Page 1

Air-Cooled Condenser Units

Installation, Start-Up and

Service Instructions

09BY006-024

5to20Tons

CONTENTS

SAFETY CONSIDERATIONS .................1

GENERAL ..................................1

INSTALLATION ............................1-12

Step 1 − Complete Pre-Installation Checks ..1

Step 2 − Rig and Place Unit ................7

• RIGGING

• PLACING THE UNIT

• VIBRATION ISOLATION

• POSITIONING THE 09BY UNIT

• VERTICAL DISCHARGE

Step 3 − Install Accessory Low-Ambient Kit or

Inlet Filter Kit (If Required) ................8

Step 4 − Install Rain Drain .................8

Step 5 − Complete Refrigerant Piping .......8

• GENERAL

• REFRIGERANT LINE SIZING

• PRESSURE RELIEF

• REFRIGERANT RECEIVER

• LIQUID LIFT

• SWEAT CONNECTIONS

• FIELD PIPING

• MANIFOLDING CIRCUITS

• CHECK VALVE

• SERVICE VALVES

Step 6 − Ductwork ........................10

• CONDENSER AIR DUCT INSULATION

Step 7 − Insulate the Unit .................11

Step 8 − Complete Electrical Connections ..11

• GENERAL

• MAIN POWER WIRING

• CONTROL CIRCUIT POWER WIRING

• GENERAL WIRING NOTES

START-UP .................................13

System Evacuation and Dehydration ........13

Charging Procedure .......................13

Check Operation of Condenser Fan Motor

Controls and Rotation of Fans ...........13

Adjust Fan Speed .........................13

SERVICE .................................13-15

Cleaning Condenser Coils .................13

Lubrication ................................13

Condenser Fan Adjustment ................13

• TO CHANGE FAN SPEED

• PULLEY ALIGNMENT

• BELT TENSION ADJUSTMENT

• TO CHANGE FAN WHEEL

• TO REPLACE FAN BEARING

MAINTENANCE ............................15

Cleaning ..................................15

Inspection .................................15

Air Filters .................................15

Condensate Drain .........................15

TROUBLESHOOTING ......................16

START-UP CHECKLIST ................CL-1,CL-2

Page

SAFETY CONSIDERATIONS

Installing, startingup,and servicing air-conditioning equipment can be hazardous due to system pressures, electrical

components, and equipment location.

Only trained, qualified installers and service mechanics

should install, start-up, and service this 09BY equipment

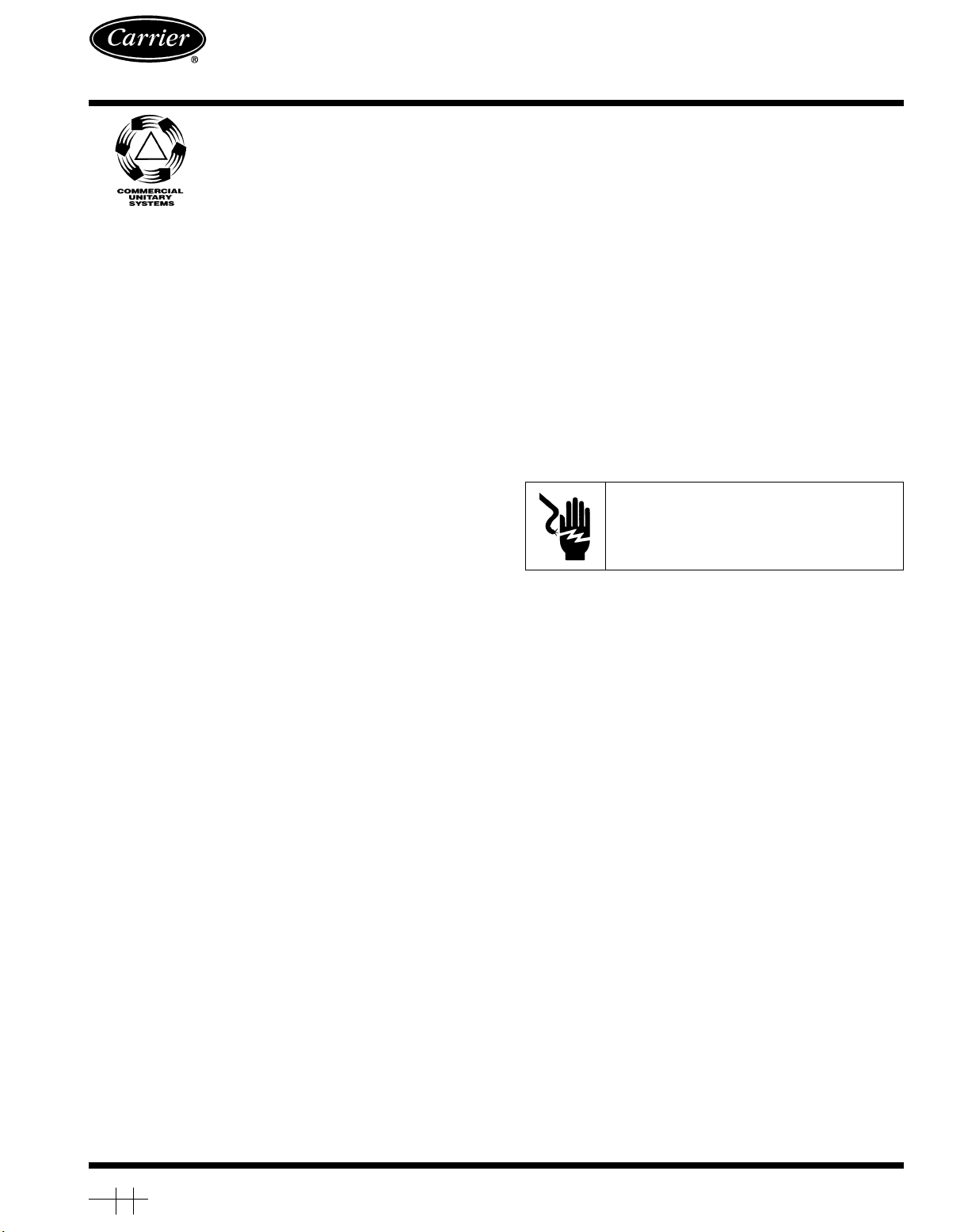

(Fig. 1).

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glassesand workgloves.

Keep quenching cloth and fire extinguisher nearby when brazing. Use care in handling, rigging, and setting bulky

equipment.

ELECTRIC SHOCK HAZARD

Separate power sources (main and control

power circuits) are used for these units. Be

sure both main and control power circuits are

disconnected before servicing.

GENERAL

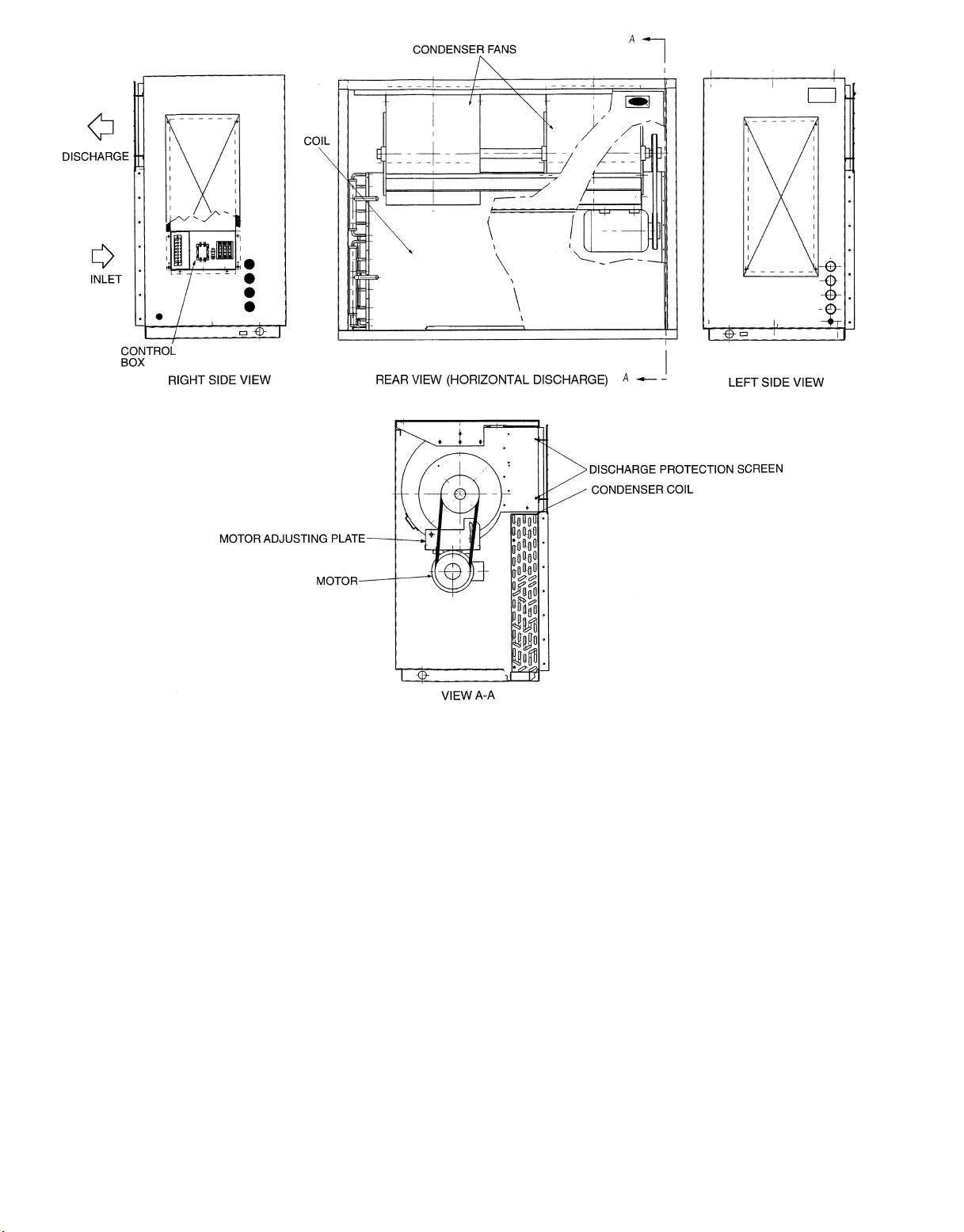

The 09BY air-cooledcondenser is a remote air-cooled condenser designed to be used with the 50BZ vertical packaged

units. See Table 1. Airflow is horizontal, both into and out

from the same face of the unit. The unit is designed to be

mounted indoors in a window, through the wall in high-rise

buildings, or on the wall on the building exterior. See Fig. 2

for typical applications. Ductwork is not needed, but may be

added easily if required by the application. Airflow is provided by centrifugal fans with an adjustable belt drive to meet

varying static requirements. Units may also be matched with

other compressor and evaporator combinations. Contact your

local representative for more details.

Check space requirements, service clearances, floor strength,

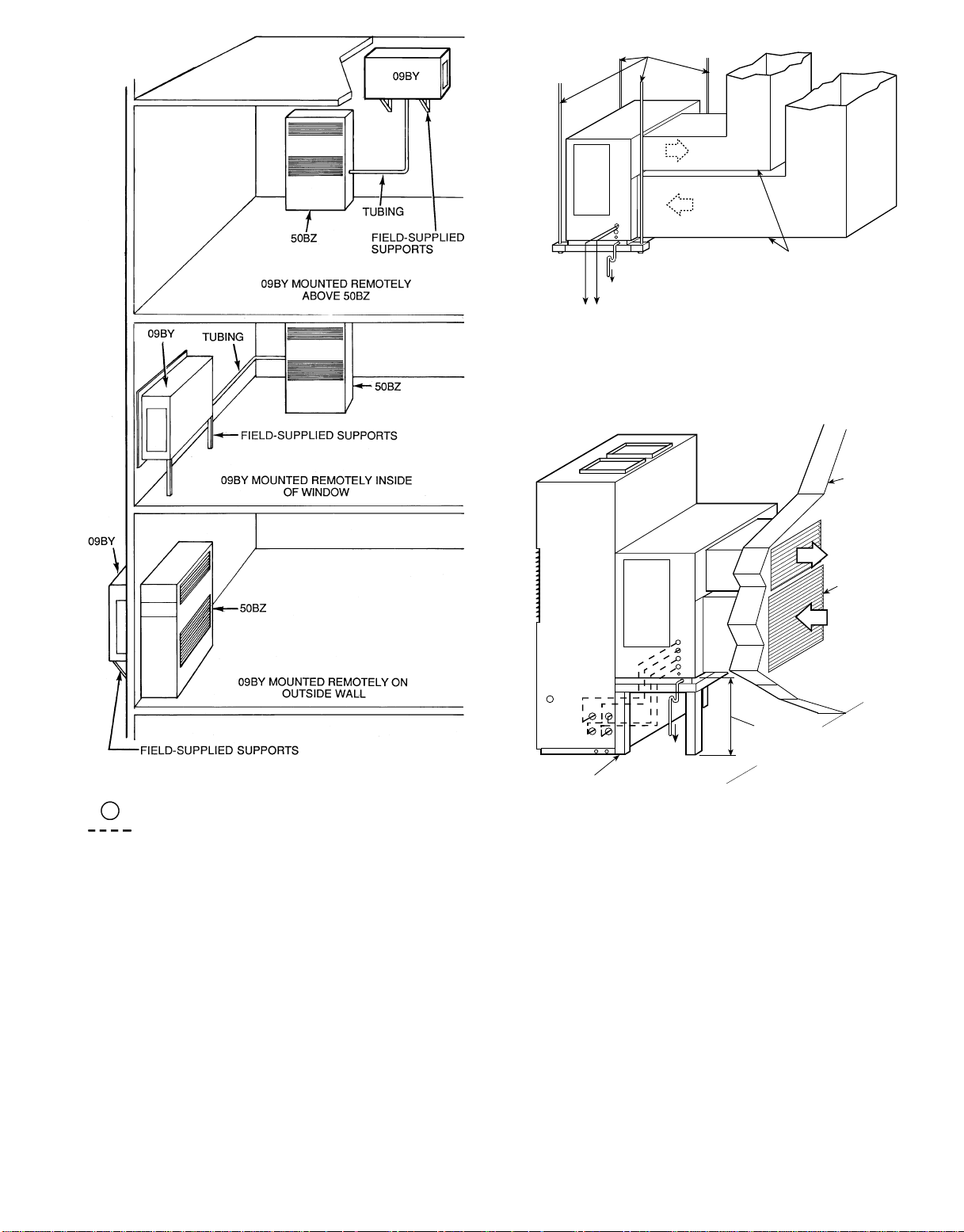

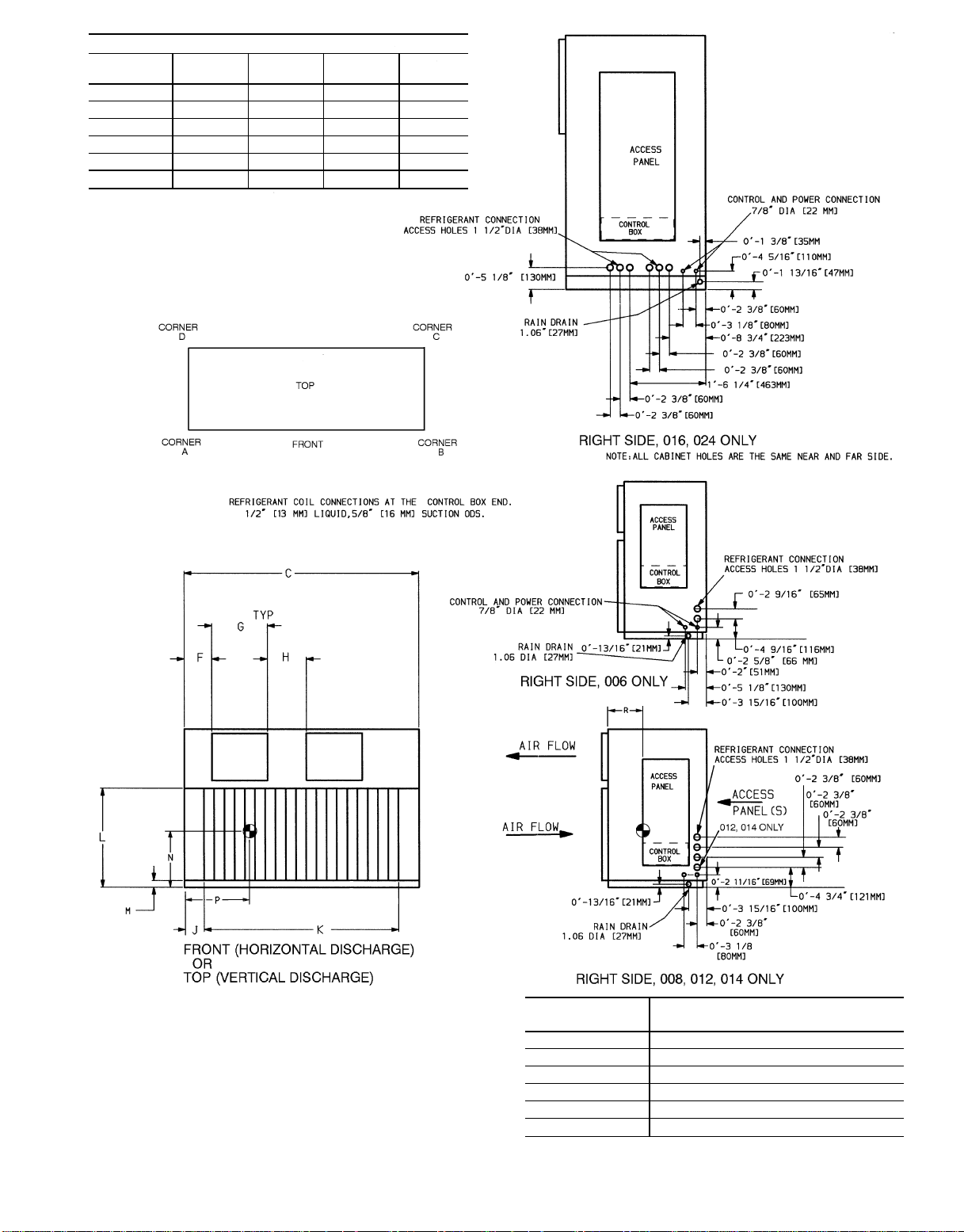

location of piping, size of power supply,and location of ductwork (if used) before installing. See Fig. 3 for unit dimensions and Table 2 for unit operating weights.

INSTALLATION

Step 1 — Complete Pre-Installation Checks —

Examine unit for damage incurred during shipment. File claim

immediately with transit company if damage is found. Check

the shipment for completeness. Verify that the nameplate electrical requirements match the available power supply.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2 4

Tab 4a 4a

PC 111 Catalog No. 530-969 Printed in U.S.A. Form 09BY-2SI Pg 1 9-96 Replaces: 09BY-1SI

Page 2

Fig. 1 — 09BY Unit (008-014 Shown)

2

Page 3

09BY

HANGER

RODS

DISCHARGE

DUCT

INLET

DUCT

TO OUTSIDE

TO RAIN DRAIN

(REQUIRED IF RAIN

WILL ENTER UNIT)

TO REFRIGERANT

PIPING COMPRESSOR/

EVAPORATOR UNIT

INSULATE IF THROUGH

CONDITIONED SPACE

09BY IN REMOTE APPLICATION WITH DUCTWORK

(Shown Suspended from Ceiling)

OUTSIDE

WALL

OUT

WALL

LOUVERS

50BZ

POWER

CONNECTION

09BY

(FIELD

SUPPLIED)

IN

LEGEND

Refrigerant Connection

Field-Supplied Refrigerant Piping

*Field-Supplied Floor Stand (Height to Match Wall Opening).

Fig. 2 — Mounting Applications

HEIGHT AS

REQUIRED

FOR WINDOW

OR WALL

OPENING

FLOOR

STAND*

TO RAIN

DRAIN

(REQUIRED

IF RAIN WILL

ENTER UNIT)

09BY DIRECT CONNECTION TO 50BZ UNIT

3

Page 4

09BY DIMENSIONS (English)

09BY DIMENSIONS (SI)

DIMENSION

A 2-11

B 1- 7

006

(Ft-in.)

008

(Ft-in.)

1

⁄23- 613⁄163- 613⁄163- 613⁄165- 0

11

⁄161-115⁄81-115⁄81-115⁄82- 97⁄

012

(Ft-in.)

014

(Ft-in.)

C 4- 07⁄164- 8 5- 31⁄25-11 7- 69⁄

D 1-111⁄42- 39⁄162- 39⁄162- 39⁄162-11

E 0-11

1

⁄81- 2 1- 2 1- 2 1- 73⁄

F 0- 63⁄160- 57⁄80- 711⁄160-117⁄161-1111⁄

G 1- 15⁄161- 35⁄81- 47⁄81- 47⁄82- 0

H 0- 9

5

⁄160-11 0-11 0-11 1- 31⁄

J 0- 3 0- 3 0- 3 0- 3 0- 27⁄

K 3- 51⁄84- 01⁄44- 75⁄85- 31⁄47- 01⁄

L 1-105⁄82- 3 2- 3 2- 3 2- 9

M 0- 1

9

⁄160- 19⁄160- 19⁄160- 19⁄160- 31⁄

N 0- 6 0- 7 0- 7 0- 7 0-10

P 2- 5 2- 9 3- 2 3- 7 4- 6

R 1- 2 1- 5 1- 5 1- 5 2- 0

016,024

(Ft-in.)

16

16

4

2

16

4

8

DIMENSION

006

(mm)

008

(mm)

012

(mm)

014

(mm)

016,024

(mm)

A 902 1087 1087 1087 1526

B 500 600 600 600 850

C 1231 1422 1613 1804 2300

D 590 701 701 701 911

E 282 357 357 357 502

16

F 156 150 195 290 347

G 338 396 428 428 610

H 236 280 318 318 394

J 76 76 76 76 63

K 1044 1226 1413 1607 2140

L 575 686 686 686 838

M 40 40 40 40 80

N 152 178 178 178 254

P 737 838 965 1092 1372

R 356 432 432 432 610

Fig. 3 — Base Unit Dimensions

4

Page 5

CORNER WEIGHTS (Lb)

UNIT

SIZE

006 55 73 59 42

008 61 89 73 44

012 86 114 93 64

014 107 142 114 78

016 123 159 127 91

024 132 195 158 95

ABCD

NOTES:

1. Operational clearances are 0 in. on all sides of the unit.

2. Service clearances are 0 in. (minimum) on the top, rear,and front

of the unit. A minimum of 3 ft service clearance is required on the

unit right side, anda3ftclearance is recommended on the left

side (2 ft is the minimum). One side of the unit (either right, left, or

rear) should have the following minimum clearance for removal of

the blower shaft:

Fig. 3 — Base Unit Dimensions (cont)

UNIT

SIZE

006 41.0

008 47.0

012 51.0

014 51.0

016 55.5

024 73.0

APPROX. SHAFT LENGTH

(in.)

5

Page 6

Table 1 — Condenser Unit Application

UNIT

50BZ

006 008 012 014 016 024

09BY

006 S

008 S

012 OS

014 OS

016 OS

024 OS

LEGEND

S—Standard

O—Optional

NOTE: Contact your local representative for use with reciprocating air-cooled chillers and other compressor-bearing unit combinations.

Table 2 — Physical Data

UNIT 09BY 006 008 012 014 016 024

NOMINAL TONS 57

OPERATING WEIGHT (Lb) 267 357 441 471 837 970

REFRIGERANT R-22

Number of Circuits 11222 3

Minimum Charge (Lb/Ckt) 6 11 6 6/11 11 11

Optimum Charge (Lb/Ckt) 8.38 14.5 8.38 8.38/14.5 14.5 14.5

Storage Volume Ft

Holding Charge Nitrogen Charge

CONDENSER FAN Belt Drive, Centrifutal

Nominal Airflow (Cfm) 3000 4500 6000 7200 9000 12,000

Cfm Range 2000-4500 3400-6400 4500-7000 6000-7600 6700-9750 7500-11,000

Quantity 22222 2

Size (in.) 8.8 × 8.8 11.0 × 11.0 11.0 × 11.0 11.0 × 11.0 12.4 × 12.4 14.0 × 14.0

Pulley Size (in.) 5

Motor Pulley Range (in.) 43⁄16-51⁄

Rpm Range 1365-1566 960-1260 1106-1455 1045-1306 840-1050 686-847

Maximum Fan Rpm 1705 1365 1365 1365 1210 955

Belt Quantity...Size 1...A41 1...B46 1...B45 2...A45 2...B88 3...B90

Pulley Center Line Distance (in.) 11.2/12.6 13.6/15.0 13.6/15.0 13.6/15.0 32.6/33.8 30.0/30.7

Fan Shaft (mm)* 20 25 25 25 25 30

Motor Shaft (in.)

Motor Hp...Type 2...TEFC† 3...TEFC 3...TEFC 5...TEFC 5...TEFC 10...TEFC

Motor Frame Size 145T 182T 182T 184T 184T 215T

Maximum Motor Hp 3555510

CONDENSER COIL

Rows...Fins per in. 4...14 5...14 5...14 5...14 4...15 5...15

Face Area (sq ft) 6.33 8.75 10.12 11.45 19.38 19.38

CONNECTIONS

Hot Gas

Quantity 11222 3

Size (in.)

Liquid Line

Quantity 11222 3

Size (in.)

Condensate Drain (in.)

3

/Ckt) 0.31 0.47 0.31 0.31/0.47 0.47 0.47

11

⁄

16

2

7

⁄

8

1

⁄

2

1

⁄

2

CONTROLS 24-V Control Fan Contactor Provided in Unit

*Metric size.

†TEFC — Totally Enclosed Fan Cooled.

NOTE: Optimum charge is based on 15° F subcooling. Minimum charge is based on 5° F subcooling.

1

⁄

2

75⁄

8

43⁄16-51⁄

2

11⁄

8

3

⁄8-in. OD Enhanced Copper Tube, Aluminum Fin

1

⁄

2

1

⁄

2

10 12 15 20

65⁄

8

4-5 4-5 43⁄4-6 53⁄8-65⁄

11⁄

8

1

⁄

2

1

⁄

2

3

⁄4FPT

611⁄

11⁄

1

⁄

2

1

⁄

2

16

8

10 1311⁄

11⁄

8

1

⁄

2

1

⁄

2

13⁄

16

8

8

1

⁄

2

1

⁄

2

6

Page 7

Step 2 — Rig and Place Unit

RIGGING — The 09BY units are mounted on skids. Leave

the unit on the skid until it is in the final position. While on

the skid, the unit can be rolled, dragged or forklifted; do not

apply force to the unit. Use a minimum of 3 rollers when

rolling, and raise from above to remove the skid when unit

is in the final position. See Fig. 4 for rigging details.

PLACING THE UNIT — Locate the condenser where an

adequate supply of outdoor air is available for the unit inlet.

NOTE: Unit inlet and discharge may both be ducted to the

outside.

Either provide inlet filters to protect the condenser coils,

or locate the condenser in an area free from airborne dirt or

other foreign material which could clog the coils. For multiple units, allow service clearance (Fig. 3) between units,

and locate unit discharges and inlets so that recirculation of

condenser air is prevented. Placement area must be level and

strong enough to support operating weight of the unit

(Table 2). Bolt unit securely in place when unit is positioned

and leveled. Fasteners for mounting unit are field supplied.

NOTE: It will be necessary to drill holes in the unit base or

side wall where bolts are to be mounted.

IMPORTANT: Use care if rain will enter the unit (if

unit is located fully or partially outdoors). DO NOT

drill through the unit drain pan or leaks will result.

POSITIONING THE 09BY UNIT — Refer to notes in

Fig. 3 for typical service clearances.

To suspend the unit, use 4, field-supplied,

1

⁄2-in. diameter

(or larger) threaded rods. Mount 2 heavy channels under the

entire width of the unit, allowing them to protrude beyond

the width of the unit so that supporting rods can be installed

on the channel ends. Attach minimum1⁄2-in. threaded supporting rods (field-supplied) to channels through a rubber or

spring isolator. See. Fig. 5.

DO NOT use rods smaller than1⁄2-in. diameter. Smaller

rods may not be strong enough to support the unit. Rods

must be securely anchored in ceiling joists.

Use a double hex nut when attaching hanger rods to brackets.Asingle nut could loosen from vibration of the unit. Pitch

unit approximately1⁄4-in. toward drainin bothdirections (lengthwise and widthwise) to aid in condensate and/or rain

removal.

Before sliding unit into final position, check for clearance

to access panels and service area to install piping.

VERTICALDISCHARGE — The 09BY units can be mounted

on a field-supplied stand as shown in Fig. 6 for vertical discharge. Also, provide a rain drain on the back of the unit.

VIBRATION ISOLATION — Units mounted in or above

occupied spaces should employ some type of vibration isolation. For units that are floor mounted, rubber pads may be

located under each unit corner or unit may be mounted on

rubber shear isolators or on spring isolators. Unit may be

supported by its 4 corners, or a field-supplied support rail

may be used for each side. Size isolators with the corner

weights shown in Fig. 3. Units may also be suspended from

above. See Positioning the 09BY Unit section below and

Fig. 5 for recommended support and isolator mounting.

Ductwork attached to the condenser should be isolated from

the unit with a flexible collar on the inlet and outlet ducts.

SPREADER BAR

09BY

UNIT

*Field supplied.

BRACKET*

DOUBLE HEX NUT*

FIELD SUPPLIED

1/2" THREADED

ROD*

Fig. 5 — Threaded Rod Installed in Bracket

PROTRUDING

CHANNEL END*

RUBBER

ISOLATOR*

WASHER*

SUPPORTS

UNDER SKID

Fig. 4 — Unit Rigging

Fig. 6 — 09BY Vertical Discharge

7

Page 8

Step 3 — Install Accessory Low-Ambient Kit or

Inlet Filter Kit (If Required) —

erated with inlet air to the condenser below 50 F, a lowambient damper may be required. The low-ambient kit controls head pressure by discharge dampers on the condenser

fan. The dampers are actuated by a refrigerant-operated piston connected to the discharge line of the condenser. If lowambient accessory will be used, install it at this time (before

final refrigerant and ductwork connections are made).

An accessory filter rack may also be installed on the condenser air inlet to help keep the coil clean. This filter rack

should be installed before the ductwork is attached to the

unit, and before unit is mounted against a wall louver (if

required in your specific application).

Refer to installation instructions provided with the accessories for installation details.

If the unit will be op-

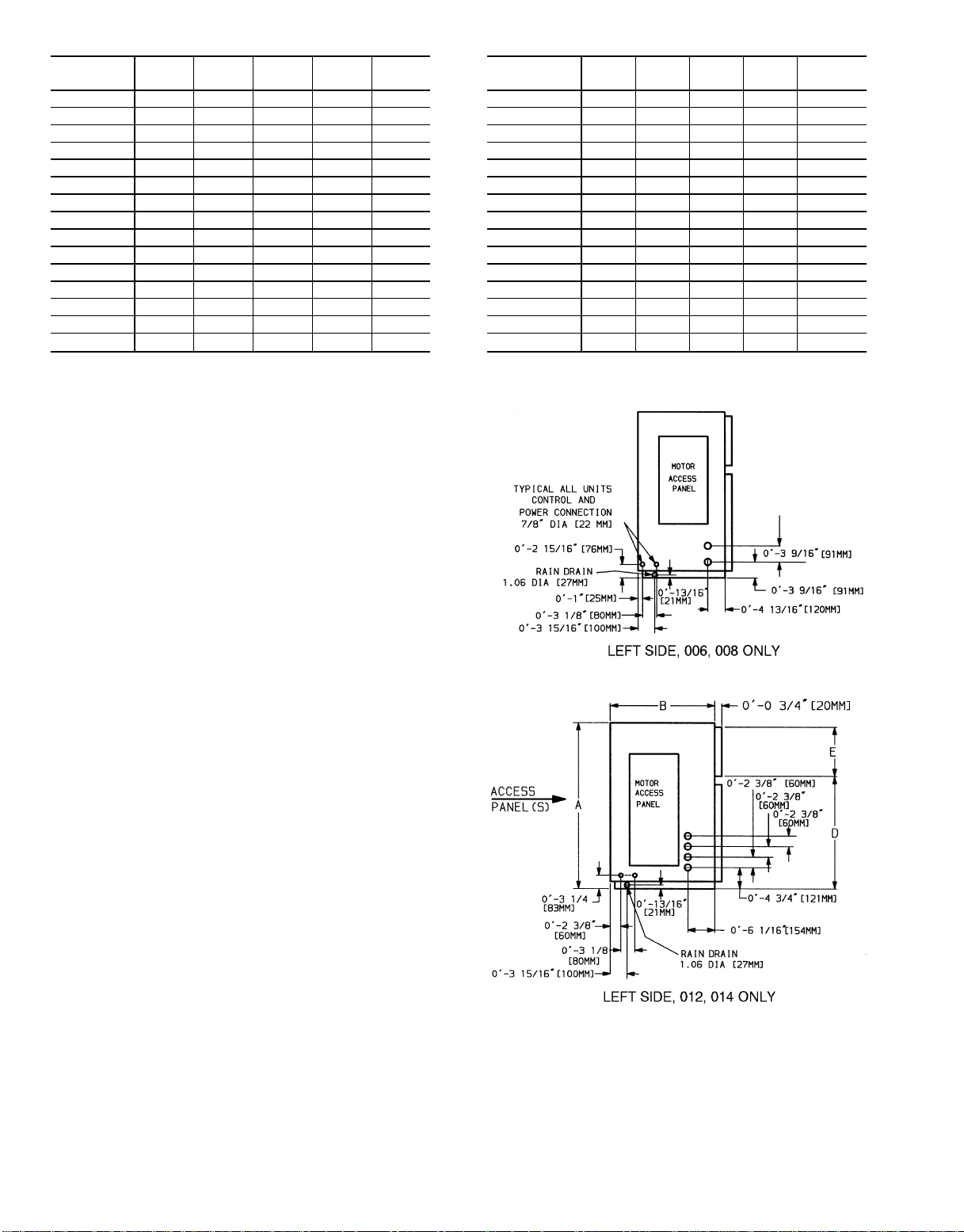

Step 4 — Install Rain Drain (See Fig. 7)

IMPORTANT: A rain drain connection MUST BE

USED if any possibility exists of rain water entering

the unit.

The 09BY unit provides a choice of 2 drain locations. Rain

drain connection can be made on either side of the unit. Block

whichever drain is not being used, but DO NOT BLOCK

BOTH drain locations.

NOTE: Dimensions in [ ] are in millimeters.

Fig. 7 — Rain Drains

A drain kit is provided (shipped in the fan section). This

kit consists of PVC drain fittings to adapt to field-supplied

threaded pipe. Make connections through the unit side panel.

Some applications may require connection to either galvanized steel or copper drain pipe; consult local code requirements for details.

If unit is located inside the building, the drain connection

near the refrigerant piping can be used for external drainage.

Run drain connection to a trapped drain, and plug unused

connection.

IMPORTANT: NEVER use pipe smaller than

3

⁄4in.

in the drain run.

For vertical discharge units, provide a rain drain on the

back of the unit.

Pitch drain pipe downward at a slope of at least

1

⁄4-in. per

ft for proper drainage. Provide tees plugged on one side for

cleanouts. Leave clearance for servicing, and observe all local sanitary codes.

Refer to Carrier System Design Manual for additional pip-

ing details.

Step 5 — Complete Refrigerant Piping

GENERAL — All field leak and pressure testing should be

done in accordance with local code requirements. If a local

code does not exist, use ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) Standard 15, Safety Code for Mechanical Refrigeration.

For leak testing procedures, refer to the Carrier ‘‘Refrig-

erant Service Techniques’’ book, Form SFT-01.

For any parts that need to be removed, use a mini tubing

cutter. Perform phos-copper brazing on all field-made connections while protecting adjacent joints from heat.

REFRIGERANT LINE SIZING — Sizing depends on length

of lines between various sections of the refrigerant system.

Consider the amount of liquid lift and drop in the system as

well as proper compressor oil return. Consult Carrier

System Design Manual, Part 3, or Carrier E20-IIt Refrigerant Piping Computer Program for proper piping sizes and

design.

PRESSURE RELIEF — The ASHRAE Standard 15, Safety

Code for Mechanical Refrigeration states: ‘‘Every refrigerating system shall be protected by a pressure relief device or

some other means designed to safely relieve pressure due to

fire or other abnormal conditions.’’ Since 09BY condensers

do not have pressure relief devices, one must be field supplied and installed either before the liquid line service valve

or inside the 09BY unit. Each circuit must have its own pressure relief.

If desired, the pressure relief requirement can also be satisfied by installing a fusible plug in the liquid line. To do so,

install a tee in the liquid line with a

tee side, and install a fusible plug (part no. EK02KK105 or

similar). The temperature rating of the fusible plug should

be between 205 F and 220 F (96 C and 104 C). If a service

valve is used on the liquid line, be sure that both the piping

system and the condenser are protected for relief if all service valves are closed. Note that if the condenser is located

indoors, requirements for venting the fusible plug to the outdoors may apply. Consult local code requirements.

REFRIGERANT RECEIVER —Arefrigerant receiver is not

furnished with 09BY condensers and is not recommended

for normal applications.

1

⁄4-in. NPT fitting on the

8

Page 9

LIQUID LIFT — Amount of liquid lift available before refrigerant flashing occurs depends on amount of liquid subcooling in the system.

All 09BY condensers have positive subcooling when applied with optimum charge. With subcooling, it is possible

to overcome an appreciable pressure drop and/or static head

pressure (due to elevation of the liquid metering device above

the condenser when condenser is below evaporator coil).

When 09BY condensers are applied with minimum charge,

they do not provide positive subcooling. If subcooling is required, it must be obtained by external means such as a liquid suction interchanger.

It is recommended that the evaporator be either at the same

level as the condenser or lower than the condenser when minimum is used.

SWEAT CONNECTIONS — Connections are made inside

the unit, and piping may enter from either side. For ease in

brazing, it is recommended that all internal solder joints be

made before unit is placed in its final position. See 50BZ (or

other compressor-bearing unit) base unit installation instructions for proper line sizing and piping procedures.

FIELD PIPING — For 09BY remote installation, select pipe

sizes according to length from Table 3.

Use refrigerant grade piping. If tubing size is other than

unit connection sizes, use adapter fittings.

Refer to 50BZ (or other compressor-bearing unit) base unit

installation instructions to determine refrigerant charge adjustment for remote and special piping applications.

NOTE: When installing 09BY units in systems, add charge

for other components (i.e., filter drier, moisture indicator, etc.)

to determine system charge quantity. Record charge.

MANIFOLDING CIRCUITS — The 09BY units with 2 or

3 circuits (012-024 units) may be manifolded together to be

used as a single-circuit condenser. See Fig. 8 for a typical

connection of a 2-circuit condenser for use on one circuit.

Three-circuit units (024) may be manifolded in any combination of 1, 2, or 3 circuits per compressor. When manifolding circuits, NEVER CONNECT TWO SEPARATE COMPRESSOR EVAPORATO RCIRCUITSTOGETHER ON THE

SAME CONDENSER CIRCUIT. Pipe sizes for the combined circuit should be no smaller than the sizes shown in

Table 3.

Fig.8—Typical 2-Circuit Condenser Manifolded

For Single-Circuit Use

Table 3 — Minimum Refrigerant Line Size Data

UNIT

09BY

006 1

008 1

012*

014*

016*

024*

*Circuits may be manifolded to a single compressor. Multiple con-

denser circuits should be on the same evaporator. See Manifolding

Circuits section on this page for details.

NOTES:

1. A standard number of elbows and fittings have been considered

insizing piping (approximately 20% loss).Special applications may

require different minimum refrigerant line sizes. Contact your local

representative for assistance as required.

0TO15FT 16TO25FT 26TO50FT 51TO75FT 76TO100FT

Hot Gas

Qty

Line

2

1

2

1

2

11

2or3

11

(in.)

1

⁄

2

1

⁄

2

1

⁄

2

7

⁄

8

1

⁄

2

7

⁄

8

1

⁄

2

1

⁄

1

⁄

2

1

⁄

8

8

Liquid

Line

(in.)

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

5

⁄811

1

⁄22or37⁄

5

⁄811

Qty

1

1

2

1

2

1

2

Hot Gas

Line

(in.)

5

⁄

8

7

⁄

8

5

⁄

8

7

⁄

8

7

⁄

8

7

⁄

8

7

⁄

8

1

⁄

8

1

⁄

8

8

Liquid

Line

(in.)

Qty

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

5

⁄

8

1

⁄

2

5

⁄811

1

⁄22or3

5

⁄811

LENGTH OF PIPE

Hot Gas

Line

(in.)

1

1

2

11

2

11

2

7

⁄

8

7

⁄

8

7

⁄

8

1

⁄

8

7

⁄

8

1

⁄

8

7

⁄

8

1

⁄

8

7

⁄

8

1

⁄

8

2. Line sizes are in inches.

3. A hot gas line check valve is recommended when the 09BY condenser is installed above the compressor. Pressure loss through

recommended hot gas line check valve has been included in 16

to 100 ft length applications.

Liquid

Line

(in.)

1

⁄

2

1

⁄

2

1

⁄

2

5

⁄811

1

⁄

2

5

⁄811

1

⁄

2

5

⁄811

1

⁄22or37⁄

7

⁄811

Qty

1

1

2

2

2

Hot Gas

Line

(in.)

7

⁄

8

7

⁄

8

7

⁄

8

1

⁄

7

⁄

8

1

⁄

7

⁄

8

1

⁄

8

3

⁄

8

8

8

8

Liquid

Line

(in.)

1

⁄

2

1

⁄

2

1

⁄

2

5

⁄811

1

⁄

2

5

⁄811

1

⁄

2

7

⁄811

1

⁄22or37⁄

7

⁄811

Qty

1

1

2

2

2

Hot Gas

Line

(in.)

7

⁄

8

7

⁄

8

7

⁄

8

1

⁄

8

7

⁄

8

1

⁄

8

7

⁄

8

3

⁄

8

8

3

⁄

8

Liquid

Line

(in.)

1

⁄

2

5

⁄

8

1

⁄

2

5

⁄

8

5

⁄

8

7

⁄

8

5

⁄

8

7

⁄

8

5

⁄

8

7

⁄

8

9

Page 10

CHECK VALVE — When the 09BY condenser is installed

with the condenser located above the compressor evaporator, it is recommended that a field-supplied check valve be

installed on the hot gas discharge line. This prevents refrigerant which condenses in the discharge line during the off

cycle from draining back into the compressor. Install the check

valve at the compressor line before the line goes up to the

condenser. Check valve part no. EC37BP183 or similar may

be used.

SERVICE VALVES — Service valves are not factory installed on the 09BYunits. If isolation of the refrigerant charge

in the condenser from the unit or the piping system is desired, it is recommended that field-supplied service valves

be installed in the discharge and liquid line inside the 09BY

condenser.A Schrader port connection is also recommended

on the liquid and discharge line at the condenser for ease in

troubleshooting when the condenser is located out of sight

from the compressor evaporator unit.

Step 6 — Ductwork — The 09BY unit is designed for

use either with or without ductwork or rain louvers. If either

is used, care must be taken to eliminate air recirculation. Recirculation can be minimized by blocking the front discharge and discharging through an extension elbow. When

properly designed, hinged discharge louvers can be applied

to ductwork and to the condenser air discharge. Fixed rain

louvers over discharge outlets can cause excessive recirculation and nuisance high-pressure switch cutouts. Obstructions closer than 10 ft to the discharge air pattern can cause

significant recirculation. See Fig. 9 for ductwork installation

to prevent recirculation of air.

If ductwork is used from standard discharge openings and

another bird screen is provided, remove factory-supplied screen

to reduce static pressure loss. Units 09BY006-014 have a

factory-installed flange to connect ductwork to the condenser air inlet. Units 09BY016 and 024 are provided with

flanges taped inside the unit for shipping. To attach the duct

to the unit inlet, mount the flange by removing the screws

that hold the condenser coil. Insert the flange and replace the

screws. See Fig. 10. Take care not to puncture the coil when

removing and installing screws.

CONDENSER AIR DUCT INSULATION — The condenser air duct must be insulated on indoor installations to

prevent moisture condensation on the unit panels during cold

weather. Insulate as follows:

1. If metal ductwork is used, insulation may be applied on

the inside of the duct. This installation should be extended to cover the inside of the 09BY duct flanges.

It is necessary to insulate the inside of the ducts at the

duct flanges to reduce heat loss from the metal cabinet by

conduction through the duct flanges and into the cold duct.

Interior insulation allows the metal duct to approach room

temperature. It also prevents condensation from forming

and collecting under the insulation which will occur with

exterior duct insulation.

NOTE: Fiberglass duct board may also be used if permitted by local codes.

2. If insulation is applied to the outside of the metal duct,

the inside must be insulated for a length of 10 in. from

the unit (including the duct flanges) or up to the flexible

duct vapor barrier on the outside, which must be tightly

sealed to prevent condensation under the insulation.

DIMENSIONS (in.)

UNIT

09BY

006 24 11

008 24 14 6 20 161⁄8267⁄8481⁄

012 24 14 6 20 161⁄8267⁄8555⁄

014 30 14 6 20 303⁄8267⁄8631⁄

016 30 20 6 26 303⁄8363⁄8859⁄

024 30 20 6 26 303⁄8367⁄8857⁄

ABCD E F G

1

⁄86171⁄8161⁄8223⁄8411⁄

8

4

8

4

16

16

Fig. 9 — Condenser Ductwork Details

10

Page 11

Fig. 10 — Placement of Duct Flanges on Units

09BY016 and 09BY024

3. Ahigh-density fiberglass (2 lb minimum density) or semirigid foamed insulation such as Styrofoam™ will be required inside the ducts to prevent air erosion. The insulation must be firmly secured in the discharge duct near

the blower discharge to withstand the high air velocity.

Step 7 — Insulate the Unit — The 09BY units are

not insulated. If the unit will be operated during cold weather

and the equipment room is not at outdoor temperatures, the

unit cabinet should be insulated to prevent condensation. Insulate the unit in the same manner as the ductwork insulation described in Condenser Air Duct Insulation section on

page 10.

Step 8 — Complete Electrical Connections

IMPORTANT: Units may be used on 208, 230, 460,

or 575 v, 3-phase systems. As shipped from the factory, units are wired for 460 v or 575 v operation. If

the unit will be used on a 208 or 230 v system, rewire

the condenser fan motor prior to unit start-up. The 575-v

motor is connected to the proper voltage as shipped,

and all connections are internal to the motor.

To rewire the unit, disconnect and reconnect the wires at

the motor junction box as shown on the connection diagram

on the unit motor cover or in the unit wiring book.

GENERAL — Verify that nameplate electrical requirements

match available power supply.Voltage at condenser must be

within the minimum and maximum shown in Table 4 and

phases must be balanced within 2%. Contact local power company for line voltage corrections. Never operate a motor where

a phase imbalance in supply voltage is greater than 2%. Use

the following formula to determine the percentage of voltage imbalance:

% Voltage Imbalance

= 100 x

Example: Supply voltage is 240-3-60.

max voltage deviation from average voltage

average voltage

AB = 243 v

BC = 236 v

AC = 238 v

Average Voltage =

243 + 236 + 238

717

=

3

3

= 239 v

Table 4 — Electrical Data

UNIT

09BY

006

008

012

014

016

024

FLA — Full Load Amps

MCA — Minimum Circuit Amps. Used for wire sizing.

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

*Units are suitable for use on electrical systems where voltage sup-

plied to the unit terminals is within listed minimum and maximum

limits.

(Complies with NEC Section 430-24.)

VOLTAGE

(3 Ph, 60 Hz)

208/230 187 254 7.5

460 414 508 3.4 4.3 15

575 518 632 2.7 3.4 15

208/230 187 254 10.5

460 414 508 4.8 6.0 15

575 518 632 3.9 4.9 15

208/230 187 254 10.5

460 414 508 4.8 6.0 15

575 518 632 3.9 4.9 15

208/230 187 254 16.7

460 414 508 7.6 9.5 15

575 518 632 6.1 7.6 15

208/230 187 254 16.7

460 414 508 7.6 9.5 15

575 518 632 6.1 7.6 15

208/230 187 254 30.8

460 414 508 14.0 17.5 30

575 518 632 11.0 13.8 20

LEGEND

SUPPLY VOLTAGE* FAN POWER SUPPLY

Min Max FLA Hp MCA MOCP

9.4 15

2

13.6 20

3

13.6 20

3

20.9 35

5

20.9 35

5

38.5 60

10

NOTES:

1. Maximum allowable phase imbalance:Voltage± 2%;Amps± 10%.

2. Maximum incoming wire size for power circuit is 2/0 max.

11

Page 12

Determine maximum deviation from average voltage:

(AB) 243 – 239=4v

(BC) 239 – 236=3v

(AC) 239 – 238=1v

Maximum deviation is then 4 v.To determine the percentage

of voltage imbalance:

% Voltage Imbalance = 100 x

4

239

= 1.7%

This amount of phase imbalance is satisfactory since it is

below the allowable maximum of 2%.

IMPORTANT: If supply voltage phase imbalance is

more than 2%, contact your local electric utility company immediately.

Condenser operation on improper line voltage or excessive phase imbalance may be considered abuse and any resulting damage may not be covered by Carrier warranty.

All wiring must be in accordance with local or NEC

(National Electrical Code) regulations. Refer to Fig. 11 for

combination field wiring.

MAIN POWER WIRING — The units must have adequate

overcurrent protection, fuses, or HACR (Heating, Air

Conditioning and Refrigeration) breakers, according to the

national and applicable local codes.

For field power connections, all main power wiring enters

the unit through a factory-punched access hole under the control box. Attach power wires to the 3 power connections in

the unit control box using field-supplied wirenuts. Be sure to

install a ground wire. See Fig. 11.

CONTROL CIRCUIT POWER WIRING — Connect 24-v

control wires to the 2 low-voltage connections at the compressor contactor. Use field-supplied wirenuts to make the

connections in the control box low-voltage section.

GENERAL WIRING NOTES

1. Power entry is at one end only.

2. Fan motors are thermally protected. All motors are pro-

tected against primary single-phasing conditions.

3. Replacement of factory wires must be with appliance wir-

ing material rated 105 C or its equivalent.

4. Factory wiring is in accordance with NEC. Field modi-

fications or additions must be in compliance with all applicable codes.

LEGEND

EQUIP — Equipment

FMC — Fan Motor Contactor

GND — Ground

Field Wiring

Factory Wiring

Field Splice

Marked Terminal

Fig. 11 — Combination Field Wiring

12

Page 13

START-UP

Condenser Fan Adjustment

To prevent personal injury, be sure wire fan guards are

secured in place over each fan discharge (or that fans

are ducted) before starting the unit.

Complete Unit Start-Up Checklist on page CL-1 prior to

start-up of this system.

System Evacuation and Dehydration — Refer to

GTAC II, Module 4, ‘‘Dehydration for Proper Evacuation

and Dehydration Techniques.’’

Charging Procedure — BEFORE CHARGING THE

SYSTEM, INSTALL OR REPLACE THE FILTER DRIER(S) CONNECTED TO THE LIQUID LINE IN THE

INDOOR UNIT TO PREVENT CONT AMINATIONWITHIN

THE SYSTEM. Refer to GTAC II, Module 5 ‘‘Charging,

Recovery,Recycling, and Reclamation’’for proper charging

techniques.

Check Operation of Condenser Fan Motor Controls and Rotation of Fans —

clockwise as viewed from belt access panel.

IMPORTANT: Check for proper fan rotation. If rotation needs to be reversed, disconnect main power supply and switch any 2 leads at the load side of the disconnect switch.

Rotation should be

Adjust Fan Speed — The 09BY units are belt-driven

condenser units and allow for a wide range of inlet static and

condenser airflow requirements. It may be necessary to adjust the condenser airflow to account for these inlet conditions. Inadequate airflow will result in poor unit performance

and possible nuisance tripping of high-pressure switches.

If an airflow is not specified, use the nominal airflow from

Table 2 and adjust the fan speed to compensate for actual

job conditions. Use Table 5 to determine proper fan speed.

If the unit trips on high pressure due to high condensing temperature, then it may be necessary to increase the fan speed

and condenser airflow.

To prevent personal injury, be sure wire fan guards are

secured in place over each fan discharge (or that fans

are ducted) before starting the unit.

TO CHANGE FAN SPEED

1. Shut off unit power supply.

2. Loosen fan belt by loosening fan motor from mounting

bracket. Do not loosen fan motor mounting bracket from

unit.

3. Loosen movable pulley flange setscrew (Fig. 12).

4. Screw movable flange toward fixed flange to increase fan

speed and away from fixed flange to decrease speed. Increasing fan speed increases load on motor. Do not exceed maximum allowable fan speed (Table 2) or motor

full load amps indicated on motor nameplate and in

Table 4.

5. Set movable flange setscrew at nearest flat of pulley hub

and tighten setscrew.

6. Check pulley alignment and belt tension adjustment as

described below.

7. Check fan operation. Repeat above procedure as

required.

PULLEYALIGNMENT — Shut off unit power supply.Loosen

fan motor pulley setscrews and slide fan pulley along fan

shaft. Make angular alignment by loosening motor from mounting bracket (see Fig. 12). Check alignment with a

straightedge.

BELT TENSIONADJUSTMENT — Shut off unit power supply. Loosen fan motor mounting plate bolts. Do not loosen

motor mounting bracket from unit. Move fan motor mounting plate until proper belt tension is achieved (approximately

span).

1

⁄2-in. deflection with 8-lb tension at midpoint of belt

SERVICE

Cleaning Condenser Coils

Do not use high-pressure water or air. Damage to fins

may result.

Clean coils with a vacuum cleaner, fresh water, compressed air, or a bristle brush (not wire). Backflush coil to

remove debris. Commercial coil cleaners may also be used

to help remove grease and dirt. Steam cleaning is NOT recommended. Units installed in corrosive environments should

be cleaned as part of a planned maintenance schedule. In

this type of application, all accumulations of dirt should be

cleaned off the coil.

Lubrication — Fan motors have permanently lubricated

bearings.

Fig. 12 — Condenser Fan Pulley Adjustment

13

Page 14

Table 5 — Condenser Fan Performance

UNIT

09BY

006

008

012

014

016

024

BHP — Brake Horsepower

NOTES:

1. Shaded areas indicate field supplied drive and or motor are required.

2. Nominal cfm is 600 cfm/ton.

AIRFLOW

(Cfm)

2000 676 0.26 905 0.51 1085 0.80 1230 1.08 1348 1.34 1449 1.60

2500 845 0.51 1039 0.82 1197 1.14 1339 1.51 1466 1.88 1570 2.21

3000 1014 0.88 1188 1.28 1321 1.61 1450 2.02 1569 2.46 1684 2.93

3500 1183 1.39 1336 1.86 1458 2.26 1575 2.70 1683 3.18 — —

4000 1352 2.08 1487 2.61 1608 3.15 1704 3.53 ————

3000 589 0.43 766 0.79 900 1.21 1000 1.61 1101 2.00 1201 2.44

4000 785 1.03 923 1.45 1051 2.04 1157 2.61 1234 3.10 1307 3.63

4500 883 1.48 1009 1.93 1118 2.50 1236 3.26 1315 3.82 — —

5000 982 2.00 1098 2.54 1194 3.09 1300 3.87 ————

6000 1178 3.46 1279 4.13 1364 4.73 — — — — ——

4000 594 0.74 720 1.06 879 1.76 957 2.15 1028 2.61 1099 3.01

5000 743 1.44 846 1.87 957 2.41 1089 3.38 1154 3.79 1214 4.40

6000 892 2.49 984 2.99 1058 3.48 1163 4.31 1283 5.63 1346 6.17

7000 1040 3.96 1129 4.60 1187 5.17 1255 5.66 1348 6.72 — —

8000 1189 5.91 1274 6.74 1323 7.24 ——————

5000 777 1.19 894 1.62 990 1.98 1077 2.34 1166 2.73 1258 3.21

6000 932 2.06 1033 2.60 1118 3.04 1196 3.47 1268 3.92 1343 4.35

7000 1088 3.27 1176 3.88 1255 4.45 1323 4.96 ————

8000 1243 4.89 1323 5.61 ————————

9000 ————————————

6000 578 0.83 655 1.04 736 1.32 823 1.63 893 1.99 1005 3.09

8000 771 1.97 830 2.31 881 2.51 944 2.88 1017 3.36 1081 3.75

9000 867 2.81 918 3.19 976 3.47 1017 3.74 1072 4.20 1139 4.75

10000 964 3.85 1009 4.27 1064 4.65 1096 4.87 1147 5.26 1195 5.79

12000 1157 6.65 1198 7.08 ————————

8000 496 1.14 547 1.56 631 1.83 701 2.21 763 2.68 807 3.13

10000 586 1.63 598 2.09 668 2.35 743 2.83 799 3.25 854 3.76

12000 703 3.85 760 4.62 809 5.09 859 5.37 917 5.85 — —

14000 821 6.12 872 7.02 912 7.70 955 8.30 ————

16000 938 9.14 ——————————

LEGEND

0.0 0.2 0.4 0.6 0.8 1.0

Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp Rpm Bhp

EXTERNAL STATIC PRESSURE (in. wg)

14

Page 15

TO CHANGE FAN WHEEL — If a fan wheel should fail,

it may be replaced as follows:

1. Remove belts from fan pulley.

2. Loosen locking collars on the fan bearings and set screws

on the fan wheels.

3. Remove the shaft through the access panel on either side

of the unit.

4. Remove the fan cut-off plate in the fan discharge.

5. Remove the fan wheel through the fan discharge

opening.

6. Replace the wheel, and reverse Steps 1-4 above.

TO REPLACE FAN BEARING — If a fan bearing fails,

replace it as follows:

1. Remove belts from the fan pulley.

2. Support fan shaft.

3. Loosen locking collar on fan bearing.

4. Remove bearing from the shaft.

5. Install new bearing onto the shaft, and reverse Steps 1-3

above.

NOTE: Fan bearing and shaft are metric sizes.

MAINTENANCE

Cleaning—

inside and out. Frequency of cleaning will depend on unit

location and area conditions.

The 09BY unit should be thoroughly cleaned

Drains must be kept free of dirt and trash. Coils can be

cleaned with a stiff brush, vacuum cleaner, or compressed

air. Coil can be reached through access panels.

Inspection — Check coil baffles for tight fit to prevent

air from bypassing the coil.

Check panels for air leakage, particularly those sealing the

fan and coil compartments.

Check for loose electrical connections, oil level, proper

refrigerant charge, and refrigerant piping leaks. The 09BY

fan motor and fan shaft bearings are permanently lubricated.

Further lubrication is not required. Before start-up, be sure

all service valves are open (backseated).

Air Filters — Air filters may be installed on the con-

denser air inlet. Air filters should be replaced or cleaned on

a regular basis depending on how dirty the operating environment is. Failure to clean air filters regularly will result in

loss of unit performance and possible nuisance tripping of

the high-pressure switch.

Condensate Drain — If the 09BY unit is used with a

condensate drain to remove rain water, the drain pan and

trap should be cleaned at least twice per year.After cleaning,

test the condensate drain for proper operation by pouring a

bucket of water into the condensate drain pan. The water

should flow out immediately and evenly.

15

Page 16

TROUBLESHOOTING

See Table 6 for problems and possible solutions.

Table6—Troubleshooting

PROBLEM POTENTIAL CAUSE SOLUTION

1. Fan belts are slipping or broken.

Unit is tripping on

high-pressure switch

or high discharge

pressure is noted.

Compressor or

evaporator is

losing capacity.

Unit is noisy.

Water drips from

the unit.

Fan motor trips

on internal

protection.

*Airflow should be within the range shown in Table 2, and should also be as close as possible to nominal airflow shown in Table 2 for optimum

performance.

2. Fan is not delivering adequate air for condenser.

3. Low-ambient damper is not functioning correctly

(if equipped).

4. Dirty coil or plugged or restricted air filter and/or

louvers.

5. Service valve(s) is closed.

1. Dirty coil or plugged or restricted air filter and/or

louvers.

2. Airflow is not adequate.

1. Airflow is turned too high.

2. Belt and pulley are not properly aligned.

3. Proper vibration isolation has not been applied.

1. Rain water drain not functioning properly.

2. Unit is not insulated to prevent condensation.

Airflow is set too high for motor (motor amps exceed nameplate value).

1. Check and replace belts as necessary.

2. Check airflow (see Table 2)*.

3. Check damper operation and adjust as required.

4. Check and clean coil, filter, and louver as required.

5. Open valve(s) and check for restrictions in

refrigerant lines.

1. Check and clean coil, filter, and louver as required.

2. Check airflow and determine if proper subcooling

is provided.

1. Slow down motor and check discharge pressure.

2. Check and adjust alignment.

3. Isolate unit properly.

1. Clean drain and check drain operation.

2. Insulate unit as required.

Slow motor down and check discharge

pressure.

16

Page 17

Page 18

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2 4

Tab 4a 4a

PC 111 Catalog No. 530-969 Printed in U.S.A. Form 09BY-2SI Pg 18 9-96 Replaces: 09BY-1SI

Page 19

START-UP CHECKLIST

A. Preliminary Information

COMPRESSOR BEARING UNIT: MODEL NO. SERIAL NO.

09BY UNIT: MODEL NO. SERIAL NO.

FIELD-INSTALLED ACCESSORIES

B. Pre-Start-Up

CONDENSING UNIT

IS THERE ANY SHIPPING DAMAGE?

IF SO, WHERE:

WILL THIS DAMAGE PREVENT UNIT START-UP? (Y/N)

CHECK POWER SUPPLY. DOES IT AGREE WITH UNIT? (Y/N)

HAS THE GROUND WIRE BEEN CONNECTED? (Y/N)

HAS THE CIRCUIT PROTECTION BEEN SIZED AND INSTALLED PROPERLY? (Y/N)

ARE THE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? (Y/N)

HAVE DRAINAGE CONNECTIONS BEEN COMPLETED? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

HAS CORRECT FAN ROTATION BEEN CONFIRMED? (Y/N)

HAS WATER BEEN PLACED IN DRAIN PAN TO CONFIRM PROPER DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

(Y/N)

CONTROLS

HAVE THERMOSTAT AND INDOOR-FAN CONTROL WIRING CONNECTIONS BEEN

MADE AND CHECKED? (Y/N)

ARE ALL WIRING TERMINALS (including main power supply) TIGHT? (Y/N)

HAS CRANKCASE HEATER (IF EQUIPPED) ON UNIT BEEN ENERGIZED

FOR 24 HOURS? (Y/N)

09BY UNIT

HAS WATER BEEN PLACED IN DRAIN PAN (IF REQUIRED) TO CONFIRM PROPER

DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

HAS CORRECT FAN ROTATION BEEN CONFIRMED? (Y/N)

PIPING

HAVE LEAK CHECKS BEEN MADE AT COMPRESSOR, CONDENSER, EVAPORATOR,

TXVs (Thermostatic Expansion Valves), SOLENOID VALVES, FILTER DRIERS, AND FUSIBLE PLUGS

WITH A LEAK DETECTOR? (Y/N)

LOCATE, REPAIR, AND REPORT ANY LEAKS

HAVE ALL COMPRESSOR SERVICE VALVES BEEN FULLY OPENED (BACKSEATED)? (Y/N)

HAVE LIQUID LINE SERVICE VALVES BEEN OPENED? (Y/N)

IS THE OIL LEVEL IN THE COMPRESSOR CRANKCASE ON THE UNIT IN VIEW IN THE

COMPRESSOR SIGHT GLASS (IF APPROPRIATE)? (Y/N)

HAS CONDENSER PRESSURE RELIEF BEEN PROVIDED? (Y/N)

CL-1

Page 20

CHECK VOLTAGE IMBALANCE

IS CONDENSER MOTOR WIRED FOR CORRECT VOLTAGE? (Y/N)

LINE-TO-LINE VOLTS: AB VACVBCV

(AB + AC + BC)/3 = AVERAGE VOLTAGE =

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE =

V

V

VOLTAGE IMBALANCE = 100 X (MAX DEVIATION)/(AVERAGE VOLTAGE) =

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START SYSTEM!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

C. Start-Up

CHECK INDOOR (EVAPORATOR) FAN SPEED AND RECORD.

CHECK OUTDOOR (CONDENSER) FAN SPEED AND RECORD.

AFTER AT LEAST 15 MINUTES RUNNING TIME, RECORD THE FOLLOWING MEASUREMENTS:

OIL PRESSURE (Where Appropriate)

SUCTION PRESSURE

SUCTION LINE TEMP

DISCHARGE PRESSURE

DISCHARGE LINE TEMP

ENTERING CONDENSER-AIR TEMP

LEAVING CONDENSER-AIR TEMP

EVAP ENTERING-AIR DB (dry bulb) TEMP

EVAP ENTERING-AIR WB (wet bulb) TEMP

EVAP LEAVING-AIR DB TEMP

EVAP LEAVING-AIR WB TEMP

%

COMPRESSOR AMPS:

CIRCUIT A (L1/L2)

CIRCUIT B (L1/L2) /

CIRCUIT C (L1/L2) /

NOTES:

/

CUT ALONG DOTTED LINE CUT ALONG DOTTED LINE

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2 4

Tab 4a 4a

PC 111 Catalog No. 530-969 Printed in U.S.A. Form 09BY-2SI Pg CL-2 9-96 Replaces: 09BY-1SI

----------------------------------------------------------------------------------------

Loading...

Loading...