Page 1

Carrier

: .¿'K 5:-K , w

ci"' i/''

s io 80 Tons

9AB,09DC

DESCRIPTION

Capacities to 10 Tons

9AB Air-Cooled Condensers available in nominal

capacities of 5, 7% and 10 tons are designed for verti

cal installations with horizontal air flow. They may be

located in any area having unobstructed air circula

tion; the low silhouette permits installation in varied

ground or roof locations. Each unit consists of a direct

drive motor (or motors), fan (or fans), fan guards,

motor mounts, condenser coil with integral subcooling

circuit, wind deflector, and electrical junction box.

Weather Armor* enclosures (which are also provided

for 09DC016) have a baked enamel finish which pro

vides maximum weather protection.

FEATURES

• Multiple Fans and Motors provide inexpensive, re

liable system control in intermediate seasons. Standby

protection is provided in case one fan motor fails.

• Subcooling permits greater liquid lift in vertical

risers without liquid flashing. Special coil circuiting

cools liquid refrigerant below the saturated condensing

temperature, extending system capacity without in

creasing motor horsepower.

• Direct Drive Fans require no tensioning device or

pulleys. Alignment problems, belt maintenance, and

friction loss are eliminated.

• Three Types of Head Pressure Control (Accessory)

are available to maintain a refrigeration load by hold-

Air-Cooled Condensers

Capacities 15 Tons and Over

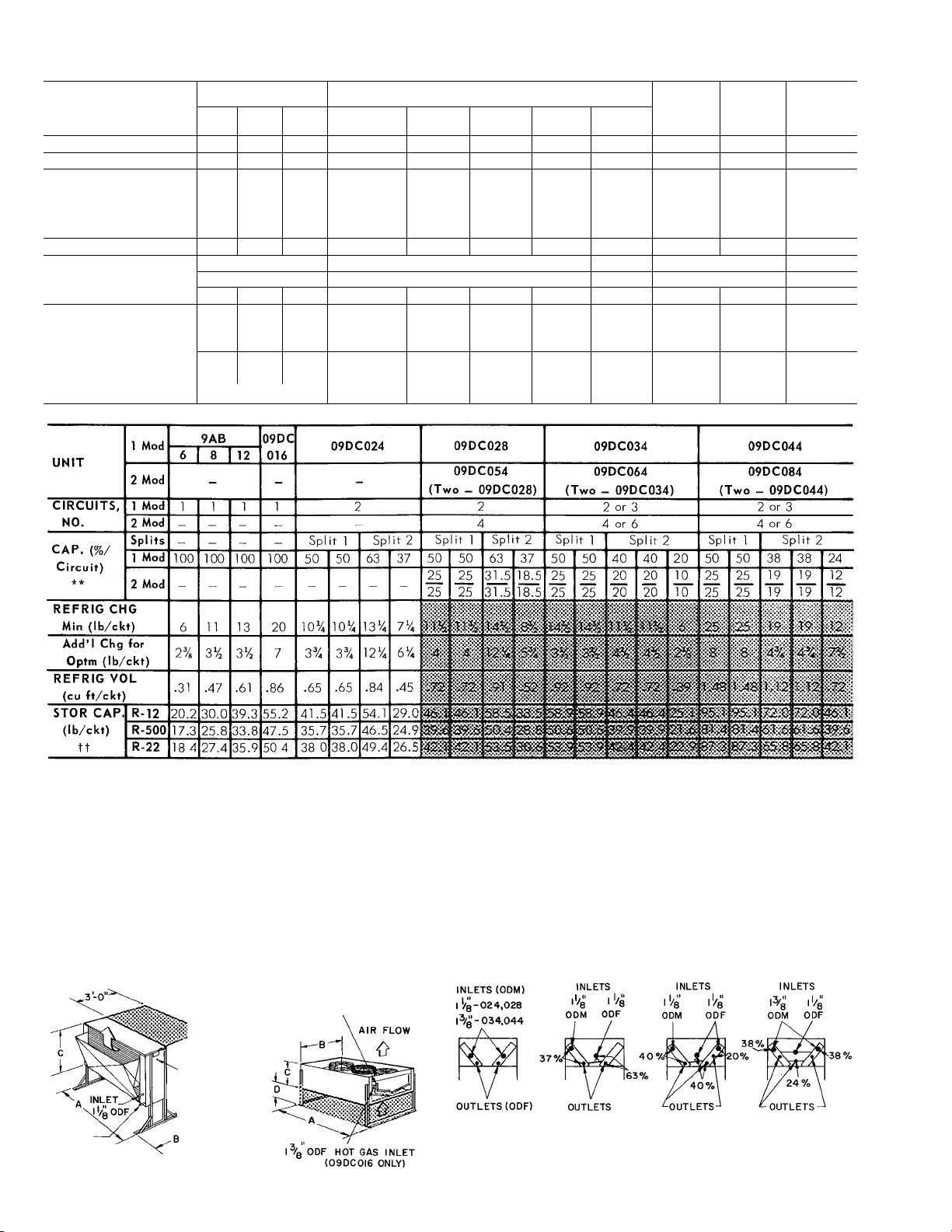

09DC Air-Cooled Condensers are available in 15-,

20-, 25-, 30- and 40-ton sizes. The 25-, 30- and 40-ton

sizes are designed for use in multiples to give capacities

of 50, 60 and 80 tons. Each size has three direct drive

fans, three motors and motor mounts, three guards,

a junction box, and a condenser coil with integral sub

cooling circuit. The 20-, 25-, 30- and 40-ton units, all

using vertical air flow, may have 2 or 3 circuits, each

with an integral subcooling circuit. Each circuit may

be used as a separate condenser for a single system.

Double-weight, hot dipped, galvanized steel enclosures

give maximum protection.

ing a minimum head pressure and reducing condenser

capacity at low outdoor temperatures.

1. Motormaster Electronic Control (9AB6, 8, 12 and

09DC016, single-phase) modulates condenser fan

motor speed from zero to full rpm.

2. Fan Cycling Control cycles one fan (9AB8, 12) or

two fans (09DC) for control during intermediate

seasons.

3. Head Pressure Control Damper (09DC024, 084),

mounted below unit at the uncontrolled fan section,

further reduces capacity.

• Winter Start Control — Optional package permits

start-up of compressor regardless of low temperatures.

© Carrier Corporation 1966

•SINGLE FEATURE SHEET AVAILABLE

Form 9AB, 09DC-2P

Page 2

PHYSICAL DATA

UNIT

RATING (tons)*

NET WEIGHT (lb)t

FAN (Prop.), No.

Prop. Diom (in.)

Rpm

Cfm

MOTORS, No. ... Hp

COILS, Type

No.

Face Area (sq ft)

DIMENSIONS (ft-in.)

Length (each) A

Width (module) B

Height, w/o Legs

Adj Stand (in.) D

9 AB

6 8 12 016

6.8 10.5 13.8

215 315

1

22

1120

410

2 2 3

22 22

1 120

1120

4400 6600 8800

2...Vs 2... Vs

1.. Vs

3-row

1

9 0

3-7Vs 5-2 Vs

13 5

18 0

6-8Vs

3-1 Vs 3-1 Vs 3-1 Vs

C

3-2Vi6

lOV or

3-2 Vs

3-2Vs

16 V.

09DC

024

15.8

22.1

550 854

028

28.0

904

3 3

22 26

1120

13,000

3...V

1140

18,200 25,200

3...%

30

1140 1140

3 . 1

3-row

2

26.2 35.4 39 0 49.6

6-9Vs

4-6 V.

9- 7% 9- 1% 9- 7V.

3-1IV.

3-1IV. 4-lOV.

1-8V. 2- 4 Vs 2- 4 Vs

12Vsor 19Vs 16 or 24

16 or 24

09DC054

034 044

35.8 46.7 56.0

1225

1600

3 3 6

30 32 30

1140 1140 1140

28,200 31,000

3...1 3...1

4-row

2

60.4 78 0 99 2

9-lOV.

9-lOVst

6- OV. 3-1IV.

3- iVs

18 or 26 20 or 28

3- r/s

16 or 24 18 or 26

(T wo

028’s)

(Two

034*s)

71.7

09DC064

1808

2450

6 6

30

50,400 56,400

6...1

6...1

3-row

4

9- 1% 9- 7%

4-lOV.

2- 4 Vs

3- iVs 3- r/s

09DC084

(Two

044’s)

93.4

3200

32

1140

62,000

6...1

4-row

4

120.8

9-lOV.

9-lOVst

6- OV.

20 or 28

Data common to 1- and 2-module units.

*Tons of refrig effect at 30 F temp diff with 1 20 compr heat rejec

tion factor for R-22.

tWithout damper or refrigerant.

iFor three-circuit coil.

DIMENSIONS

9AB6,8,12 09DC016, 024, 028,

034, 044

5/„ ODF LIQUID OUTLET

“ (09DC0I6 ONLY)

AIR FLOW

ELECTRICAL

KNOCKOUT

OUTLET

'''a' ODE

S3 SPACE FOR AIR FLOW

**Use 50/50 split for single circuit. 09DC034 coil 40/40/20 split

may be field modified into 40/60 split.

tt80% liquid, 20% vapor at 90 F.

NOTES:

1. For 09DC024 thru 084, use maximum adjustable stand height

when using a damper section.

2. Certified dimension drawings available on request.

024,028.034,044

50/50

COIL SPLIT

1/2-024,028

7/"-034, 044

024,028

63/37

COIL SPLIT

ODF

RIGHT END VIEWS

7/^' ODF Vg" ODF

034

40/40/20

COIL SPLIT

044

38/38/24

COIL SPLIT

7/g ODF

Page 3

CONDENSER RATINGS TYPICAL ARRANGEMENTS

(Two-Module Condensers)

la. Select minimum or optimum charge ratings.

Use optimum charge when compressor, condenser, and

evaporator may be selected as a package and the com

ponents may be balanced* to secure maximum benefits

of 15 F subcooling (for example, in selecting 09DC con

densers with Carrier compressors rated at 15 F sub

cooling). Optimum charge activates the subcooling

circuit, resulting in higher system capacity at slightly

higher head pressure and corresponding condensing

temperature. Liquid refrigerant leaves the system sub

cooled to a stable condition to allow greater length of

refrigerant run or lift.

Otherwise, use minimum charge which gives higher heaf

rejection, since entire surface of condenser and sub

cooling circuit is used for condensing only. Minimum

charge ratings, however, do not represent greatest po

tential system capacity. They are comparable to com

petitive ratings without subcooling.

b. List the refrigerant, total heat rejection (THR), suction

and discharge temperatures as determined from com

pressor data.

2. Determine condensing temperature (saturated discharge

temperature minus discharge line loss).

3. Determine temperature difference (condensing tempera

ture minus entering air temp).

4. Enter Condenser Ratings table (minimum or optimum

charge as determined in Step 1) at selected refrigerant

and established temperature difference. Read across

to total heat rejection equal to or greater than required.

Interpolate if necessary. Read unit size.

Example (Optimum Charge)

1. Given:

R-22, Optimum Charge

THR (including subcooling)

Saturated Disch Temp................................................................................123.8 F

Saturated Suction Temp..................................................................................40 F

Entering Air Temp............................................................................................95 F

Disch Line Loss.................................................................................................2 F

2. CondTemp^ 123.8F-2F= 121.8F

3. TD = 121.8F-95F- 26.8 F

4. Interpolate in Condenser Ratings table (optimum charge)

and obtain capacity of 09DC028 as 30,0 tons and 09DC024

as 23.6 tons. Select the 09DC028.

..........................................................

29.4 Tons

Example (Minimum Charge)

1. Given:

R-12, Minimum Charge

THR . . ■

....................................................................................

Saturated Disch Temp...................................................................................122 F

Saturated Suction Temp..................................................................................40 F

Entering Air Temp...........................................................................................95 F

Disch Line Loss ............................................................................................2 F

2. Cond Temp = 122 F-2 F - 120 F

3. TD= 120 F-95 F-25 F

4. Enter Condenser Ratings table (minimum charge) and

select 09DC016 with 15,2 tons THR. (Note that with

optimum charge this unit has THR of 14.8 tons which

does not meet specifications).

*See Carrier System Design Manual.

15.0 Tons

Page 4

HEAD PRESSURE CONTROL

General — Efficient operation of evaporator expansion

valves requires a 90 F minimum condensing temperature for

100% compressor capacity, 80 F for 75% capacity, and 70 F

for 50% and 25% capacity. The capacity of an air-cooled

condenser increases with increased temperature difference

(cond temp minus entering air temp) and decreases with

decreased temperature difference. Therefore, a drop in en

tering air temperature lowers the condensing temperature

for a given heat rejection. When outdoor air temperatures

drop below prescribed minimums, some form of head pres

sure control is required. (See Head Pressure Control Data

table for minimum outdoor temperatures and specific head

pressure controls for 9AB and 09DC units.)

9AB, 09DC Head Pressure Controls — Head pressure on

9AB and 09DC condensers may be controlled by the Motor-

master Electronic Control, by fan cycling, or by fan cycling

supplemented by the Motormaster or a modulating damper.

Motormaster — When outdoor temperatures are low enough

to cause low condensing pressures, the Motormaster modu

lates the motor speed of one condenser fan from full to zero

rpm to maintain a constant saturated condensing tempera

ture. The Motormaster, available only with single-phase

motors (on unit sizes thru 09DC016), may be the sole con

trol on single fan units or may be used in conjunction with

fan cycling control on multiple fan units for full year-round

head pressure control.

Fan Cycling — The fan cycling control, used primarily

during intermediate seasons, cycles one fan or two fans.

On two-module condensers (09DC034, 064, 024), the fan

cycling control cycles four of the six condenser fans (two

of three in each module) from a two-step thermostat respond

ing to variations in ambient temperature. The first step of

the thermostat cuts out two corresponding fan motors, one in

each module; the second step cuts out a second pair of cor

responding fan motors. The two condenser modules are

controlled from a single, completely wired fan cycling con

trol box consisting of one two-stage thermostat, one power

and one control terminal block, and two quick-connect re

ceptacles (one at the end of a 10-foot flexible conduit).

HEAD PRESSURE CONTROL DATA

HEAD

UNIT

SIZES

All

9AB6 Motormaster

^ABS,Ï2

9AB8,12

024j,028,

OH 044i

09DC016

09DC024,

028, 034,

044t

PRESSURE

CONTROL

Far\

Ort i'<>>

Fan Cycling,

One Fan with

Motormaster

Tw«^ FiTK,

Fan Cycl ing,

Two Fans with

Motormaster

Fan Cyc 1 ing,

With Mod Damper

Winter Season

None

С/с''в^ j,

Two Fans

TD

30

25

20

30

25

20

3Q

2S

20 :

30

25

20

: 30

: 25

ГС

30

25

20

30

25

20

Ш

TD - Temperature Diff (cond temp minus ent air temp)

* Interpolation permitted.

t Based on 90 F minimum cond temp at 100% capacity, 80 F at 75%

and 70 F at 50% and 25%. (Motormaster holds cond temp to 100 ±

10 F at all loads and at temperatures down to -20 F.) On some ap

plications with multiple DX coils, the compressor may be unloaded

while individual coil(s) are still fully loaded. In this case, expan

sion valve selection must be based on condensing temperatures

listed, or the minimum outdoor air temperature must be raised by

the difference between listed cond temp and cond temp used for

valve selection.

t Applied also to each module of 09DC054, 064 and 084.

COMPR CAP. (%)*

100 75 50 25

Min Outdoor Temp (F)t

57

61

65

-20 -20

38

42

45

4?

5i

52

-20 -20

26

30

! m

55

57

60

60

65

70

-20

1 S3 i

43

52

-20 -20

3

1 4'i

-20 -20

-20 -20

-20 -20

-20-213

62

64

65

-20

'S3

43

S2 SS

25

SCHEMATIC WIRING DIAGRAM

— CONDENSER CONTROL

(Single Refrigerant Circuit, Single Phase)

Head Pressure Control Damper — An accessory head

pressure control damper is available to supplement the

fan cycling control on the 09DC024 and larger units. The

09DC054, 064, and 084 require two damper packages in

stalled for parallel throttling of air to the two uncontrolled

fans. Each damper assembly has a pressure-operated actu

ator to operate the damper blades which modulate inlet air

flow to the uncontrolled fan in response to head pressure

variations. The pressure sensing tubing (capillary) for both

pressure actuators is connected to the same point in the

liquid line serving the last refrigerant circuit to shut down.

Each capillary is provided with a 1/4-inch flare connection.

A single shut-off valve at the liquid line is recommended,

for service.

Multiple Circuit Condensers — Multiple circuit conden

sers applied to separate refrigeration cycles present special

problems when head pressure is controlled from a single

control point. For such applications, more positive system

control may be ensured by using individual condensers and

head pressure controls.

LP — Low Pressure Switch ^

HP — High Pressure Switch

NOTES:

1. For three-phase service, holding coils are wired in parallel.

2. Multicircuit units may be similarly controlled by wiring fan motor

holding coil(s) in series with thermostat, compressor overloads,

and low pressurestat of each refrigerant circuit

3. Two or more condensers, piped in parallel on a single refrig

erant circuit, must be of equal size and wired in parallel.

Page 5

SCHEMATIC WIRING —HEAD PRESSURE CONTROL

ТШЙЙОЗТЙТ i i

COMMON FOR

ALL WIRING

JiNTERLOCKED

[FC

[with СОМРЙ

■9AB WITH MOTORMASTER

,^5-9AB8,12 fan cycling ONE FAN / MOTORMASTER

iSl+m - 09DC0I6 FAN CYCLING TWO FANS/MOTORMASTER

CONTROL TERMINAL BLOCK

(FAN CYCLING CONTROL BOX)

2-STAGE

THERMOSTAT

FAN CYCLING TWO FANS (EACH MODULE) 09DC0I6, 024.028,034,044

QUICK-CONNECT

INTERLOCKED

WITH COMPR

BULB

LOCATED IN

AIRSTREAM

OF FM|

PLUG -Л

208/230/ i

TO fUSED DISCONNECT

3-PHASE POWER

TO FUSED DISCONNECT

\

FC| [

FM|)

" ; 1

____

a;

FM,

___

hi

1 i

u

FC2

FC3

'I'

POWER

TERMINAL

BLOCK

(FAN

CYCLING

CONTROL

BOX)

QUICK-CONNECT_J

PLUG

FM|

(FM^

(FM3,

“i±:

TO FUSED DISCONNECT

_FLEXIBLE

CONDUIT

(PART OF

FAN CYCLING

CONTROL BOX

PACKAGE)

208/230 V

LEGEND

— Fan Contactor

— Fan Motor

Ad(d this wiring

for 054,064,084

TYPICAL PIPING AND WIRING CONNECTIONS (09DC Units shown)

l-CIRCUIT

FUSED DISCONNECT SWITCHES

FROM POWER SOURCE

3 WIRES (Зф) OIG, _

024,028,034,044

2 WIRES(lф)OI6

1

NOTES:

1. Single-phase motors (9AB, 09DC016) require one field-supplied

contactor to start all fans. Three-phase motors (09DC016, 024,

028, 034 and 044) require one field-supplied contactor for each

fan unless supplied with accessory fan cycling control.

2. All pip ing between two mocdule units is fielid supplied.

3. Wiring and piping shown are general points-of-connection guides

only and do not include detai is required for specific instaI lotions,

4. All wiring must comply with appl ¡cable notional and local codes.

HOT GAS

2-CIRCUIT

ACCESSORY FAN

CYCLING CONTROL

(INCLUDES CONTACTORS;

THREE-PHASE)

JUNCTION BOX

LIQUID TO EVAPORATOR

WIRE AS IN EITHER

OF ABOVE DIAGRAMS

3-ClRCUIT

ACCESSORY DAMPER

SECTION 024, 028, 034

"3

LIQUID

All piping must follow standard refrigerant piping practices.

Piping to two-module units (09DC054, 064 and 084) should

follow standard proctice for multiple condensers. See Carrier

System Design Manual for details.

For pressure relief requirements, see latest revision of Safety

Code for Mechanical Refrigeration - ASA-B9 1.

AND 044 (USE ONLY WITH

FAN CYCLING CONTROL)

Page 6

ELECTRICAL DATA (60-cycle)

UNIT

9AB6

9AB8

9AB12

09DC016

09DC024

VOLTS

208/230

208/230

208/230

208/230

208/230

208/230

208/230

460

575

208

230 3

460

575

208 3

PHASE

09DC028, 230 3

034, 044

460

575 3

1

1

1 2

1

1

1

3

3 1.0

3 4 0

3

3 1.6

3

FANS FLA

No.

1

2

T otal

T Ota 1

3

T otal

1

1

1

1

1

2

3

3

3

Hp

(ea)

2 1*

V3

2.1*

V3

2.4

/3

2.1*

V3

2 4

%

V3 3 3*

4 0

V2

1 2

V2

3 8

/4

1.9

5 3

4 8

2 4

1 9

FLA - Full Load Amps

*These are special motors suitable for use with Motormaster head pres

sure control.

NOTE:

All 208/230-volt single-phase units are suitable for operation on either

voltage.

GUIDE SPECIFICATIONS

Furnish and Install as shown on the drawing—^—air

cooled condensers suitable for tons each of total

heat rejection, when condensing refrigerant at , F

saturated condensing temperature with air entering at«

F dry-bulb temperature. Units shall be arranged for hori

zontal (vertical) air flow.

Units shall consist of: coils, with integral subcooling, 2.

supporting casing with stand, and wind deflector (9AB only).

Coil shall be constructed of plate aluminum fins on mechani

cally expanded copper tubes, cleaned, dehydrated, sealed,

and leak tested at 400 psig (9AB), 410 psig (09DC016), or

420 psig (09DC024 and larger).

Fans shall be direct drive, propeller type, protected by

guards. Motors shall be permanent split-capacitor (9AB,

09DC016) or 3-phase, 60-cycle (09DC016, 024, 028, 034,

044, 054, 064, 084). All motors shall be resiliently mounted

and prelubricated, with built-in overload protection. Fan

shaft shall be corrosion protected and mounted in prelubri

cated bearings. Fan blades shall have an iridite finish. A

magnetic contactor shall be field supplied for 9AB, 09DC- 3.

016, and shall be field supplied for 09DC024, 028, 034, 044,

054, 064, 084 if head pressure control is not used.

Casing shall be painted, Galvanneal steel (9AB, 09DC-

016) or heavy-gage, double-weight (2-1/2 oz zinc/sq ft)

galvanized steel (09DC024, 028, 034, 044). Access panels

shall be provided for electrical connections.

Accessories (To specify from Items 1 thru 4 below, refer to 4.

Head Pressure Control Data table.)

1. Motormaster Electronic Head Pressure Control — Units

shall be provided with a completely transistorized vari

able speed fan control to modulate unit capacity in re

sponse to variations in head pressure. The control en- 5.

Manufacturer reserves the right to change any

closure shall be weathertight and shall have Weather

Armor finish. Mounting hardware shall also be provided.

Control shall modulate fan motor speed from full to

zero rpm to maintain a saturated condensing temperature

of approximately 100 F at outdoor temperatures down

to —20 F.

Fan Cycling Control — Unit(s) shall be provided with a

control to cycle one of two fans (9AB8,12), two of three

fans (09DC016,024,028,034,044), or four of six fans

(09DC054,064,084), in response to outdoor ambient temp

erature. Control package shall include; thermostat and

remote bulb (9AB8,12); contactor(s), terminal strip(s),

plug, and two-stage thermostat (09DC016,024,028,034,

044); contactors, two-stage thermostat, power control

terminal blocks and two quick-connect receptacles, one

at end of 10-foot flexible conduit (09DC054,064,084).

Controls shall be enclosed in weathertight sheet metal

box with cover. Necessary mounting hardware shall be

provided.

Head Pressure Control Damper — Unit(s) shall be pro

vided with a control for further reduction in condenser

capacity to meet system part load operation or lower

outdoor ambient temperatures. This assembly shall in

clude: flanged damper frame, movable damper blades,

operating linkages, self-contained pressure-operated

damper actuator with capillary, and necessary mounting

hardware.

Winter Start Control (required when minimum ambient

temperature is below design coil suction temperature) —

Unit(s) shall be provided with a Winter Start Control

Package which shall temporarily bypass the system low

pressurestat to permit start-up at low temperature.

Floor Mounting Stand (9AB8 and 12).

product specifications without notice.

CARRIER AIR CONDITIONING

Tab 5

Form 9AB,09DC-2P Supersedes 9AB,09DC-1P

COMPANY • SYRACUSE, NEW YORK

Printed in U.S.A.

2-66

Codes C and MC (520902)

Loading...

Loading...