Page 1

Air-Cooled Condenser Units

Installation, Start-Up and

Service Instructions

09DK020-044

50/60 Hz

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Step 1 — Complete Pre-Installation Checks . . . . . . 2

Step 2 — Locate and Rig Unit, Remove

Shipping Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

•LOCATION

• RIGGING

• PLACING UNIT

• MOUNTING UNIT

Step 3 — Complete Refrigerant Piping . . . . . . . . . . . 6

• GENERAL

• COIL CIRCUITING CONVERSION

INSTRUCTIONS

• REFRIGERANT LINE SIZING

• LIQUID SHUTOFF VALVE AND

SIGHT GLASS

• PRESSURE RELIEF

• REFRIGERANT RECEIVER

• COIL CONNECTIONS

Step 4 — Complete Electric Connections. . . . . . . . 18

• GENERAL

• CONNECTIONS

•POWER WIRING

• GENERAL WIRING NOTES

Step 5 — Add Accessories as Needed. . . . . . . . . . . 18

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-20

System Evacuation and Dehydration . . . . . . . . . . . . 18

Charging Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Check Operation of Condenser Fan Motor

Controls and Rotation of Fans . . . . . . . . . . . . . . . . 18

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21,22

Fan Guard Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning Standard Coils. . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning and Maintaining E-Coated Coils . . . . . . . 21

Fan Motor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Head Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• FAN CYCLING

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equip-

ment can be hazardous due to system pressures, electrical components and equipment location (roofs, elevated structures,

etc.).

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment (Fig. 1).

Untrained personnel can perform basic maintenance func-

tions such as cleaning coils. All other operations should be performed by trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Keep quenching cloth and fire extinguisher nearby

when brazing. Use care in handling, rigging, and setting bulky

equipment.

ELECTRIC SHOCK HAZARD

Open all remote disconnects before servicing

this equipment.

DO NOT USE TORCH to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective gloves and goggles and proceed as follows:

a. Shut off electrical power to unit.

b. Recover refrigerant to relieve all pressure from sys-

tem using both high-pressure and low pressure ports.

c. Traces of vapor should be displaced with nitrogen

and the work area should be well ventilated. Refrigerant in contact with an open flame produces toxic

gases.

d. Cut component connection tubing with tubing cutter

and remove component from unit. Use a pan to catch

any oil that may come out of the lines and as a gage

for how much oil to add to the system.

e. Carefully unsweat remaining tubing stubs when nec-

essary. Oil can ignite when exposed to torch flame.

Failure to follow these procedures may result in personal

injury or death.

DO NOT re-use compressor oil or any oil that has been

exposed to the atmosphere. Dispose of oil per local codes

and regulations. DO NOT leave refrigerant system open to

air any longer than the actual time required to service the

equipment. Seal circuits being serviced and charge with

dry nitrogen to prevent oil contamination when timely

repairs cannot be completed. Failure to follow these procedures may result in damage to equipment.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 530-917 Printed in U.S.A. Form 09DK-13SI Pg 1 612 11-99 Replaces: 09DK-11SI

Page 2

INTRODUCTION

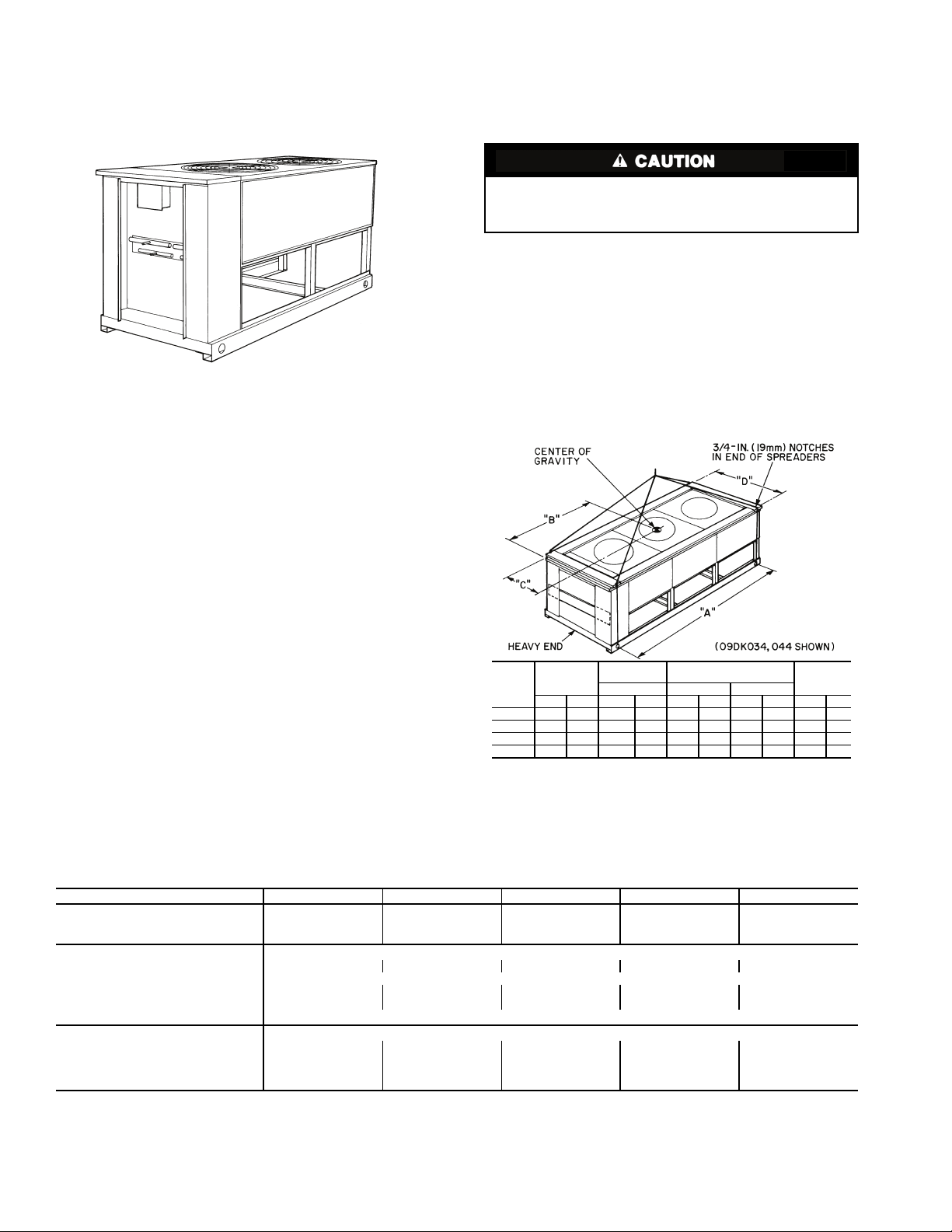

Fig. 1 — Model 09DK (Size 028 Shown)

Fig. 2 — Rigging with Spreader Bars

(Field Supplied)

UNIT

09DK

MAX. SHIP

WT

LIFTING

HOLES

CENTER OF

GRAVITY

D

ABC

lb kg in. mm in. mm in. mm in. mm

020,024 989 449 95.7 2432 55.2 1403 24.7 628 49.5 1256

028 1209 548 95.7 2432 54.7 1391 36.7 933 73.5 1867

034 1835 832 142.0 3608 80.0 2032 36.7 933 73.5 1867

044 2017 915 142.0 3608 80.0 2032 36.7 933 73.5 1867

These instructions describe installation, start-up, and service of 09DK020-044 air-cooled condensers (Fig. 1). See

Table 1 for general unit physical data.

INSTALLATION

Step 1 — Complete Pre-Installation Checks —

Examine for damage incurred during shipment. File claim

immediately with transit company if damage is found. Verify

that the nameplate electrical requirements match the available

power supply. Check the shipment for completeness.

Step 2 — Locate and Rig Unit, Remove Shipping Skid

LOCATION — If roof installation is specified, make certain

that roof structure can support the condenser weight. Refer to

Table 1.

Locate condenser where an adequate supply of inlet outdoor

air is available. Do not locate where the possibility of air recirculation exists, such as under a roof overhang.

Locate condenser in an area free from airborne dirt or other

foreign material which could clog condenser coils.

RIGGING — Preferred method is with spreader bars from

above the unit. Use 2-in. (50 mm) OD pipe or hooks in lifting

holes. Rig with 4 cables and spreader bars. All panels must be

in place when rigging. See rigging label on unit for details concerning shipping weights, distance between lifting holes, center of gravity, and spreader bar dimensions. Also see Fig. 2.

If overhead rigging is not possible, place unit on skid or pad

for rolling or dragging. When rolling, use minimum of 3 rollers. When dragging, pull the pad. Do not apply force to the

unit. When in final position, raise from above to lift unit off

pad.

All panels must be in place when rigging. Do not forklift

unit if no skid is supplied. If unit has skid, use forklift truck

from sides only.

PLACING UNIT — There must be 4 ft (1.22 m) for service

and for unrestricted airflow on all sides of unit, and a minimum

of 8 ft (2.44 m) clean air space above units. See Fig. 3, 4, and

5. For multiple units, allow 8 ft (2.44 m) separation between

units for airflow and service.

MOUNTING UNIT — When unit is in proper location, use

mounting holes in base rails for securing unit to supporting

structure. Fasteners for mounting unit must be field supplied. If

unit is to be mounted on vibration isolators, drill mounting

holes in bottom of base rail at support points 1-4 (shown in

Fig. 3, 4, and 5) and locate isolators at those points.

Table 1 — Physical Data — 50 and 60 Hz

UNIT 09DK 020 024 028 034 044

OPERATING WEIGHT, lb (kg)

Aluminum-Fin Units 797 (361.5) 797 (361.5) 983 (445.9) 1495 (678.1) 1676 (760.2)

Copper-Fin Units 921 (417.8) 921 (417.8) 1137 (515.7) 1700 (771.1) 1984 (900.0)

CONDENSER FANS, TYPE Propeller Type, Direct Driven

No. 22233

Diam, in. (mm) 30 (762)

Total Airflow cfm 10,600 13,500 15,700 21,100 23,700

Speed, Rpm (rps) 1140 (19), 60 Hz 950 (15.8), 50 Hz

CONDENSER COIL, TYPE Horizontal, Plate Fin

Rows 33223

Fins/in. (Fins/m) 17 (669) 17 (669) 19 (748) 17 (669) 17 (669)

Total Face Area, sq ft 23.5 23.5 39.2 58.4 58.4

L/s 5,000 6,370 7,400 9,950 11,200

sq m 2.18 2.18 3.64 5.43 5.43

2

Page 3

Fig. 3 — Dimensions, 09DK020-028

DIMENSIONS — MM [FT-IN.]

NOTES:

1. There must be 1220 mm [4-0] for service and for unrestricted airflow on

all sides of unit.

2. There must be minimum 2440 mm [8-0] clear air space above unit.

3. The approximate operating weight of the unit follows:

4. Dimensions are in millimeters. Dimensions in [ ] are in feet-inches.

UNIT

09DK

ABCDEF

020,024

1131

[3-8

1

/2]

1007

[3-311/16]

240

[97/16]

432

[1-0]

228

[0-9]

559

[1-10]

028

1742

[5-8

5

/8]

1619

[5-33/4]

496

[1-79/16]

914

[3-0]

445

[1-51/2]

762

[2-6]

UNIT 09DK

TOTAL

WEIGHT

OPERATING WT. AT SUPPORT

POINTS

Lb Kg Lb Kg Lb Kg

020,024 797 361.5 186 84.4 212 96.2

020C,024C 921 417.8 215 97.5 245 111.1

028 983 445.9 229 103.9 262 118.8

028C 1137 515.7 268 121.6 300 136.1

C—Units with optional copper-fin coils

1&2

3&4

3

Page 4

Fig. 4 — Dimensions, 09DK034

DIMENSIONS — MM [FT-IN.]

NOTES:

1. There must be 1220 mm [4-0] for service and for unrestricted airflow on

all sides of unit.

2. There must be minimum 2440 mm [8-0] clear air space above unit.

3. The approximate operating weight of the unit follows:

4. Dimensions are in millimeters. Dimensions in [ ] are in feet-inches.

UNIT

09DK

BCDE F

034

112

[1-2

7

/16]

496

[1-79/16]

914

[3-0]

445

[1-51/2]

762

[2-6]

UNIT 09DK

TOTAL

WEIGHT

OPERATING WT. AT SUPPORT

POINTS

Lb Kg Lb Kg Lb Kg

034 1495 678.1 349 158.3 399 181.0

034C 1700 771.1 396 179.6 454 205.9

C—Units with optional copper-fin coils

1&2

3&4

4

Page 5

Fig. 5 — Dimensions, 09DK044

COIL CONNECTION DIMENSIONS — MM [IN.]

NOTES:

1. There must be 1220 mm [4-0] for service and for unrestricted airflow on

all sides of unit.

2. There must be minimum 2440 mm [8-0] clear air space above unit.

3. The approximate operating weight of the unit follows:

4. Dimensions are in mm. Dimensions in [ ] are in feet-inches.

5. Dimension “E” for 34.9 mm I.D. is 118 mm [4

5

/8].

Dimension “E” for 28.5 mm I.D. is 112 mm [4

7

/16].

UNIT

09DK

ABCD E

044

34.9 I.D.

[1

3

/8]

28.5 I.D.

[11/8]

22.2 I.D.

[7/8]

15.9 I.D.

[5/8]

SEE

NOTE #5

UNIT 09DK

TOTAL

WEIGHT

OPERATING WT. AT SUPPORT

POINTS

Lb Kg Lb Kg Lb Kg

044 1676 760.2 391 177.4 447 202.8

044C 1984 900.0 462 209.6 529 240.0

C—Units with optional copper-fin coils

1&2

3&4

5

Page 6

Step 3 — Complete Refrigerant Piping

GENERAL — All field leak and pressure testing should be in

accordance with local code requirements. If no local code

exists, follow American National Standards Institute (ANSI)/

American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) Safety Standard 15, latest

revision.

For leak testing procedures, refer to the Carrier Refrigerant

Service Techniques Manual.

COIL CIRCUITING CONVERSION INSTRUCTIONS —

See Table 2 for standard unit circuiting and for the circuiting

available by installing the supplied parts kits. Note that for

044 size units, all circuiting must be field installed using field

supplied parts. Field supplied and installed parts are also

required for 100% circuiting of all 020-034 size units.

The following sections describe how to modify the standard

unit circuiting (as shipped from the factory) for optional splits.

NOTE: All coils are purged with dry air and then capped prior

to shipment. The coils DO NOT contain a refrigerant holding

charge.

Table 2 — Coil Circuiting Options

UNIT 09DK

020 50/50% 67/33%*

024 50/50% 67/33%*

028 50/50% 60/40%* or 40/40/20%*

034 50/50% 60/40%* or 40/40/20%*

044 Uncircuited†

*Parts kits for field circuiting conversions are supplied with the unit. Replacement parts kits are available as follows:

For 020 and 024 size units, part no. 09DK400138; for 028 and 034 units, part no. 09DK400139. Replacement parts kits are not

available for 044 units.

†The 044 unit is shipped from the factory uncircuited, with plastic caps on all connections. The unit must be field converted to the

desired split with field supplied parts.

FAC TOR Y

CIRCUITING

FIELD-CONVERTED

CIRCUITING

100% or 74/26% or 66/34% or

60/40% or 53/47% or 40/13/13/34%

6

Page 7

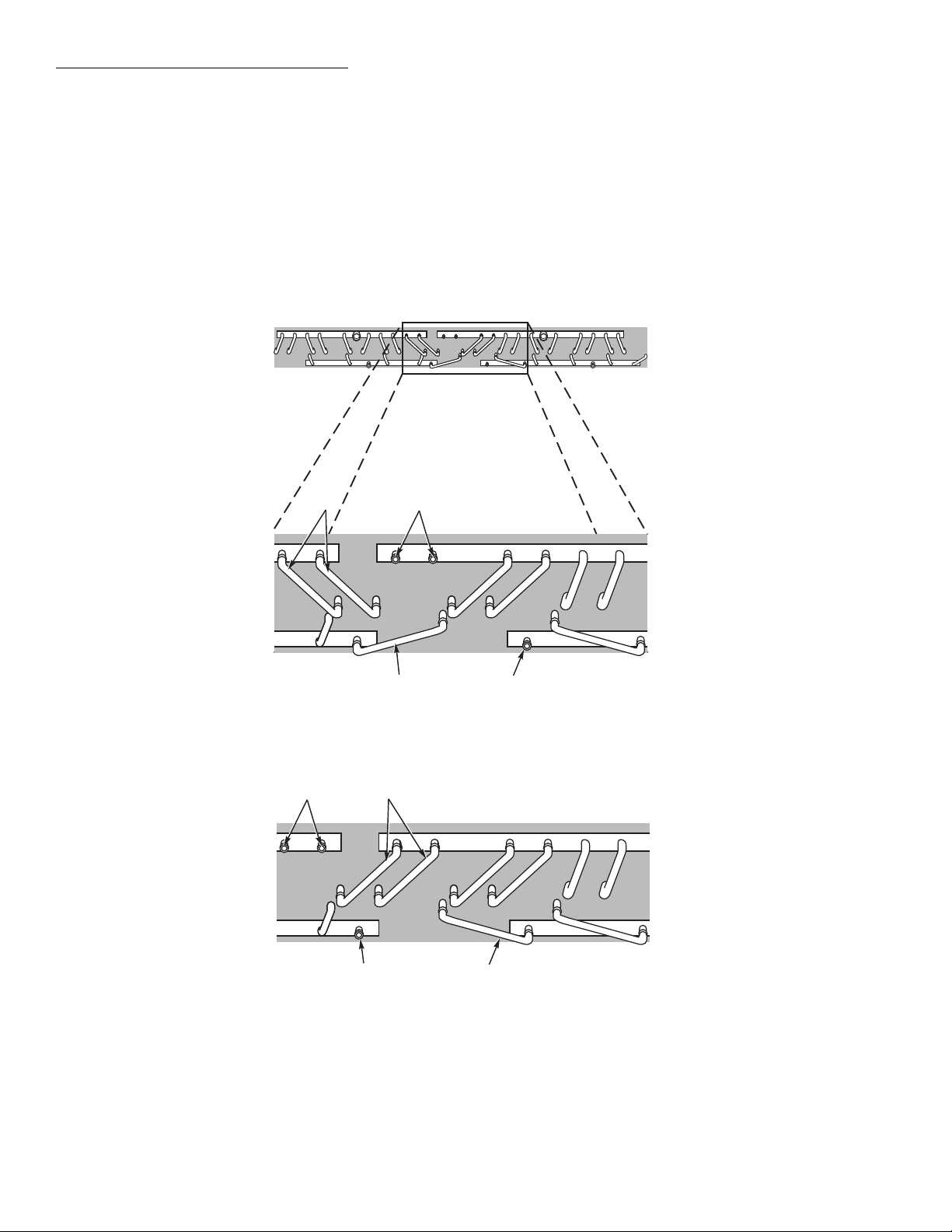

09DK020,024 67/33% Circuiting Modification

CA

AB

Fig. 6 — Parts Removed from 09DK020,024

(50/50%) Unit for 67/33% Circuiting

Fig. 7 — Parts Added to 09DK020,024 Unit

(To Obtain 67/33% Circuiting)

— To convert the 09DK020 or 09DK024 coil from the 50/50% to

67/33% circuiting, perform the following steps:

1. Use a mini tubing cutter to remove specified parts:

a. Both

3

/8-in. diam tube nipples connecting the left

hot gas header to the coil. See Fig. 6, Item A.

b. The

3

/8-in. diam tube nipple connecting the left

liquid header to the coil. See Fig. 6, Item B.

c. Caps, where 2 are located on the right gas header,

and one is located on the right liquid header. See

Fig. 6, Item C.

2. Attach following specified parts contained in the parts

kit. Perform phos-copper brazing on all field-made

connections while protecting adjacent joints from heat.

a. Cap the open stub tubes on the left headers, where

two are located on the gas header, and one on the

liquid header. See Fig. 7, Item A.

b. Insert both 3

5

/8-in. length tube nipples into the

open stub tubes located on the right side of the coil

to connect the right gas header to the top row of

the coil. See Fig. 7, Item B.

c. Insert the 4

11

/16-in. length tube nipple into the

open stub tubes on the right side of the coil to connect the right liquid header to the bottom row. See

Fig. 7, Item C.

3. Install or replace filter-drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

7

Page 8

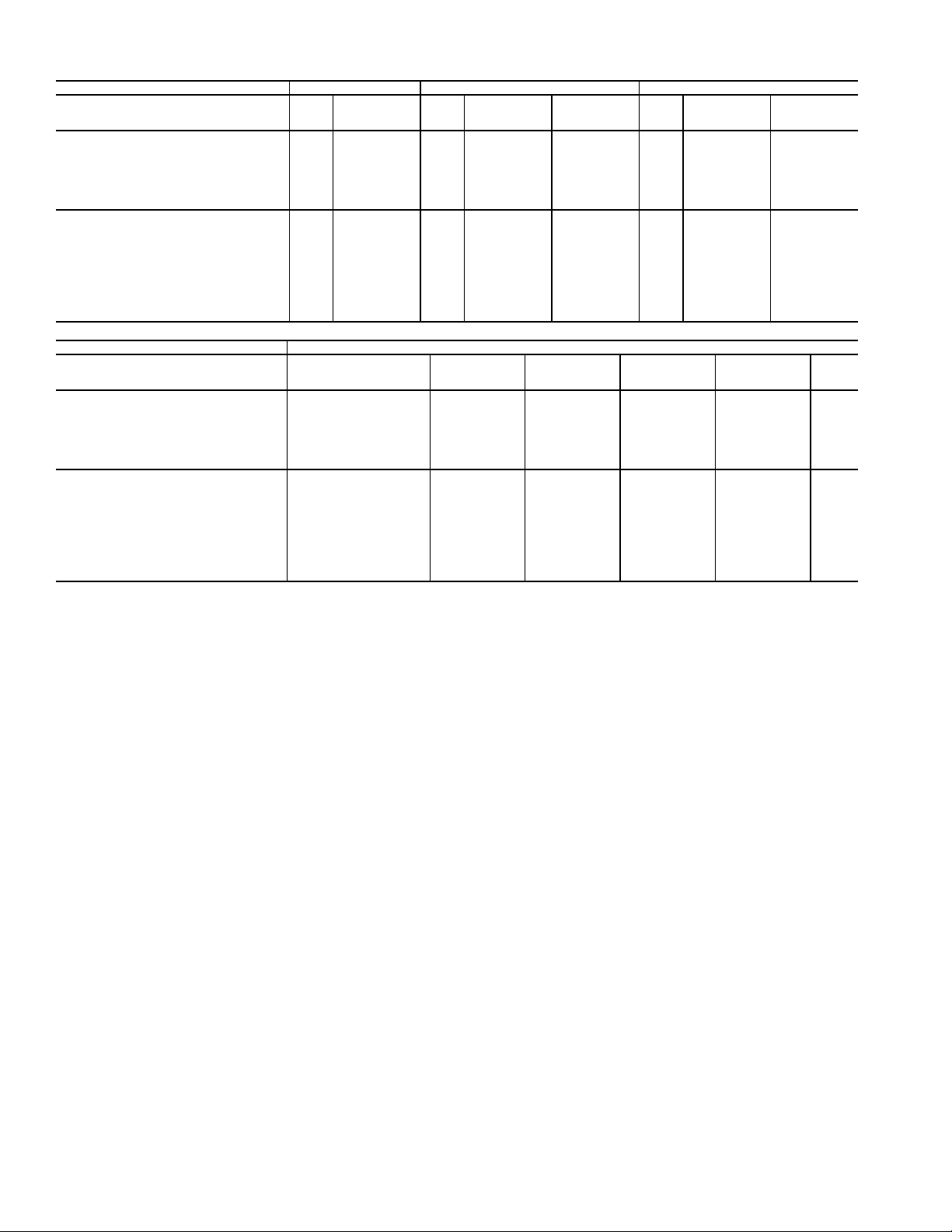

09DK028,034 60/40% Circuiting Modification

B

C

A

C

B

A

C

A

Fig. 8 — Parts Removed from 09DK028,034 (50/50%) Unit for 60/40% Circuiting

Fig. 9 — Parts Added to 09DK028,034 Unit

(To Obtain 60/40% Circuiting)

— To convert the 09DK028 or 09DK034 coil from the 50/50% to

60/40% circuiting, perform the following steps:

1. Use a mini tubing cutter to remove specified parts:

a. Both

3

/8-in. diam tube nipples connecting the left

hot gas header to the coil. See Fig. 8, Item A.

b. The

3

/8-in. diam tube nipple connecting the left

liquid header to the coil. See Fig. 8, Item B.

c. Caps, where 2 are located on the right gas header,

and one is located on the right liquid header. See

Fig. 8, Item C.

2. Attach following specified parts contained in the parts

kit. Perform phos-copper brazing on all field-made

connections while protecting adjacent joints from heat.

a. Cap the open stub tubes on the left headers, where

two are located on the gas header, and one on the

liquid header. See Fig. 9, Item A.

b. Insert both 4

1

/16-in. length tube nipples into the

open stub tubes on the right side of the coil, connecting the gas header to the top row. See Fig. 9,

Item B.

c. Insert the 4

11

/16-in. length tube nipple into the

open stub tubes on the right side of the coil, connecting the liquid header to the bottom row. See

Fig. 9, Item C.

3. Install or replace filter-drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

8

Page 9

09DK028,034 40/40/20% Circuiting Modification

BB

A

A

A A

ABAC

Fig. 10 — Parts Removed from 09DK028,034 (50/50%) Unit for 40/40/20% Circuiting

Fig. 11 — Parts Added to 09DK028,034 Unit

(To Obtain 40/40/20% Circuiting)

— To

convert the 09DK028 or 09DK034 coil from the 50/50% to

40/40/20% circuiting, perform the following steps:

1. Use a mini tubing cutter to remove specified parts:

a. Four

3

/8-in. diam tube nipples connecting the hot

gas headers to the coil. See Fig. 10, Item A.

b. Both

3

/8-in. diam tube nipples connecting the liq-

uid headers to the coil. See Fig. 10, Item B.

2. Attach following specified parts contained in the parts

kit. Perform phos-copper brazing on all field-made

connections while protecting adjacent joints from heat.

a. Cap the open stub tubes on the left and right gas

and liquid headers with stub tube caps supplied in

the parts kit. See Fig. 11, Item A.

b. Insert the

7

/8-in. diam header into the stub tubes

located in the top row of the coil. See Fig. 11,

Item B.

c. Insert the 6-in. length U tube into the stub tubes

located in the bottom row of the coil. See Fig. 11,

Item C.

3. Install or replace filter-drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

9

Page 10

09DK044 100% Circuiting Modification

A

B

B

A

C

D

C

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 12 — 09DK044 Unit with 100% Circuiting

— To configure the

09DK044 for a single 100% refrigerant circuit using field supplied parts, perform the following steps:

1. Remove all plastic caps. Refer to Fig. 12.

2. Attach following parts as shown in Fig. 12. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Construct one (1) gas tubing assembly (Item A),

consisting of the following parts, and braze it into

gas headers as shown:

3

2 —1

/8-in. OD tubes

3

2 —1

/8-in. 90° long-radius elbows

3

1 —1

/8-in. tee (see note at right)

3

2 —1

/8-in. OD nipples (cut to length as required)

b. Construct 2 gas “U” tube assemblies (Item B),

consisting of the following parts, and braze them

into the gas headers as shown.

1

1 —1

/8-in. OD tube

1

2 —1

/8-in. 90° long-radius elbows

1

2 —1

/8-in. OD nipples (cut to length as required)

c. Construct one liquid tubing assembly (Item C),

consisting of the following parts, and braze it into

liquid headers as shown.

7

2 —

/8-in. OD tubes

7

1 —

/8-in. 90° long-radius elbow

7

1 —

/8-in. tee (see note below)

7

2 —

/8-in. OD nipples (cut to length as required)

d. Construct 2 liquid “U” tube assemblies (Item D),

consisting of the following parts, and braze them

into the gas headers as shown.

5

1 —

/8-in. OD tube

5

2 —

/8-in. 90° long-radius elbows

5

2 —

/8-in. OD nipples (cut to length as required)

NOTE: Diameter of tee’s interconnecting pipe

opening is dependent upon interconnecting system

piping diameter. Refer to Carrier System Design

Manual, Part 3, for hot gas and liquid pipe sizing

information.

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

10

Page 11

09DK044 74/26% Circuiting Modification

AE

B

E

C

ED

E

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 13 — 09DK044 Unit with 74/26% Circuiting

— To configure

the 09DK044 for two refrigerant circuits (one with 74%

capacity and one with 26% capacity) using field supplied

parts, perform the following steps:

1. Remove all plastic caps. Refer to Fig. 13.

2. Attach following parts as shown in Fig. 13. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Construct the 74% gas tubing assembly (Item A),

consisting of the following parts, and braze it into

gas headers as shown in Fig. 13, Item A:

3

2 —1

/8-in. OD tubes (cut to length as required)

3

2 —1

/8-in. 90° long-radius elbows

3

1 —1

/8-in. tee (see note at right)

3

2 —1

/8-in. OD nipples (cut to length as required)

b. Construct the 26% gas tubing assembly (Item B),

consisting of the following parts, and braze it into

the gas headers as shown in Fig. 13, Item B:

1

1 — 1

/8-in. OD tube (cut to length as required)

1

2 — 1

/8-in. 90° long-radius elbows

1

1 — 1

/8-in. tee (see note at right)

1

2 — 1

/8-in. OD nipples (cut to length as required)

c. Construct the 74% liquid tubing assembly

(Item C), consisting of the following parts, and

braze it into liquid headers as shown in Fig. 13,

Item C:

7

2 —

/8-in. OD tubes (cut to length as required)

7

2 —

/8-in. 90° long-radius elbows

7

1 —

/8-in. tee (see note at right)

7

2 —

/8-in. OD nipples (cut to length as required)

d. Construct the 26% liquid tube assembly (Item D),

consisting of the following parts, and braze it into

the gas headers as shown in Fig. 13, Item D:

5

1 —

/8-in. OD tube

5

2 —

/8-in. 90° long-radius elbows

5

1 —

/8-in. tee (see note below)

5

2 —

/8-in. OD nipples (cut to length as required)

e. Plug the two open 1

the gas headers and the two open

1

/8-in. diameter stub tubes on

5

/8-in. diameter

stub tubes on the liquid headers as shown in

Fig. 13, Item E. Parts required:

1

2 —1

/8-in. plug fittings

5

2 —

/8-in. plug fittings

NOTE: Diameter of tee’s interconnecting pipe

opening is dependent upon interconnecting system

piping diameter. Refer to Carrier System Design

Manual, Part 3, for hot gas and liquid pipe sizing

information.

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

11

Page 12

09DK044 66/34% Circuiting Modification

A

C

B

C

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 14 — 09DK044 Unit with 66/34% Circuiting

— To configure

the 09DK044 for two refrigerant circuits (one with 66% capacity and one with 34% capacity) using field supplied parts,

perform the following steps:

1. Remove all plastic caps. Refer to Fig. 14.

2. Attach following parts as shown in Fig. 14. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Construct the 66% gas tubing assembly (Item A),

consisting of the following parts, and braze it into

gas headers as shown in Fig. 14, Item A:

1

2 — 1

/8-in. OD tubes (cut to length as required)

1

2 — 1

/8-in. 90° long-radius elbows

1

1 — 1

/8-in. tee (see note at right)

1

3 — 1

/8-in. OD nipples (cut to length as required)

b. Construct the 66% liquid tubing assembly

(Item B), consisting of the following parts, and

braze it into liquid headers as shown in Fig. 14,

Item B:

5

2 —

/8-in. OD tubes (cut to length as required)

5

2 —

/8-in. 90° long-radius elbows

5

1 —

/8-in. tee (see note at right)

5

3 —

/8-in. OD nipples (cut to length as required)

c. Plug the open 1

right gas header and the open

1

/8-in. diameter stub tube on the

5

/8-in. diameter stub

tube on the right liquid header as shown in Fig. 14,

Item C. Parts required:

1

1 — 1

/8-in. plug fitting

5

1 —

/8-in. plug fitting

NOTE: Diameter of tee’s interconnecting pipe

opening is dependent upon interconnecting system

piping diameter. Refer to Carrier system Design

Manual, Part 3 for hot gas and liquid pipe sizing

information.

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

12

Page 13

09DK044 60/40% Circuiting Modification

C

A

C

B

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 15 — 09DK044 Unit with 60/40% Circuiting

— To configure

the 09DK044 for two refrigerant circuits (one with 60%

capacity and one with 40% capacity) using field supplied

parts, perform the following steps:

1. Remove all plastic caps. Refer to Fig. 15.

2. Attach following parts as shown in Fig. 15. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Construct the 60% gas tubing assembly (Item A),

consisting of the following parts, and braze it into

gas headers as shown in Fig. 15, Item A:

1

2 — 1

/8-in. OD tubes (cut to length as required)

1

2 — 1

/8-in. 90° long-radius elbows

1

1 — 1

/8-in. tee (see note at right)

1

3 — 1

/8-in. OD nipples (cut to length as required)

b. Construct the 60% liquid-tubing assembly

(Item B) consisting of the following parts and

braze it into liquid headers as shown in Fig. 15,

Item B:

5

2 —

/8-in. OD tubes (cut to length as required)

5

2 —

/8-in. 90 long-radius elbows

5

1 —

/8-in. tee (see note at right)

5

3 —

/8-in. OD nipples (cut to length as required)

c. Plug the open 1

left gas header and the open

1

/8-in. diameter stub tube on the

5

/8-in. diameter stub

tube on the left liquid header as shown in Fig. 15,

Item C. Parts required:

1

1 — 1

/8 in. plug fitting

5

1 —

/8-in. plug fitting

NOTE: Diameter of tee’s interconnecting pipe

opening is dependent upon interconnecting system

piping diameter. Refer to Carrier System Design

Manual, Part 3 for hot gas and liquid pipe sizing

information.

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

13

Page 14

09DK044 53/47% Circuiting Modification

A

C

B

D

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 16 — 09DK044 Unit with 53/47% Circuiting

— To configure the 09DK044 for two refrigerant circuits (one with 53%

capacity and one with 47% capacity) using field supplied

parts, perform the following steps:

1. Remove all plastic caps. Refer to Fig. 16.

2. Attach following parts as shown in Fig. 16. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Construct the 53% gas tubing assembly (Item A),

consisting of the following parts, and braze it into

gas headers as shown in Fig. 16, Item A:

1

2 — 1

/8-in. OD tubes (cut to length as required)

1

2 — 1

/8-in. 90° long-radius elbows

1

2 — 1

/8-in. OD nipples (cut to length as required)

b. Construct the 53% liquid tubing assembly

(Item B), consisting of the following parts, and

braze it into liquid headers as shown in Fig. 16,

Item B:

5

2 —

/8-in. OD tubes (cut to length as required)

5

2 —

/8-in. 90° long-radius elbows

5

2 —

/8-in. OD nipples (cut to length as required)

c. Construct the 47% gas tubing assembly (Item C),

consisting of the following parts, and braze it into

gas headers as shown in Fig. 16, Item C:

1

2 — 1

/8-in. OD tubes (cut to length as required)

1

2 — 1

/8-in. 90° long-radius elbows

1

2 — 1

/8-in. OD nipples (cut to length as required)

d. Construct the 47% liquid tubing assembly

(Item D), consisting of the following parts, and

braze it into liquid headers as shown in Fig. 16,

Item D:

5

2 —

/8-in. OD tubes (cut to length as required)

5

2 —

/8-in. 90 long-radius elbows

5

2 —

/8-in. OD nipples (cut to length as required)

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

14

Page 15

09DK044 40/13/13/34% Circuiting Modification

A

B

PLASTIC CAPS REMOVED FROM UNIT

FIELD-SUPPLIED PARTS ADDED TO UNIT

Fig. 17 — 09DK044 Unit with 40/13/13/34% Circuiting

— To configure the 09DK044 for four refrigerant circuits (one with

40% capacity, two with 13% capacity, and one with 30%

capacity) using field supplied parts, perform the following

steps:

1. Remove all plastic caps. Refer to Fig. 17.

2. Attach following parts as shown in Fig. 17. Perform

phos-copper brazing on all field-made connections

while protecting adjacent joints from heat.

a. Plug the open 1

1

/8-in. stub tubes at the inside of

each of the large gas headers as shown in Fig. 17,

Item A. Parts required:

1

2 — 1

/8-in. plug fittings

5

b. Plug the open

/8-in. stub tubes at the inside of

each of the large gas headers as shown in Fig. 17,

Item B. Parts required:

5

2 —

/8-in. plug fittings

3. Install or replace filter drier(s). Before charging the

system, install or replace filter drier(s) connected to

the liquid line near the indoor unit to prevent contamination in the system.

15

Page 16

REFRIGERANT LINE SIZING — Sizing depends on length

*Field supplied.

NOTES:

1. Hot gas lines should rise above refrigerant level in condenser

circuit.

2. Trap should be installed on hot gas lines to prevent condenser

oil and refrigerant vapor migration from accumulating on compressor heads during off cycle.

3. Refer to Carrier System Design Manual, part 3 for proper piping sizes and design.

4. For piping lengths greater than 50 ft (15.2 m), provide support

to liquid and gas lines near the connections to the coil.

Fig. 18 — Typical Piping for 09DK Condenser with a Single Compressor

of lines between various sections of the refrigerant system.

Consider the amount of liquid lift and drop in the system as

well as proper compressor oil return. Consult Carrier System

Design Manual, Part 3, for proper piping sizes and design.

LIQUID SHUTOFF VALVE AND SIGHT GLASS — A

shut-off valve is not supplied with 09DK condensers. It is

strongly recommended that a full line size liquid shutoff valve

(see Fig. 18 and 19) be field supplied near condenser to allow

for servicing parts of the refrigerant circuit. A field-supplied

moisture indicating sight glass is recommended for use in

charging and servicing the system. Refer to Fig. 20.

PRESSURE RELIEF — The American National Standards

Institute and American Society of Heating, Refrigeration, and

Air Conditioning Engineers Safety Code for Mechanical

Refrigeration (ANSI/ASHRAE) 15 states the following:

“Every refrigerant system shall be protected by a pressure

relief device unless so constructed that the pressure due to fire

conditions will be safely relieved by some part of the system.”

Since 09DK condensers have no pressure relief device, one

should be field supplied and installed just before the liquid line

service valve. (See Fig. 18 and 19.) When the split coil is used

with multiple systems, each system must have its own pressure

relief.

REFRIGERANT RECEIVER — A refrigerant receiver is not

furnished with 09DK condensers and is not recommended for

normal applications as its use will be detrimental to the desired

effects of subcooling. However, if a particular application

requires a receiver to increase refrigerant holding capacity of

the condenser, a receiver can be used. When a receiver is to be

used all year, it should be installed indoors. Carrier recommends the following installation in such a case (see Fig. 20).

Locate valves on each side of the receiver so receiver may be

isolated from system for normal operation.

16

Page 17

Procedure for Using the Refrigerant Receiver

*Field supplied.

NOTES:

1. Hot gas lines should rise above refrigerant level in condenser

circuit.

2. Trap should be installed on hot gas lines to prevent condenser

oil and refrigerant vapor migration from accumulating on compressor heads during off cycle.

3. Refer to Carrier System Design Manual, part 3 for proper piping

sizes and design.

4. For piping lengths greater than 50 ft (15.2 m), provide support

to liquid and gas lines near the connections to the coil.

Fig. 19 — Typical Piping for 09DK Condenser with a Dual Split System

*Field-supplied service valves.

A—Bypass valve

B—Receiver inlet valve

C—Receiver outlet

valve

Fig. 20 — Piping for Optional Receiver

During normal operation — Valve A is open and valves B and

C are closed. Receiver is isolated from the system.

For servicing — Valves A and C are closed and valve B is

open. Run unit until all the refrigerant is in the receiver and

then close valve B. Unit is now ready for servicing.

To resume operation — Leave valve A closed and open valves

B and C. Run unit until the stored refrigerant is drawn into the

system. To completely remove the refrigerant from the

receiver, throttle valve B while noting condition of refrigerant

in the liquid line sight glass; also monitor the suction pressure.

A sudden surge of bubbles in the sight glass and a rapid

decrease in suction pressure indicates that all the refrigerant

has been withdrawn from the receiver. Immediately close

valves B and C and then open valve A. The unit should now be

ready for normal operation, with the receiver isolated from the

system. The system should be charged to a clear sight glass

when under normal operation.

COIL CONNECTIONS — See Fig. 3-5, 18, and 19 for the

necessary connections.

— See Fig. 20.

17

Page 18

Step 4 — Complete Electrical Connections

GENERAL — Verify that nameplate electrical requirements

match available power supply. Voltage at condenser must be

within the minimum and maximum shown in Table 3 and

phases must be balanced within 2%. Contact local power company for line voltage corrections. Never operate a motor where

a phase imbalance in supply voltage is greater than 2%. Use

the following formula to determine the percentage of voltage

imbalance:

% Voltage

Imbalance

= 100 x

Example: Supply voltage is 240-3-60.

Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 volts

(BC) 239 – 236 = 3 volts

(AC) 239 – 238 = 1 volt

Maximum deviation is then 4 volts. To determine the percentage of voltage imbalance:

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory since it is

below the maximum allowable of 2%.

IMPORTANT: If supply voltage phase imbalance is

more than 2%, contact your local electric utility

company immediately.

Condenser operation on improper line voltage or excessive

phase imbalance may be considered abuse and any resulting

damage may not be covered by Carrier warranty.

All wiring must be in accordance with NEC (National Electrical Code, U.S.A.) regulations or local codes.

CONNECTIONS — Refer to Table 3 and Fig. 21.

Install a field-supplied disconnect capable of being locked

at OFF position.

POWER WIRING — Install field-supplied branch circuit

fused disconnect(s) of a type that can be locked OFF or OPEN.

Disconnect(s) must be within sight from and readily accessible

from unit in compliance with NEC Article 440-14 (U.S.A.) or

local code.

max voltage deviation

from average voltage

Average voltage

AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage =

=1.7%

243 + 236 + 238

717

=

3

= 239 volts

4

239

3

GENERAL WIRING NOTES

1. The control circuit field supply disconnect should

never be open except when unit is being serviced or is

to be down for a prolonged period.

2. Power entry is at one end only.

3. Terminals for field power supply are suitable for copper, copper-clad aluminum, or aluminum conductors.

Insulation must be rated 60 C minimum.

4. Field power supply wires based on minimum 26 C

ambient temperature air are 8 AWG (American Wire

Gage) for Models 09DK034, 044 (208/230-3-60,

230-3-50), 12 AWG for all other models.

5. Connect field power wires to factory-supplied 8 AWG

wire from contactor with factory-supplied nut.

6. Route field wiring through factory-supplied wire ties

and base rail holes. See Fig. 3-5.

7. Control circuit power is as follows:

CONTROL CIRCUIT

V-H z

220-60 380-60

230-50

115-60

NOTE: Use 14 AWG (American Wire Gage) copper conductors only

for control circuit wiring.

POWER

SUPPLY V-Hz

230-50

400-50

208/230-60

460-60

575-60

Step 5 — Add Accessories as Needed —

Accessories include fan cycling head-pressure control, winter

start control, fan cycling, and electrical interlock. Refer to

installation instructions furnished with each accessory.

START-UP

System Evacuation and Dehydration —

GTAC II, Module 4, “Dehydration for Proper Evacuation and

Dehydration techniques.”

Refer to

Charging Procedure — BEFORE CHARGING THE

SYSTEM, INSTALL OR REPLACE THE FILTERDRIER(S) CONNECTED TO THE LIQUID LINE WITHIN

THE IN-DOOR UNIT(S) TO PREVENT CONTAMINATION WITHIN THE SYSTEM. Charge to a clear sight glass.

Refer to GTAC II, Module 5 “Charging, Recovery, Recycling,

and Reclamation” and Carrier Refrigerant Service Techniques

manual for proper charging techniques. Add 10 lbs (4.5 kg) of

R-22 over clear sight glass to flood subcooler sections of the

condenser coils. See Table 4 for charging data.

Check Operation of Condenser Fan Motor

Controls and Rotation of Fans — Rotation should

be counterclockwise as viewed from top of unit.

Before starting unit, be sure wire fan guards are secured in

place over each fan.

18

Page 19

020

Fig. 21 — Wiring Diagram, Power Schematic; 09DK020-044

FC — Fan Contactor

FM — Fan Motor

TB — Terminal Block Connection

Terminal Block Connection

Marked Terminal

Unmarked Terminal

Splice

Factory Wire

Field Control Wiring

Field Power Wiring

LEGEND

024

028

034

044

024

028

034

044

Table 3 — 09DK Electrical Data

60 HERTZ

UNIT

09DK

500 208/230 187 254 14.8 20

200 380 342 418 8.8 15 3.9 220

600 460 414 508 7.4 15 3.3 115

100 575 518 632 7.6 15 3.4 115

500 208/230 187 254 14.8 20 6.6 115

200 380 342 418 8.8 15 3.9 220

600 460 414 508 7.0 15 3.3 115

100 575 518 632 7.6 15 3.4 115

500 208/230 187 254 13.9 20 6.6 115

200 380 342 418 8.8 15 3.9 220

600 460 414 508 7.4 15 3.3 115

100 575 518 632 7.6 15 3.4 115

500 208/230 187 254 21.4 25

200 380 342 418 12.7 20 3.9 220

600 460 414 508 10.7 15 3.3 115

100 575 518 632 11.0 15 3.4 115

500 208/230 187 254 20.1 25 6.6 115

200 380 342 418 12.7 20 3.9 220

600 460 414 508 10.1 15 3.3 115

100 575 518 632 11.0 15 3.4 115

UNIT

09DK

800 230 207 254 14.4 20

900 400 342 440 6.7 15 3.0 230

800 230 207 254 14.4 20 6.4 230

900 400 342 440 6.7 15 3.0 230

800 230 207 254 20.8 30

900 400 342 440 9.7 15 3.0 230

800 230 207 254 20.8 30 6.4 230

900 400 342 440 9.7 15 3.0 230

Volts -3 Ph

Volts -3 Ph

Supplied Volts

Min Max

Supplied Volts

Min Max

UNIT FAN MOTORS CONTROL CIRCUIT

MCA

MOCP

(Fuse)

No. FLA (ea) Volts -1 Ph Amps

6.6 115

2

6.2 115

3

50 HERTZ

UNIT FAN MOTORS CONTROL CIRCUIT

MCA

MOCP

(Fuse)

No. FLA (ea) Volts -1 Ph Amps

6.4 230

2

6.4 230

3

7

7

FLA — Full Load Amps

MCA — Minimum Circuit Amps (for wire sizing). Complies with

MOCP — Maximum Overcurrent Protective Device (Amps).

NEC (National Electrical Code, U.S.A.) Section 430-24.

19

Page 20

Table 4 — Refrigerant Circuit Data

COIL

No. of Ckts 2112112121121

Cap. (% Ckt) 50 67 33 50 60 40 40 20 50 60 40 40 20

REFRIGERANT

Min. Operating Chg/Ckt* kg 4.8 6.4 3.2 5.3 6.4 4.3 4.3 2.1 8.0 9.5 6.4 6.4 3.2

Optimum Operating Chg/Ckt† kg 5.7 7.5 3.8 6.3 7.5 5.0 5.0 2.5 9.4 11.2 7.5 7.5 3.7

Vol /C kt m

STORAGE CAPACITY

(Per Ckt)**

R-12 kg 8.7 11.7 5.8 9.6 11.5 7.7 7.7 3.8 14.2 17.1 11.3 11.3 5.7

R-22 kg 7.9 10.6 5.3 8.8 10.5 7.0 7.0 3.5 13.0 15.6 10.4 10.4 5.2

R-500 kg 7.5 10.0 4.9 8.3 9.9 6.6 6.6 3.3 12.2 14.7 9.8 9.8 4.9

R-502 kg 8.3 11.1 5.5 9.2 11.0 7.3 7.3 3.7 13.6 16.3 10.8 10.8 5.4

UNIT 09DK 020, 024 028 034

lb 10.6 14.1 7.1 11.8 14.1 9.4 9.4 4.7 17.5 21.0 14.0 14.0 7.0

lb 12.5 16.6 8.3 13.8 16.6 11.1 11.1 5.5 20.6 24.8 16.5 16.5 8.3

3

0.008 0.01 0.006 0.009 0.01 0.007 0.007 0.004 0.014 0.017 0.011 0.011 0.006

cu ft 0.30 0.40 0.20 0.33 0.40 0.26 0.26 0.14 0.49 0.59 0.39 0.39 0.20

lb 19.2 25.7 12.7 21.1 25.3 16.9 16.9 8.4 31.3 37.6 25.0 25.0 12.5

lb 17.5 23.3 11.7 19.3 23.2 15.4 15.4 7.7 28.7 34.4 23.0 23.0 11.5

lb 16.5 22.1 10.9 18.2 21.8 14.5 14.5 7.3 26.9 32.3 21.5 21.5 10.8

lb 18.3 24.5 12.1 20.2 24.2 16.1 16.1 8.1 29.9 35.9 23.9 23.9 12.0

COIL

No. of Ckts 112111111111

Cap. (% Ckt) 40 34 13 74 26 66 34 60 40 53 47 100

REFRIGERANT

Min. Operating Chg/Ckt* kg 9.5 7.9 3.1 17.4 6.4 15.9 8.0 14.3 9.5 12.7 11.2 23.9

Optimum Operating Chg/Ckt† kg 11.2 9.4 3.7 20.5 7.6 18.7 9.4 16.8 11.2 14.9 13.2 28.1

Vol /C kt m

STORAGE CAPACITY

(Per Ckt)**

R-12 kg 17.3 14.7 5.6 31.6 11.7 29.0 14.2 25.9 17.3 22.9 20.3 43.2

R-22 kg 15.8 13.4 5.1 28.8 10.7 26.4 13.2 23.7 15.8 21.0 18.6 39.6

R-500 kg 14.9 12.6 4.8 27.1 10.0 24.8 12.4 22.3 14.9 19.7 17.4 37.2

R-502 kg 16.5 14.1 5.4 30.2 11.2 23.1 13.7 24.8 16.5 21.9 19.4 41.3

LEGEND

Ckt — Circuit

Min. — Minimum

Vol — Vo lu me

*Minimum operating charge based on 5° F (2.8° C) subcooling.

†Optimum operating charge based on 15° F (8.3° C) subcooling.

**Storage capacity calculated for 80% liquid and 20% vapor at 32.2 C (90 F).

UNIT 09DK 044

lb 21.0 17.4 6.8 38.4 14.2 35.1 17.5 31.6 21.0 27.9 24.7 52.6

lb 24.8 20.6 8.3 45.2 16.7 41.3 20.6 37.1 24.8 32.8 29.1 61.9

3

0.016 0.014 0.005 0.031 0.011 0.028 0.014 0.025 0.017 0.022 0.02 0.042

cu ft 0.60 0.52 0.19 1.09 0.40 1.0 0.49 0.89 0.60 0.79 0.70 1.49

lb 38.1 32.4 12.4 69.6 25.7 64.0 31.3 57.2 38.1 50.5 44.8 95.3

lb 34.8 29.6 11.3 63.6 23.5 58.1 29.0 52.3 34.8 46.2 40.9 87.1

lb 32.8 27.8 10.6 59.8 22.1 54.6 27.3 49.1 32.8 43.4 38.4 81.9

lb 36.4 31.0 11.8 66.5 24.6 51.0 30.1 54.7 36.4 48.3 42.8 91.1

20

Page 21

SERVICE

Fig. 22 — Location of Propeller on Motor Shaft

from Outside of Orifice Ring

PROP LOCATION

“A” in. (mm)

Min Max

60 Hz

09DK020 3.12 (79.2) 3.38 (85.9)

09DK024,028,044 3.62 (91.9) 3.88 (98.6)

09DK034 Fan No. 1 and 3 3.62 (91.9) 3.88 (98.6)

Fan No. 2 3.12 (79.2) 3.38 (85.9)

50 Hz

09DK024,028,044 1.56 (39.6) 1.68 (42.7)

09DK034 Fan No. 1 and 3 3.12 (79.2) 3.38 (85.9)

Fan No. 2 3.62 (91.9) 3.88 (98.6)

Fan Guard Removal —

5

14 x

/8-in. long self-tapping hex head screws per guard and

remove guard.

On all sizes, remove eight 1/4 x

Fan Adjustment

1. Make certain condenser power is off.

2. Remove fan guard.

3. Remove cap and setscrews on fan hub.

4. Adjust fan. See Fig. 22.

5. Tighten fan hub securely on motor shaft with setscrew

which bears against the key.

6. Replace permagum and rubber cap over end of motor

shaft to prevent moisture from causing fan to rust on

shaft.

Lubrication — Fan motors have permanently lubricated

bearings. No provisions are made for lubrication.

Cleaning Standard Coils — Clean standard coils with

stiff brush, vacuum cleaner, or compressed air. Low-pressure

water may be used to clean coils by removing fan guard and

spraying coil from inside. Condenser fan motors are drip-proof

but not waterproof. Routine cleaning of coil surfaces is essential to minimize contamination build-up and remove harmful

residue. Inspect coils monthly and clean as required.

Cleaning and Maintaining E-Coated Coils —

Routine cleaning of condenser coil surfaces is essential to

maintain proper operation of the unit. Elimination of contamination and removal of harmful residue will greatly increase the

life of the coil and extend the life of the unit. The following

maintenance and cleaning procedures are recommended as

part of the routine maintenance activities to extend the life of

the coil.

REMOVE SURFACE LOADED FIBERS — Debris such as

dirt and fibers on the surface of the coil should be removed

with a vacuum cleaner. If a vacuum cleaner is not available, a

soft brush may be used. The cleaning tool should be applied in

the direction of the fins. Coil surfaces can be easily damaged

(fin edges bent over) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose,

against a surface loaded coil will drive the fibers and dirt

into the coil. This will make cleaning efforts more difficult.

Surface debris must be completely removed prior to using

low velocity clean water rinse.

PERIODIC CLEAN WATER RINSE — A periodic clean

water rinse is very beneficial for coils that are applied in

coastal or industrial environments. However, it is very important that the water rinse is made with very low velocity water

stream to avoid damaging the fin edges. Monthly cleaning is

recommended.

ROUTINE CLEANING OF E-COATED COIL SURFACES — Monthly cleaning with E-Coat Enzyme Coil

Cleaner is essential to extend the life of coils. It is recommended that all coils including standard aluminum, pre-coated,

copper/copper, or E-coated coils be cleaned with the E-Coat

Enzyme Coil Cleaner as described below. Coil cleaning should

be part of the regularly scheduled maintenance procedures of

the unit to ensure long life of the coil. Failure to clean the coils

may result in reduced durability in the environment.

E-Coat Enzyme Coil Cleaner is non-bacterial, biodegradable, and will not harm the coil or surrounding components

such as electrical wiring, painted metal surfaces, or insulation.

Use of non-recommended coil cleaners is strongly discouraged

since coil and unit durability could be affected.

The following field-supplied equipment is required for coil

cleaning:

1

•2

/2 gallon garden sprayer

• water rinse with low velocity spray nozzle

21

Page 22

E-COAT ENZYME CLEANER APPLICATION

INSTRUCTIONS — Perform the following procedure to

clean the coil.

NOTE: Wear proper eye protection such as safety glasses

during mixing and application.

1. Remove all surface debris and dirt from the coil with a

vacuum cleaner.

2. Thoroughly wet finned surfaces with clean water and a

low velocity garden hose, being careful not to bend

fins.

3. Mix E-Coat Enzyme Cleaner in a 2

1

/2 gallon garden

sprayer according to the instructions included with the

Enzyme Cleaner. The optimum solution temperature is

100 F.

DO NOT USE water in excess of 130 F. Enzymes in coil

cleaner will be destroyed and coil cleaner will not be

effective.

4. Thoroughly apply E-Coat Enzyme Cleaner solution to

all coil surfaces including finned area, tube sheets and

coil headers. Hold garden sprayer nozzle close to

finned areas and apply cleaner with a vertical, up-anddown motion. Avoid spraying in horizontal pattern to

minimize potential for fin damage. Ensure cleaner

thoroughly penetrates deep into finned areas. Interior

and exterior finned areas must be thoroughly cleaned.

5. Allow finned surfaces to remain wet with cleaning

solution for 10 minutes. Ensure surfaces are not

allowed to dry before rinsing. Reapply cleaner as

needed to ensure 10-minute saturation is achieved.

6. Thoroughly rinse all surfaces with low velocity clean

water using downward rinsing motion of water spray

nozzle. Protect fins from damage from the spray

nozzle

.

Do not use bleach, harsh chemicals, or acid cleaners on

outdoor or indoor coils of any kind. These types of cleaners

are difficult to rinse, and they promote rapid corrosion of

the fin collar-copper tube connection. Only use the E-Coat

Enzyme Coil Cleaner.

Never use high pressure air or liquids to clean coils.

High pressures damage coils and increase the airside pressure drop. To promote unit integrity, follow cleaning and

maintenance procedures in this document.

Fan Motor Removal

1. Make certain condenser power is off.

2. Remove fan guard and fan.

3. Loosen nut on motor holding clamp securing motor to

motor support.

4. Lift motor upward. Remove wire connectors.

Head Pressure Control — This feature reduces con-

densing capacity under low ambient temperature conditions.

FAN CYCLING — Model 09DK units have accessory provi-

sion for fully automatic intermediate-season head pressure

control through condenser fan cycling. Fan number 2 and 3

cycling (fan number 3 on 09DK034 and 044 only) is controlled by outdoor-air temperature through air temperature

switches (ATS) 1 and 2.

The air temperature switches are located in the lower divider panel underneath the coil header. The sensing element is exposed to air entering the no. 1 fan compartment through a hole

in the panel. Fan no. 1 is non-cycling. Table 5 shows operating

settings of the air temperature switches.

Table 5 — Fan Cycling Controls

UNIT 09DK 020 024 028 034 044

No. 2 Fan

Tem p Clos e, F (C) 70 ± 3 (21.1 ± 1.7) 65 ± 3 (18.3 ± 1.7)

Open, F (C) 60 ± 3 (15.6 ± 1.7) 55 ± 3 (12.8 ± 1.7)

No. 3 Fan

Temp Close, F (C) — — — 80 ± 3 (26.7 ± 1.7)

Open, F (C) — — — 70 ± 3 (21.1 ± 1.7)

22

Page 23

Page 24

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs are available, using popular video-based formats and materials. All include video and/or slides, plus companion book.

Classroom Service Training which includes “hands-on” experience with the products in our labs

can mean increased confidence that really pays dividends in faster troubleshooting and fewer callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-644-5544

[ ] Packaged Service Training [ ] Classroom Service Training

Copyright 1999 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 530-917 Printed in U.S.A. Form 09DK-13SI Pg 24 612 11-99 Replaces: 09DK-11SI

Loading...

Loading...