Page 1

q

y

g

g

g

Air-Cooled Condenser Units

Motormaster® Low Ambient Controls

Wiring Diagrams

50/60 Hz

WIRING DIAGRAM INDEX

Fig. No.

Standard Unit Control Schematic 09DK . . . . . . . . . . . . . . . . . 3

®

Motormaster

Motormaster, 09DK 460 v, 575 v (60 Hz) . . . . . . . . . . . . . . . . 5

Fan Cycling Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

, 09DK 208/230 (60 Hz) . . . . . . . . . . . . . . . . . . 4

LEGEND

(For All Figures)

09DK020-044

ATS —

EQUIP —

FC —

FM —

GND —

TB —

Air Temperature Switch Terminal Block Connection

uipment Marked Terminal

E

Fan Contactor Unmarked Terminal

Fan Motor Factor

Ground Field Control Wirin

Terminal Block Connection Field Power Wirin

NOTES (Figs. 3-5)

1. For field power connections, splice field wires to (3)

leads from contactor number 1 (FC1).

.

2.

Control Circuit

Wiring

220 v 380 v, 60 Hz

230 v

115 v

Use 14 AWG copper conductors only for

control circuit wiring.

Power Supply

Wiring

230 v, 50 Hz

400 v, 50 Hz

208/230 v, 60 Hz

460 v, 60 Hz

575 v, 60 Hz

Wirin

3. Fan motors are terminally protected. Thre e-phase motors

are protected against primary single-phasing conditions.

4. Replacement of original wire s must be with type 90 C

wire or its equivalent.

5. Factory wiring is in accordanc e with National Electrical

(NEC). Field modifications or additions must be in compliance with all applicable codes.

6. Wiring for field power supply must be rated 60 C. Use

copper, copper-clad aluminum or aluminum conductors.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 4 a

PC 111 Catalog No. 530-913 Printed in U.S.A. Form 09DK-4W Pg 1 4-00 Replaces: 09DK-1W

Page 2

SAFETY CONSIDERATIONS

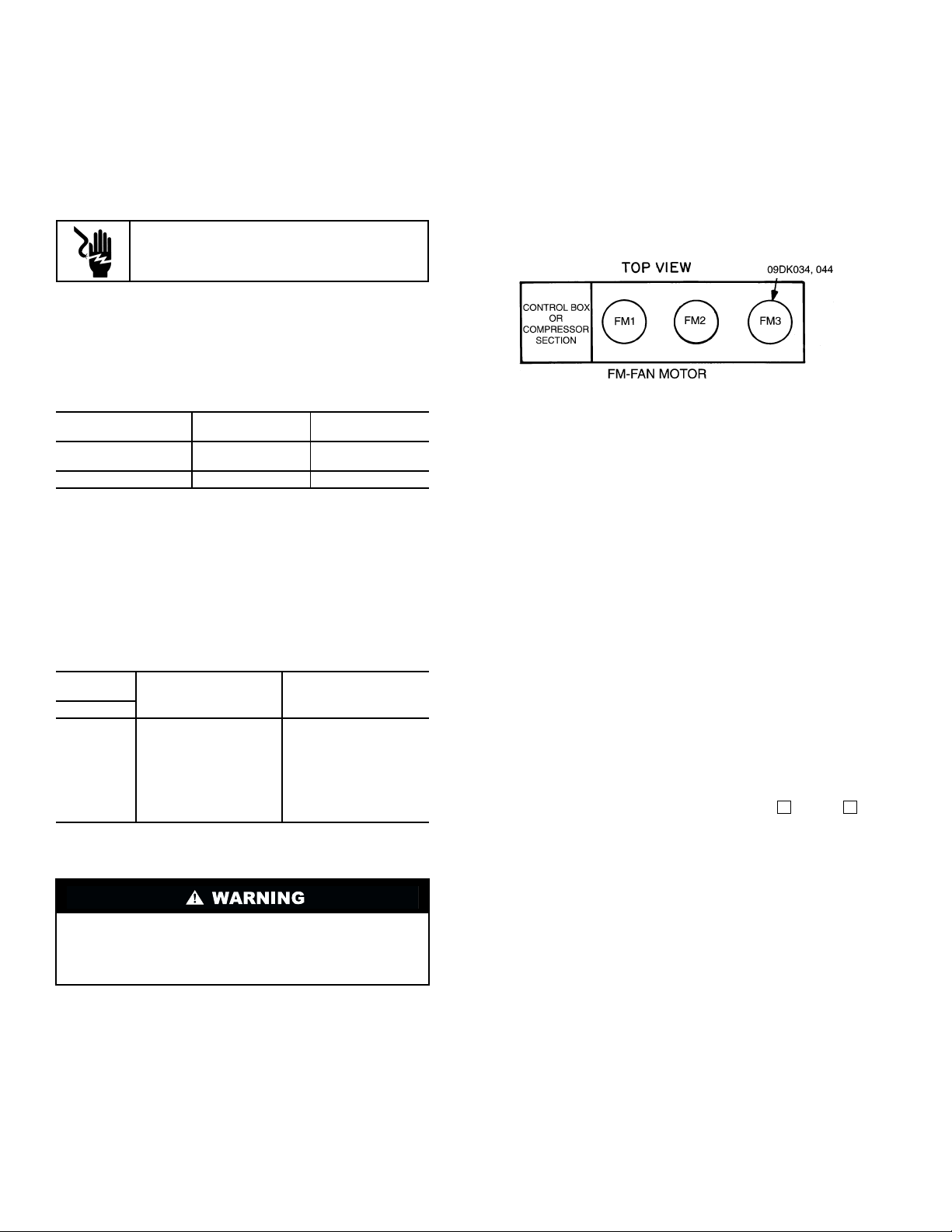

Fig. 1 — Fan Motor Locations

Installing, starting up, and servicing air conditioning equipment can be hazardous due to system pressures, electrical components, and equipment location.

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment. When

working on the equipment, observe precautions in the literature

and on tags, stickers, and labels attached to the equipment. Follow all safety codes. Wear safety glasses and work gloves.

ELECTRIC SHOCK HAZARD

Open all remote disconnects before servicing

this equipment.

MOTORMASTER® LOW AMBIENT CONTROL

NOTE: Installation of Motormaster Low Ambient Control

requires use of fan cycling control accessory, see page 7.

Introduction

There are two accessory packages as follows:

2. Remove FM1 (fan motor no. 1) fan guard (see Fig. 1)

located next to control box end.

3. Disconnect FM1 wiring in the motor junction box and remove FM1 from unit.

4. Remove fan propeller from FM1 and save. Fan propeller

is reinstalled on the speed control motor in a later step.

5. Place motor mount spacer in place over FM1 motor

mount.

6. Install speed control motor with rainshield (included in

package) in place of FM1.

PACKAGE NO.

50DJ-902---801

50DJ-902---811

*For Motormaster head pressure control operation, 575-v unit

requires installation of transformer (Carrier Part No. HT01AH854)

not included in package.

UNIT

Volt s-Ph-H z

208/230-3-60

575-3-60*

460-3-60 200/230-1-60

MOTOR

Volt s-Ph-H z

200/230-1-60

Each accessory package contains the parts listed in Table 1.

Note that these installation instructions are for 60 Hz units,

but installation procedures for 50 Hz units are similar. See

price pages for required parts for 50 Hz Motormaster applications. Contact Application Engineering if installation assistance is required.

Table 1 — Package Contents

PACKAGE

NOS. 50DJ-902---801 50DJ-902---811

Quantity

1

1

1

1

1

1

1

1

Speed Control Motor Speed Control Motor

Motor Mount Spacer Motor Mount Spacer

Capacitor Capacitor

Capacitor Boot Capacitor Boot

Motormaster Controller Motormaster Controller

Fastener Package Fastener Package

Instruction Booklet Instruction Booklet

—Transformer

Installation

1. Disconnect all power to the unit and open control box.

To avoid possible electrical shock and personal injury, all

power to unit must be disconnected before working on

unit. T ag all disconnects to alert others unit is being worked

on.

7. Because the standard fan motor is 3-phase, and the speed

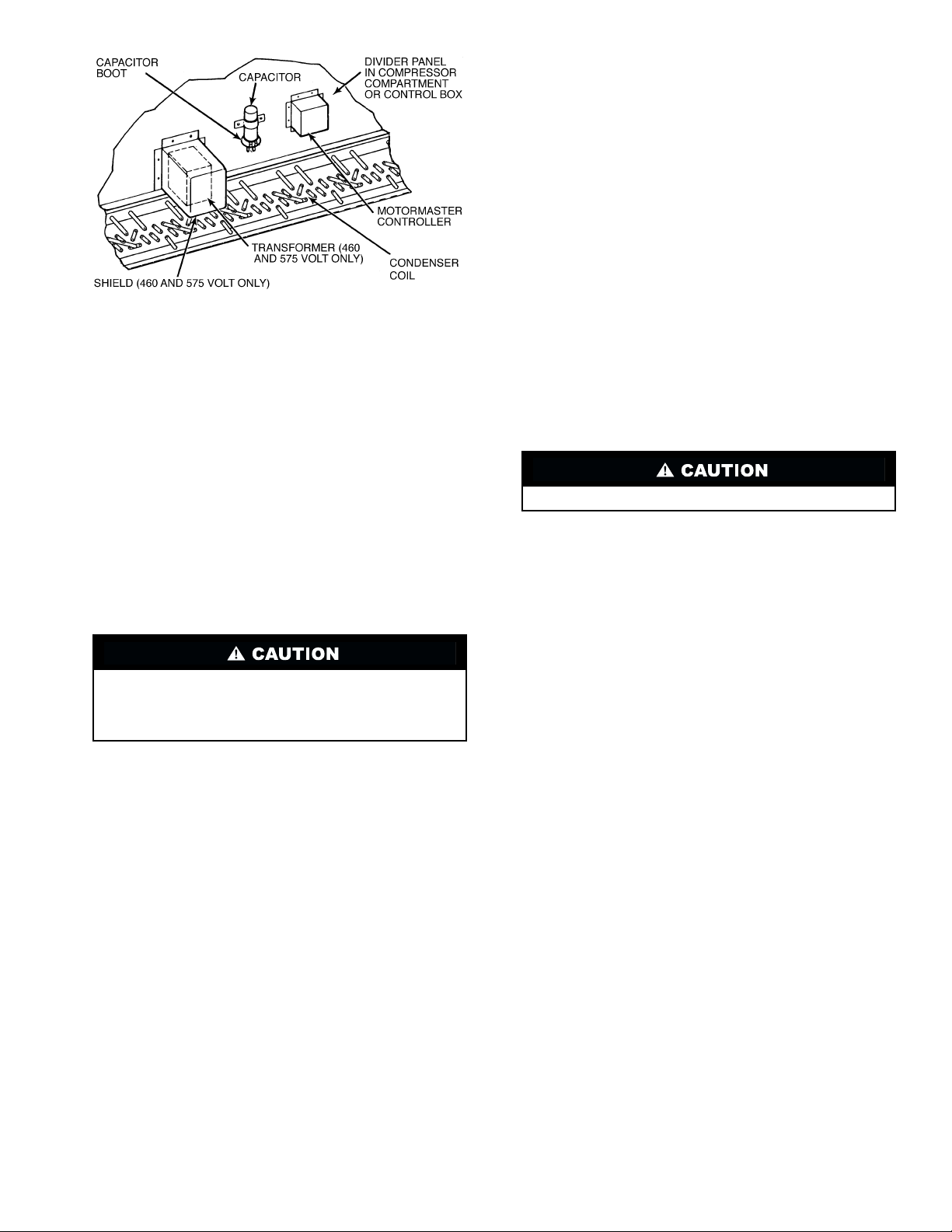

control motor is single-phase, it is necessary to add a capacitor. Install the capacitor on the divider panel above

the condenser coil.

8. Mount the capacitor upside down (terminals pointing

down) using capacitor strap and screws (holes must be

field drilled). See Fig. 2. To prevent capacitor from slipping down, insert an additional screw through the panel

for the capacitor to rest on.

9. Disconnect black wire connecting FM1 junction box to

TB1 terminal 2 (575-v only). See Fig. 3. Disconnect yellow wire from FC1 terminal 12. Disconnect blue wire

from FC1 terminal 13.

10. Connect yellow wire from capacitor to the red wire (T8)

in the speed control motor junction box. Use wire nut to

connect. See Fig. 4. Connect blue wire from other side of

capacitor to the yellow wire (T4) in the speed control motor junction box. Use wire nut to connect.

11. From the same terminal on the capacitor as blue wire connection, run a field-supplied wire to FC1 terminal 12. Tie

the blue (T1) and black (T5) wires in the motor junction

box together, using a wire nut.

12. Remove the black jumper connecting TB1 to TB1

1 2

in the control box.

13. Mount the Motormaster

®

controller vertically on the divider panel next to the capacitor. See Fig. 2. It must be

mounted vertically with the leads coming out the bottom.

Using the template at the back of these instructions, drill

the required 4 mounting holes. Use 4 no. 10 sheet metal

screws and star washers provided to attach the controller.

The star washers must be used to ensure electrical

ground.

2

Page 3

OTES:

1. Transformer shield and 575-v transformer are field supplied

(transformer part no. HT01AH854).

2. Exact mounting locations on divider panel for capacitor, Motormaster controller, and transformer are at discretion of installer.

There are no wires or obstructions on reverse side of divider

panel to interfere with mounting screws.

Fig. 2 — Mounting Motormaster® Controller,

Capacitor, and 575-V or 460-V Transformer

16. For 460-v and 575-v units only, mount and wire

transformer (460-v — P/N HT01AH852, 575-v —

P/N HT01AH854) as follows:

a. Mount tran sformer to the di vider panel . See Fi g. 2.

Drill required mounting holes.

b. Connect field-supplied wire from FC1 terminal 21

to the primary side of the transformer. See Fig. 5.

Connect a field-supplied wire from FC1

terminal 22 to the other primary of the transformer.

c. Run field-supplied wire from the secondary of the

transformer to the capacitor. Run field-supplied

wire from the other secondary of the transformer

to one of the black wires on the controller. See

Fig. 5.

d. Install field-supplied shield o ver the transformer.

See Fig. 2.

17. Reinstall the fan propeller and fan guard. Ensure that center of propeller is correct distance from top of fan orifice.

See Fig. 5.

18. Route the sensor wire from the controller to the sensor

location. Secure sensor wire to avoid contact with condenser coil.

14. For 208/230-v only:

Connect a field-supplied wire from TB1 terminal 1 to one

of the black wires in the Motormaster controller. Use wire

nut to connect. See Fig. 4.

15. Take the black wire that was disconnected in Step 3 and

connect it to the purple wire (P1) in the speed control motor junction box. Use wire nut to connect. Replace junction box cover.

Be sure the wires running to the speed control motor are

wire-tied securely to the motor mount, to prevent the wires

from becoming entangled in the propeller fan whe n unit is

running.

The sensor assembly is fragile. Handle with care.

19. For 09DK020-034 units, secure the sensor to the coil return bend. For 09DK044, secure the sensor to crossover

tube. See Fig. 7 for proper location for each unit. Use

no. 4-40 screw, two plate washers, and nut provided. See

Fig. 8.

20. Coil up excess wire and secure it to controller.

21. Protect sensor wire from physical damage by installing

field-supplied protective material.

22. Replace control box cover.

Winter Start Control —

These compressorless condenser sections do not need to be directly modified. However,

the total system may require winter start control. Refer to base

unit instructions.

3

Page 4

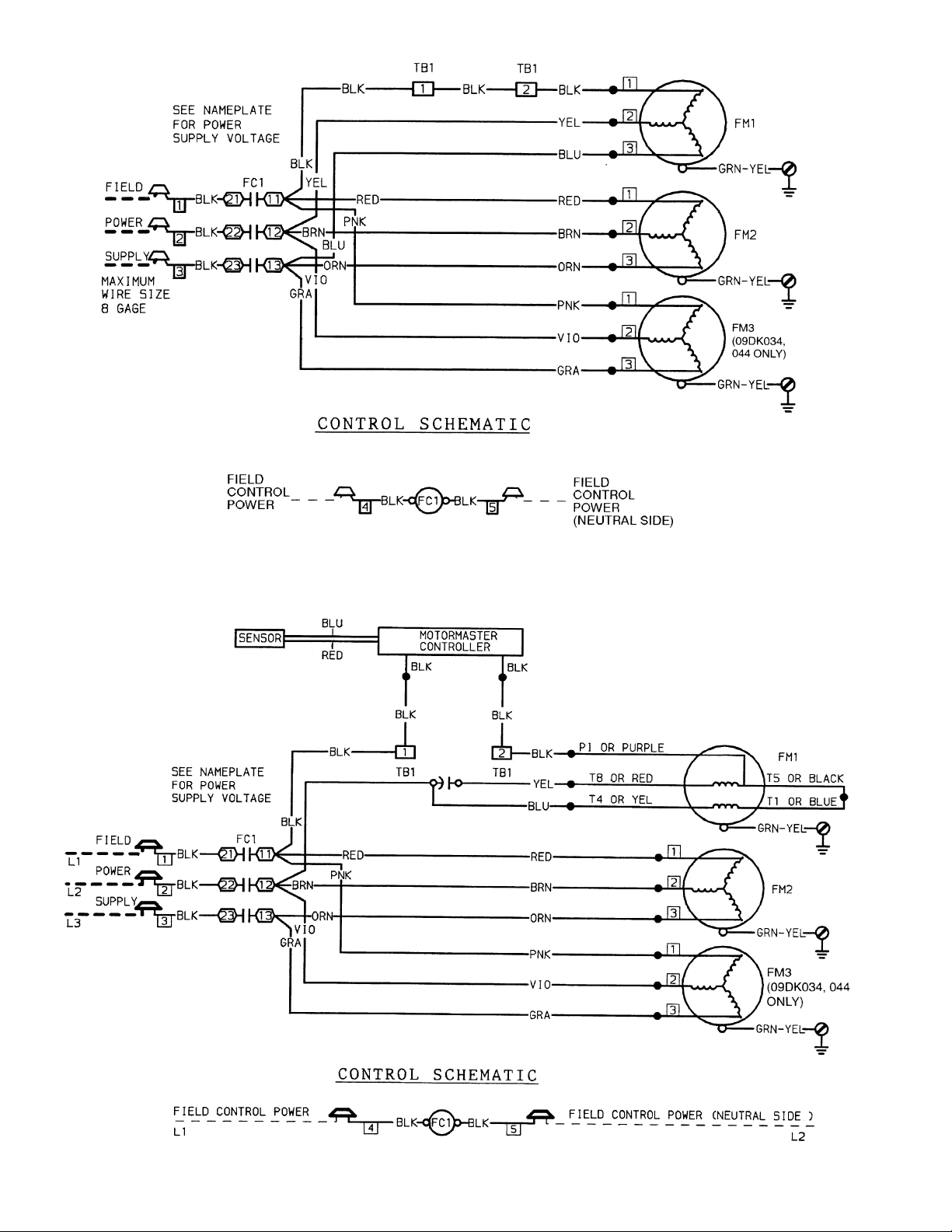

Fig. 3 — Standard Unit Power and Control Schematic, 09DK

Fig. 4 — Motormaster

®

Controller Wiring; 09DK 208/230-Volt Units

4

Page 5

Fig. 5 — Motormaster® Controller Wiring; 09DK 460-Volt and 575-Volt Units

Fig. 6 — Location of Propeller on Motor Shaft from

Outside of Orifice Ring

5

Page 6

NOTE: When using multiple indoor units, or a dual compressor

indoor unit, place sensor on circuit containing refrigerant from

leading compressor. Only one sensor is required.

Fig. 7 — Motormaster® Sensor Locations on Condenser Coil Header End, 09DK Units

Fig. 8 — Sensor Installation

6

Page 7

ACCESSORY FAN CYCLING CONTROL

Fig. 9 — Model 09DK (028 Shown)

Accessory Fan Cycling Control Usage

PACKAGE

NUMBER 09DK

500070

500071

500072

500073

QTY PER KIT NO.

070 071 072 073

1122Temperature Actuated Switch

1111Terminal Block

0011Terminal Adapter

1122Contactor

1111Instructor

1111Parts Bag

PARTS BAG CONTENTS:

5555Mounting Screws

2244Screws, 8-18 x

2244Screws, 6AB x

5588Wire Assemblies

3333Wire Ties

CONTROL CKT VOLTAGE

3 Ph, 60 Hz 3 Ph, 50 Hz

208230,

460,575

380 230,400

208230,

460,575

380 230,400 034,044

—

020 (60 Hz only),

— 034,044

Accessory Kit Contents — 09DK

USED ON

09DK

020,024,

028

024,028

ITEM

1

/2-in. long

1

/2-in. long

General —

The Accessory Fan Cycling Control maintains

unit cooling capacity control during changes in outside ambient

temperature. If full cooling is not required during certain operating periods, the accessory can save energy by supplying power to fewer fans.

Before Installation —

Check kit contents for missing or

damaged items. File claim immediately with transit company if

anything is missing or damaged. Check to be sure ac cessory

control voltage matches available power supply.

Fan Cycling Control Installation

1. Shut off power to unit.

Electrical shock can cause personal injury or death. Before

installing this accessory, be sure power to unit is disconnected. There may be more than one disconnect switch.

Attach tags at disconnect(s) to alert others not to restore

power until installation is completed.

2. Remove unit control box cover. See Fig. 9.

3. 09DK020-028 Units: Mount temperature actuated switch

(ATS) onto the bottom inner divider panel of unit, using

two no. 6AB x

are predrilled in panel. See Fig. 9.

09DK034,044 Units: Mount temperature actuated switches (A TS and ATS2) onto the bottom inner divider panel of

unit, using two no. 6AB x

(2 screws for each switch). Mount switches side by si de

in predrilled holes. See Fig. 9.

1

/2-in. long screws provided. Screw holes

1

/2-in. long screws provided.

4. 09DK020-028 Units: Install fan contactor FC2 and terminal block TB2 inside control box. See Fig 10. Disconnect

red wire from FC1 and orange wire from FC1 .

Connect red wire to FC2 . Connect orange wire to

23

FC2 . Attach 8-in. black wire provided in accessory

package to FC1 and FC2 . Connect the 8-in. blue

wire to FC1 and FC2 . Next, connect the 8-in.

white wire to FC1 neutral side, and FC2 . Attach the

18-in. black wire to FC1 control power side and TB2 .

Connect one lead of ATS to TB2 and connect the other

lead to FC2 .

11 13

21

11 11

13 13

C2

1

1

C1

7

Page 8

09DK034,044 Units: Install fan contactors FC2 and FC3

Fig. 10 — Component Arrangement

Fig. 11 — Terminal Adapter

and terminal block TB2 inside control box. See Fig 9.

Add terminal adapter to TB2 . See Fig. 10 and 11. Disconnect red and pink wires from FC1 . Also, disconnect orange and gray wires from FC1 . Connect red

wire to FC2 and pink wire to FC3 . Also, con-

21 21

nect orange wire to FC2 and gray wire to FC3 .

1

11

13

23 23

Attach 8-in. black wire provided in accessory package to

11 11

FC1 and FC2 . Connect the other 8-in. black

wire to FC1 and FC3 . Connect an 8-in. blue

wire to FC1 and FC2 . Attach the other 8-in. blue

wire to FC1 and FC3 . Next, connect an 8-in.

white wire to FC1 neutral side and FC2 . Attach the

other 8-in. white wire to FC2 and FC3 . Connect

11 11

13 13

13 13

C2

C2 C2

the 18-in. black wire to FC1 control power side and

1

TB2 . Attach one lead of ATS (Air Temperature

Switch) to TB2 and th e other lead to FC2 . Connect one lead of ATS2 to TB2 and the other lead to

C1

FC3 . See Fig. 12 for wiring connections.

1

1

C1

5. Route the wire leads of ATS around the coil, keeping

them away from the coil and any sharp metal edges. Install wire ties provided through predrilled holes in upper

divider panel. See Fig. 9. Run ATS wire leads through

wire ties, then into t he 1

3

/8-in. (35 mm) diameter control

box opening.

6. The underside of the ATS is the thermal sensor area that

senses the temperature of air entering the coil. The air

temperature switch opens at 60 ± 3 F and closes at 70 ±

3 F (020,024,028 units only). On 09DK034 and

09DK044 units, ATS opens at 55 ± 3 F and closes at 65 ±

3 F , and ATS2 opens at 70 ± 3 F and closes at 80 ± 3 F.

7. ATS controls fan motor (FM2). O n 09DK034 and 044

units, ATS2 controls fan motor (FM3).

8. If Motormaster

®

control is to be used to modulate fan

motor (FM1), see installation instructions included with

09DK wiring book, and see 32LT Motormaster control

installation instructions for additional general reference.

8

Page 9

Fig. 12 — Accessory Fan Cycling Control Wiring

9

Page 10

Copyright 2000 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 4 a

PC 111 Catalog No. 530-913 Printed in U.S.A. Form 09DK-4W Pg 10 4-00 Replaces: 09DK-1W

Page 11

Page 12

MOUNTING TEMPLATE FOR MOTORMASTER® CONTROL

Copyright 2000 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 4 a

PC 111 Catalog No. 530-913 Printed in U.S.A. Form 09DK-4W Pg 12 4-00 Replaces: 09DK-1W

Loading...

Loading...