECTION

NUMBER

1,3,5,7

2,4,6,8

2,4/6,8 7/8

2,4,6/8

1/7/3,5

2/8/4,6

1/7/3/5

2/8/4/6

COIL CONNECTION

in.-ODM* in.-ODMf

1 3/8

7/8 1 1/8

1 3/8 1 5/8

1 3/8 1 5/8 1 3/8

7/8 7/8

1 3/8

7/8

1 3/8

7/8

TUBING CONNECTION

7/8 7/8

2 1/8

(3) 1 3/8

(3) 7/8

084

PERCENT CAPACITY

SPLIT

100

50/50

67/33

33/33/33

33/33/17/17

•Connection sizes reflect size of each coil header nozzle

tA tubing package is factory supplied to facilitate field piping installation for the 100, 50/50 and 67/33 capacity split applications See installation instructions for more

information.

LINE TYPE

Hot Gas

Liquid 2,4,6,8 7/8 1 1/8

Hot Gas 1,3/5,7 1 3/8

Liquid 2,4/6,8

Hot Gas 1,3,5/7 1 3/8

Liquid 2,4,6/8

Hot Gas 1/7/3,5

Liquid 2/8/4,6

Hot Gas

Liquid

COIL CONNECTION

NUMBER in.-ODM*

1,3,5,7 1 3/8

1/7/3/5

2/8/4/6

COIL CONNECTION TUBING CONNECTION

7/8 7/8

7/8

1 3/8

7/8

1 3/8

7/8

in.-ODMt

2 1/8

1 5/8

1 5/8

1 1/8 7/8

(3) 1 3/8

(3) 7/8

Fig. 9 — Coil Connection Data

15

1 3/8

7/8

1 1/8

7/8

1 5/8

7/8

1 5/8

7/8

1 3/8

Page 16

100% Coil Circuiting Applications: 084 Units

1. Piping — Refer to Fig. 9 and 21 for field piping details

for 100% coil circuiting. Note that tubes 16 and 20 require

a cut on the longer leg of the tubes. Two 7/8-in. OD tubes,

approximately 3 in. (72.6 mm) long, must be cut from the

remaining tubes (22 or 23) and brazed between the tees

(item 9) and coil header stubs. The remaining tubes are not

used in this application and may be discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies to designated hole locations on tubes 20

and 24. Insert valve cores into valve core bodies by thread

ing into place and tightening to 1 5 to 3 in.-lb (169.5 to

339 mN-m) Install FCPSl and FCPS2 at designated loca

tions on tubes 20 and 24. Cut the 3/8-in. field-supplied FCPS

conduit at a desired length to fit between each FCPS loca

tion and the junction box on the unit. See Fig. 11 for typ

ical conduit installation. Feed FCPS wires through each conduit

and secure at the switch by utilizing each conduit connec

tor. See Fig. 13. Secure the conduit at the junction box

with 3/8-in. field-supplied conduit connectors. Wire FCPSl

and FCPS2 according to Fig. 18. At the location specified

in Fig. 21, clamp hot gas line, tube 28, using 2 1/8-in.

clamp and 2 screws provided. Clamp the liquid line, tube

25, using 1 1/8-in. clamp and 2 screws provided.

50/50% Coil Circuiting Applications: 084 Units

1. Piping — Refer to Fig. 9 and 22 for field piping details

for 50/50% coil circuiting. Note that tube 20 requires a cut

on the longer leg of the tube. Tube 23 will require a cut

located exactly at the location of the hole in the tube, and

will be used at the two locations specified. Two 7/8-in. OD

tubes, approximately 3 in. (72.6 mm) long, must be cut

from the remaining tubes (22, 26, and 27) and be brazed

between the tees (item 9) and coil header stubs. The re

maining tubes are not used in this application and may be

discarded.

2. Install Fan Cycle Pressure Switches and Clamps — Braze 2

valve core bodies (item 6) to designated hole locations on

tubes 20 and 24. Insert valve cores (item 7) into valve core

bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Install FCPSl and FCPS2

(item 8) at designated locations on tubes 20 and 24. Cut the

3/8-in. field-supplied FCPS conduit at a desired length to

fit between each FCPS location and the junction box on the

unit. See Fig. 11 for typical conduit installation. Feed FCPS

wires through each conduit and secure at the switch by us

ing each conduit connector. See Fig. 13. Secure the con

duit at the junction box with 3/8-in. field-supplied conduit

connectors. Wire FCPSl and FCPS2 according to Fig. 18.

At the location specified in Fig. 22, clamp hot gas line,

tube 16, using two 1 5/8-in. clamps and 4 screws provided.

Clamp the liquid lines, tubes 23, using two 7/8-in. clamps

(item 1) and 4 screws provided.

Fig. 10 — Typical Factory-Supplied Coil Circuiting,

09DK054-084 Units (084 Shown)

CONDUITS

Fig. 11 — Typicai Coil Circuiting for 09DK054-084

Units (67/33% Split Option; 084 Unit Shown)

16

Page 17

6113?)% Coil Circuiting Applications: 084 Units

NOTE: To operate 084 condenser units with 67/33% coil

circuiting, an accessory fan control kit is required.

See accessory installation instructions for more

information.

1. Piping — Refer to Fig. 9 and 23 for field piping details

for 67/33% coil circuiting. Note that tubes 17 and 20

require a cut on the longer leg of the tubes. Tube 17 will

be used in the two locations specified. Also, a 7/8-in. OD

tube, approximately 3 in. (72.6 mm) long must be cut from

the remaining tubes (22 or 27) and brazed between the tee

(item 9) and coil header stub. The remaining tubes are not

used in this application and may be discarded.

2 Install Fan Cycle Pressure Switches and Clamps — Braze 3

valve core bodies (item 6) to designated hole locations on

tubes 20, 23, and 24. Insert valve cores (item 7) into valve

core bodies by threading into place and tightening to 1.5 to

3 in.-lb (169.5 to 339 mN-m). Note that the accessory

fan control kit is required for this coil circuiting. An extra

FCPS and valve assembly is provided with the kit. Install

FCPSl, FCPS2, and FCPS4 (item 8) at designated loca

tions on tubes 20, 23, and 24. Cut the 3/8-in. field-supplied

FCPS conduit at a desired length to fit between each FCPS

location and the junction box on the unit. See Fig. 11 for

typical conduit installation. Feed FCPS wires through each

conduit and secure at the switch by utilizing each conduit

connector. See Fig. 13. Secure the conduit at the junction

box with 3/8-in. field-supplied conduit connector. Wire FCPSl,

FCPS2, and FCPS4 according to Fig. 18. Note that FCPS2

and FCPS4 are wired in parallel. Fan 4 is shared by the

33% and 67% refrigeration circuit. If either circuit needs

the fan to be on, it will be on. At the location specified in

Fig. 23, clamp hot gas lines, tube 15 with a 1 3/8-in. clamp

(item 3) and tube 16 with a 1 5/8-in. clamp (item 4) with

the 4 screws supplied Clamp the liquid lines, tube 23 with

a 7/8-in. clamp (item 1) and tube 25 with a 1 1/8-in. clamp

(item 2) with 4 screws supplied.

THREE AND FOUR COIL SPLIT, COIL CIRCUITING

APPLICATIONS; 054-084 UNITS

NOTE: To operate 054-084 condenser units with the 3

and 4 coil split coil circuiting, the fan control kit is re

quired. See accessory installation instructions for more

information.

1. Piping — Piping is not provided in the tubing package

for these coil circuiting options. Tubing is field fabricated

and installed, according to the coil circuiting shown in

Fig. 8. For pipe sizing information, refer to Refrigerant Line

Sizing, page 18. To secure the piping, it should be routed

to the brackets supplied on the unit.

100%

FCPS — Fan Cycle Pressure Switch

Fig. 12 — 100% Coil Circuiting; 054 and 064 Units

NOTES:

1. Dimensions in ( ) are in millimeters

2. See Fig 5 for tubing package contents.

17

Page 18

2. Install Fan Cycle Pressure Switches and Clamps — Four

FCPSs should be used. Locate holes, valve core assem

blies, and FCPS’s 1, 2, 3, and 4 at the specified locations.

See Fig. 8. Insert valve cores into valve core bodies by

threading into place and tightening to 1.5 to 3 in.-lb (169.5

to 339 mN-m). The additional two FCPSs and valve core

assemblies are provided with the accessory fan control kit.

Cut the 3/8-in. field-supplied FCPS conduit at a desired length

to fit between each FCPS location and the junction box on

the unit. See Fig. 11 for typical conduit installation. Feed

FCPS wires through each conduit and secure at the switch

by utilizing each conduit connector. See Fig. 13. Secure

the conduit at the junction box with 3/8-in. field-supplied

conduit connectors. Wire the FCPSs according to Fig. 14

and 18. Note that FCPS2 and 4 and FCPSl and 3 are wired

in parallel. Fans 3 and 4 are being shared by two different

refrigeration circuits. If either refrigeration circuit needs the

fan to be on, it will be on. Clamp all lines to brackets sup

plied on the unit.

REFRIGERANT LINE SIZING - Sizing depends on length

of lines between various sections of the refrigerant system.

See Fig. 9 for coil connection details. Consider the amount

of liquid lift and drop in the system as well as proper com

pressor oil return. See Liquid Lift section for more infor

mation. Consult Carrier System Design Manual, Part 3, or

Carrier E20-II Refrigerant Piping Computer Program for proper

piping sizes and design

LIQUID SHUTOFF VALVE AND SIGHT GLASS - A

shutoff valve is not supplied with 09DK condensers. It is

strongly recommended that a full line size liquid shutoff

valve be field supplied near condenser to allow for servic

ing parts of the refrigerant circuit A field-supplied mois

ture indicating sight glass is recommended for use in charg

ing and servicing the system. Refer to Fig. 7.

PRESSURE RELIEF - The ASHRAE Standard 15, Safety

Code for Mechanical Refrigeration states; “Every refriger

ating system shall be protected by a pressure relief device

or some other means designed to safely relieve pressure due

to fire or other abnormal conditions ” Since 09DK con

densers do not have pressure relief devices, one must be

field supplied and installed just before the liquid line ser

vice valve. (See Fig. 7.) When the split coil is used with

multiple systems, each system must have its own pressure

relief.

Procedure for Using the Refrigerant Receiver — See

Fig. 24.

1. During normal operation — Valve A is open and valves

B and C are closed. Receiver is isolated from the

system.

2. For servicing — Valves A and C are closed and valve B

is open. Run unit until all the refrigerant is in the re

ceiver and then close valve B. Unit is now ready for ser

vicing.

3. To resume operation — Leave valve A closed and open

valves B and C. Run unit until the stored refrigerant is

drawn into the system. To completely remove the re

frigerant from the receiver, throttle valve B while noting

condition of refrigerant in the liquid line sight glass; also,

watch the suction pressure. A sudden surge of bubbles

in the sight glass and a rapid decrease in suction pres

sure indicates that all the refrigerant has been withdrawn

from the receiver. Immediately close valves B and C

and then open valve A. The unit should now be ready

for normal operation, with the receiver isolated from the

system. The system should be charged to a clear sight

glass when under normal operation.

LIQUID LIFT — Amount of liquid lift available before re

frigerant flashing occurs depends on amount of liquid sub

cooling in the system.

All 09DK condensers have positive subcooling when ap

plied with optimum charge. With subcooling, it is possible

to overcome an appreciable friction drop and/or static head

(due to elevation of the liquid metering device above the

condenser).

When 09DK condensers are applied with minimum charge,

no positive subcooling in condenser is realized; therefore,

if subcooling is required it must be obtained by external

means such as a liquid suction interchanger.

The average amount of liquid lift available is shown in

Table 3 for refrigerants R-22, R-502, and R-134A. Avail

able subcooling is greatly reduced when R-12 and R-500

are used in these units. It is recommended that the evapo

rator be at the same level as the condenser, or lower.

1/4 SAE FLARE WITH

56 (14 2) HEX

REFRIGERANT RECEIVER — A refrigerant receiver is

not furnished with 09DK condensers and is not recom

mended for normal applications as its use will be detrimen

tal to the desired effects of subcooling. However, if a par

ticular application requires a receiver to increase refrigerant

holding capacity of the condenser, a receiver can be used.

When a receiver is to be used year-round, it should be in

stalled indoors. Carrier recommends the following installa

tion in such a case (see Fig 24): locate valves on each side

of the receiver so receiver may be isolated from system for

normal operation.

SAE — Society of Automotive Engineers

Fig. 13 — Fan Cycle Pressure Switch

18

CONDUIT

CONNECTOR

Page 19

09DK05^.054 POWER SCHEMATIC

09Dk:054.064 standard control schematic

nOO% 8 50X/50X CAPACITY SPLITS)

ir FW CONTROI. (IT IS USED. SEE FW CONTRa CIt (tCCESSOAri SOOUTIC

09DIC054.064 FAN CONTROL KIT CACCESSOftYJ SCHEMATIC

C67X/33X.33X/33X/33X g 33X/33X/17X/17% CAPACITY SPLITS)

l2Xi CDNIML VCL1ACE Oi«.r>

o

2

09PK054.064 COMPONENT ARRANGEMENT

& cSl

& cui

(D>®®

oO o

M2 №1

®®<32)

o

0 0

0U2 Ml

o>

o

NOTES.

1

Units are factory wired for a 50%/50% capacity split. If 100% capacity is required, con

nect the factory-supplied jumpers from TB2-1 to TB3-1 and from TB2-2 to TB3-2.

2. When a fan control kit is used, the jumper from TB2-1 to TB3-1 and from TB2-2 to TB3-2

must be connected. The fan control kit is factory wired for 67%/33% capacity split. If a

33%/33%/33% capacity split is required, remove the jumper from TB4-1 to TB5-1 and

from TB4-2 to TB5-2. If a 33%/33%h 7%/17% capacity split is required, remove the jump

ers from TB4-1 to TB5-1 to TB7-1 and from TB4-2 to TB5-2 to TB7-2.

3. On fan control kits, 208/230 v units are factory wired for 230 v power supply. For 208 v

power supply, connect yellow wire to terminal marked H2.

4. Terminal blocks TB2, TB3, TB4, TBS, TB6 and TB7 are for external field control connec

tions. Control connections are to be class 1 wiring, 14 AWG copper conductors only.

5. Wiring for field power supply must be rated 75° C minimum. Use copper, copper-clad

aluminum, or aluminum conductors. Maximum incoming wire size for each terminal block

IS 2/0.

6. Replacement of factory wires must be with 105° C wire or its equivalent.

7. Factory wiring is in accordance with National Electrical Code (NEC). Field modifications

or additions must be in compliance with all applicable codes.

8. Fan motors are thermally protected. Three-phase motors are protected against primary

single phasing conditions.

9. Line numbers on the left side of the label diagrams indicate the contact number. The

numbers on the right side of label diagrams match the contacts with their corresponding

coils. A plain number indicates normally open contacts. An underlined number indicates

normally closed contacts.

Fig. 14 — Wiring Diagram and Component Arrangement; 054 and 064 Units

dXJKD

<D®<D

O

o

o0

□= C

CONTRCC RELIT

outrr TERnlNii.

’ EOUIRHENT

FAN COKTACIOA

FAN CTCLINC FRESSURE S

FACJ9ST INSIALLEB »Hi

NOIOfi NASTER SENSOR

PRINAftr

SCCCMOAAT

TERNiNAL eiOCi:

TRV6FCFUCR

r~l TERNINAL 8L0CC CC»»«C1ICN

O "*»F£D TERNINAl

O LMURCED TERnlNAL

Page 20

50 / 50%

FCPS — Fan Cycle Pressure Switch

Fig. 15 — 50/50% Coil Circuiting; 054 and 064 Units

NOTES:

1. Dimensions in ( ) are in millimeters

2 See Fig. 5 for tubing package contents.

FCPS — Fan Cycle Pressure Switch

Fig. 16 — 66/34% Coil Circuiting; 054 and 064 Units

NOTES:

1. Dimensions in ( ) are in millimeters

2. See Fig 5 for tubing package contents

20

Page 21

Table 3 — Available Liquid Lift Ft (m)

REFRIGERANT R-22

UNIT

054

09DK

NOTES:

1 The liquid lift data allows for a 7 psi (48 kpa) drop for liquid line

accessories, and a 2° F (1.rC), iiquid line ioss with maximum

change.

2. Temperature difference = Saturated condensing temperature (en

tering) — Entering-air temperature (dry buib) in degree F (° C)

3. The liquid iift data is based on 15° F (8 3° C) subcooiing, 95 F

(35 C) entering-air temperature, and a 50/50% capacity split appiication Subcooling based on condenser subcooling = Satu

rated condensing temperature entering - Actual temperature leaving

the coii

064

074

084

Temperature Difference F (C)

20

30

(16.7)

(11.1)

50

60

(15 2)60(18.3)

(18.3)

41

(12 5)31(9.5)

44

(13.4)34(10.4)

51

(15.6)41(12.5)51(15.6)

R-502 R-134A

20

30

(16.7)20(11.1)

(11.1)

44

(13.4)

41

(12.5)

44

(13.4)28(8.5)18(5.5)7(2.1)

(10.7)22(6.7)

25

(7 6)

35

(8.8)26(7.9)

(6.1)6(1.8)

29

20

30

(16.7)

10

(3 1)

Example: Supply voltage is 240-3-60.

AB = 243 V

BC = 236 V

AC = 238 V

Average Voltage

243 -F 236 -f 238

^ 717

3

= 239 V

Determine maximum deviation from average voltage:

(AB) 243 - 239 = 4 V

(BC) 239 - 236 = 3 V

(AC) 239 - 238 = 1 V

Maximum deviation is then 4 v. To determine the percent

voltage imbalance:

% Voltage Imbalance = 100 x----------

4

239

= 1.7%

This amount of phase imbalance is satisfactory since it is

below the maximum allowable of 2%.

Step 4 — Complete Electrical Connections

GENERAL — Verify nameplate electrical requirements match

available power supply. Voltage at condenser must be within

the minimum and maximum shown in Table 4 and phases

must be balanced within 2%. Contact local power company

for line voltage corrections. Never operate a motor where a

phase imbalance in supply voltage is greater than 2%.

Use the following formula to determine the percent voltage

imbalance:

max voltage deviation

% Voltage _ from average voltage

Imbalance ^ average voltage

IMPORTANT: If supply voltage phase imbalance is

more than 2%, contact your local electric utility com

pany immediately.

Condenser operation on improper line voltage or exces

sive phase imbalance may be considered abuse and any re

sulting damage may not be covered by Carrier warranty.

All wiring must be in accordance with local or NEC

(National Electrical Code) regulations.

FIELD CONNECTIONS - Refer to Table 4 and Fig. 14,

18, and 25 for field wiring details.

100%

Fig. 17 - 100% Coil Circuiting; 074 Units

21

Page 22

09DK074.0B4 POWER SCHEMATIC

090K074.084 FAN CONTROL KIT CACCESSORY^ SCHEMATIC

C67X/33-4.33X/33X/33X g 33X/33X/1 7X/1 7% CAPACITY SPLITS)

09DK074.0B4 COMPONENT ARRANGEMENT

Ni

to

FIELD COKlAa.

COMCTIWS CN.T

09DK074.084 STANDARD CONTROL SCHEMATIC

(^00% 8 50X/50X CAPACITY SPLIT53

[|F PM nwrttx Ell IS USED. SEE PM CMTUX Ell (UCESSOftr) SCICIUtK)

FUSTE»

- BBN TO FNI cowccT Piuo Fca aeovtsoHz)

- «CES50BT

«-.JL

(H5V CWiaOL YOtTIGE 0*T

—©

----------------------------------------------------

230V CONTROL ONLY

-----------»-------

-HI —O FC3

NOTES:

1. Units are factory wired for a 50%/50% capacity split. If 100% capacity is required, con

nect the factory-supplied jumpers from TB2-1 to TB3-1 and from TB2-2 to TB3-2.

2. When a fan control kit is used, the jumper from TB2-1 to TB3-1 and from TB2-2 to TB3-2

must be connected. The fan control kit is factory wired for 67%/33% capacity split, if a

33%/33%/33% capacity split is required, remove the jumper from TB4-1 to TB5-1 and

from TB4-2 to TB5-2. If a 33%/33%/17%/17% capacity split Is required, remove the jump

ers from TB4-1 to TB5-1 to TB7-1 and from TB4-2 to TB5-2 to TB7-2.

3. On fan control kits, 208/230 v units are factory wired for 230 v power supply. For 208 v

power supply, connect yellow wire to terminal marked H2.

^S0D

---

4. Terminal blocks TB2, TB3, TB4, TBS, TB6 and TB7 are for external field control connec

tions. Control connections are to be class 1 winng, 14 AWG copper conductors only.

5. Wiring for field power supply must be rated 75° C minimum. Use copper, copper-clad

aluminum, or alurTwnum conductors. Maximum incoming wire size for each terminal block

IS 2/0.

6. Replacement of factory wires must be with 105° C wire or its equivalent.

7. Factory wiring is in accordance with National Electncal Code (NEC). Field modifications

or additions must be in compliance with all applicable codes.

8. Fan motors are thermally protected. Three phase motors are protected against primary

single phasing conditions.

9. Line numbers on the left side of the label diagrams indicate the contact number. The

numbers on the nght side of label diagrams match the contacts with their corresponding

coils. A plain number indicates normally open contacts. An underlined number indicates

normally closed contacts.

Fig. 18 — Wiring Diagram and Component Arrangement; 074 and 084 Units

FN, 3S §

1

HNinOL BOX

(D<D(Z>

0X2)0

(KCESSoen

Jn C

©o®

o o

FIELD CCmaOL PI

0 o o

o

o o

CONTROL EIT 0W.T)

|o

>m TE>MBlTL(lf SKITCK

COKTOOL RELIT

DLPTIT TERXINIL

' EauiPHENT

FIN CCMTICTOR

FICTWT II6IILLED S>1l<

lEmiNiL euXE

®®®

®®®

o

o

r~l TEftBlNAl ÍL0CE CC*»«CTIi»l

C

O

Page 23

50 / 50%

FCPS — Fan Cycle Pressure Switch

Fig. 19 — 50/50% Coil Circuiting; 074 Units

32 / 68%

Page 24

100%

50 / 50%

FCPS — Fan Cycle Pressure Switch

Fig. 22 — 50/50% Coil Circuiting; 084 Units

24

Page 25

33 / 67%

1 Dimensions in ( ) are in millimeters.

2 See Fig. 6 for tubing package contents.

A — Bypass valve

B — Receiver inlet valve

C — Receiver outlet valve

Fig. 24 — Piping for Optional Receiver

Fig. 23 — 67/33% Coil Circuiting; 084 Units

25

Page 26

09DK

054

-500 208/230-3-60

-600 460-3-60

-100 575-3-60

-200

-900

064

-500

-600

-100 575-3-60 518

-200 380-3-60

-900 380/415-3-50

074

-500 208/230-3-60 187

-600

-100

-200

-900

NAMEPLATE

V-PH-HZ

380-3-60 342

380/415-3-50

208/230-3-60

460-3-60

460-3-60 414

575-3-60 518

380-3-60

380/415-3-50 342

084

-500 208/230-3-60

-600 460-3-60

-100 575-3-60 518

-200

-900

380-3-60

380/415-3-50

Control Circuit Information

09DK

CONTROL POWER

ALL

UNITS

-500

-600

-100 115-1-60

-200

-900

V-PH-HZ

115-1-60 103

115-1-60 103 127

230-1-60

230-1-50 207 253

Table 4 — 09DK Electrical Data

SUPPLY VOLTAGE*

Min

187

414

518

342

187

414

342

342 440

342

187

414

342

342

SUPPLY

VOLTAGE*

103 127

207

OVERCURRENT

PROTECTION

127

253

Max

254

508

632 14.5

418

440

254

508

632

418

254 34 0

508

632 21.3

418

440

254 34.0

508

632

418

440

MCA MOCP NO. FANS

23.2 25 4

11.7

166

128

23.2 25

11 7 15 4

14.5 15

166 20

128 15

17.1 20 6 93 (1,2) 2.8 (3-6) 2.7

24.4 25 6 93 (1-6)3 9

18.8 20 6 9.3 (1-6)3 0

17.1 20

21 3

24 4

188 20

AMPS

10

10

10

10

10

FAN MOTORS

Total Kw

6.2 (1,2) 5.5 (3,4) 5.4

15 4

15 4

20 4

15 4

4 6.2 (1,2) 5 5 (3,4) 5 4

4 62

4 6.2 (1-4) 3.9

4 6.2 (1-4) 3.0

35 6 93 (1,2) 5.5 (3-6) 5.4

25 6 93

35 6 9.3 (1,2) 5.5 (3-6) 5 4

25 6 9.3 (1-6) 3.4

25

LEGEND

FLA

— Full Load Amps

MCA

— Minimum Circuit Amps; Used for wire sizing

6 93 (1,2)2 8(3-6) 2.7

6

6 93 (1-6) 3.0

(Complies with NEC Sectien 430-24)

6.2

6.2

62

62

62

9.3 (1-6) 3.9

(Fan no.)

FLA for ea. fan

(1,2) 2.8 (3,4) 2.7

(1-4) 3.4

(1-4) 3.9

(1-4) 3.0

(1,2) 2.8 (3,4)2 7

(1-4) 3.4

(1-6)3 4

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

'Units are suitable for use on electrical systems where voltage sup

plied to the unit terminals is within listed minimum and maximum

limits.

NOTES:

1. Maximum allowable phase imbalance: Voltage ± 2%; Amps ± 10%

2. Maximum incoming wire size for power circuit is 2/0 max

3. Control Circuit: Uses no. 8 screws for wire connections at the ter

minal block.

4. 100 va is required for the 09DK054-084 control circuit

26

Page 27

NOTES:

1. Factory wiring is in accordance with National Electrical Code (NEC),

field modifications or additions must be in compliance with all ap

plicable codes.

2. Wiring for field power supply must be rated 75 C minimum. Use

copper, copper-clad aluminum, or aluminum conductors. Maxi

mum incoming wire size for each terminal block is 2/0.

3. Terminal blocks TB2, TBS, TB4, TBS, TB6, and TB7 are for

external field control connections. Control connections are to be

class 1 wiring.

4. Replacement of factory wires must be with type 105 C wire or its

equivalent.

5. Units are factory wired for a 50%/50% capacity split. If 100% ca

pacity is required, connect the factory-supplied jumpers from TB2-1

to TB3-1 and from TB2-2 to TB3-2.

6. If a fan control kit is to be used, the jumper from TB2-1 to TB3-1

and the jumper from TB2-2 to TB3-2 must be connected. The

fan control kit is factory wired for a 67%/33% capacity split. If a

33%/33%/33% capacity split is required, remove the jumper from

TB4-1 to TB5-1 and from TB4-2 to TB5-2. If a 33%/33%/17%/17%

capacity split is required, remove the jumpers from TB4-1 to TB5-1

to TB7-1 and from TB4-2 to TB5-2 to TB7-2.

K)

CONTROL BOX

STANDARD UNITS

Fig. 25 — Field Wiring; 054-084 Units

UNITS WITH FAN CONTROL LIT tACCESSORV)

CONTROL BOX

Page 28

MAIN POWER WIRING — These units must have ade

quate overcurrent protection, fuses, or HACR (Heating, Air

Conditioning and Refrigeration) breakers, according to the

national and applicable local codes.

For field power connections, all main power wiring en

ters the unit through a factory-punched access hole under

the control box. Two access holes are provided, the larger

should be used for 208/230 v applications. See Fig. 26.

Wiring must be rated at 75 C minimum. Use copper, copperclad aluminum, or aluminum conductors. Field power sup

ply connections are made at terminal block 1 (TBl). Max

imum incoming wire size for each terminal connection on

TBl is 2/0, and all power wiring must comply with appli

cable local and national codes. Refer to the unit power cir

cuit information to determine incoming wire sizes. (See

Table 4.) Refer to Table 5 for American and European wire

conversion information.

CONTROL CIRCUIT POWER WIRING - Provide a sep

arate single phase power source for each control circuit (de

pending on the coil refrigerant circuit split), with the re

quired overcurrent protection (fuses or circuit breakers). See

Table 4 for control circuit overcurrent protection amps.

For field control circuit connections, units are factory wired

for a 50/50% capacity split and would utilize terminal blocks

2 and 3 (TB2 and TB3). TB2 will control fans 1, 3, and 5;

TB3 will control fans 2, 4, and 6. Fans 5 and 6 are on 074

and 084 units only. If 100% condenser application is re

quired, connect the factory supplied jumpers from TB2-1 to

TB3-1 and from TB2-2 to TB3-2, and bring incoming con

nections to either TB2 or TB3. Factory-punched access holes

under the control box are provided for the incoming wires.

See Fig. 26 for access hole details. Terminal block connec

tions utilize no. 8 screws. Wiring must be class 1, 14 AWG

(American Wire Gage) copper conductors only. Power re

quired for control circuits is 100 va. See Table 4 for control

circuit voltage data.

GENERAL WIRING NOTES

1. Power entry is at one end only.

2. Fan motors are thermally protected. Three-phase motors

are protected against primary single-phasing conditions.

3. Replacement of factory wires must be with appliance

wiring material, rated 105 C, or its equivalent.

4 Factory wiring is in accordance with NEC. Field mod

ifications or additions must be in compliance with all

applicable codes.

DESCRIPTION OF CONTROLS - The condenser units

utilize a dual voltage control scheme: a 3-phase power cir

cuit for the fan system operation and a single-phase control

circuit voltage for fan cycling control. The number of con

trol circuit voltages will depend on the coil split application

used. See head pressure control description in the service

section for a detailed description of the controls function.

Table 5 — American/European Wire Conversions

AMERICAN EUROPEAN

Industry

Standard Size

18 AWG 0.82

16 AWG 1 30 1.5

14 AWG 2.08 2.5

12 AWG 3 30 40

10 AWG 5 25

8 AWG 6.36 100

6 AWG 13.29 16.0

4 AWG 21.14 25.0

3 AWG 26.65

2 AWG 33.61 35 0

1 AWG 42.39 50.0

1/0 AWG 53.49

2/0 AWG 67.42 70.0

3/0 AWG 85.00 95.0

4/0 AWG 107.19 120.0

250 kcmil 126 64

300 kcmil 151 97

350 kcmil 177 90

400 kcmil 202 63

500 kcmil 253 29

600 kcmil 303 95 —

LEGEND

AWG — American Wire Gage

kcmil — Thousand Circular Mils

American

Conversion

(mm^)

Industry

Standard

Size (mm^)

1.0

60

—

—

150.0

—

185 0

240 0

300 0

Step 5 — Add Accessories As Needed — The

following accessories are available for the 09DK054-084

condensers: fan sound reduction kit, condenser coastal coil

filter, security grille package, condenser coil hail guard pack

age, accessory control transformer, Motormaster® III de

vice, Motormaster III Relay/Sensor Kit, and accessory fancontrol kit. Winter Start and any special electrical interlock

must be considered separately. Refer to installation instruc

tions furnished with each accessory for more information.

2 13/32"

Fig. 26 — Power Wiring Access Holes; 054-084 Units

28

Page 29

START-UP

System Evacuation and Dehydration — Refer

to GTAC II, Module 4, “Dehydration for Proper Evacua

tion and Dehydration techniques.”

Charging Procedure — Charge to a clear sight glass.

Refer to GTAC II, Module 5 “Charging, Recovery, Recy

cling, and Reclamation” for proper charging techniques.

Add 10 lbs (4.5 kg) of R-22 over clear sight glass to flood

subcooler sections of the condenser coils. This 10 lbs

(4.5 kg) is added to the total unit charge, and must be pro

portioned by the percentage of circuits when multiple cir